ect GREAT WALL FLORID 2008 Manual Online

[x] Cancel search | Manufacturer: GREAT WALL, Model Year: 2008, Model line: FLORID, Model: GREAT WALL FLORID 2008Pages: 281, PDF Size: 43.97 MB

Page 130 of 281

Downloaded from www.Manualslib.com manuals search engine 123Brake System

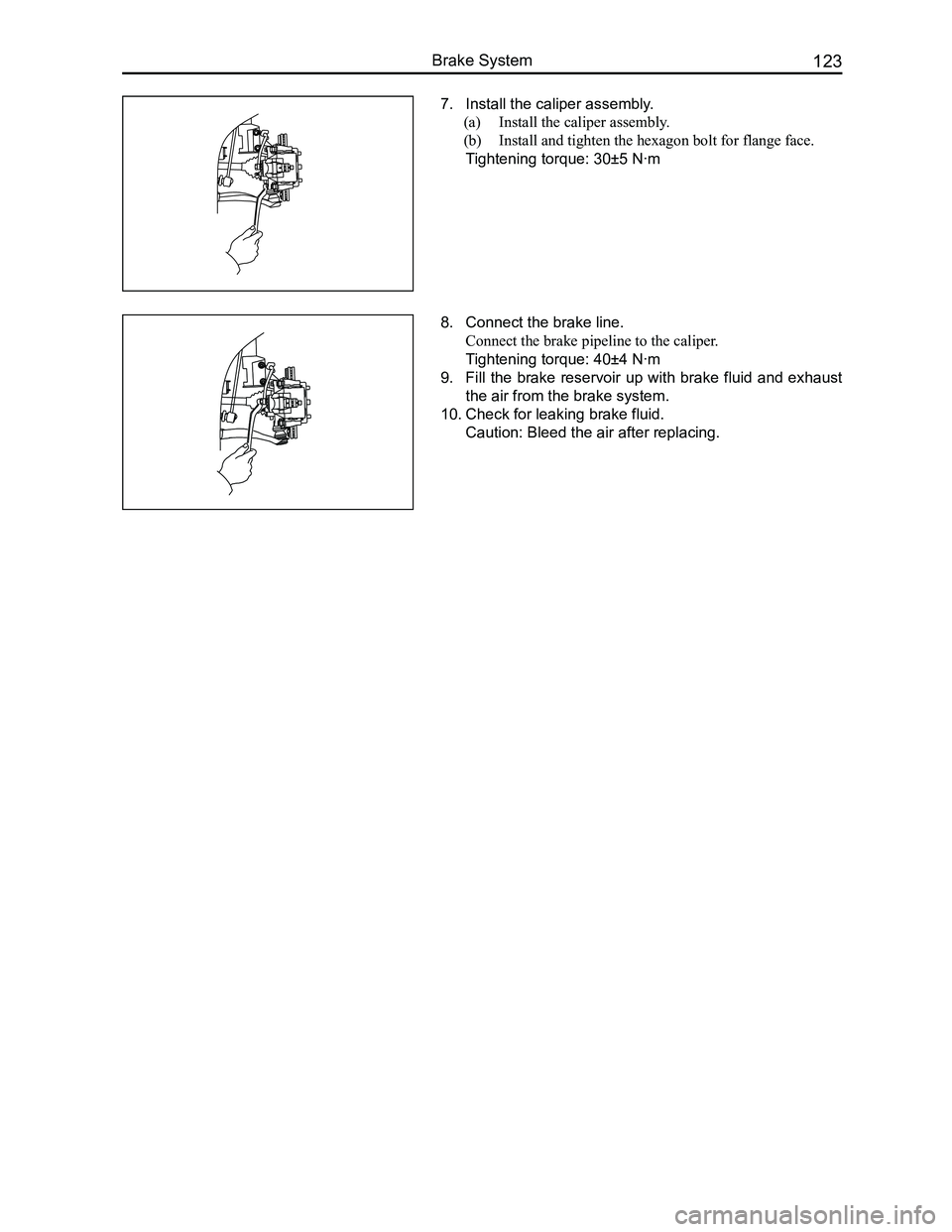

7. Install the caliper assembly.

(a) Install the caliper assembly.

(b) Install and tighten the hexagon bolt for flange face.

Tightening torque: 30±5 N·m

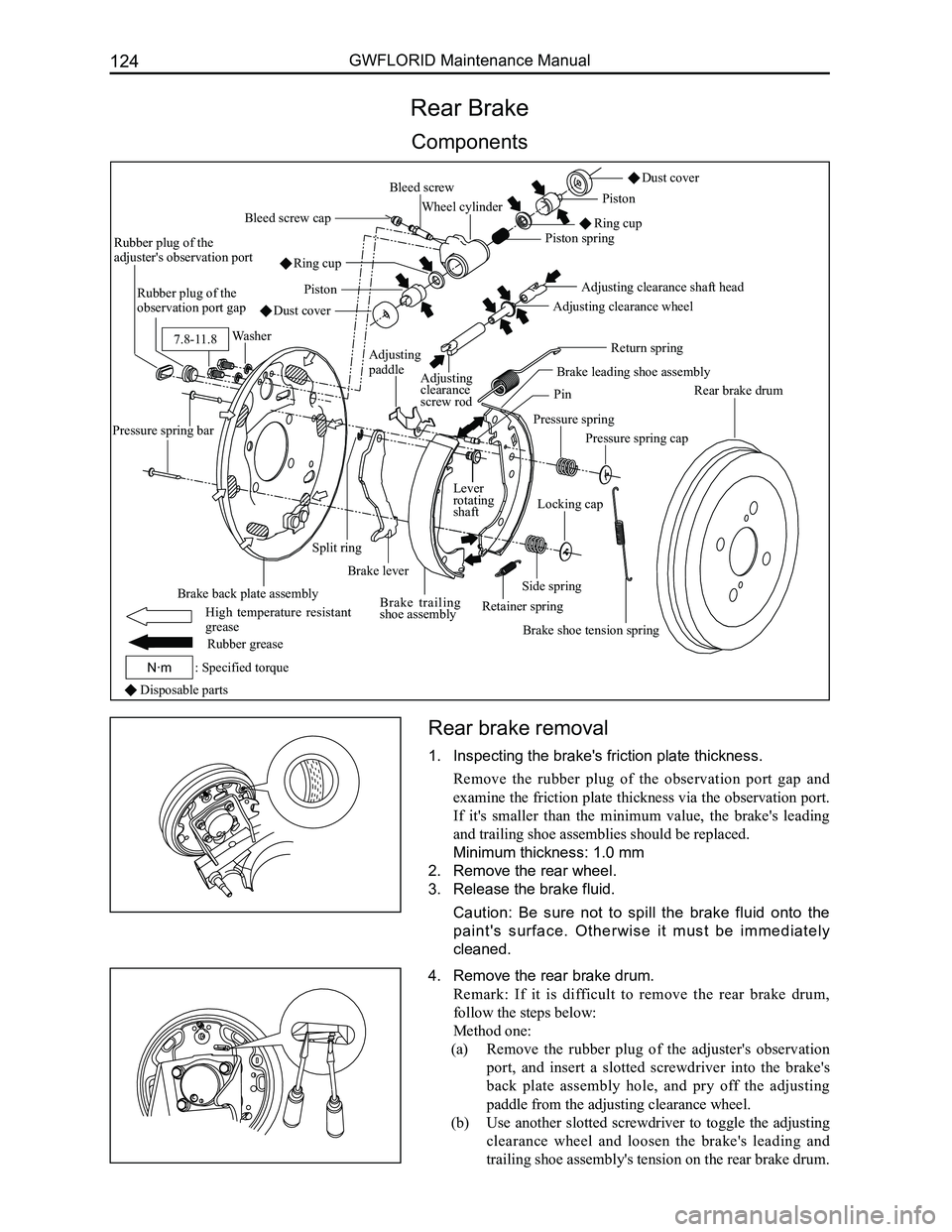

8. Connect the brake line.

Connect the brake pipeline to the caliper.

Tightening torque: 40±4 N·m

9. Fill the brake reservoir up with brake fluid and exhaust

the air from the brake system.

10. Check for leaking brake fluid.

Caution: Bleed the air after replacing.

Page 131 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual124

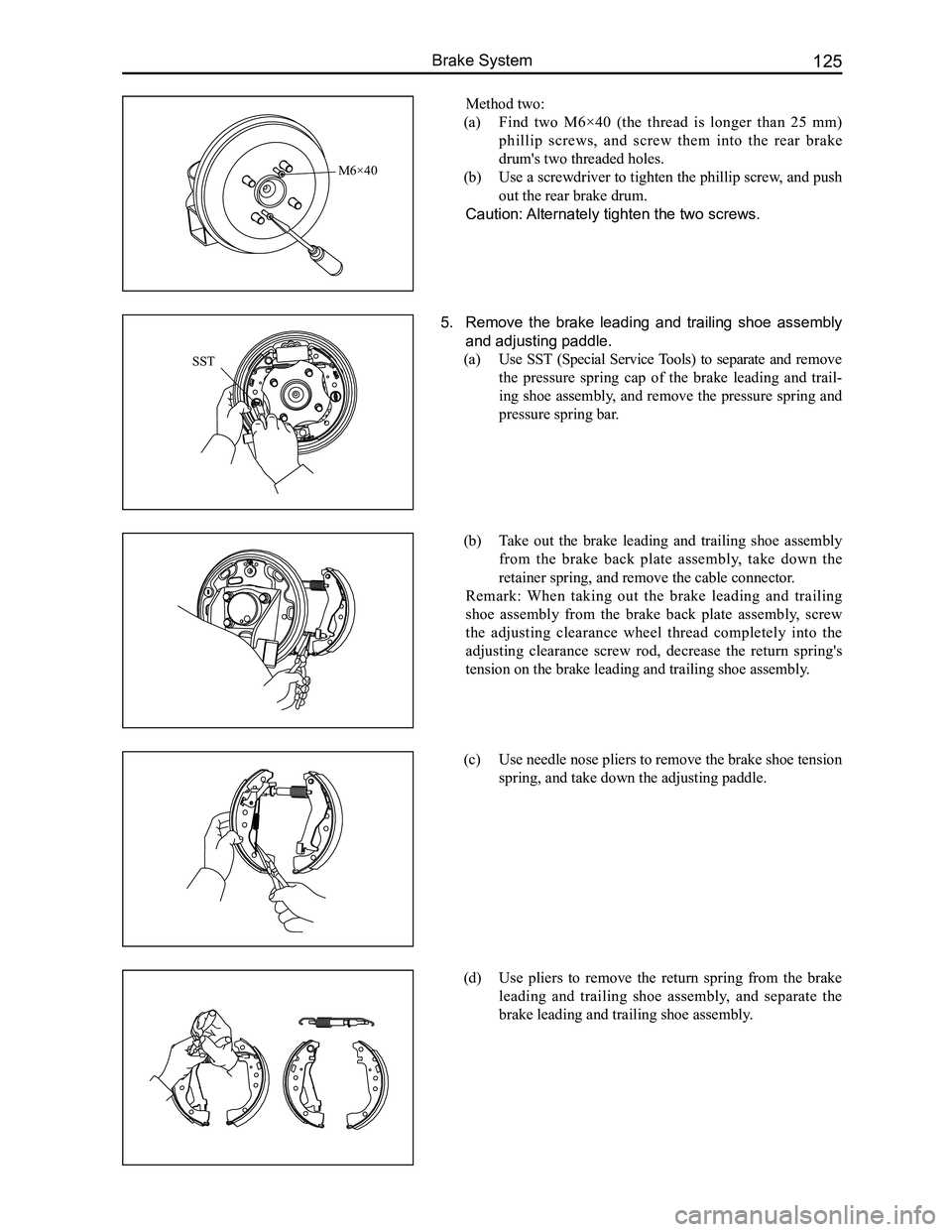

Rear Brake

Components

4. Remove the rear brake drum.

Remark: If it is difficult to remove the rear brake drum,

follow the steps below:

Method one:

(a) Remove the rubber plug of the adjuster's observation

port, and insert a slotted screwdriver into the brake's

back plate assembly hole, and pry off the adjusting

paddle from the adjusting clearance wheel.

(b) Use another slotted screwdriver to toggle the adjusting

clearance wheel and loosen the brake's leading and

trailing shoe assembly's tension on the rear brake drum.

Disposable parts

Dust cover

Brake leading shoe assembly

Pressure spring

Pressure spring cap

Brake shoe tension spring

Rear brake drum

Lever rotating shaft

Retainer spring

Locking cap

Split ring

Brake lever

Brake trailing shoe assembly

Brake back plate assembly

Pressure spring bar

Rubber plug of the adjuster's observation port

Rubber plug of the observation port gap

Washer

Bleed screw cap

Bleed screwPiston

Ring cup

Piston spring

Wheel cylinder

Adjusting clearance shaft head

Adjusting clearance wheel

Adjusting clearance screw rod

Return springAdjusting paddle

Pin

Side spring

Dust cover

Piston

Ring cup

Rubber grease

: Specified torqueN·m

7.8-11.8

High temperature resistant grease

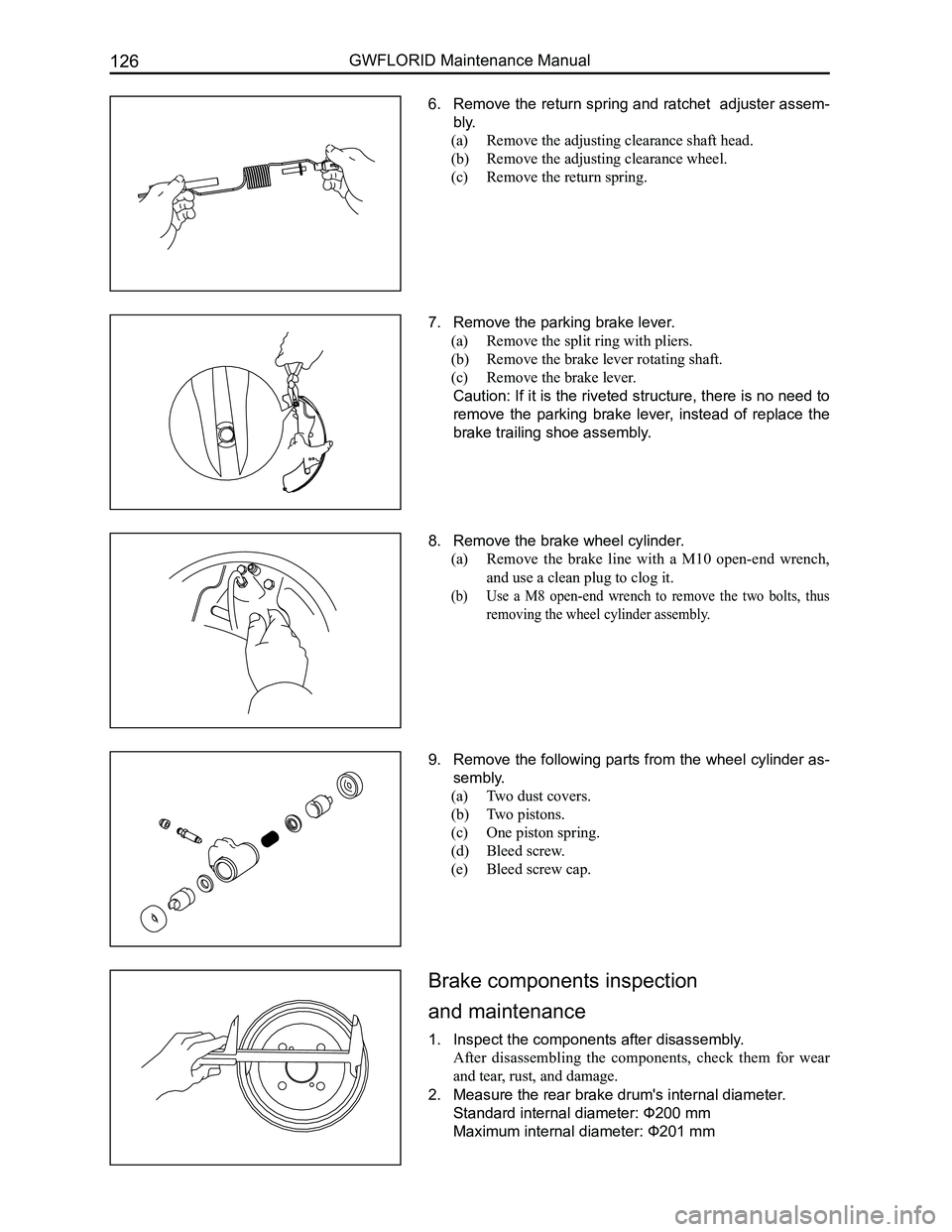

Rear brake removal

1. Inspecting the brake's friction plate thickness.

Remove the rubber plug of the observation port gap and

examine the friction plate thickness via the observation port.

If it's smaller than the minimum value, the brake's leading

and trailing shoe assemblies should be replaced.

Minimum thickness: 1.0 mm

2. Remove the rear wheel.

3. Release the brake fluid.

Caution: Be sure not to spill the brake fluid onto the

paint's surface. Otherwise it must be immediately

cleaned.

Page 132 of 281

Downloaded from www.Manualslib.com manuals search engine 125Brake System

Method two:

(a) Find two M6×40 (the thread is longer than 25 mm)

phillip screws, and screw them into the rear brake

drum's two threaded holes.

(b) Use a screwdriver to tighten the phillip screw, and push

out the rear brake drum.

Caution: Alternately tighten the two screws.

5. Remove the brake leading and trailing shoe assembly

and adjusting paddle.

(a) Use SST (Special Service Tools) to separate and remove

the pressure spring cap of the brake leading and trail-

ing shoe assembly, and remove the pressure spring and

pressure spring bar.

(b) Take out the brake leading and trailing shoe assembly

from the brake back plate assembly, take down the

retainer spring, and remove the cable connector.

Remark: When taking out the brake leading and trailing

shoe assembly from the brake back plate assembly, screw

the adjusting clearance wheel thread completely into the

adjusting clearance screw rod, decrease the return spring's

tension on the brake leading and trailing shoe assembly.

(c) Use needle nose pliers to remove the brake shoe tension

spring, and take down the adjusting paddle.

(d) Use pliers to remove the return spring from the brake

leading and trailing shoe assembly, and separate the

brake leading and trailing shoe assembly.

SST

M6×40

Page 133 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual126

6. Remove the return spring and ratchet adjuster assem-

bly.

(a) Remove the adjusting clearance shaft head.

(b) Remove the adjusting clearance wheel.

(c) Remove the return spring.

7. Remove the parking brake lever.

(a) Remove the split ring with pliers.

(b) Remove the brake lever rotating shaft.

(c) Remove the brake lever.

Caution: If it is the riveted structure, there is no need to

remove the parking brake lever, instead of replace the

brake trailing shoe assembly.

8. Remove the brake wheel cylinder.

(a) Remove the brake line with a M10 open-end wrench,

and use a clean plug to clog it.

(b) Use a M8 open-end wrench to remove the two bolts, thus

removing the wheel cylinder assembly.

9. Remove the following parts from the wheel cylinder as-

sembly.

(a) Two dust covers.

(b) Two pistons.

(c) One piston spring.

(d) Bleed screw.

(e) Bleed screw cap.

Brake components inspection

and maintenance

1. Inspect the components after disassembly.

After disassembling the components, check them for wear

and tear, rust, and damage.

2. Measure the rear brake drum's internal diameter.

Standard internal diameter: Ф200 mm

Maximum internal diameter: Ф201 mm

Page 135 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual128

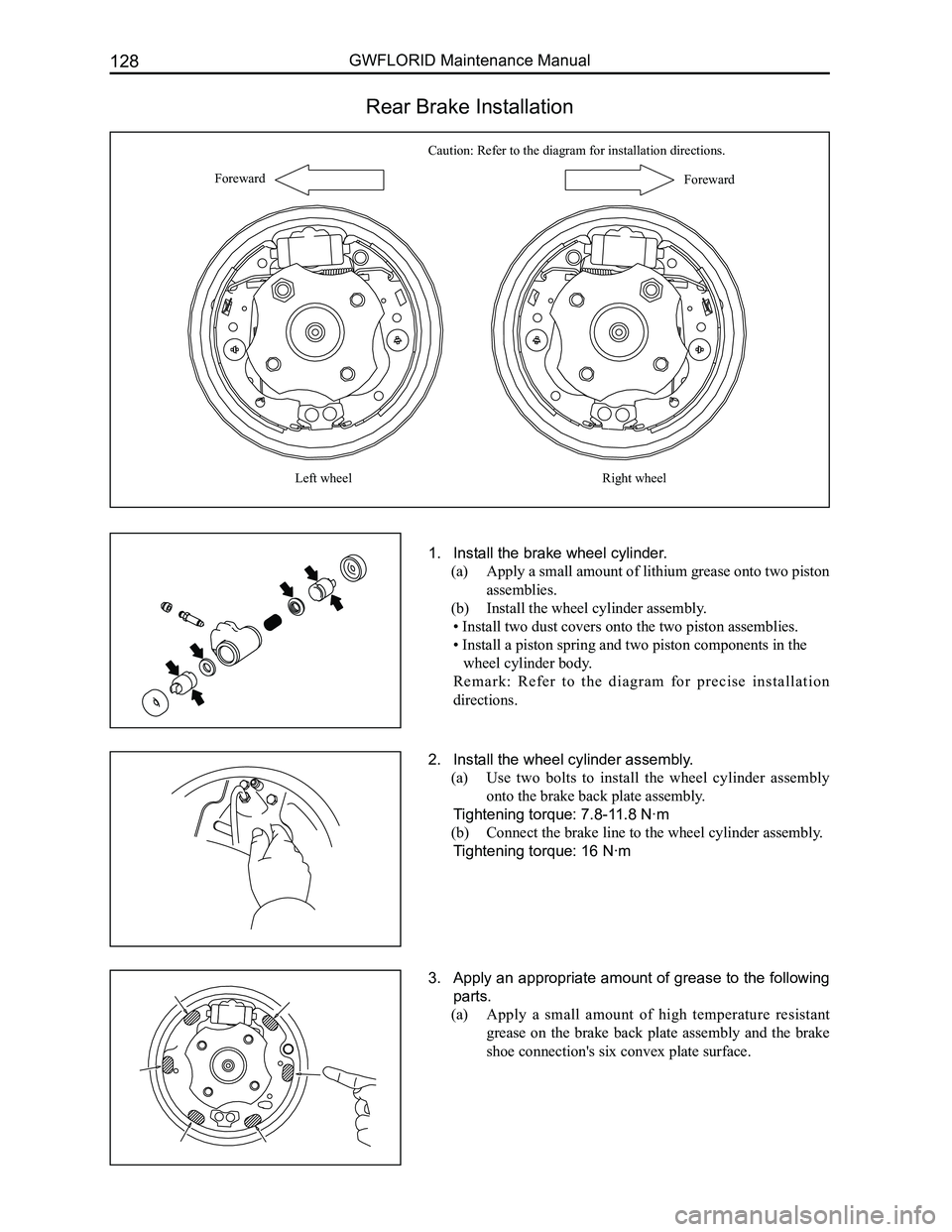

Rear Brake Installation

1. Install the brake wheel cylinder.

(a) Apply a small amount of lithium grease onto two piston

assemblies.

(b) Install the wheel cylinder assembly.

• Install two dust covers onto the two piston assemblies.

• Install a piston spring and two piston components in the

wheel cylinder body.

R e m a r k : R e f e r t o t h e d i a g r a m f o r p r e c i s e i n s t a l l a t i o n

directions.

2. Install the wheel cylinder assembly.

(a) Use two bolts to install the wheel cylinder assembly

onto the brake back plate assembly.

Tightening torque: 7.8-11.8 N·m

(b) Connect the brake line to the wheel cylinder assembly.

Tightening torque: 16 N·m

3. Apply an appropriate amount of grease to the following

parts.

(a) Apply a small amount of high temperature resistant

grease on the brake back plate assembly and the brake

shoe connection's six convex plate surface.

Caution: Refer to the diagram for installation directions.

ForewardForeward

Left wheelRight wheel

Page 137 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual130

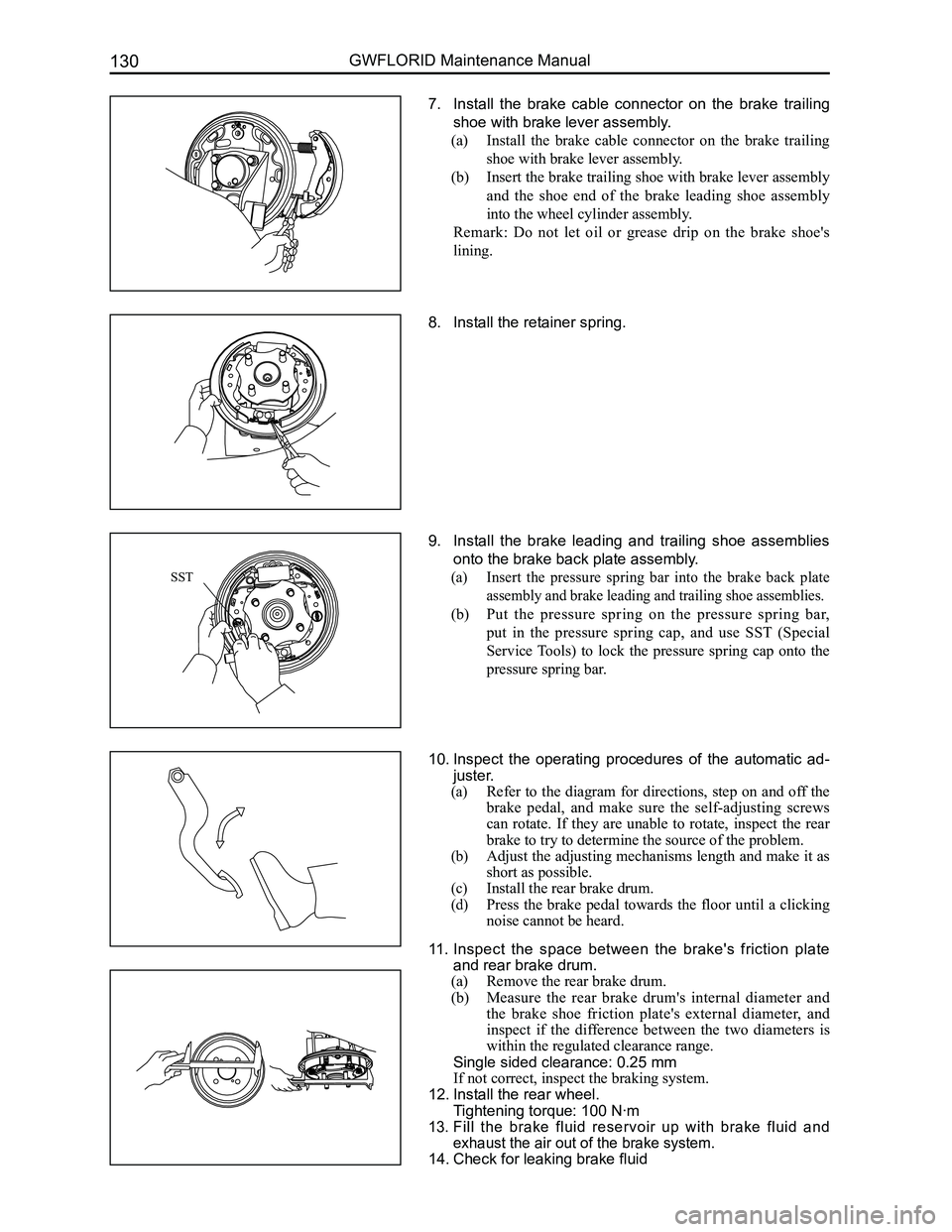

7. Install the brake cable connector on the brake trailing

shoe with brake lever assembly.

(a) Install the brake cable connector on the brake trailing

shoe with brake lever assembly.

(b) Insert the brake trailing shoe with brake lever assembly

and the shoe end of the brake leading shoe assembly

into the wheel cylinder assembly.

Remark: Do not let oil or grease drip on the brake shoe's

lining.

8. Install the retainer spring.

9. Install the brake leading and trailing shoe assemblies

onto the brake back plate assembly.

(a) Insert the pressure spring bar into the brake back plate

assembly and brake leading and trailing shoe assemblies.

(b) Put the pressure spring on the pressure spring bar,

put in the pressure spring cap, and use SST (Special

Service Tools) to lock the pressure spring cap onto the

pressure spring bar.

10. Inspect the operating procedures of the automatic ad-

juster.

(a) Refer to the diagram for directions, step on and off the

brake pedal, and make sure the self-adjusting screws

can rotate. If they are unable to rotate, inspect the rear

brake to try to determine the source of the problem.

(b) Adjust the adjusting mechanisms length and make it as

short as possible.

(c) Install the rear brake drum.

(d) Press the brake pedal towards the floor until a clicking

noise cannot be heard.

11. Inspect the space between the brake's friction plate

and rear brake drum.

(a) Remove the rear brake drum.

(b) Measure the rear brake drum's internal diameter and

the brake shoe friction plate's external diameter, and

inspect if the difference between the two diameters is

within the regulated clearance range.

Single sided clearance: 0.25 mm

If not correct, inspect the braking system.

12. Install the rear wheel.

Tightening torque: 100 N·m

13. Fill the brake fluid reservoir up with brake fluid and

exhaust the air out of the brake system.

14. Check for leaking brake fluid

SST

Page 138 of 281

Downloaded from www.Manualslib.com manuals search engine 131Brake System

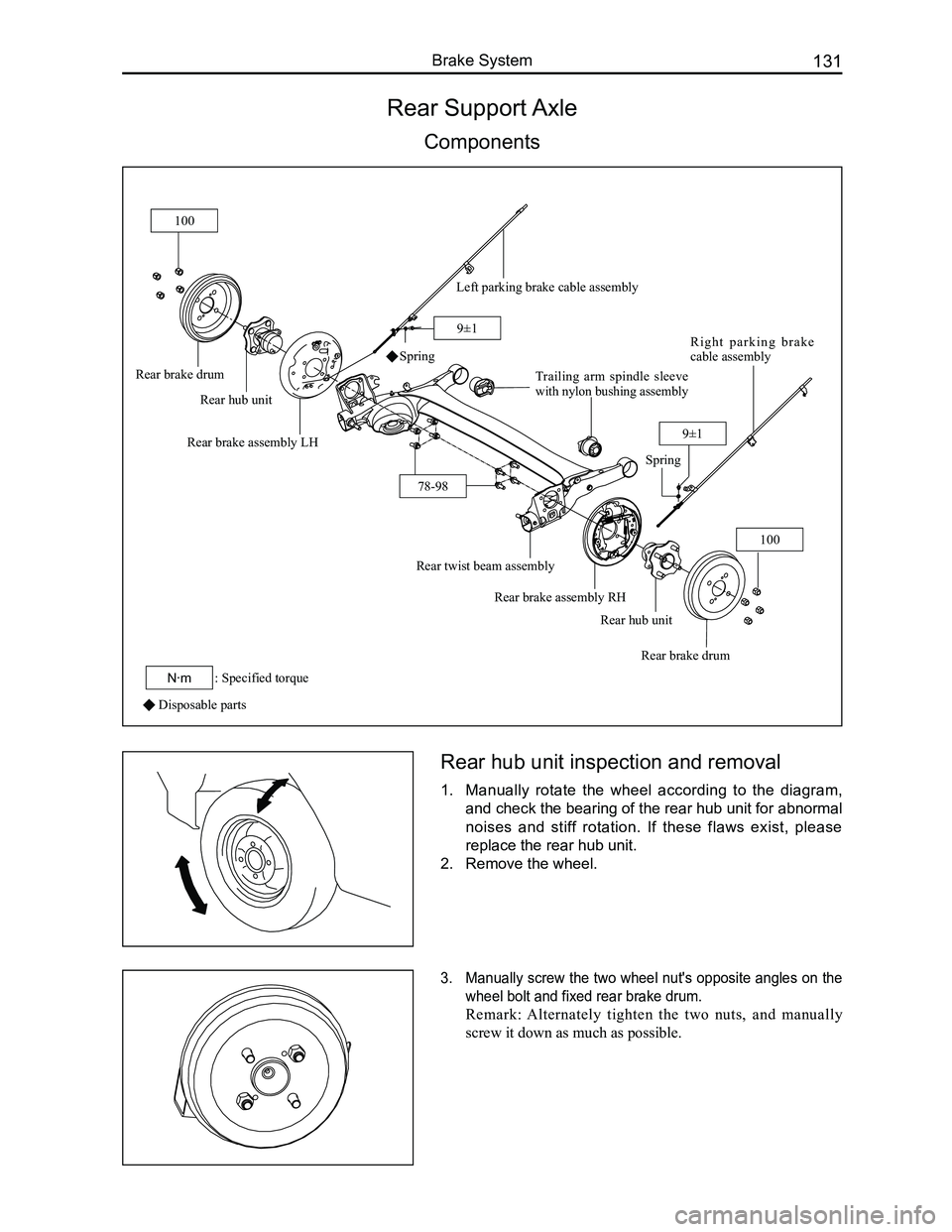

Rear Support Axle

Components

Rear hub unit inspection and removal

1. Manually rotate the wheel according to the diagram,

and check the bearing of the rear hub unit for abnormal

noises and stiff rotation. If these flaws exist, please

replace the rear hub unit.

2. Remove the wheel.

3. Manually screw the two wheel nut's opposite angles on the

wheel bolt and fixed rear brake drum.

Remark: Alternately tighten the two nuts, and manually

screw it down as much as possible.

Rear brake drum

Rear brake assembly RH

R i g h t p a r k i n g b r a k e cable assembly

Rear hub unit

Trailing arm spindle sleeve with nylon bushing assembly

Rear twist beam assembly

Rear brake assembly LH

Rear brake drum

Rear hub unit

Left parking brake cable assembly

Disposable parts

Spring

Spring

9±1

: Specified torqueN·m

78-98

9±1

100

100

Page 139 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual132

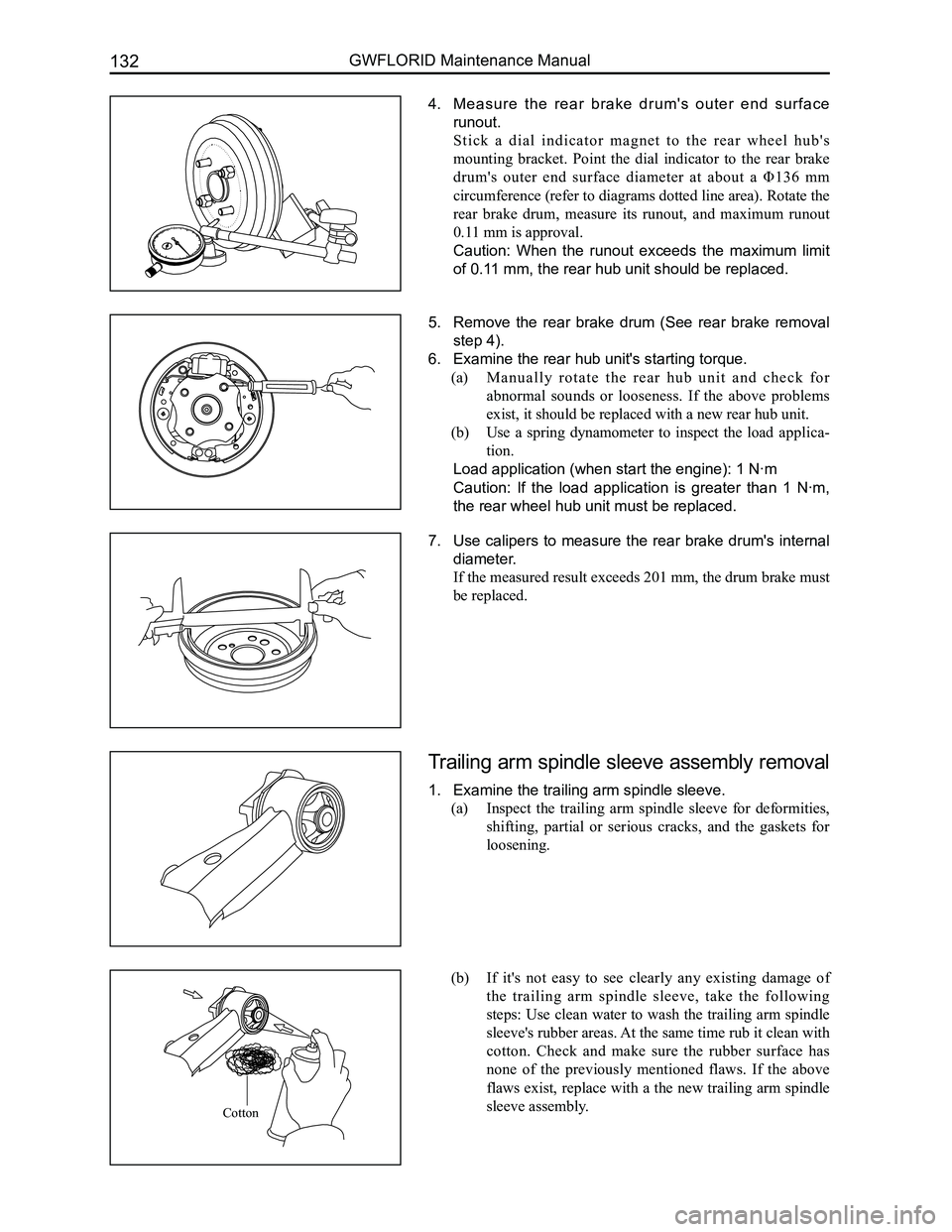

4. Measure the rear brake drum's outer end surface

runout.

S t i c k a d i a l i n d i c a t o r m a g n e t t o t h e r e a r w h e e l h u b ' s

mounting bracket. Point the dial indicator to the rear brake

drum's outer end surface diameter at about a Φ136 mm

circumference (refer to diagrams dotted line area). Rotate the

rear brake drum, measure its runout, and maximum runout

0.11 mm is approval.

Caution: When the runout exceeds the maximum limit

of 0.11 mm, the rear hub unit should be replaced.

5. Remove the rear brake drum (See rear brake removal

step 4).

6. Examine the rear hub unit's starting torque.

(a) M a n u a l l y r o t a t e t h e r e a r h u b u n i t a n d c h e c k f o r

abnormal sounds or looseness. If the above problems

exist, it should be replaced with a new rear hub unit.

(b) Use a spring dynamometer to inspect the load applica-

tion.

Load application (when start the engine): 1 N·m

Caution: If the load application is greater than 1 N·m,

the rear wheel hub unit must be replaced.

7. Use calipers to measure the rear brake drum's internal

diameter.

If the measured result exceeds 201 mm, the drum brake must

be replaced.

Trailing arm spindle sleeve assembly removal

1. Examine the trailing arm spindle sleeve.

(a) Inspect the trailing arm spindle sleeve for deformities,

shifting, partial or serious cracks, and the gaskets for

loosening.

(b) If it's not easy to see clearly any existing damage of

the trailing arm spindle sleeve, take the following

steps: Use clean water to wash the trailing arm spindle

sleeve's rubber areas. At the same time rub it clean with

cotton. Check and make sure the rubber surface has

none of the previously mentioned flaws. If the above

flaws exist, replace with a the new trailing arm spindle

sleeve assembly.Cotton

Page 140 of 281

Downloaded from www.Manualslib.com manuals search engine 133Brake System

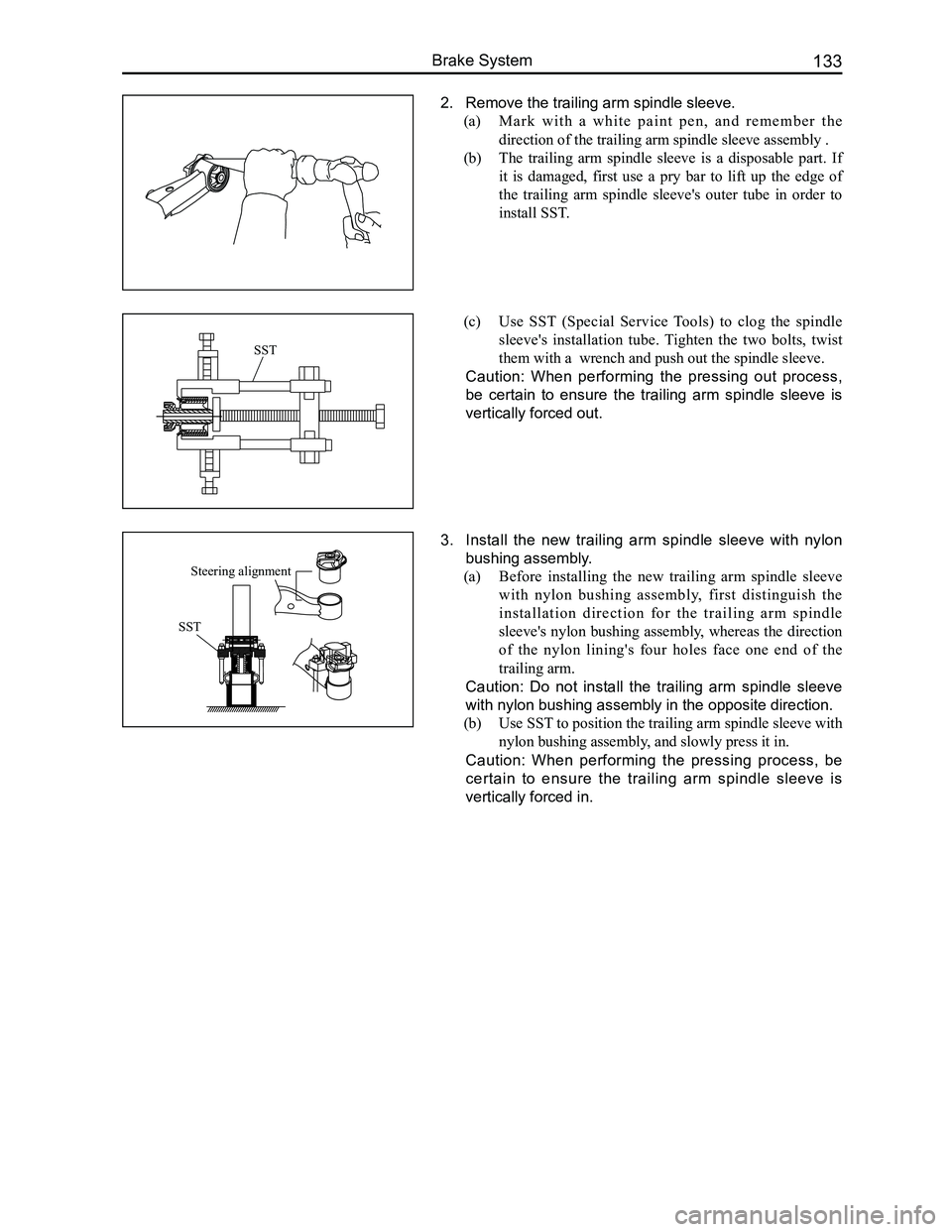

2. Remove the trailing arm spindle sleeve.

(a) M a r k w i t h a w h i t e p a i n t p e n , a n d r e m e m b e r t h e

direction of the trailing arm spindle sleeve assembly .

(b) The trailing arm spindle sleeve is a disposable part. If

it is damaged, first use a pry bar to lift up the edge of

the trailing arm spindle sleeve's outer tube in order to

install SST.

(c) Use SST (Special Service Tools) to clog the spindle

sleeve's installation tube. Tighten the two bolts, twist

them with a wrench and push out the spindle sleeve.

Caution: When performing the pressing out process,

be certain to ensure the trailing arm spindle sleeve is

vertically forced out.

3. Install the new trailing arm spindle sleeve with nylon

bushing assembly.

(a) Before installing the new trailing arm spindle sleeve

with nylon bushing assembly, first distinguish the

installation direction for the trailing arm spindle

sleeve's nylon bushing assembly, whereas the direction

of the nylon lining's four holes face one end of the

trailing arm.

Caution: Do not install the trailing arm spindle sleeve

with nylon bushing assembly in the opposite direction.

(b) Use SST to position the trailing arm spindle sleeve with

nylon bushing assembly, and slowly press it in.

Caution: When performing the pressing process, be

certain to ensure the trailing arm spindle sleeve is

vertically forced in.

SST

Steering alignment

SST

Page 142 of 281

Downloaded from www.Manualslib.com manuals search engine 135Steering System

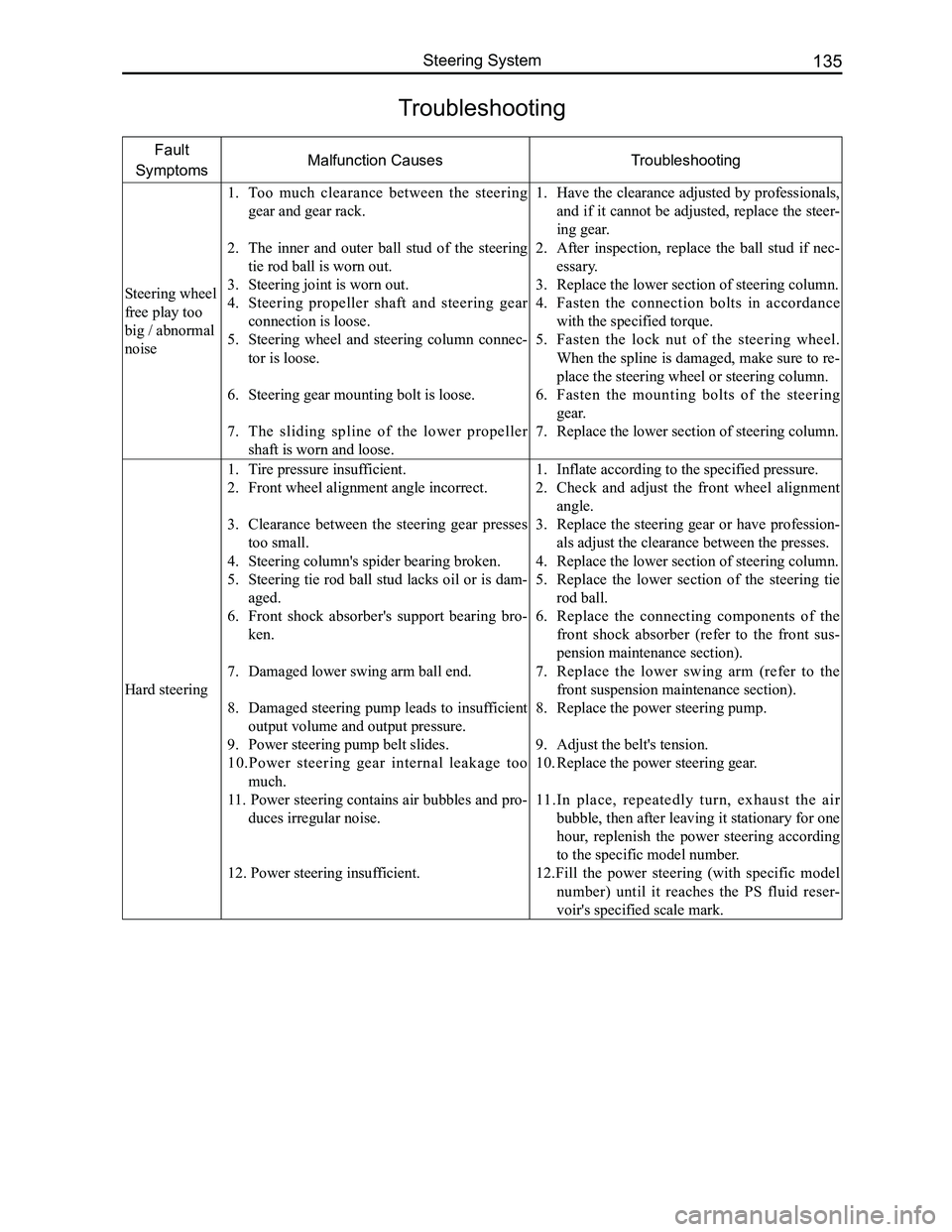

Troubleshooting

Fault

SymptomsMalfunction CausesTroubleshooting

Steering wheel

free play too

big / abnormal

noise

1. Too much clearance between the steering

gear and gear rack.

2. The inner and outer ball stud of the steering

tie rod ball is worn out.

3. Steering joint is worn out.

4. Steering propeller shaft and steering gear

connection is loose.

5. Steering wheel and steering column connec-

tor is loose.

6. Steering gear mounting bolt is loose.

7. The sliding spline of the lower propeller

shaft is worn and loose.

1. Have the clearance adjusted by professionals,

and if it cannot be adjusted, replace the steer-

ing gear.

2. After inspection, replace the ball stud if nec-

essary.

3. Replace the lower section of steering column.

4. Fasten the connection bolts in accordance

with the specified torque.

5. Fasten the lock nut of the steering wheel.

When the spline is damaged, make sure to re-

place the steering wheel or steering column.

6. Fasten the mounting bolts of the steering

gear.

7. Replace the lower section of steering column.

Hard steering

1. Tire pressure insufficient.

2. Front wheel alignment angle incorrect.

3. Clearance between the steering gear presses

too small.

4. Steering column's spider bearing broken.

5. Steering tie rod ball stud lacks oil or is dam-

aged.

6. Front shock absorber's support bearing bro-

ken.

7. Damaged lower swing arm ball end.

8. Damaged steering pump leads to insufficient

output volume and output pressure.

9. Power steering pump belt slides.

10.Power steering gear internal leakage too

much.

11. Power steering contains air bubbles and pro-

duces irregular noise.

12. Power steering insufficient.

1. Inflate according to the specified pressure.

2. Check and adjust the front wheel alignment

angle.

3. Replace the steering gear or have profession-

als adjust the clearance between the presses.

4. Replace the lower section of steering column.

5. Replace the lower section of the steering tie

rod ball.

6. Replace the connecting components of the

front shock absorber (refer to the front sus-

pension maintenance section).

7. Replace the lower swing arm (refer to the

front suspension maintenance section).

8. Replace the power steering pump.

9. Adjust the belt's tension.

10. Replace the power steering gear.

11.In place, repeatedly turn, exhaust the air

bubble, then after leaving it stationary for one

hour, replenish the power steering according

to the specific model number.

12.Fill the power steering (with specific model

number) until it reaches the PS fluid reser-

voir's specified scale mark.