fuel pressure GREAT WALL FLORID 2008 Service Manual

[x] Cancel search | Manufacturer: GREAT WALL, Model Year: 2008, Model line: FLORID, Model: GREAT WALL FLORID 2008Pages: 281, PDF Size: 43.97 MB

Page 19 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual12

Ride

Performance

Outter acceleration noise dB (A)≤74≤75

60 km/h constant velocity interior noise dB (A)≤65≤65

Driver operating noise dB (A)≤90≤90

Emission

CO emission (g/km)≤2.30≤1.00≤0.64

HC emission (g/km)≤0.20≤0.10/

NOx emission (g/km)≤0.15≤0.08≤0.5

Particle emission (g/km)//≤0.05

Smoke density//≤4.0

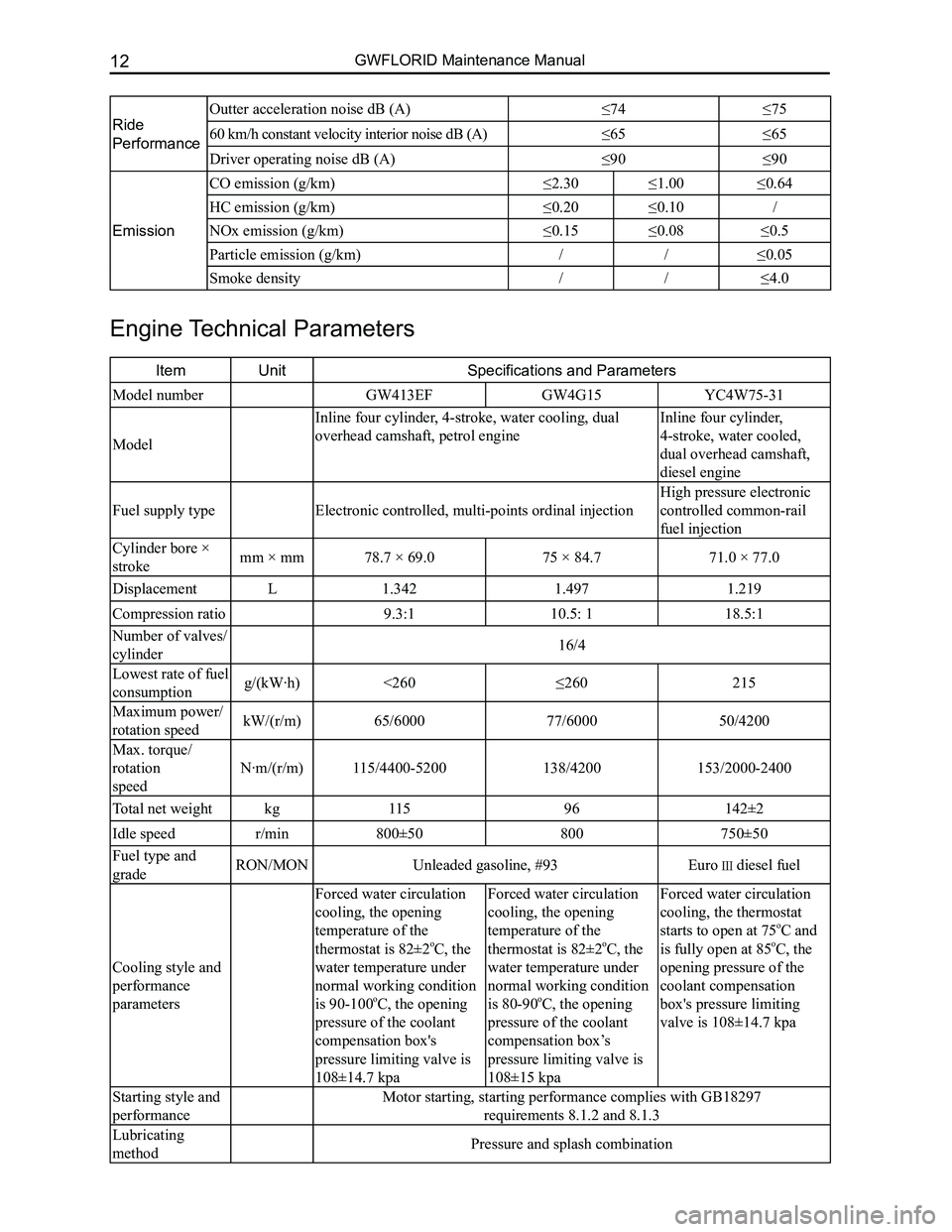

Engine Technical Parameters

ItemUnitSpecifications and Parameters

Model numberGW413EFGW4G15YC4W75-31

Model

Inline four cylinder, 4-stroke, water cooling, dual

overhead camshaft, petrol engine

Inline four cylinder,

4-stroke, water cooled,

dual overhead camshaft,

diesel engine

Fuel supply typeElectronic controlled, multi-points ordinal injection

High pressure electronic

controlled common-rail

fuel injection

Cylinder bore ×

strokemm × mm78.7 × 69.075 × 84.771.0 × 77.0

DisplacementL1.3421.4971.219

Compression ratio9.3:110.5: 118.5:1

Number of valves/

cylinder16/4

Lowest rate of fuel

consumption g/(kW·h)<260≤260215

Maximum power/

rotation speed kW/(r/m)65/600077/600050/4200

Max. torque/

rotation

speed

N·m/(r/m)115/4400-5200138/4200153/2000-2400

Total net weightkg11596142±2

Idle speedr/min800±50800750±50

Fuel type and

gradeRON/MONUnleaded gasoline, #93Euro diesel fuel

Cooling style and

performance

parameters

Forced water circulation

cooling, the opening

temperature of the

thermostat is 82±2oC, the

water temperature under

normal working condition

is 90-100oC, the opening

pressure of the coolant

compensation box's

pressure limiting valve is

108±14.7 kpa

Forced water circulation

cooling, the opening

temperature of the

thermostat is 82±2oC, the

water temperature under

normal working condition

is 80-90oC, the opening

pressure of the coolant

compensation box’s

pressure limiting valve is

108±15 kpa

Forced water circulation

cooling, the thermostat

starts to open at 75oC and

is fully open at 85oC, the

opening pressure of the

coolant compensation

box's pressure limiting

valve is 108±14.7 kpa

Starting style and

performance

Motor starting, starting performance complies with GB18297

requirements 8.1.2 and 8.1.3

Lubricating

methodPressure and splash combination

Page 20 of 281

Downloaded from www.Manualslib.com manuals search engine 13Overall Parameters

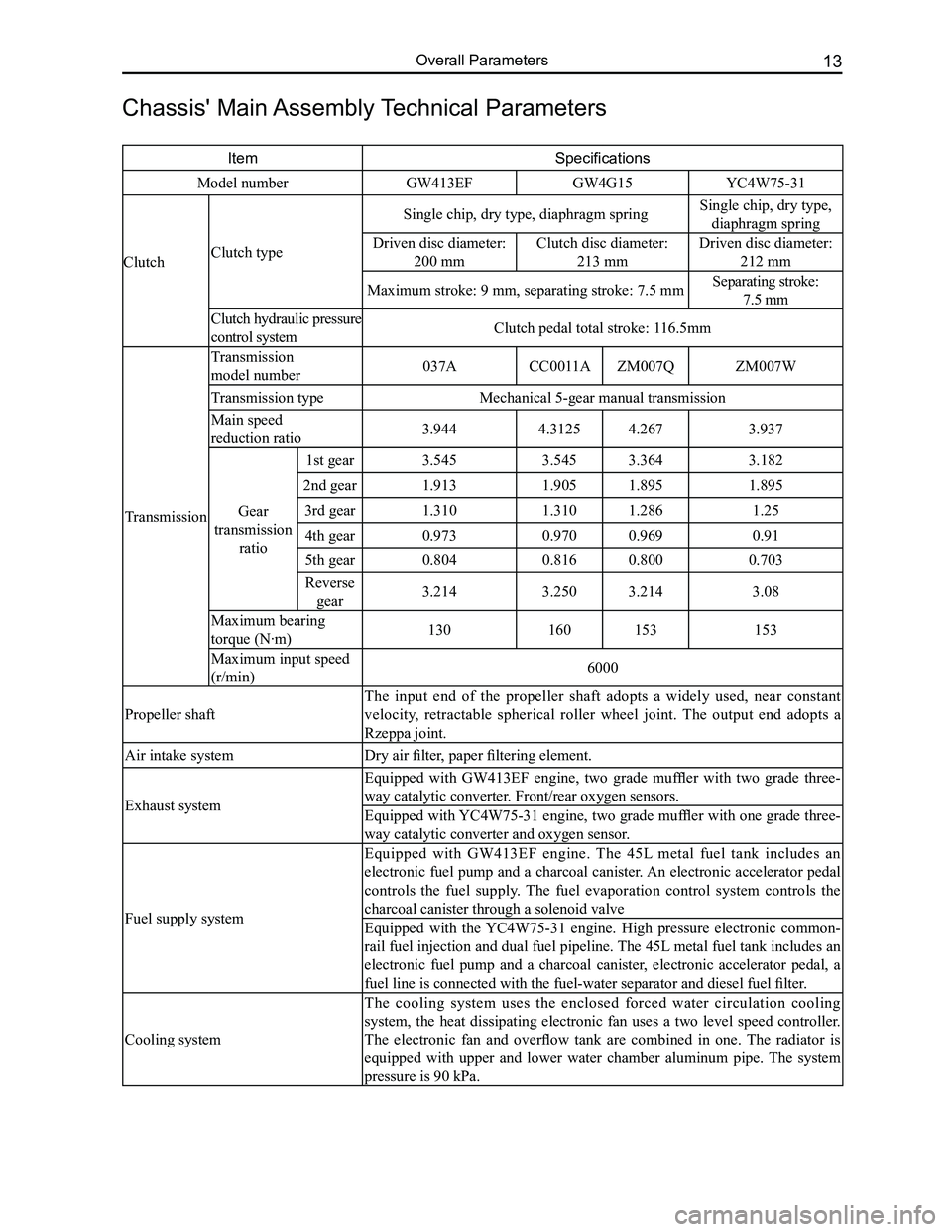

Chassis' Main Assembly Technical Parameters

ItemSpecifications

Model numberGW413EFGW4G15YC4W75-31

ClutchClutch type

Single chip, dry type, diaphragm springSingle chip, dry type,

diaphragm spring

Driven disc diameter:

200 mm

Clutch disc diameter:

213 mm

Driven disc diameter:

212 mm

Maximum stroke: 9 mm, separating stroke: 7.5 mmSeparating stroke:

7.5 mm

Clutch hydraulic pressure

control systemClutch pedal total stroke: 116.5mm

Transmission

Transmission

model number037ACC0011AZM007QZM007W

Transmission typeMechanical 5-gear manual transmission

Main speed

reduction ratio3.9444.31254.2673.937

Gear

transmission

ratio

1st gear3.5453.5453.3643.182

2nd gear1.9131.9051.8951.895

3rd gear1.3101.3101.2861.25

4th gear0.9730.9700.9690.91

5th gear0.8040.8160.8000.703

Reverse

gear3.2143.2503.2143.08

Maximum bearing

torque (N·m)130160153153

Maximum input speed

(r/min)6000

Propeller shaft

The input end of the propeller shaft adopts a widely used, near constant

velocity, retractable spherical roller wheel joint. The output end adopts a

Rzeppa joint.

Air intake systemDry air filter, paper filtering element.

Exhaust system

Equipped with GW413EF engine, two grade muffler with two grade three-

way catalytic converter. Front/rear oxygen sensors.

Equipped with YC4W75-31 engine, two grade muffler with one grade three-

way catalytic converter and oxygen sensor.

Fuel supply system

Equipped with GW413EF engine. The 45L metal fuel tank includes an

electronic fuel pump and a charcoal canister. An electronic accelerator pedal

controls the fuel supply. The fuel evaporation control system controls the

charcoal canister through a solenoid valve

Equipped with the YC4W75-31 engine. High pressure electronic common-

rail fuel injection and dual fuel pipeline. The 45L metal fuel tank includes an

electronic fuel pump and a charcoal canister, electronic accelerator pedal, a

fuel line is connected with the fuel-water separator and diesel fuel filter.

Cooling system

The cooling system uses the enclosed forced water circulation cooling

system, the heat dissipating electronic fan uses a two level speed controller.

The electronic fan and overflow tank are combined in one. The radiator is

equipped with upper and lower water chamber aluminum pipe. The system

pressure is 90 kPa.

Page 24 of 281

Downloaded from www.Manualslib.com manuals search engine 17Overall Parameters

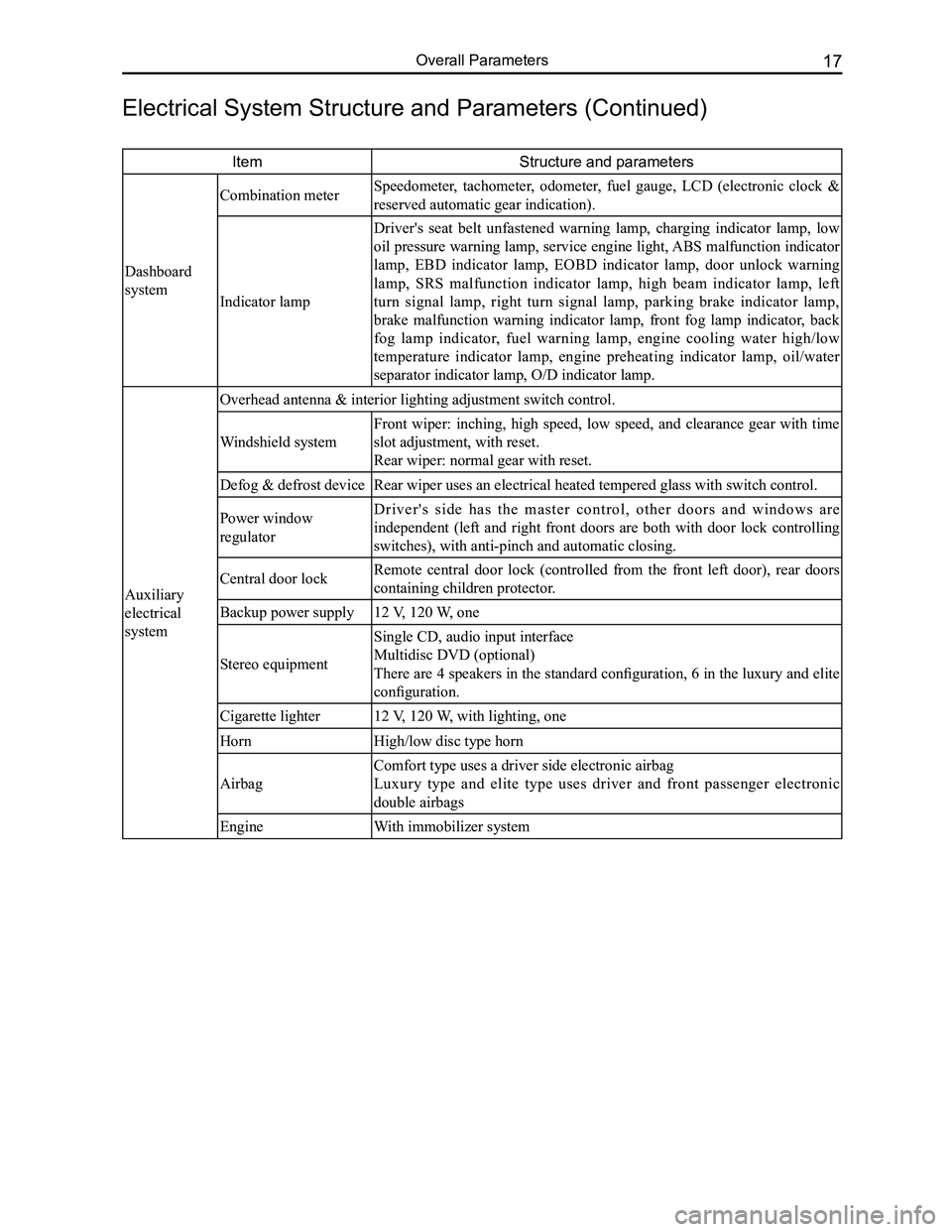

ItemStructure and parameters

Dashboard

system

Combination meter Speedometer, tachometer, odometer, fuel gauge, LCD (electronic clock &

reserved automatic gear indication).

Indicator lamp

Driver's seat belt unfastened warning lamp, charging indicator lamp, low

oil pressure warning lamp, service engine light, ABS malfunction indicator

lamp, EBD indicator lamp, EOBD indicator lamp, door unlock warning

lamp, SRS malfunction indicator lamp, high beam indicator lamp, left

turn signal lamp, right turn signal lamp, parking brake indicator lamp,

brake malfunction warning indicator lamp, front fog lamp indicator, back

fog lamp indicator, fuel warning lamp, engine cooling water high/low

temperature indicator lamp, engine preheating indicator lamp, oil/water

separator indicator lamp, O/D indicator lamp.

Auxiliary

electrical

system

Overhead antenna & interior lighting adjustment switch control.

Windshield system

Front wiper: inching, high speed, low speed, and clearance gear with time

slot adjustment, with reset.

Rear wiper: normal gear with reset.

Defog & defrost deviceRear wiper uses an electrical heated tempered glass with switch control.\

Power window

regulator

D r i v e r ' s s i d e h a s t h e m a s t e r c o n t r o l , o t h e r d o o r s a n d w i n d o w s a r e

independent (left and right front doors are both with door lock controlling

switches), with anti-pinch and automatic closing.

Central door lockRemote central door lock (controlled from the front left door), rear doors

containing children protector.

Backup power supply12 V, 120 W, one

Stereo equipment

Single CD, audio input interface

Multidisc DVD (optional)

There are 4 speakers in the standard configuration, 6 in the luxury and elite

configuration.

Cigarette lighter12 V, 120 W, with lighting, one

HornHigh/low disc type horn

Airbag

Comfort type uses a driver side electronic airbag

Luxury type and elite type uses driver and front passenger electronic

double airbags

EngineWith immobilizer system

Electrical System Structure and Parameters (Continued)

Page 38 of 281

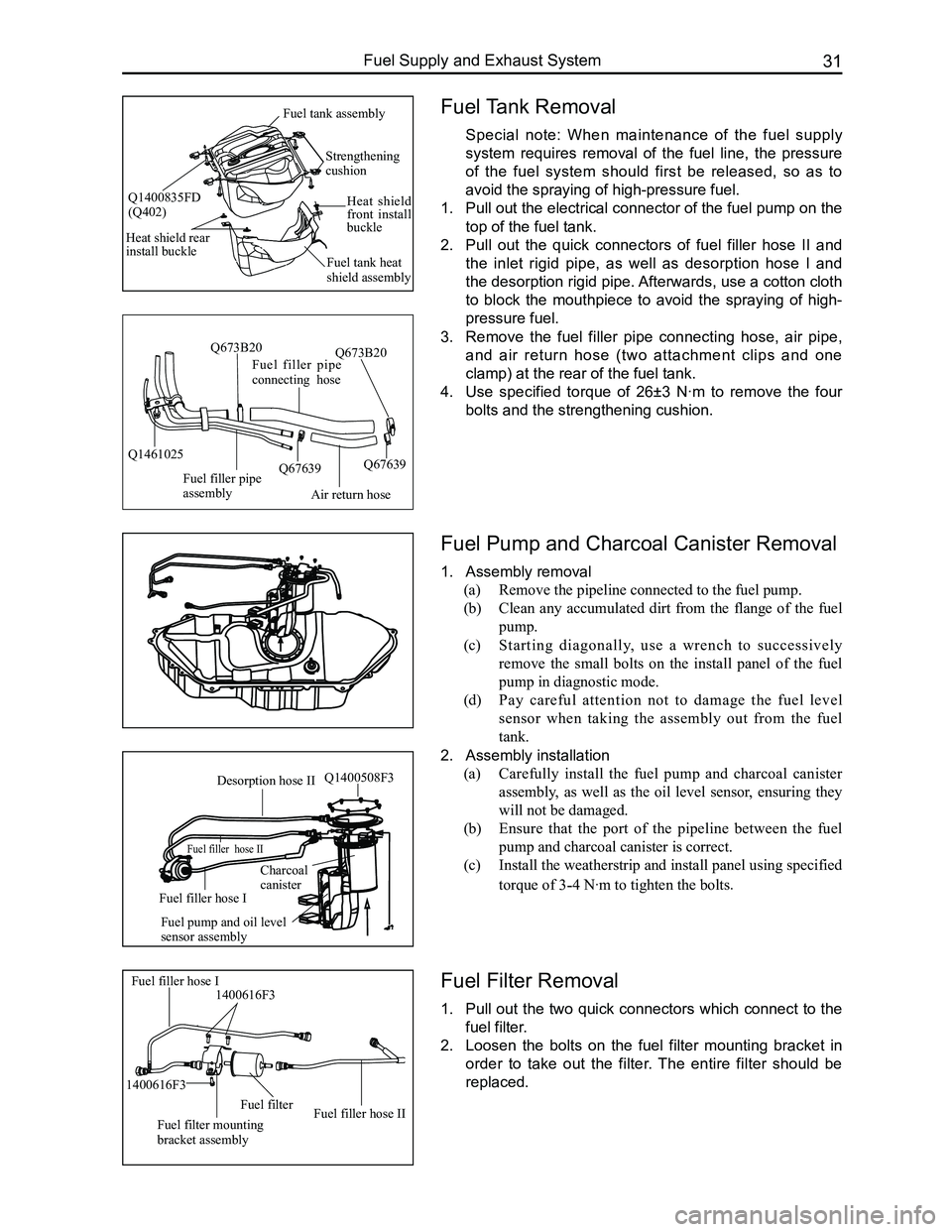

Downloaded from www.Manualslib.com manuals search engine 31Fuel Supply and Exhaust System

Fuel Tank Removal

Special note: When maintenance of the fuel supply

system requires removal of the fuel line, the pressure

of the fuel system should first be released, so as to

avoid the spraying of high-pressure fuel.

1. Pull out the electrical connector of the fuel pump on the

top of the fuel tank.

2. Pull out the quick connectors of fuel filler hose II and

the inlet rigid pipe, as well as desorption hose I and

the desorption rigid pipe. Afterwards, use a cotton cloth

to block the mouthpiece to avoid the spraying of high-

pressure fuel.

3. Remove the fuel filler pipe connecting hose, air pipe,

and air return hose (two attachment clips and one

clamp) at the rear of the fuel tank.

4. Use specified torque of 26±3 N·m to remove the four

bolts and the strengthening cushion.

Fuel Pump and Charcoal Canister Removal

1. Assembly removal

(a) Remove the pipeline connected to the fuel pump.

(b) Clean any accumulated dirt from the flange of the fuel

pump.

(c) Starting diagonally, use a wrench to successively

remove the small bolts on the install panel of the fuel

pump in diagnostic mode.

(d) Pay careful attention not to damage the fuel level

sensor when taking the assembly out from the fuel

tank.

2. Assembly installation

(a) Carefully install the fuel pump and charcoal canister

assembly, as well as the oil level sensor, ensuring they

will not be damaged.

(b) Ensure that the port of the pipeline between the fuel

pump and charcoal canister is correct.

(c) Install the weatherstrip and install panel using specified

torque of 3-4 N·m to tighten the bolts.

Fuel Filter Removal

1. Pull out the two quick connectors which connect to the

fuel filter.

2. Loosen the bolts on the fuel filter mounting bracket in

order to take out the filter. The entire filter should be

replaced.

Air return hose

Fuel filler pipe connecting hose

Fuel filler pipe assembly

Q1461025Q67639

Q673B20

Q67639

Q673B20

Fuel filler hose I1400616F3

Fuel filter mounting bracket assembly

Fuel filterFuel filler hose II

1400616F3

Desorption hose II

Fuel filler hose II

Fuel filler hose I

Charcoalcanister

Fuel pump and oil level sensor assembly

Q1400508F3

Strengthening cushion

Heat shield front install buckle

Fuel tank heat shield assembly

Heat shield rear install buckle

Fuel tank assembly

Q1400835FD(Q402)

Page 162 of 281

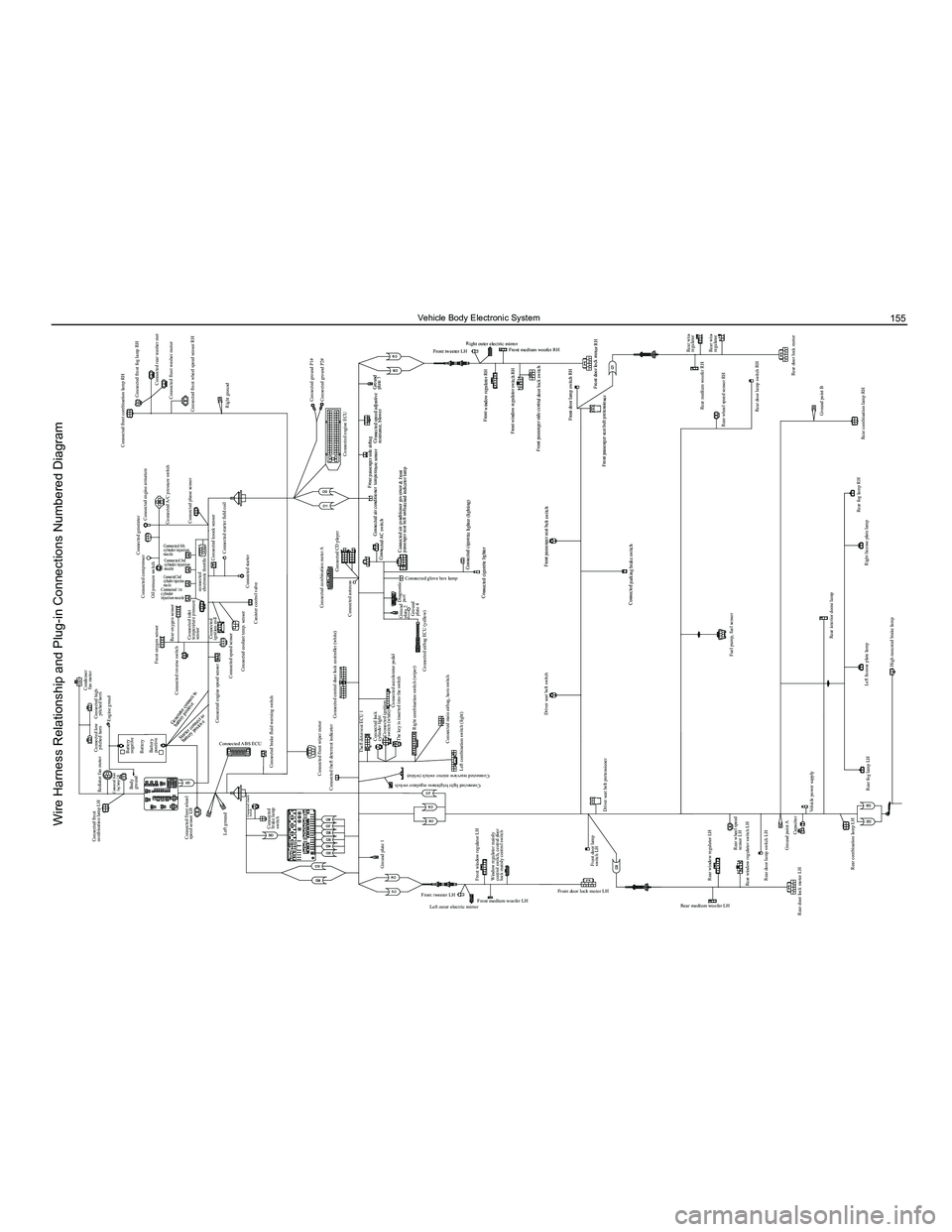

Downloaded from www.Manualslib.com manuals search engine 155Vehicle Body Electronic System

Condenser fan motor

Connected compressor

Oil pressure switch

Front oxygen sensor

Connected reverse switch

Connected engine speed sensor Connected

ignition coil

Connected speed sensor Connected coolant temp. sensor

Canister control valve

Connected combination meter A

Connected antenna

Diagnostic port

Connected AC switch Connected air conditioner temperature sensor

Front passenger side airbag

Connected speed adjustive resistance, blower

Front window regulator RH

Front window regulator switch RH

Front medium woofer RH

Front tweeter LH Right outer electric mirror

Front passenger side central door lock switch

Front door lamp switch RH

Front passenger seat belt pretensioner Front door lock motor RH

Ground

plate 3

Connected cigarette lighter (lighting)

Connected cigarette lighter

Front passenger seat belt switch

Connected parking brake switch Connected air conditioner governor & front

passenger seat belt unfastened indicator lamp

Connected CD player

Connected engine ECUConnected ground P1#

Connected ground P2#

Connected starter

Connected knock sensor

Connected starter field coil

Connected inlet

temperature pressure

sensor

connected

electronic throttle

Rear oxygen sensor

Connected 4th

cylinder injection

nozzle

Connected 3rd

cylinder injection

nozzle

Connected 2nd

cylinder injection

nozzle

Connected 1st

cylinder

injection nozzle

Connected generator

Connected engine armature Connected front combination lamp RH

Connected front fog lamp RH

Connected rear washer motor

Connected front washer motor

Connected front wheel speed sensor RH

Right ground

Connected A/C pressure switch

Connected phase sensor

Connected low

pitched horn

Connected front

combination lamp LH

Rediator fan motor

Connected front

fog lamp LH

Connected high pitched horn

Battery

negative

Body

ground

Battery

Left ground Connected

brake lamp

switch Connected brake fluid warning switch

Connected theft deterrent indicator Theft deterrent ECU 1Connected lock

cylinder lightConnected ignition

switch (white)

The key is inserted into the switch

Right combination switch (wiper) Connected airbag ECU (yellow)Ground

plate 2

Ground

plate 4

Connected accelerator pedal

Ground plate 1

Left outer electric mirror

Front medium woofer LH Front door lock motor LH

Rear medium woofer LH

Rear window regulator switch LH

Rear door lock motor LH Rear door lamp switch LH

Ground point ACapacitor

Vehicle power supply

Rear fog lamp LH Left license plate lamp

High mounted brake lamp

Ground point Trunk opener switch

Trunk motorRear wiper motor

Rear windshield defroster “-”

Trunk lamp switch Right license plate lamp

Rear fog lamp RH

Rear combination lamp RHRear wheel speed sensor RH

Rear window

regulator RH

Rear window

regulator switch RH

Rear door lock motor RH

Rear door lamp switch RH Rear medium woofer RH

Ground point B

Rear combination lamp LH

Rear windshield defroster “+”

Rear wheel speed

sensor LH

Rear window regulator LH

Fuel pump, fuel sensor

Rear interior dome lamp

Front door lamp

switch LH

Driver seat belt pretensioner Driver seat belt switch

Front tweeter LH

Connected light brightness regulator switch

Connected rearview mirror switch (white)

Connected glove box lamp

Front window regulator LH Left combination switch (light)

Connected main airbag, horn switch

Window regulator mainly

control switch, central door

lock mainly control switch Connected central door lock controller (white)

Connected front wiper motor

Connected clutch

switch

Connected ABS ECUBattery

positive

Connected front wheel

speed sensor LH Engine groud

Starter connect to

battery positive

Generator connect to

battery positive

Wire Harness Relationship and Plug-in Connections Numbered Diagram

Page 176 of 281

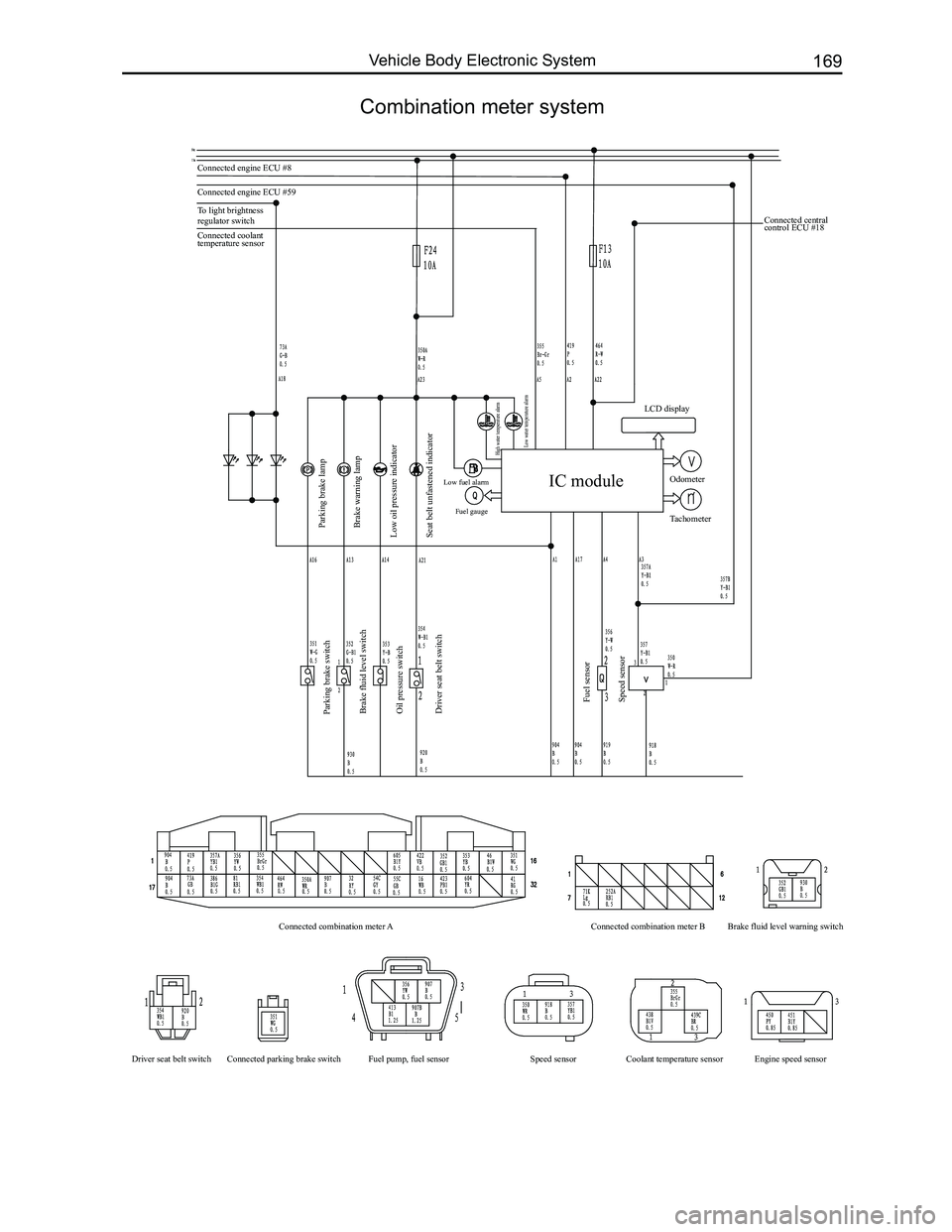

Downloaded from www.Manualslib.com manuals search engine 169Vehicle Body Electronic System

Combination meter system

Connected engine ECU #8

Connected engine ECU #59

To light brightness

regulator switch

Parking brake lamp

Parking brake switch

Brake fluid level switch

Oil pressure switch

Driver seat belt switch

Fuel sensor

Speed sensor

Connected combination meter A

Driver seat belt switch Connected parking brake switch Fuel pump, fuel sensor Coolant temperature sensor Engine speed sensor

Speed sensor Connected combination meter B

Brake fluid level warning switch

Brake warning lamp

Low oil pressure indicator

Seat belt unfastened indicator

Low fuel alarm Fuel gauge

High water temperature alarm

Low water temperature alarm

Connected coolant

temperature sensor Connected central

control ECU #18

IC module

LCD display

Odometer

Tachometer

Page 180 of 281

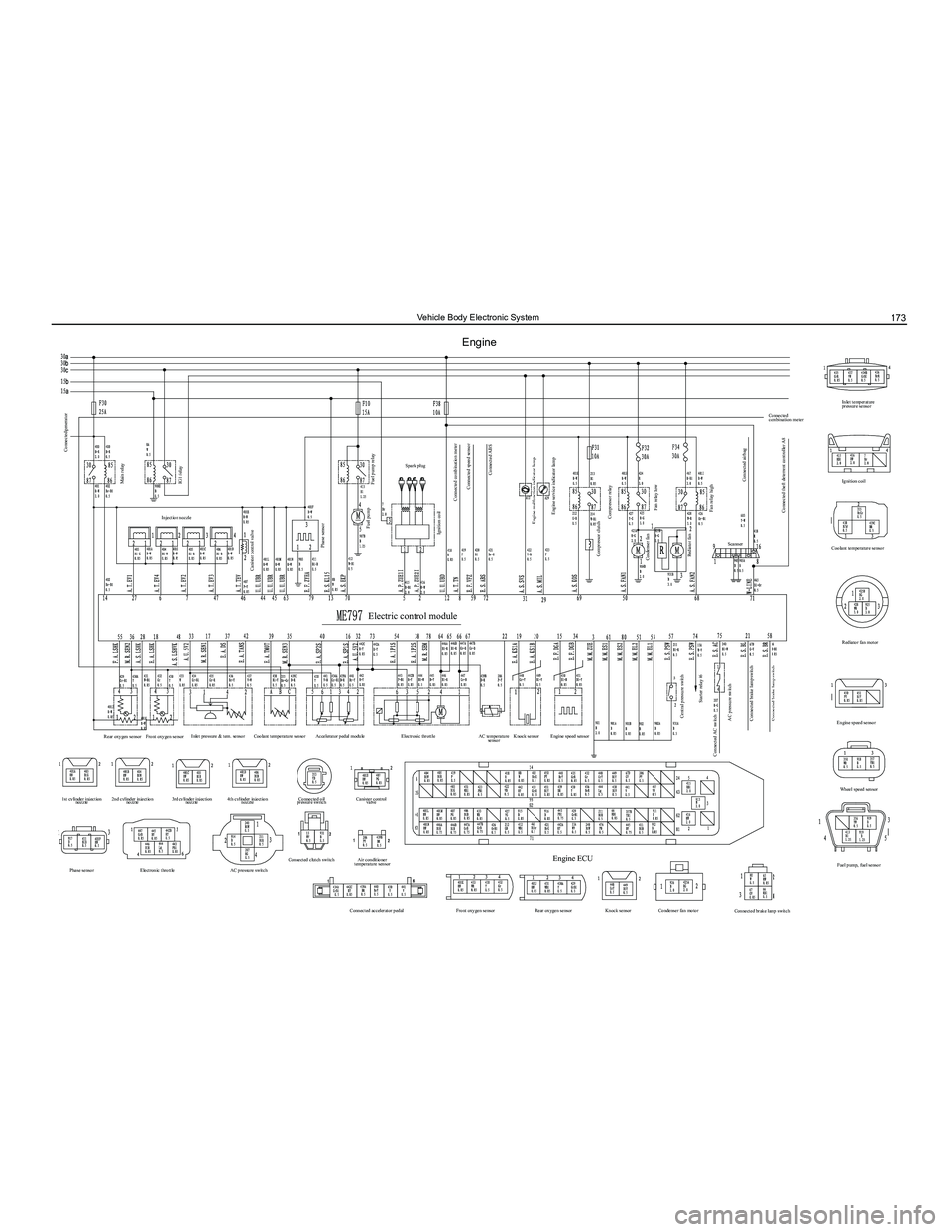

Downloaded from www.Manualslib.com manuals search engine 173Vehicle Body Electronic System

Engine

Connected generator

Canister control valve

Rear oxygen sensor

1st cylinder injection nozzle

Phase sensor Electronic throttle AC pressure switchConnected clutch switch

Air conditioner

temperature sensor

Connected accelerator pedal Front oxygen sensorRear oxygen sensorKnock sensorCondenser fan motor

Connected brake lamp switch

Engine ECU

2nd cylinder injection

nozzle 3rd cylinder injection

nozzle 4th cylinder injection

nozzle Connected oil

pressure switch Canister control

valve

Front oxygen sensor

Inlet pressure & tem. sensor

Coolant temperature sensor Accelerator pedal module Electronic throttle AC temperature

sensor Knock sensor

Engine speed sensor

Phase sensor

Fuel pump relay

Connected combination meter Connected speed sensor

Engine malfunction indicator lamp Engine service indicator lamp

Compressor relay

Compressor clutch

Central pressure switch Starter relay 86

Connected AC switch AC pressure switch

Connected brake lamp switch

Connected brake lamp switch Condenser fan

Rediator fan Fan relay lowScanner

Fan relay high

Connected airbag

Connected theft deterrent controller A8

Connected

combination meter

Ignition coil

Coolant temperature sensor

Rediator fan motor

Engine speed sensor Wheel speed sensor

Fuel pump, fuel sensor Inlet temperature

pressure sensor

Connected ABS

Spark plug

Fuel pump

Electric control module

Ignition coil

Main relay

Injection nozzle

IG1 relay

Page 187 of 281

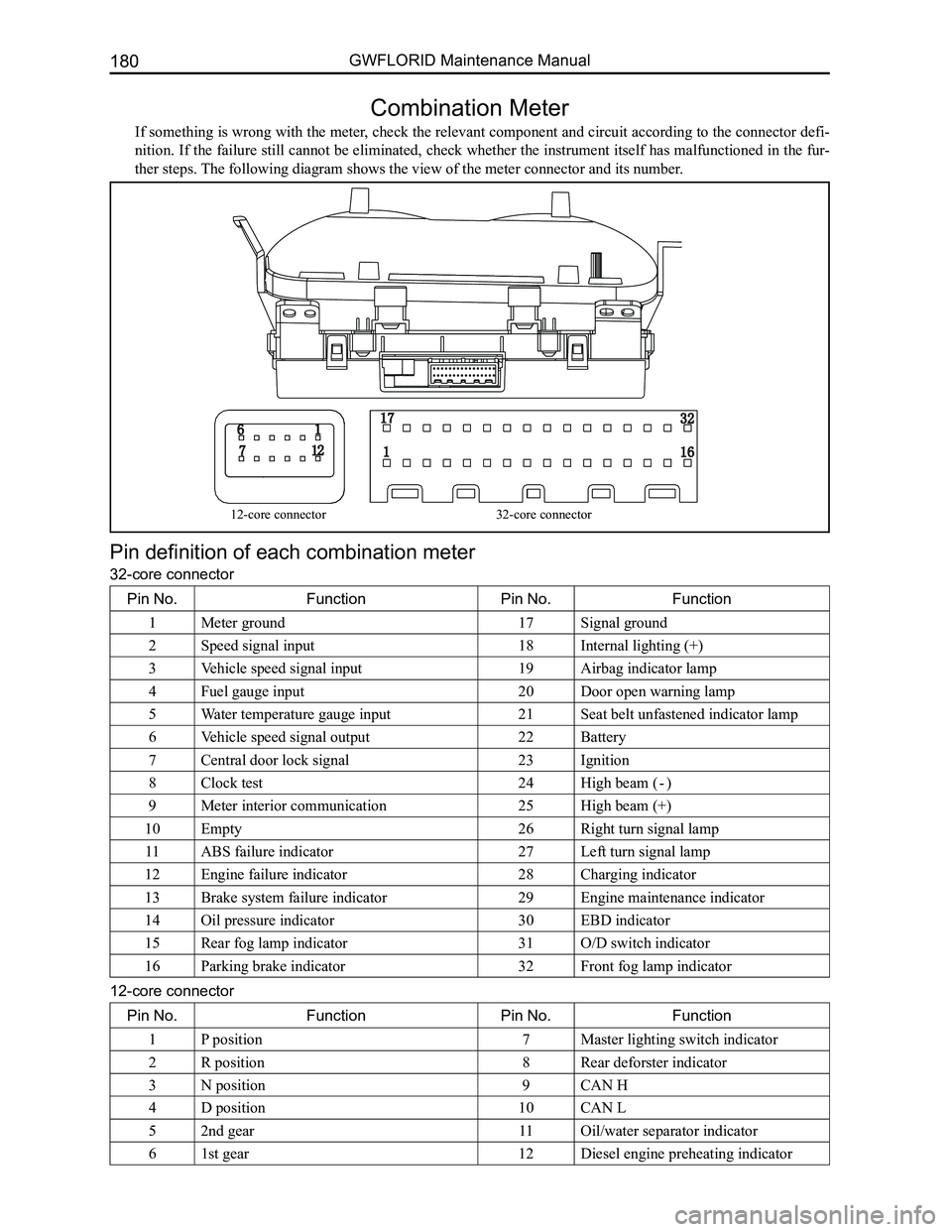

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual180

Combination Meter

If something is wrong with the meter, check the relevant component and circuit according to the connector defi-

nition. If the failure still cannot be eliminated, check whether the instrument itself has malfunctioned in the fur-

ther steps. The following diagram shows the view of the meter connector and its numb\

er.

Pin definition of each combination meter

32-core connector

Pin No.FunctionPin No.Function

1Meter ground17Signal ground

2Speed signal input18Internal lighting (+)

3Vehicle speed signal input19Airbag indicator lamp

4Fuel gauge input20Door open warning lamp

5Water temperature gauge input21Seat belt unfastened indicator lamp

6Vehicle speed signal output22Battery

7Central door lock signal23Ignition

8Clock test24High beam ( - )

9Meter interior communication25High beam (+)

10Empty26Right turn signal lamp

11ABS failure indicator27Left turn signal lamp

12Engine failure indicator28Charging indicator

13Brake system failure indicator29Engine maintenance indicator

14Oil pressure indicator30EBD indicator

15Rear fog lamp indicator31O/D switch indicator

16Parking brake indicator32Front fog lamp indicator

12-core connector

Pin No.FunctionPin No.Function

1P position7Master lighting switch indicator

2R position8Rear deforster indicator

3N position9CAN H

4D position10CAN L

52nd gear11Oil/water separator indicator

61st gear12Diesel engine preheating indicator

12-core connector32-core connector