ESP GREAT WALL HOVER 2006 Service User Guide

[x] Cancel search | Manufacturer: GREAT WALL, Model Year: 2006, Model line: HOVER, Model: GREAT WALL HOVER 2006Pages: 425, PDF Size: 26.05 MB

Page 125 of 425

Automatic transmission-49

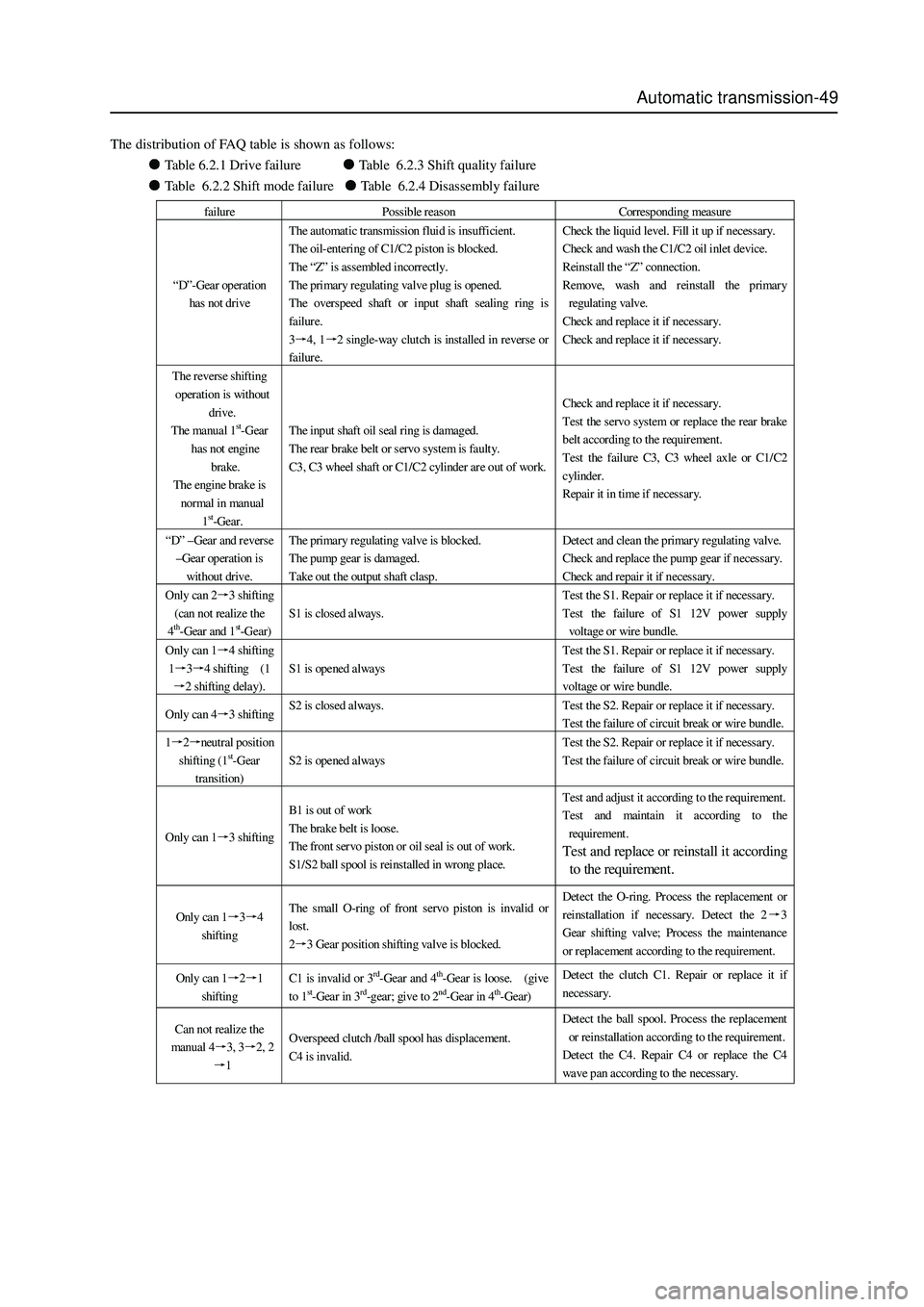

The distribution of FAQ table is shown as follows:

Table 6.2.1 Drive failure Table 6.2.3 Shift quality failure

Table 6.2.2 Shift mode failure Table 6.2.4 Disassembly failure

failure Possible reason Corresponding measure

“D”-Gear operation

has not drive The automatic transmission fluid is insufficient.

The oil-entering of C1/C2 piston is blocked.

The “Z” is assembled incorrectly.

The primary regulating valve plug is opened.

The overspeed shaft or input shaft sealing ring is

failure.

3→4, 1→2 single-way clut ch is installed in revers e or

failure. Check the liquid level. Fill it up if necessary.

Check and wash the C1/C2 oil inlet device.

Reinstall the “Z” connection.

Remove, wash and reinstall the primary

regulating valve.

Check and replace it if necessary.

Check and replace it if necessary.

The reverse shifting

operation is without

drive.

The manual 1

st-Gear

has not engine

brake.

The engine brake is

normal in manual

1

st-Gear. The input shaft oil seal ring is damaged.

The rear brake belt or servo system is faulty.

C3, C3 wheel shaft or C1/C2 cylinder are out of work. Check and replace it if necessary.

Test the servo system or replace the rear brake

belt according to the requirement.

Test the failure C3, C3 wheel axle or C1/C2

cylinder.

Repair it in time if necessary.

“D” –Gear and reverse

–Gear operation is

without drive. The primary regulating valve is blocked.

The pump gear is damaged.

Take out the output shaft clasp. Det ect and clean the primary regulating valve.

Check and replace the pump gear if necessary.

Check and repair it if necessary.

Only can 2→3 shifting

(can not realize the

4

th-Gear and 1st-Gear) S1 is closed always. Test the S1. Repair or replace it if necessary.

Test the failure of S1 12V power supply

voltage or wire bundle.

Only can 1→4 shifting

1→3→4 shifting (1

→2 shifting delay). S1 is opened always Test the S1. Repair or replace it if necessary.

Test the failure of S1 12V power supply

voltage or wire bundle.

Only can 4→3 shifting S2 is closed always.

Test the S2. Repair or replace it if necessary.

Test the failure of circuit break or wire bundle.

1→2→neutral position

shifting (1st-Gear

transition) S2 is opened always Test the S2. Repair or replace it if necessary.

Test the failure of circuit break or wire bundle.

Only can 1→3 shifting B1 is out of work

The brake belt is loose.

The front servo piston or oil s eal is out of work.

S1/S2 ball spool is reinstalled in wrong place. Test and adjust it according to the requirement.

Test and maintain it according to the

requirement. Test and replace or reinstall it according

to the requirement.

Only can 1→3→4

shifting The small O-ring of front s ervo piston is invalid or

lost.

2→3 Gear position shifting valve is blocked. Det ect the O-ring. Process the replacement or

reinstallation if necessary. Detect the 2→3

Gear shifting valve; Process the maintenance

or replacement according to the requirement.

Only can 1→2→1

shifting C1 is invalid or 3rd-Gear and 4th-Gear is loose. (give

to 1st-Gear in 3rd-gear; give to 2nd-Gear in 4th-Gear) Det ect the clutch C1. Repair or replace it if

necessary.

Can not realize the

man ual 4→3, 3→2, 2

→1 Overspeed clutch /ball spool has displacement.

C4 is invalid. Detect the ball spool. Process the replacement

or reinstallation according to the requirement.

Det ect the C4. Repair C4 or r eplace the C4

wave pan according to the necessary.

Page 128 of 425

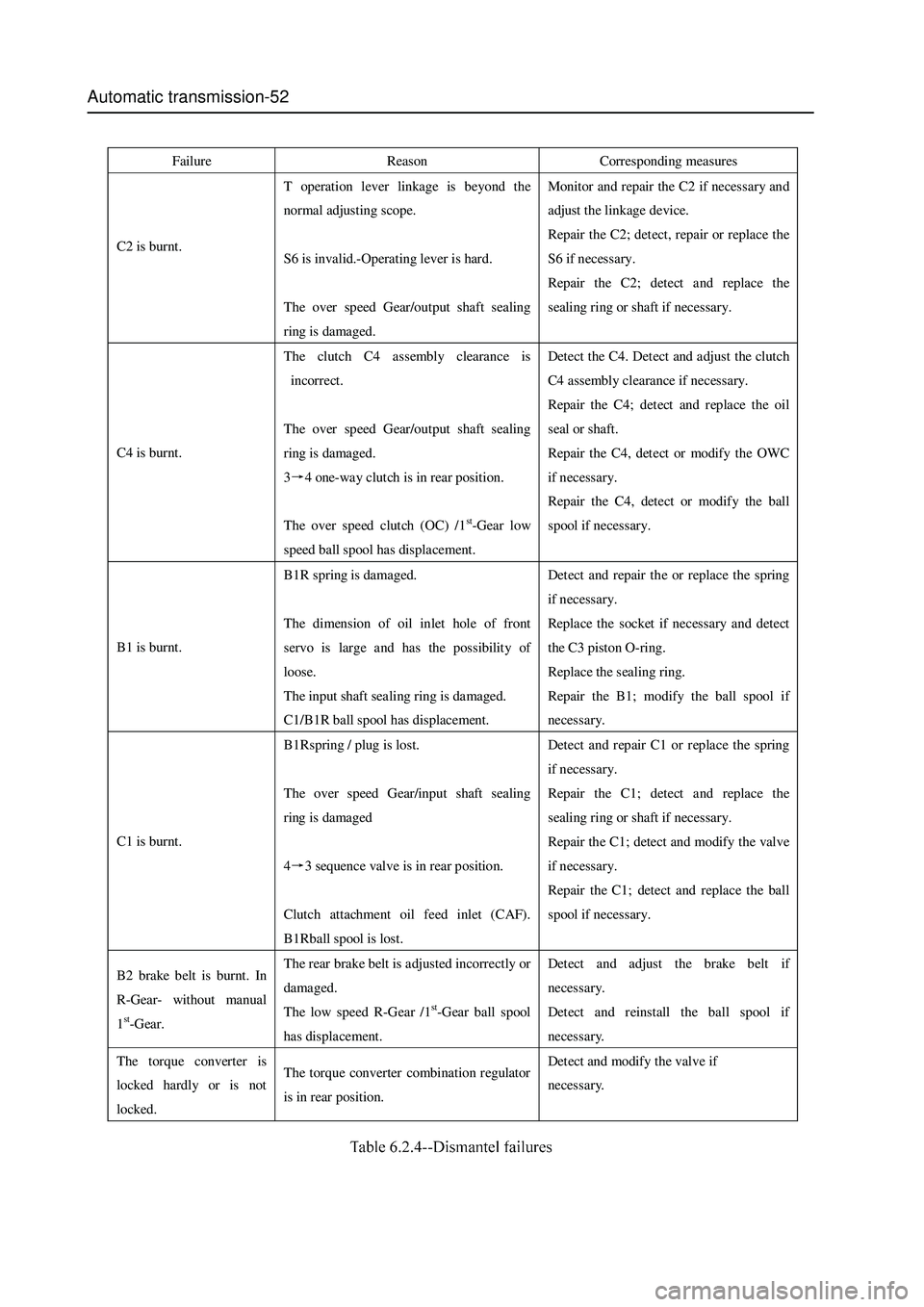

Automatic transmission-52

Failure Reason Corresponding measures

C2 is burnt.

T operation lever linkage is beyond the

normal adjusting scope.

S6 is invalid.-Operating lever is hard.

The over speed Gear/output shaft sealing

ring is damaged. Monitor and repair the C2 if necessary and

adjust the linkage device.

Repair the C2; detect, repair or replace the

S6 if necessary.

Repair the C2; detect and replace the

sealing ring or shaft if necessary.

C4 is burnt. The clutch C4 assembly clearance is

incorrect.

The over speed Gear/output shaft sealing

ring is damaged.

3→4 one-way clutch is in rear position.

The over speed clutch (OC) /1

st-Gear low

speed ball spool has displacement. Detect the C4. Det ect and adjust the clutch

C4 assembly clearance if necessary.

Repair the C4; detect and replace the oil

seal or shaft.

Repair the C4, detect or modify the OWC

if necessary.

Repair the C4, detect or modify the ball

spool if necessary.

B1 is burnt. B1R spring is damaged.

The dimension of oil inlet hole of front

servo is large and has the possibility of

loose.

The input shaft sealing ring is damaged.

C1/B1R ball spool has displacement. Detect and repair the or replace the spring

if necessary.

Replace the socket if necessary and detect

the C3 piston O-ring.

Replace the sealing ring.

Repair the B1; modify the ball spool if

necessary.

C1 is burnt. B1Rspring / plug is lost.

The over speed Gear/input shaft sealing

ring is damaged

4→3 sequence valve is in rear position.

Clutch attachment oil feed inlet (CAF).

B1Rball spool is lost. Detect and repair C1 or replace the spring

if necessary.

Repair the C1; detect and replace the

sealing ring or shaft if necessary.

Repair the C1; detect and modify the valve

if necessary.

Repair the C1; detect and replace the ball

spool if necessary.

B2 brake belt is burnt. In

R-Gear- without manual

1

st-Gear. The rear brake belt is adjusted incorrectly or

damaged.

The low speed R-Gear /1

st-Gear ball spool

has displacement. Detect and adjust the brake belt if

necessary.

Detect and reinstall the ball spool if

necessary.

The torque converter is

locked hardly or is not

locked. The torque converter combination regulator

is in rear position. Detect and modify the valve if

necessary.

Page 131 of 425

Figure 8.1 Removal of typical pump

Disassembly /assembly

Cautions for assembly

It should notice the following items before reassemble the transmission system:

1. Ensure the cooler pipeline is washed and all chip is removed when replace the transmission. It can

be realized by using the compressed air to enter into the rear cooler pipeline to remove the oil and

all foreign material in the front cooler.

2. It should check the cooler after the transmission is installed. Ensure the front and rear cooler

pipeline is connected to the proper container. Rotate the vehicle in P-Gear in idle-speed, measure

the flow rate within 15s.

3. The flow within 15s should be more than 1L.

4. It should avoid any water entering into the transmission. This will cause the transmission fluid to

generate the foam or make the transmission fluid flows out form the respirator.

5. Ensure that two grounding wires in vehicle (one end to battery, one end to vehicle) are connected

before the installation of the anode of battery.

6. If the power control module and transmission control unit is exchanged, then calibrate the pro-

gram refer to related throttle position in Part

Removal

1. Transmission

Caution:

It should remove the gear-position sensor before wash the transmission in solvent or hot abluent.

When need to remove the transmission from the vehicle, it should drainage the transmission fluid,

and use the special removal tools.

The removal of the transmission should be processed in module method, the details of removal of each module is described

in following section in detail. Refer to details of special tools listed in table 9.10 and 9.6 when remove it.

The technician needs a set of quality tools when inspect the transmission, especially for dual hexagon spanner of model

30, 40, 50 and 8mm, 10mm, 12mm.

It should abide by the following procedure when disassemble the transmission:

a. Remove the shell of torque converter and torque converter.

b. Place the transmission on the saddle platform.

c. Remove the oil pan and oil pan sealing.

d. Remove the filter retainer of each valve and remove the filter.

e. Remove the wire on solenoid valve, place it in side.

f. Remove the protection screw in the valve and remove the valve from the main housing (remove the model Z connecting bar).

g. Remove the front servo circlip, cover and piston.

Caution:

The plastic servo block on used for piston return spring.

h. Remove the flange shaft fork, then remove the transmission housing (2WD and Chairman).

Use the 8mm hexagon wrench to move the pump to the housing bolt.

Page 137 of 425

Caution:

Some valves are pulled by the spring and may fall down form the valve.

m. Press down the plug of 4-3 sequence valve and take out the locking nut disc.

n. Take out the plug, valve and spring.

o. Press down the solenoid valve 5 gate. Remove the fixed pin, valve and spring.

Caution:

The valve is pulled by the spring and may fall down form the valve.

p . Press down the line pressure blow-off valve , then remove the fixed pin, disc (if proper) spring and valve.

q. Take out the roller pin and remove the spring and ball spool detection valve adjacent BAR.

Assembly

The transmission is assembled in the method of module. The detailed assembly process of each module is described in the

following chapter in detail.

Refer to Table 8.1 (end of section 8.3) for the description of used torque specification. The Table 9.10 in section 9.6 describes

the necessary special tools for assembly.

The technician also needs to select the quality Torx tools, especially for the two-screw socket wrench with code of 40, 50,

8mm,10mm and 12mm to detect the transmission completely.

1.Transmission

Caution:

Ensure the BIR retainer is proper for the case (otherwise, the valve will damage the separation disk).

Ensure the E clip is installed on the cross shaft.

Ensure all parts of parking machine can operate normally.

The assembly procedure of transmission is shown as follows:

a. Place the upper transmission on the platform upwardly and place it on the transmission bracket.

b. Install all accessories, bolts and bleed devices. Paint the sealant on the sealing place. Tighten all components according

to the specification. Ensure the cleanness of all bleed devices. Ensure the rear oil filling nozzle of housing is correct and

without blocking material. Refer to Figure 8.19.

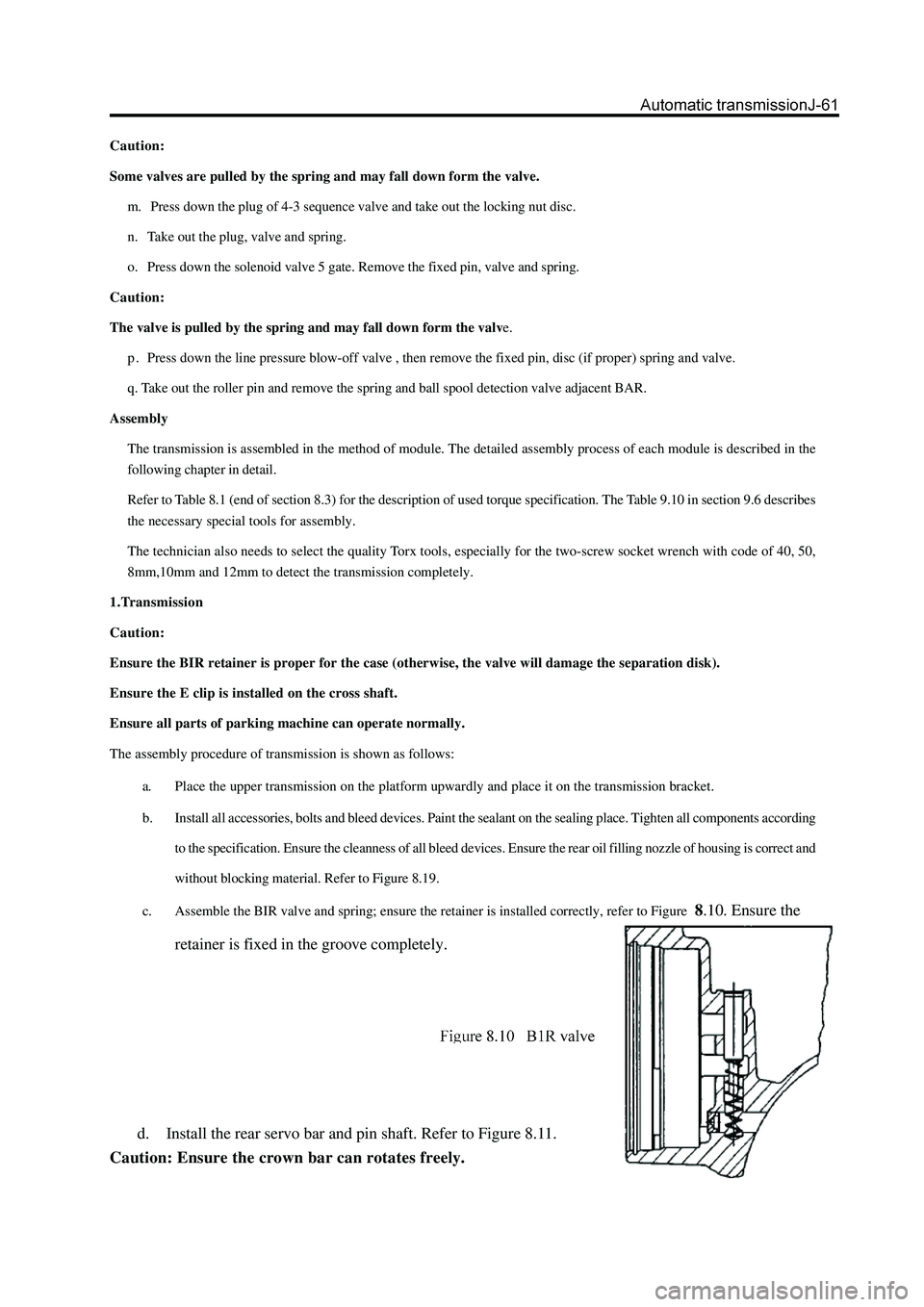

c. Assemble the BIR valve and spring; ensure the retainer is installed correctly, refer to Figure

8.10. Ensure the

retainer is fixed in the groove completely.

d. Install the rear servo bar and pin shaft. Refer to Figure 8.11.

Caution: Ensure the crown bar can rotates freely.

Page 140 of 425

2.output shaft and gear assembly

The assembly procedure of output shaft and gear assembly (Refer to Figure 8.19),is shown as follows:

a. Check the output shaft bush for damage, replace it if necessary.

b. Check the parking detent on the ring gear for damage ; replace it if necessary.

c. Check the sealing ring groove for damage.

d. Use the automatic transmission liquid to lubricate the gasket.

e. Place the scarfing notch upwardly and install the sealing ring on the output shaft.

f. If has been removed., it should use the ring spring for reinforcement when install the ring gear on the output shaft. Ensure the

ring spring is fixed in the groove.

g. Use the Vaseline oil for lubrication; install the thrust bearing assembly NO.10 on the output shaft.

h. It should be carefully when install the output shaft on the box to avoid the damage of sealing ring.

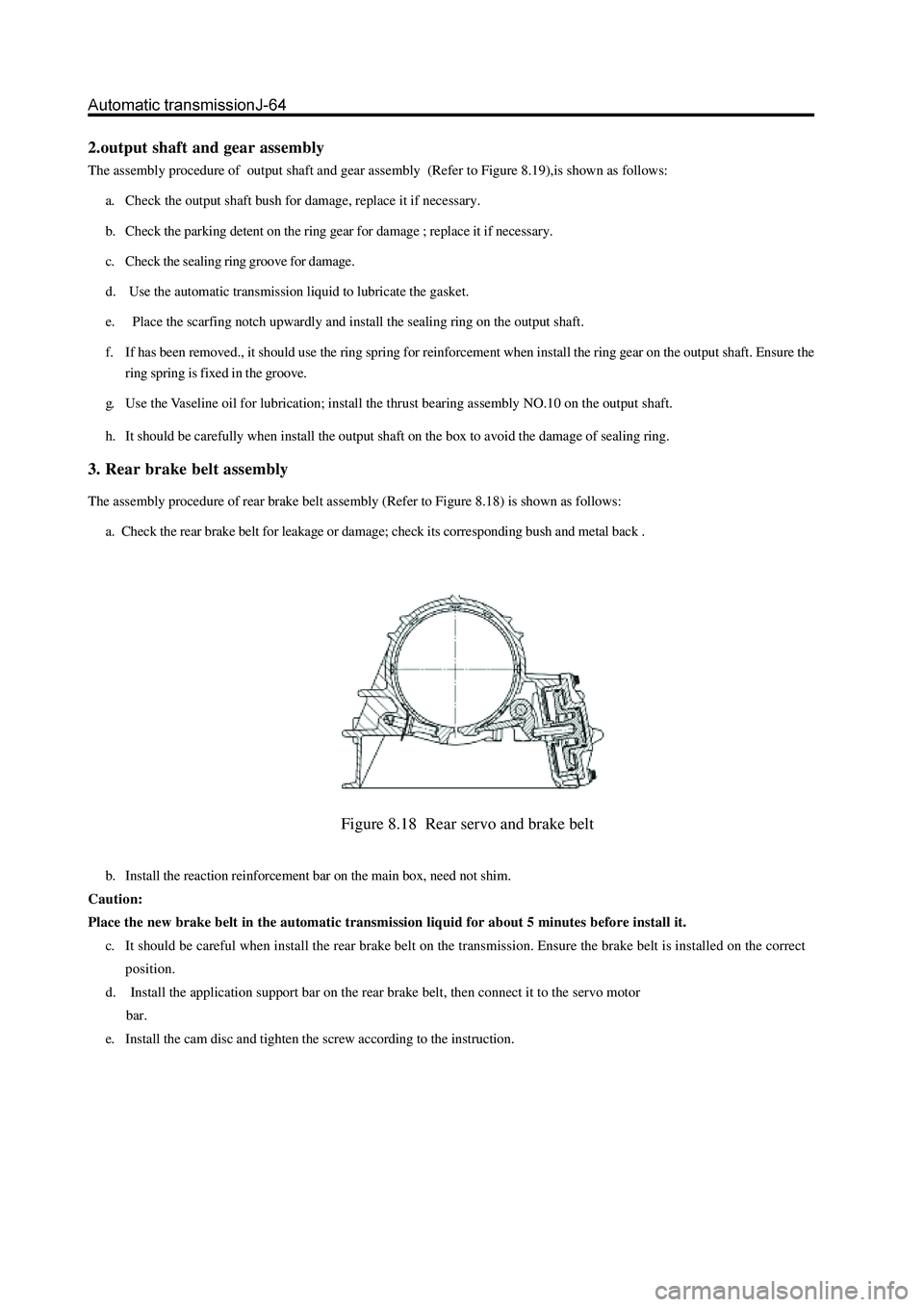

3. Rear brake belt assembly

The assembly procedure of rear brake belt assembly (Refer to Figure 8.18) is shown as follows:

a. Check the rear brake belt for leakage or damage; check its corresponding bush and metal back .

Figure 8.18 Rear servo and brake belt

b. Install the reaction reinforcement bar on the main box, need not shim.

Caution:

Place the new brake belt in the automatic transmission liquid for about 5 minutes before install it.

c. It should be careful when install the rear brake belt on the transmission. Ensure the brake belt is installed on the correct

position.

d. Install the application support bar on the rear brake belt, then connect it to the servo motor

bar.

e. Install the cam disc and tighten the screw according to the instruction.

Page 144 of 425

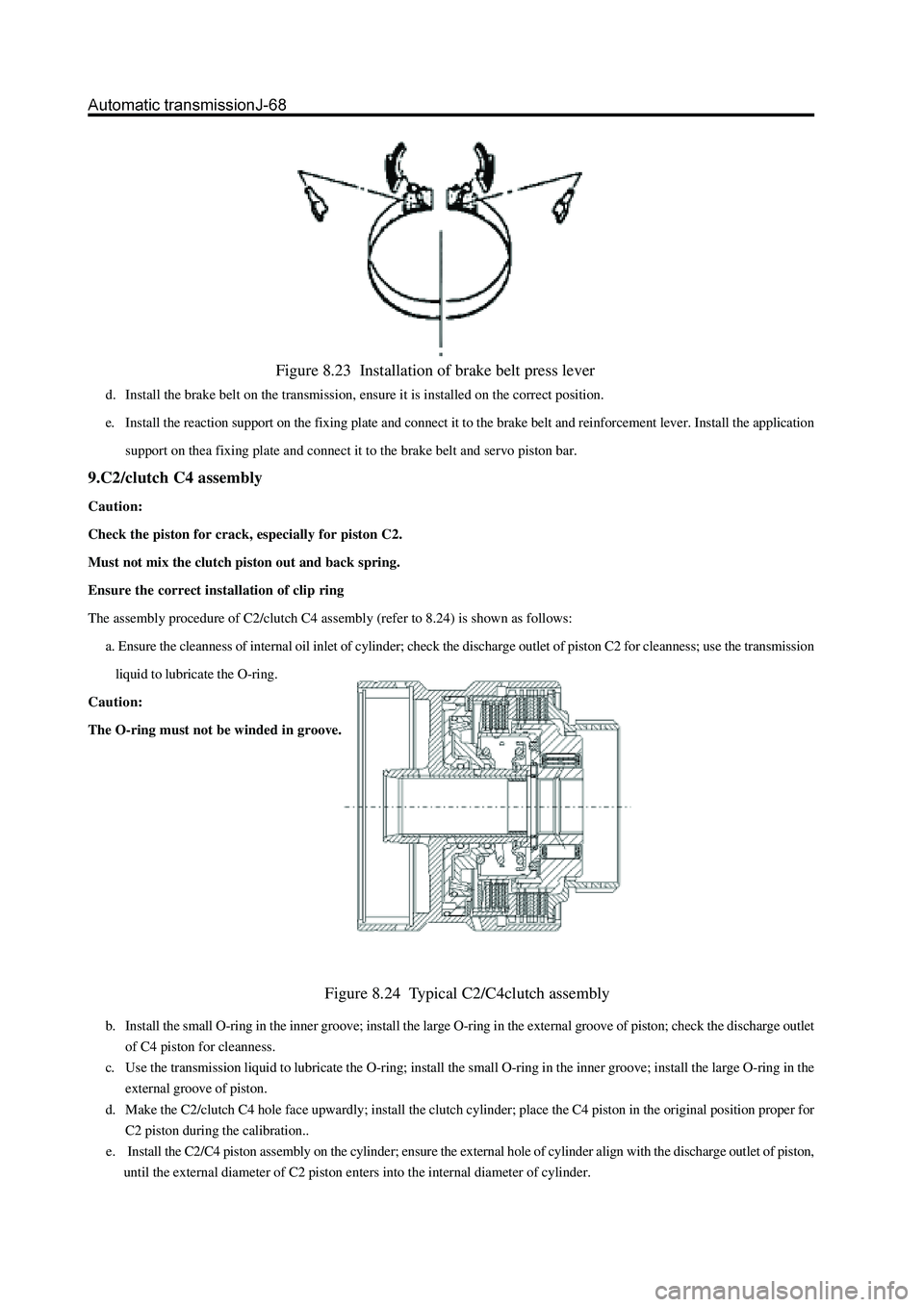

Figure 8.23 Installation of brake belt press lever

d. Install the brake belt on the transmission, ensure it is installed on the correct position.

e. Install the reaction support on the fixing plate and connect it to the brake belt and reinforcement lever. Install the application

support on thea fixing plate and connect it to the brake belt and servo piston bar.

9.C2/clutch C4 assembly

Caution:

Check the piston for crack, especially for piston C2.

Must not mix the clutch piston out and back spring.

Ensure the correct installation of clip ring

The assembly procedure of C2/clutch C4 assembly (refer to 8.24) is shown as follows:

a. Ensure the cleanness of internal oil inlet of cylinder; check the discharge outlet of piston C2 for cleanness; use the transmission

liquid to lubricate the O-ring.

Caution:

The O-ring must not be winded in groove.

Figure 8.24 Typical C2/C4clutch assembly

b. Install the small O-ring in the inner groove; install the large O-ring in the external groove of piston; check the discharge outlet

of C4 piston for cleanness.

c. Use the transmission liquid to lubricate the O-ring; install the small O-ring in the inner groove; install the large O-ring in the

external groove of piston.

d. Make the C2/clutch C4 hole face upwardly; install the clutch cylinder; place the C4 piston in the original position proper for

C2 piston during the calibration..

e. Install the C2/C4 piston assembly on the cylinder; ensure the external hole of cylinder align with the discharge outlet of piston,

until the external diameter of C2 piston enters into the internal diameter of cylinder.

Page 145 of 425

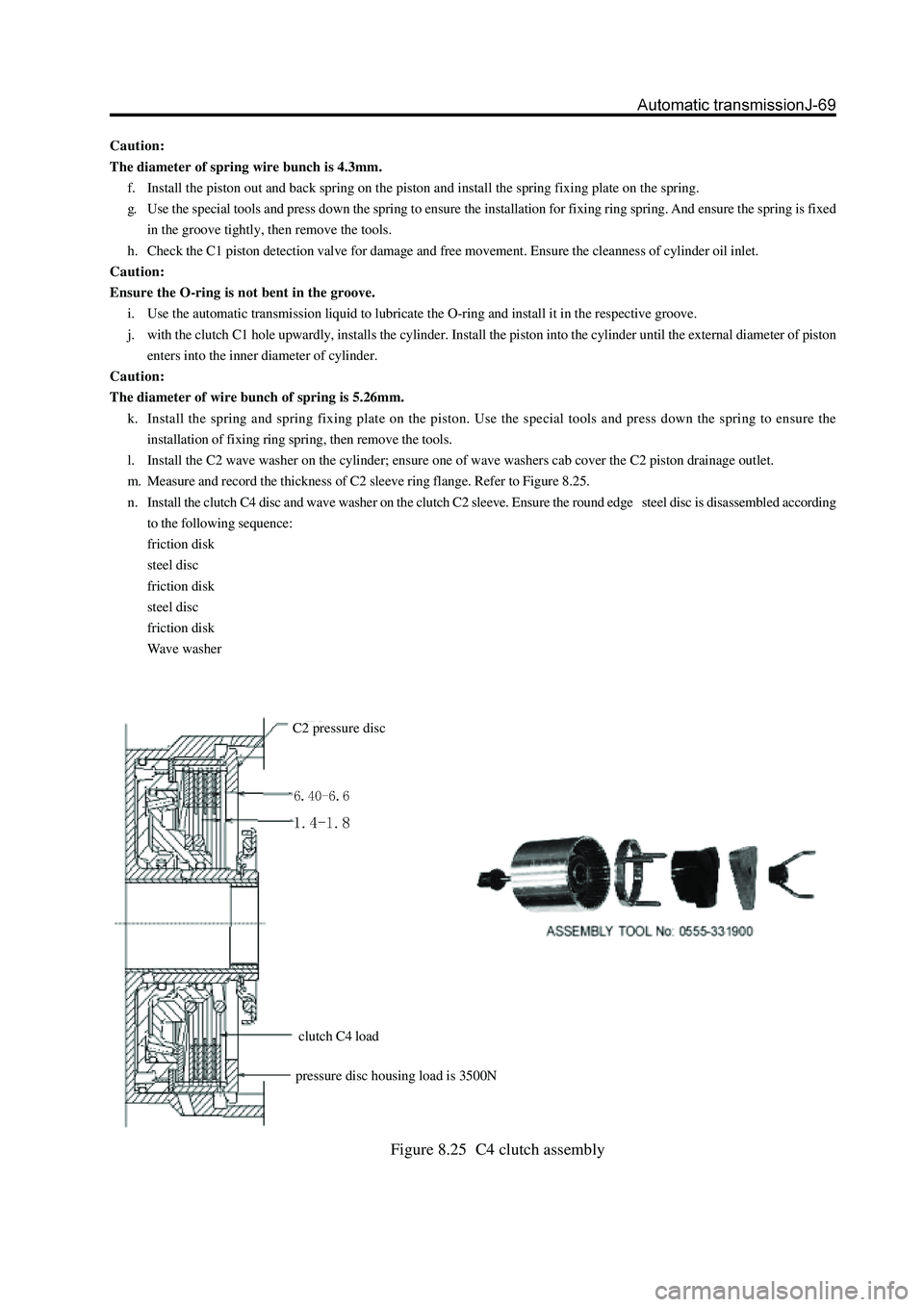

Figure 8.25 C4 clutch assembly

Caution:

The diameter of spring wire bunch is 4.3mm.

f. Install the piston out and back spring on the piston and install the spring fixing plate on the spring.

g. Use the special tools and press down the spring to ensure the installation for fixing ring spring. And ensure the spring is fixed

in the groove tightly, then remove the tools.

h. Check the C1 piston detection valve for damage and free movement. Ensure the cleanness of cylinder oil inlet.

Caution:

Ensure the O-ring is not bent in the groove.

i. Use the automatic transmission liquid to lubricate the O-ring and install it in the respective groove.

j. with the clutch C1 hole upwardly, installs the cylinder. Install the piston into the cylinder until the external diameter of piston

enters into the inner diameter of cylinder.

Caution:

The diameter of wire bunch of spring is 5.26mm.

k. Install the spring and spring fixing plate on the piston. Use the special tools and press down the spring to ensure the

installation of fixing ring spring, then remove the tools.

l. Install the C2 wave washer on the cylinder; ensure one of wave washers cab cover the C2 piston drainage outlet.

m. Measure and record the thickness of C2 sleeve ring flange. Refer to Figure 8.25.

n. Install the clutch C4 disc and wave washer on the clutch C2 sleeve. Ensure the round edge steel disc is disassembled according

to the following sequence:

friction disk

steel disc

friction disk

steel disc

friction disk

Wave washer

C2 pressure disc

pressure disc housing load is 3500N

clutch C4 load

Page 182 of 425

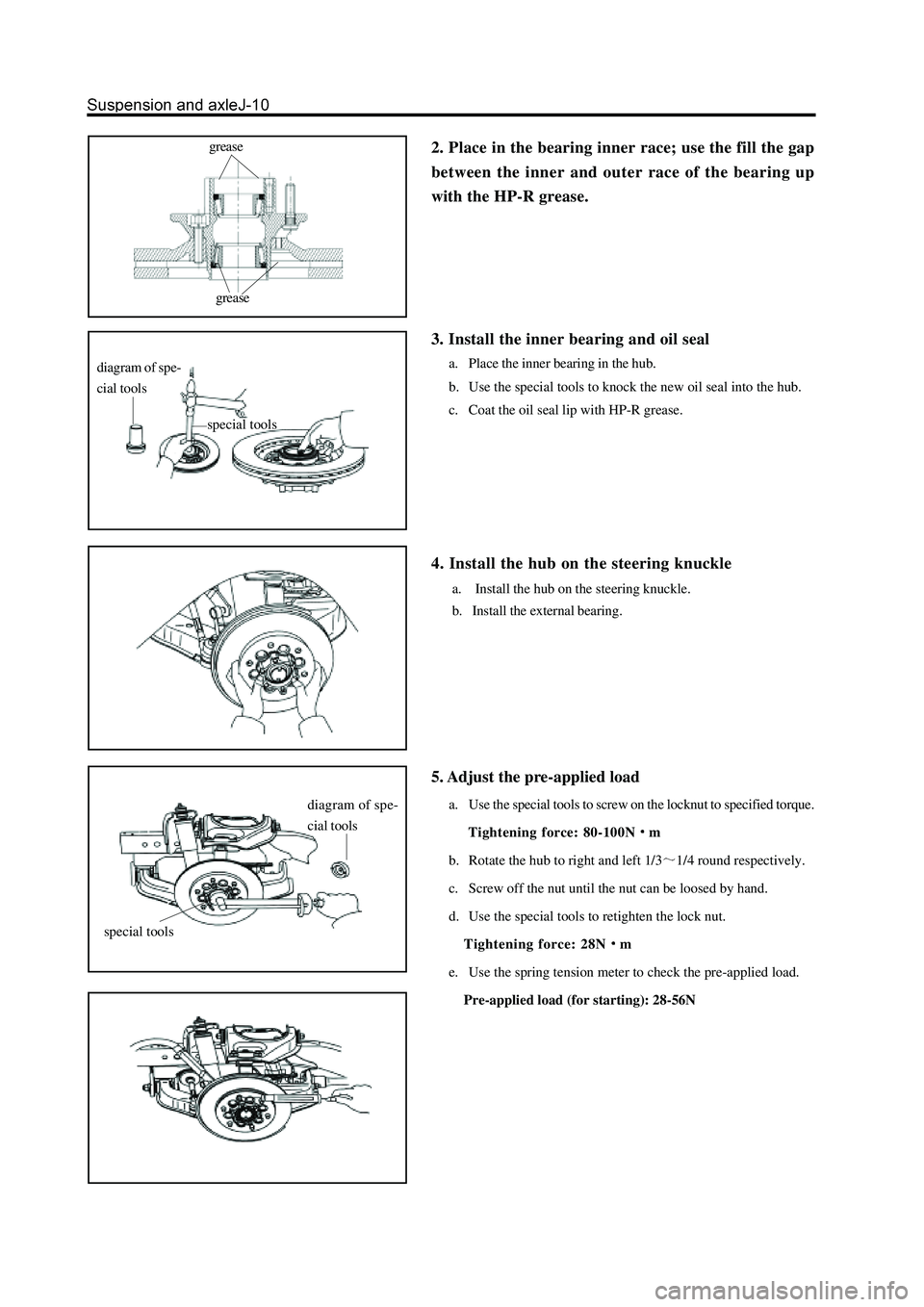

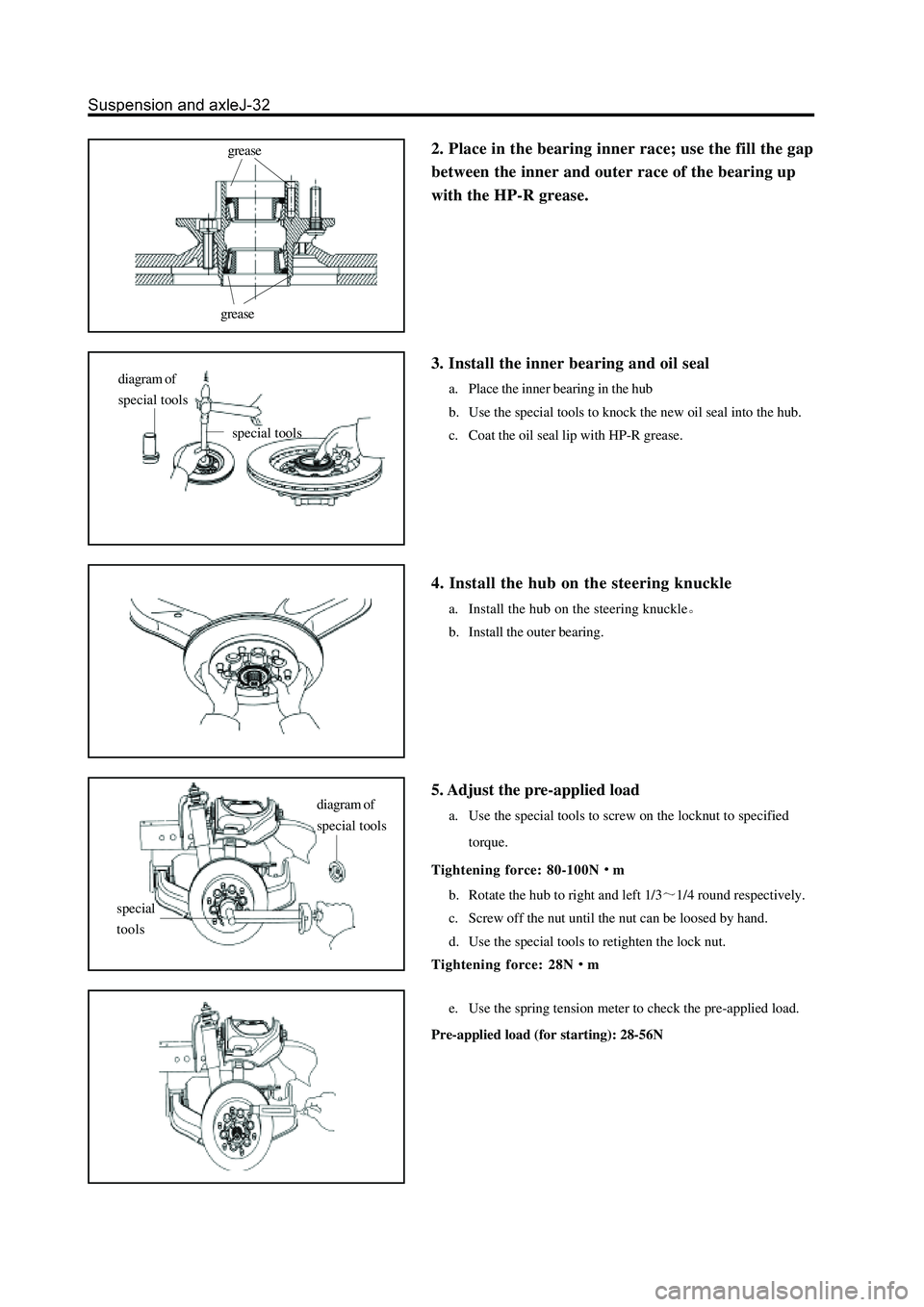

2. Place in the bearing inner race; use the fill the gap

between the inner and outer race of the bearing up

with the HP-R grease.grease

grease

3. Install the inner bearing and oil seal

a. Place the inner bearing in the hub.

b. Use the special tools to knock the new oil seal into the hub.

c. Coat the oil seal lip with HP-R grease.

4. Install the hub on the steering knuckle

a. Install the hub on the steering knuckle.

b. Install the external bearing.

diagram of spe-

cial tools

special tools

5. Adjust the pre-applied load

a. Use the special tools to screw on the locknut to specified torque.

Tightening force: 80-100N

m

b. Rotate the hub to right and left 1/3

1/4 round respectively.

c. Screw off the nut until the nut can be loosed by hand.

d. Use the special tools to retighten the lock nut.

Tightening force: 28N

m

e. Use the spring tension meter to check the pre-applied load.

Pre-applied load (for starting): 28-56N

diagram of spe-

cial tools

special tools

Page 204 of 425

2. Place in the bearing inner race; use the fill the gap

between the inner and outer race of the bearing up

with the HP-R grease.grease

grease

3. Install the inner bearing and oil seal

a. Place the inner bearing in the hub

b. Use the special tools to knock the new oil seal into the hub.

c. Coat the oil seal lip with HP-R grease.diagram of

special tools

special tools

4. Install the hub on the steering knuckle

a. Install the hub on the steering knuckle

b. Install the outer bearing.

5. Adjust the pre-applied load

a. Use the special tools to screw on the locknut to specified

torque.

Tightening force: 80-100N

m

b. Rotate the hub to right and left 1/3

1/4 round respectively.

c. Screw off the nut until the nut can be loosed by hand.

d. Use the special tools to retighten the lock nut.

Tightening force: 28N

m

e. Use the spring tension meter to check the pre-applied load.

Pre-applied load (for starting): 28-56N

special

tools

diagram of

special tools

Page 231 of 425

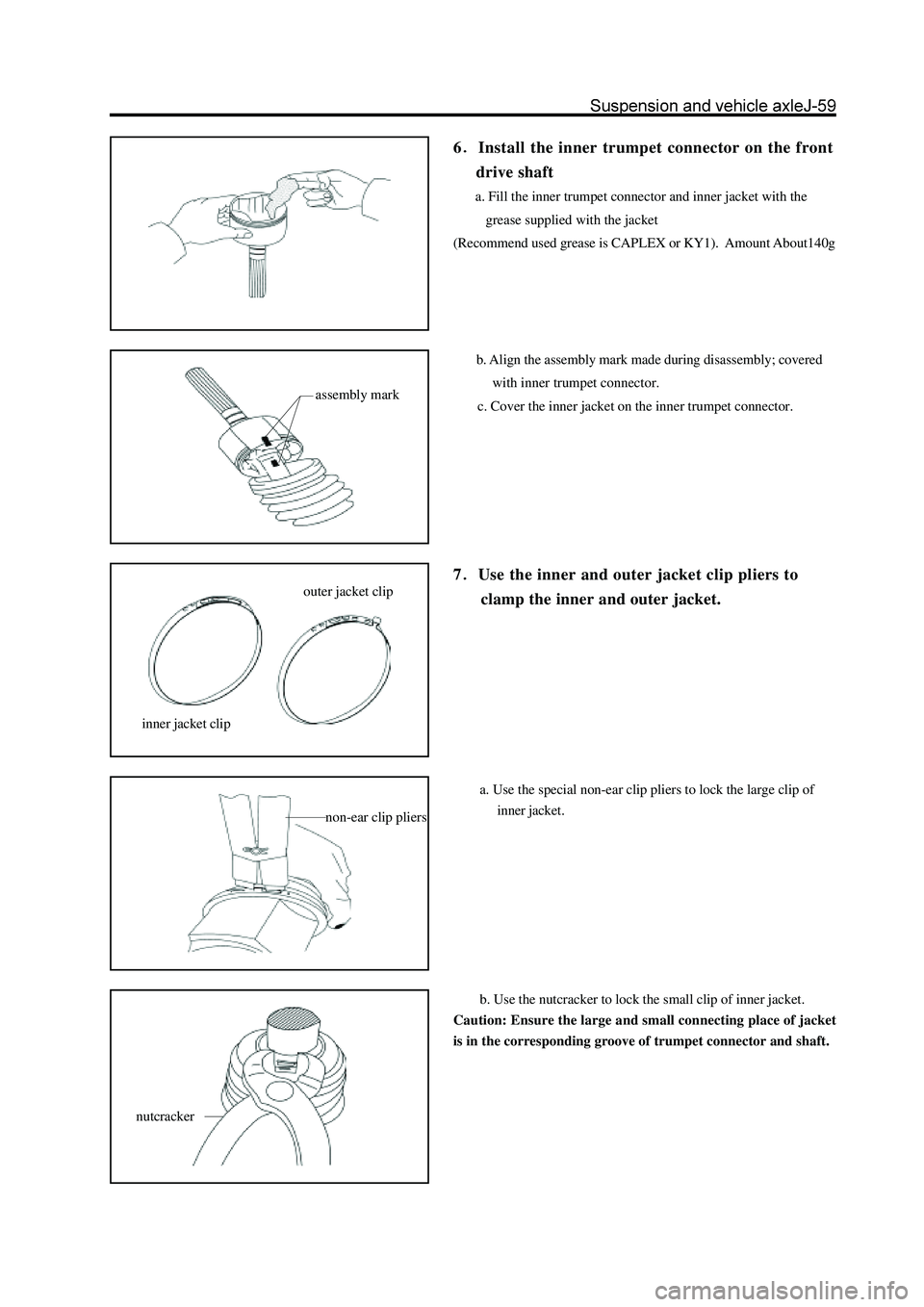

6Install the inner trumpet connector on the front

drive shaft

a. Fill the inner trumpet connector and inner jacket with the

grease supplied with the jacket

(Recommend used grease is CAPLEX or KY1). Amount About140g

b. Align the assembly mark made during disassembly; covered

with inner trumpet connector.

c. Cover the inner jacket on the inner trumpet connector.

7Use the inner and outer jacket clip pliers to

clamp the inner and outer jacket.

a. Use the special non-ear clip pliers to lock the large clip of

inner jacket.

b. Use the nutcracker to lock the small clip of inner jacket.

Caution: Ensure the large and small connecting place of jacket

is in the corresponding groove of trumpet connector and shaft.

assembly mark

outer jacket clip

inner jacket clip

non-ear clip pliers

nutcracker