remove seats GREAT WALL FLORID 2008 Service Manual

[x] Cancel search | Manufacturer: GREAT WALL, Model Year: 2008, Model line: FLORID, Model: GREAT WALL FLORID 2008Pages: 281, PDF Size: 43.97 MB

Page 16 of 281

Downloaded from www.Manualslib.com manuals search engine 9Overview

General Repair Methods and Operations

1. If a jack is needed, please kindly comply to the safety procedures liste\

d below.

2. Park the vehicle on a flat surface, stablize the front and the back wheels using any fixed object or tool,

jack up the vehicle, support it with the chassis, and then start the mai\

ntenance.

3. Disconnect the battery's negative cable before maintenance, in order to reduce the possibility of

damaging and burning out the cable due to a short circuit.

4. Cover the vehicle body, seats, and floor to prevent them from being damaged and polluted.

5. Handle brake fluid and antifreeze fluid carefully, because it may damage the vehicle's surface paint

and its surroundings.

6. Using the proper tools or basic tools that have been recommended and are purchasable is very

important in guaranteeing an effective and reliable maintenance result.

7. Dispose the used dowel pins, gaskets, O-rings, oil seals, lock washers, and self-locking nuts. Prepare

new parts for installation. Normal functions are not guaranteed if these\

parts are reused.

8. Store the removed parts in order and in groups to make reassembly more c\

onvenient.

9. Store bolts and nuts separately, because their hardness levels and designs are different according to

the installation locations.

10. Clean parts before they are inspected or reassembled. In addition, parts that come in contact with

engine oil also need to be cleaned, as well as checked for blockage by u\

sing compressed air.

11. Before installation, use engine oil or grease to lubricate the rotating and sliding sides of the necessary

parts.

12. When necessary, use sealant on gaskets to avoid leakage.

13. Please carefully comply to all tightening torque specifications of b\

olts and nuts.

14. After maintenance, check to make sure whether the repairs were performed correctly and whether the

malfunctions have been fixed.

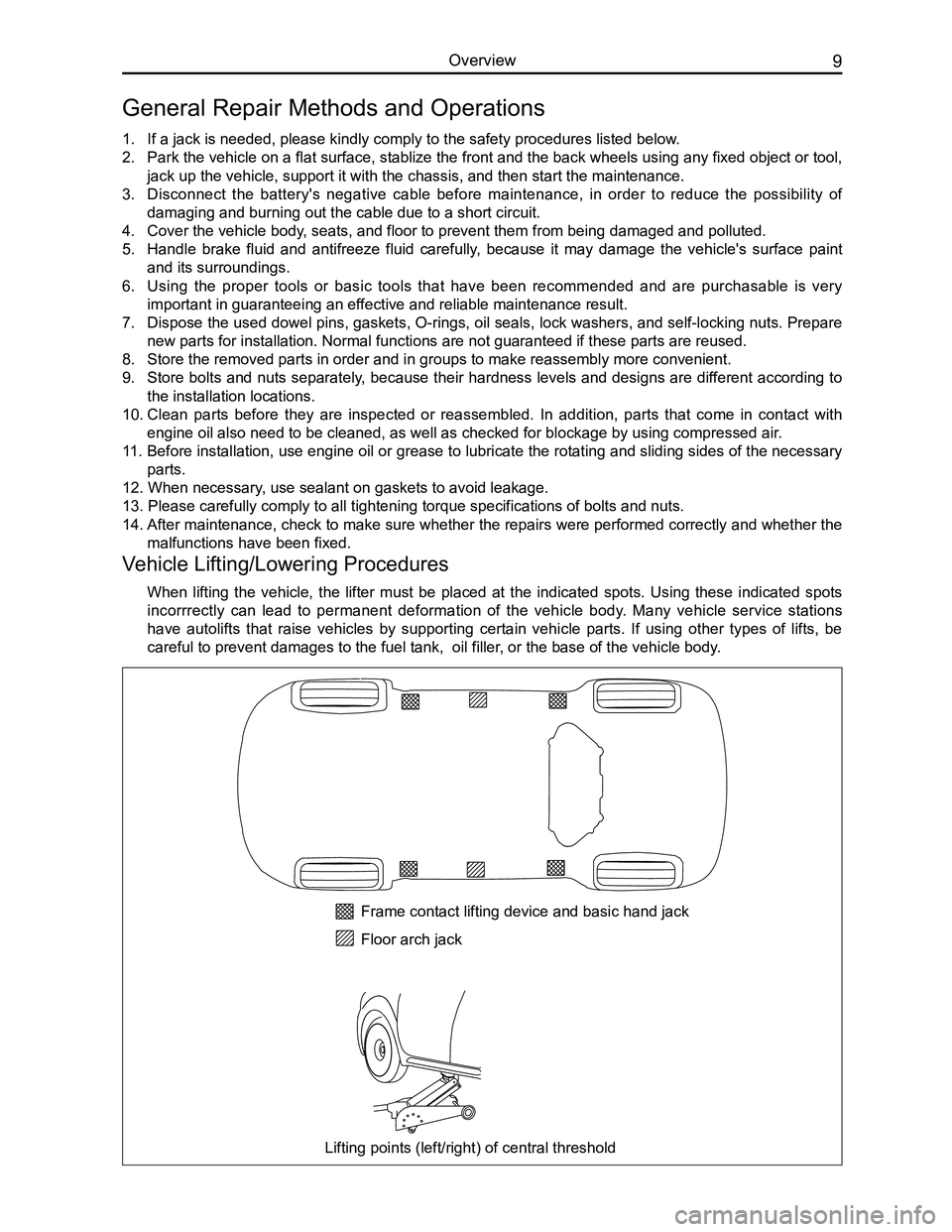

Vehicle Lifting/Lowering Procedures

When lifting the vehicle, the lifter must be placed at the indicated spots. Using these indicated spots

incorrrectly can lead to permanent deformation of the vehicle body. Many vehicle service stations

have autolifts that raise vehicles by supporting certain vehicle parts. If using other types of lifts, be

careful to prevent damages to the fuel tank, oil filler, or the base of the vehicle body.

Frame contact lifting device and basic hand jack

Floor arch jack

Lifting points (left/right) of central threshold

Page 273 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual266

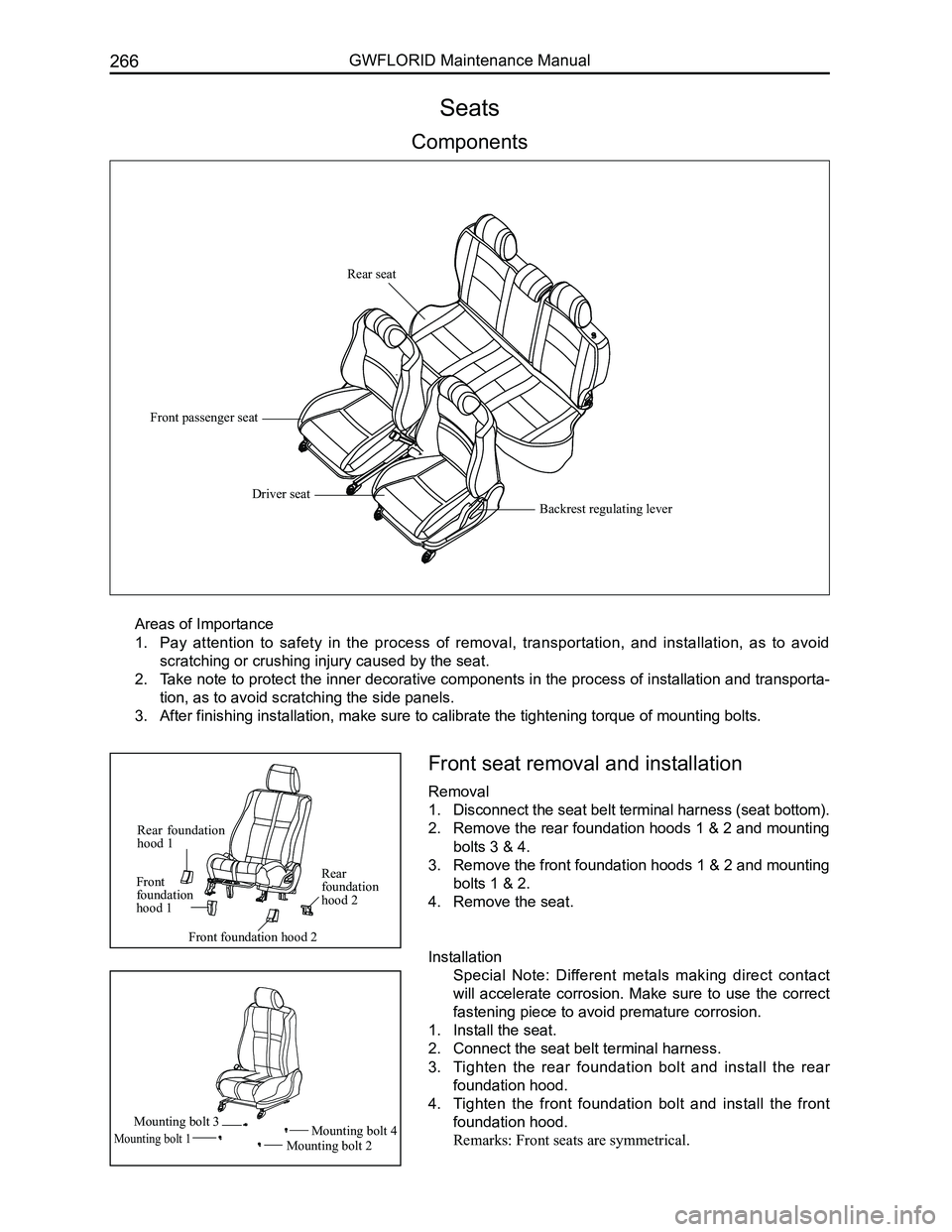

Front seat removal and installation

Removal

1. Disconnect the seat belt terminal harness (seat bottom).

2. Remove the rear foundation hoods 1 & 2 and mounting

bolts 3 & 4.

3. Remove the front foundation hoods 1 & 2 and mounting

bolts 1 & 2.

4. Remove the seat.

Installation

Special Note: Different metals making direct contact

will accelerate corrosion. Make sure to use the correct

fastening piece to avoid premature corrosion.

1. Install the seat.

2. Connect the seat belt terminal harness.

3. Tighten the rear foundation bolt and install the rear

foundation hood.

4. Tighten the front foundation bolt and install the front

foundation hood.

Remarks: Front seats are symmetrical.

Seats

Components

Areas of Importance

1. Pay attention to safety in the process of removal, transportation, and installation, as to avoid

scratching or crushing injury caused by the seat.

2. Take note to protect the inner decorative components in the process of installation and transporta-

tion, as to avoid scratching the side panels.

3. After finishing installation, make sure to calibrate the tightening torq\

ue of mounting bolts.

Rear seat

Front passenger seat

Driver seat

Backrest regulating lever

Rear foundation hood 1

Rear foundation hood 2

Front foundation hood 1

Front foundation hood 2

Mounting bolt 1Mounting bolt 2

Mounting bolt 4Mounting bolt 3