washer fluid GREAT WALL FLORID 2008 Service Manual

[x] Cancel search | Manufacturer: GREAT WALL, Model Year: 2008, Model line: FLORID, Model: GREAT WALL FLORID 2008Pages: 281, PDF Size: 43.97 MB

Page 16 of 281

Downloaded from www.Manualslib.com manuals search engine 9Overview

General Repair Methods and Operations

1. If a jack is needed, please kindly comply to the safety procedures liste\

d below.

2. Park the vehicle on a flat surface, stablize the front and the back wheels using any fixed object or tool,

jack up the vehicle, support it with the chassis, and then start the mai\

ntenance.

3. Disconnect the battery's negative cable before maintenance, in order to reduce the possibility of

damaging and burning out the cable due to a short circuit.

4. Cover the vehicle body, seats, and floor to prevent them from being damaged and polluted.

5. Handle brake fluid and antifreeze fluid carefully, because it may damage the vehicle's surface paint

and its surroundings.

6. Using the proper tools or basic tools that have been recommended and are purchasable is very

important in guaranteeing an effective and reliable maintenance result.

7. Dispose the used dowel pins, gaskets, O-rings, oil seals, lock washers, and self-locking nuts. Prepare

new parts for installation. Normal functions are not guaranteed if these\

parts are reused.

8. Store the removed parts in order and in groups to make reassembly more c\

onvenient.

9. Store bolts and nuts separately, because their hardness levels and designs are different according to

the installation locations.

10. Clean parts before they are inspected or reassembled. In addition, parts that come in contact with

engine oil also need to be cleaned, as well as checked for blockage by u\

sing compressed air.

11. Before installation, use engine oil or grease to lubricate the rotating and sliding sides of the necessary

parts.

12. When necessary, use sealant on gaskets to avoid leakage.

13. Please carefully comply to all tightening torque specifications of b\

olts and nuts.

14. After maintenance, check to make sure whether the repairs were performed correctly and whether the

malfunctions have been fixed.

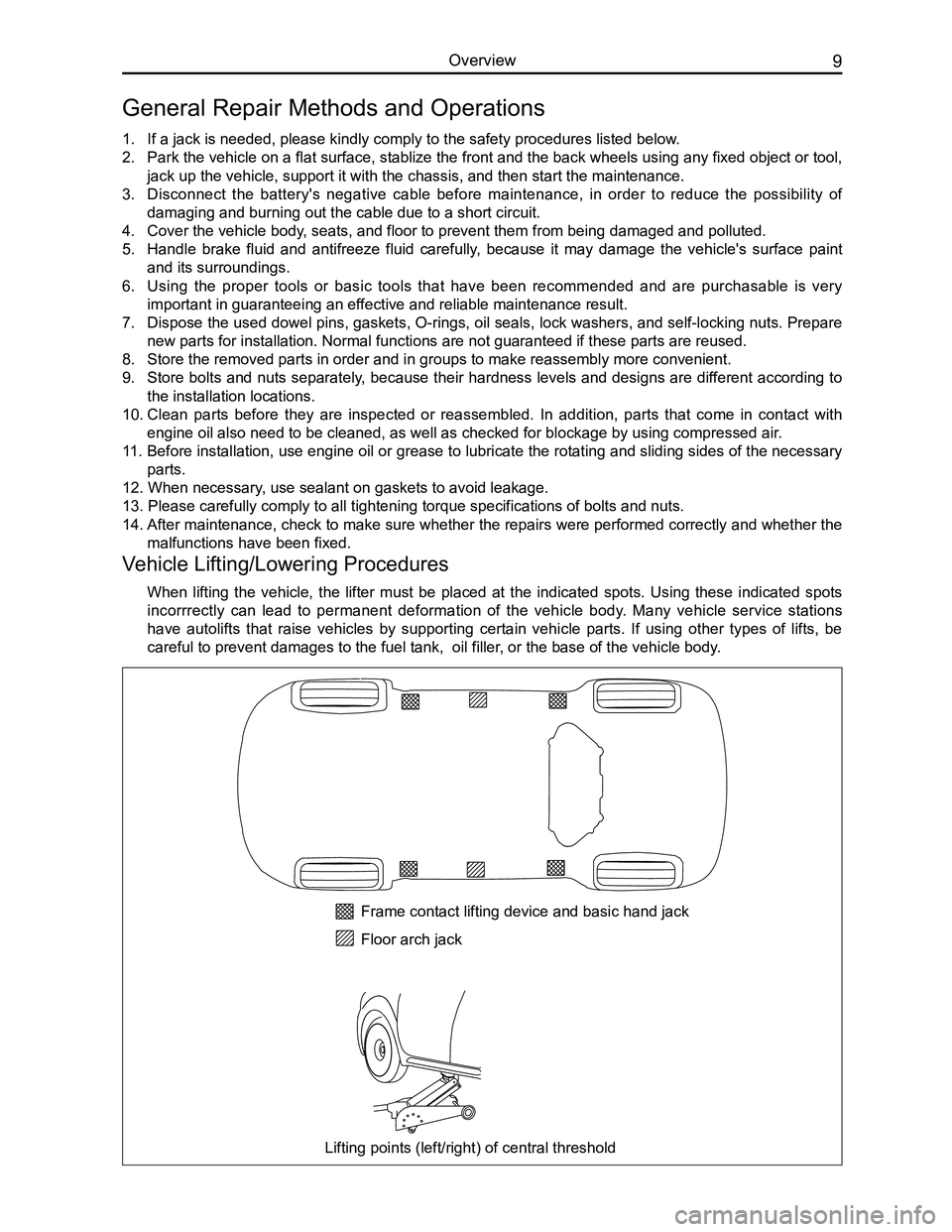

Vehicle Lifting/Lowering Procedures

When lifting the vehicle, the lifter must be placed at the indicated spots. Using these indicated spots

incorrrectly can lead to permanent deformation of the vehicle body. Many vehicle service stations

have autolifts that raise vehicles by supporting certain vehicle parts. If using other types of lifts, be

careful to prevent damages to the fuel tank, oil filler, or the base of the vehicle body.

Frame contact lifting device and basic hand jack

Floor arch jack

Lifting points (left/right) of central threshold

Page 25 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual18

Torque Specifications for Key Operational Bolts

Any part that has a tightening torque requirement for fastening piece connections should be fastened according

to specifications, the tightening torque of fastening pieces that have no tightening torque specification should

satisfy the QC/T 518—1999 regulations.

Tightening torque for key operational bolts are shown in the table below.

No.Important fastening piece locationsFastening piece name

and model numberQuantity

Tightening

torque

(N·m)

1Chassis

1.01Left mount & left side memberHexagon bolt for flange face1112±10

Left mount & left mounting bracketHexagon bolt for flange face264±5

1.02Left mounting bracket & transmissionHexagon bolt for flange face364±5

Right mount & engineHexagon nut for flange face141±4

1.03Right mount & engineHexagon bolt for flange face264±5

Right mount & vehicle bodyHexagon bolt for flange face 264±5

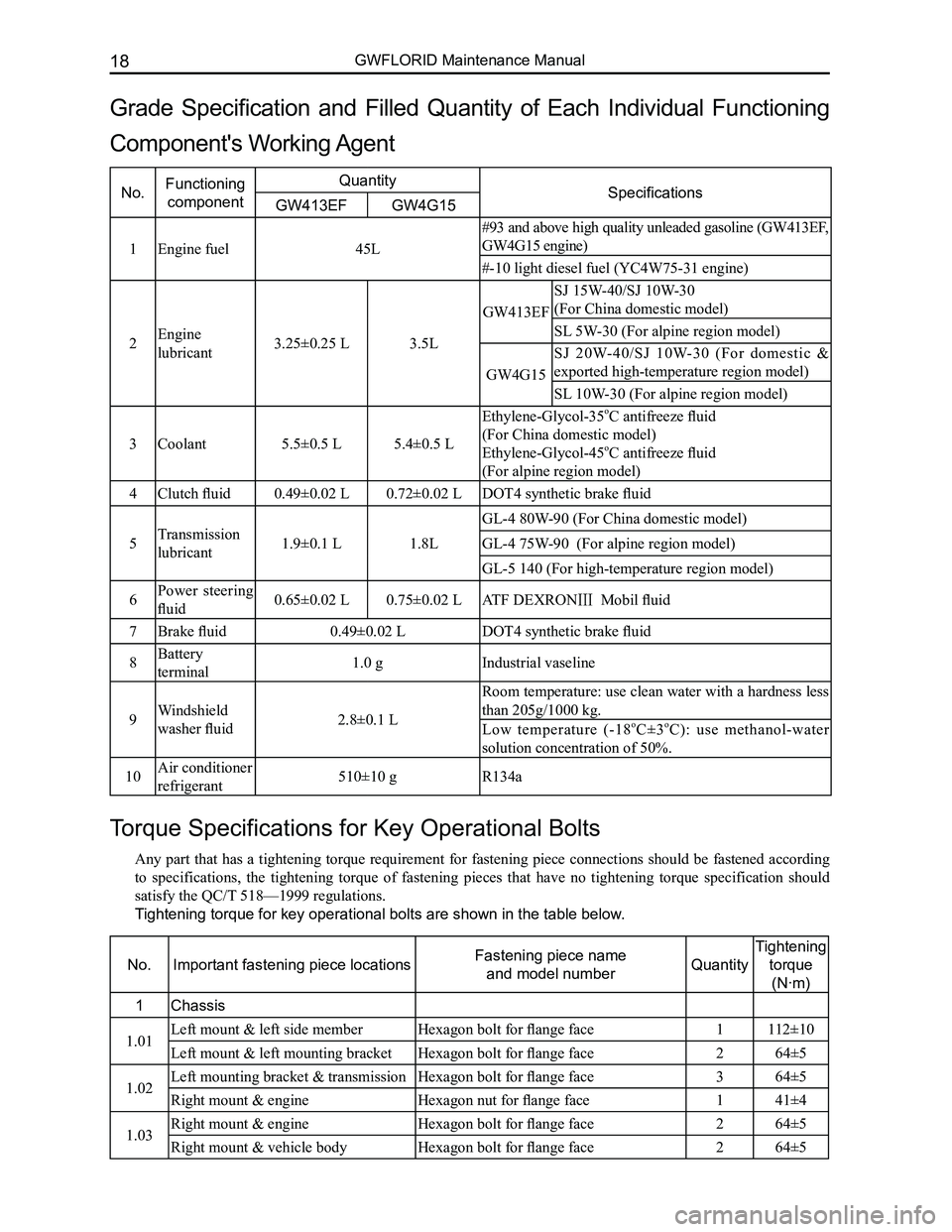

Grade Specification and Filled Quantity of Each Individual Functioning

Component's Working Agent

No.Functioning

component

QuantitySpecificationsGW413EFGW4G15

1Engine fuel45L

#93 and above high quality unleaded gasoline (GW413EF,

GW4G15 engine)

#-10 light diesel fuel (YC4W75-31 engine)

2Engine

lubricant3.25±0.25 L3.5L

GW413EF

SJ 15W-40/SJ 10W-30

(For China domestic model)

SL 5W-30 (For alpine region model)

GW4G15

SJ 20W-40/SJ 10W-30 (For domestic &

exported high-temperature region model)

SL 10W-30 (For alpine region model)

3Coolant5.5±0.5 L5.4±0.5 L

Ethylene-Glycol-35oC antifreeze fluid

(For China domestic model)

Ethylene-Glycol-45oC antifreeze fluid

(For alpine region model)

4Clutch fluid0.49±0.02 L0.72±0.02 LDOT4 synthetic brake fluid

5Transmission

lubricant1.9±0.1 L1.8L

GL-4 80W-90 (For China domestic model)

GL-4 75W-90 (For alpine region model)

GL-5 140 (For high-temperature region model)

6Power steering

fluid0.65±0.02 L0.75±0.02 LATF DEXRONⅢ Mobil fluid

7Brake fluid0.49±0.02 LDOT4 synthetic brake fluid

8Battery

terminal1.0 gIndustrial vaseline

9Windshield

washer fluid2.8±0.1 L

Room temperature: use clean water with a hardness less

than 205g/1000 kg.

Low temperature (-18oC±3oC): use methanol-water

solution concentration of 50%.

10Air conditioner

refrigerant510±10 gR134a

Page 115 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual108

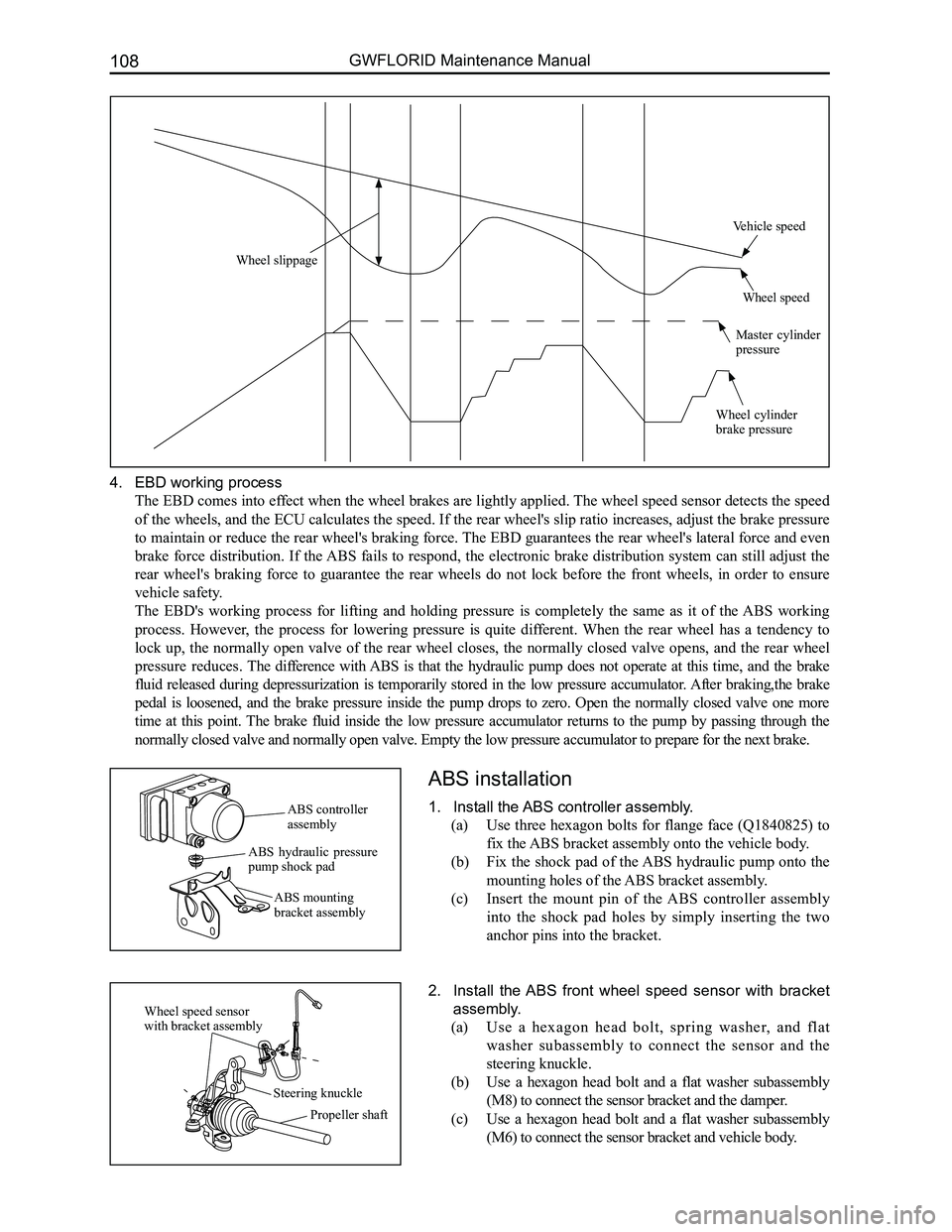

4. EBD working process

The EBD comes into effect when the wheel brakes are lightly applied. The wheel speed sensor detects the speed

of the wheels, and the ECU calculates the speed. If the rear wheel's slip ratio increases, adjust the brake pressure

to maintain or reduce the rear wheel's braking force. The EBD guarantees the rear wheel's lateral force and even

brake force distribution. If the ABS fails to respond, the electronic brake distribution system can still adjust the

rear wheel's braking force to guarantee the rear wheels do not lock before the front wheels, in order to ensure

vehicle safety.

The EBD's working process for lifting and holding pressure is completely the same as it of the ABS working

process. However, the process for lowering pressure is quite different. When the rear wheel has a tendency to

lock up, the normally open valve of the rear wheel closes, the normally closed valve opens, and the rear wheel

pressure reduces. The difference with ABS is that the hydraulic pump does not operate at this time, and the brake

fluid released during depressurization is temporarily stored in the low pressure accumulator. After braking,the brake

pedal is loosened, and the brake pressure inside the pump drops to zero. Open the normally closed valve one more

time at this point. The brake fluid inside the low pressure accumulator returns to the pump by passing through the

normally closed valve and normally open valve. Empty the low pressure ac\

cumulator to prepare for the next brake.

ABS installation

1. Install the ABS controller assembly.

(a) Use three hexagon bolts for flange face (Q1840825) to

fix the ABS bracket assembly onto the vehicle body.

(b) Fix the shock pad of the ABS hydraulic pump onto the

mounting holes of the ABS bracket assembly.

(c) Insert the mount pin of the ABS controller assembly

into the shock pad holes by simply inserting the two

anchor pins into the bracket.

2. Install the ABS front wheel speed sensor with bracket

assembly.

(a) Use a hexagon head bolt, spring washer, and flat

washer subassembly to connect the sensor and the

steering knuckle.

(b) Use a hexagon head bolt and a flat washer subassembly

(M8) to connect the sensor bracket and the damper.

(c) Use a hexagon head bolt and a flat washer subassembly

(M6) to connect the sensor bracket and vehicle body.

ABS controller assembly

ABS hydraulic pressure pump shock pad

ABS mounting bracket assembly

Wheel speed sensor with bracket assembly

Steering knuckle

Propeller shaft

Wheel slippage

Vehicle speed

Wheel speed

Master cylinder pressure

Wheel cylinder brake pressure

Page 131 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual124

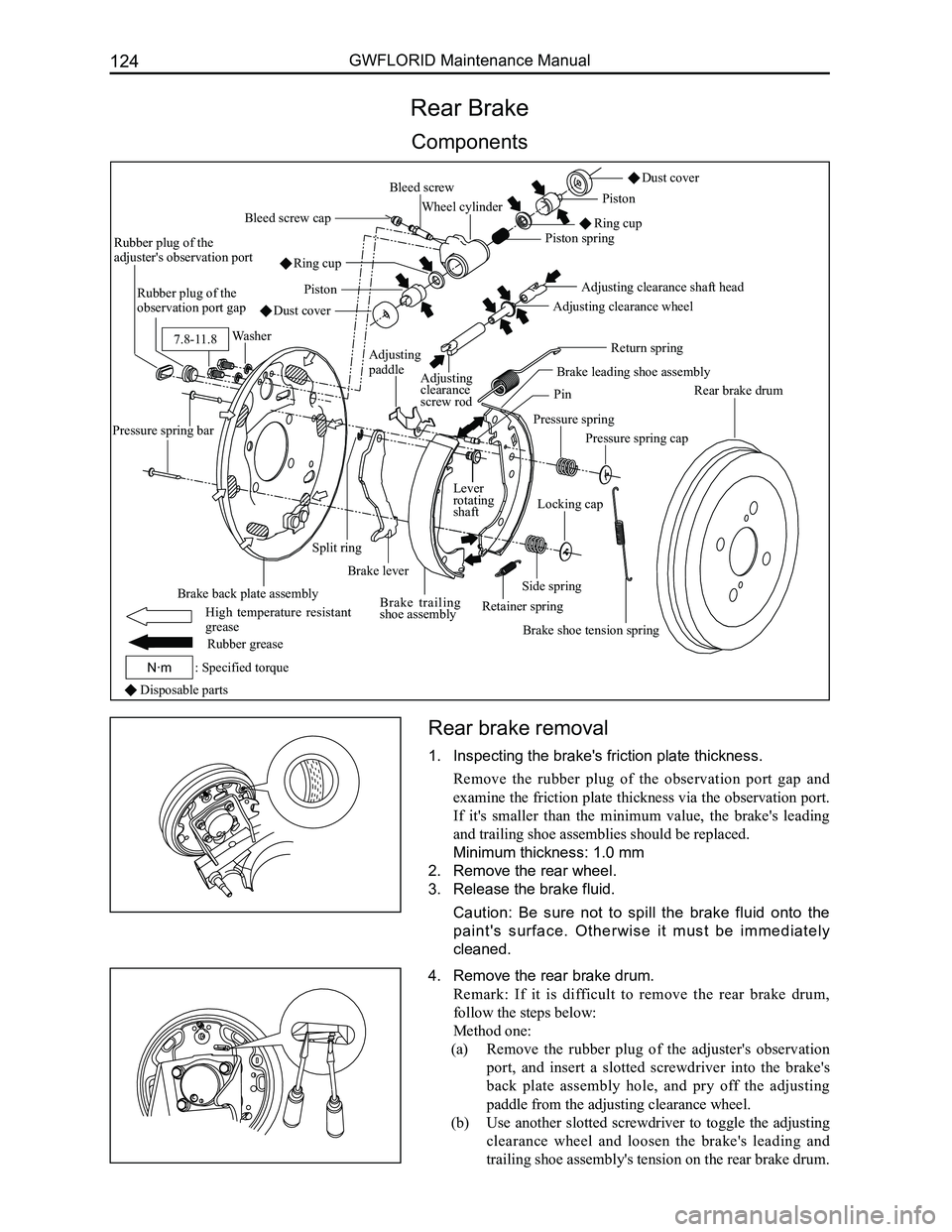

Rear Brake

Components

4. Remove the rear brake drum.

Remark: If it is difficult to remove the rear brake drum,

follow the steps below:

Method one:

(a) Remove the rubber plug of the adjuster's observation

port, and insert a slotted screwdriver into the brake's

back plate assembly hole, and pry off the adjusting

paddle from the adjusting clearance wheel.

(b) Use another slotted screwdriver to toggle the adjusting

clearance wheel and loosen the brake's leading and

trailing shoe assembly's tension on the rear brake drum.

Disposable parts

Dust cover

Brake leading shoe assembly

Pressure spring

Pressure spring cap

Brake shoe tension spring

Rear brake drum

Lever rotating shaft

Retainer spring

Locking cap

Split ring

Brake lever

Brake trailing shoe assembly

Brake back plate assembly

Pressure spring bar

Rubber plug of the adjuster's observation port

Rubber plug of the observation port gap

Washer

Bleed screw cap

Bleed screwPiston

Ring cup

Piston spring

Wheel cylinder

Adjusting clearance shaft head

Adjusting clearance wheel

Adjusting clearance screw rod

Return springAdjusting paddle

Pin

Side spring

Dust cover

Piston

Ring cup

Rubber grease

: Specified torqueN·m

7.8-11.8

High temperature resistant grease

Rear brake removal

1. Inspecting the brake's friction plate thickness.

Remove the rubber plug of the observation port gap and

examine the friction plate thickness via the observation port.

If it's smaller than the minimum value, the brake's leading

and trailing shoe assemblies should be replaced.

Minimum thickness: 1.0 mm

2. Remove the rear wheel.

3. Release the brake fluid.

Caution: Be sure not to spill the brake fluid onto the

paint's surface. Otherwise it must be immediately

cleaned.

Page 159 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual152

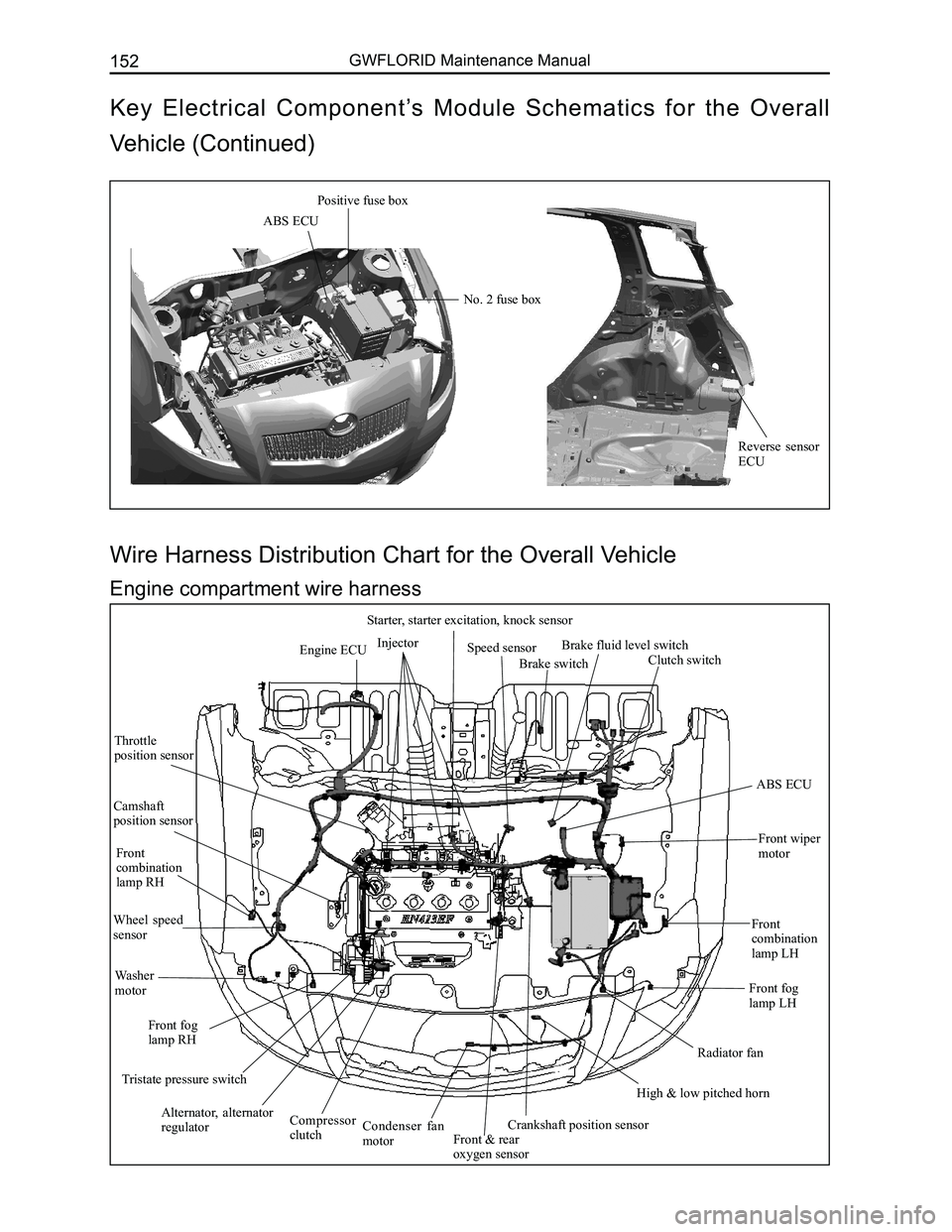

Engine ECUInjector

Starter, starter excitation, knock sensor

Speed sensor

Brake switch

Brake fluid level switch

Clutch switch

ABS ECU

Front wiper

motor

Front combination lamp LH

Front fog lamp LH

Radiator fan

High & low pitched horn

Crankshaft position sensorFront & rear oxygen sensor

Condenser fan motor

Compressor clutch

Alternator, alternator regulator

Tristate pressure switch

Front fog lamp RH

Washer motor

Wheel speed sensor

Front combination lamp RH

Camshaft position sensor

Throttle position sensor

Wire Harness Distribution Chart for the Overall Vehicle

Engine compartment wire harness

ABS ECU

Positive fuse box

No. 2 fuse box

Reverse sensor ECU

Key Electrical Component’s Module Schematics for the Overall

Vehicle (Continued)

Page 162 of 281

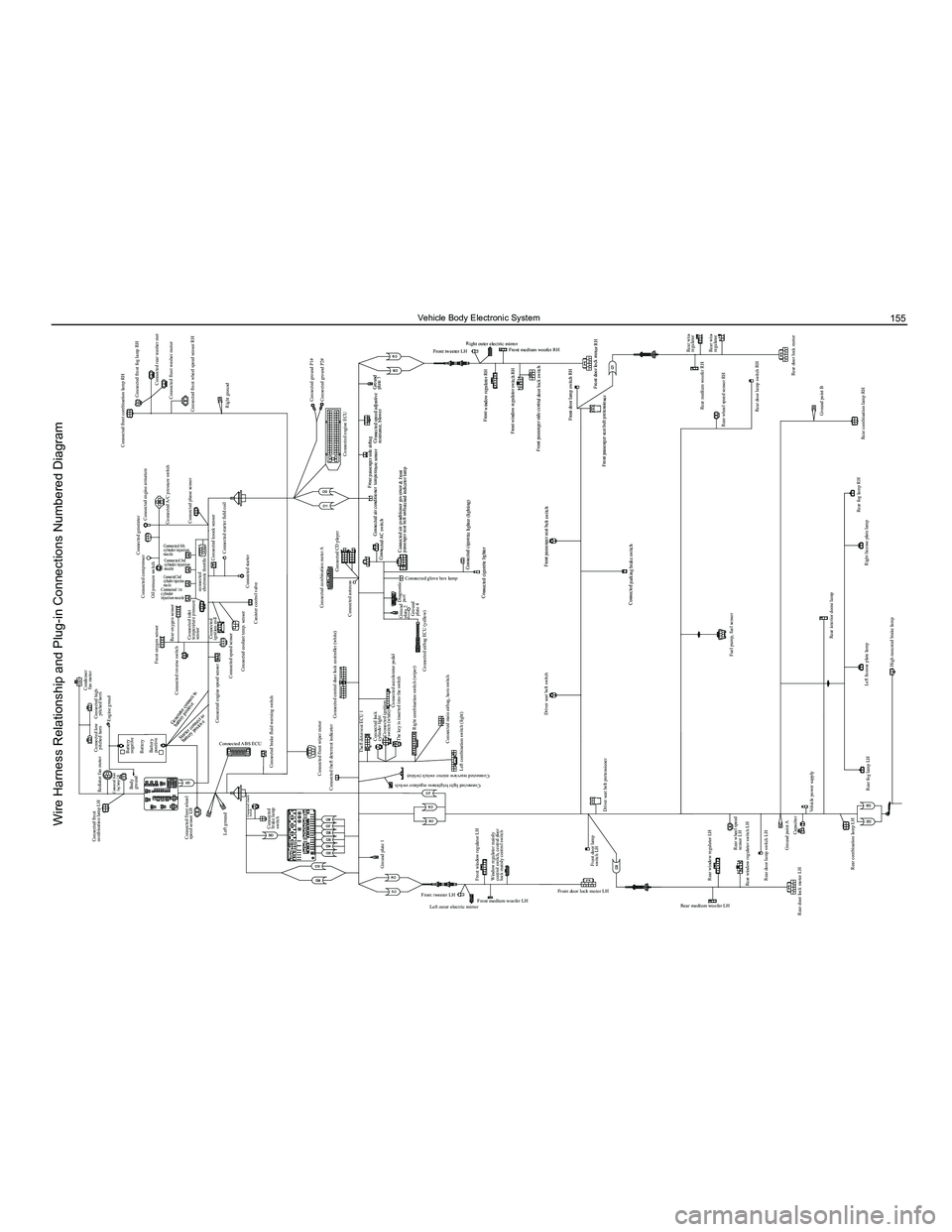

Downloaded from www.Manualslib.com manuals search engine 155Vehicle Body Electronic System

Condenser fan motor

Connected compressor

Oil pressure switch

Front oxygen sensor

Connected reverse switch

Connected engine speed sensor Connected

ignition coil

Connected speed sensor Connected coolant temp. sensor

Canister control valve

Connected combination meter A

Connected antenna

Diagnostic port

Connected AC switch Connected air conditioner temperature sensor

Front passenger side airbag

Connected speed adjustive resistance, blower

Front window regulator RH

Front window regulator switch RH

Front medium woofer RH

Front tweeter LH Right outer electric mirror

Front passenger side central door lock switch

Front door lamp switch RH

Front passenger seat belt pretensioner Front door lock motor RH

Ground

plate 3

Connected cigarette lighter (lighting)

Connected cigarette lighter

Front passenger seat belt switch

Connected parking brake switch Connected air conditioner governor & front

passenger seat belt unfastened indicator lamp

Connected CD player

Connected engine ECUConnected ground P1#

Connected ground P2#

Connected starter

Connected knock sensor

Connected starter field coil

Connected inlet

temperature pressure

sensor

connected

electronic throttle

Rear oxygen sensor

Connected 4th

cylinder injection

nozzle

Connected 3rd

cylinder injection

nozzle

Connected 2nd

cylinder injection

nozzle

Connected 1st

cylinder

injection nozzle

Connected generator

Connected engine armature Connected front combination lamp RH

Connected front fog lamp RH

Connected rear washer motor

Connected front washer motor

Connected front wheel speed sensor RH

Right ground

Connected A/C pressure switch

Connected phase sensor

Connected low

pitched horn

Connected front

combination lamp LH

Rediator fan motor

Connected front

fog lamp LH

Connected high pitched horn

Battery

negative

Body

ground

Battery

Left ground Connected

brake lamp

switch Connected brake fluid warning switch

Connected theft deterrent indicator Theft deterrent ECU 1Connected lock

cylinder lightConnected ignition

switch (white)

The key is inserted into the switch

Right combination switch (wiper) Connected airbag ECU (yellow)Ground

plate 2

Ground

plate 4

Connected accelerator pedal

Ground plate 1

Left outer electric mirror

Front medium woofer LH Front door lock motor LH

Rear medium woofer LH

Rear window regulator switch LH

Rear door lock motor LH Rear door lamp switch LH

Ground point ACapacitor

Vehicle power supply

Rear fog lamp LH Left license plate lamp

High mounted brake lamp

Ground point Trunk opener switch

Trunk motorRear wiper motor

Rear windshield defroster “-”

Trunk lamp switch Right license plate lamp

Rear fog lamp RH

Rear combination lamp RHRear wheel speed sensor RH

Rear window

regulator RH

Rear window

regulator switch RH

Rear door lock motor RH

Rear door lamp switch RH Rear medium woofer RH

Ground point B

Rear combination lamp LH

Rear windshield defroster “+”

Rear wheel speed

sensor LH

Rear window regulator LH

Fuel pump, fuel sensor

Rear interior dome lamp

Front door lamp

switch LH

Driver seat belt pretensioner Driver seat belt switch

Front tweeter LH

Connected light brightness regulator switch

Connected rearview mirror switch (white)

Connected glove box lamp

Front window regulator LH Left combination switch (light)

Connected main airbag, horn switch

Window regulator mainly

control switch, central door

lock mainly control switch Connected central door lock controller (white)

Connected front wiper motor

Connected clutch

switch

Connected ABS ECUBattery

positive

Connected front wheel

speed sensor LH Engine groud

Starter connect to

battery positive

Generator connect to

battery positive

Wire Harness Relationship and Plug-in Connections Numbered Diagram