low beam GREAT WALL FLORID 2008 Service Manual

[x] Cancel search | Manufacturer: GREAT WALL, Model Year: 2008, Model line: FLORID, Model: GREAT WALL FLORID 2008Pages: 281, PDF Size: 43.97 MB

Page 2 of 281

Downloaded from www.Manualslib.com manuals search engine PREFACE

GWFLORID will build 1.3L (GW413EF, GW4G13) or 1.5L (GW4G15) gasoline engines, in which the

GW4G13 and GW4G15 engines will both incorporate the newest VVT technology which meets the Euro IV

emission standards. GWFLORID features McPherson technology on its chassis system. With an ultra light

body made from structural steel and high-intensity front and rear fender impact beams as well as a collision

impact absorption system, it is able to maintain the cab's integrity and safety to greater extent. We wrote this

maintenance manual in order to meet the demand of Great Wall after-sales service technicians. This manual

mainly introduces the areas of importance in regard to maintenance and care, and removal and installation of

each system's assembly and maintenance technical parameters.

To reduce the possibility of injury or property damage, read and follow t\

he instructions carefully:

This manual is provided by the Great Wall Motor Co., Ltd, and is written for the technician use. Any

maintenance or repair without proper prior training and tools or devices may result in personal injury of the

person performing the maintenance or others in the vicinity. It is also possible that damage to the vehicle will

occur or will lead to mechanical failure during normal operation.

Correct vehicle maintenance and repair is essential for the safety of the person performing regular

maintenance as well as the vehicle itself. If there is any component that needs to be replaced, use a

component with the same serial number or a serial number specified by the Great Wall Motor Co., Ltd. Never

use any part that has not been authorized by the Great Wall Motor Co., Ltd.

Any maintenance procedure introduced in this manual is effective for maintenance and repair. Some of

these procedures need specially designed tools.

Therefore, before using any vehicle part following any maintenance procedure or working with a tool

that has not been authorized by the Great Wall Motor Co., Ltd, check to make sure that none of the above

will endanger the safety of the person performing the work or the correc\

t operation of the vehicle.

This manual includes multiple "Warnings" and "Cautions," which should be strictly followed, so as to

reduce the possibility of injury during maintenance or repair. Improper maintenance or repair of the vehicle

may cause potential safety hazards. These "Warnings" and "Cautions" are not exhaustive. It is impossible for

the Great Wall Motor Co., Ltd, to warn against all the potential dangers caused by not properly following the

instructions.

Please read carefully the "Areas of Importance" before carrying out any maintenance or repair on the

airbag system's components or its surrounding electrical components. Action contrary to any of the "Areas of

Importance" may lead to the deployment of the airbag, resulting in injur\

y or unnecessary repair of the airbag.

To avoid accidental deployment of the airbag and its resulting injury, we suggest repairing the airbag

system before other vehicle systems if the airbag and the other vehicle \

systems both need repairing.

We have received generous support and help from many professional technicians during the preparation

of this manual. We would like to express our heartfelt gratitude to all of them.

Although we have tried our best to write this manual well, we do not guarantee that the entire content

in this manual is absolutely correct. Users may not make any legal claim against the Great Wall Motor Co.,

Ltd. in regards to this manual. Any loss caused by using this manual is not our responsibility. Because of

the writer's limited experience, there are likely mistakes in this manual, therefore we welcome any user

comments, suggestions, and corrections.

Great Wall Motor Co., Ltd. reserves the final right of explanation.

\

Editor

May 2008

Page 23 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual16

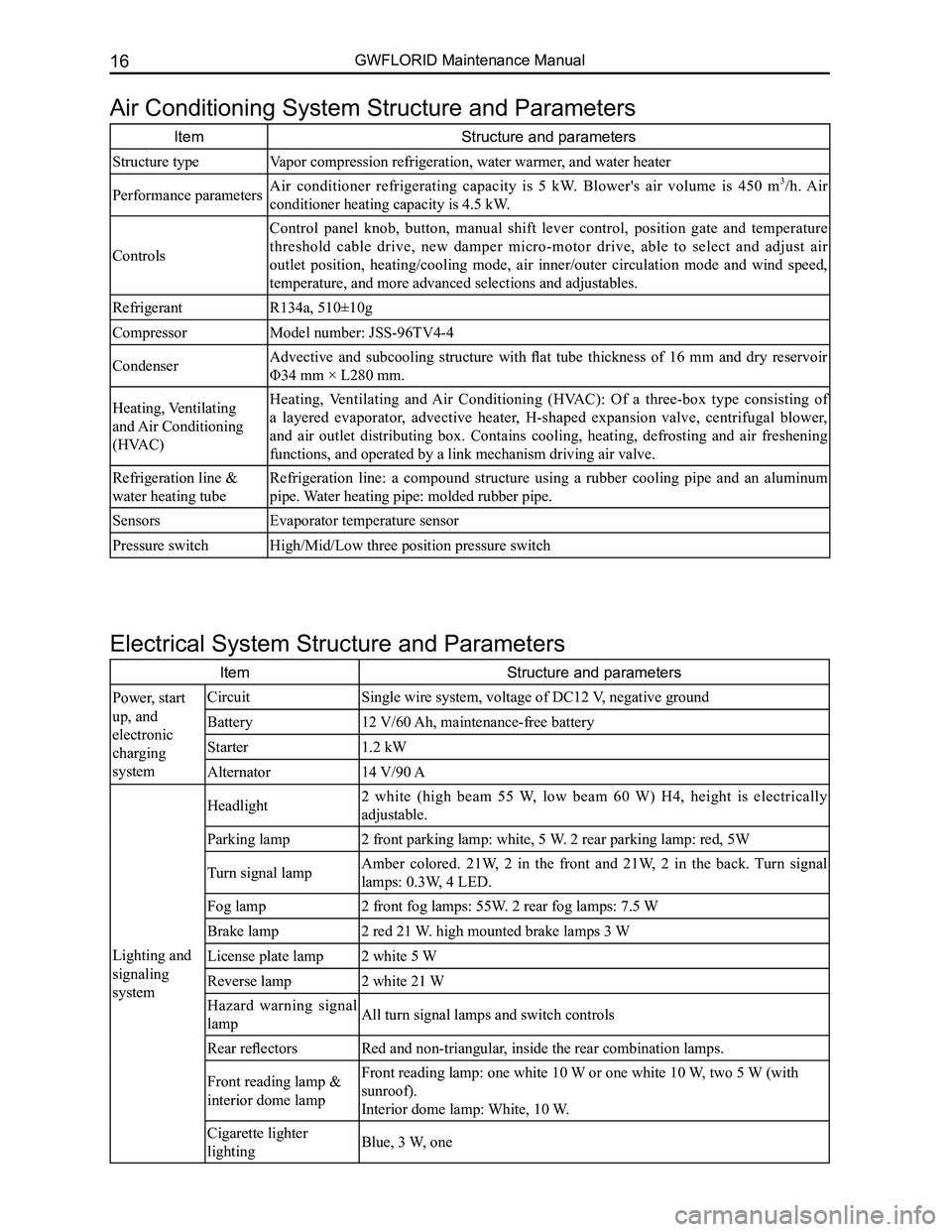

Air Conditioning System Structure and Parameters

ItemStructure and parameters

Structure typeVapor compression refrigeration, water warmer, and water heater

Performance parametersAir conditioner refrigerating capacity is 5 kW. Blower's air volume is 450 m3/h. Air

conditioner heating capacity is 4.5 kW.

Controls

Control panel knob, button, manual shift lever control, position gate and temperature

threshold cable drive, new damper micro-motor drive, able to select and adjust air

outlet position, heating/cooling mode, air inner/outer circulation mode and wind speed,

temperature, and more advanced selections and adjustables.

RefrigerantR134a, 510±10g

CompressorModel number: JSS-96TV4-4

CondenserAdvective and subcooling structure with flat tube thickness of 16 mm and dry reservoir

Φ34 mm × L280 mm.

Heating, Ventilating

and Air Conditioning

(HVAC)

Heating, Ventilating and Air Conditioning (HVAC): Of a three-box type consisting of

a layered evaporator, advective heater, H-shaped expansion valve, centrifugal blower,

and air outlet distributing box. Contains cooling, heating, defrosting and air freshening

functions, and operated by a link mechanism driving air valve.

Refrigeration line &

water heating tube

Refrigeration line: a compound structure using a rubber cooling pipe and an aluminum

pipe. Water heating pipe: molded rubber pipe.

SensorsEvaporator temperature sensor

Pressure switchHigh/Mid/Low three position pressure switch

Electrical System Structure and Parameters

ItemStructure and parameters

Power, start

up, and

electronic

charging

system

CircuitSingle wire system, voltage of DC12 V, negative ground

Battery12 V/60 Ah, maintenance-free battery

Starter1.2 kW

Alternator14 V/90 A

Lighting and

signaling

system

Headlight2 white (high beam 55 W, low beam 60 W) H4, height is electrically

adjustable.

Parking lamp2 front parking lamp: white, 5 W. 2 rear parking lamp: red, 5W

Turn signal lampAmber colored. 21W, 2 in the front and 21W, 2 in the back. Turn signal

lamps: 0.3W, 4 LED.

Fog lamp2 front fog lamps: 55W. 2 rear fog lamps: 7.5 W

Brake lamp2 red 21 W. high mounted brake lamps 3 W

License plate lamp2 white 5 W

Reverse lamp2 white 21 W

Hazard warning signal

lampAll turn signal lamps and switch controls

Rear reflectorsRed and non-triangular, inside the rear combination lamps.

Front reading lamp &

interior dome lamp

Front reading lamp: one white 10 W or one white 10 W, two 5 W (with

sunroof).

Interior dome lamp: White, 10 W.

Cigarette lighter

lightingBlue, 3 W, one

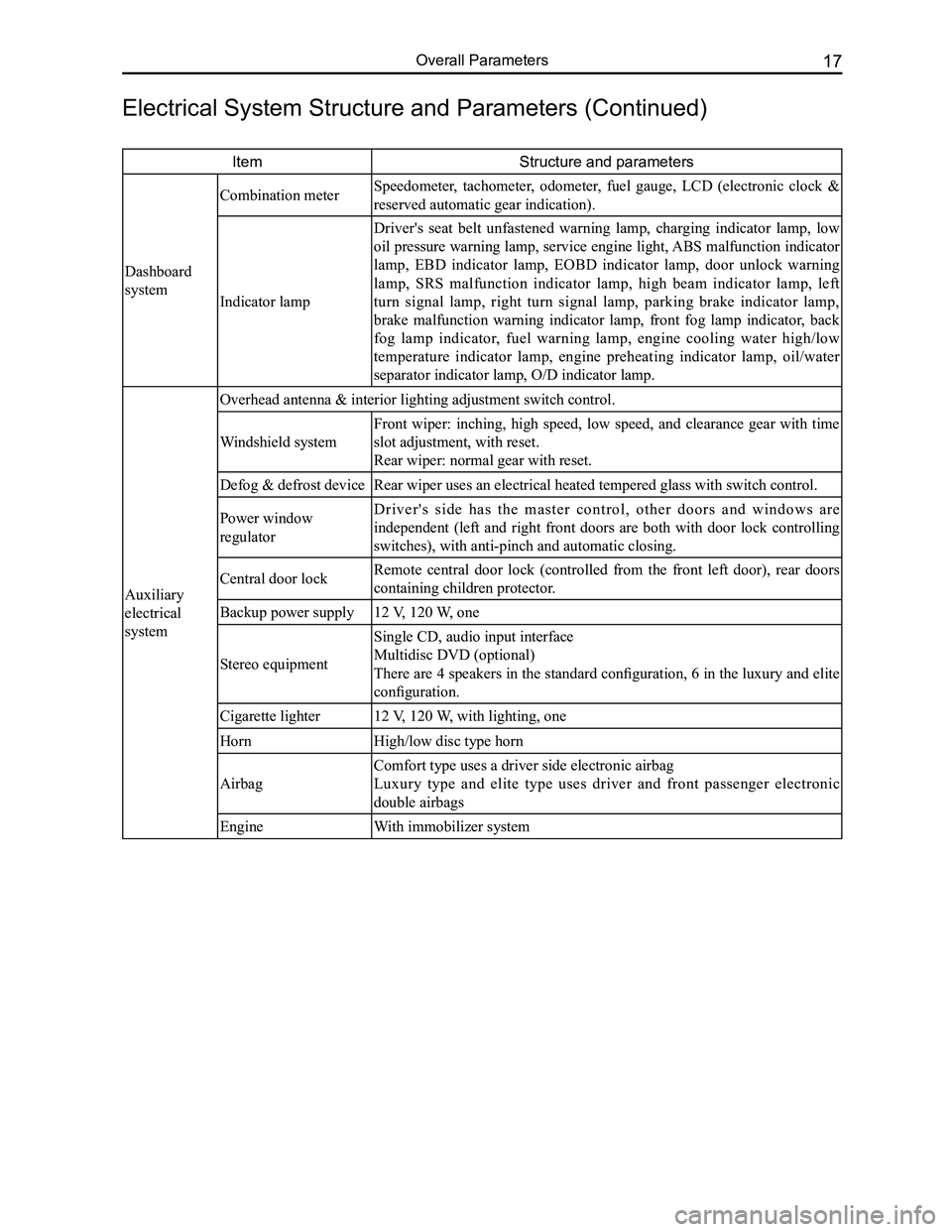

Page 24 of 281

Downloaded from www.Manualslib.com manuals search engine 17Overall Parameters

ItemStructure and parameters

Dashboard

system

Combination meter Speedometer, tachometer, odometer, fuel gauge, LCD (electronic clock &

reserved automatic gear indication).

Indicator lamp

Driver's seat belt unfastened warning lamp, charging indicator lamp, low

oil pressure warning lamp, service engine light, ABS malfunction indicator

lamp, EBD indicator lamp, EOBD indicator lamp, door unlock warning

lamp, SRS malfunction indicator lamp, high beam indicator lamp, left

turn signal lamp, right turn signal lamp, parking brake indicator lamp,

brake malfunction warning indicator lamp, front fog lamp indicator, back

fog lamp indicator, fuel warning lamp, engine cooling water high/low

temperature indicator lamp, engine preheating indicator lamp, oil/water

separator indicator lamp, O/D indicator lamp.

Auxiliary

electrical

system

Overhead antenna & interior lighting adjustment switch control.

Windshield system

Front wiper: inching, high speed, low speed, and clearance gear with time

slot adjustment, with reset.

Rear wiper: normal gear with reset.

Defog & defrost deviceRear wiper uses an electrical heated tempered glass with switch control.\

Power window

regulator

D r i v e r ' s s i d e h a s t h e m a s t e r c o n t r o l , o t h e r d o o r s a n d w i n d o w s a r e

independent (left and right front doors are both with door lock controlling

switches), with anti-pinch and automatic closing.

Central door lockRemote central door lock (controlled from the front left door), rear doors

containing children protector.

Backup power supply12 V, 120 W, one

Stereo equipment

Single CD, audio input interface

Multidisc DVD (optional)

There are 4 speakers in the standard configuration, 6 in the luxury and elite

configuration.

Cigarette lighter12 V, 120 W, with lighting, one

HornHigh/low disc type horn

Airbag

Comfort type uses a driver side electronic airbag

Luxury type and elite type uses driver and front passenger electronic

double airbags

EngineWith immobilizer system

Electrical System Structure and Parameters (Continued)

Page 26 of 281

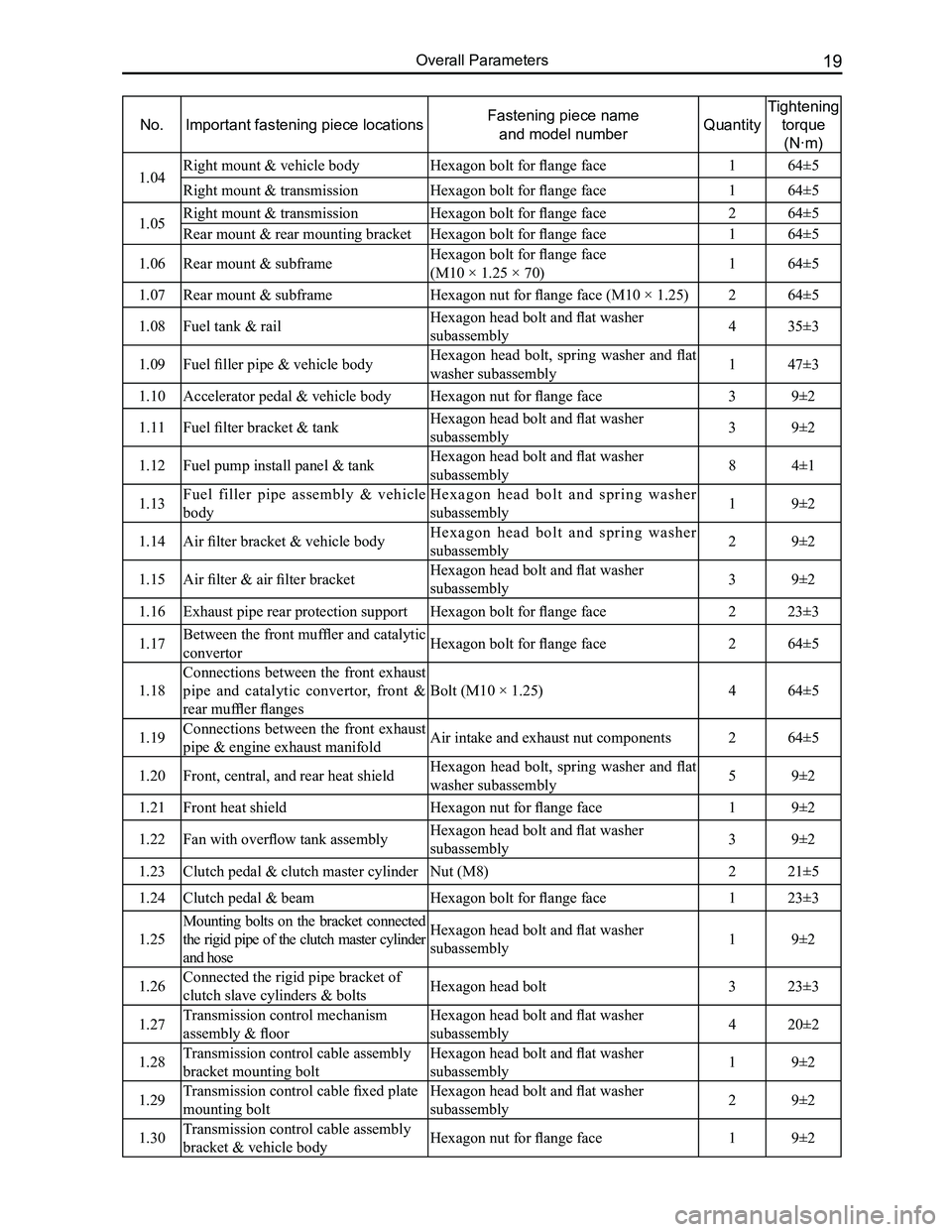

Downloaded from www.Manualslib.com manuals search engine 19Overall Parameters

No.Important fastening piece locationsFastening piece name

and model numberQuantity

Tightening

torque

(N·m)

1.04Right mount & vehicle bodyHexagon bolt for flange face164±5

Right mount & transmissionHexagon bolt for flange face 164±5

1.05Right mount & transmissionHexagon bolt for flange face 264±5

Rear mount & rear mounting bracketHexagon bolt for flange face 164±5

1.06Rear mount & subframeHexagon bolt for flange face

(M10 × 1.25 × 70)164±5

1.07Rear mount & subframeHexagon nut for flange face (M10 × 1.25)264±5

1.08Fuel tank & railHexagon head bolt and flat washer

subassembly435±3

1.09Fuel filler pipe & vehicle bodyHexagon head bolt, spring washer and flat

washer subassembly147±3

1.10Accelerator pedal & vehicle bodyHexagon nut for flange face39±2

1.11Fuel filter bracket & tankHexagon head bolt and flat washer

subassembly39±2

1.12Fuel pump install panel & tankHexagon head bolt and flat washer

subassembly84±1

1.13Fuel filler pipe assembly & vehicle

body

H e x a g o n h e a d b o l t a n d s p r i n g w a s h e r

subassembly19±2

1.14Air filter bracket & vehicle bodyH e x a g o n h e a d b o l t a n d s p r i n g w a s h e r

subassembly29±2

1.15Air filter & air filter bracketHexagon head bolt and flat washer

subassembly39±2

1.16Exhaust pipe rear protection supportHexagon bolt for flange face223±3

1.17Between the front muffler and catalytic

convertorHexagon bolt for flange face264±5

1.18

Connections between the front exhaust

pipe and catalytic convertor, front &

rear muffler flanges

Bolt (M10 × 1.25)464±5

1.19Connections between the front exhaust

pipe & engine exhaust manifoldAir intake and exhaust nut components264±5

1.20Front, central, and rear heat shieldHexagon head bolt, spring washer and flat

washer subassembly59±2

1.21Front heat shieldHexagon nut for flange face19±2

1.22Fan with overflow tank assemblyHexagon head bolt and flat washer

subassembly39±2

1.23Clutch pedal & clutch master cylinderNut (M8)221±5

1.24Clutch pedal & beamHexagon bolt for flange face123±3

1.25

Mounting bolts on the bracket connected

the rigid pipe of the clutch master cylinder

and hose

Hexagon head bolt and flat washer

subassembly19±2

1.26Connected the rigid pipe bracket of

clutch slave cylinders & boltsHexagon head bolt323±3

1.27Transmission control mechanism

assembly & floor

Hexagon head bolt and flat washer

subassembly420±2

1.28Transmission control cable assembly

bracket mounting bolt

Hexagon head bolt and flat washer

subassembly19±2

1.29Transmission control cable fixed plate

mounting bolt

Hexagon head bolt and flat washer

subassembly29±2

1.30Transmission control cable assembly

bracket & vehicle bodyHexagon nut for flange face19±2

Page 79 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual72

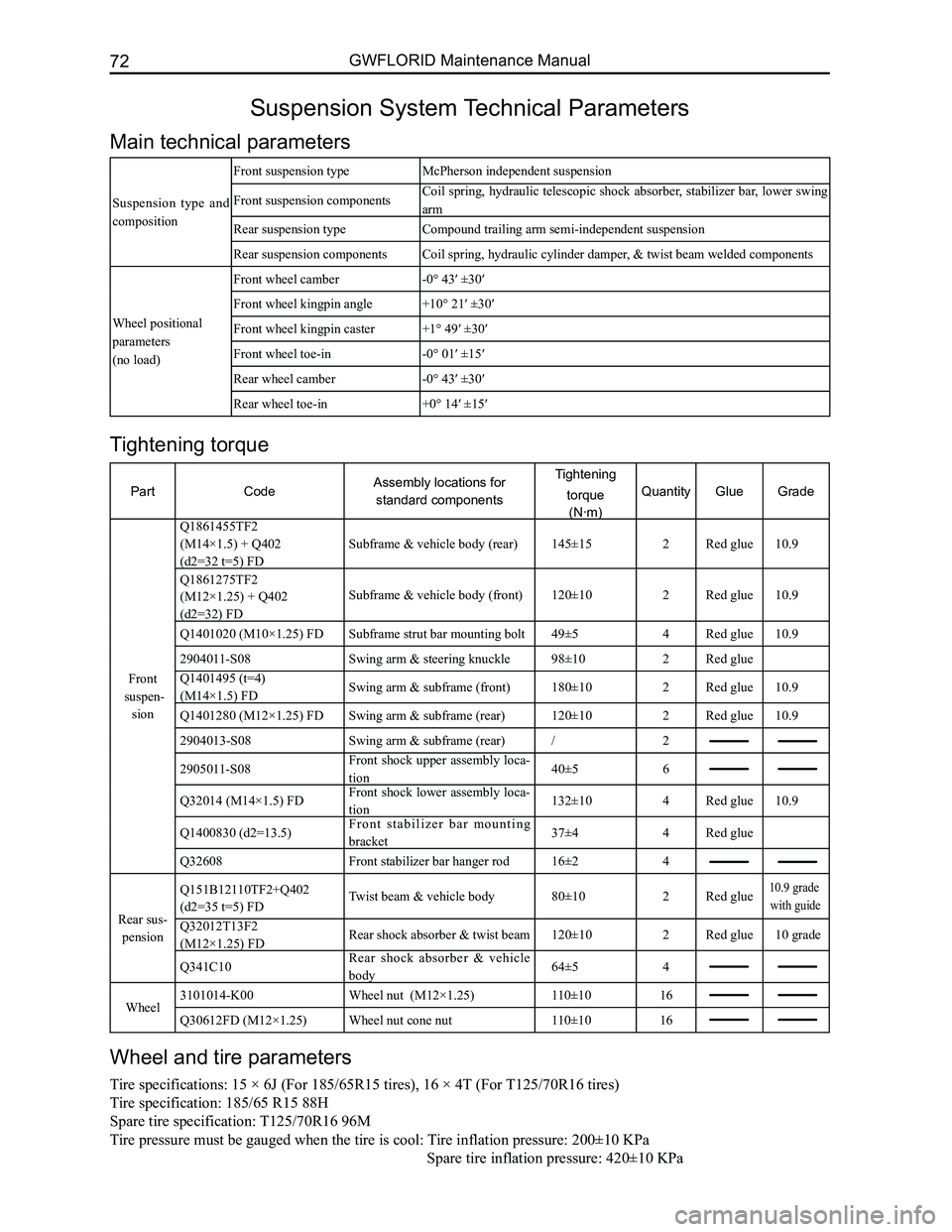

Suspension System Technical Parameters

Main technical parameters

Suspension type and

composition

Front suspension typeMcPherson independent suspension

Front suspension componentsCoil spring, hydraulic telescopic shock absorber, stabilizer bar, lower swing

arm

Rear suspension typeCompound trailing arm semi-independent suspension

Rear suspension componentsCoil spring, hydraulic cylinder damper, & twist beam welded components

Wheel positional

parameters

(no load)

Front wheel camber-0° 43′ ±30′

Front wheel kingpin angle+10° 21′ ±30′

Front wheel kingpin caster+1° 49′ ±30′

Front wheel toe-in-0° 01′ ±15′

Rear wheel camber-0° 43′ ±30′

Rear wheel toe-in+0° 14′ ±15′

Wheel and tire parameters

Tire specifications: 15 × 6J (For 185/65R15 tires), 16 × 4T (For T125/70R16 tires)

Tire specification: 185/65 R15 88H

Spare tire specification: T125/70R16 96M

Tire pressure must be gauged when the tire is cool: Tire inflation pressure: 200±10 KPa

Spare tir e inflation pressure: 420±10 KPa

Tightening torque

PartCodeAssembly locations for

standard components

Tightening

torque

(N·m)

QuantityGlueGrade

Front

suspen-

sion

Q1861455TF2

(M14×1.5) + Q402

(d2=32 t=5) FD

Subframe & vehicle body (rear)145±15 2Red glue10.9

Q1861275TF2

(M12×1.25) + Q402

(d2=32) FD

Subframe & vehicle body (front)120±102Red glue10.9

Q1401020 (M10×1.25) FDSubframe strut bar mounting bolt49±54Red glue10.9

2904011-S08Swing arm & steering knuckle98±102Red glue

Q1401495 (t=4)

(M14×1.5) FDSwing arm & subframe (front)180±102Red glue10.9

Q1401280 (M12×1.25) FDSwing arm & subframe (rear)120±102Red glue10.9

2904013-S08Swing arm & subframe (rear)/2

2905011-S08Front shock upper assembly loca-

tion40±56

Q32014 (M14×1.5) FDFront shock lower assembly loca-

tion132±104Red glue10.9

Q1400830 (d2=13.5)F r o n t s t a b i l i z e r b a r m o u n t i n g

bracket37±44Red glue

Q32608Front stabilizer bar hanger rod16±24

Rear sus-

pension

Q151B12110TF2+Q402

(d2=35 t=5) FDTwist beam & vehicle body80±102Red glue10.9 grade

with guide

Q32012T13F2

(M12×1.25) FDRear shock absorber & twist beam120±102Red glue10 grade

Q341C10Rear shock absorber & vehicle

body64±54

Wheel3101014-K00Wheel nut (M12×1.25)110±1016

Q30612FD (M12×1.25)Wheel nut cone nut110±1016

Page 93 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual86

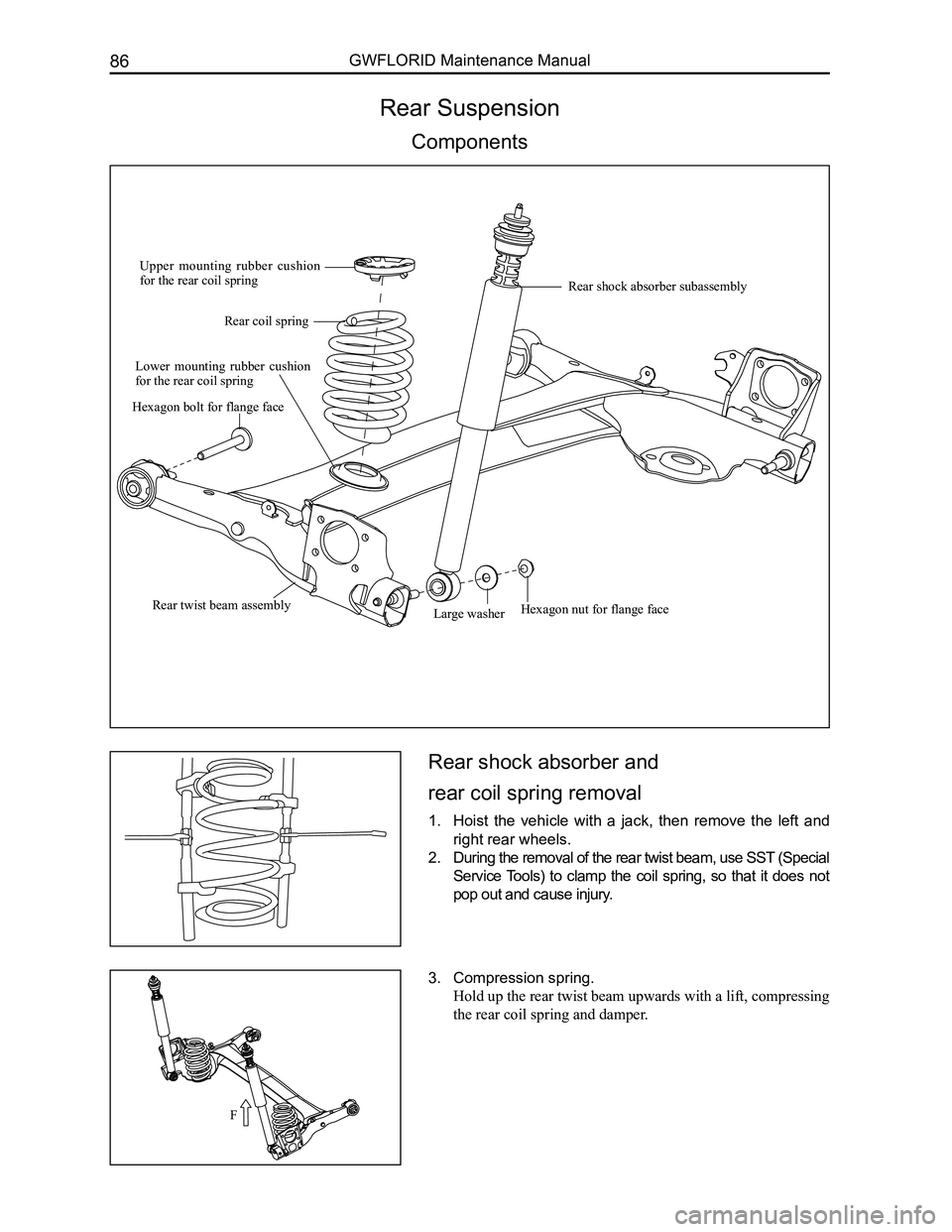

Rear Suspension

Components

Rear shock absorber and

rear coil spring removal

1. Hoist the vehicle with a jack, then remove the left and

right rear wheels.

2. During the removal of the rear twist beam, use SST (Special

Service Tools) to clamp the coil spring, so that it does not

pop out and cause injury.

3. Compression spring.

Hold up the rear twist beam upwards with a lift, compressing

the rear coil spring and damper.

Upper mounting rubber cushion for the rear coil spring

Rear coil spring

Lower mounting rubber cushion for the rear coil spring

Large washerRear twist beam assembly

Rear shock absorber subassembly

Hexagon bolt for flange face

Hexagon nut for flange face

F

Page 94 of 281

Downloaded from www.Manualslib.com manuals search engine 87Suspension System

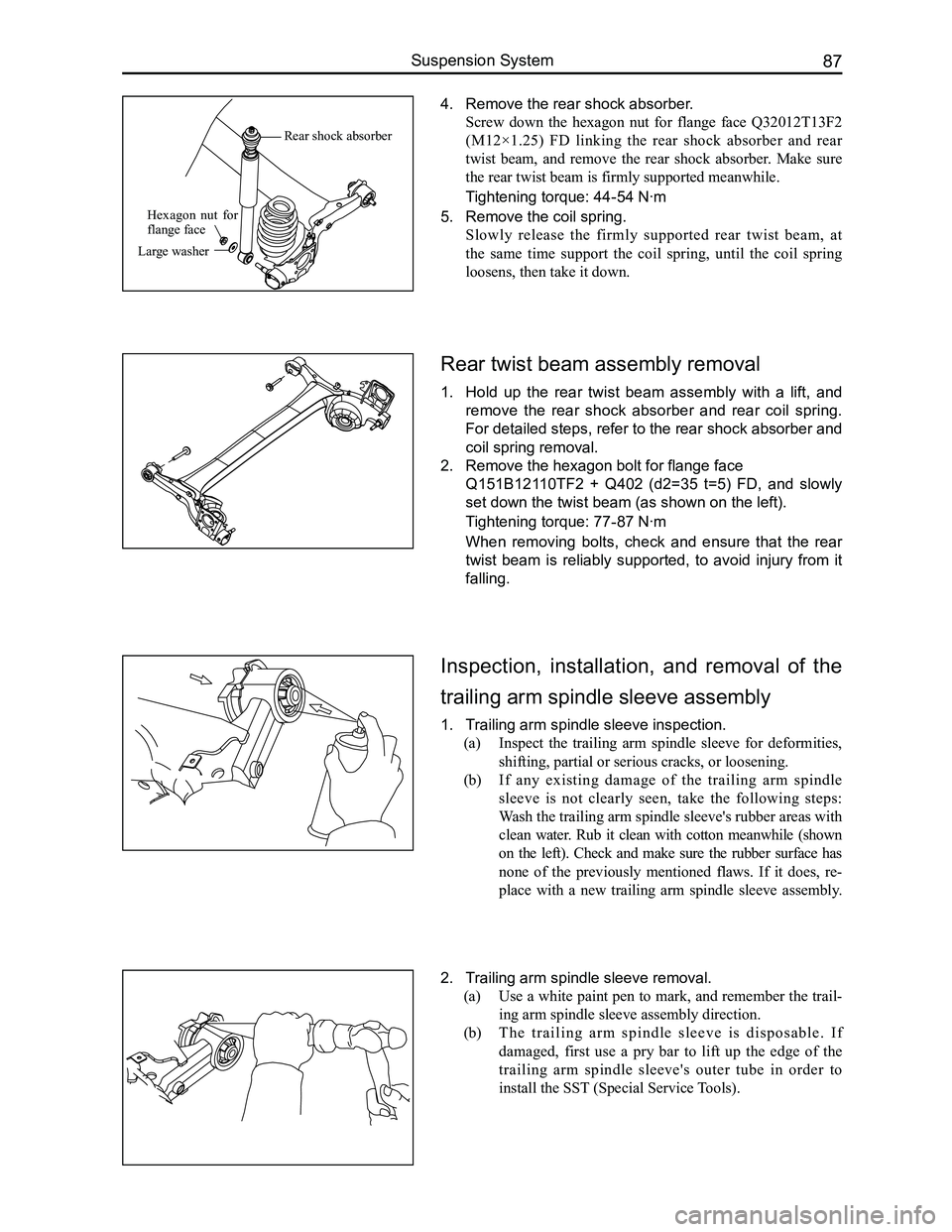

Inspection, installation, and removal of the

trailing arm spindle sleeve assembly

1. Trailing arm spindle sleeve inspection.

(a) Inspect the trailing arm spindle sleeve for deformities,

shifting, partial or serious cracks, or loosening.

(b) If any existing damage of the trailing arm spindle

sleeve is not clearly seen, take the following steps:

Wash the trailing arm spindle sleeve's rubber areas with

clean water. Rub it clean with cotton meanwhile (shown

on the left). Check and make sure the rubber surface has

none of the previously mentioned flaws. If it does, re-

place with a new trailing arm spindle sleeve assembly.

2. Trailing arm spindle sleeve removal.

(a) Use a white paint pen to mark, and remember the trail-

ing arm spindle sleeve assembly direction.

(b) T h e t r a i l i n g a r m s p i n d l e s l e e v e i s d i s p o s a b l e . I f

damaged, first use a pry bar to lift up the edge of the

trailing arm spindle sleeve's outer tube in order to

install the SST (Special Service Tools).

Rear twist beam assembly removal

1. Hold up the rear twist beam assembly with a lift, and

remove the rear shock absorber and rear coil spring.

For detailed steps, refer to the rear shock absorber and

coil spring removal.

2. Remove the hexagon bolt for flange face

Q151B12110TF2 + Q402 (d2=35 t=5) FD, and slowly

set down the twist beam (as shown on the left).

Tightening torque: 77-87 N·m

When removing bolts, check and ensure that the rear

twist beam is reliably supported, to avoid injury from it

falling.

4. Remove the rear shock absorber.

Screw down the hexagon nut for flange face Q32012T13F2

(M12×1.25) FD linking the rear shock absorber and rear

twist beam, and remove the rear shock absorber. Make sure

the rear twist beam is firmly supported meanwhile.

Tightening torque: 44-54 N·m

5. Remove the coil spring.

Slowly release the firmly supported rear twist beam, at

the same time support the coil spring, until the coil spring

loosens, then take it down.

Rear shock absorber

Large washer

Hexagon nut for flange face

Page 116 of 281

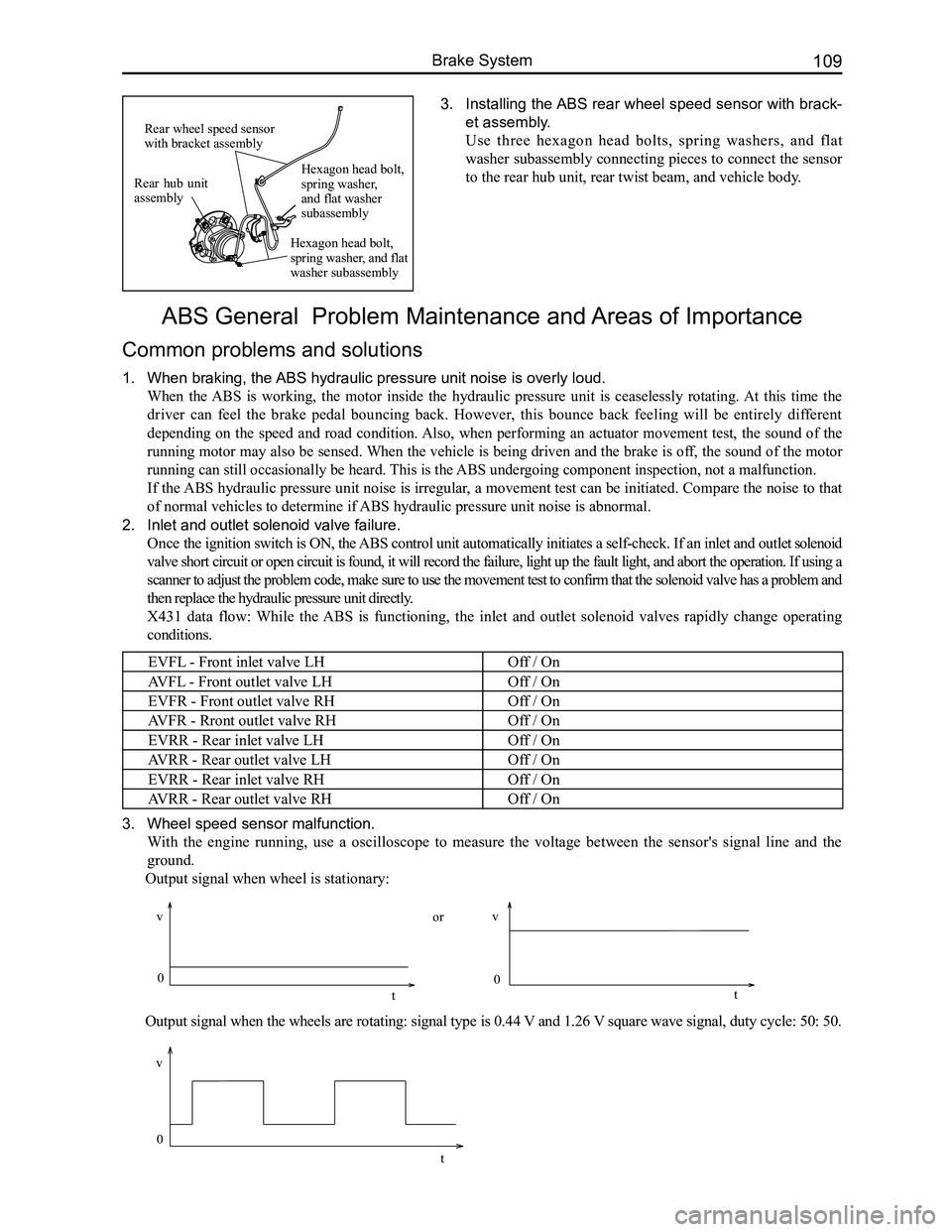

Downloaded from www.Manualslib.com manuals search engine 109Brake System

3. Installing the ABS rear wheel speed sensor with brack-

et assembly.

Use three hexagon head bolts, spring washers, and flat

washer subassembly connecting pieces to connect the sensor

to the rear hub unit, rear twist beam, and vehicle body.

ABS General Problem Maintenance and Areas of Importance

Common problems and solutions

1. When braking, the ABS hydraulic pressure unit noise is overly loud.

When the ABS is working, the motor inside the hydraulic pressure unit is ceaselessly rotating. At this time the

driver can feel the brake pedal bouncing back. However, this bounce back feeling will be entirely different

depending on the speed and road condition. Also, when performing an actuator movement test, the sound of the

running motor may also be sensed. When the vehicle is being driven and the brake is off, the sound of the motor

running can still occasionally be heard. This is the ABS undergoing component inspection, not a malfunction.

If the ABS hydraulic pressure unit noise is irregular, a movement test can be initiated. Compare the noise to that

of normal vehicles to determine if ABS hydraulic pressure unit noise is abnormal.

2. Inlet and outlet solenoid valve failure.

Once the ignition switch is ON, the ABS control unit automatically initiates a self-check. If an inlet and outlet solenoid

valve short circuit or open circuit is found, it will record the failure, light up the fault light, and abort the operation. If using a

scanner to adjust the problem code, make sure to use the movement test t\

o confirm that the solenoid valve has a problem and

then replace the hydraulic pressure unit directly.

X431 data flow: While the ABS is functioning, the inlet and outlet solenoid valves rapidly change operating

conditions.

EVFL - Front inlet valve LHOff / On

AVFL - Front outlet valve LHOff / On

EVFR - Front outlet valve RHOff / On

AVFR - Rront outlet valve RHOff / On

EVRR - Rear inlet valve LHOff / On

AVRR - Rear outlet valve LHOff / On

EVRR - Rear inlet valve RHOff / On

AVRR - Rear outlet valve RHOff / On

3. Wheel speed sensor malfunction.

With the engine running, use a oscilloscope to measure the voltage between the sensor's signal line and the

ground.

Output signal when wheel is stationary:

Output signal when the wheels are rotating: signal type is 0.44 V and 1.26 V square wave signal, duty cycle: 50: 50.

Rear hub unit assembly

Rear wheel speed sensor with bracket assembly

Hexagon head bolt, spring washer, and flat washer subassembly

Hexagon head bolt, spring washer, and flat washer subassembly

0

v

t

vv

0 0

tt

or

Page 153 of 281

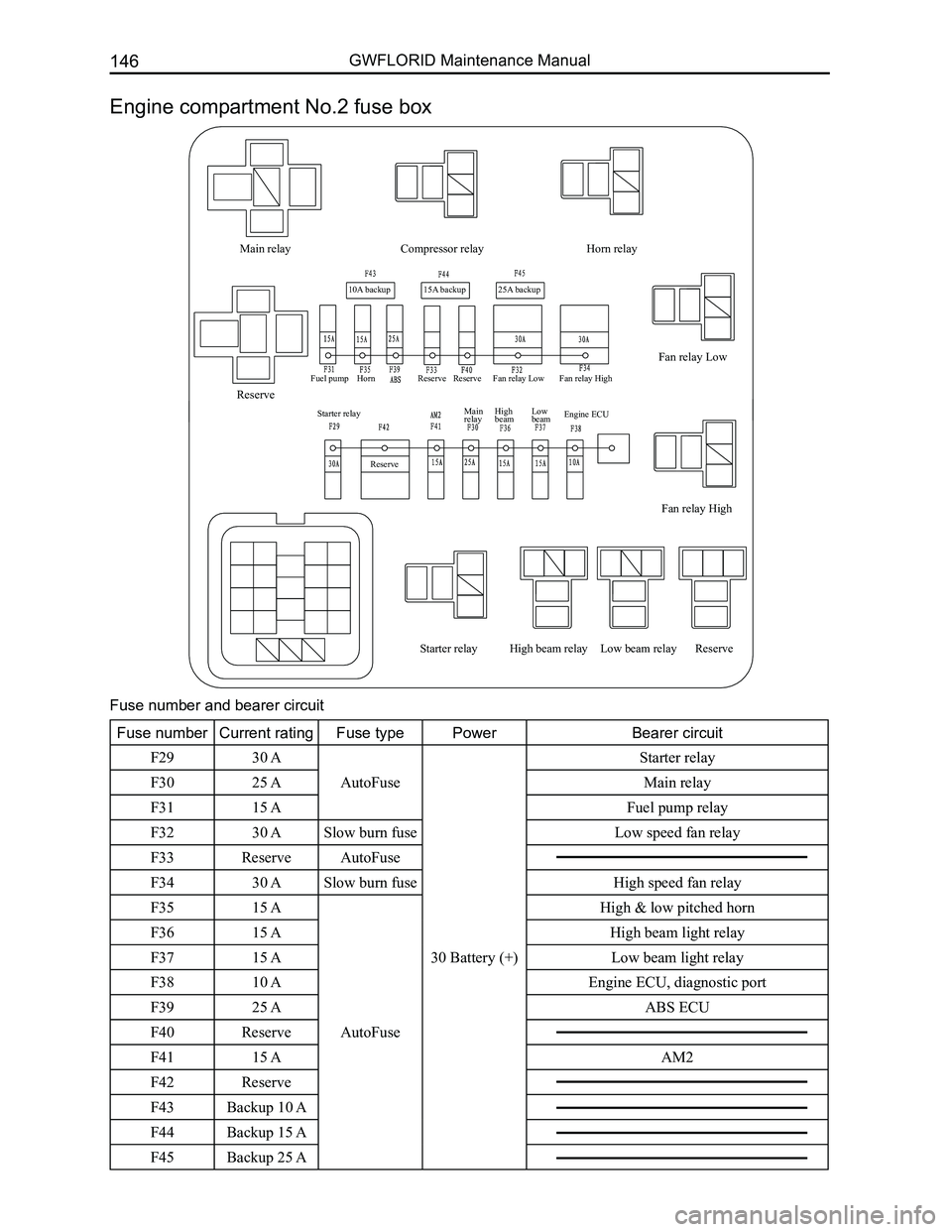

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual146

Main relay

10A backup 15A backup 25A backup

Compressor relay

Reserve

Reserve

Fuel pump

Starter relay Main

relay High

beam Low

beam

Engine ECU

Fan relay High

Starter relay High beam relay Low beam relay Reserve

Horn Reserve Reserve Fan relay Low

Fan relay Low

Fan relay High

Horn relay

Engine compartment No.2 fuse box

Fuse number and bearer circuit

Fuse numberCurrent ratingFuse typePowerBearer circuit

F2930 A

AutoFuse

30 Battery (+)

Starter relay

F3025 AMain relay

F3115 AFuel pump relay

F3230 ASlow burn fuse Low speed fan relay

F33ReserveAutoFuse

F3430 ASlow burn fuse High speed fan relay

F3515 A

AutoFuse

High & low pitched horn

F3615 AHigh beam light relay

F3715 ALow beam light relay

F3810 AEngine ECU, diagnostic port

F3925 AABS ECU

F40Reserve

F4115 AAM2

F42Reserve

F43Backup 10 A

F44Backup 15 A

F45Backup 25 A

Page 182 of 281

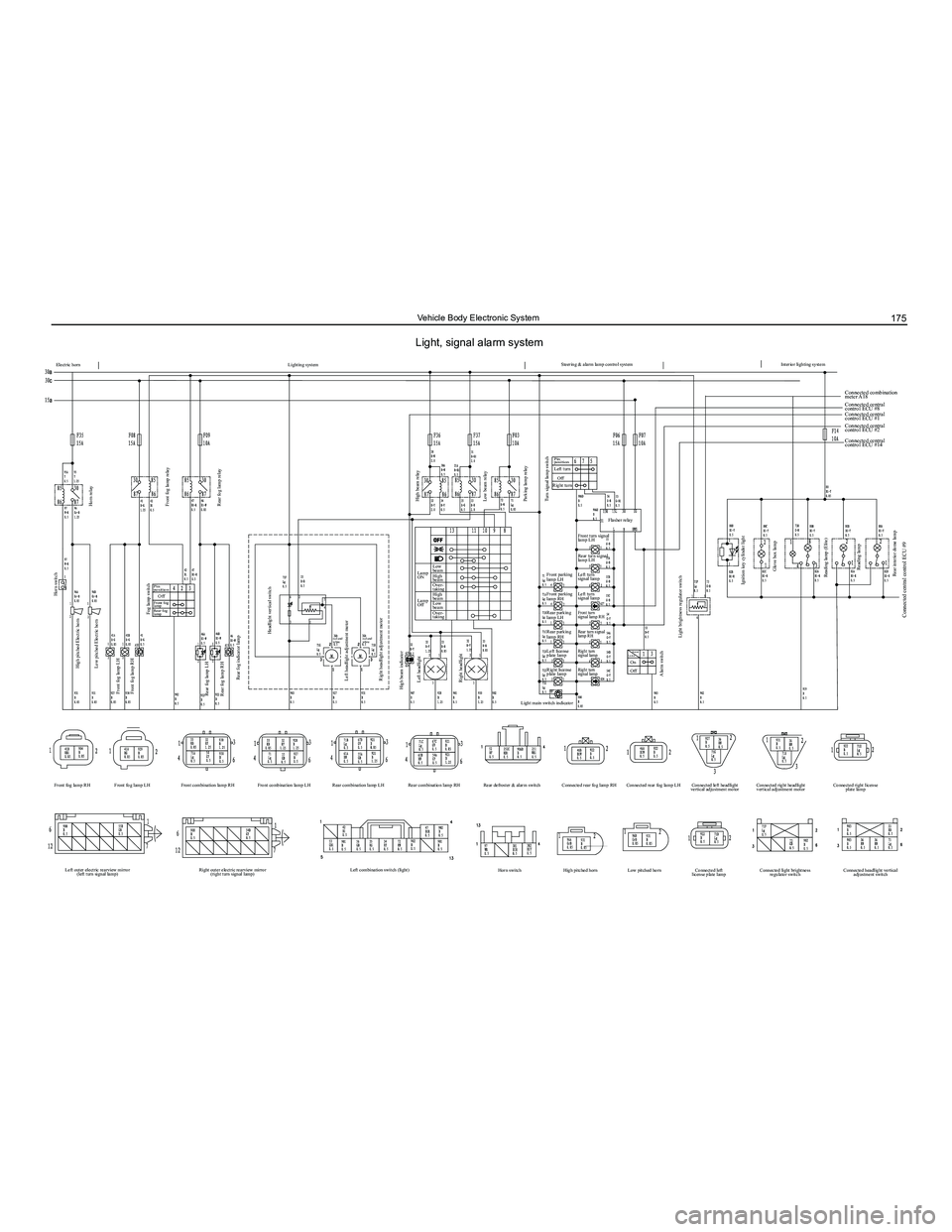

Downloaded from www.Manualslib.com manuals search engine 175Vehicle Body Electronic System

Electric horn

Horn switch

High pitched Electric horn

Low pitched Electric horn

Front fog lamp LH

Front fog lamp RH

Left outer electric rearview mirror (left turn signal lamp) Right outer electric rearview mirror

(right turn signal lamp) Left combination switch (light)

Horn switch High pitched horn Low pitched horn Connected left

license plate lamp Connected light brightness

regulator switch Connected headlight vertical

adjustment switch

Front fog lamp LH

Front combination lamp RH Front combination lamp LH Rear combination lamp LH Rear combination lamp RH Rear defroster & alarm switch Connected rear fog lamp RH Connected rear fog lamp LH Connected left headlight

vertical adjustment motor Connected right headlight

vertical adjustment motor Connected right license

plate lamp

Front fog lamp RH

Rear fog lamp LH

Rear fog lamp RH

Rear fog indicator lamp

Left headlight adjustment motor

Right headlight adjustment motor High beam relay

Lamp

ON Low

beam

Low

beam High

beam

High

beam Over-

taking

Over-

taking

Lamp

Off

Low beam relay

Parking lamp relay

Flasher relay

Connected combination

meter A18

Connected central

control ECU #8

Connected central

control ECU #1

Connected central

control ECU #2

Connected central

control ECU #14

Front parking

lamp LH Front turn signal

lamp LH

Rear turn signal

lamp LH

Left turn

signal lamp

Left turn

signal lamp

Front turn

signal lamp RH

Rear turn signal

lamp RH

Right turn

signal lamp

Right turn

signal lamp

Front parking

lamp RH

Rear parking

lamp LH

Rear parking

lamp RH

Left license

plate lamp

Right license

plate lamp

Light main switch indicator

Turn signal lamp switch

Alarm switch Light brightness regulator switch

Ignition key cylinder light Glove box lamp

Reading lamp (Elite) Reading lamp

Rear interior dome lamp

Connected central control ECU #9

High beam indicator Left headlight

Right headlight Headlight vertical switch

red and

white

red and

white

Fog lamp switch

Pin

position Pin

position

Left turn

Right turn Off

Front fog

lamp

Rear fog

lamp Off

Horn relay

Front fog lamp relay

Rear fog lamp relay

Lighting system Steering & alarm lamp control system

Interior lighting system

Terminal

Location

Off On

Light, signal alarm system