ESP GREAT WALL HOVER 2006 Service Owner's Manual

[x] Cancel search | Manufacturer: GREAT WALL, Model Year: 2006, Model line: HOVER, Model: GREAT WALL HOVER 2006Pages: 425, PDF Size: 26.05 MB

Page 245 of 425

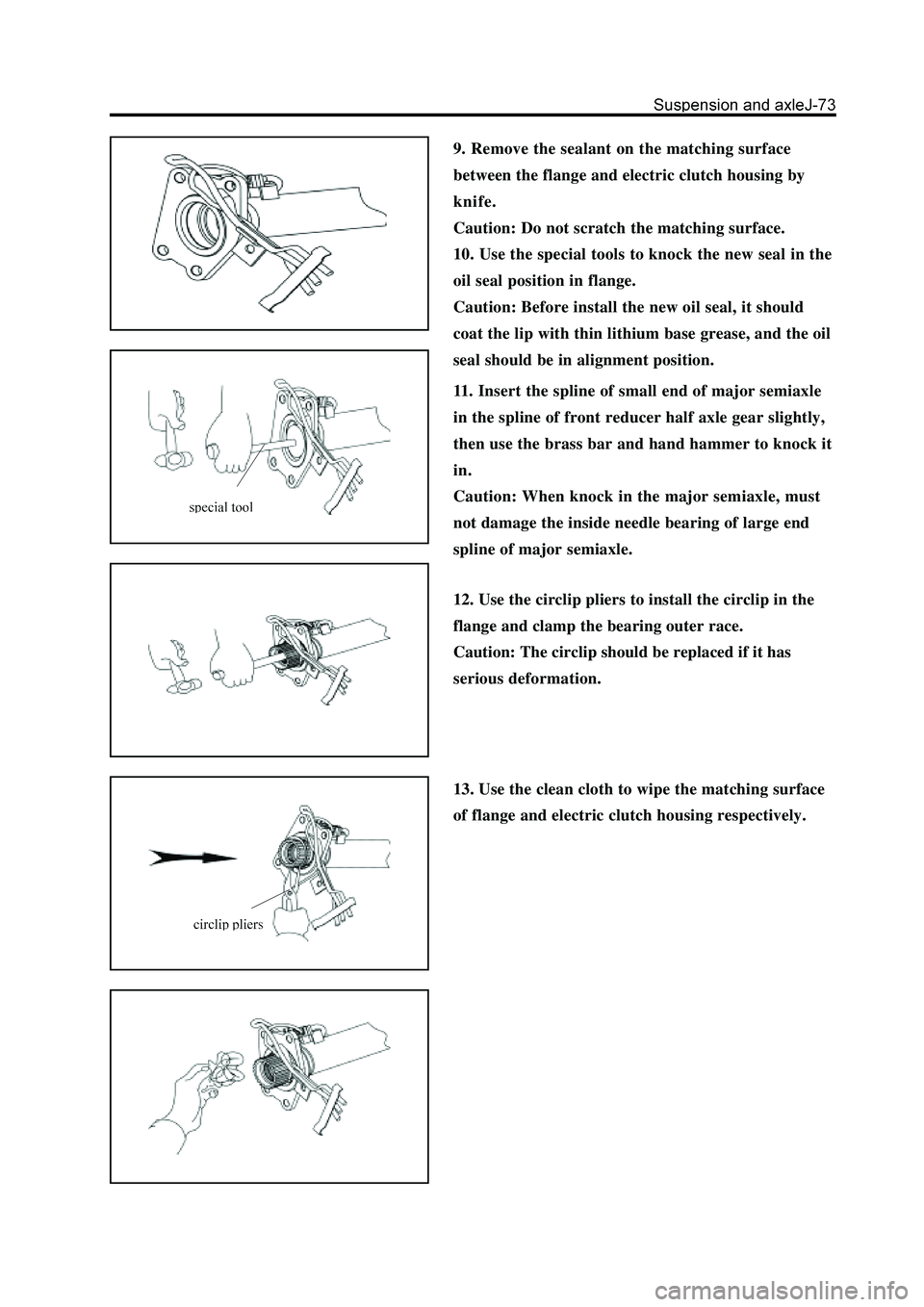

9. Remove the sealant on the matching surface

between the flange and electric clutch housing by

knife.

Caution: Do not scratch the matching surface.

10. Use the special tools to knock the new seal in the

oil seal position in flange.

Caution: Before install the new oil seal, it should

coat the lip with thin lithium base grease, and the oil

seal should be in alignment position.

11. Insert the spline of small end of major semiaxle

in the spline of front reducer half axle gear slightly,

then use the brass bar and hand hammer to knock it

in.

Caution: When knock in the major semiaxle, must

not damage the inside needle bearing of large end

spline of major semiaxle.

12. Use the circlip pliers to install the circlip in the

flange and clamp the bearing outer race.

Caution: The circlip should be replaced if it has

serious deformation.

13. Use the clean cloth to wipe the matching surface

of flange and electric clutch housing respectively.

Page 259 of 425

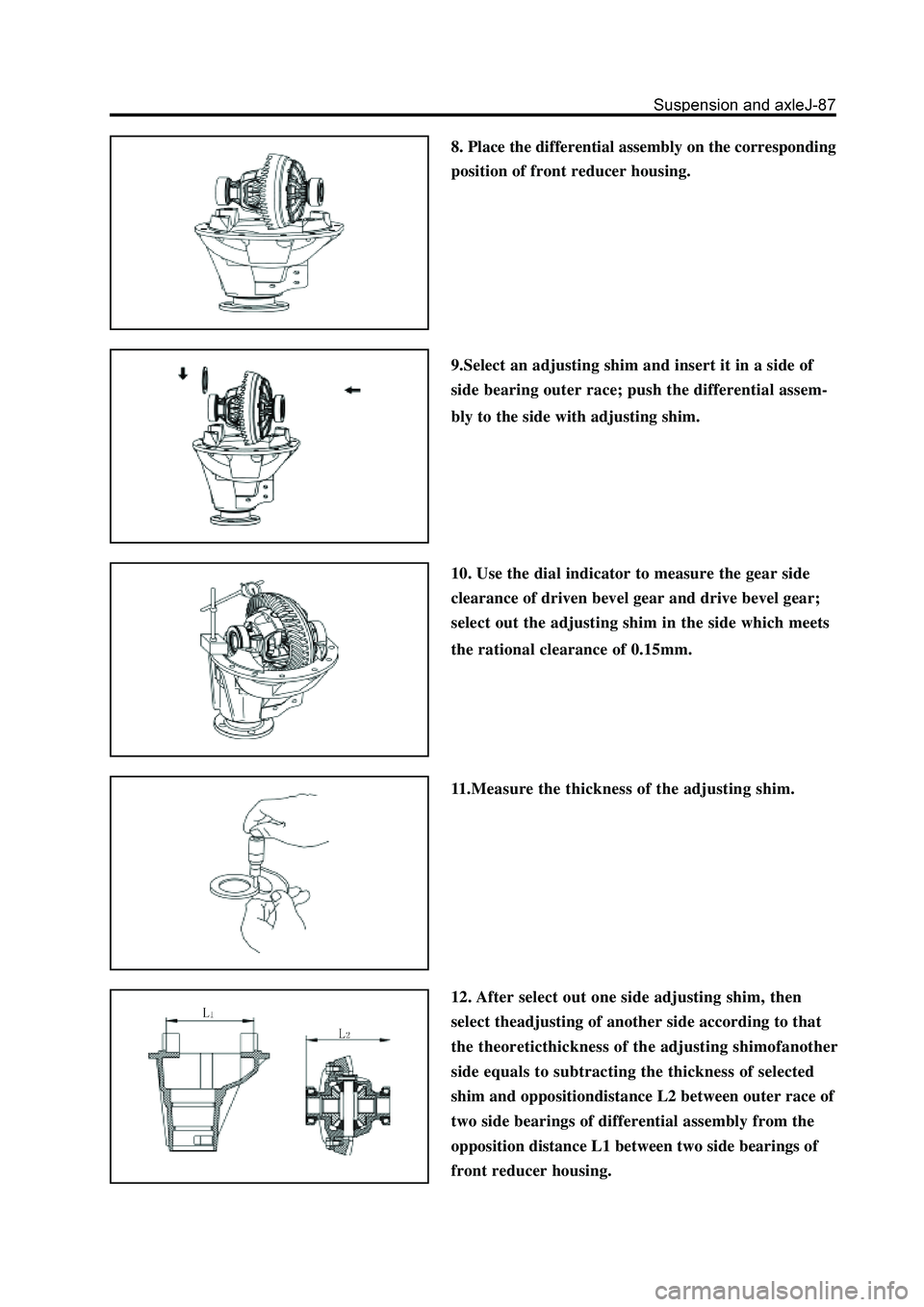

8. Place the differential assembly on the corresponding

position of front reducer housing.

9.Select an adjusting shim and insert it in a side of

side bearing outer race; push the differential assem-

bly to the side with adjusting shim.

10. Use the dial indicator to measure the gear side

clearance of driven bevel gear and drive bevel gear;

select out the adjusting shim in the side which meets

the rational clearance of 0.15mm.

11.Measure the thickness of the adjusting shim.

12. After select out one side adjusting shim, then

select theadjusting of another side according to that

the theoreticthickness of the adjusting shimofanother

side equals to subtracting the thickness of selected

shim and oppositiondistance L2 between outer race of

two side bearings of differential assembly from the

opposition distance L1 between two side bearings of

front reducer housing.

Page 262 of 425

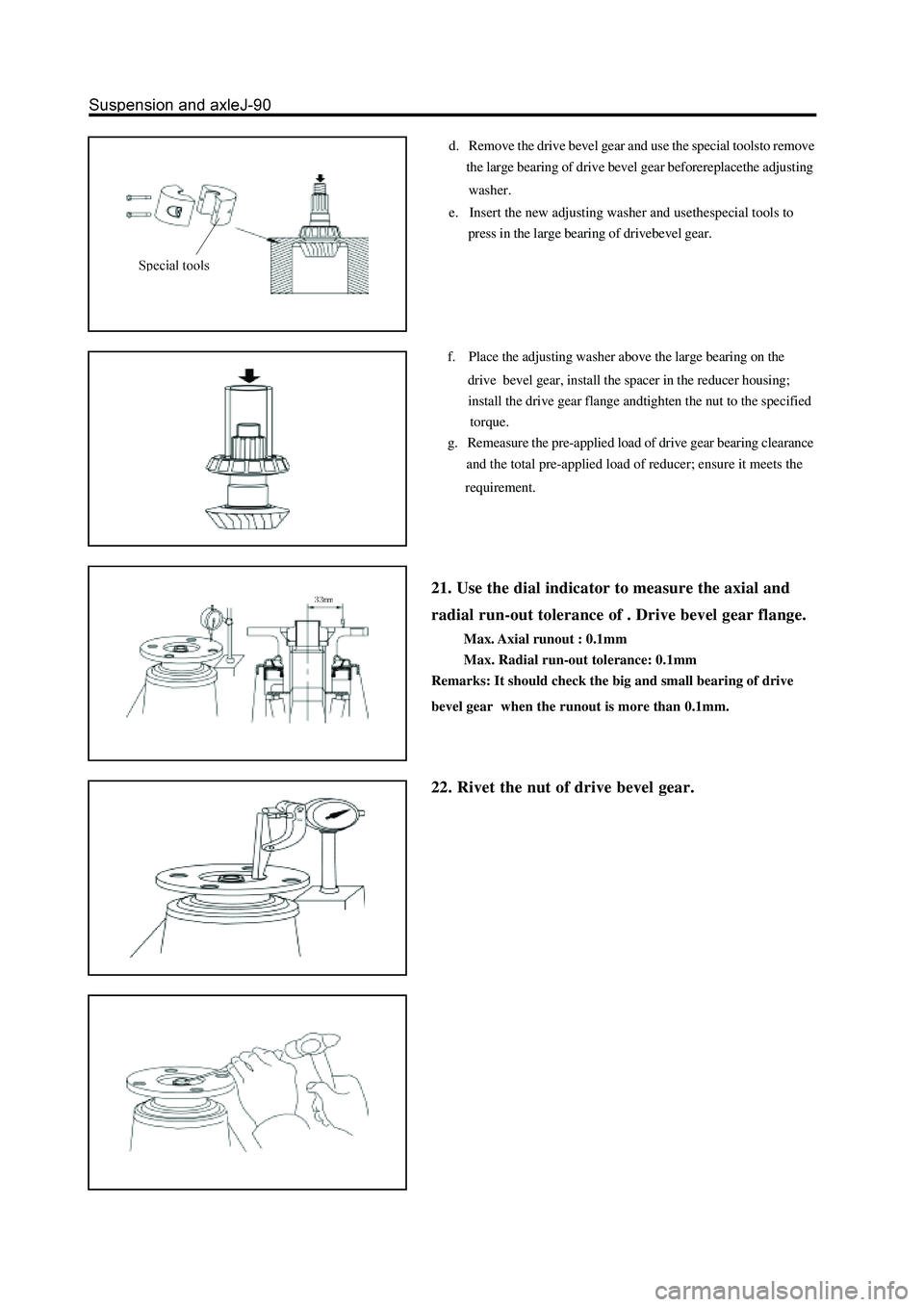

d. Remove the drive bevel gear and use the special toolsto remove

the large bearing of drive bevel gear beforereplacethe adjusting

washer.

e. Insert the new adjusting washer and usethespecial tools to

press in the large bearing of drivebevel gear.

f. Place the adjusting washer above the large bearing on the

drive bevel gear, install the spacer in the reducer housing;

install the drive gear flange andtighten the nut to the specified

torque.

g. Remeasure the pre-applied load of drive gear bearing clearance

and the total pre-applied load of reducer; ensure it meets the

requirement.

21. Use the dial indicator to measure the axial and

radial run-out tolerance of . Drive bevel gear flange.

Max. Axial runout : 0.1mm

Max. Radial run-out tolerance: 0.1mm

Remarks: It should check the big and small bearing of drive

bevel gear when the runout is more than 0.1mm.

22. Rivet the nut of drive bevel gear.

Page 263 of 425

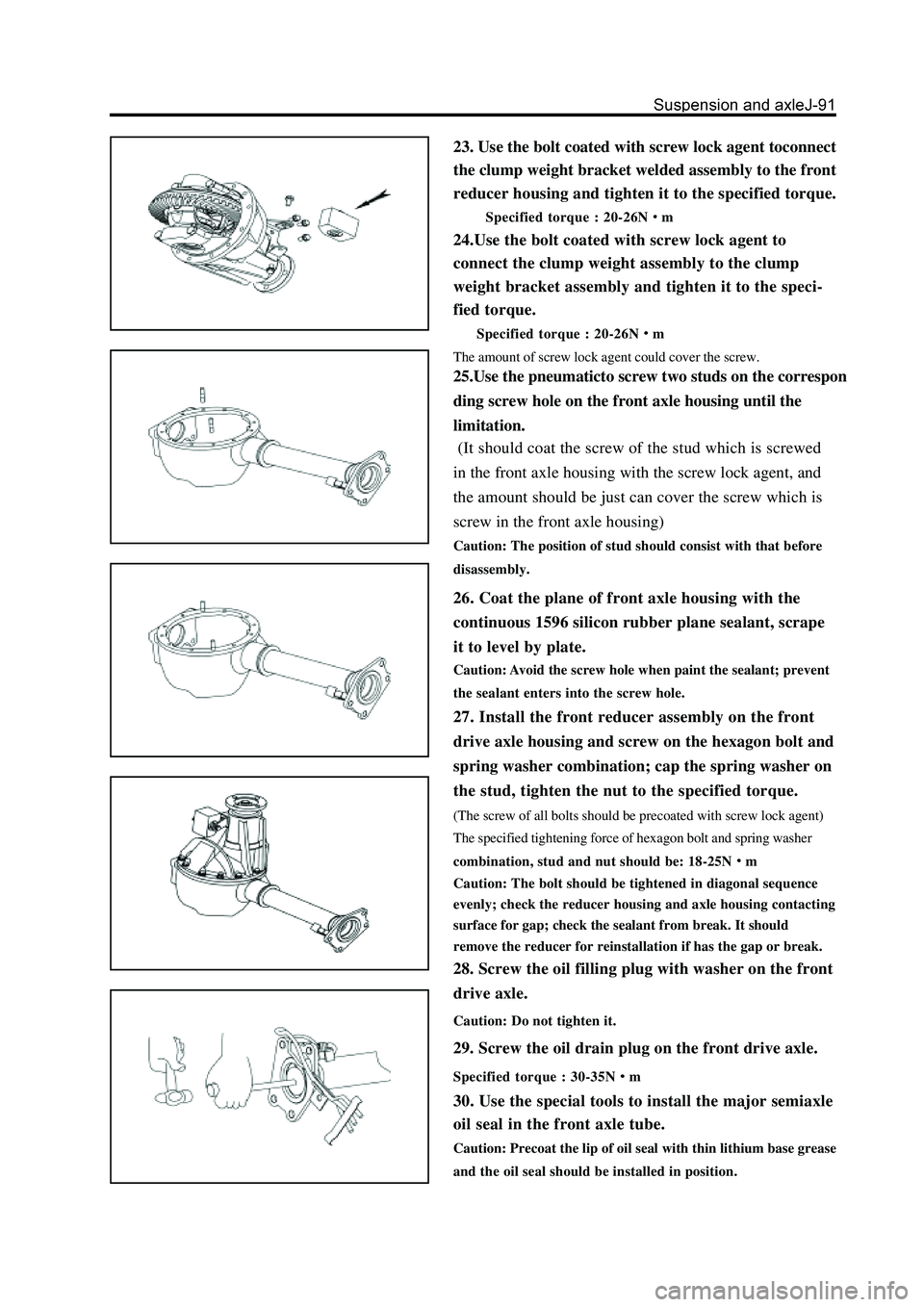

23. Use the bolt coated with screw lock agent toconnect

the clump weight bracket welded assembly to the front

reducer housing and tighten it to the specified torque.

Specified torque : 20-26Nm

24.Use the bolt coated with screw lock agent to

connect the clump weight assembly to the clump

weight bracket assembly and tighten it to the speci-

fied torque.

Specified torque : 20-26Nm

The amount of screw lock agent could cover the screw.

25.Use the pneumaticto screw two studs on the correspon

ding screw hole on the front axle housing until the

limitation.

26. Coat the plane of front axle housing with the

continuous 1596 silicon rubber plane sealant, scrape

it to level by plate.

Caution: Avoid the screw hole when paint the sealant; prevent

the sealant enters into the screw hole.

27. Install the front reducer assembly on the front

drive axle housing and screw on the hexagon bolt and

spring washer combination; cap the spring washer on

the stud, tighten the nut to the specified torque.

(The screw of all bolts should be precoated with screw lock agent)

The specified tightening force of hexagon bolt and spring washer

combination, stud and nut should be: 18-25N

m

Caution: The bolt should be tightened in diagonal sequence

evenly; check the reducer housing and axle housing contacting

surface for gap; check the sealant from break. It should

remove the reducer for reinstallation if has the gap or break.

28. Screw the oil filling plug with washer on the front

drive axle.

Caution: Do not tighten it.

29. Screw the oil drain plug on the front drive axle.

Specified torque : 30-35Nm

30. Use the special tools to install the major semiaxle

oil seal in the front axle tube.

Caution: Precoat the lip of oil seal with thin lithium base grease

and the oil seal should be installed in position.

(It should coat the screw of the stud which is screwed

in the front axle housing with the screw lock agent, and

the amount should be just can cover the screw which is

screw in the front axle housing)

Caution: The position of stud should consist with that before

disassembly.

Page 265 of 425

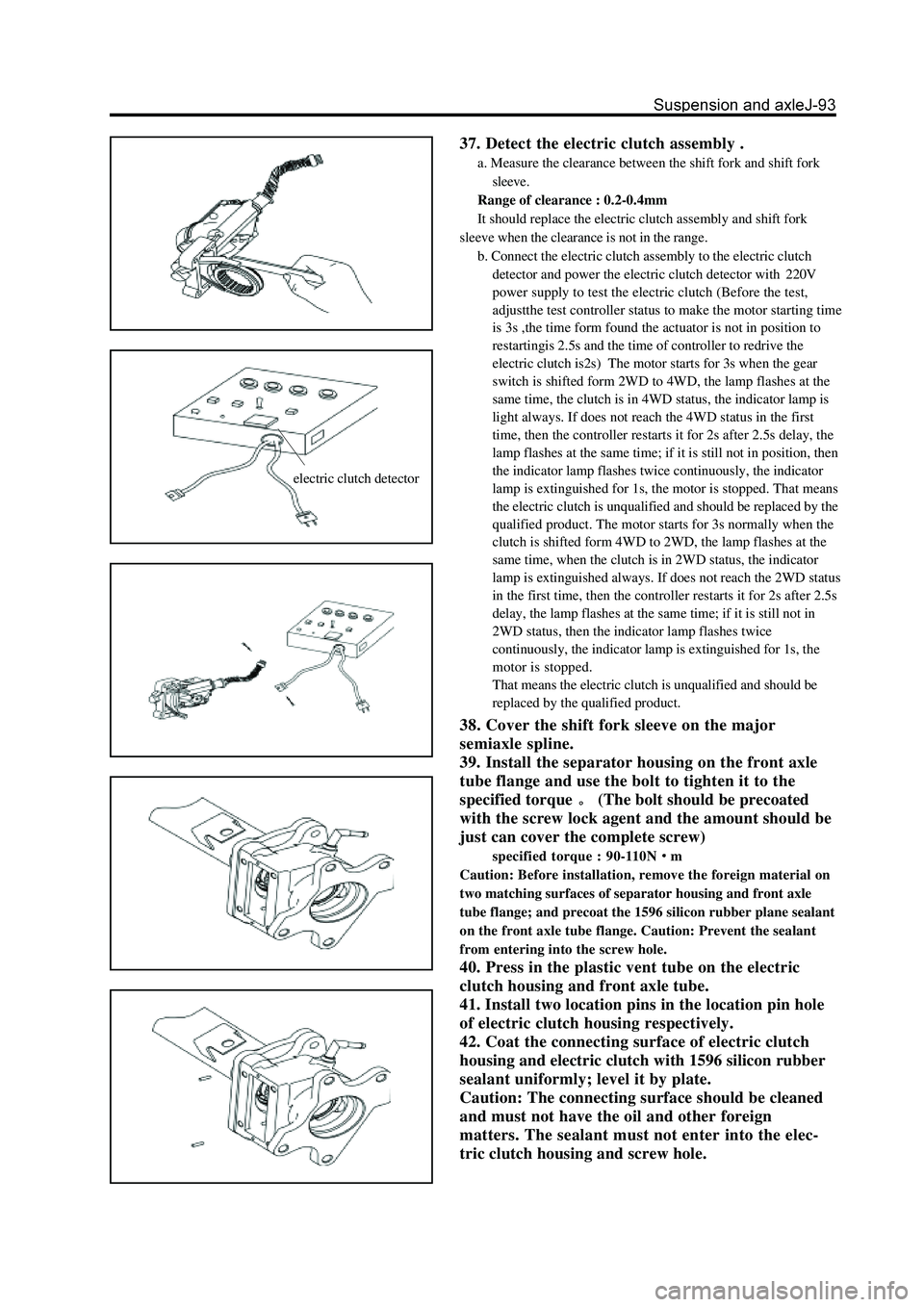

electric clutch detector

37. Detect the electric clutch assembly .

a. Measure the clearance between the shift fork and shift fork

sleeve.

Range of clearance : 0.2-0.4mm

It should replace the electric clutch assembly and shift fork

sleeve when the clearance is not in the range.

b. Connect the electric clutch assembly to the electric clutch

detector and power the electric clutch detector with220V

power supply to test the electric clutch (Before the test,

adjustthe test controller status to make the motor starting time

is 3s ,the time form found the actuator is not in position to

restartingis 2.5s and the time of controller to redrive the

electric clutch is2s) The motor starts for 3s when the gear

switch is shifted form 2WD to 4WD, the lamp flashes at the

same time, the clutch is in 4WD status, the indicator lamp is

light always. If does not reach the 4WD status in the first

time, then the controller restarts it for 2s after 2.5s delay, the

lamp flashes at the same time; if it is still not in position, then

the indicator lamp flashes twice continuously, the indicator

lamp is extinguished for 1s, the motor is stopped. That means

the electric clutch is unqualified and should be replaced by the

qualified product. The motor starts for 3s normally when the

clutch is shifted form 4WD to 2WD, the lamp flashes at the

same time, when the clutch is in 2WD status, the indicator

lamp is extinguished always. If does not reach the 2WD status

in the first time, then the controller restarts it for 2s after 2.5s

delay, the lamp flashes at the same time; if it is still not in

2WD status, then the indicator lamp flashes twice

continuously, the indicator lamp is extinguished for 1s, the

motor is stopped.

That means the electric clutch is unqualified and should be

replaced by the qualified product.

38. Cover the shift fork sleeve on the major

semiaxle spline.

39. Install the separator housing on the front axle

tube flange and use the bolt to tighten it to the

specified torque

(The bolt should be precoated

with the screw lock agent and the amount should be

just can cover the complete screw)

specified torque : 90-110Nm

Caution: Before installation, remove the foreign material on

two matching surfaces of separator housing and front axle

tube flange; and precoat the 1596 silicon rubber plane sealant

on the front axle tube flange. Caution: Prevent the sealant

from entering into the screw hole.

40. Press in the plastic vent tube on the electric

clutch housing and front axle tube.

41. Install two location pins in the location pin hole

of electric clutch housing respectively.

42. Coat the connecting surface of electric clutch

housing and electric clutch with 1596 silicon rubber

sealant uniformly; level it by plate.

Caution: The connecting surface should be cleaned

and must not have the oil and other foreign

matters. The sealant must not enter into the elec-

tric clutch housing and screw hole.

Page 269 of 425

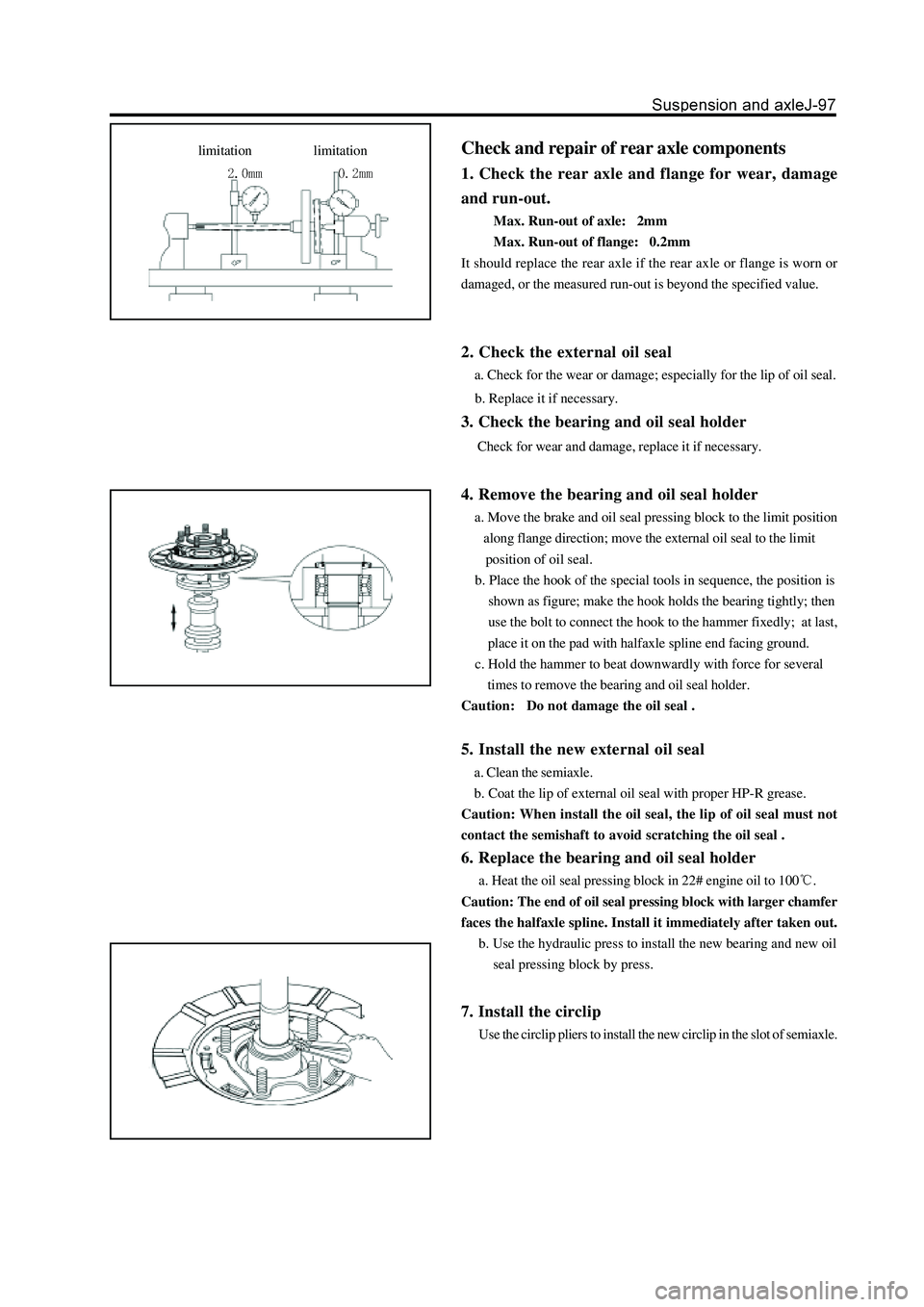

limitationlimitationCheck and repair of rear axle components

1. Check the rear axle and flange for wear, damage

and run-out.

Max. Run-out of axle: 2mm

Max. Run-out of flange: 0.2mm

It should replace the rear axle if the rear axle or flange is worn or

damaged, or the measured run-out is beyond the specified value.

2. Check the external oil seal

a. Check for the wear or damage; especially for the lip of oil seal.

b. Replace it if necessary.

3. Check the bearing and oil seal holder

Check for wear and damage, replace it if necessary.

4. Remove the bearing and oil seal holder

a. Move the brake and oil seal pressing block to the limit position

along flange direction; move the external oil seal to the limit

position of oil seal.

b. Place the hook of the special tools in sequence, the position is

shown as figure; make the hook holds the bearing tightly; then

use the bolt to connect the hook to the hammer fixedly; at last,

place it on the pad with halfaxle spline end facing ground.

c. Hold the hammer to beat downwardly with force for several

times to remove the bearing and oil seal holder.

Caution: Do not damage the oil seal .

5. Install the new external oil seal

a. Clean the semiaxle.

b. Coat the lip of external oil seal with proper HP-R grease.

Caution: When install the oil seal, the lip of oil seal must not

contact the semishaft to avoid scratching the oil seal .

6. Replace the bearing and oil seal holder

a. Heat the oil seal pressing block in 22# engine oil to 100.

Caution: The end of oil seal pressing block with larger chamfer

faces the halfaxle spline. Install it immediately after taken out.

b. Use the hydraulic press to install the new bearing and new oil

seal pressing block by press.

7. Install the circlip

Use the circlip pliers to install the new circlip in the slot of semiaxle.

Page 300 of 425

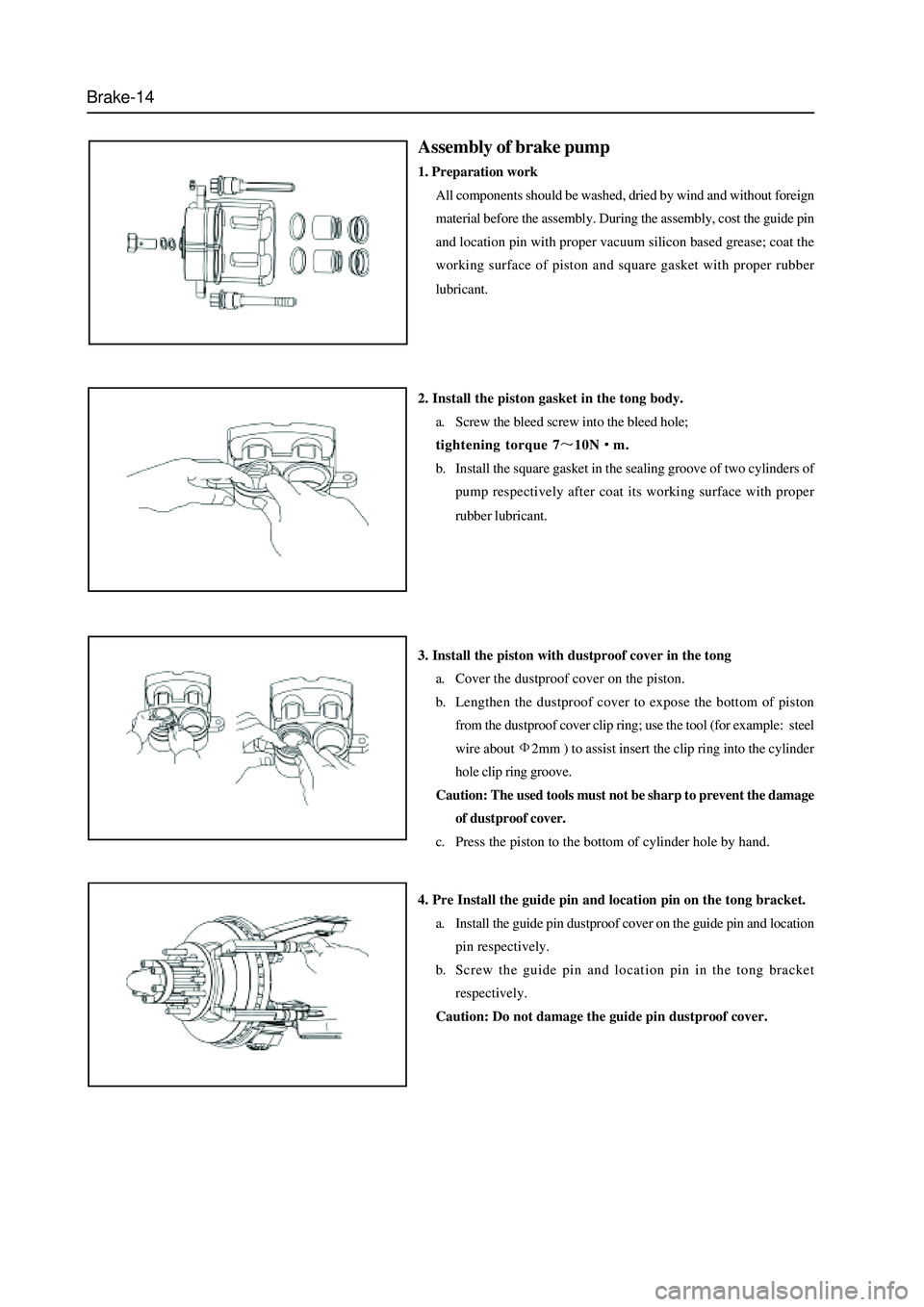

Brake-14

Assembly of brake pump

1. Preparation work

All components should be washed, dried by wind and without foreign

material before the assembly. During the assembly, cost the guide pin

and location pin with proper vacuum silicon based grease; coat the

working surface of piston and square gasket with proper rubber

lubricant.

2. Install the piston gasket in the tong body.

a. Screw the bleed screw into the bleed hole;

tightening torque 7

10Nm.

b. Install the square gasket in the sealing groove of two cylinders of

pump respectively after coat its working surface with proper

rubber lubricant.

3. Install the piston with dustproof cover in the tong

a. Cover the dustproof cover on the piston.

b. Lengthen the dustproof cover to expose the bottom of piston

from the dustproof cover clip ring; use the tool (for example: steel

wire about

2mm ) to assist insert the clip ring into the cylinder

hole clip ring groove.

Caution: The used tools must not be sharp to prevent the damage

of dustproof cover.

c. Press the piston to the bottom of cylinder hole by hand.

4. Pre Install the guide pin and location pin on the tong bracket.

a. Install the guide pin dustproof cover on the guide pin and location

pin respectively.

b. Screw the guide pin and location pin in the tong bracket

respectively.

Caution: Do not damage the guide pin dustproof cover.

Page 308 of 425

Brake-22

2. Install the piston gasket in the tong body.

a. Screw the bleed screw into the bleed hole;

b. Install the square gasket in the sealing groove of two cylinders of

pump respectively after coat its working surface with proper

rubber lubricant.

Tightening torque 7

10Nm.

3. Connect the brake pipeline

Connect the brake oil pipe to the tong.

Tightening force: 50

5Nm

4. Fill up the brake system with the brake fluid and drain the air

in the brake system.

5. Check for leakage of brake fluid.

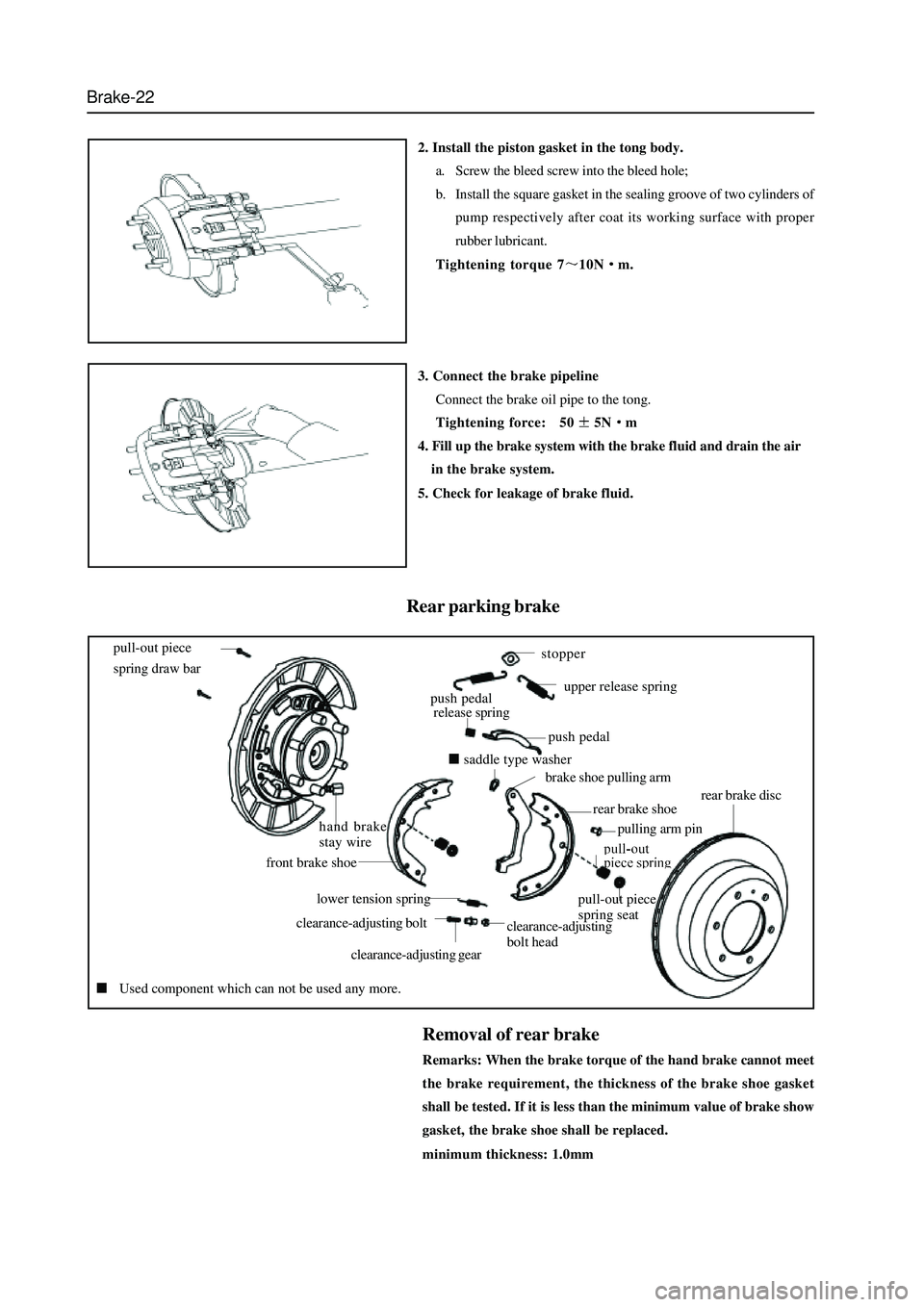

Rear parking brake

pull-out piece

spring draw bar

hand brake

stay wire

front brake shoe

lower tension spring

clearance-adjusting bolt

clearance-adjusting gear

clearance-adjusting

bolt head

pull-out piece

spring seat

pulling arm pin

rear brake shoe

brake shoe pulling arm

saddle type washer

push pedal

push pedal

release spring

stopper

upper release spring

rear brake disc

Used component which can not be used any more.

Removal of rear brake

Remarks: When the brake torque of the hand brake cannot meet

the brake requirement, the thickness of the brake shoe gasket

shall be tested. If it is less than the minimum value of brake show

gasket, the brake shoe shall be replaced.

minimum thickness: 1.0mm

Page 376 of 425

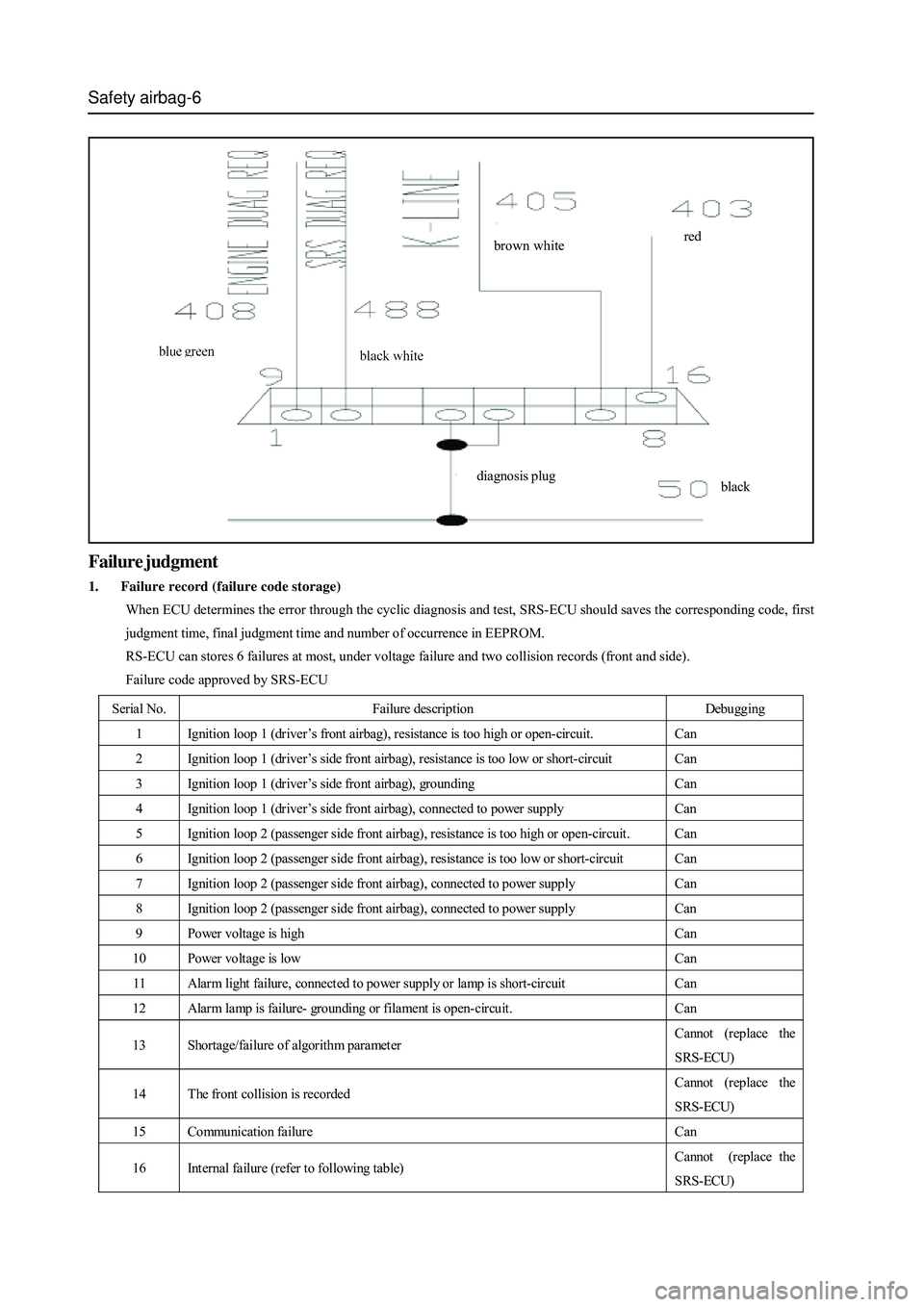

Safety airbag-6

brown whitered

diagnosis plug

black

Failure judgment

1. Failure record (failure code storage)

When ECU determines the error through the cyclic diagnosis and test, SRS-ECU should saves the corresponding code, first

judgment time, final judgment time and number of occurrence in EEPROM.

RS-ECU can stores 6 failures at most, under voltage failure and two collision records (front and side).

Failure code approved by SRS-ECU

Serial No. Failure description Debugging

1 Ignition loop 1 (driver ’s front airbag), resistance is too high or open-circuit. Can

2 Ignition loop 1 (driver ’s side front airbag), resistance is too low or short-circuit Can

3 Ignition loop 1 (driver ’s side front airbag), grounding Can

4 Ignition loop 1 (driver’s side front airbag), connected to power supply Can

5 Ignition loop 2 (passenger side front airbag), resistance is too high or open-circuit. Can

6 Ignition loop 2 (passenger side front airbag), resistance is too low or short-circuit Can

7 Ignition loop 2 (passenger side front airbag), connect ed t o power supply Can

8 Ignition loop 2 (passenger side front airbag), connect ed t o power supply Can

9 Power voltage is high Can

10 Power voltage is low Can

11 Alarm light failure, connect ed to power supply or lamp is short-circuit Can

12 Alarm lamp is failure- grounding or filament is open-circuit. Can

13 Shortage/failure of algorithm parameter Cannot (replace the

SRS-ECU)

14 The front collision is recorded Cannot (replace the

SRS-ECU)

15 Communication failure Can

16 Internal failure (refer to following table) Cannot (replace the

SRS-ECU)

Page 379 of 425

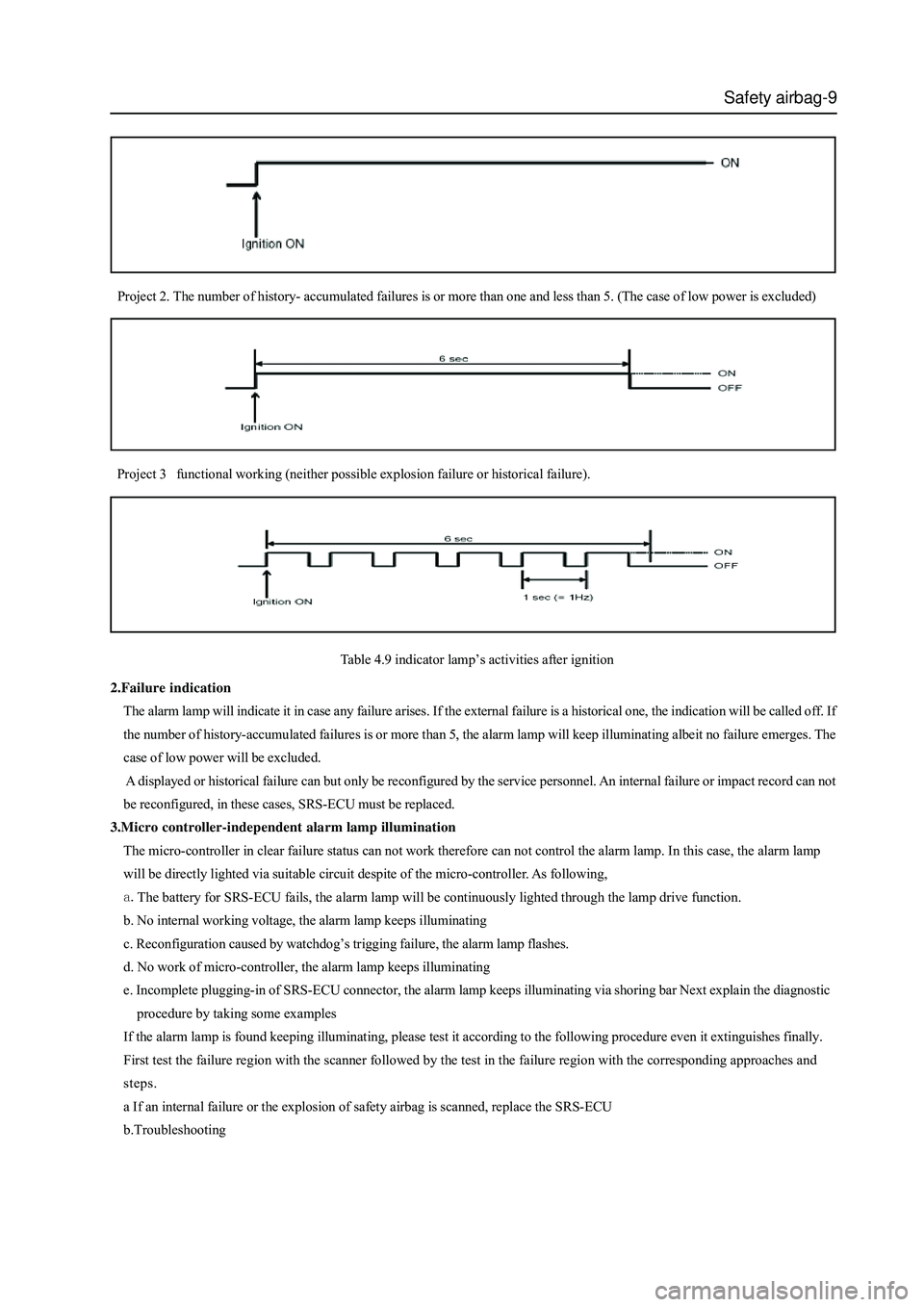

Safety airbag-9

Project 3 functional working (neither possible explosion failure or historical failure).

Table 4.9 indicator lamp’s activities after ignition

2.Failure indication

The alarm lamp will indicate it in case any failure arises. If the external failure is a historical one, the indication will be called off. If

the number of history-accumulated failures is or more than 5, the alarm lamp will keep illuminating albeit no failure emerges. The

case of low power will be excluded.

A displayed or historical failure can but only be reconfigured by the service personnel. An internal failure or impact record can not

be reconfigured, in these cases, SRS-ECU must be replaced.

3.Micro controller-independent alarm lamp illumination

The micro-controller in clear failure status can not work therefore can not control the alarm lamp. In this case, the alarm lamp

will be directly lighted via suitable circuit despite of the micro-controller. As following,

The battery for SRS-ECU fails, the alarm lamp will be continuously lighted through the lamp drive function.

b. No internal working voltage, the alarm lamp keeps illuminating

c. Reconfiguration caused by watchdog’s trigging failure, the alarm lamp flashes.

d. No work of micro-controller, the alarm lamp keeps illuminating

e. Incomplete plugging-in of SRS-ECU connector, the alarm lamp keeps illuminating via shoring bar Next explain the diagnostic

procedure by taking some examples

If the alarm lamp is found keeping illuminating, please test it according to the following procedure even it extinguishes finally.

First test the failure region with the scanner followed by the test in the failure region with the corresponding approaches and

steps.

a If an internal failure or the explosion of safety airbag is scanned, replace the SRS-ECU

b.Troubleshooting Project 2. The number of history- accumulated failures is or more than one and less than 5. (The case of low power is excluded)