brake fluid GREAT WALL FLORID 2008 Service Manual

[x] Cancel search | Manufacturer: GREAT WALL, Model Year: 2008, Model line: FLORID, Model: GREAT WALL FLORID 2008Pages: 281, PDF Size: 43.97 MB

Page 5 of 281

Downloaded from www.Manualslib.com manuals search engine Chapter Five: Transmission ........................................................................\

................................42

037A Transmission’s Overall External Schematics ....................................................43

Main Technical Parameters ..................................................................................\

....43

Transmission’s Proper Use and Care ........................................................................44

Technical Specifications for Transmission Installation and Adjustment .....................44

Areas of Importance ..................................................................................\

................45

Troubleshooting ..................................................................................\

.......................46

037A Transmission Structural Schematics ................................................................47

Clutch ...................................................................................\

......................................48

Gear Shift Fork and Fork Shaft ..................................................................................49

Transmission Case ..................................................................................\

..................50

Disassembling the Input Shaft Subassembly ............................................................56

Disassembling the Output Shaft Subassembly ..........................................................60

Disassembling the Shift Cover Subassembly ............................................................64

Disassembling the Differential Subassembly .............................................................68

Chapter Six: Suspension System ........................................................................\

.......................71

Suspension System Technical Parameters ...............................................................72

Front Suspension ...................................................................................\

....................73

Subframe and Front Stabilizer Bar ............................................................................77

Lower Swing Arm ...................................................................................\

....................80

Drive Shaft ..................................................................................\

...............................84

Rear Suspension ..................................................................................\

.....................86

Wheel and Tire ...................................................................................\

........................89

Chapter Seven: Brake System ........................................................................\

...........................94

Brake System Components Arrangement Schematics ..............................................95

Brake System Maintenance ...................................................................................\

....96

Brake Pedal ..................................................................................\

.............................98

Parking Brake Control Mechanism Assembly ..........................................................102

Vacuum Booster with Brake Cylinder Assembly ......................................................103

Anti-lock Brake System ...................................................................................\

.........107

ABS General Problem Maintenance and Areas of Importance ................................109

Steering Knuckle and Hub Brake Assembly ............................................................112

Front Brake Caliper ...................................................................................\

...............118

Rear Brake ...................................................................................\

............................124

Rear Support Axle ...................................................................................\

.................131

Chapter Eight: Steering System ........................................................................\

.......................134

Troubleshooting ..................................................................................\

.....................135

Steering System Maintenance .................................................................................137

Power Steering Fluid Instructions ............................................................................141

Page 16 of 281

Downloaded from www.Manualslib.com manuals search engine 9Overview

General Repair Methods and Operations

1. If a jack is needed, please kindly comply to the safety procedures liste\

d below.

2. Park the vehicle on a flat surface, stablize the front and the back wheels using any fixed object or tool,

jack up the vehicle, support it with the chassis, and then start the mai\

ntenance.

3. Disconnect the battery's negative cable before maintenance, in order to reduce the possibility of

damaging and burning out the cable due to a short circuit.

4. Cover the vehicle body, seats, and floor to prevent them from being damaged and polluted.

5. Handle brake fluid and antifreeze fluid carefully, because it may damage the vehicle's surface paint

and its surroundings.

6. Using the proper tools or basic tools that have been recommended and are purchasable is very

important in guaranteeing an effective and reliable maintenance result.

7. Dispose the used dowel pins, gaskets, O-rings, oil seals, lock washers, and self-locking nuts. Prepare

new parts for installation. Normal functions are not guaranteed if these\

parts are reused.

8. Store the removed parts in order and in groups to make reassembly more c\

onvenient.

9. Store bolts and nuts separately, because their hardness levels and designs are different according to

the installation locations.

10. Clean parts before they are inspected or reassembled. In addition, parts that come in contact with

engine oil also need to be cleaned, as well as checked for blockage by u\

sing compressed air.

11. Before installation, use engine oil or grease to lubricate the rotating and sliding sides of the necessary

parts.

12. When necessary, use sealant on gaskets to avoid leakage.

13. Please carefully comply to all tightening torque specifications of b\

olts and nuts.

14. After maintenance, check to make sure whether the repairs were performed correctly and whether the

malfunctions have been fixed.

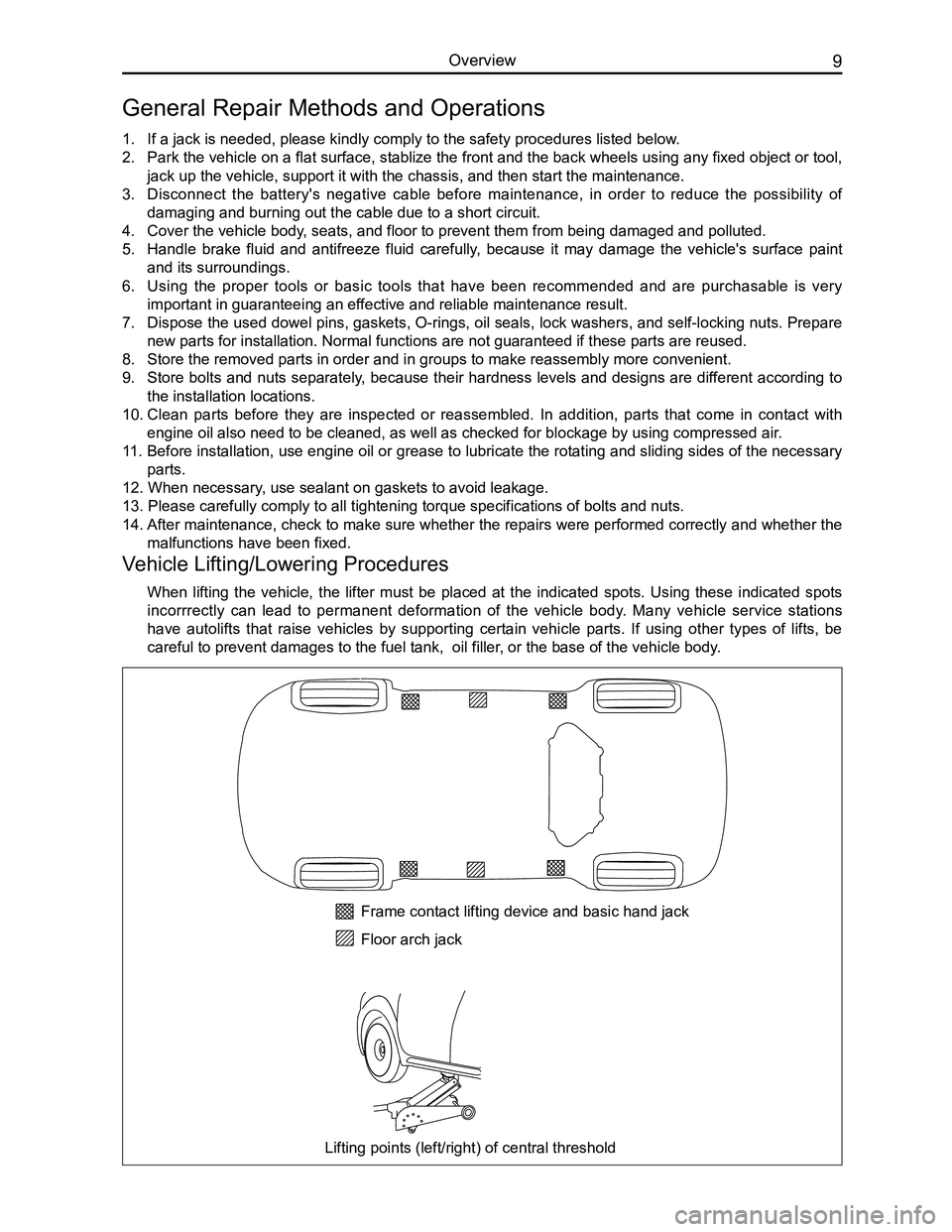

Vehicle Lifting/Lowering Procedures

When lifting the vehicle, the lifter must be placed at the indicated spots. Using these indicated spots

incorrrectly can lead to permanent deformation of the vehicle body. Many vehicle service stations

have autolifts that raise vehicles by supporting certain vehicle parts. If using other types of lifts, be

careful to prevent damages to the fuel tank, oil filler, or the base of the vehicle body.

Frame contact lifting device and basic hand jack

Floor arch jack

Lifting points (left/right) of central threshold

Page 21 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual14

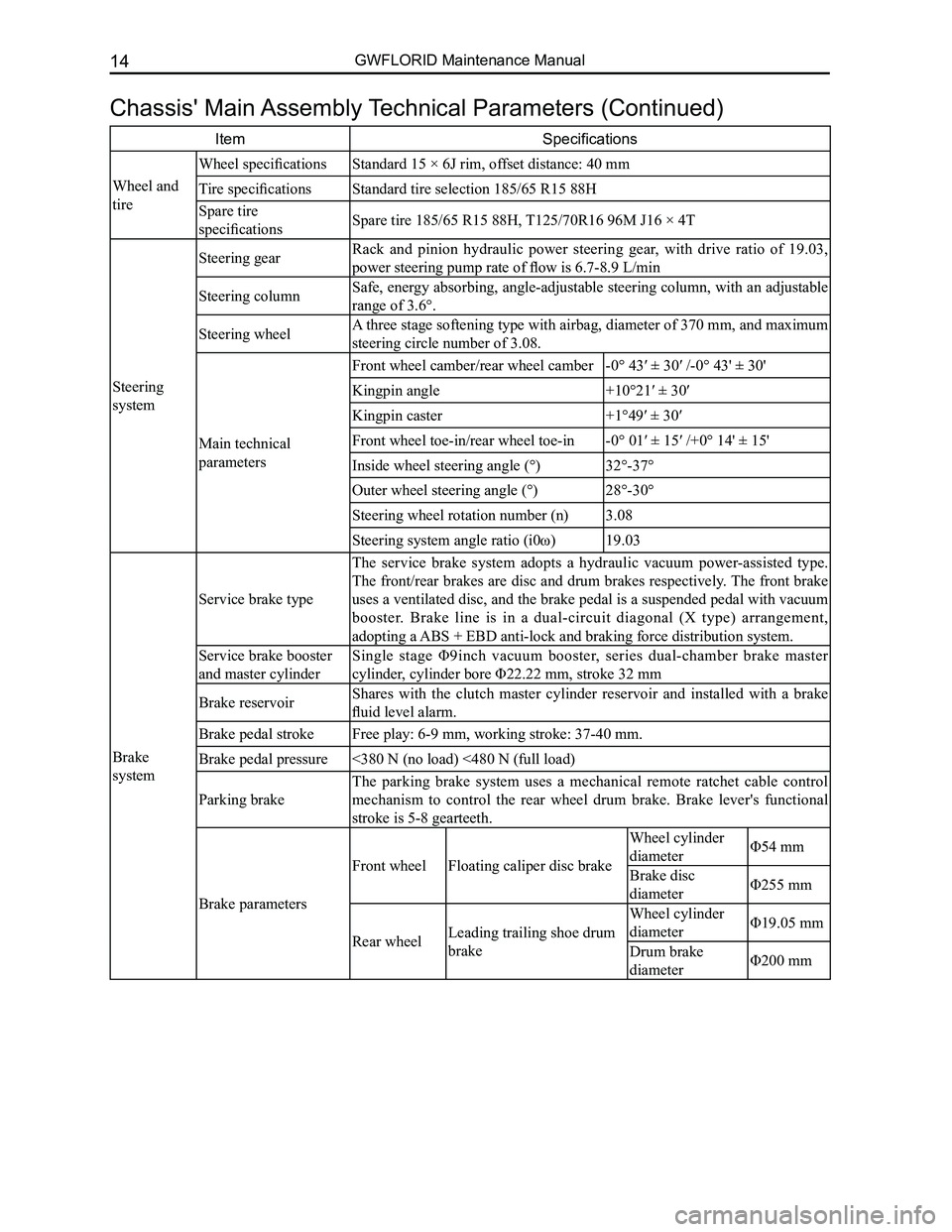

Chassis' Main Assembly Technical Parameters (Continued)

ItemSpecifications

Wheel and

tire

Wheel specificationsStandard 15 × 6J rim, offset distance: 40 mm

Tire specificationsStandard tire selection 185/65 R15 88H

Spare tire

specificationsSpare tire 185/65 R15 88H, T125/70R16 96M J16 × 4T

Steering

system

Steering gearRack and pinion hydraulic power steering gear, with drive ratio of 19.03,

power steering pump rate of flow is 6.7-8.9 L/min

Steering columnSafe, energy absorbing, angle-adjustable steering column, with an adjustable

range of 3.6°.

Steering wheelA three stage softening type with airbag, diameter of 370 mm, and maximum

steering circle number of 3.08.

Main technical

parameters

Front wheel camber/rear wheel camber-0° 43′ ± 30′ /-0° 43' ± 30'

Kingpin angle+10°21′ ± 30′

Kingpin caster+1°49′ ± 30′

Front wheel toe-in/rear wheel toe-in-0° 01′ ± 15′ /+0° 14' ± 15'

Inside wheel steering angle (°)32°-37°

Outer wheel steering angle (°)28°-30°

Steering wheel rotation number (n)3.08

Steering system angle ratio (i0ω)19.03

Brake

system

Service brake type

The service brake system adopts a hydraulic vacuum power-assisted type.

The front/rear brakes are disc and drum brakes respectively. The front brake

uses a ventilated disc, and the brake pedal is a suspended pedal with vacuum

booster. Brake line is in a dual-circuit diagonal (X type) arrangement,

adopting a ABS + EBD anti-lock and braking force distribution system.

Service brake booster

and master cylinder

Single stage Φ9inch vacuum booster, series dual-chamber brake master

cylinder, cylinder bore Φ22.22 mm, stroke 32 mm

Brake reservoirShares with the clutch master cylinder reservoir and installed with a brake

fluid level alarm.

Brake pedal strokeFree play: 6-9 mm, working stroke: 37-40 mm.

Brake pedal pressure<380 N (no load) <480 N (full load)

Parking brake

The parking brake system uses a mechanical remote ratchet cable control

mechanism to control the rear wheel drum brake. Brake lever's functional

stroke is 5-8 gearteeth.

Brake parameters

Front wheelFloating caliper disc brake

Wheel cylinder

diameterΦ54 mm

Brake disc

diameterΦ255 mm

Rear wheelLeading trailing shoe drum

brake

Wheel cylinder

diameterΦ19.05 mm

Drum brake

diameterΦ200 mm

Page 25 of 281

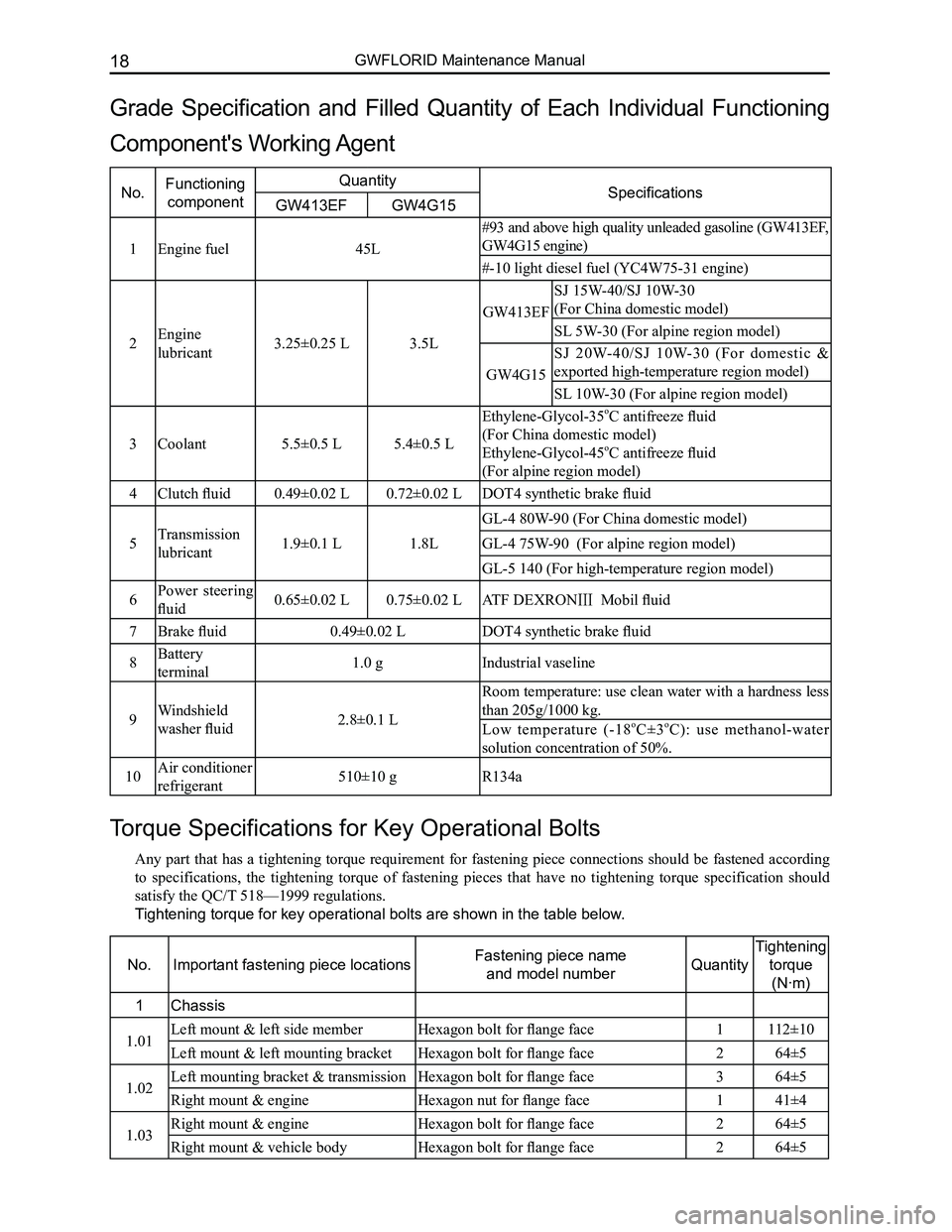

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual18

Torque Specifications for Key Operational Bolts

Any part that has a tightening torque requirement for fastening piece connections should be fastened according

to specifications, the tightening torque of fastening pieces that have no tightening torque specification should

satisfy the QC/T 518—1999 regulations.

Tightening torque for key operational bolts are shown in the table below.

No.Important fastening piece locationsFastening piece name

and model numberQuantity

Tightening

torque

(N·m)

1Chassis

1.01Left mount & left side memberHexagon bolt for flange face1112±10

Left mount & left mounting bracketHexagon bolt for flange face264±5

1.02Left mounting bracket & transmissionHexagon bolt for flange face364±5

Right mount & engineHexagon nut for flange face141±4

1.03Right mount & engineHexagon bolt for flange face264±5

Right mount & vehicle bodyHexagon bolt for flange face 264±5

Grade Specification and Filled Quantity of Each Individual Functioning

Component's Working Agent

No.Functioning

component

QuantitySpecificationsGW413EFGW4G15

1Engine fuel45L

#93 and above high quality unleaded gasoline (GW413EF,

GW4G15 engine)

#-10 light diesel fuel (YC4W75-31 engine)

2Engine

lubricant3.25±0.25 L3.5L

GW413EF

SJ 15W-40/SJ 10W-30

(For China domestic model)

SL 5W-30 (For alpine region model)

GW4G15

SJ 20W-40/SJ 10W-30 (For domestic &

exported high-temperature region model)

SL 10W-30 (For alpine region model)

3Coolant5.5±0.5 L5.4±0.5 L

Ethylene-Glycol-35oC antifreeze fluid

(For China domestic model)

Ethylene-Glycol-45oC antifreeze fluid

(For alpine region model)

4Clutch fluid0.49±0.02 L0.72±0.02 LDOT4 synthetic brake fluid

5Transmission

lubricant1.9±0.1 L1.8L

GL-4 80W-90 (For China domestic model)

GL-4 75W-90 (For alpine region model)

GL-5 140 (For high-temperature region model)

6Power steering

fluid0.65±0.02 L0.75±0.02 LATF DEXRONⅢ Mobil fluid

7Brake fluid0.49±0.02 LDOT4 synthetic brake fluid

8Battery

terminal1.0 gIndustrial vaseline

9Windshield

washer fluid2.8±0.1 L

Room temperature: use clean water with a hardness less

than 205g/1000 kg.

Low temperature (-18oC±3oC): use methanol-water

solution concentration of 50%.

10Air conditioner

refrigerant510±10 gR134a

Page 44 of 281

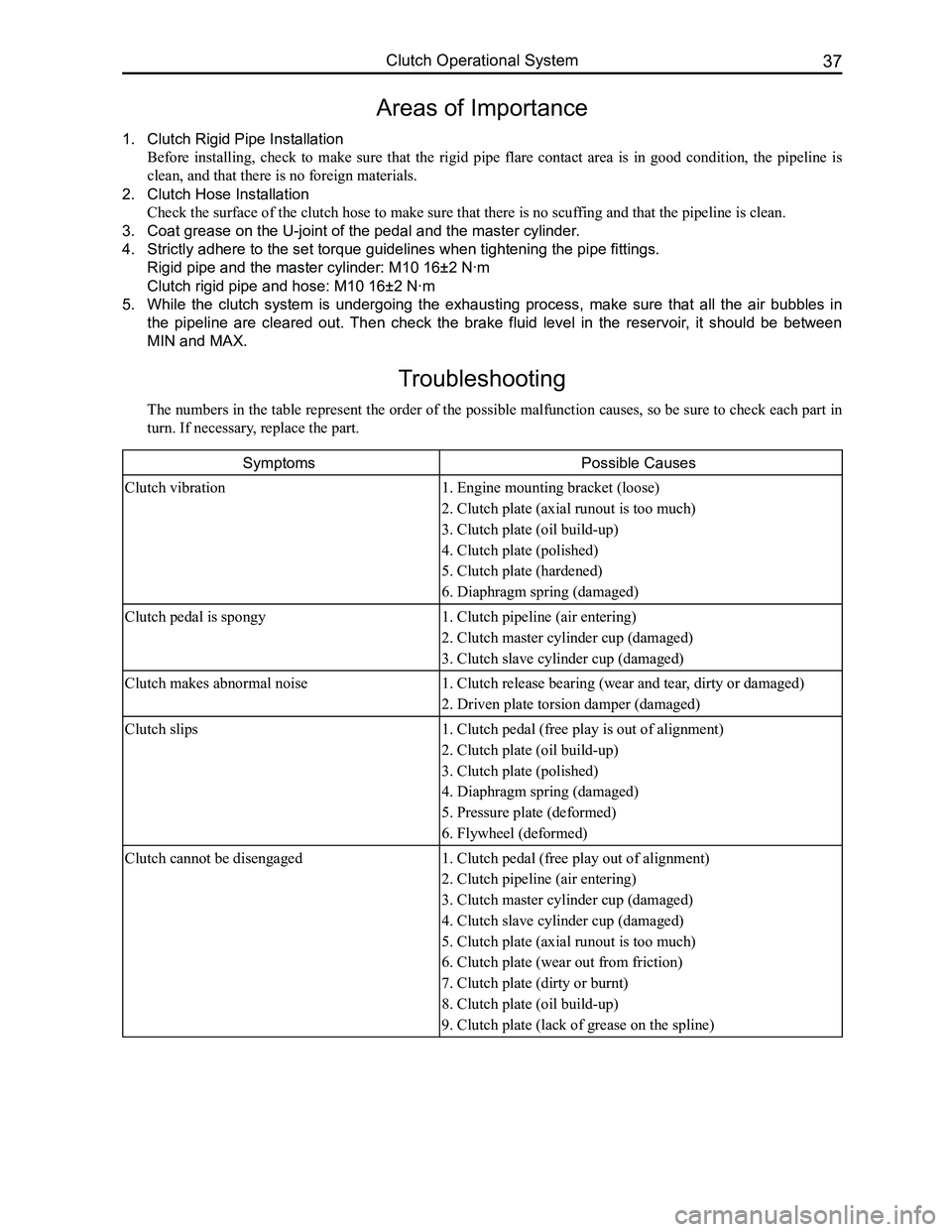

Downloaded from www.Manualslib.com manuals search engine 37Clutch Operational System

Areas of Importance

1. Clutch Rigid Pipe Installation

Before installing, check to make sure that the rigid pipe flare contact area is in good condition, the pipeline is

clean, and that there is no foreign materials.

2. Clutch Hose Installation

Check the surface of the clutch hose to make sure that there is no scuffing and that the pipeline is clean.

3. Coat grease on the U-joint of the pedal and the master cylinder.

4. Strictly adhere to the set torque guidelines when tightening the pipe fittings.

Rigid pipe and the master cylinder: M10 16±2 N·m

Clutch rigid pipe and hose: M10 16±2 N·m

5. While the clutch system is undergoing the exhausting process, make sure that all the air bubbles in

the pipeline are cleared out. Then check the brake fluid level in the reservoir, it should be between

MIN and MAX.

Troubleshooting

The numbers in the table represent the order of the possible malfunction causes, so be sure to check each part in

turn. If necessary, replace the part.

SymptomsPossible Causes

Clutch vibration1. Engine mounting bracket (loose)

2. Clutch plate (axial runout is too much)

3. Clutch plate (oil build-up)

4. Clutch plate (polished)

5. Clutch plate (hardened)

6. Diaphragm spring (damaged)

Clutch pedal is spongy1. Clutch pipeline (air entering)

2. Clutch master cylinder cup (damaged)

3. Clutch slave cylinder cup (damaged)

Clutch makes abnormal noise1. Clutch release bearing (wear and tear, dirty or damaged)

2. Driven plate torsion damper (damaged)

Clutch slips1. Clutch pedal (free play is out of alignment)

2. Clutch plate (oil build-up)

3. Clutch plate (polished)

4. Diaphragm spring (damaged)

5. Pressure plate (deformed)

6. Flywheel (deformed)

Clutch cannot be disengaged1. Clutch pedal (free play out of alignment)

2. Clutch pipeline (air entering)

3. Clutch master cylinder cup (damaged)

4. Clutch slave cylinder cup (damaged)

5. Clutch plate (axial runout is too much)

6. Clutch plate (wear out from friction)

7. Clutch plate (dirty or burnt)

8. Clutch plate (oil build-up)

9. Clutch plate (lack of grease on the spline)

Page 45 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual38

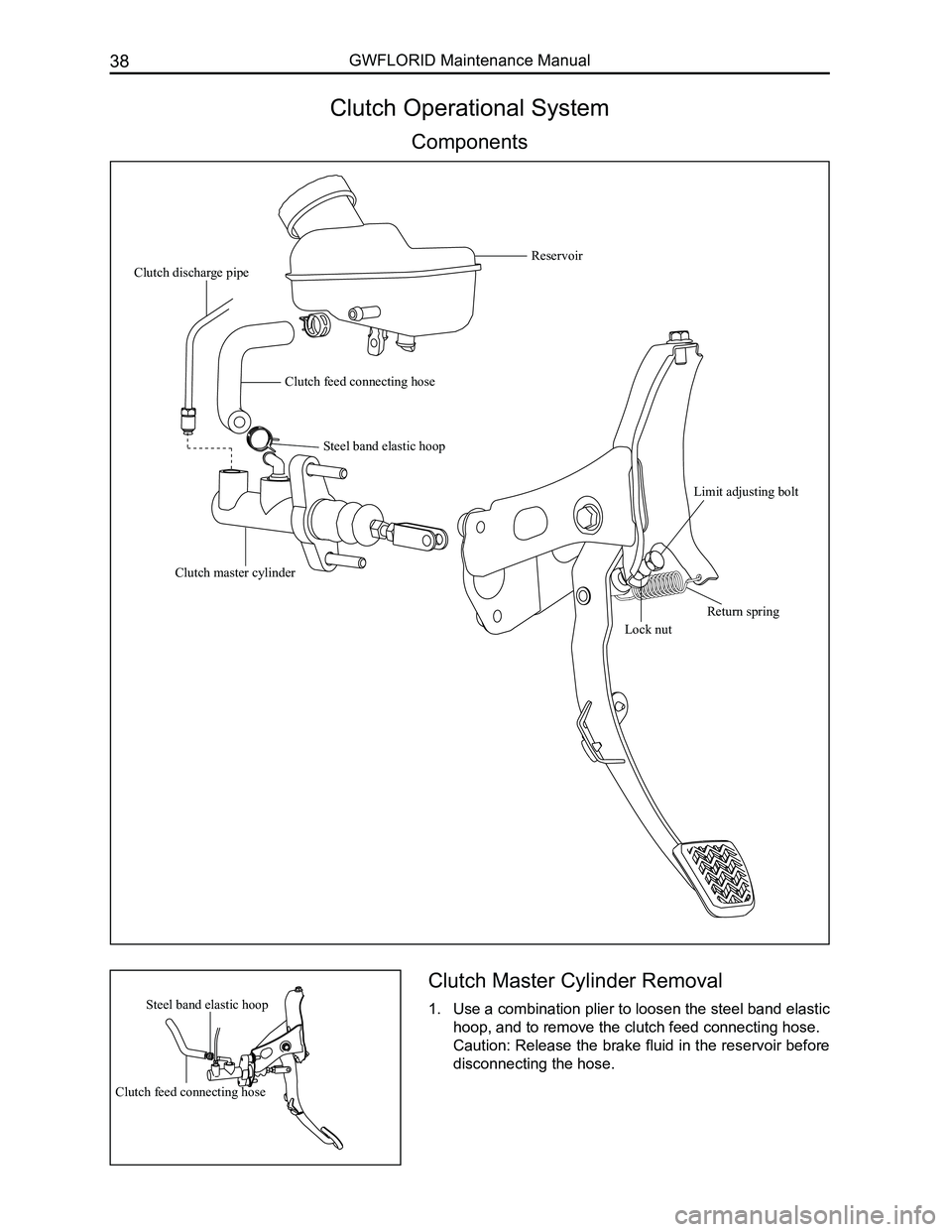

Clutch Operational System

Components

Clutch Master Cylinder Removal

1. Use a combination plier to loosen the steel band elastic

hoop, and to remove the clutch feed connecting hose.

Caution: Release the brake fluid in the reservoir before

disconnecting the hose.

Steel band elastic hoop

Clutch feed connecting hose

Reservoir

Steel band elastic hoop

Clutch feed connecting hose

Clutch discharge pipe

Clutch master cylinder

Limit adjusting bolt

Return spring

Lock nut

Page 47 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual40

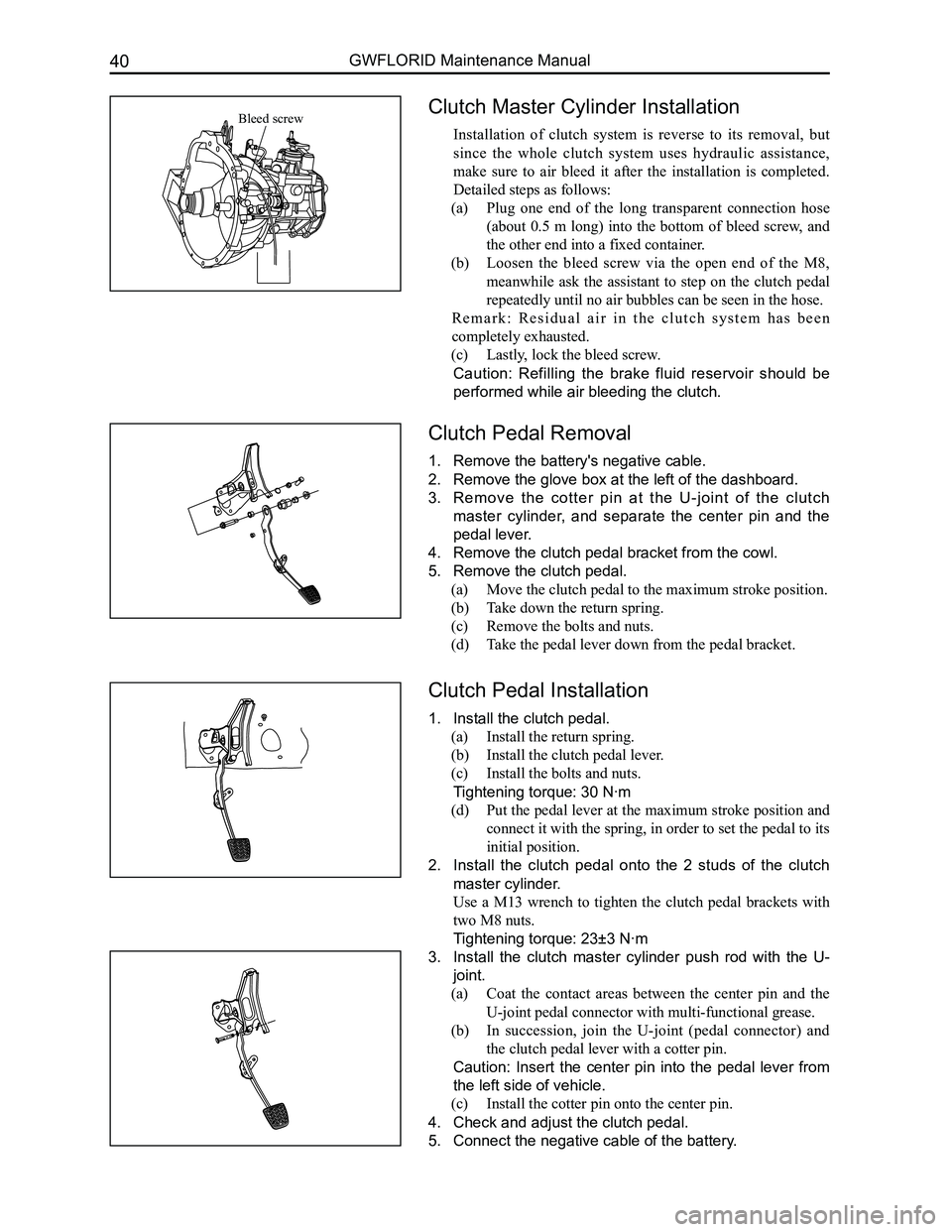

Clutch Master Cylinder Installation

Installation of clutch system is reverse to its removal, but

since the whole clutch system uses hydraulic assistance,

make sure to air bleed it after the installation is completed.

Detailed steps as follows:

(a) Plug one end of the long transparent connection hose

(about 0.5 m long) into the bottom of bleed screw, and

the other end into a fixed container.

(b) Loosen the bleed screw via the open end of the M8,

meanwhile ask the assistant to step on the clutch pedal

repeatedly until no air bubbles can be seen in the hose.

R e m a r k : R e s i d u a l a i r i n t h e c l u t c h s y s t e m h a s b e e n

completely exhausted.

(c) Lastly, lock the bleed screw.

Caution: Refilling the brake fluid reservoir should be

performed while air bleeding the clutch.

Clutch Pedal Removal

1. Remove the battery's negative cable.

2. Remove the glove box at the left of the dashboard.

3. Remove the cotter pin at the U-joint of the clutch

master cylinder, and separate the center pin and the

pedal lever.

4. Remove the clutch pedal bracket from the cowl.

5. Remove the clutch pedal.

(a) Move the clutch pedal to the maximum stroke position.

(b) Take down the return spring.

(c) Remove the bolts and nuts.

(d) Take the pedal lever down from the pedal bracket.

Clutch Pedal Installation

1. Install the clutch pedal.

(a) Install the return spring.

(b) Install the clutch pedal lever.

(c) Install the bolts and nuts.

Tightening torque: 30 N·m

(d) Put the pedal lever at the maximum stroke position and

connect it with the spring, in order to set the pedal to its

initial position.

2. Install the clutch pedal onto the 2 studs of the clutch

master cylinder.

Use a M13 wrench to tighten the clutch pedal brackets with

two M8 nuts.

Tightening torque: 23±3 N·m

3. Install the clutch master cylinder push rod with the U-

joint.

(a) Coat the contact areas between the center pin and the

U-joint pedal connector with multi-functional grease.

(b) In succession, join the U-joint (pedal connector) and

the clutch pedal lever with a cotter pin.

Caution: Insert the center pin into the pedal lever from

the left side of vehicle.

(c) Install the cotter pin onto the center pin.

4. Check and adjust the clutch pedal.

5. Connect the negative cable of the battery.

Bleed screw

Page 81 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual74

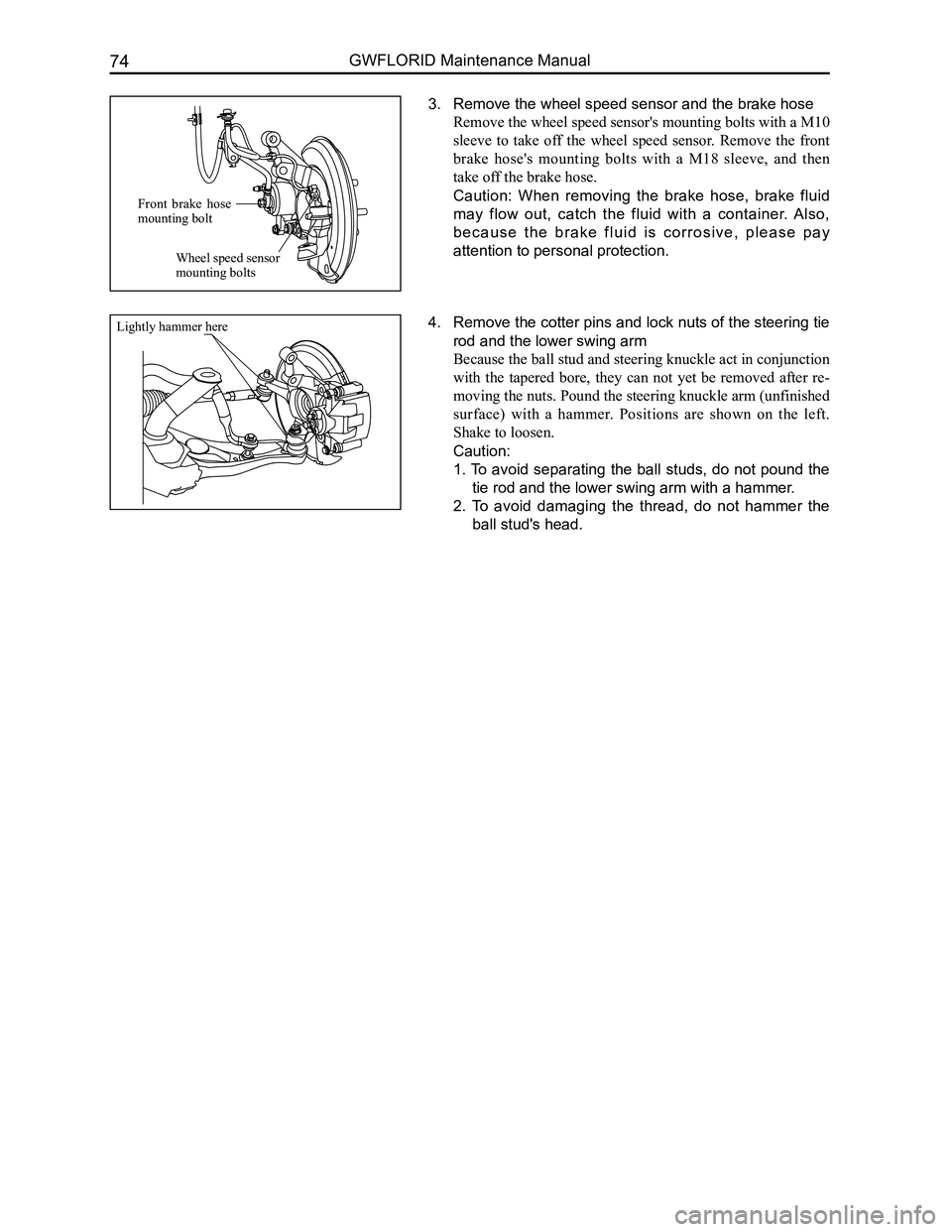

3. Remove the wheel speed sensor and the brake hose

Remove the wheel speed sensor's mounting bolts with a M10

sleeve to take off the wheel speed sensor. Remove the front

brake hose's mounting bolts with a M18 sleeve, and then

take off the brake hose.

Caution: When removing the brake hose, brake fluid

may flow out, catch the fluid with a container. Also,

b e c a u s e t h e b r a k e f l u i d i s c o r r o s i v e , p l e a s e p a y

attention to personal protection.

4. Remove the cotter pins and lock nuts of the steering tie

rod and the lower swing arm

Because the ball stud and steering knuckle act in conjunction

with the tapered bore, they can not yet be removed after re-

moving the nuts. Pound the steering knuckle arm (unfinished

surface) with a hammer. Positions are shown on the left.

Shake to loosen.

Caution:

1. To avoid separating the ball studs, do not pound the

tie rod and the lower swing arm with a hammer.

2. To avoid damaging the thread, do not hammer the

ball stud's head.

Front brake hose mounting bolt

Wheel speed sensor mounting bolts

Lightly hammer here

Page 103 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual96

Brake System Maintenance

Brake fluid inspection and replacement

Brake fluid directly influences the brake performance and the operating conditions and use life of the brake

system components. Brake fluid has very strong hygroscopic properties, and thus absorbs water easily,

which will then deteriorate the metal and rubber pieces. Polluted and deteriorated brake fluid or its mixture

would cause the brake fluid to boil and gasify, hence reduces braking efficiency. Therefore, pay attention to

the items below when filling or changing the brake fluid:

1. Containers used to hold brake fluid must be tightly closed and sealed

2. Brake fluid is poisonous and damaging to the paint. Hence if it gets on the vehicle surface, rub it

off at once

3. If water or other contaminates found in the brake fluid, and the brake master cylinder's piston seal

has been broken, then the brake fluid and all the rubber pieces inside the brake system including

the brake hose must be replaced

4. The correct brake fluid level in the reservoir must be between MAX and MIN. After the vehicle has

been driven for over 1000 km, check the brake fluid level in the reservoir. If the brake fluid level is

not up to regulation, more brake fluid should be added to the reservoir \

until it reaches MAX.

Hydraulic component inspection and system flushing

1. If the oil-based solvent gets into the hydraulic system, flush the whole system and change all of

the rubber pieces

2. Clean your hands before installing new rubber pieces or other components

3. Do not use regular solvents (kerosene, gas, etc.) when inspecting or cleaning hydraulic

components, instead use absorbing alcohol or brake fluid

4. After inspecting the components, drain the brake fluid from the system. Use new brake fluid to

flush the system. Afterwards, add new brake fluid to perform hydraulic system exhaust

5. Flushing completion sign: When the brake fluid flowing out of the dump valve is clear from any

contaminate.

Hydraulic pressure system drainage

If the brake fluid inside the whole hydraulic pressure system needs to be emptied, open all the bleed screws

with each connected to a hose, as to allow the brake fluid to flow into a container. Step on the pedal slowly

until only air flows out. During the whole procedure, make sure all the \

valves are open.

Hydraulic pressure system air bleeding

The hydraulic brake system must work under a vacuum environment. The air will cause spongy brake or

overall brake failure when it flows into the hydraulic system. It is extremely necessary to bleed system air

when performing any operation on the brake system or if any air inside t\

he brake system is suspected.

1. Air bleeding sequence

If air inside the brake master cylinder is suspected, first perform air bleeding.

(a) If numerous valves are equipped, air bleed each valve

(b) Another sequence principle is: Air bleed from the wheel brake furthest away from the master cylinder.

The air bleeding sequence for the LHD modules is: rear right wheel - left rear wheel - front right wheel

- front left wheel, Right rudder vehicles: rear right wheel - left rear wheel - front left wheel - front right

wheel.

2. Air bleeding method

(1) Manual air bleeding

Use the brake pedal or pump as the air bleeding power source. When the air bleed screws are open, vent the

brake fluid containing the bubbles from the system. Usually this is simultaneously done by two people. One

steps on the brake pedal and the other operates the air bleed screws. Important points to take note of when

performing the operation:

(a) Place the ignition switch to the off position and step on the pedal repeatedly to remove the

vacuum pressure or hydraulic pressure.

(b) Before and after air bleeding, add clean brake fluid into the master cylinder until it reaches

the correct (stated) level.

(c) Check the fluid level frequently to make sure that more than half of the reservoir's capacity is

available.

(d) Bleed screws should only be opened when the pedal is pressed down, and closed before the

pedal is loosened. Meanwhile, check if the vented brake fluid has bubble\

s inside.

Page 104 of 281

Downloaded from www.Manualslib.com manuals search engine 97Brake System

(e) Make sure not to let the system valves block the air bleeding.

(f) When the brake fluid that flows out of the hose or connector has no bubbles, it means that the air

in the system has been exhausted. There is still air inside the system if the hose inserted into the

brake fluid is still bubbling when pressing down the pedal.

(g) Keep the free end of the hose immerged in the brake fluid to avoid air from flowing into the

system while opening the screw.

(h) While air bleeding, hammer the casting part of the vibrating brake device with a rubber hammer.

This is helpful for removing bubbles deep in the brake fluid.

(i) If air in the master cylinder is suspected, then perform air bleeding on the master cylinder first,

then the wheel cylinder or brake caliper.

(j) When releasing air from the tires, generally make sure to release air out of all the tires.

(k) To avoid the possibility of air reversely entering into the system, a bleeder hose that has a check

valve could be used.

(2) Pressure blow-off

Under the proper conditions, a pressure blow-off device can be used to release the air inside the brake system.

3. Air releasing sequence

(1) Master cylinder air bleeding

If the master cylinder does not have air bleed screws, perform the follo\

wing steps:

(a) Check the brake fluid level inside the master cylinder’s reservoir and add to it if necessary.

(b) Slowly take off the front brake pipe connector until the brake fluid flows out from the end.

(c) Reconnect the brake pipe, but do not tighten it.

(d) Slowly step down and press on the brake pedal, check if the brake fluid flowing out of the connector

contains bubbles.

(e) Tighten the pipe fitting.

(f) Have the assistant loosen the pedal, wait for 15 s.

(g) Repeat the above steps until all the air is released.

(h) Take off the rear brake pipe connector, repeat the above steps.

(2) Wheel brake air releasing

(a) Check the brake fluid level inside the master cylinder’s reservoir and add to it if necessary. During the

entire air releasing period, check repeatedly and add promptly.

(b) Connect one end of the bleeder hose with the bleed screw and the other end immerged in the brake fluid.

(c) Have the assistant step on the pedal several times, raise the pedal gradually until it cannot be stepped on

any more, then forcibly press on the pedal once more.

(d) Loosen the bleed screw, check if there are any bubbles in the brake fluid flowing out. Meanwhile, slowly

lower the pedal.

(e) When the brake pedal is close to the stroke end or the out flowing brake fluid does not have any bubbles,

tighten the bleed screw.

(f) Have the assistant release the pedal and wait for 15 s.

(g) Repeat the above steps until there are no bubbles in the flowing brake fluid when the screw is loosened.

(h) Release the air for all the wheels in turn using the same method.

(i) After releasing the air from the entire system, switch the ignition to the on position.

(j) Inspect the stroke of the brake pedal and its reaction.

(k) Inspect the lighting condition of the brake warning lamp, and repeatedly perform maintenance or air

bleeding if necessary.

( l ) Add brake fluid to the reservoir until the specified fluid level, air bleeding is complete.