check oil GREAT WALL HOVER 2006 Service Owner's Guide

[x] Cancel search | Manufacturer: GREAT WALL, Model Year: 2006, Model line: HOVER, Model: GREAT WALL HOVER 2006Pages: 425, PDF Size: 26.05 MB

Page 258 of 425

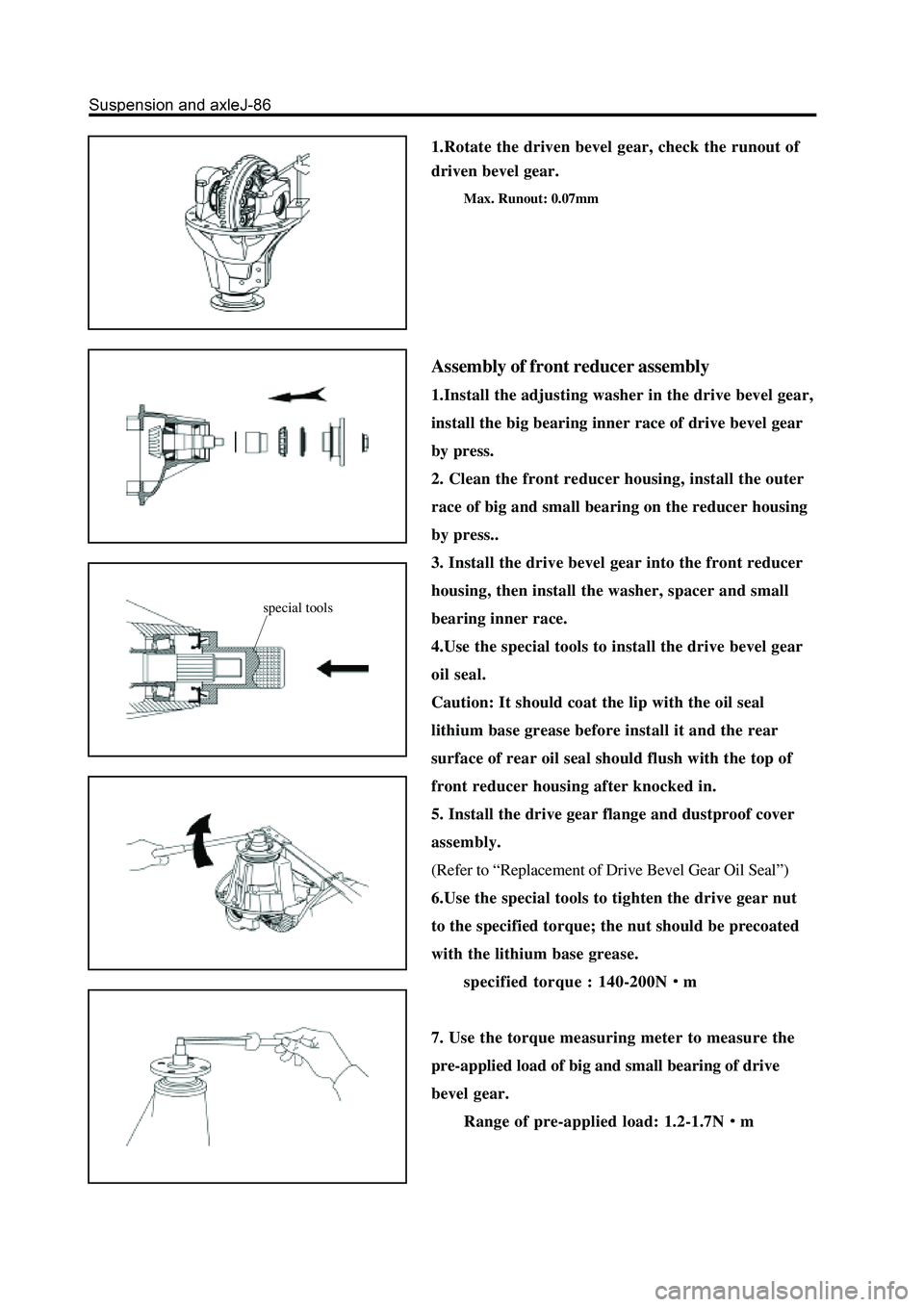

1.Rotate the driven bevel gear, check the runout of

driven bevel gear.

Max. Runout: 0.07mm

Assembly of front reducer assembly

1.Install the adjusting washer in the drive bevel gear,

install the big bearing inner race of drive bevel gear

by press.

2. Clean the front reducer housing, install the outer

race of big and small bearing on the reducer housing

by press..

3. Install the drive bevel gear into the front reducer

housing, then install the washer, spacer and small

bearing inner race.

4.Use the special tools to install the drive bevel gear

oil seal.

Caution: It should coat the lip with the oil seal

lithium base grease before install it and the rear

surface of rear oil seal should flush with the top of

front reducer housing after knocked in.

5. Install the drive gear flange and dustproof cover

assembly.

(Refer to “Replacement of Drive Bevel Gear Oil Seal”)

6.Use the special tools to tighten the drive gear nut

to the specified torque; the nut should be precoated

with the lithium base grease.

specified torque : 140-200N

m

7. Use the torque measuring meter to measure the

pre-applied load of big and small bearing of drive

bevel gear.

Range of pre-applied load: 1.2-1.7N

m

special tools

Page 263 of 425

23. Use the bolt coated with screw lock agent toconnect

the clump weight bracket welded assembly to the front

reducer housing and tighten it to the specified torque.

Specified torque : 20-26Nm

24.Use the bolt coated with screw lock agent to

connect the clump weight assembly to the clump

weight bracket assembly and tighten it to the speci-

fied torque.

Specified torque : 20-26Nm

The amount of screw lock agent could cover the screw.

25.Use the pneumaticto screw two studs on the correspon

ding screw hole on the front axle housing until the

limitation.

26. Coat the plane of front axle housing with the

continuous 1596 silicon rubber plane sealant, scrape

it to level by plate.

Caution: Avoid the screw hole when paint the sealant; prevent

the sealant enters into the screw hole.

27. Install the front reducer assembly on the front

drive axle housing and screw on the hexagon bolt and

spring washer combination; cap the spring washer on

the stud, tighten the nut to the specified torque.

(The screw of all bolts should be precoated with screw lock agent)

The specified tightening force of hexagon bolt and spring washer

combination, stud and nut should be: 18-25N

m

Caution: The bolt should be tightened in diagonal sequence

evenly; check the reducer housing and axle housing contacting

surface for gap; check the sealant from break. It should

remove the reducer for reinstallation if has the gap or break.

28. Screw the oil filling plug with washer on the front

drive axle.

Caution: Do not tighten it.

29. Screw the oil drain plug on the front drive axle.

Specified torque : 30-35Nm

30. Use the special tools to install the major semiaxle

oil seal in the front axle tube.

Caution: Precoat the lip of oil seal with thin lithium base grease

and the oil seal should be installed in position.

(It should coat the screw of the stud which is screwed

in the front axle housing with the screw lock agent, and

the amount should be just can cover the screw which is

screw in the front axle housing)

Caution: The position of stud should consist with that before

disassembly.

Page 269 of 425

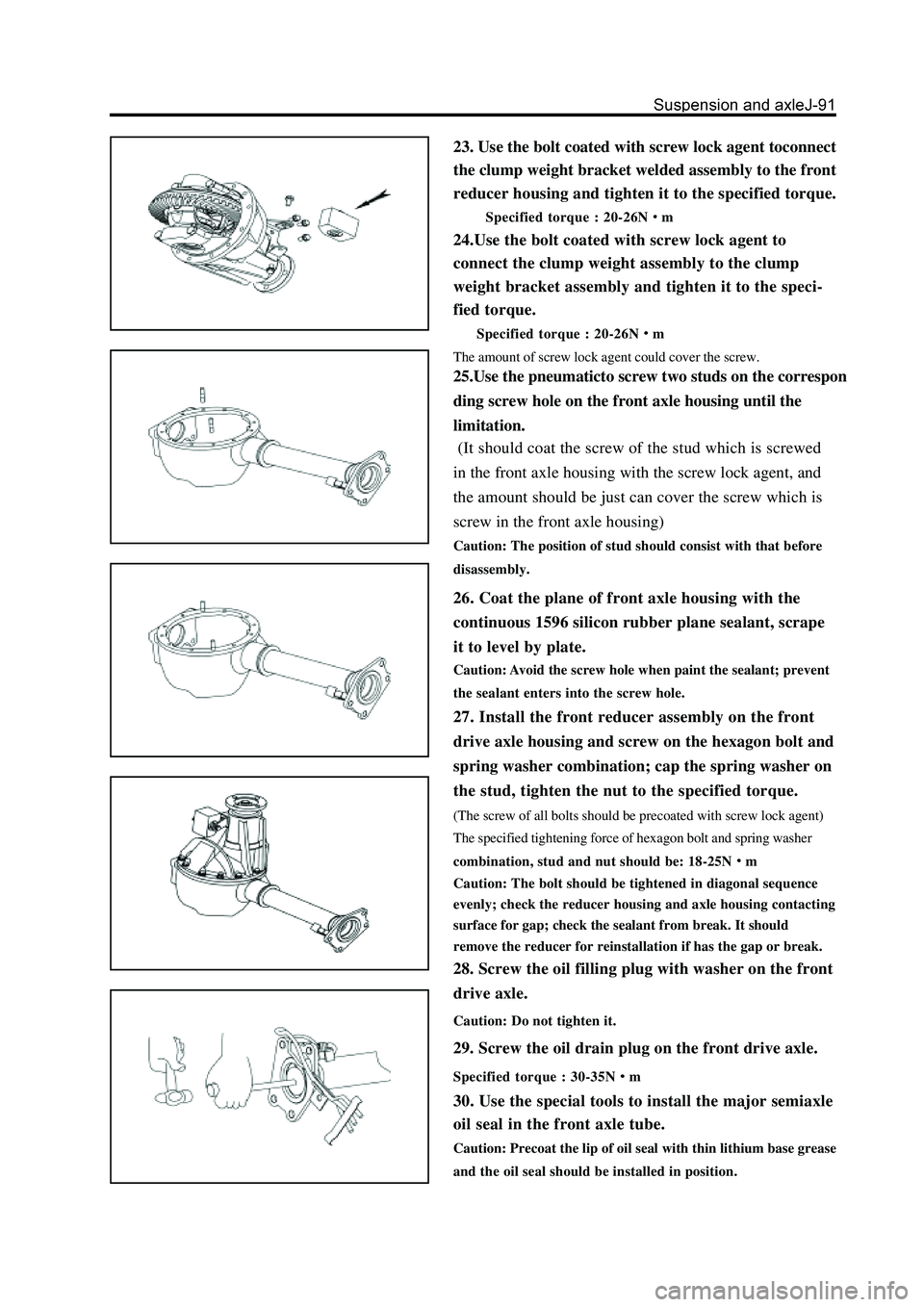

limitationlimitationCheck and repair of rear axle components

1. Check the rear axle and flange for wear, damage

and run-out.

Max. Run-out of axle: 2mm

Max. Run-out of flange: 0.2mm

It should replace the rear axle if the rear axle or flange is worn or

damaged, or the measured run-out is beyond the specified value.

2. Check the external oil seal

a. Check for the wear or damage; especially for the lip of oil seal.

b. Replace it if necessary.

3. Check the bearing and oil seal holder

Check for wear and damage, replace it if necessary.

4. Remove the bearing and oil seal holder

a. Move the brake and oil seal pressing block to the limit position

along flange direction; move the external oil seal to the limit

position of oil seal.

b. Place the hook of the special tools in sequence, the position is

shown as figure; make the hook holds the bearing tightly; then

use the bolt to connect the hook to the hammer fixedly; at last,

place it on the pad with halfaxle spline end facing ground.

c. Hold the hammer to beat downwardly with force for several

times to remove the bearing and oil seal holder.

Caution: Do not damage the oil seal .

5. Install the new external oil seal

a. Clean the semiaxle.

b. Coat the lip of external oil seal with proper HP-R grease.

Caution: When install the oil seal, the lip of oil seal must not

contact the semishaft to avoid scratching the oil seal .

6. Replace the bearing and oil seal holder

a. Heat the oil seal pressing block in 22# engine oil to 100.

Caution: The end of oil seal pressing block with larger chamfer

faces the halfaxle spline. Install it immediately after taken out.

b. Use the hydraulic press to install the new bearing and new oil

seal pressing block by press.

7. Install the circlip

Use the circlip pliers to install the new circlip in the slot of semiaxle.

Page 270 of 425

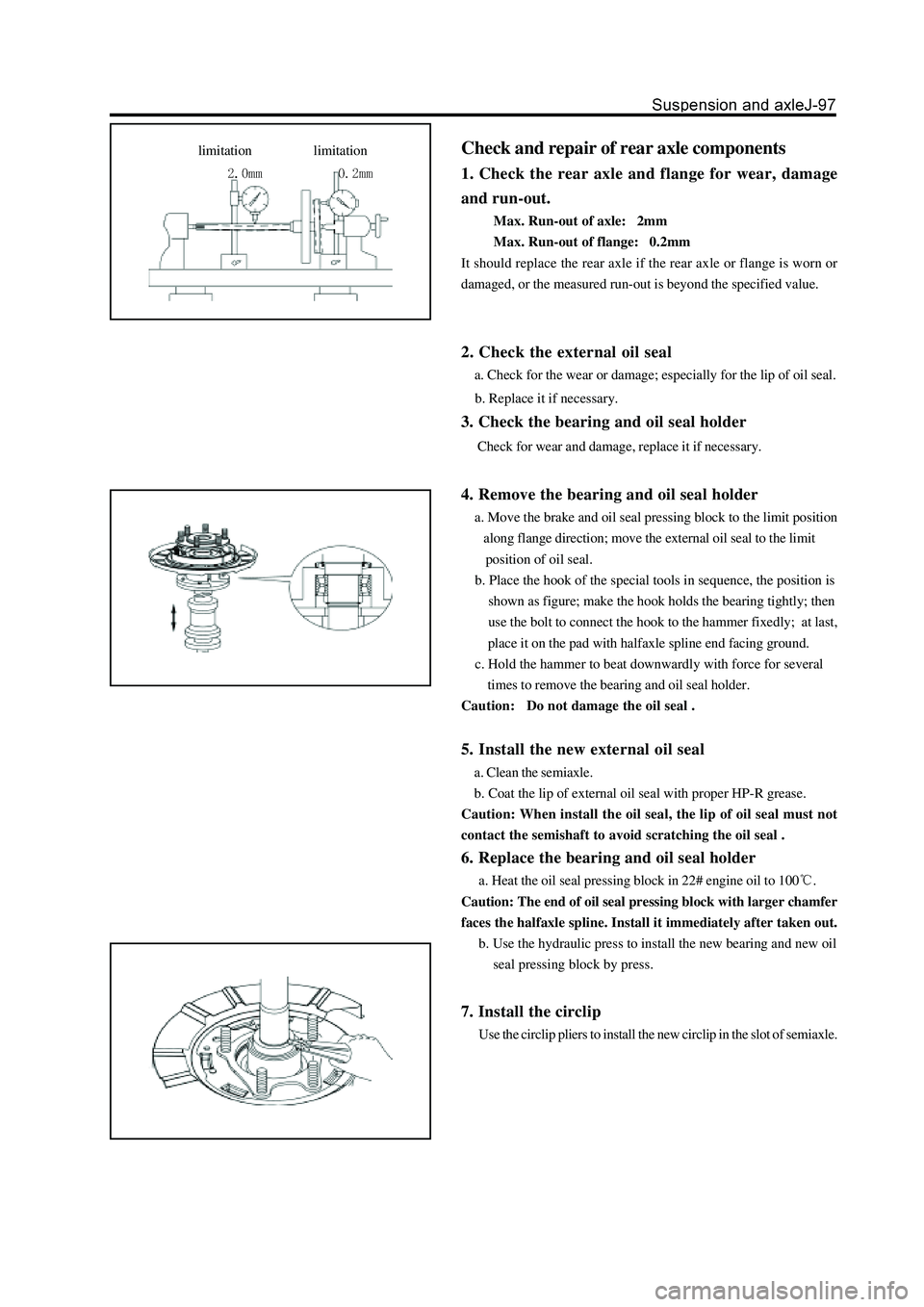

8. Check the inner oil seal for wear or damage.

9. Remove the inner oil seal

Use the special tools to remove the inner oil seal.

10. Install the new inner oil seal

a. Coat the lip of oil seal with proper HP-R grease.

b. Use the special tools to knock in the new oil seal.

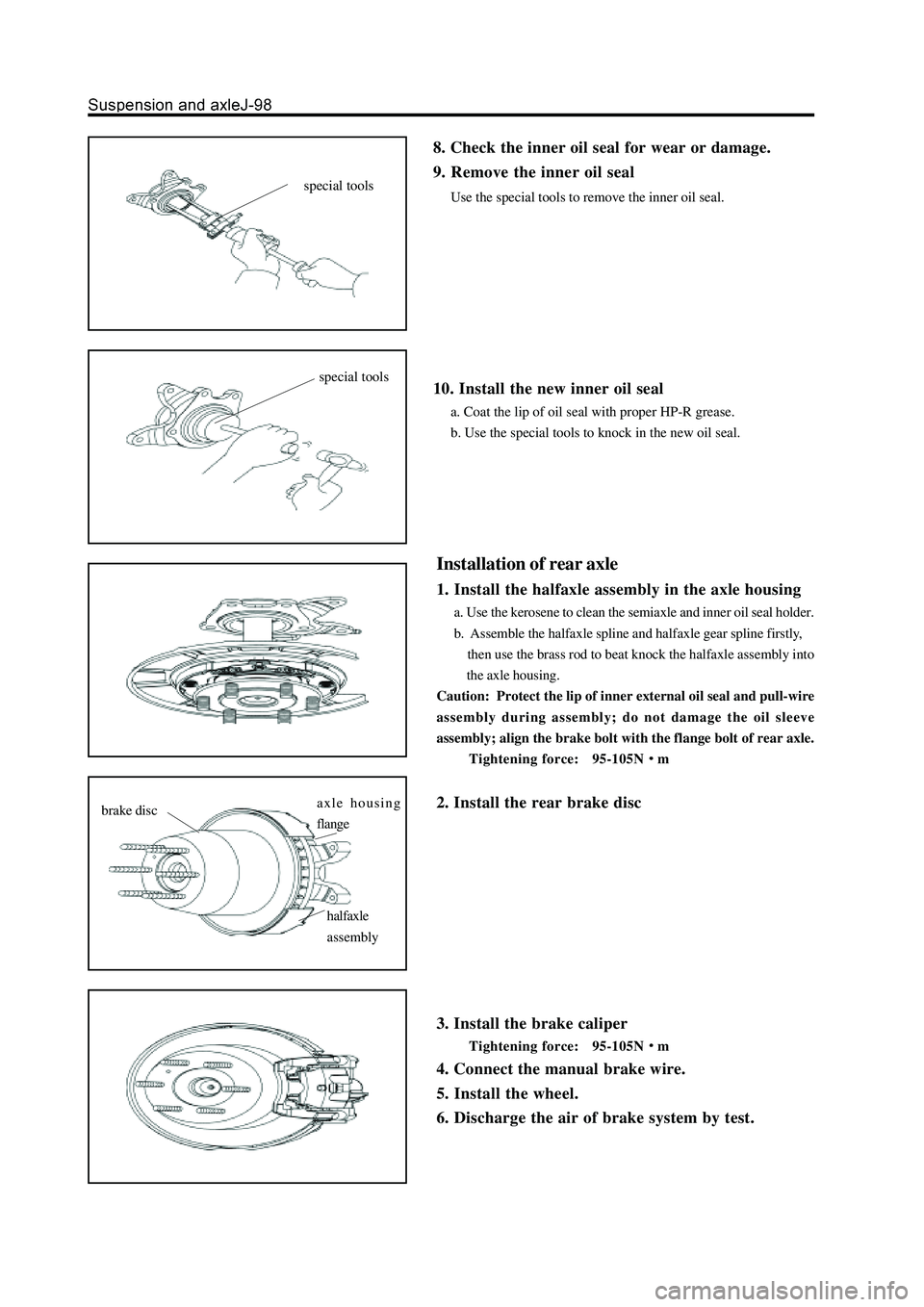

Installation of rear axle

1. Install the halfaxle assembly in the axle housing

a. Use the kerosene to clean the semiaxle and inner oil seal holder.

b. Assemble the halfaxle spline and halfaxle gear spline firstly,

then use the brass rod to beat knock the halfaxle assembly into

the axle housing.

Caution: Protect the lip of inner external oil seal and pull-wire

assembly during assembly; do not damage the oil sleeve

assembly; align the brake bolt with the flange bolt of rear axle.

Tightening force: 95-105N

m

2. Install the rear brake disc

3. Install the brake caliper

Tightening force: 95-105Nm

4. Connect the manual brake wire.

5. Install the wheel.

6. Discharge the air of brake system by test.

special tools

special tools

brake discaxle housing

flange

halfaxle

assembly

Page 272 of 425

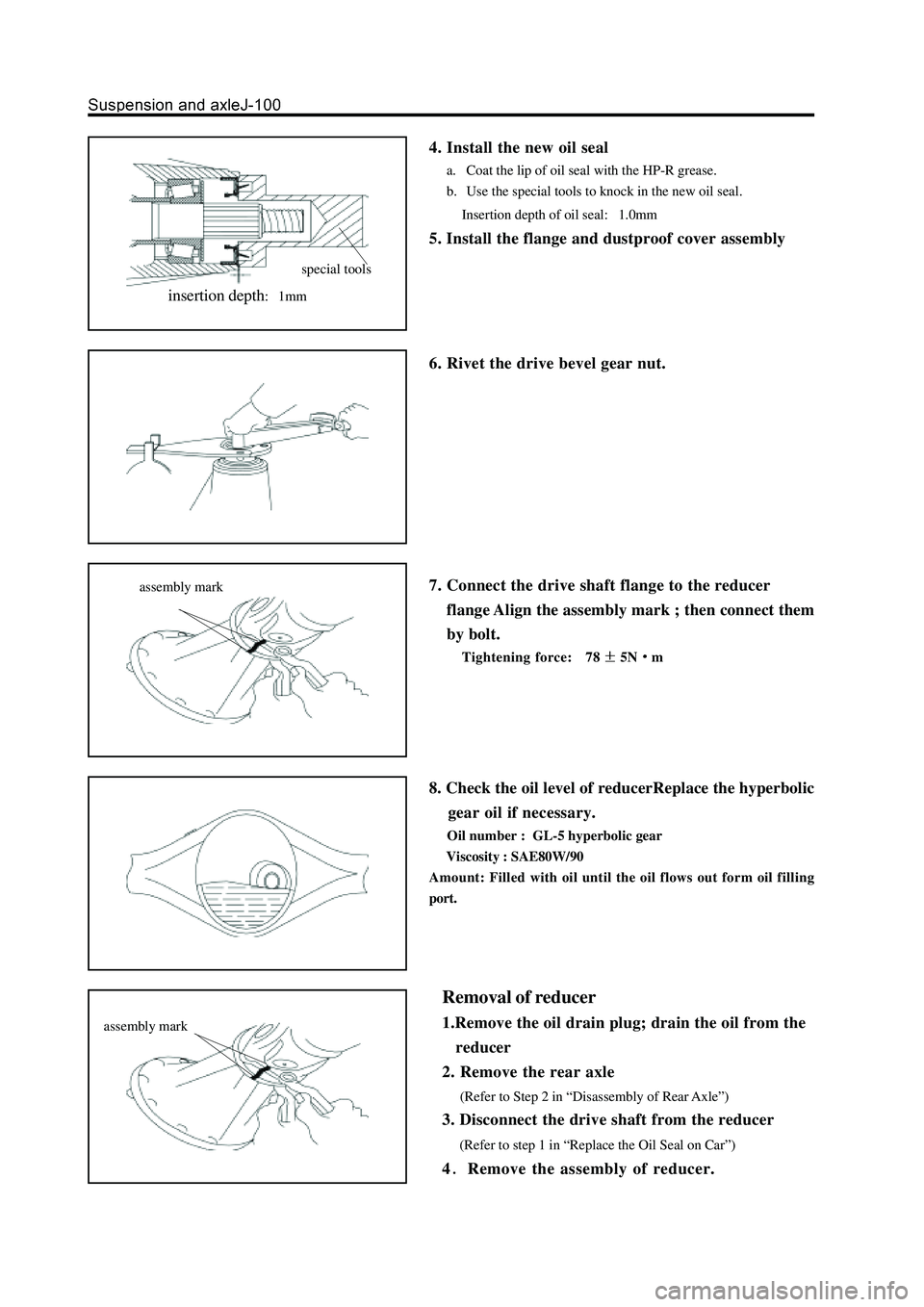

4. Install the new oil seal

a. Coat the lip of oil seal with the HP-R grease.

b. Use the special tools to knock in the new oil seal.

Insertion depth of oil seal: 1.0mm

5. Install the flange and dustproof cover assembly

6. Rivet the drive bevel gear nut.

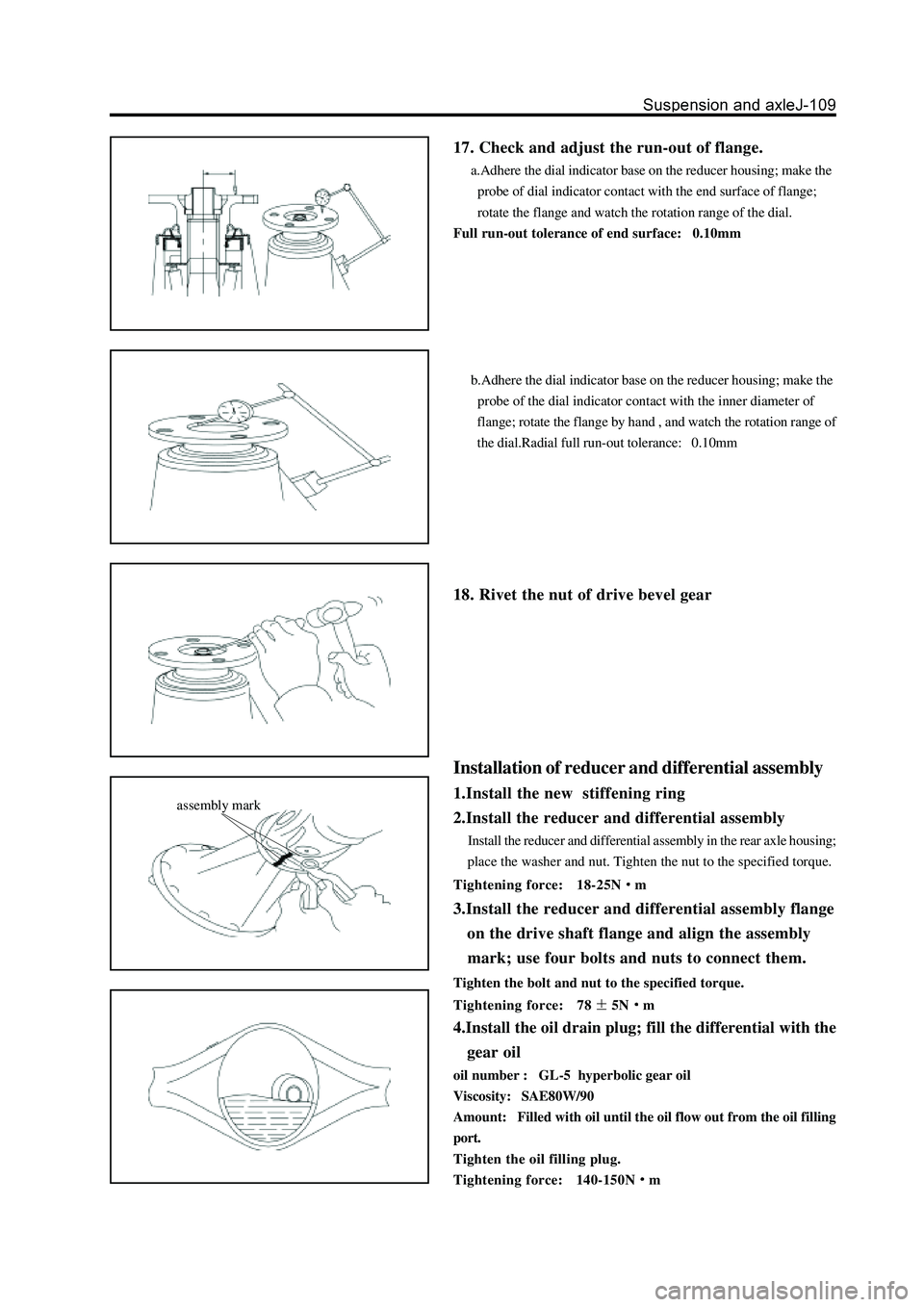

7. Connect the drive shaft flange to the reducer

flange Align the assembly mark ; then connect them

by bolt.

Tightening force: 785Nm

8. Check the oil level of reducerReplace the hyperbolic

gear oil if necessary.

Oil number : GL-5 hyperbolic gear

Viscosity : SAE80W/90

Amount: Filled with oil until the oil flows out form oil filling

port.

Removal of reducer

1.Remove the oil drain plug; drain the oil from the

reducer

2. Remove the rear axle

(Refer to Step 2 in “Disassembly of Rear Axle”)

3. Disconnect the drive shaft from the reducer

(Refer to step 1 in “Replace the Oil Seal on Car”)

4Remove the assembly of reducer.

special tools

insertion depth: 1mm

assembly mark

assembly mark

Page 281 of 425

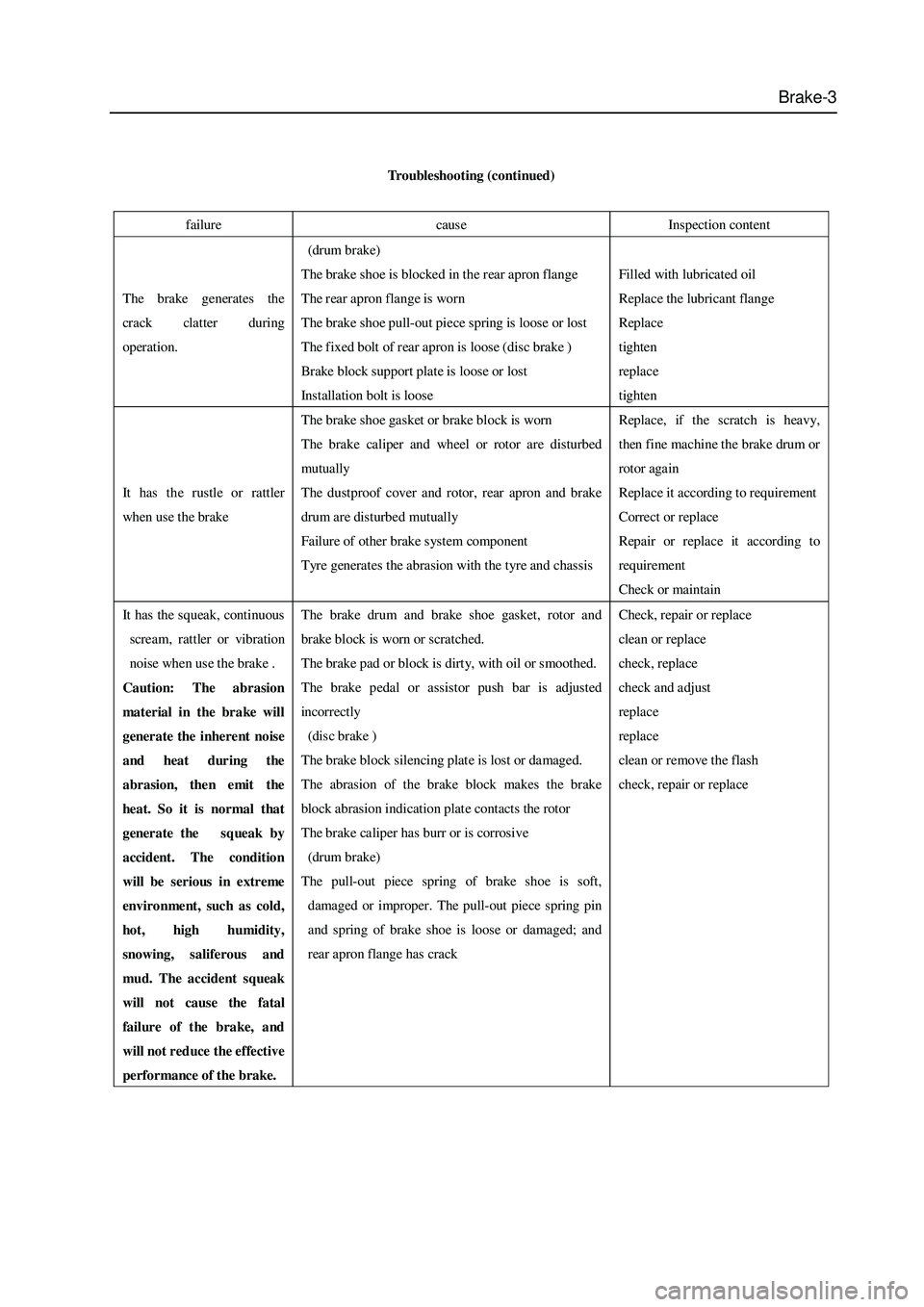

17. Check and adjust the run-out of flange.

a.Adhere the dial indicator base on the reducer housing; make the

probe of dial indicator contact with the end surface of flange;

rotate the flange and watch the rotation range of the dial.

Full run-out tolerance of end surface: 0.10mm

b.Adhere the dial indicator base on the reducer housing; make the

probe of the dial indicator contact with the inner diameter of

flange; rotate the flange by hand , and watch the rotation range of

the dial.Radial full run-out tolerance: 0.10mm

18. Rivet the nut of drive bevel gear

Installation of reducer and differential assembly

1.Install the new stiffening ring

2.Install the reducer and differential assembly

Install the reducer and differential assembly in the rear axle housing;

place the washer and nut. Tighten the nut to the specified torque.

Tightening force: 18-25N

m

3.Install the reducer and differential assembly flange

on the drive shaft flange and align the assembly

mark; use four bolts and nuts to connect them.

Tighten the bolt and nut to the specified torque.

Tightening force: 78

5Nm

4.Install the oil drain plug; fill the differential with the

gear oil

oil number : GL-5 hyperbolic gear oil

Viscosity: SAE80W/90

Amount: Filled with oil until the oil flow out from the oil filling

port.

Tighten the oil filling plug.

Tightening force: 140-150N

m

assembly mark

Page 289 of 425

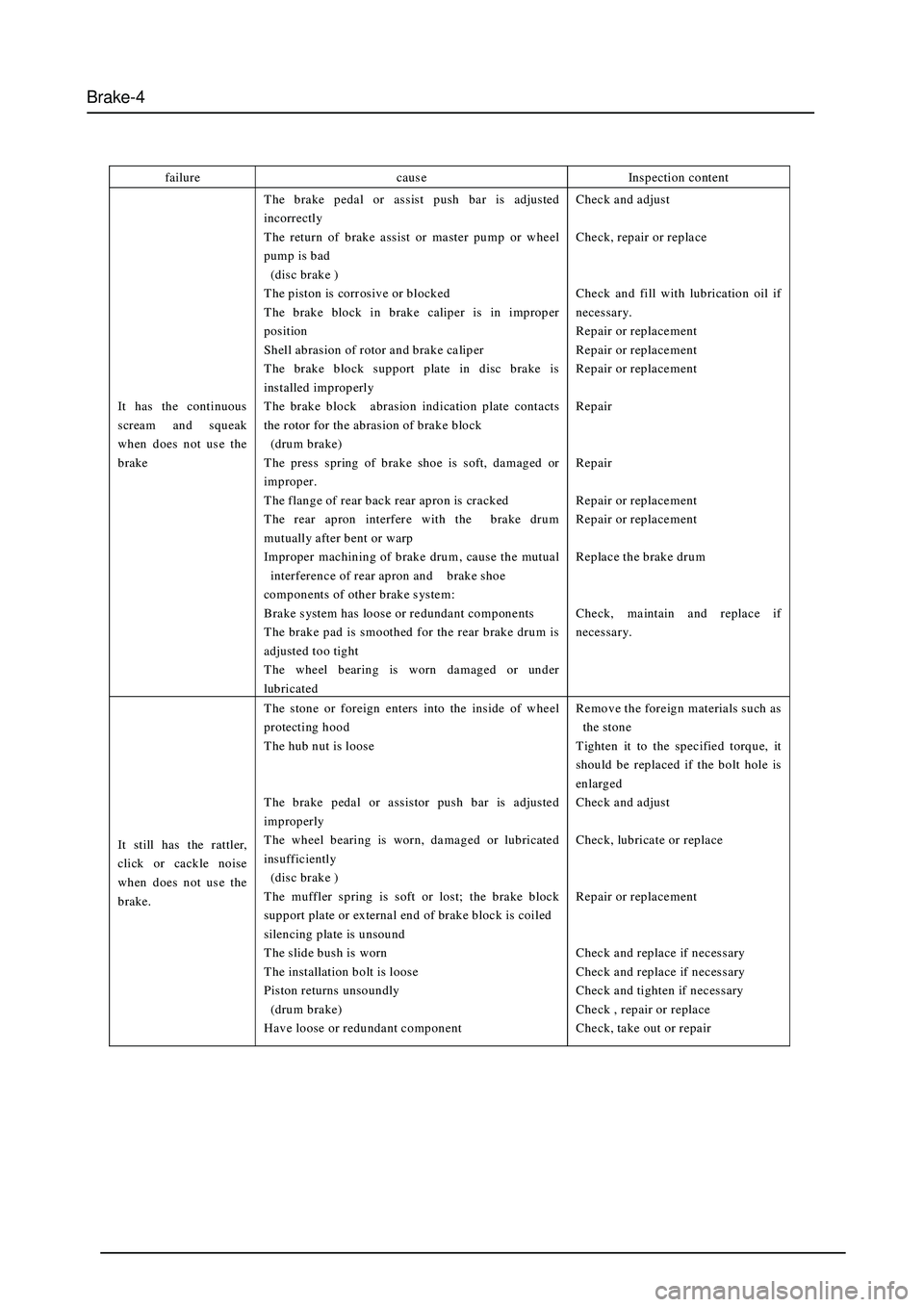

Brake-3

Troubleshooting (continued)

failure caus e Inspection content

The brake generates the

crack clatter during

operation. (drum brake)

The brake shoe is blocked in the rear apron flange

The rear apron flange is worn

The brake shoe pull-out piece spring is loose or lost

The fixed bolt of rear apron is loose (disc brake )

Brake block support plate is loose or lost

Installation bolt is loose

Filled with lubricated oil

Replace the lubricant flange

Replace

tighten

replace

tighten

It has the rustle or rattler

when use the brake The brake shoe gasket or brake block is worn

The brake caliper and wheel or rotor are disturbed

mutually

The dustproof cover and rotor, rear apron and brake

drum are disturbed mutually

Failure of other brake system component

Tyre generates the abrasion with the tyre and chassis Replace, if the scratch is heavy,

then fine machine the brake drum or

rotor again

Replace it according to requirement

Correct or replace

Repair or replace it according to

requirement

Check or maintain

It has the squeak, continuous

scream, rattler or vibration

noise when use the brake .

Caution: The abrasion

material in the brake will

generate the inherent noise

and heat during the

abrasion, then emit the

heat. So it is normal that

generate the squeak by

accident. The condition

will be serious in extreme

environment, such as cold,

hot, high humidity,

snowing, saliferous and

mud. The accident squeak

will not cause the fatal

failure of the brake, and

will not reduce the effective

performance of the brake. The brake drum and brake shoe gasket, rotor and

brake block is worn or scratched.

The brake pad or block is dirty, with oil or smoothed.

The brake pedal or assistor push bar is adjusted

incorrectly

(dis c brake )

The brake block silencing plate is lost or damaged.

The abrasion of the brake block makes the brake

block abrasion indication plate contacts the rotor

The brake ca lip er has burr or is corrosive

(drum brake)

The pull-out piece spring of brake shoe is soft,

damaged or improper. The pull-out piece spring pin

and spring of brake shoe is loose or damaged; and

rear apron flange has crack Check, repair or replace

clean or replace

check, replace

check and adjust

replace

replace

clean or remove the flash

check, repair or replace

Page 290 of 425

Brake-4

failure caus e Inspection content

It has the continuous

scream and squeak

when does not us e the

brake The brake pedal or assist push bar is adjusted

incorrectly

The return of brake assist or master pump or wheel

pump is bad

(dis c brake )

T he piston is corr osive or blocked

T he brake block in brake calip er is in improp er

position

Shell abrasion of rotor and brake caliper

The brake block support plate in disc brake is

installed improperly

The brake block abrasion indication plate contacts

the rotor for the abrasion of brake block

(drum brake)

The press spring of brake shoe is soft, damaged or

improper.

The flange of rear back rear apron is cracked

T he rear apron interfer e with the brake drum

mutually after bent or warp

Improper machining of brake drum , caus e the mutual

interference of rear apron and brake shoe

components of other brake s ystem :

Brake system has loose or redundant components

T he brake pad is smoothed for the rear brake drum is

adjusted too tight

The wheel bearing is worn damaged or under

lubricated Check and adjust

Check, repair or replace

Check and fill with lubrication oil if

necessary.

Repair or replacement

Repair or replacement

Repair or replacement

Repair

Repair

Repair or replacement

Repair or replacement

Replace the brake drum

Check, maintain and replace if

necessary.

It still has the rattler,

click or cackle noise

when does not us e the

brake. The stone or foreign enters into the inside of wheel

protecting hood

The hub nut is loose

The brake pedal or assistor push bar is adjusted

improperly

The wheel bearing is worn, damaged or lubricated

insufficiently

(dis c brake )

T he muffler spring is soft or lost; the brake block

support plate or external end of brake block is coiled

silencing plate is unsound

T he slide bush is worn

T he installation bolt is loos e

Piston returns unsoundly

(drum brake)

Have loose or redundant component Remove the foreign materials such as

the stone

Tighten it to the specified torque, it

should be replaced if the bolt hole is

enlarged

Check and adjust

Check, lubricate or replace

Repair or replacement

Check and replace if necessary

Check and replace if necessary

Check and tighten if necessary

Check , repair or replace

Check, take out or repair

Page 295 of 425

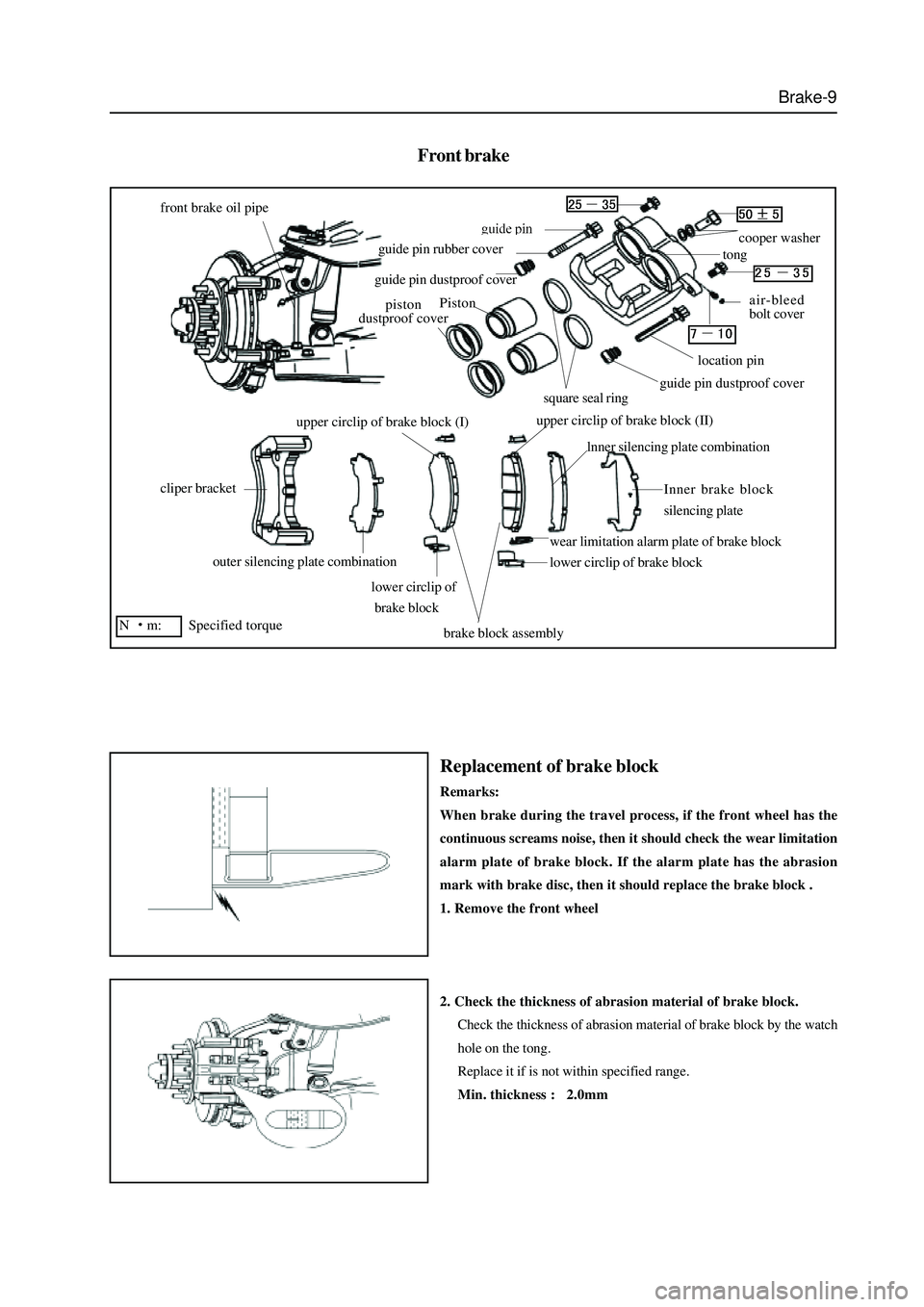

Brake-9

Front brake

front brake oil pipe

cliper bracket

outer silencing plate combination

lower circlip of

brake block

brake block assembly

lower circlip of brake block

wear limitation alarm plate of brake block

lnner silencing plate combination

Inner brake block

silencing plate

upper circlip of brake block (I)upper circlip of brake block (II)

piston

dustproof cover

guide pin dustproof cover

guide pin rubber covercooper washer

tong

air-bleed

bolt cover

location pin

guide pin dustproof coversquare seal ring

N

m: Specified torque

Piston

Replacement of brake block

Remarks:

When brake during the travel process, if the front wheel has the

continuous screams noise, then it should check the wear limitation

alarm plate of brake block. If the alarm plate has the abrasion

mark with brake disc, then it should replace the brake block .

1. Remove the front wheel

2. Check the thickness of abrasion material of brake block.

Check the thickness of abrasion material of brake block by the watch

hole on the tong.

Replace it if is not within specified range.

Min. thickness : 2.0mm

Page 301 of 425

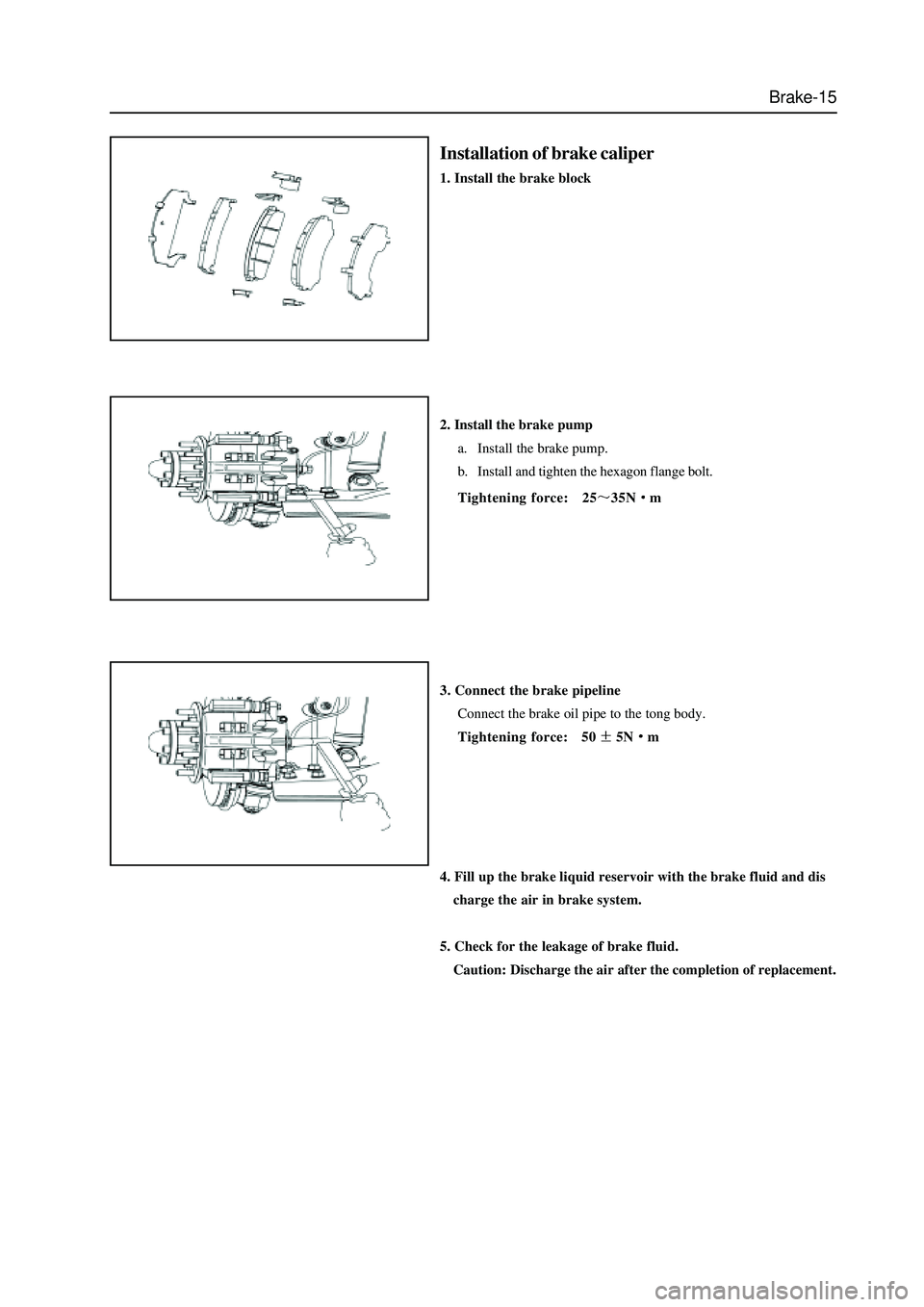

Brake-15

Installation of brake caliper

1. Install the brake block

2. Install the brake pump

a. Install the brake pump.

b. Install and tighten the hexagon flange bolt.

Tightening force: 25

35Nm

3. Connect the brake pipeline

Connect the brake oil pipe to the tong body.

Tightening force: 50

5Nm

4. Fill up the brake liquid reservoir with the brake fluid and dis

charge the air in brake system.

5. Check for the leakage of brake fluid.

Caution: Discharge the air after the completion of replacement.