engine GREAT WALL HOVER 2006 Service Repair Manual

[x] Cancel search | Manufacturer: GREAT WALL, Model Year: 2006, Model line: HOVER, Model: GREAT WALL HOVER 2006Pages: 425, PDF Size: 26.05 MB

Page 2 of 425

Preface

Since the Great Wall Hover is put into the market, it has won the favor from the customers for its

elegant appearance, excellent performance&price ratio,concept of double area and eternal safety.The car is

furnished with Mitsubishi 4G64 engine.It has both the type of five shifts manual transmission and the type of

automatic transmission as an option. At the same time, there are also options of ABS and safety airbag, etc.

Before of its complex structure, high technical intervention and difficulty of maintenance, its maintenance

needs the reference of related documents. Upon the request of the after-sale maintenance technical personnel

of Great Wall, we have prepared this Hover Maintenance Manual. The manual is oriented towards the after-

sale maintenance technical personnel of the Great Wall, and mainly introduces the disassembly of the various

systems of Hover (refer to the maintenance manual of motor for the introduction of the motor), the

troubleshooting, matters needing attention for maintenance and the related technical parameters.

During the preparation of this book, a lot of professional personnel have given support and help, here we

would like to express our sincere thanks.

Though we have made efforts to prepare this manual earnestly, we cannot guarantee that the content in

the manual is totally accurate and without error. The user cannot raise improper request to the Great Wall

Company with the manual as legal basis. We cannot bear any responsibility for the losses caused by using

this manual. Confined to the knowledge of the editor, the fault and errors are inevitable, your advice and

comment are appreciated.

The final authority for the interpretation of this manual belongs to the Great Wall Motor Co., Ltd.

Page 10 of 425

Overview of the entire car-1

Chapter 1

Overview of the entire car

Basic parameter....................................................... 2

Engine..................................................................... 4

Air inlet system........................................................ 5

Exhaust air system................................................... 5

Fuel supply system................................................... 5

Cooling system........................................................ 5

Clutch..................................................................... 5

Transmission............................................................ 6

Drive shaft............................................................... 6

Front shaft/axle........................................................ 6

Rear axle................................................................. 6

Wheel tyre............................................................... 6

Suspension.............................................................. 7

Frame..................................................................... 7

Steering system........................................................ 7

Brake system........................................................... 8

Car body................................................................. 9

Electrical system.................................................... 10

Air-conditioning system …………………..............12

Page 13 of 425

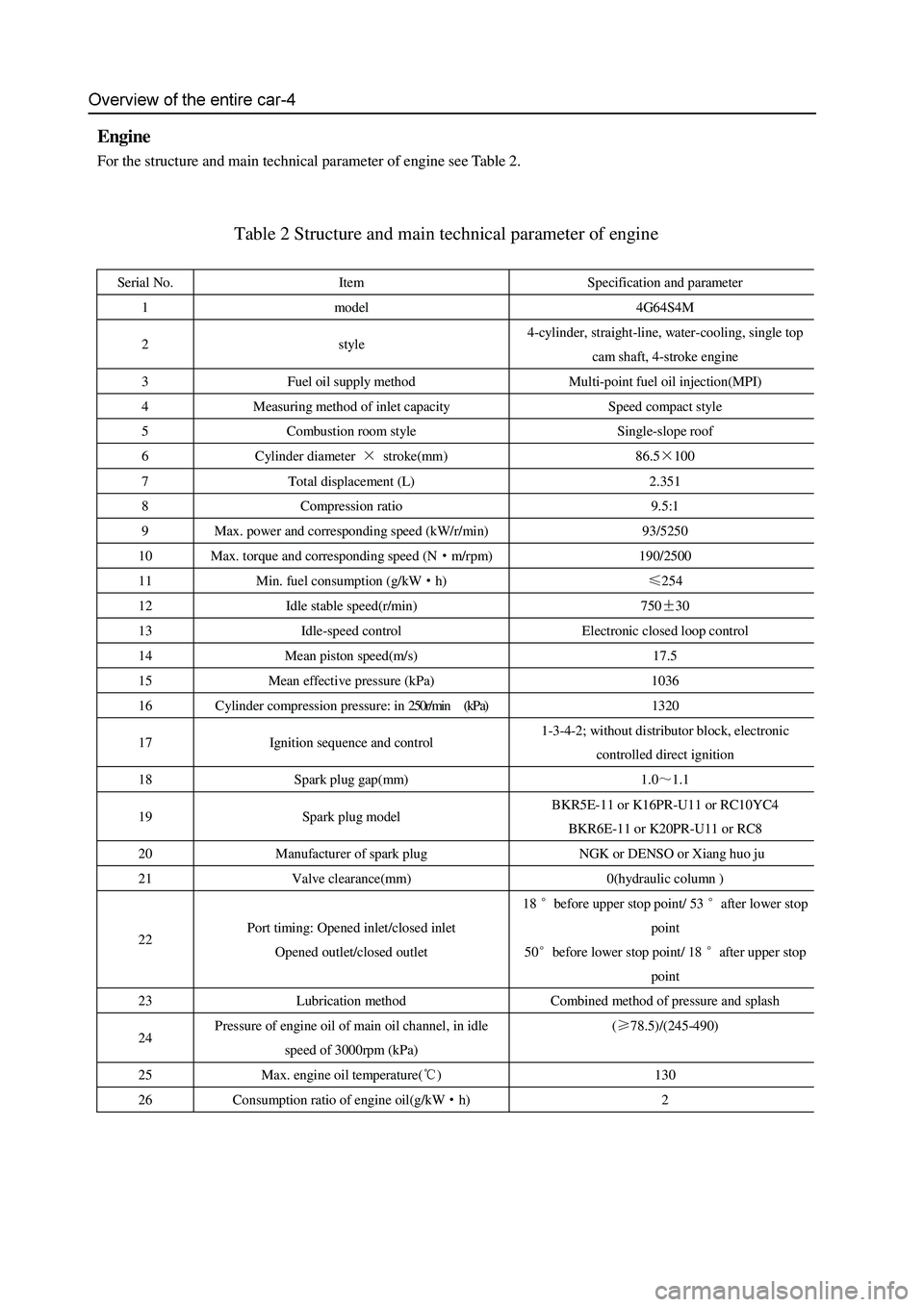

Engine

For the structure and main technical parameter of engine see Table 2.

Table 2 Structure and main technical parameter of engine

Serial No. Item Specification and parameter

1 model 4G64S4M

2 style 4-cylinder, straight-line, water-cooling, single top

cam shaft, 4-stroke engine

3 Fuel oil supply method Multi-point fuel oil injection(MPI)

4 Measuring method of inlet capacity Speed compact style

5 Combustion room style Single-slope roof

6 Cylinder diameter × stroke(mm) 86.5×100

7 Total displacement (L) 2.351

8 Compression ratio 9.5:1

9 Max. power and corresponding speed (kW/r/min) 93/5250

10 Max. torque and corresponding speed (N·m/rpm) 190/2500

11 Min. fuel consumption (g/kW·h) ≤254

12 Idle stable speed(r/min) 750±30

13 Idle-speed control Electronic closed loop control

14 Mean piston speed(m/s) 17.5

15 Mean effective pressure (kPa) 1036

1 6 C y l i n d e r c o m p r e s s i o n p r e s s u r e : i n 250r/min (kPa) 1 3 2 0

17 Ignition sequence and control 1-3-4-2; without distributor block, electronic

controlled direct ignition

18 Spark plug gap(mm) 1.0~1.1

19 Spark plug model BKR5E-11 or K16PR-U11 or RC10YC4

BKR6E-11 or K20PR-U11 or RC8

20 Manufacturer of spark plug NGK or DENSO or Xiang huo ju

21 Valve clearance(mm) 0(hydraulic column )

22 Port timing: Opened inlet/closed inlet

Opened outlet/closed outlet 18 °before upper stop point/ 53 °after lower stop

point

50°before lower stop point/ 18 °after upper stop

point

23 Lubrication method Combined method of pressure and splash

24 Pressure of engine oil of main oil channel, in idle

speed of 3000rpm (kPa) (≥78.5)/(245-490)

25 Max. engine oil temperature(℃) 130

26 Consumption ratio of engine oil(g/kW·h) 2

Page 14 of 425

Overview of the entire car-5

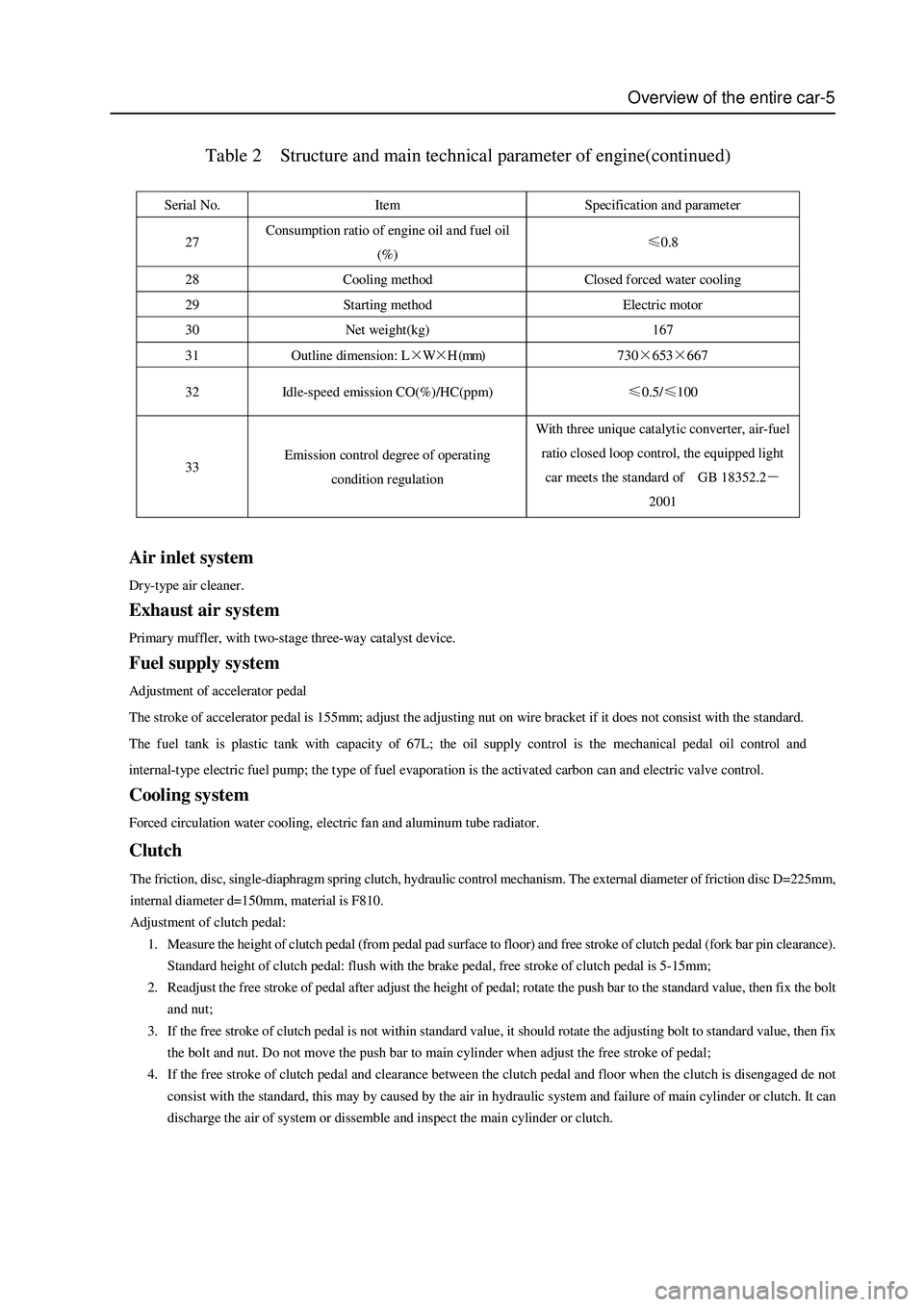

The friction, disc, single-diaphragm spring clutch, hydraulic control mechanism. The external diameter of friction disc D=225mm,

internal diameter d=150mm, material is F810.

Adjustment of clutch pedal:

1. Measure the height of clutch pedal (from pedal pad surface to floor) and free stroke of clutch pedal (fork bar pin clearance).

Standard height of clutch pedal: flush with the brake pedal, free stroke of clutch pedal is 5-15mm;

2. Readjust the free stroke of pedal after adjust the height of pedal; rotate the push bar to the standard value, then fix the bolt

and nut;

3. If the free stroke of clutch pedal is not within standard value, it should rotate the adjusting bolt to standard value, then fix

the bolt and nut. Do not move the push bar to main cylinder when adjust the free stroke of pedal;

4. If the free stroke of clutch pedal and clearance between the clutch pedal and floor when the clutch is disengaged de not

consist with the standard, this may by caused by the air in hydraulic system and failure of main cylinder or clutch. It can

discharge the air of system or dissemble and inspect the main cylinder or clutch.

Table 2 Structure and main technical parameter of engine(continued)

Serial No. Item Specification and parameter

27 Consumption ratio of engine oil and fuel oil

(%) ≤0.8

28 Cooling method Closed forced water cooling

29 Starting method Electric motor

30 Net weight(kg) 167

31 Outline dimension: L×W×H (mm) 730×653×667

32 Idle-speed emission CO(%)/HC(ppm) ≤0.5/≤100

33 Emission control degree of operating

condition regulation With three unique catalytic converter, air-fuel

ratio closed loop control, the equipped light

car meets the standard of GB 18352.2-

2001

Air inlet system

Dry-type air cleaner.

Exhaust air system

Primary muffler, with two-stage three-way catalyst device.

Fuel supply system

Adjustment of accelerator pedal

The stroke of accelerator pedal is 155mm; adjust the adjusting nut on wire bracket if it does not consist with the standard.

The fuel tank is plastic tank with capacity of 67L; the oil supply control is the mechanical pedal oil control and

internal-type electric fuel pump; the type of fuel evaporation is the activated carbon can and electric valve control.

Cooling system

Forced circulation water cooling, electric fan and aluminum tube radiator.

Clutch

Page 16 of 425

Overview of the entire car-7

Suspension

The front suspension is the torsion bar spring, double-cylinder inflatable hydraulic damper, transverse stabilizer rod, double

cross-arm independent suspension. The distance between the center of front shaft of lower arm fixing nut and level ground is

295mm±1mm.

The rear suspension is the four-connecting rod, coil spring, double-cylinder inflatable hydraulic damper, transverse stabilizer

rod, no indep endent suspension.

Carriage

Peripheral trapezoidal structure; welded by two box section longitudinal beams and several box or tube section cross beams.

Steering system

Pinion-and-rack power steering-gear, hydraulic assists steering. Breakaway front steering trapezoidal structure. Diameter of

quadriradistus steering disc φ380mm, adjustable angle, power-absorbing steering pipe. For main technical parameters of

steering s ystem refer to Table 5.

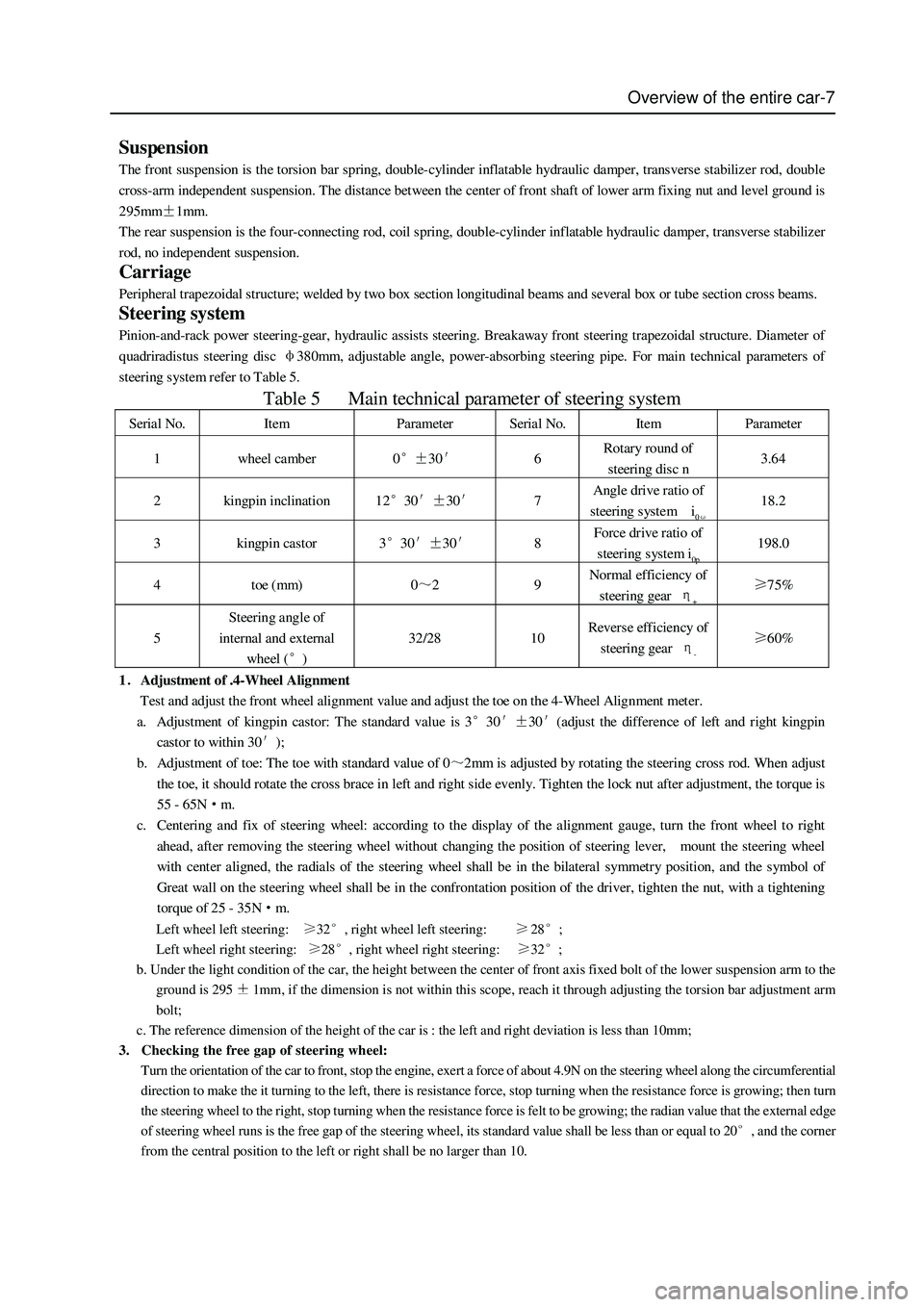

Table 5 Main technical parameter of steering system

Serial No. Item Parameter Serial No. Item Parameter

1 wheel camber 0°±30′ 6 Rotary round of

steering disc n 3.64

2 kingpin inclination 12°30′±30′ 7 Angle drive ratio of

steering system i0ω 18.2

3 kingpin castor 3°30′±30′ 8 Force drive ratio of

steering s ystem i0p 198.0

4 toe (mm) 0~2 9 Normal efficiency of

steering gear η+ ≥75%

5 Steering angle of

internal and external

wheel (°) 32/28 10 Revers e efficiency of

steering gear η- ≥60%

1.Adjustment of .4-Wheel Alignment

Test and adjust the front wheel alignment value and adjust the toe on the 4-Wheel Alignment meter.

a. Adjustment of kingpin castor: The standard value is 3°30′±30′(adjust the difference of left and right kingpin

castor to within 30′);

b. Adjustment of toe: The toe with standard value of 0~2mm is adjusted by rotating the steering cross rod. When adjust

the toe, it should rotate the cross brace in left and right side evenly. Tighten the lock nut after adjustment, the torque is

55 - 65N·m.

c. Centering and fix of steering wheel: according to the display of the alignment gauge, turn the front wheel to right

ahead, after removing the steering wheel without changing the position of steering lever, mount the steering wheel

with center aligned, the radials of the steering wheel shall be in the bilateral symmetry position, and the symbol of

Great wall on the steering wheel shall be in the confrontation position of the driver, tighten the nut, with a tightening

torque of 25 - 35N·m.

Left wheel left steering: 32, right wheel left steering:28;

Left wheel right steering:

28, right wheel right steering: 32;

b. Under the light condition of the car, the height between the center of front axis fixed bolt of the lower suspension arm to the

ground is 295

1mm, if the dimension is not within this scope, reach it through adjusting the torsion bar adjustment arm

bolt;

c. The reference dimension of the height of the car is : the left and right deviation is less than 10mm;

3. Checking the free gap of steering wheel:

Turn the orientation of the car to front, stop the engine, exert a force of about 4.9N on the steering wheel along the circumferential

direction to make the it turning to the left, there is resistance force, stop turning when the resistance force is growing; then turn

the steering wheel to the right, stop turning when the resistance force is felt to be growing; the radian value that the external edge

of steering wheel runs is the free gap of the steering wheel, its standard value shall be less than or equal to 20

, and the corner

from the central position to the left or right shall be no larger than 10.

Page 17 of 425

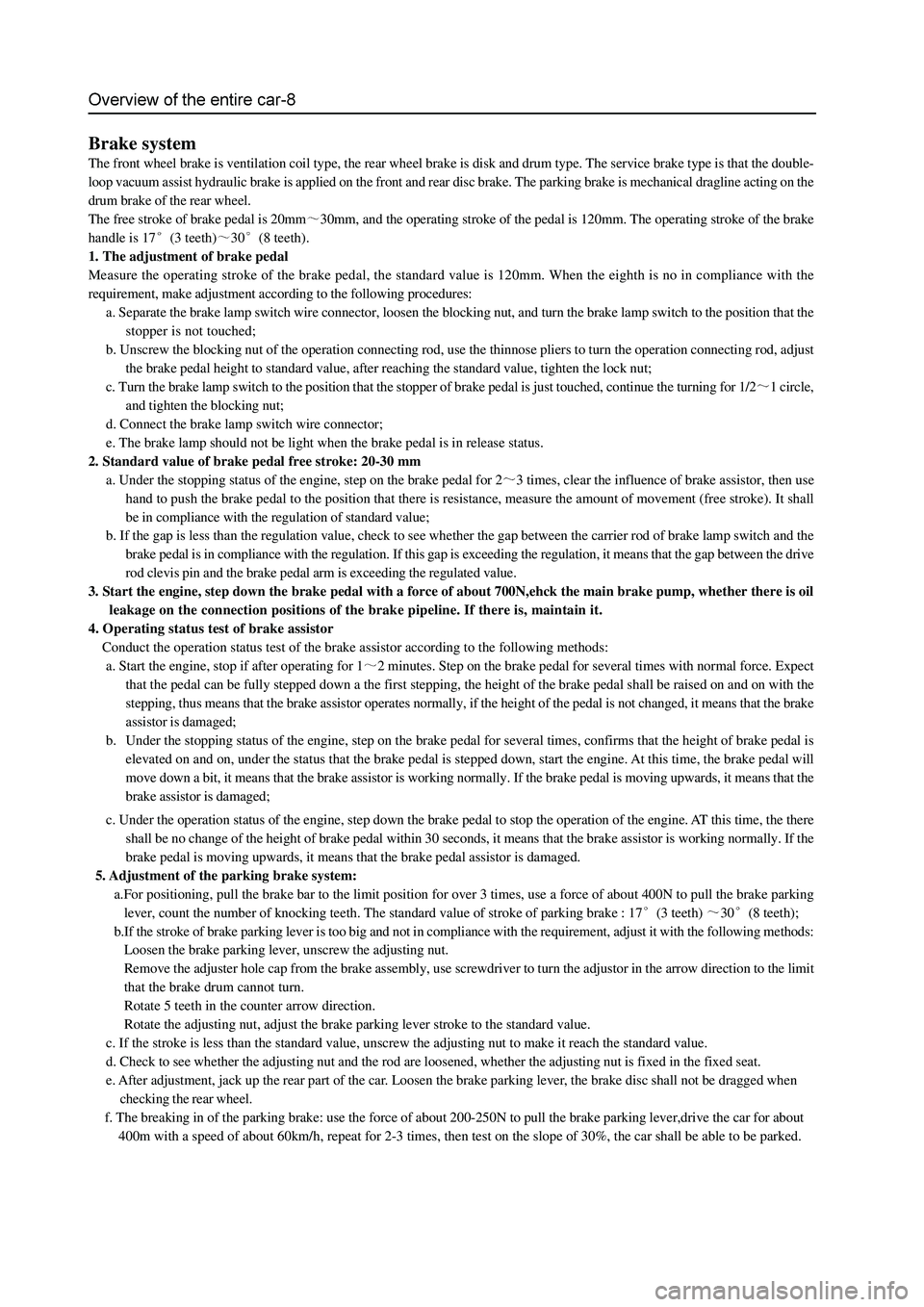

Brake system

The front wheel brake is ventilation coil type, the rear wheel brake is disk and drum type. The service brake type is that the double-

loop vacuum assist hydraulic brake is applied on the front and rear disc brake. The parking brake is mechanical dragline acting on the

drum brake of the rear wheel.

The free stroke of brake pedal is 20mm

30mm, and the operating stroke of the pedal is 120mm. The operating stroke of the brake

handle is 17

(3 teeth)30(8 teeth).

1. The adjustment of brake pedal

Measure the operating stroke of the brake pedal, the standard value is 120mm. When the eighth is no in compliance with the

requirement, make adjustment according to the following procedures:

a. Separate the brake lamp switch wire connector, loosen the blocking nut, and turn the brake lamp switch to the position that the

stopper is not touched;

b. Unscrew the blocking nut of the operation connecting rod, use the thinnose pliers to turn the operation connecting rod, adjust

the brake pedal height to standard value, after reaching the standard value, tighten the lock nut;

c. Turn the brake lamp switch to the position that the stopper of brake pedal is just touched, continue the turning for 1/2

1 circle,

and tighten the blocking nut;

d. Connect the brake lamp switch wire connector;

e. The brake lamp should not be light when the brake pedal is in release status.

2. Standard value of brake pedal free stroke: 20-30 mm

a. Under the stopping status of the engine, step on the brake pedal for 2

3 times, clear the influence of brake assistor, then use

hand to push the brake pedal to the position that there is resistance, measure the amount of movement (free stroke). It shall

be in compliance with the regulation of standard value;

b. If the gap is less than the regulation value, check to see whether the gap between the carrier rod of brake lamp switch and the

brake pedal is in compliance with the regulation. If this gap is exceeding the regulation, it means that the gap between the drive

rod clevis pin and the brake pedal arm is exceeding the regulated value.

3. Start the engine, step down the brake pedal with a force of about 700N,ehck the main brake pump, whether there is oil

leakage on the connection positions of the brake pipeline. If there is, maintain it.

4. Operating status test of brake assistor

Conduct the operation status test of the brake assistor according to the following methods:

a. Start the engine, stop if after operating for 1

2 minutes. Step on the brake pedal for several times with normal force. Expect

that the pedal can be fully stepped down a the first stepping, the height of the brake pedal shall be raised on and on with the

stepping, thus means that the brake assistor operates normally, if the height of the pedal is not changed, it means that the brake

assistor is damaged;

b. Under the stopping status of the engine, step on the brake pedal for several times, confirms that the height of brake pedal is

elevated on and on, under the status that the brake pedal is stepped down, start the engine. At this time, the brake pedal will

move down a bit, it means that the brake assistor is working normally. If the brake pedal is moving upwards, it means that the

brake assistor is damaged;

c. Under the operation status of the engine, step down the brake pedal to stop the operation of the engine. AT this time, the there

shall be no change of the height of brake pedal within 30 seconds, it means that the brake assistor is working normally. If the

brake pedal is moving upwards, it means that the brake pedal assistor is damaged.

5. Adjustment of the parking brake system:

a.For positioning, pull the brake bar to the limit position for over 3 times, use a force of about 400N to pull the brake parking

lever, count the number of knocking teeth. The standard value of stroke of parking brake : 17

(3 teeth) 30(8 teeth);

b.If the stroke of brake parking lever is too big and not in compliance with the requirement, adjust it with the following methods:

Loosen the brake parking lever, unscrew the adjusting nut.

Remove the adjuster hole cap from the brake assembly, use screwdriver to turn the adjustor in the arrow direction to the limit

that the brake drum cannot turn.

Rotate 5 teeth in the counter arrow direction.

Rotate the adjusting nut, adjust the brake parking lever stroke to the standard value.

c. If the stroke is less than the standard value, unscrew the adjusting nut to make it reach the standard value.

d. Check to see whether the adjusting nut and the rod are loosened, whether the adjusting nut is fixed in the fixed seat.

e. After adjustment, jack up the rear part of the car. Loosen the brake parking lever, the brake disc shall not be dragged when

checking the rear wheel.

f. The breaking in of the parking brake: use the force of about 200-250N to pull the brake parking lever,drive the car for about

400m with a speed of about 60km/h, repeat for 2-3 times, then test on the slope of 30%, the car shall be able to be parked.

Page 18 of 425

Overview of the entire car-9

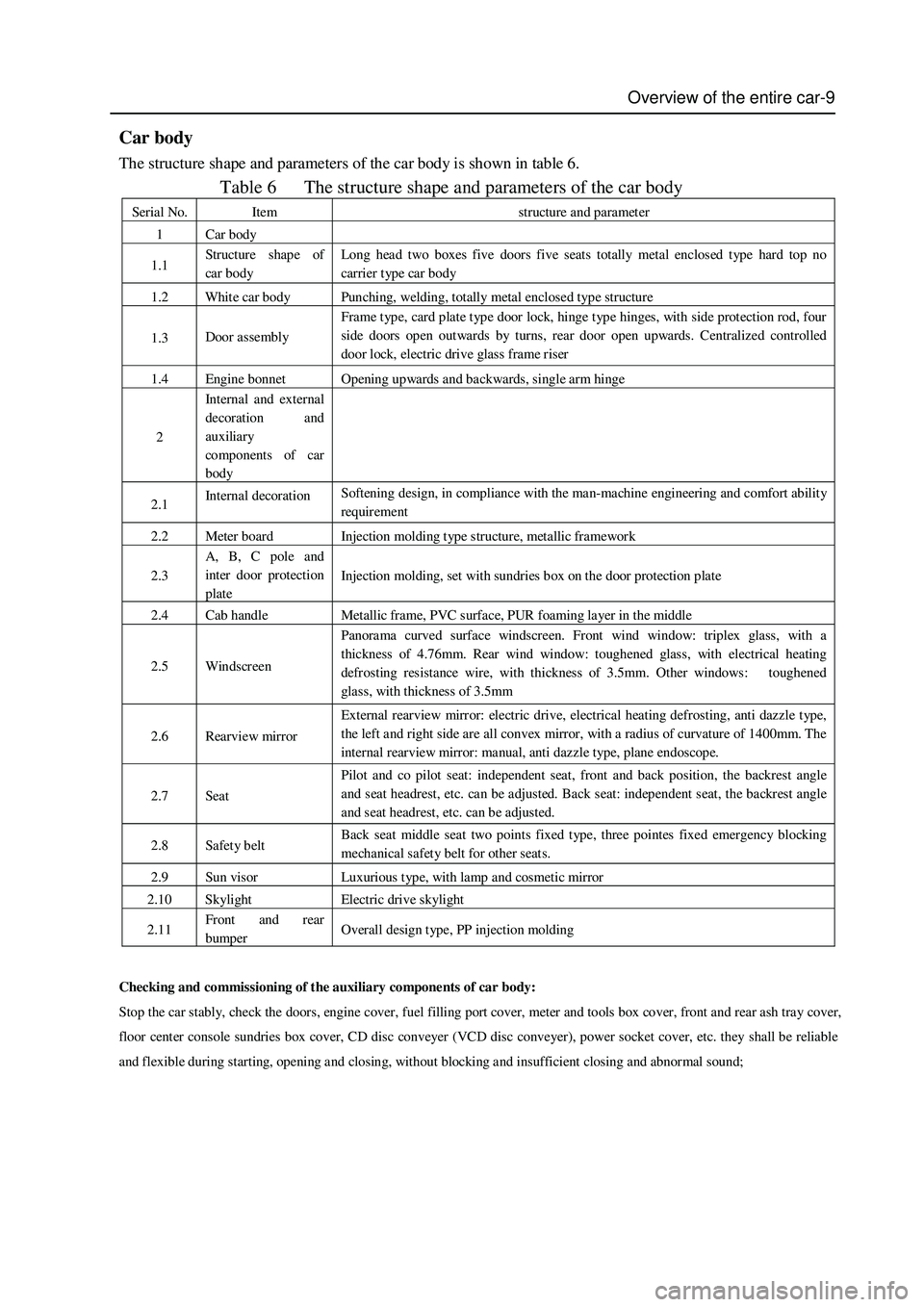

Car body

The structure shape and parameters of the car body is shown in table 6.

Table 6 The structure shape and parameters of the car body

Serial No. Item structure and parameter

1 Car body

1.1 Structure shap e of

car body Long head two boxes five doors five seats totally metal enclosed type hard top no

carrier t yp e car body

1.2 White car body Punching, welding, totally metal enclosed type structure

1.3 Door assembly Frame type, card plate type door lock, hinge type hinges, with side protection rod, four

side doors open outwards by turns, rear door open upwards. Centralized controlled

door lock, electric drive glass frame riser

1.4 Engine bonnet Opening upwards and backwards, single arm hinge

2 Int ernal and external

decoration and

auxiliary

components of car

body

2.1 Internal decoration Softening design, in compliance with the man-machine engineering and comfort ability

requirement

2.2 Meter board Injection molding type structure, metallic framework

2.3 A, B, C pole and

inter door protection

plate Injection molding, set with sundries box on the door protection plate

2.4 Cab handle Metallic frame, PVC surface, PUR foaming layer in the middle

2.5 Windscreen Panorama curved surface windscreen. Front wind window: triplex glass, with a

thickness of 4.76mm. Rear wind window: toughened glass, with electrical heating

defrosting resistance wire, with thickness of 3.5mm. Other windows: toughened

glass, with thickness of 3.5mm

2.6 Rearview mirror External rearview mirror: electric drive, electrical heating defrosting, anti dazzle type,

the left and right side are all convex mirror, with a radius of curvature of 1400mm. The

internal rearview mirror: manual, anti dazzle type, plane endoscope.

2.7 Seat Pilot and co pilot seat: independent seat, front and back position, the backrest angle

and seat headrest, etc. can be adjusted. Back seat: independent seat, the backrest angle

and seat headrest, etc. can be adjusted.

2.8 Safety belt Back seat middle seat two points fixed type, three pointes fixed emergency blocking

mechanical safety belt for other seats.

2.9 Sun visor Luxurious type, with lamp and cosmetic mirror

2.10 Skylight Electric drive skylight

2.11 Front and rear

bumper Overall design type, PP injection molding

Checking and commissioning of the auxiliary components of car body:

Stop the car stably, check the doors, engine cover, fuel filling port cover, meter and tools box cover, front and rear ash tray cover,

floor center console sundries box cover, CD disc conveyer (VCD disc conveyer), power socket cover, etc. they shall be reliable

and flexible during starting, opening and closing, without blocking and insufficient closing and abnormal sound;

Page 19 of 425

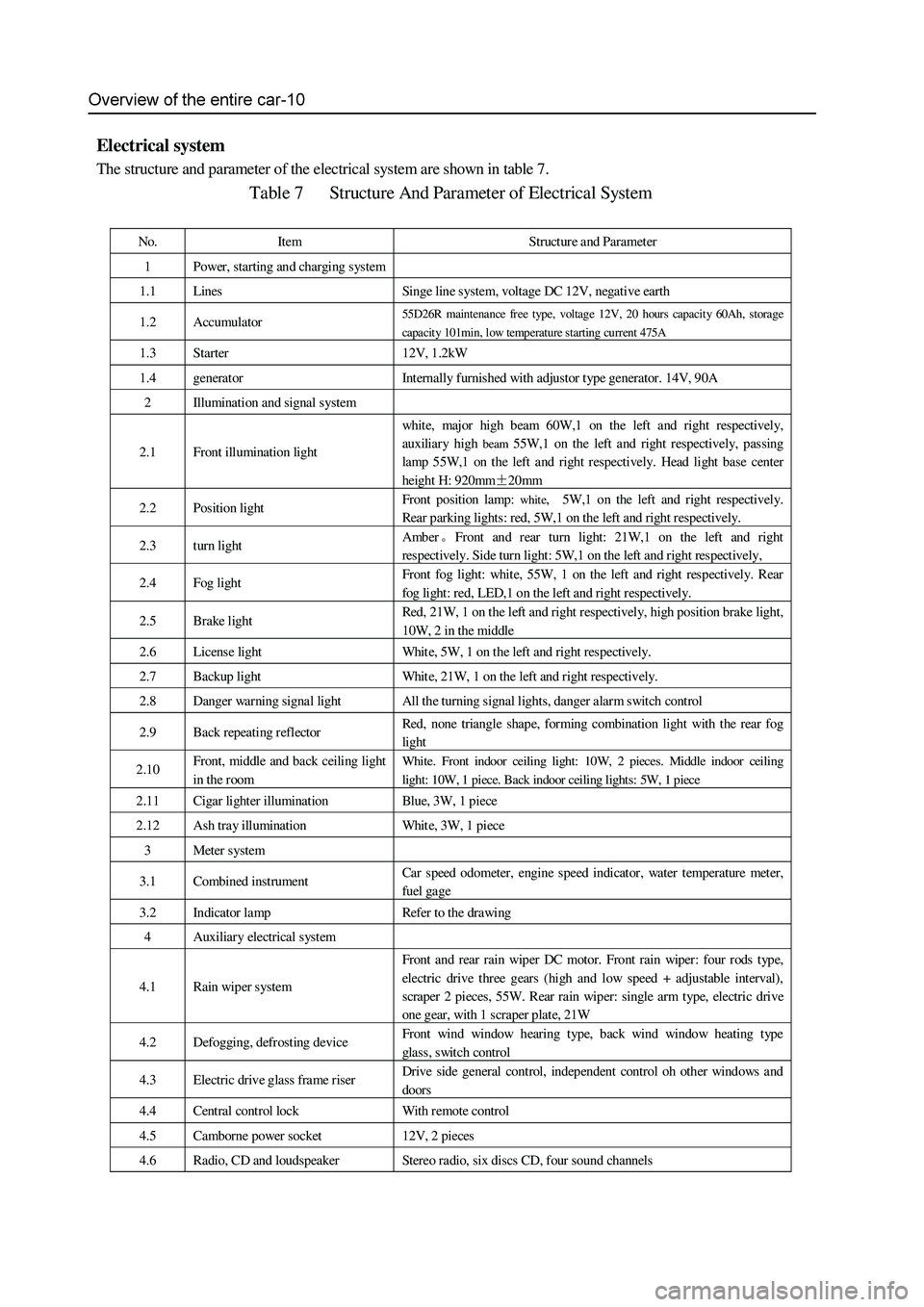

Electrical system

The structure and parameter of the electrical system are shown in table 7.

Table 7 Structure And Parameter of Electrical System

No. Item Structure and Parameter

1 Power, starting and charging system

1.1 Lines Singe line system, voltage DC 12V, negative earth

1.2 Accumulator 55D26R maintenance free type, voltage 12V, 20 hours capacity 60Ah, storage

capacity 101min, low temperature starting current 475A

1.3 Starter 12V, 1.2kW

1.4 generator Internally furnished with adjustor type generator. 14V, 90A

2 Illumination and signal s ystem

2.1 Front illumination light

white, major high beam 60W,1 on the left and right respectively,

auxiliary high

beam 55W,1 on the left and right respectively, passing

lamp 55W,1 on the left and right respectively. Head light base center

height H: 920mm±20mm

2.2 Position light Front position lamp: white, 5W,1 on the left and right respectively.

Rear parking lights: red, 5W,1 on the left and right respectively.

2.3 turn light Amber。Front and rear turn light: 21W,1 on the left and right

respectively. Side turn light: 5W,1 on the left and right respectively,

2.4 Fog light Front fog light: white, 55W, 1 on the left and right respectively. Rear

fog light: red, LED,1 on the left and right respectively.

2.5 Brake light Red, 21W, 1 on the left and right respectively, high position brake light,

10W, 2 in the middle

2.6 License light White, 5W, 1 on the left and right respectively.

2.7 Backup light White, 21W, 1 on the left and right respectively.

2.8 Danger warning signal light All the turning signal lights, danger alarm switch control

2.9 Back repeating reflector Red, none triangle shape, forming combination light with the rear fog

light

2.10 Front, middle and back ceiling light

in the room White. Front indoor ceiling light: 10W, 2 pieces. Middle indoor ceiling

light: 10W, 1 piece. Back indoor ceiling lights: 5W, 1 piece

2.11 Cigar lighter illumination Blue, 3W, 1 piece

2.12 Ash tray illumination White, 3W, 1 piece

3 Meter system

3.1 Combined instrument Car speed odometer, engine speed indicator , water t emperature met er,

fuel gage

3.2 Indicator lamp Refer to the drawing

4 Auxiliary electrical system

4.1 Rain wiper system Front and rear rain wiper DC motor. Front rain wiper: four rods type,

electric drive three gears (high and low speed + adjustable interval),

scraper 2 pieces, 55W. Rear rain wiper: single arm type, electric drive

one gear, with 1 scraper plate, 21W

4.2 Defogging, defrosting device Front wind window hearing type, back wind window heating type

glass, switch control

4.3 Electric drive glass frame riser Drive side general control, independent control oh other windows and

doors

4.4 Central control lock With r emote control

4.5 Camborne power socket 12V, 2 pieces

4.6 Radio, CD and loudspeaker Stereo radio, six discs CD, four sound channels

Page 20 of 425

Overview of the entire car-11

4.7 Cigar lighter 12V, 1 piece

4.8 Horn Treble and bass

4.9 Safety airbag Electric main and auxiliary airbag

Checking and commissioning of the auxiliary components of car body:

1. Stop the car stably, check the doors, engine cover, fuel filling port cover, meter and tools box cover, front and rear ash

tray cover, floor center console sundries box cover, CD disc conveyer (VCD disc conveyer), power socket cover, etc. they

shall be reliable and flexible during starting, opening and closing, without blocking and insufficient closing and

abnormal sound;

2. The major lamp high beam and city beam, the alternating light, taillight, turn light, brake light, front and rear mist

light, malfunction alarm light, indoor light, instrument panel light, ignition switch light, etc. shall operate normally,

without the failure of no lighting,constant lighting and error lighting , etc;

3. Checking the performance of front head light

a. The high beam luminous intensity of each head light

20000 cd/ piece

b. Beam center left and right deviation (when the beam is irradiating on the screen of 10 m away):

Left light high beam: left 17 cm right 35 cm

Right light high beam: left 35 cm right 35 cm

Left light city beam: left 17 cm right 35 cm

Right light city beam: left 17 cm right 35 cm

c. Beam center height (when the beam is irradiating on the screen of 10 m away):

Head light city beam 0.7

0.9 H; head light high beam 0.91.0 H

H means the head light center height 920

20mm.

4. The adjustment of multi functional meter:

a. Drive the car onto the trench, insert the car speed transducer, drive the car to open places, press the ADJ switch for no less than

3 seconds, the orientation indicator begins to flash. Drive the car slowly for one circle within 2 minutes, the orientation

indicator will stop flashing, it shall points to the practical normal direction.

Note: E

east, Wwest, Ssouth, Nnorth.

b. The adjustment of time:

Press the “MODE” switch for over 2 seconds, the time can be adjusted, press the MODE switch to adjust the minute, then

press the MODE again to adjust the hour, adjust the time through pressing the “

”and “” key. After the time is adjusted,

press the ”MODE” switch for over 2 seconds to quit the time adjustment mode.

c. Check to see whether the absolute altitude meter and the car speed response display are working normally.

d. Drive the car onto the trench again, pull off the car speed transducer plug.

5. The adjustment of rain wiper nozzle cleaning mixture ejection height:

a. Put the ignition switch to the ”ON” position, open the rain wiper nozzle switch, the position of front cleaning mixture nozzle

shall be evenly distributed along the middle height of the front windshield glass from left to right.

b. The position of the rear cleaning mixture nozzle is deviated to right of the center of rear windshield glass for about 20mm-

120mm, and the height is within the scope of 50mm at the center of the glass. If the deviation is large, the nozzle needs to be

adjusted.

Page 26 of 425

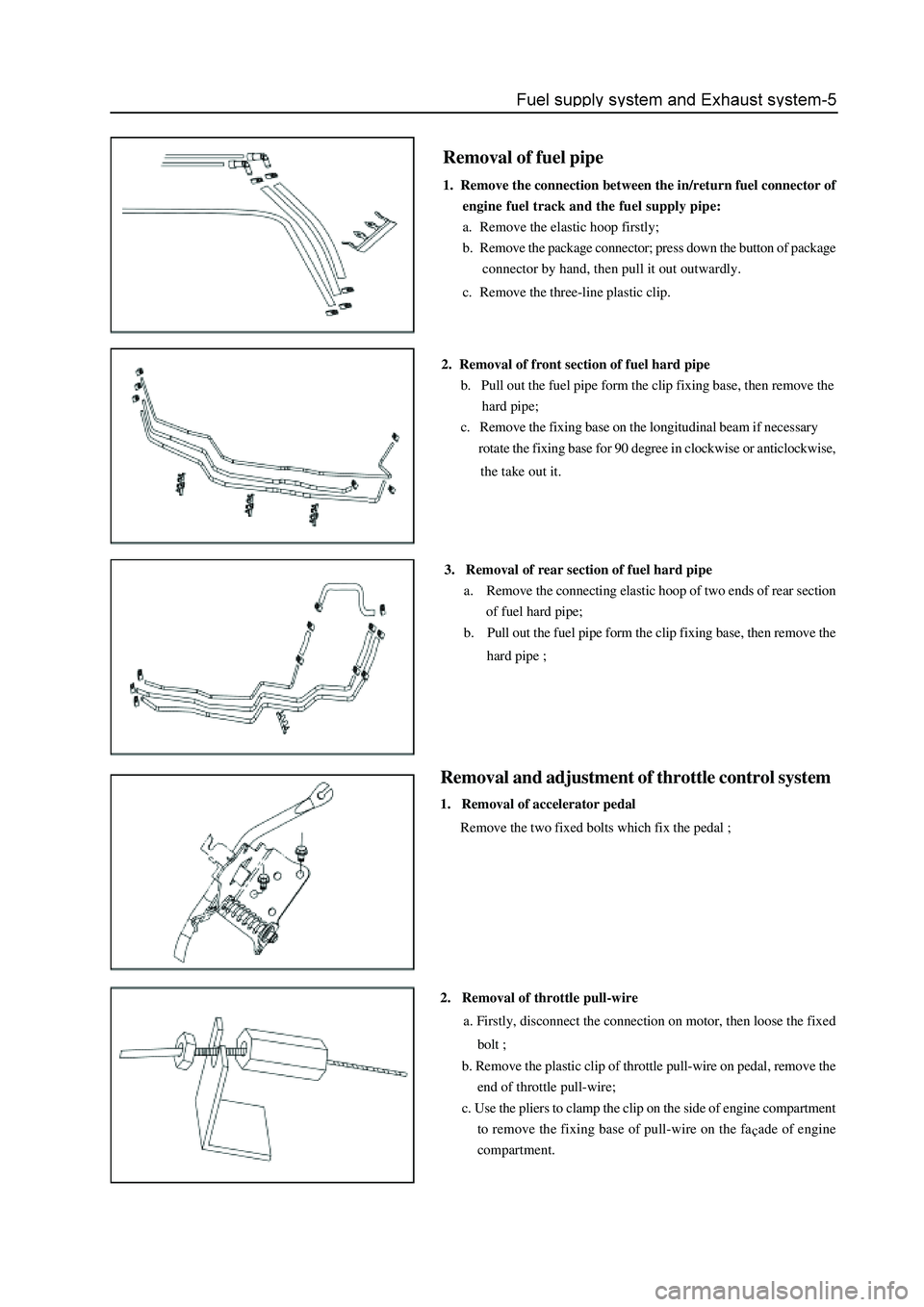

Removal of fuel pipe

1. Remove the connection between the in/return fuel connector of

engine fuel track and the fuel supply pipe:

a. Remove the elastic hoop firstly;

b. Remove the package connector; press down the button of package

connector by hand, then pull it out outwardly.

c. Remove the three-line plastic clip.

2. Removal of front section of fuel hard pipe

b. Pull out the fuel pipe form the clip fixing base, then remove the

hard pipe;

c. Remove the fixing base on the longitudinal beam if necessary

rotate the fixing base for 90 degree in clockwise or anticlockwise,

the take out it.

3. Removal of rear section of fuel hard pipe

a. Remove the connecting elastic hoop of two ends of rear section

of fuel hard pipe;

b. Pull out the fuel pipe form the clip fixing base, then remove the

hard pipe ;

Removal and adjustment of throttle control system

1. Removal of accelerator pedal

Remove the two fixed bolts which fix the pedal ;

2. Removal of throttle pull-wire

a. Firstly, disconnect the connection on motor, then loose the fixed

bolt ;

b. Remove the plastic clip of throttle pull-wire on pedal, remove the

end of throttle pull-wire;

c. Use the pliers to clamp the clip on the side of engine compartment

to remove the fixing base of pull-wire on the fa

ade of engine

compartment.