airbag GREAT WALL FLORID 2008 Service Manual

[x] Cancel search | Manufacturer: GREAT WALL, Model Year: 2008, Model line: FLORID, Model: GREAT WALL FLORID 2008Pages: 281, PDF Size: 43.97 MB

Page 2 of 281

Downloaded from www.Manualslib.com manuals search engine PREFACE

GWFLORID will build 1.3L (GW413EF, GW4G13) or 1.5L (GW4G15) gasoline engines, in which the

GW4G13 and GW4G15 engines will both incorporate the newest VVT technology which meets the Euro IV

emission standards. GWFLORID features McPherson technology on its chassis system. With an ultra light

body made from structural steel and high-intensity front and rear fender impact beams as well as a collision

impact absorption system, it is able to maintain the cab's integrity and safety to greater extent. We wrote this

maintenance manual in order to meet the demand of Great Wall after-sales service technicians. This manual

mainly introduces the areas of importance in regard to maintenance and care, and removal and installation of

each system's assembly and maintenance technical parameters.

To reduce the possibility of injury or property damage, read and follow t\

he instructions carefully:

This manual is provided by the Great Wall Motor Co., Ltd, and is written for the technician use. Any

maintenance or repair without proper prior training and tools or devices may result in personal injury of the

person performing the maintenance or others in the vicinity. It is also possible that damage to the vehicle will

occur or will lead to mechanical failure during normal operation.

Correct vehicle maintenance and repair is essential for the safety of the person performing regular

maintenance as well as the vehicle itself. If there is any component that needs to be replaced, use a

component with the same serial number or a serial number specified by the Great Wall Motor Co., Ltd. Never

use any part that has not been authorized by the Great Wall Motor Co., Ltd.

Any maintenance procedure introduced in this manual is effective for maintenance and repair. Some of

these procedures need specially designed tools.

Therefore, before using any vehicle part following any maintenance procedure or working with a tool

that has not been authorized by the Great Wall Motor Co., Ltd, check to make sure that none of the above

will endanger the safety of the person performing the work or the correc\

t operation of the vehicle.

This manual includes multiple "Warnings" and "Cautions," which should be strictly followed, so as to

reduce the possibility of injury during maintenance or repair. Improper maintenance or repair of the vehicle

may cause potential safety hazards. These "Warnings" and "Cautions" are not exhaustive. It is impossible for

the Great Wall Motor Co., Ltd, to warn against all the potential dangers caused by not properly following the

instructions.

Please read carefully the "Areas of Importance" before carrying out any maintenance or repair on the

airbag system's components or its surrounding electrical components. Action contrary to any of the "Areas of

Importance" may lead to the deployment of the airbag, resulting in injur\

y or unnecessary repair of the airbag.

To avoid accidental deployment of the airbag and its resulting injury, we suggest repairing the airbag

system before other vehicle systems if the airbag and the other vehicle \

systems both need repairing.

We have received generous support and help from many professional technicians during the preparation

of this manual. We would like to express our heartfelt gratitude to all of them.

Although we have tried our best to write this manual well, we do not guarantee that the entire content

in this manual is absolutely correct. Users may not make any legal claim against the Great Wall Motor Co.,

Ltd. in regards to this manual. Any loss caused by using this manual is not our responsibility. Because of

the writer's limited experience, there are likely mistakes in this manual, therefore we welcome any user

comments, suggestions, and corrections.

Great Wall Motor Co., Ltd. reserves the final right of explanation.

\

Editor

May 2008

Page 6 of 281

Downloaded from www.Manualslib.com manuals search engine Technical Requirements ..................................................................................\

........141

Chapter Nine: Vehicle Body Electrical System ........................................................................\

.142

Basic Information on the Electrical System .............................................................143

Fuse Box ...................................................................................\

...............................144

Overall Vehicle’s Grounding Point Schematics ........................................................150

Key Electrical Component’s Module Schematics for the Overall Vehicle ................151

Wire Harness Distribution Chart for the Overall Vehicle ..........................................152

Wire Harness Relationship and Plug-in Connections Numbered Diagram ..............155

Wire Harness Plug-in Connectors and Pin Function Diagram .................................156

Electrical Wiring Diagram for the Overall Vehicle ....................................................167

Chapter Ten: Electrical Accessories ........................................................................\

.................177

Reverse Sensor ..................................................................................\

.....................178

Combination Meter ..................................................................................\

................180

Central Door Lock ...................................................................................\

.................181

Power Windows ..................................................................................\

.....................184

Immobilizer System ..................................................................................\

...............186

CD Player ..................................................................................\

..............................193

DVD Player ..................................................................................\

............................195

Chapter Eleven: Air Conditioning System........................................................................\

........202

Areas of Importance ..................................................................................\

..............203

Technical Parameters ..................................................................................\

............203

Troubleshooting ..................................................................................\

.....................204

Air Conditioning System’s Structure Diagram and Fundamentals ...........................207

Air Conditioning System Overview ..........................................................................207

Air Conditioning System Terminal Definition ............................................................208

Compressor ..................................................................................\

...........................208

Electromagnetic Clutch ...................................................................................\

.........210

Vacuuming and Charging Refrigerant ......................................................................211

Filling Quantity and Method for Refrigerant Oil ........................................................212

Daily Maintenance of the Air Conditioning System .................................................212

Chapter Twelve: Airbags ........................................................................\

...................................213

Airbag Electronic Control Unit ..................................................................................214

Diagnostic Scanner ...................................................................................\

...............215

Troubleshooting ..................................................................................\

.....................216

Vehicle Collision Diagnostics ..................................................................................\

.226

Removal Method for Individual Components ...........................................................227

Driver Side Airbag Module (DAB), Front Passenger Side

Airbag Module (PAB), Clock Spring, and Steering Wheel .......................................228

Airbag Module Disposal ...................................................................................\

........230

Page 7 of 281

Downloaded from www.Manualslib.com manuals search engine Airbag’s Diagnostic Methods Without a Diagnostic Scanner ...................................232

Chapter Thirteen: Vehicle Body ........................................................................\

........................233

Front Door Lock Assembly ...................................................................................\

....234

Rear Door Lock Assembly ..................................................................................\

.....237

Trunk Door Lock Assembly ...................................................................................\

...239

Wiper Arm and Vent Panel Assembly ......................................................................240

Front & Rear Window Glasses ................................................................................241

Dashboard ..................................................................................\

.............................242

Cooling Unit ..................................................................................\

...........................246

Front Door Assembly ..................................................................................\

.............248

Rear Door Assembly ...................................................................................\

.............251

Trunk Door Assembly ...................................................................................\

............254

Front Bumper ...................................................................................\

........................256

Rear Bumper ..................................................................................\

.........................259

Seat Belt ..................................................................................\

................................262

Seats ...................................................................................\

.....................................266

Sunroof Assembly ...................................................................................\

.................268

Page 21 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual14

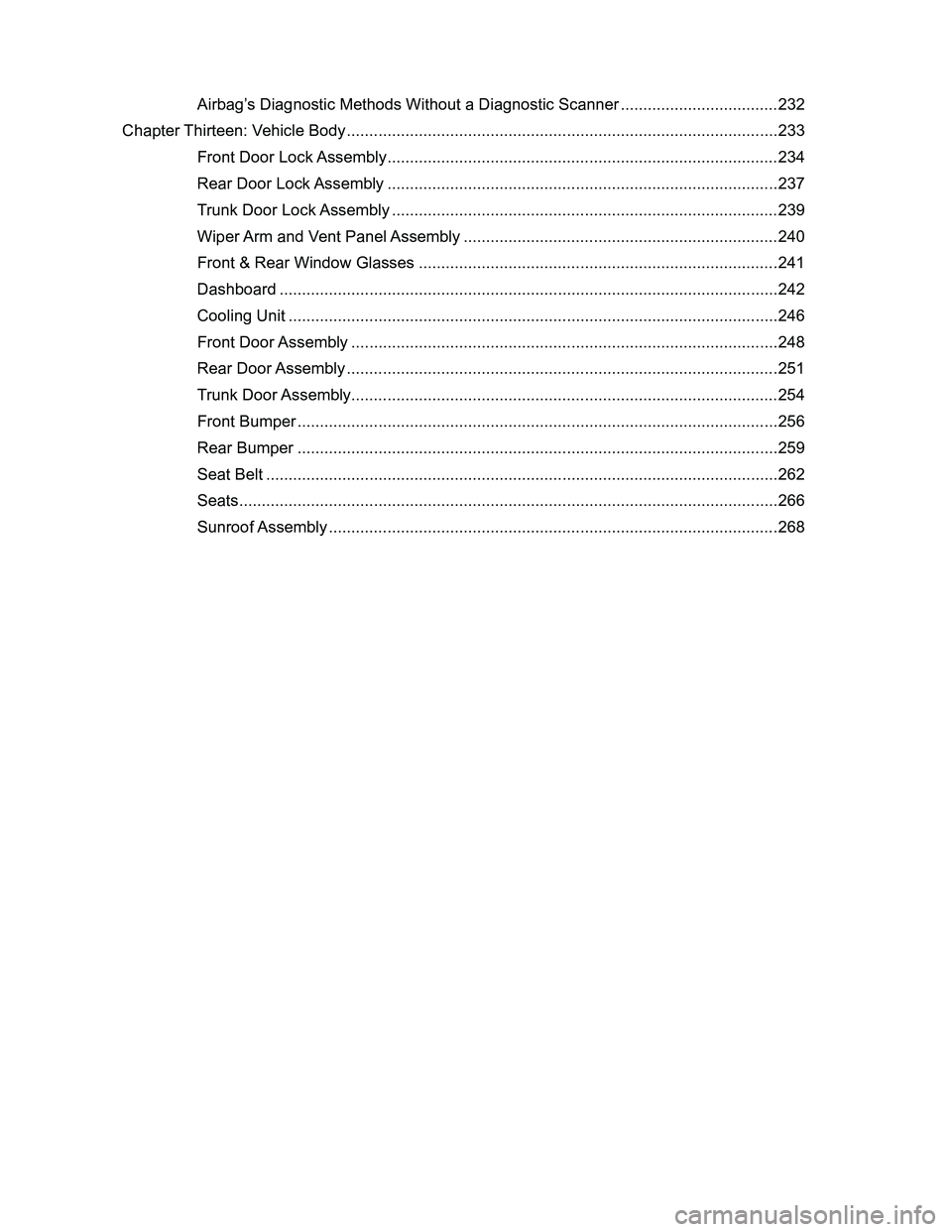

Chassis' Main Assembly Technical Parameters (Continued)

ItemSpecifications

Wheel and

tire

Wheel specificationsStandard 15 × 6J rim, offset distance: 40 mm

Tire specificationsStandard tire selection 185/65 R15 88H

Spare tire

specificationsSpare tire 185/65 R15 88H, T125/70R16 96M J16 × 4T

Steering

system

Steering gearRack and pinion hydraulic power steering gear, with drive ratio of 19.03,

power steering pump rate of flow is 6.7-8.9 L/min

Steering columnSafe, energy absorbing, angle-adjustable steering column, with an adjustable

range of 3.6°.

Steering wheelA three stage softening type with airbag, diameter of 370 mm, and maximum

steering circle number of 3.08.

Main technical

parameters

Front wheel camber/rear wheel camber-0° 43′ ± 30′ /-0° 43' ± 30'

Kingpin angle+10°21′ ± 30′

Kingpin caster+1°49′ ± 30′

Front wheel toe-in/rear wheel toe-in-0° 01′ ± 15′ /+0° 14' ± 15'

Inside wheel steering angle (°)32°-37°

Outer wheel steering angle (°)28°-30°

Steering wheel rotation number (n)3.08

Steering system angle ratio (i0ω)19.03

Brake

system

Service brake type

The service brake system adopts a hydraulic vacuum power-assisted type.

The front/rear brakes are disc and drum brakes respectively. The front brake

uses a ventilated disc, and the brake pedal is a suspended pedal with vacuum

booster. Brake line is in a dual-circuit diagonal (X type) arrangement,

adopting a ABS + EBD anti-lock and braking force distribution system.

Service brake booster

and master cylinder

Single stage Φ9inch vacuum booster, series dual-chamber brake master

cylinder, cylinder bore Φ22.22 mm, stroke 32 mm

Brake reservoirShares with the clutch master cylinder reservoir and installed with a brake

fluid level alarm.

Brake pedal strokeFree play: 6-9 mm, working stroke: 37-40 mm.

Brake pedal pressure<380 N (no load) <480 N (full load)

Parking brake

The parking brake system uses a mechanical remote ratchet cable control

mechanism to control the rear wheel drum brake. Brake lever's functional

stroke is 5-8 gearteeth.

Brake parameters

Front wheelFloating caliper disc brake

Wheel cylinder

diameterΦ54 mm

Brake disc

diameterΦ255 mm

Rear wheelLeading trailing shoe drum

brake

Wheel cylinder

diameterΦ19.05 mm

Drum brake

diameterΦ200 mm

Page 24 of 281

Downloaded from www.Manualslib.com manuals search engine 17Overall Parameters

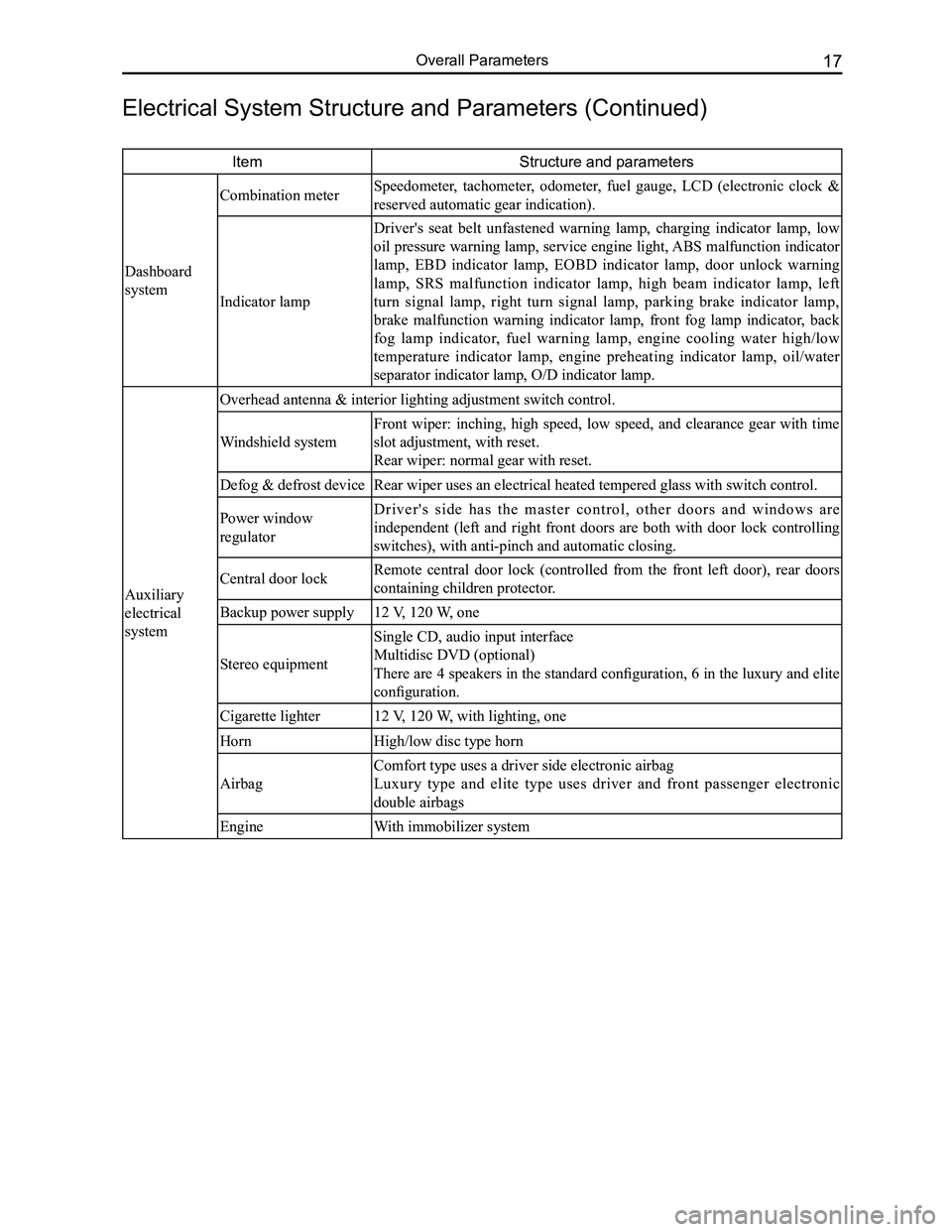

ItemStructure and parameters

Dashboard

system

Combination meter Speedometer, tachometer, odometer, fuel gauge, LCD (electronic clock &

reserved automatic gear indication).

Indicator lamp

Driver's seat belt unfastened warning lamp, charging indicator lamp, low

oil pressure warning lamp, service engine light, ABS malfunction indicator

lamp, EBD indicator lamp, EOBD indicator lamp, door unlock warning

lamp, SRS malfunction indicator lamp, high beam indicator lamp, left

turn signal lamp, right turn signal lamp, parking brake indicator lamp,

brake malfunction warning indicator lamp, front fog lamp indicator, back

fog lamp indicator, fuel warning lamp, engine cooling water high/low

temperature indicator lamp, engine preheating indicator lamp, oil/water

separator indicator lamp, O/D indicator lamp.

Auxiliary

electrical

system

Overhead antenna & interior lighting adjustment switch control.

Windshield system

Front wiper: inching, high speed, low speed, and clearance gear with time

slot adjustment, with reset.

Rear wiper: normal gear with reset.

Defog & defrost deviceRear wiper uses an electrical heated tempered glass with switch control.\

Power window

regulator

D r i v e r ' s s i d e h a s t h e m a s t e r c o n t r o l , o t h e r d o o r s a n d w i n d o w s a r e

independent (left and right front doors are both with door lock controlling

switches), with anti-pinch and automatic closing.

Central door lockRemote central door lock (controlled from the front left door), rear doors

containing children protector.

Backup power supply12 V, 120 W, one

Stereo equipment

Single CD, audio input interface

Multidisc DVD (optional)

There are 4 speakers in the standard configuration, 6 in the luxury and elite

configuration.

Cigarette lighter12 V, 120 W, with lighting, one

HornHigh/low disc type horn

Airbag

Comfort type uses a driver side electronic airbag

Luxury type and elite type uses driver and front passenger electronic

double airbags

EngineWith immobilizer system

Electrical System Structure and Parameters (Continued)

Page 144 of 281

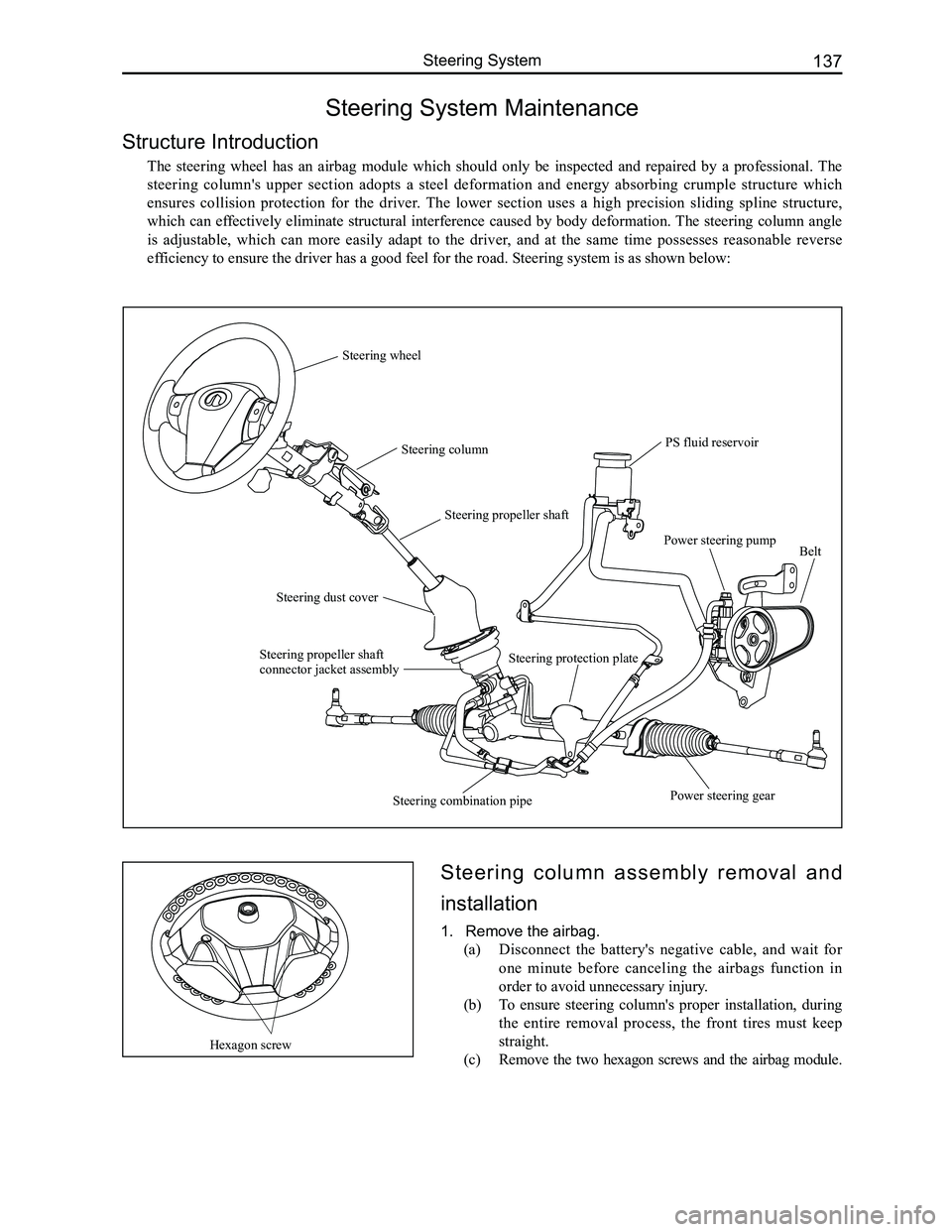

Downloaded from www.Manualslib.com manuals search engine 137Steering System

Steering System Maintenance

Structure Introduction

The steering wheel has an airbag module which should only be inspected and repaired by a professional. The

steering column's upper section adopts a steel deformation and energy absorbing crumple structure which

ensures collision protection for the driver. The lower section uses a high precision sliding spline structure,

which can effectively eliminate structural interference caused by body deformation. The steering column angle

is adjustable, which can more easily adapt to the driver, and at the same time possesses reasonable reverse

efficiency to ensure the driver has a good feel for the road. Steering sys\

tem is as shown below:

Steering column assembly removal and

installation

1. Remove the airbag.

(a) Disconnect the battery's negative cable, and wait for

one minute before canceling the airbags function in

order to avoid unnecessary injury.

(b) To ensure steering column's proper installation, during

the entire removal process, the front tires must keep

straight.

(c) Remove the two hexagon screws and the airbag module.

Hexagon screw

Steering wheel

Steering column

Steering propeller shaft

PS fluid reservoir

Power steering pumpBelt

Power steering gearSteering combination pipe

Steering propeller shaft connector jacket assembly

Steering dust cover

Steering protection plate

Page 151 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual144

Double-colored wire: Primary color is Red, secondary color is Blue, mark\

ed as RBl.

0.5BrGr means Brown wire with a Gray fine wire, and sectional area is 0.\

5 mm2.

Areas of importance in circuit maintenance

1. Before operating any electronic devices, and when tools or maintenance devices may easily make

contact with an uncovered electronic terminal, please make sure to turn the ignition switch to the LOCK

position, and then disconnect the battery's negative cable to avoid injury or vehicle damage. When the

ignition switch is on the ON position, please do not disconnect the battery's connecting wire or take out

the power's fuse, regardless if the engine is running or not.Otherwise it would seriously damage the

ECU and related microelectronic devices such as sensors.

2. When changing the fuse, please make sure that the new fuse possesses the proper current rating,

and is not above or below this rating.

3. When repairing the wire harnesses of the airbag and pretensioner, only specified contact points,

plugs, and wires are allowed to be used.

4. Before repairing the wire harness, make sure to eliminate any factor that might cause damage,

for example, the edge of a vehicle body part is too sharp, or the used electronics are damaged or

corroded.

5. Shielded wire should not be repaired, it must be replaced entirely once it is damaged.

6. Unless it is specified during the test, please do not use an analog multimeter to test the ECU and

sensor, instead use a high-impedance digital multimeter (internal resistance should be ≥10 kΩ) or a

vehicle multimeter for inspection.

7. When inspecting the connector with a digital multimeter, take the waterproof rubber cover off the

connector, and tightly insert the test pen along the connecting terminal. Don't use too much force, as

to avoid cracking the connector.

Circuit inspection steps

The principle of troubleshooting is to confirm the "possible cause". Once the possible cause is confirmed, the

components that need to be inspected are limited to the components that are related to the possible cause. The

confirmed possible cause should be based on theory and be supported by facts, but not just by intuition. If

one tries to solve the problem but does not adopt the proper troubleshooting steps, it may make the problem

worse. Then the possible cause not only can't be confirmed, but also maintenance can't be performed properly.

Troubleshooting should adhere to the four steps below:

1. Observe the symptoms carefully, inspect if there is anything else abnormal, and record it.

2. While confirming the possible causes, study the circuit diagram carefully, and regard it as a whole

system in order to understand the circuit. Thorough knowledge of switches, relays, and other

electronic components is obligatory for proper analysis.

3. Inspect and eliminate the problems one by one until the cause is found.

4. After the malfunction is fixed, make sure to check if the inspected system is working properly, and also

check if the maintenance may have caused any new problems.

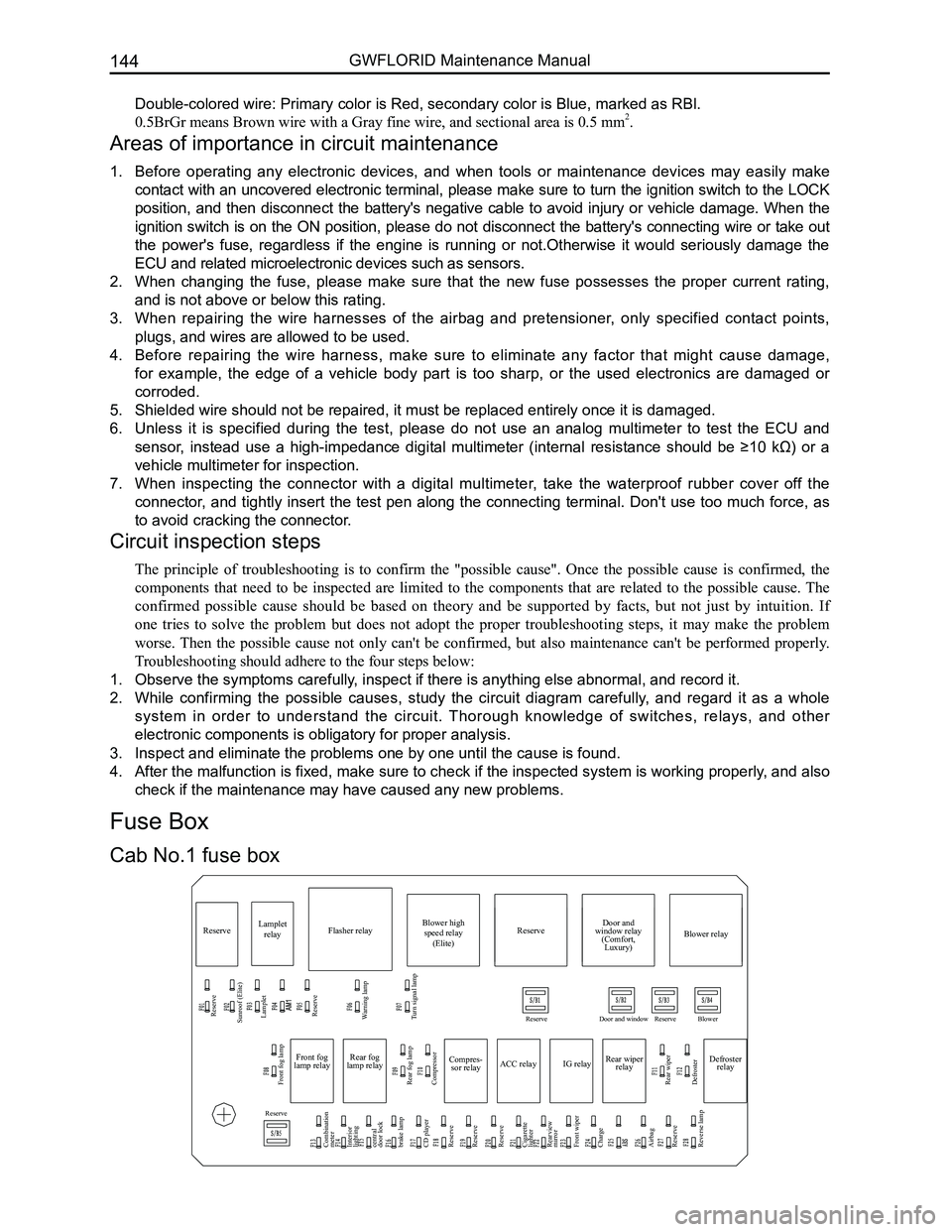

Compres-

sor relay

Reserve

Sunroof (Elite) Lamplet

Reserve

Reserve

Reserve

Reserve Door and window Reserve Blower

Lamplet

relay Flasher relay Blower high

speed relay (Elite) Door and

window relay (Comfort, Luxury) Blower relay

Reserve

Front fog lamp

Combination

meter

Interior

lighting

central

door lock

brake lamp

CD player

Reserve

Reserve

Reserve

Cigarette

lighter

Rearview

mirror

Front wiper

Charge

Airbag

Reserve

Reverse lamp Rear fog lamp

Rear wiper

Defroster Compressor

ACC relay

IG relayRear wiper

relay Defroster

relay

Front fog

lamp relay Rear fog

lamp relay

Warning lamp

Turn signal lamp

Cab No.1 fuse box

Fuse Box

Page 152 of 281

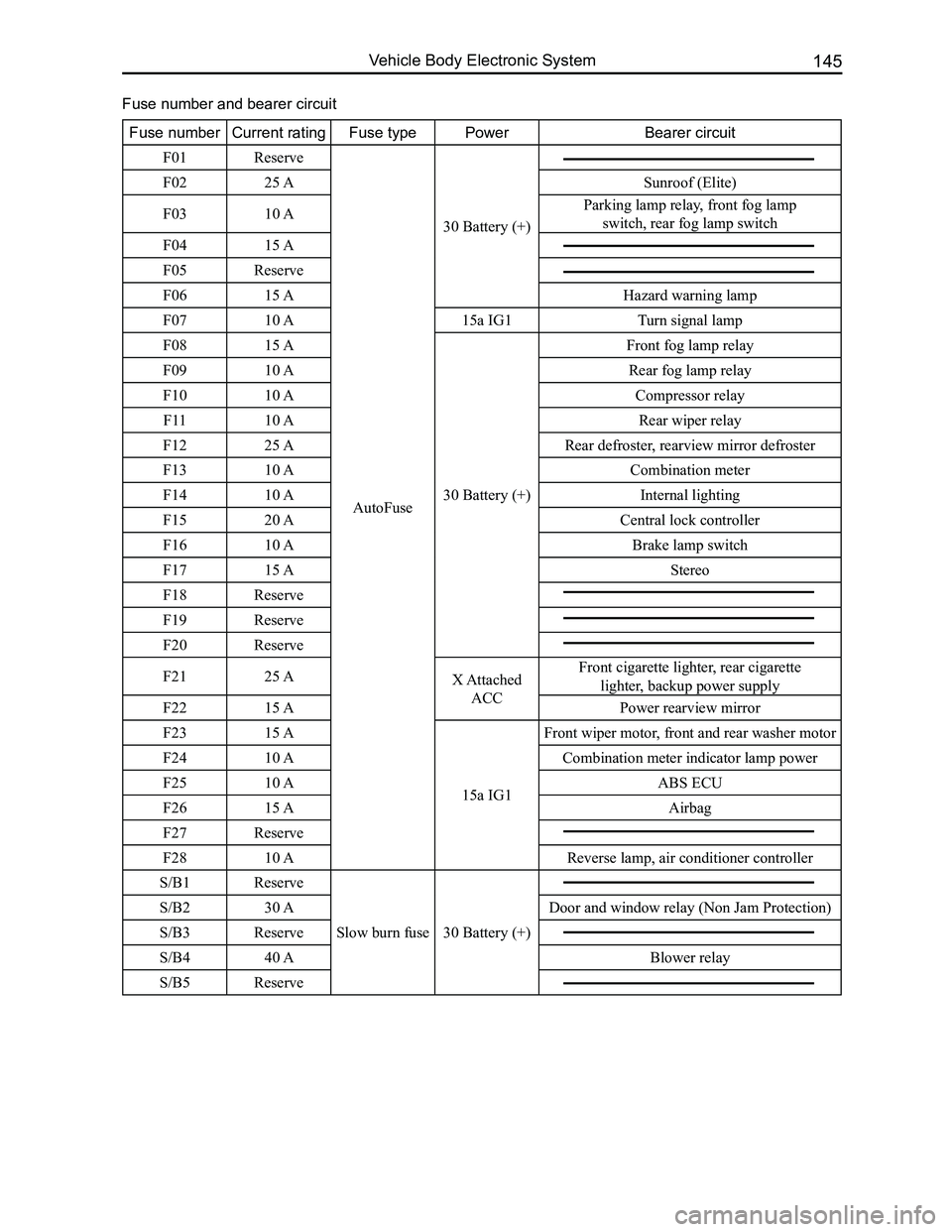

Downloaded from www.Manualslib.com manuals search engine 145Vehicle Body Electronic System

Fuse numberCurrent ratingFuse typePowerBearer circuit

F01Reserve

AutoFuse

30 Battery (+)

F0225 ASunroof (Elite)

F0310 AParking lamp relay, front fog lamp

switch, rear fog lamp switch

F0415 A

F05Reserve

F0615 AHazard warning lamp

F0710 A15a IG1 Turn signal lamp

F0815 A

30 Battery (+)

Front fog lamp relay

F0910 ARear fog lamp relay

F1010 ACompressor relay

F1110 ARear wiper relay

F1225 ARear defroster, rearview mirror defroster

F1310 ACombination meter

F1410 AInternal lighting

F1520 ACentral lock controller

F1610 ABrake lamp switch

F1715 AStereo

F18Reserve

F19Reserve

F20Reserve

F2125 AX Attached

ACC

Front cigarette lighter, rear cigarette

lighter, backup power supply

F2215 APower rearview mirror

F2315 A

15a IG1

Front wiper motor, front and rear washer motor

F2410 ACombination meter indicator lamp power

F2510 AABS ECU

F2615 AAirbag

F27Reserve

F2810 AReverse lamp, air conditioner controller

S/B1Reserve

Slow burn fuse 30 Battery (+)

S/B230 ADoor and window relay (Non Jam Protection)

S/B3Reserve

S/B440 ABlower relay

S/B5Reserve

Fuse number and bearer circuit

Page 155 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual148

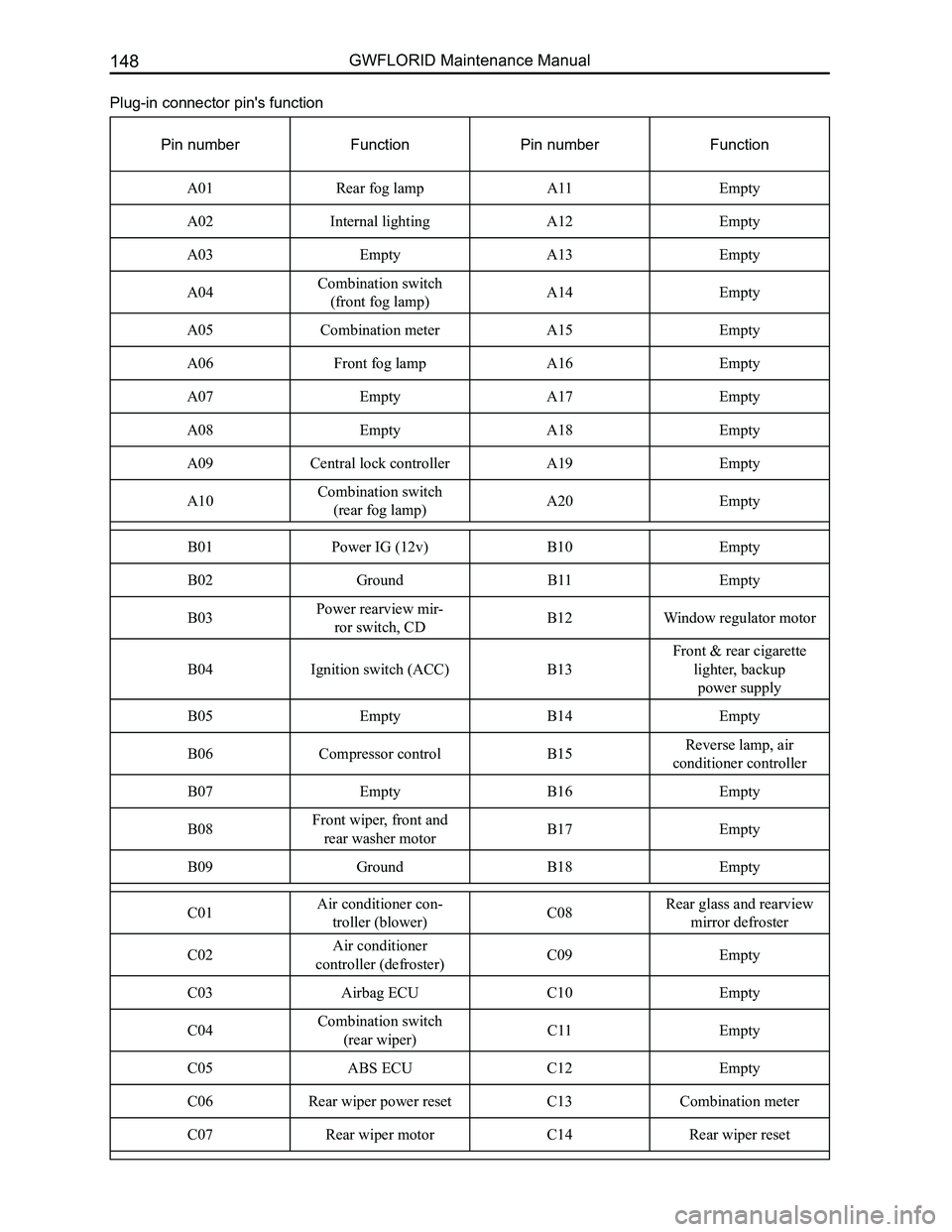

Plug-in connector pin's function

Pin numberFunctionPin numberFunction

A01Rear fog lampA11Empty

A02Internal lightingA12Empty

A03EmptyA13Empty

A04Combination switch

(front fog lamp)A14Empty

A05Combination meter A15Empty

A06Front fog lampA16Empty

A07EmptyA17Empty

A08EmptyA18Empty

A09Central lock controllerA19Empty

A10Combination switch

(rear fog lamp)A20Empty

B01Power IG (12v)B10Empty

B02GroundB11Empty

B03Power rearview mir-

ror switch, CDB12Window regulator motor

B04Ignition switch (ACC)B13

Front & rear cigarette

lighter, backup

power supply

B05EmptyB14Empty

B06Compressor controlB15Reverse lamp, air

conditioner controller

B07EmptyB16Empty

B08Front wiper, front and

rear washer motorB17Empty

B09GroundB18Empty

C01Air conditioner con-

troller (blower) C08Rear glass and rearview

mirror defroster

C02Air conditioner

controller (defroster) C09Empty

C03Airbag ECU C10Empty

C04Combination switch

(rear wiper) C11Empty

C05ABS ECUC12Empty

C06Rear wiper power resetC13Combination meter

C07Rear wiper motorC14Rear wiper reset

Page 158 of 281

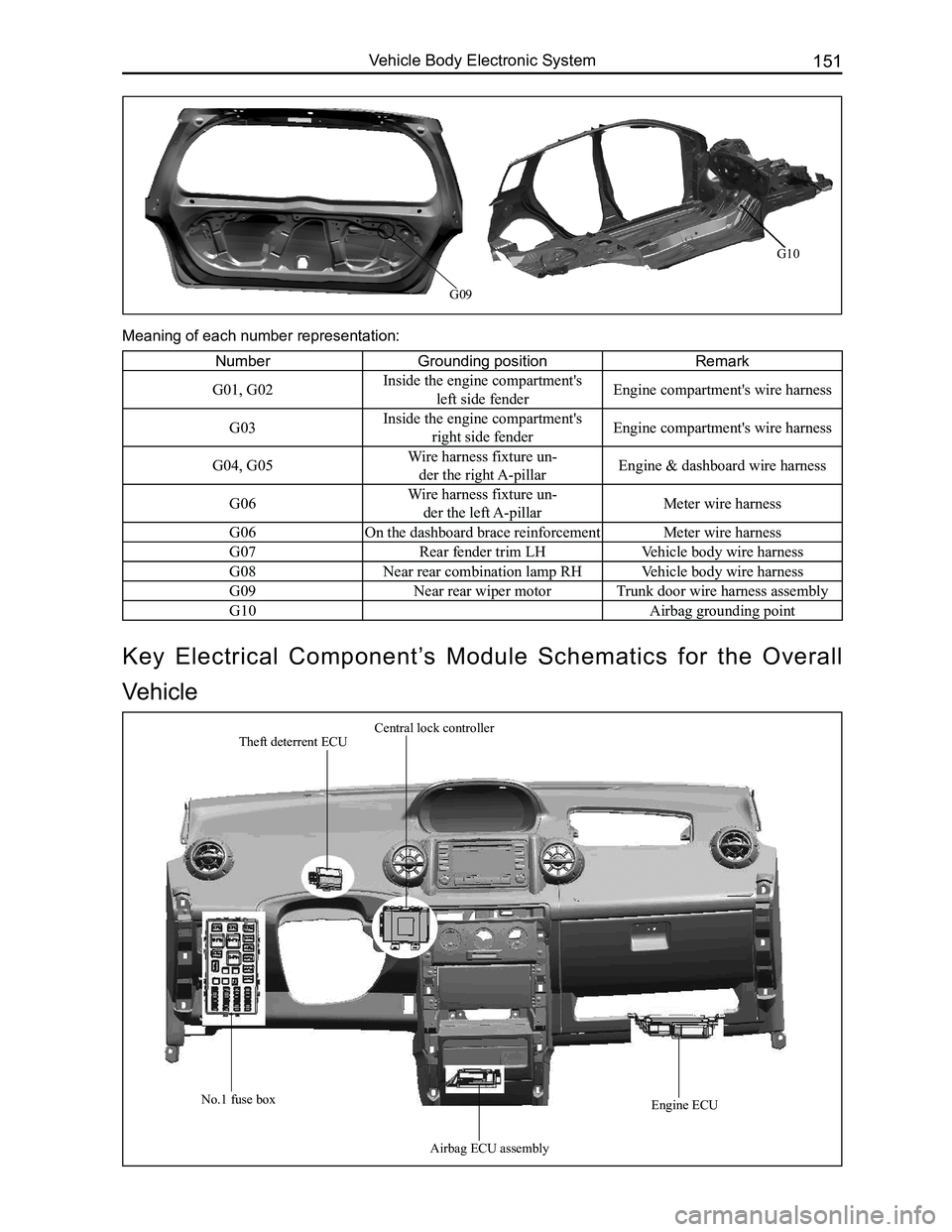

Downloaded from www.Manualslib.com manuals search engine 151Vehicle Body Electronic System

G09

NumberGrounding positionRemark

G01, G02Inside the engine compartment's

left side fenderEngine compartment's wire harness

G03Inside the engine compartment's

right side fenderEngine compartment's wire harness

G04, G05Wire harness fixture un-

der the right A-pillarEngine & dashboard wire harness

G06Wire harness fixture un-

der the left A-pillarMeter wire harness

G06 On the dashboard brace reinforcementMeter wire harness

G07Rear fender trim LHVehicle body wire harness

G08Near rear combination lamp RHVehicle body wire harness

G09Near rear wiper motorTrunk door wire harness assembly

G10Airbag grounding point

Meaning of each number representation:

Key Electrical Component’s Module Schematics for the Overall

Vehicle

Theft deterrent ECUCentral lock controller

No.1 fuse box

Airbag ECU assembly

Engine ECU

G10