ect GREAT WALL FLORID 2008 Manual PDF

[x] Cancel search | Manufacturer: GREAT WALL, Model Year: 2008, Model line: FLORID, Model: GREAT WALL FLORID 2008Pages: 281, PDF Size: 43.97 MB

Page 117 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual110

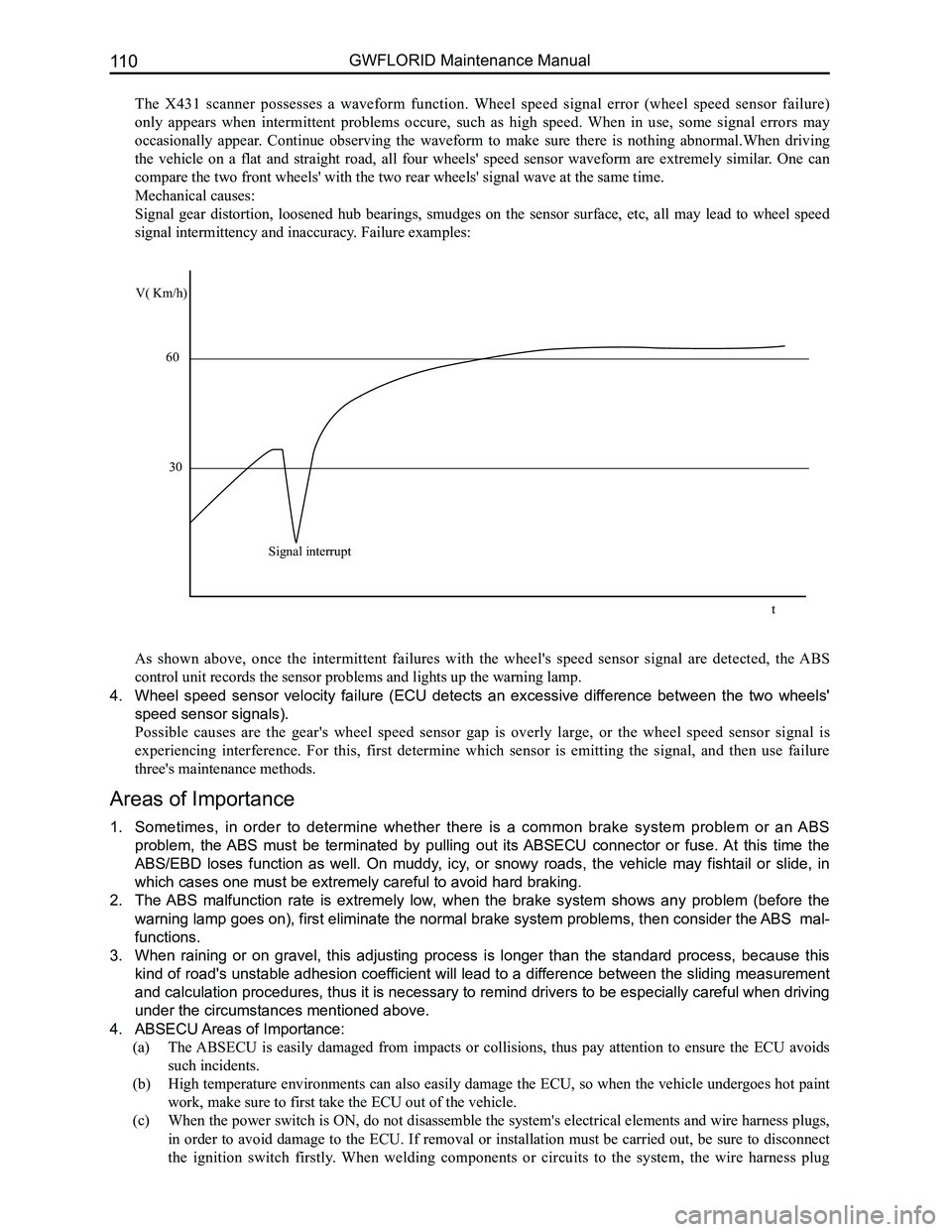

The X431 scanner possesses a waveform function. Wheel speed signal error (wheel speed sensor failure)

only appears when intermittent problems occure, such as high speed. When in use, some signal errors may

occasionally appear. Continue observing the waveform to make sure there is nothing abnormal.When driving

the vehicle on a flat and straight road, all four wheels' speed sensor waveform are extremely similar. One can

compare the two front wheels' with the two rear wheels' signal wave at t\

he same time.

Mechanical causes:

Signal gear distortion, loosened hub bearings, smudges on the sensor surface, etc, all may lead to wheel speed

signal intermittency and inaccuracy. Failure examples:

As shown above, once the intermittent failures with the wheel's speed sensor signal are detected, the ABS

control unit records the sensor problems and lights up the warning lamp.\

4. Wheel speed sensor velocity failure (ECU detects an excessive difference between the two wheels'

speed sensor signals).

Possible causes are the gear's wheel speed sensor gap is overly large, or the wheel speed sensor signal is

experiencing interference. For this, first determine which sensor is emitting the signal, and then use failure

three's maintenance methods.

Areas of Importance

1. Sometimes, in order to determine whether there is a common brake system problem or an ABS

problem, the ABS must be terminated by pulling out its ABSECU connector or fuse. At this time the

ABS/EBD loses function as well. On muddy, icy, or snowy roads, the vehicle may fishtail or slide, in

which cases one must be extremely careful to avoid hard braking.

2. The ABS malfunction rate is extremely low, when the brake system shows any problem (before the

warning lamp goes on), first eliminate the normal brake system problems, then consider the ABS mal-

functions.

3. When raining or on gravel, this adjusting process is longer than the standard process, because this

kind of road's unstable adhesion coefficient will lead to a difference between the sliding measurement

and calculation procedures, thus it is necessary to remind drivers to be especially careful when driving

under the circumstances mentioned above.

4. ABSECU Areas of Importance:

(a) The ABSECU is easily damaged from impacts or collisions, thus pay attention to ensure the ECU avoids

such incidents.

(b) High temperature environments can also easily damage the ECU, so when the vehicle undergoes hot paint

work, make sure to first take the ECU out of the vehicle.

(c) When the power switch is ON, do not disassemble the system's electrical elements and wire harness plugs,

in order to avoid damage to the ECU. If removal or installation must be carried out, be sure to disconnect

the ignition switch firstly. When welding components or circuits to the system, the wire harness plug

V( Km/h)

60

30

Signal interrupt

t

Page 118 of 281

Downloaded from www.Manualslib.com manuals search engine 111Brake System

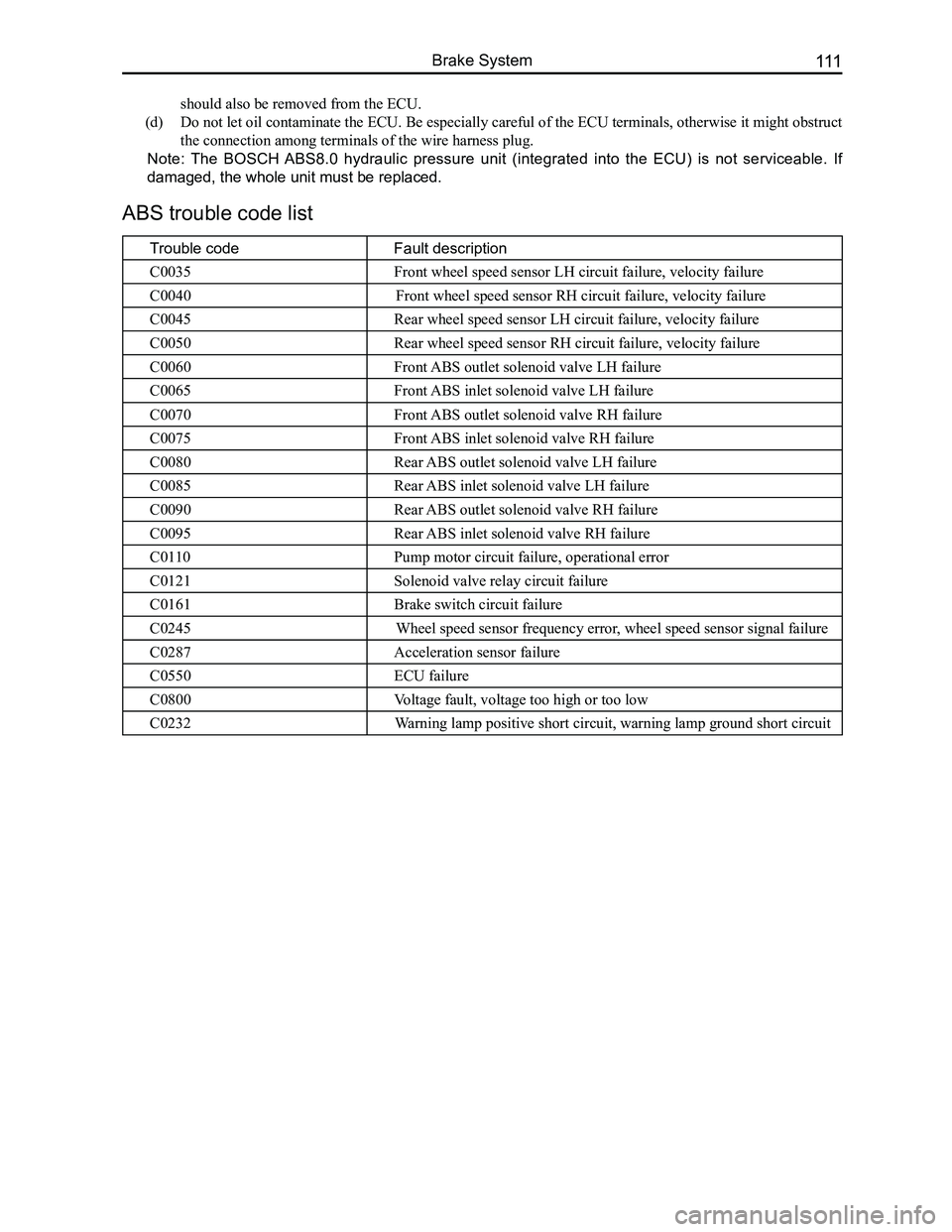

ABS trouble code list

Trouble codeFault description

C0035Front wheel speed sensor LH circuit failure, velocity failure

C0040Front wheel speed sensor RH circuit failure, velocity failure

C0045Rear wheel speed sensor LH circuit failure, velocity failure

C0050Rear wheel speed sensor RH circuit failure, velocity failure

C0060Front ABS outlet solenoid valve LH failure

C0065Front ABS inlet solenoid valve LH failure

C0070Front ABS outlet solenoid valve RH failure

C0075Front ABS inlet solenoid valve RH failure

C0080Rear ABS outlet solenoid valve LH failure

C0085Rear ABS inlet solenoid valve LH failure

C0090Rear ABS outlet solenoid valve RH failure

C0095Rear ABS inlet solenoid valve RH failure

C0110Pump motor circuit failure, operational error

C0121Solenoid valve relay circuit failure

C0161Brake switch circuit failure

C0245Wheel speed sensor frequency error, wheel speed sensor signal failure

C0287Acceleration sensor failure

C0550ECU failure

C0800Voltage fault, voltage too high or too low

C0232Warning lamp positive short circuit, warning lamp ground short circuit

should also be removed from the ECU.

(d) Do not let oil contaminate the ECU. Be especially careful of the ECU terminals, otherwise it might obstruct

the connection among terminals of the wire harness plug.

Note: The BOSCH ABS8.0 hydraulic pressure unit (integrated into the ECU) is not serviceable. If

damaged, the whole unit must be replaced.

Page 119 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual112

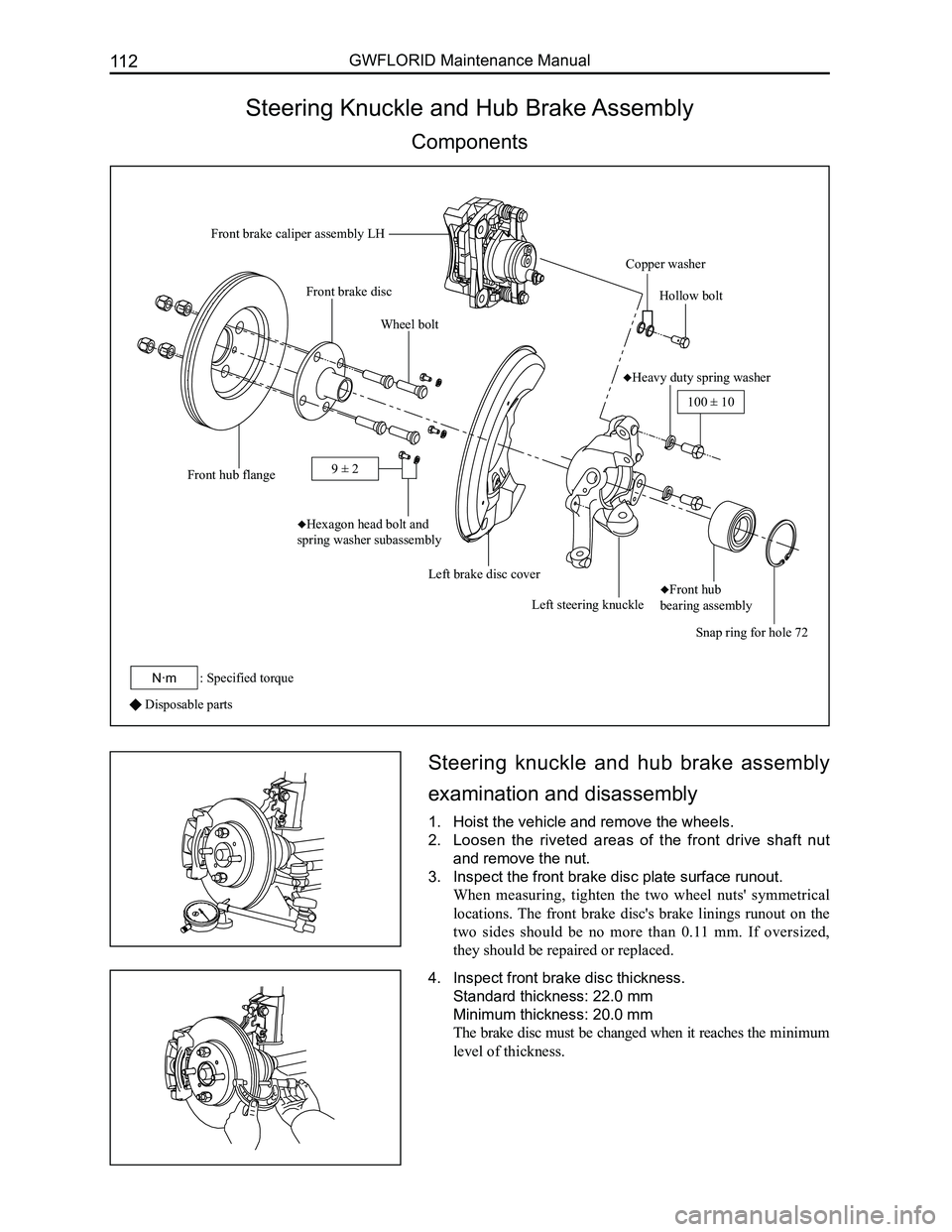

Steering Knuckle and Hub Brake Assembly

Components

Disposable parts

Steering knuckle and hub brake assembly

examination and disassembly

1. Hoist the vehicle and remove the wheels.

2. Loosen the riveted areas of the front drive shaft nut

and remove the nut.

3. Inspect the front brake disc plate surface runout.

When measuring, tighten the two wheel nuts' symmetrical

locations. The front brake disc's brake linings runout on the

two sides should be no more than 0.11 mm. If oversized,

they should be repaired or replaced.

4. Inspect front brake disc thickness.

Standard thickness: 22.0 mm

Minimum thickness: 20.0 mm

The brake disc must be changed when it reaches the minimum

level of thickness.

Front brake caliper assembly LH

Copper washer

Hollow bolt

♦Heavy duty spring washer

Snap ring for hole 72

♦Front hub

bearing assemblyLeft steering knuckle

Left brake disc cover

♦Hexagon head bolt and

spring washer subassembly

Wheel bolt

Front hub flange

Front brake disc

100 ± 10

: Specified torqueN·m

9 ± 2

Page 120 of 281

Downloaded from www.Manualslib.com manuals search engine 113Brake System

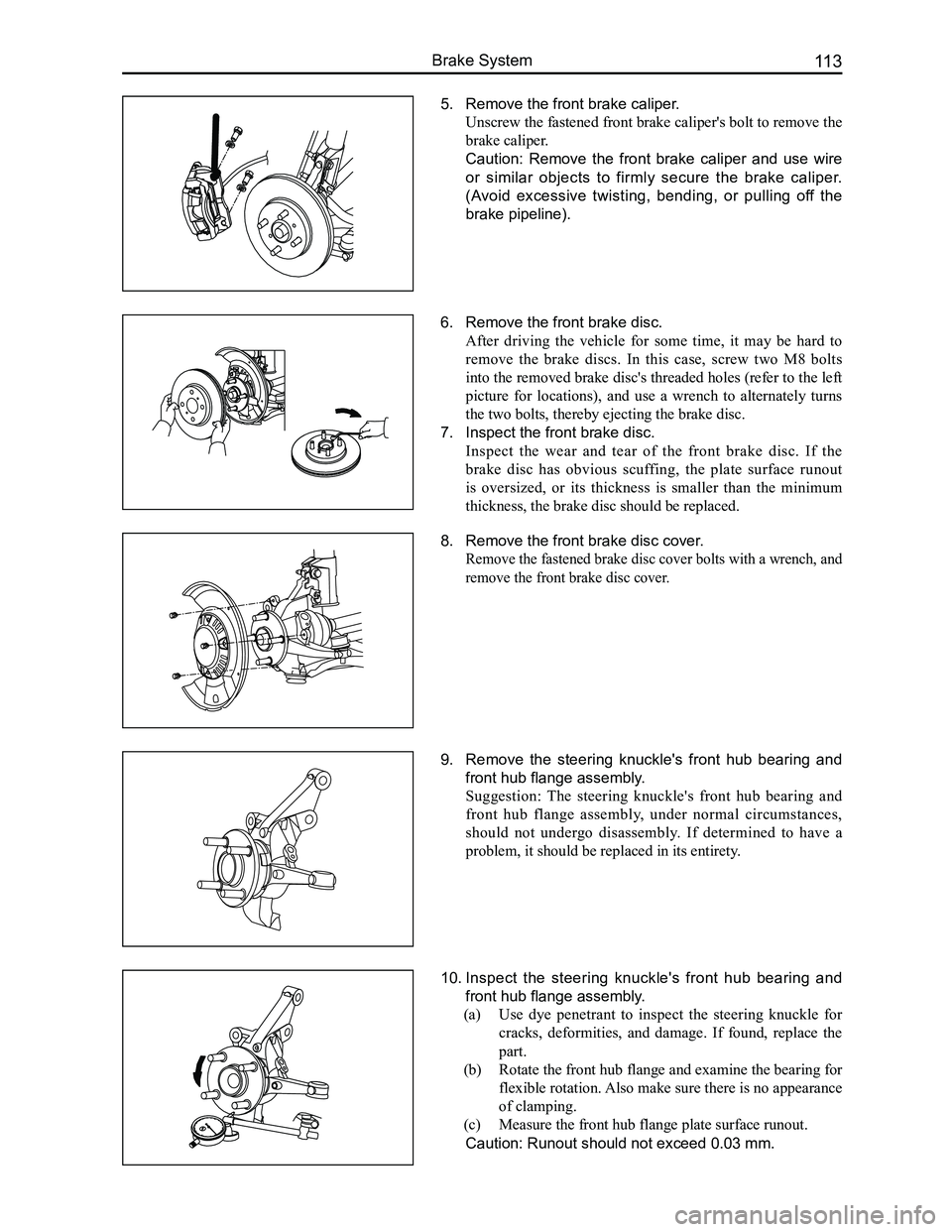

5. Remove the front brake caliper.

Unscrew the fastened front brake caliper's bolt to remove the

brake caliper.

Caution: Remove the front brake caliper and use wire

or similar objects to firmly secure the brake caliper.

(Avoid excessive twisting, bending, or pulling off the

brake pipeline).

6. Remove the front brake disc.

After driving the vehicle for some time, it may be hard to

remove the brake discs. In this case, screw two M8 bolts

into the removed brake disc's threaded holes (refer to the left

picture for locations), and use a wrench to alternately turns

the two bolts, thereby ejecting the brake disc.

7. Inspect the front brake disc.

Inspect the wear and tear of the front brake disc. If the

brake disc has obvious scuffing, the plate surface runout

is oversized, or its thickness is smaller than the minimum

thickness, the brake disc should be replaced.

8. Remove the front brake disc cover.

Remove the fastened brake disc cover bolts with a wrench, and

remove the front brake disc cover.

9. Remove the steering knuckle's front hub bearing and

front hub flange assembly.

Suggestion: The steering knuckle's front hub bearing and

front hub flange assembly, under normal circumstances,

should not undergo disassembly. If determined to have a

problem, it should be replaced in its entirety.

10. Inspect the steering knuckle's front hub bearing and

front hub flange assembly.

(a) Use dye penetrant to inspect the steering knuckle for

cracks, deformities, and damage. If found, replace the

part.

(b) Rotate the front hub flange and examine the bearing for

flexible rotation. Also make sure there is no appearance

of clamping.

(c) Measure the front hub flange plate surface runout.

Caution: Runout should not exceed 0.03 mm.

Page 121 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual114

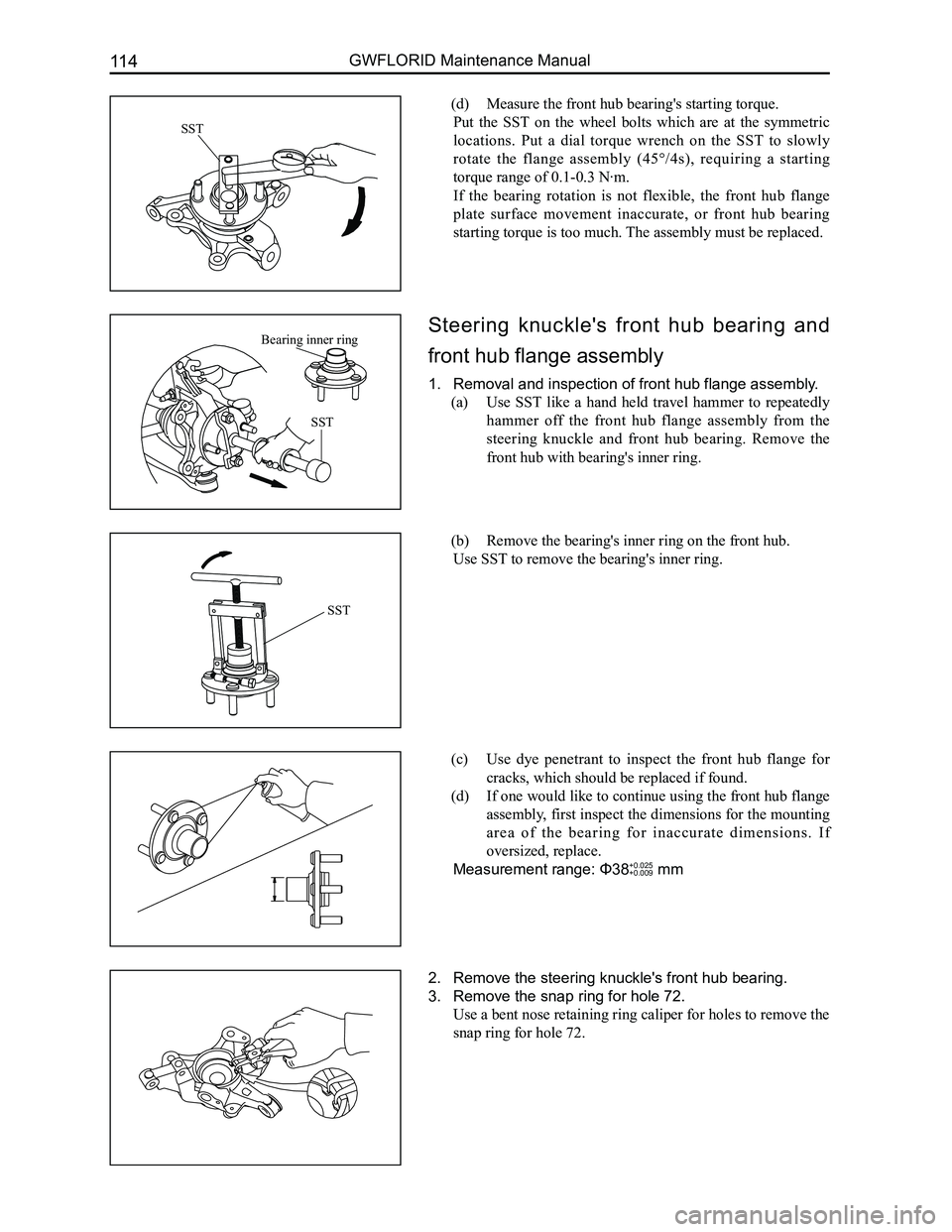

(d) Measure the front hub bearing's starting torque.

Put the SST on the wheel bolts which are at the symmetric

locations. Put a dial torque wrench on the SST to slowly

rotate the flange assembly (45°/4s), requiring a starting

torque range of 0.1-0.3 N·m.

If the bearing rotation is not flexible, the front hub flange

plate surface movement inaccurate, or front hub bearing

starting torque is too much. The assembly must be replaced.

Steering knuckle's front hub bearing and

front hub flange assembly

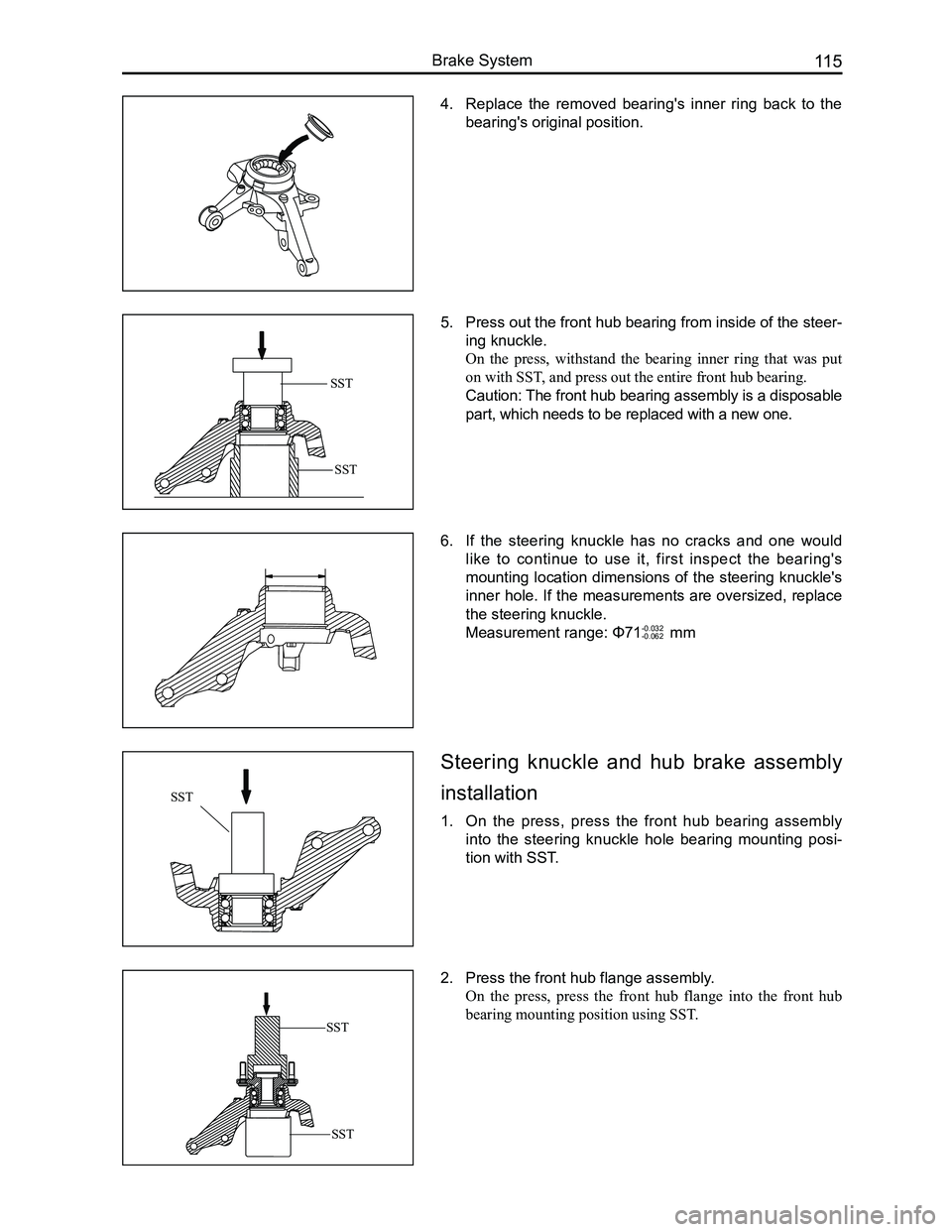

1. Removal and inspection of front hub flange assembly.

(a) Use SST like a hand held travel hammer to repeatedly

hammer off the front hub flange assembly from the

steering knuckle and front hub bearing. Remove the

front hub with bearing's inner ring.

(b) Remove the bearing's inner ring on the front hub.

Use SST to remove the bearing's inner ring.

SST

SST

Bearing inner ring

SST

(c) Use dye penetrant to inspect the front hub flange for

cracks, which should be replaced if found.

(d) If one would like to continue using the front hub flange

assembly, first inspect the dimensions for the mounting

area of the bearing for inaccurate dimensions. If

oversized, replace.

Measurement range: Φ38+0.025 +0.009 mm

2. Remove the steering knuckle's front hub bearing.

3. Remove the snap ring for hole 72.

Use a bent nose retaining ring caliper for holes to remove the

snap ring for hole 72.

Page 122 of 281

Downloaded from www.Manualslib.com manuals search engine 115Brake System

4. Replace the removed bearing's inner ring back to the

bearing's original position.

5. Press out the front hub bearing from inside of the steer-

ing knuckle.

On the press, withstand the bearing inner ring that was put

on with SST, and press out the entire front hub bearing.

Caution: The front hub bearing assembly is a disposable

part, which needs to be replaced with a new one.

Steering knuckle and hub brake assembly

installation

1. On the press, press the front hub bearing assembly

into the steering knuckle hole bearing mounting posi-

tion with SST.

SST

SST

SST

6. If the steering knuckle has no cracks and one would

like to continue to use it, first inspect the bearing's

mounting location dimensions of the steering knuckle's

inner hole. If the measurements are oversized, replace

the steering knuckle.

Measurement range: Φ71-0.032 -0.062 mm

2. Press the front hub flange assembly.

On the press, press the front hub flange into the front hub

bearing mounting position using SST.

SST

SST

Page 125 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual118

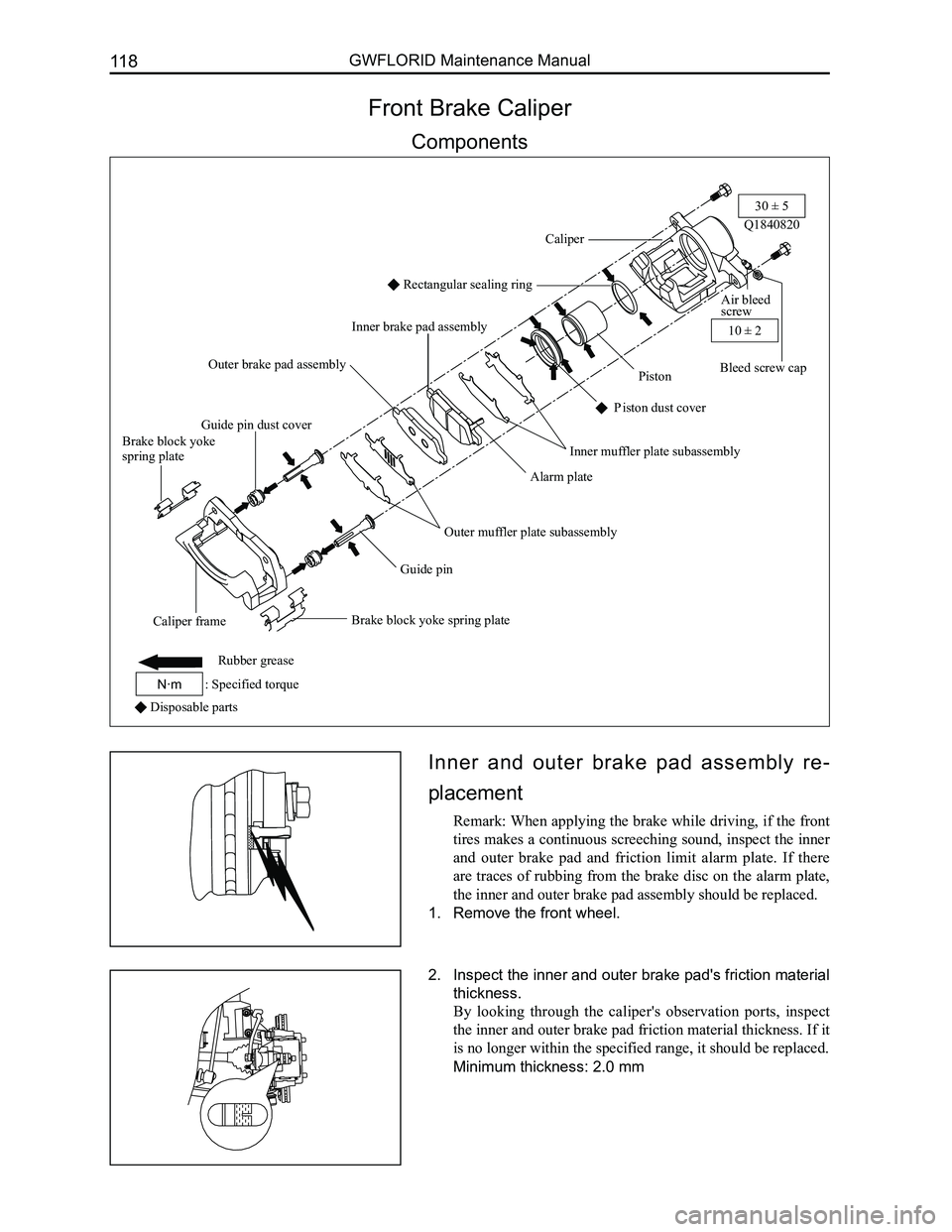

Front Brake Caliper

Components

Disposable parts

Inner and outer brake pad assembly re-

placement

Remark: When applying the brake while driving, if the front

tires makes a continuous screeching sound, inspect the inner

and outer brake pad and friction limit alarm plate. If there

are traces of rubbing from the brake disc on the alarm plate,

the inner and outer brake pad assembly should be replaced.

1. Remove the front wheel.

2. Inspect the inner and outer brake pad's friction material

thickness.

By looking through the caliper's observation ports, inspect

the inner and outer brake pad friction material thickness. If it

is no longer within the specified range, it should be replaced.

Minimum thickness: 2.0 mm

Bleed screw cap

Air bleed screw

Caliper

Rectangular sealing ring

Piston

P iston dust cover

Inner muffler plate subassembly

Alarm plate

Inner brake pad assembly

Outer brake pad assembly

Outer muffler plate subassembly

Guide pin

Guide pin dust cover

Caliper frame

Brake block yoke spring plate

Brake block yoke spring plate

30 ± 5

: Specified torqueN·m

10 ± 2

Q1840820

Rubber grease

Page 126 of 281

Downloaded from www.Manualslib.com manuals search engine 119Brake System

3. Remove the caliper assembly.

(a) Remove the hexagon bolt for flange face connecting

the caliper and caliper frame's lower end.

(b) Lift the caliper assembly and use a rope to hang it up to

protect the brake pipeline.

Remark: Do not unscrew the brake pipeline and bleed screw.

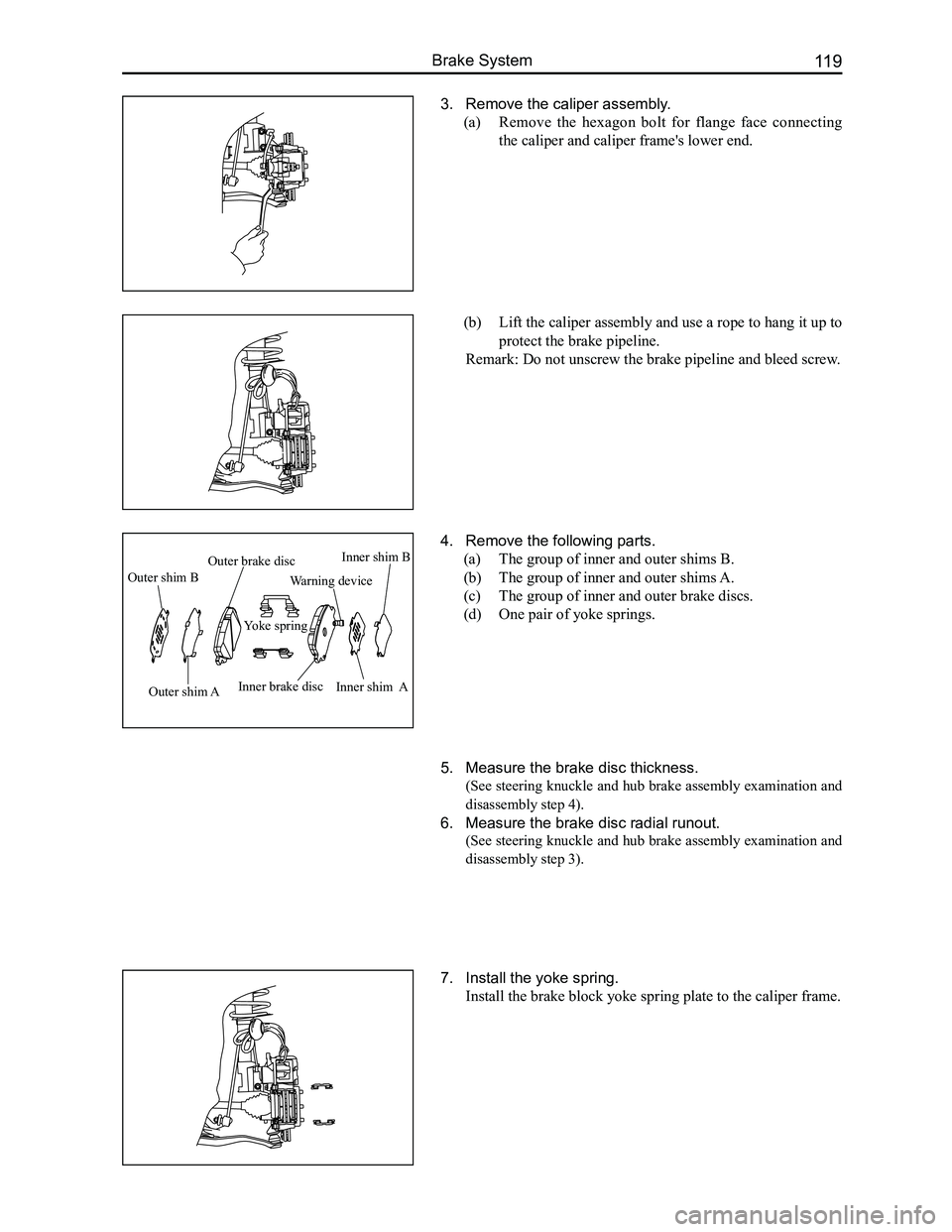

4. Remove the following parts.

(a) The group of inner and outer shims B.

(b) The group of inner and outer shims A.

(c) The group of inner and outer brake discs.

(d) One pair of yoke springs.

5. Measure the brake disc thickness.

(See steering knuckle and hub brake assembly examination and

disassembly step 4).

6. Measure the brake disc radial runout.

(See steering knuckle and hub brake assembly examination and

disassembly step 3).

7. Install the yoke spring.

Install the brake block yoke spring plate to the caliper frame.

Outer shim B

Outer shim AInner brake disc

Warning device

Inner shim B

Inner shim A

Outer brake disc

Yoke spring

Page 128 of 281

Downloaded from www.Manualslib.com manuals search engine 121Brake System

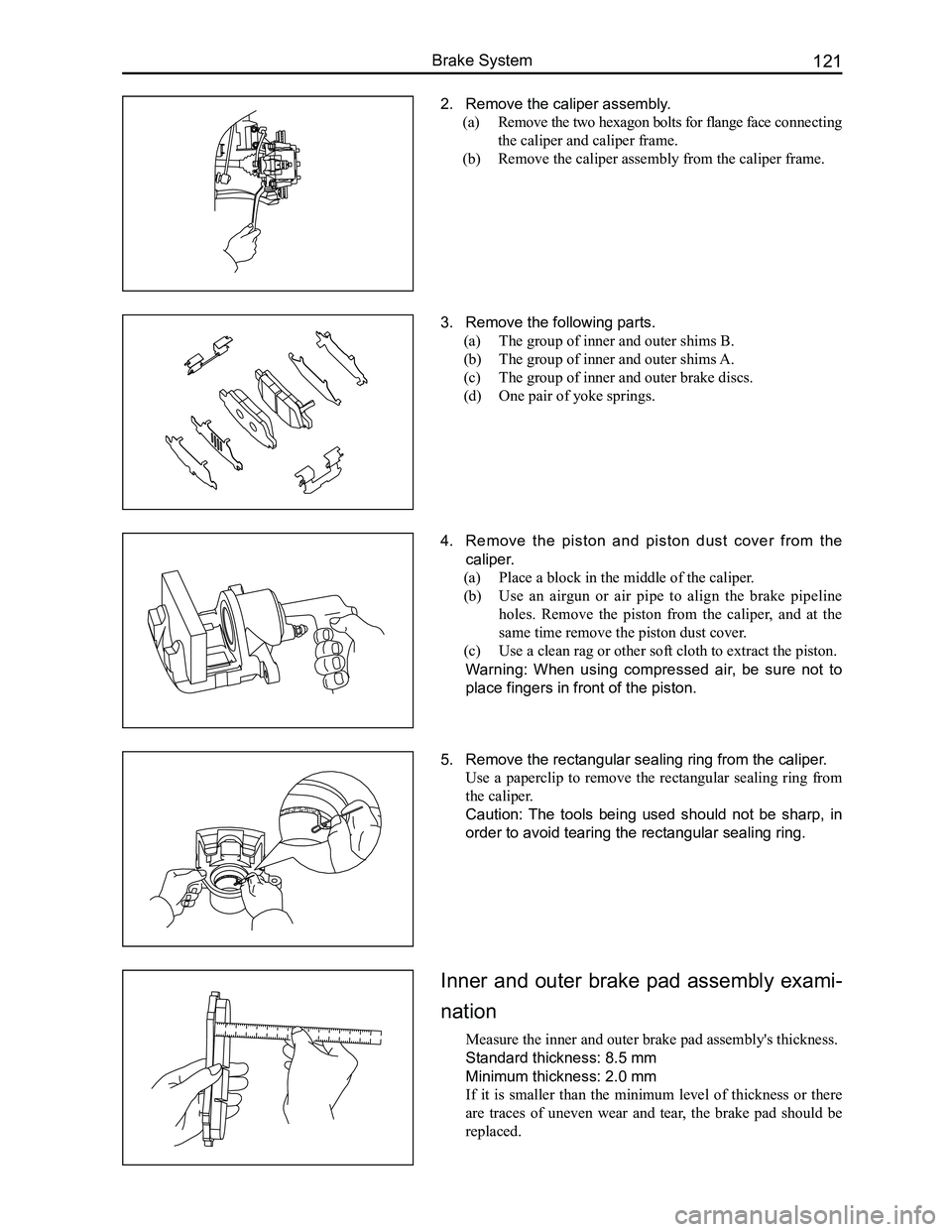

2. Remove the caliper assembly.

(a) Remove the two hexagon bolts for flange face connecting

the caliper and caliper frame.

(b) Remove the caliper assembly from the caliper frame.

3. Remove the following parts.

(a) The group of inner and outer shims B.

(b) The group of inner and outer shims A.

(c) The group of inner and outer brake discs.

(d) One pair of yoke springs.

4. Remove the piston and piston dust cover from the

caliper.

(a) Place a block in the middle of the caliper.

(b) Use an airgun or air pipe to align the brake pipeline

holes. Remove the piston from the caliper, and at the

same time remove the piston dust cover.

(c) Use a clean rag or other soft cloth to extract the piston.

Warning: When using compressed air, be sure not to

place fingers in front of the piston.

5. Remove the rectangular sealing ring from the caliper.

Use a paperclip to remove the rectangular sealing ring from

the caliper.

Caution: The tools being used should not be sharp, in

order to avoid tearing the rectangular sealing ring.

Inner and outer brake pad assembly exami-

nation

Measure the inner and outer brake pad assembly's thickness.

Standard thickness: 8.5 mm

Minimum thickness: 2.0 mm

If it is smaller than the minimum level of thickness or there

are traces of uneven wear and tear, the brake pad should be

replaced.

Page 129 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual122

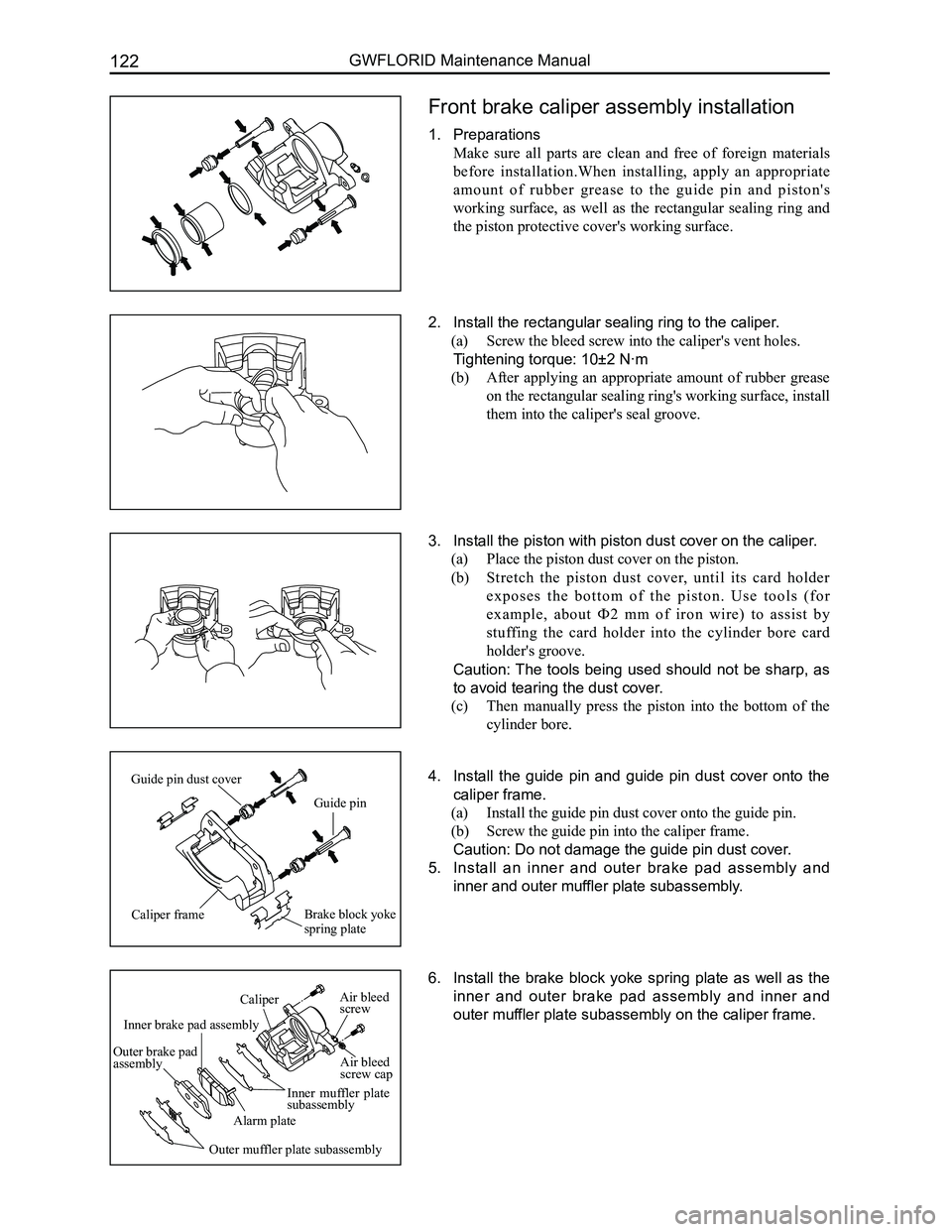

Front brake caliper assembly installation

1. Preparations

Make sure all parts are clean and free of foreign materials

before installation.When installing, apply an appropriate

amount of rubber grease to the guide pin and piston's

working surface, as well as the rectangular sealing ring and

the piston protective cover's working surface.

2. Install the rectangular sealing ring to the caliper.

(a) Screw the bleed screw into the caliper's vent holes.

Tightening torque: 10±2 N·m

(b) After applying an appropriate amount of rubber grease

on the rectangular sealing ring's working surface, install

them into the caliper's seal groove.

3. Install the piston with piston dust cover on the caliper.

(a) Place the piston dust cover on the piston.

(b) Stretch the piston dust cover, until its card holder

exposes the bottom of the piston. Use tools (for

example, about Ф2 mm of iron wire) to assist by

stuffing the card holder into the cylinder bore card

holder's groove.

Caution: The tools being used should not be sharp, as

to avoid tearing the dust cover.

(c) Then manually press the piston into the bottom of the

cylinder bore.

4. Install the guide pin and guide pin dust cover onto the

caliper frame.

(a) Install the guide pin dust cover onto the guide pin.

(b) Screw the guide pin into the caliper frame.

Caution: Do not damage the guide pin dust cover.

5. Install an inner and outer brake pad assembly and

inner and outer muffler plate subassembly.

6. Install the brake block yoke spring plate as well as the

inner and outer brake pad assembly and inner and

outer muffler plate subassembly on the caliper frame.

Guide pin

Guide pin dust cover

Caliper frameBrake block yoke spring plate

Air bleed screw cap

Air bleed screw Caliper

Inner muffler plate subassembly

Alarm plate

Inner brake pad assembly

Outer brake pad assembly

Outer muffler plate subassembly