check oil GREAT WALL HOVER 2006 Service Owner's Manual

[x] Cancel search | Manufacturer: GREAT WALL, Model Year: 2006, Model line: HOVER, Model: GREAT WALL HOVER 2006Pages: 425, PDF Size: 26.05 MB

Page 152 of 425

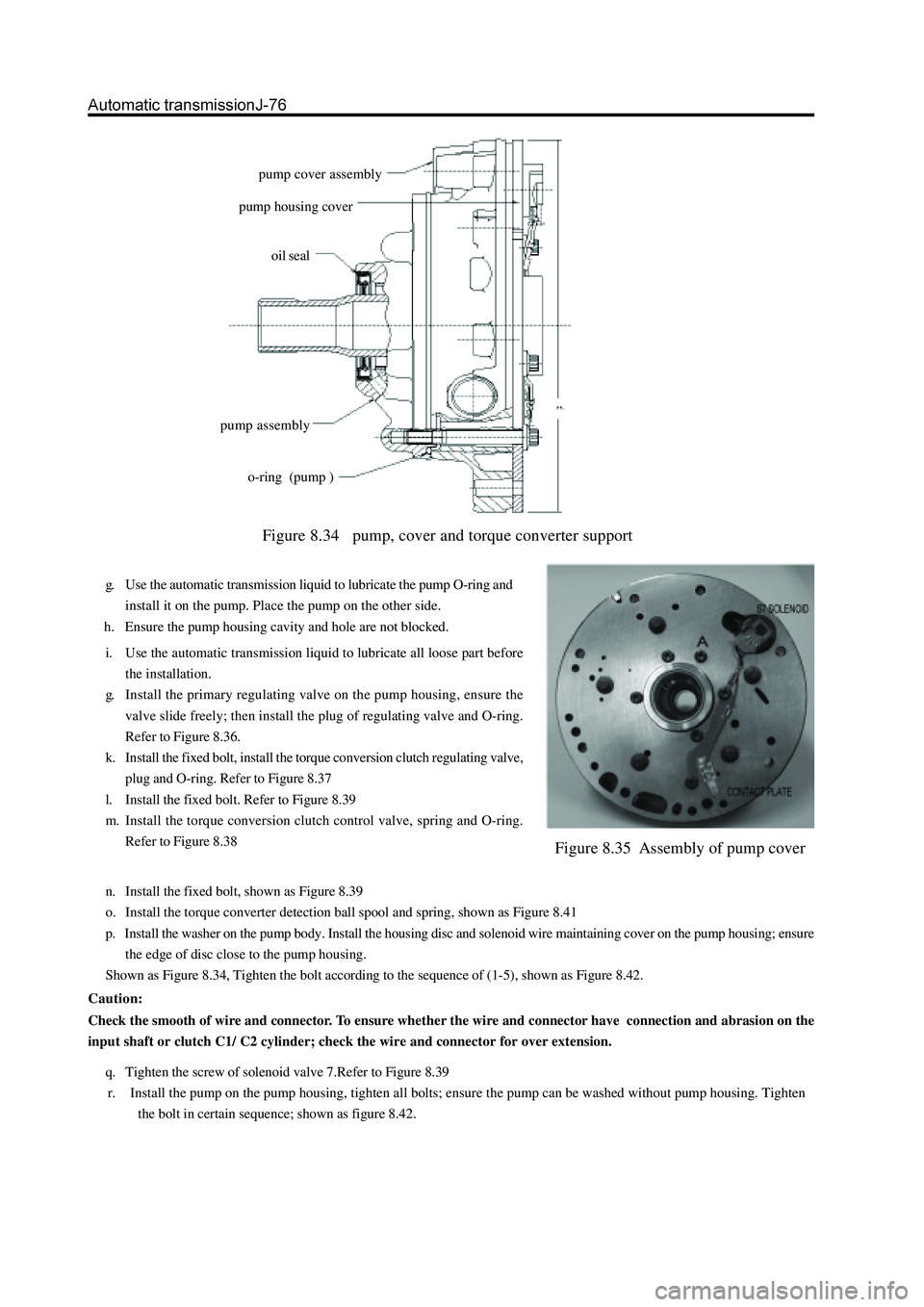

Figure 8.34 pump, cover and torque converter support

g. Use the automatic transmission liquid to lubricate the pump O-ring and

install it on the pump. Place the pump on the other side.

h. Ensure the pump housing cavity and hole are not blocked.

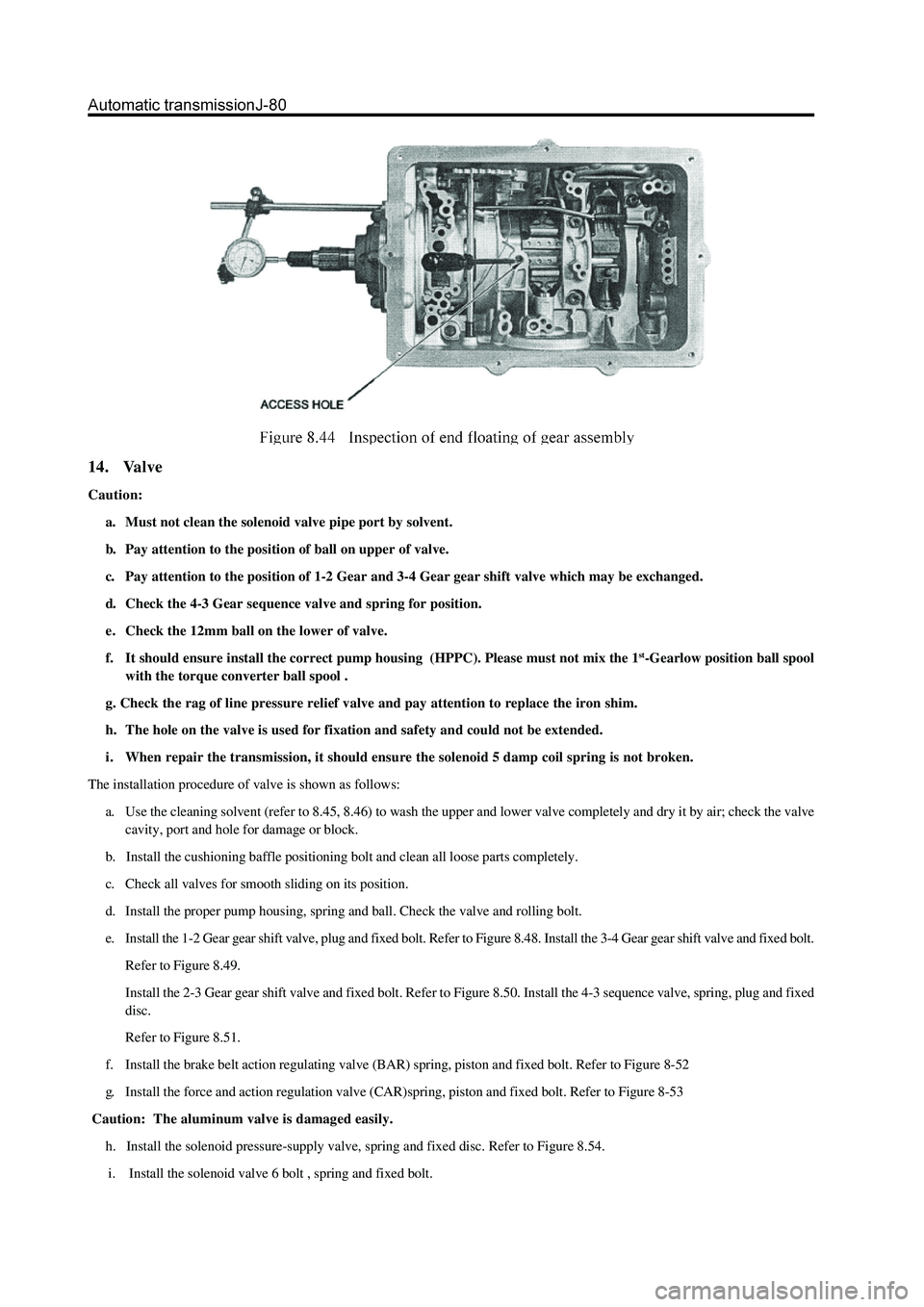

Figure 8.35 Assembly of pump cover

i. Use the automatic transmission liquid to lubricate all loose part before

the installation.

g. Install the primary regulating valve on the pump housing, ensure the

valve slide freely; then install the plug of regulating valve and O-ring.

Refer to Figure 8.36.

k. Install the fixed bolt, install the torque conversion clutch regulating valve,

plug and O-ring. Refer to Figure 8.37

l. Install the fixed bolt. Refer to Figure 8.39

m. Install the torque conversion clutch control valve, spring and O-ring.

Refer to Figure 8.38pump cover assembly

pump housing cover

oil seal

pump assembly

o-ring (pump )

n. Install the fixed bolt, shown as Figure 8.39

o. Install the torque converter detection ball spool and spring, shown as Figure 8.41

p. Install the washer on the pump body. Install the housing disc and solenoid wire maintaining cover on the pump housing; ensure

the edge of disc close to the pump housing.

Shown as Figure 8.34, Tighten the bolt according to the sequence of (1-5), shown as Figure 8.42.

Caution:

Check the smooth of wire and connector. To ensure whether the wire and connector have connection and abrasion on the

input shaft or clutch C1/ C2 cylinder; check the wire and connector for over extension.

q. Tighten the screw of solenoid valve 7.Refer to Figure 8.39

r. Install the pump on the pump housing, tighten all bolts; ensure the pump can be washed without pump housing. Tighten

the bolt in certain sequence; shown as figure 8.42.

Page 156 of 425

14. Valve

Caution:

a. Must not clean the solenoid valve pipe port by solvent.

b. Pay attention to the position of ball on upper of valve.

c. Pay attention to the position of 1-2 Gear and 3-4 Gear gear shift valve which may be exchanged.

d. Check the 4-3 Gear sequence valve and spring for position.

e. Check the 12mm ball on the lower of valve.

f. It should ensure install the correct pump housing (HPPC). Please must not mix the 1

st-Gearlow position ball spool

with the torque converter ball spool .

g. Check the rag of line pressure relief valve and pay attention to replace the iron shim.

h. The hole on the valve is used for fixation and safety and could not be extended.

i . When repair the transmission, it should ensure the solenoid 5 damp coil spring is not broken.

The installation procedure of valve is shown as follows:

a. Use the cleaning solvent (refer to 8.45, 8.46) to wash the upper and lower valve completely and dry it by air; check the valve

cavity, port and hole for damage or block.

b. Install the cushioning baffle positioning bolt and clean all loose parts completely.

c. Check all valves for smooth sliding on its position.

d. Install the proper pump housing, spring and ball. Check the valve and rolling bolt.

e. Install the 1-2 Gear gear shift valve, plug and fixed bolt. Refer to Figure 8.48. Install the 3-4 Gear gear shift valve and fixed bolt.

Refer to Figure 8.49.

Install the 2-3 Gear gear shift valve and fixed bolt. Refer to Figure 8.50. Install the 4-3 sequence valve, spring, plug and fixed

disc.

Refer to Figure 8.51.

f. Install the brake belt action regulating valve (BAR) spring, piston and fixed bolt. Refer to Figure 8-52

g. Install the force and action regulation valve (CAR)spring, piston and fixed bolt. Refer to Figure 8-53

Caution: The aluminum valve is damaged easily.

h. Install the solenoid pressure-supply valve, spring and fixed disc. Refer to Figure 8.54.

i. Install the solenoid valve 6 bolt , spring and fixed bolt.

Page 162 of 425

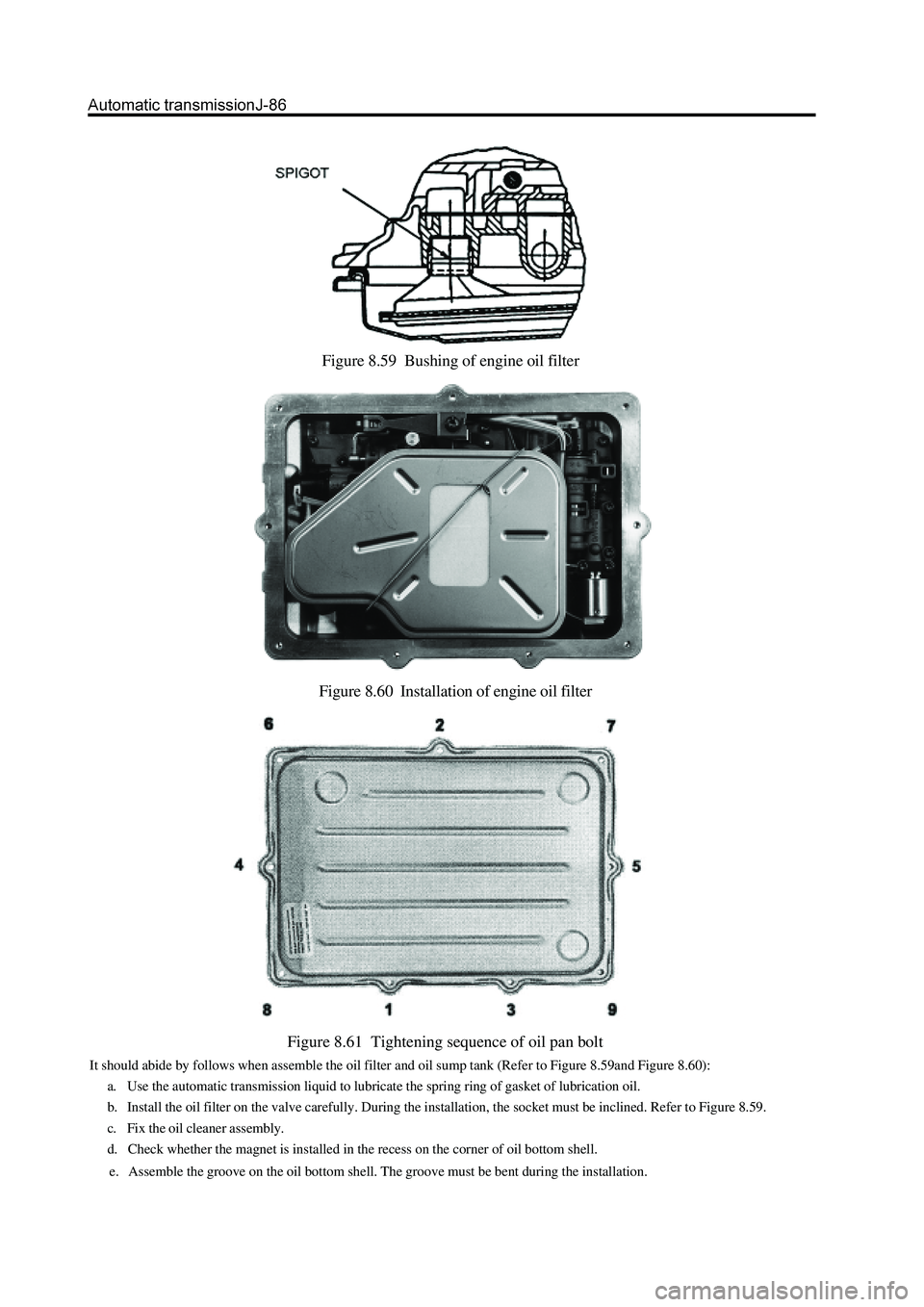

Figure 8.59 Bushing of engine oil filter

Figure 8.60 Installation of engine oil filter

Figure 8.61 Tightening sequence of oil pan bolt

It should abide by follows when assemble the oil filter and oil sump tank (Refer to Figure 8.59and Figure 8.60):

a. Use the automatic transmission liquid to lubricate the spring ring of gasket of lubrication oil.

b. Install the oil filter on the valve carefully. During the installation, the socket must be inclined. Refer to Figure 8.59.

c. Fix the oil cleaner assembly.

d. Check whether the magnet is installed in the recess on the corner of oil bottom shell.

e. Assemble the groove on the oil bottom shell. The groove must be bent during the installation.

Page 174 of 425

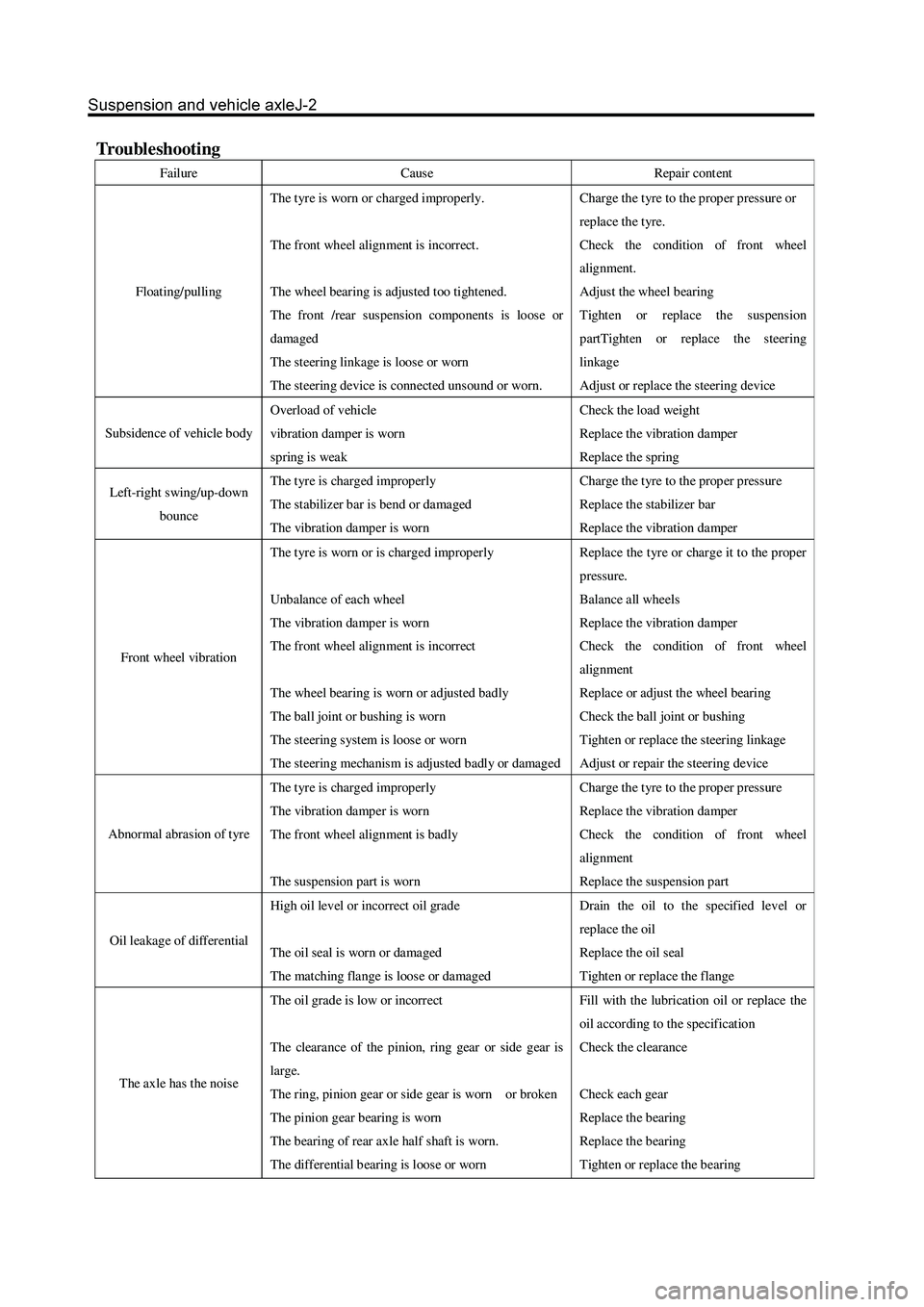

Troubleshooting

Failure Cause Repair cont ent

Floating/pulling The t yre is worn or charged improperly.

The front wheel alignment is incorrect.

The wheel bearing is adjusted too tightened.

The front /rear suspension components is loose or

damaged

The steering linkage is loose or worn

The steering device is connect ed unsound or worn. Charge the t yre to the prop er pressur e or

repla ce the t yre.

Check the condition of front wheel

alignment.

Adjust the wheel bearing

Tighten or replace the suspension

partTighten or replace the steering

linkage

Adjust or replace the steering device

Subsidence of vehicle body Overload of vehicle

vibration damper is worn

spring is weak Check the load weight

Replace the vibration damper

Replace the spring

Left-right swing/up-down

bounce The t yre is charged improperly

The stabilizer bar is bend or damaged

The vibration damper is worn Charge the t yre to the prop er pressur e

Replace the stabilizer bar

Replace the vibration damper

Front wheel vibration The t yre is worn or is charged improperly

Unbalance of each wheel

The vibration damper is worn

The front wheel alignment is incorrect

The wheel bearing is worn or adjusted badly

The ball joint or bushing is worn

The steering system is loose or worn

The steering mechanism is adjusted badly or damaged Repla ce the t yr e or char ge it to the prop er

pressure.

Balance all wheels

Replace the vibration damper

Check the condition of front wheel

alignment

Replace or adjust the wheel bearing

Check the ball joint or bushing

Tighten or replace the steering linkage

Adjust or repair the steering device

Abnormal abrasion of tyre The t yre is charged improperly

The vibration damper is worn

The front wheel alignment is badly

The suspension part is worn Charge the t yre to the prop er pressur e

Replace the vibration damper

Check the condition of front wheel

alignment

Replace the suspension part

Oil leakage of differential High oil level or incorrect oil grade

The oil seal is worn or damaged

The matching flange is loose or damaged Drain the oil to the specified level or

repla ce the oil

Replace the oil seal

Tighten or replace the flange

The axle has the nois e The oil grade is low or incorrect

The clearance of the pinion, ring gear or side gear is

large.

The ring, pinion gear or side gear is worn or broken

The pinion gear bearing is worn

The b earing of rear axle half shaft is worn.

The differential b earing is loos e or worn Fill with the lubrication oil or replace the

oil according to the specification

Check the clearance

Check each gear

Replace the bearing

Replace the bearing

Tighten or replace the bearing

Page 181 of 425

special tools

diagram of special tools

grease

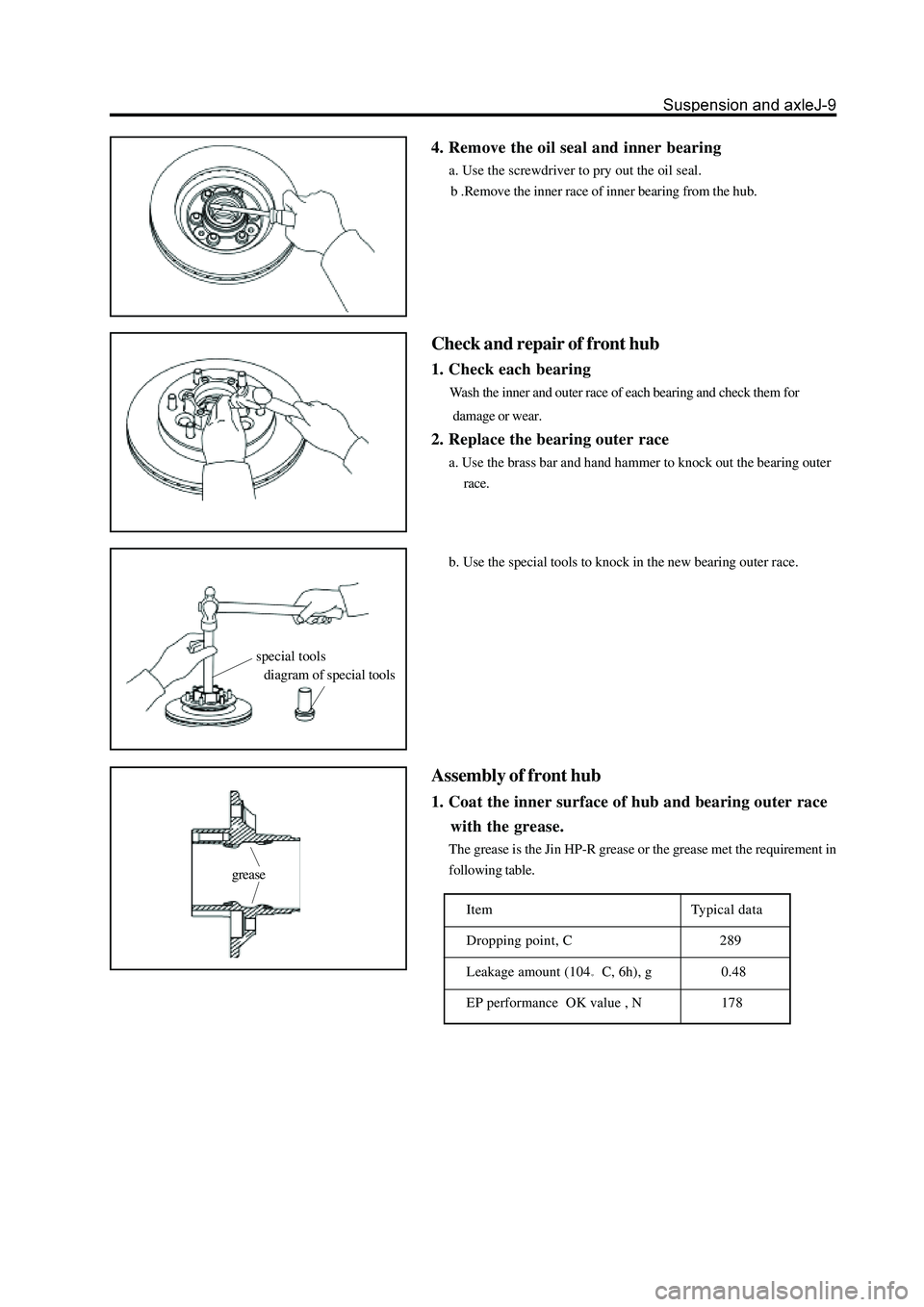

4. Remove the oil seal and inner bearing

a. Use the screwdriver to pry out the oil seal.

b .Remove the inner race of inner bearing from the hub.

Check and repair of front hub

1. Check each bearing

Wash the inner and outer race of each bearing and check them for

damage or wear.

2. Replace the bearing outer race

a. Use the brass bar and hand hammer to knock out the bearing outer

race.

b. Use the special tools to knock in the new bearing outer race.

Assembly of front hub

1. Coat the inner surface of hub and bearing outer race

with the grease.

The grease is the Jin HP-R grease or the grease met the requirement in

following table.

Item Typical data

Dropping point, C

289

Leakage amount (104

C, 6h), g 0.48

EP performance OK value , N

178

Page 182 of 425

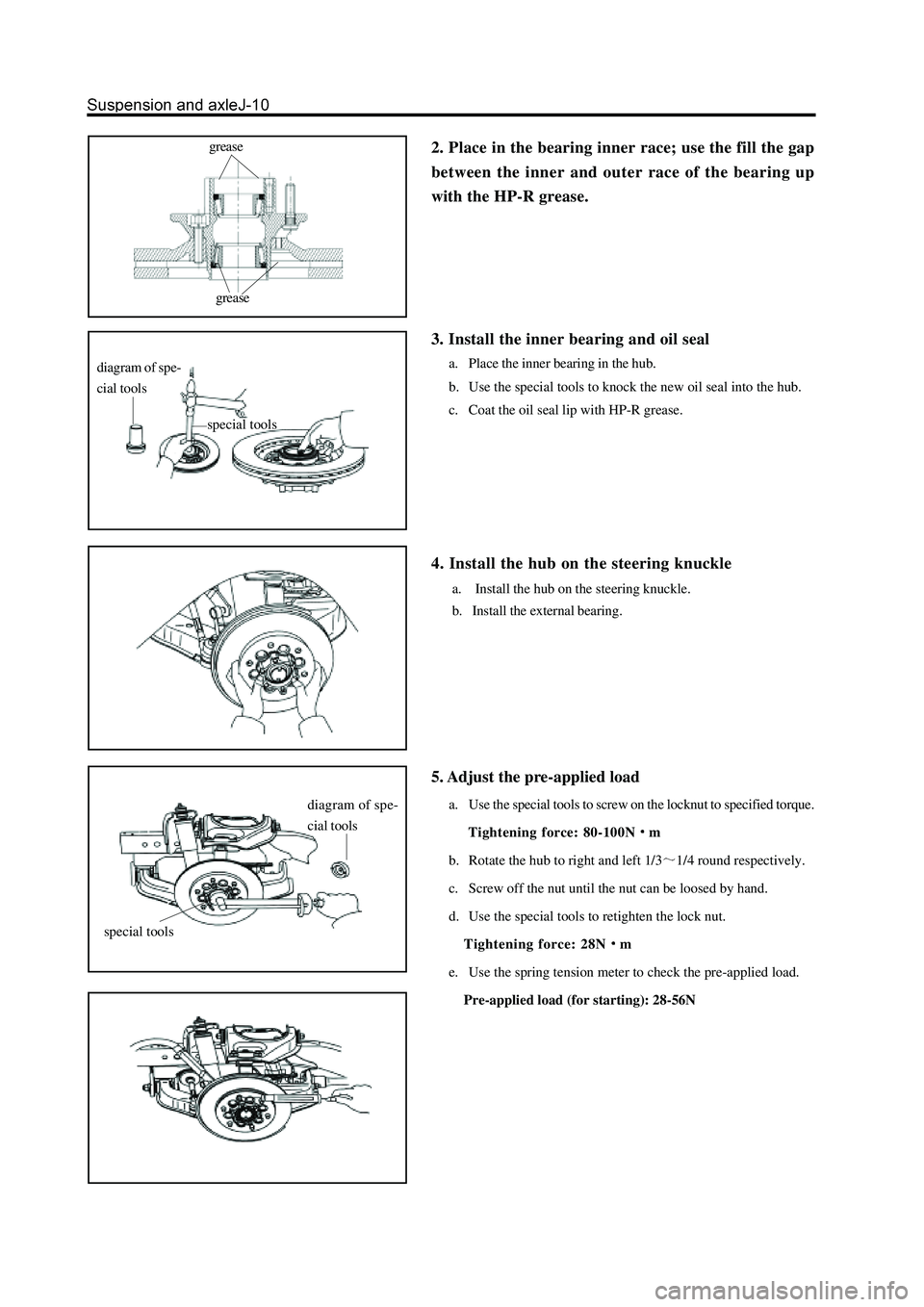

2. Place in the bearing inner race; use the fill the gap

between the inner and outer race of the bearing up

with the HP-R grease.grease

grease

3. Install the inner bearing and oil seal

a. Place the inner bearing in the hub.

b. Use the special tools to knock the new oil seal into the hub.

c. Coat the oil seal lip with HP-R grease.

4. Install the hub on the steering knuckle

a. Install the hub on the steering knuckle.

b. Install the external bearing.

diagram of spe-

cial tools

special tools

5. Adjust the pre-applied load

a. Use the special tools to screw on the locknut to specified torque.

Tightening force: 80-100N

m

b. Rotate the hub to right and left 1/3

1/4 round respectively.

c. Screw off the nut until the nut can be loosed by hand.

d. Use the special tools to retighten the lock nut.

Tightening force: 28N

m

e. Use the spring tension meter to check the pre-applied load.

Pre-applied load (for starting): 28-56N

diagram of spe-

cial tools

special tools

Page 203 of 425

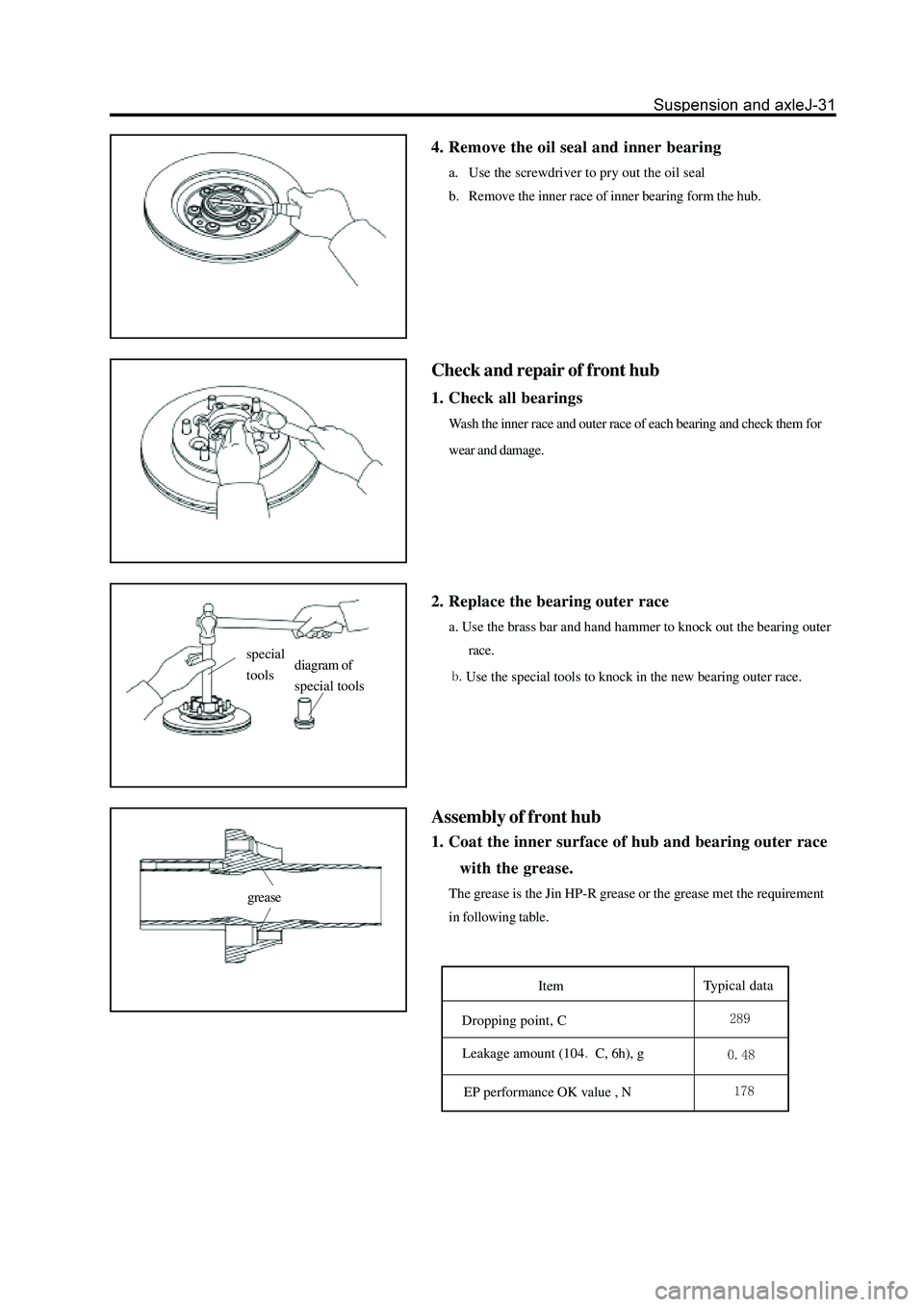

4. Remove the oil seal and inner bearing

a. Use the screwdriver to pry out the oil seal

b. Remove the inner race of inner bearing form the hub.

Check and repair of front hub

1. Check all bearings

Wash the inner race and outer race of each bearing and check them for

wear and damage.

2. Replace the bearing outer race

a. Use the brass bar and hand hammer to knock out the bearing outer

race.

Use the special tools to knock in the new bearing outer race.

Assembly of front hub

1. Coat the inner surface of hub and bearing outer race

with the grease.

The grease is the Jin HP-R grease or the grease met the requirement

in following table.

special

toolsdiagram of

special tools

grease

Dropping point, C

Leakage amount (104C, 6h), g

EP performance OK value , N

ItemTypical data

Page 204 of 425

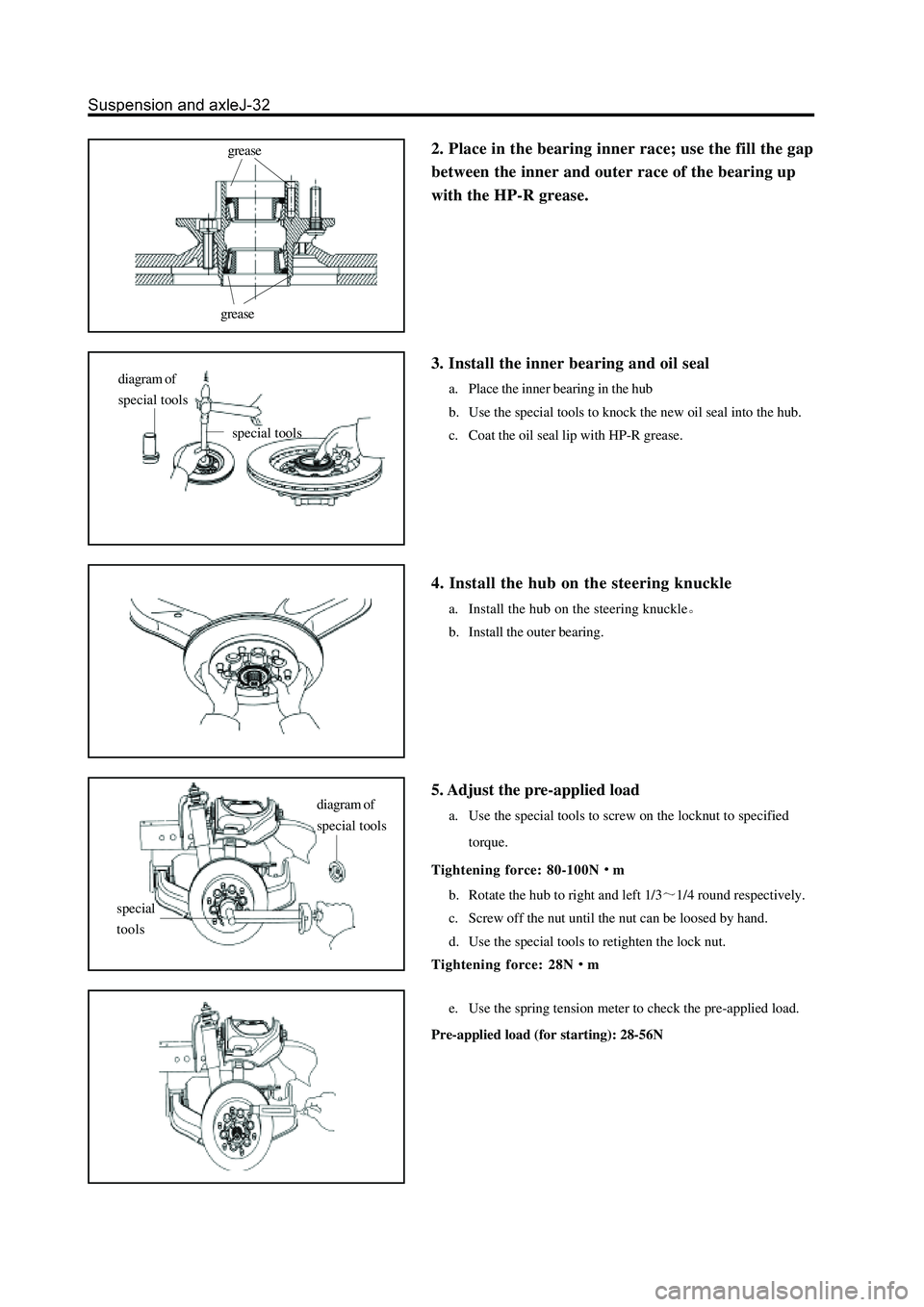

2. Place in the bearing inner race; use the fill the gap

between the inner and outer race of the bearing up

with the HP-R grease.grease

grease

3. Install the inner bearing and oil seal

a. Place the inner bearing in the hub

b. Use the special tools to knock the new oil seal into the hub.

c. Coat the oil seal lip with HP-R grease.diagram of

special tools

special tools

4. Install the hub on the steering knuckle

a. Install the hub on the steering knuckle

b. Install the outer bearing.

5. Adjust the pre-applied load

a. Use the special tools to screw on the locknut to specified

torque.

Tightening force: 80-100N

m

b. Rotate the hub to right and left 1/3

1/4 round respectively.

c. Screw off the nut until the nut can be loosed by hand.

d. Use the special tools to retighten the lock nut.

Tightening force: 28N

m

e. Use the spring tension meter to check the pre-applied load.

Pre-applied load (for starting): 28-56N

special

tools

diagram of

special tools

Page 207 of 425

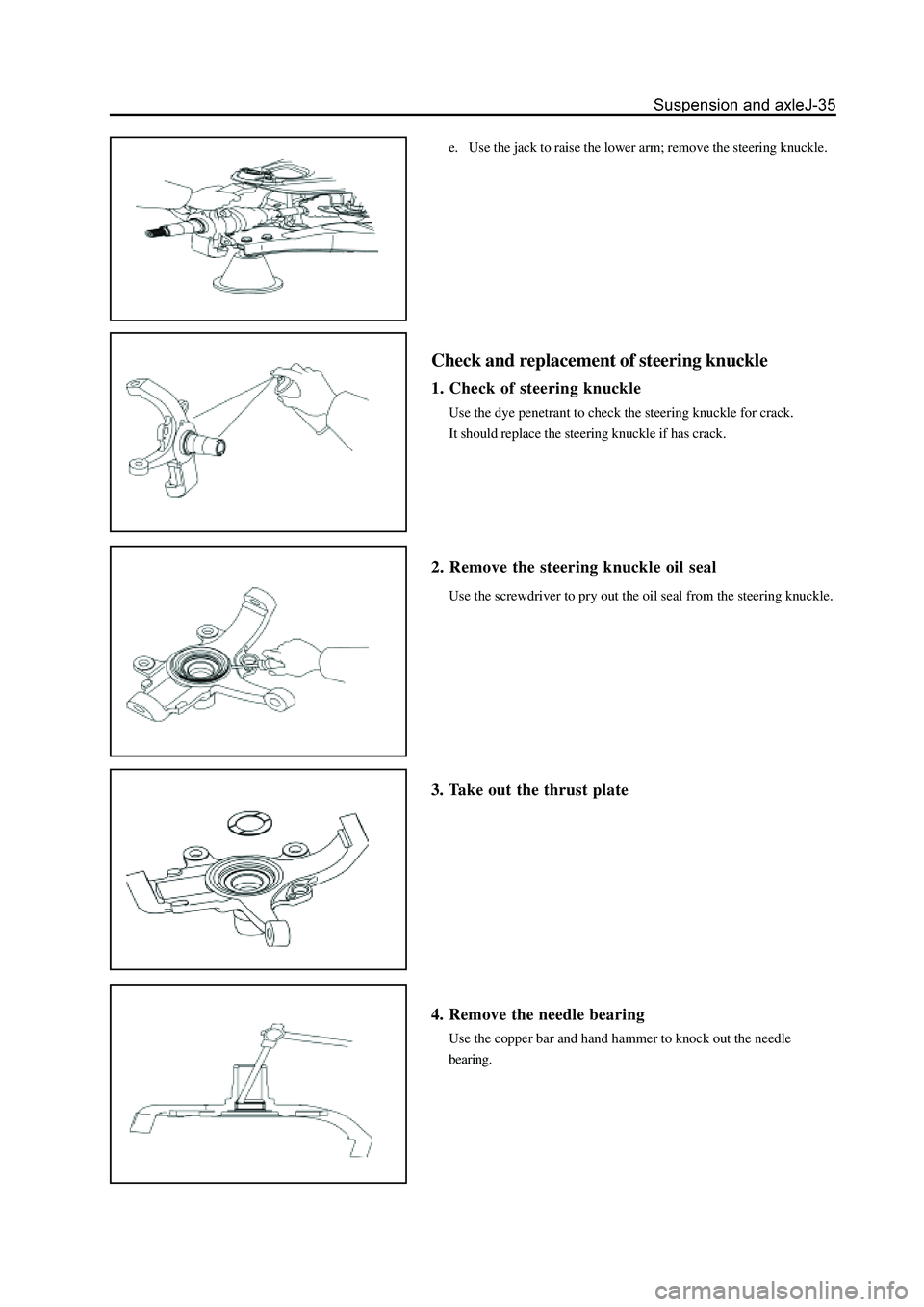

e. Use the jack to raise the lower arm; remove the steering knuckle.

Check and replacement of steering knuckle

1. Check of steering knuckle

Use the dye penetrant to check the steering knuckle for crack.

It should replace the steering knuckle if has crack.

2. Remove the steering knuckle oil seal

Use the screwdriver to pry out the oil seal from the steering knuckle.

3. Take out the thrust plate

4. Remove the needle bearing

Use the copper bar and hand hammer to knock out the needle

bearing.

Page 233 of 425

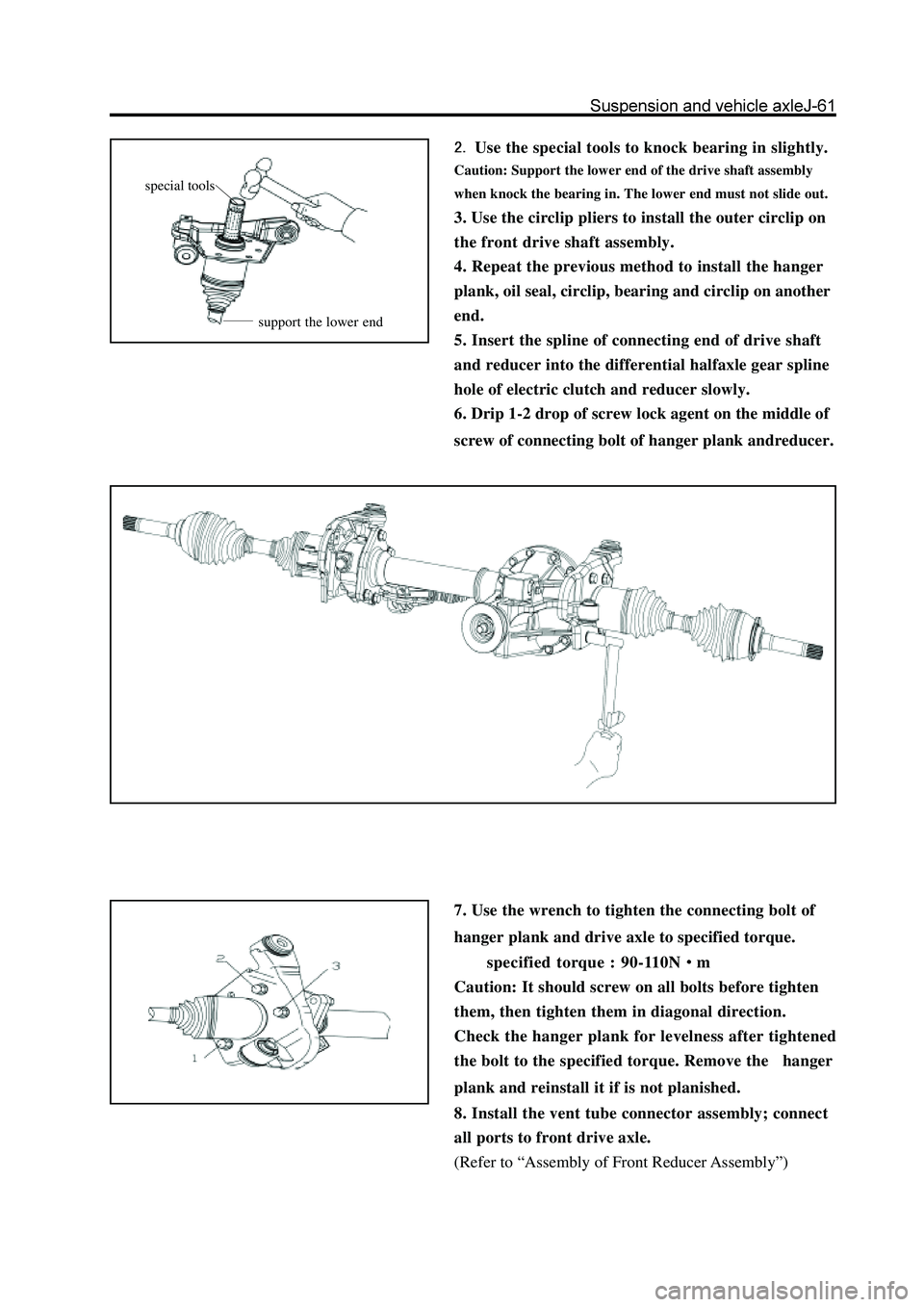

Use the special tools to knock bearing in slightly.

Caution: Support the lower end of the drive shaft assembly

when knock the bearing in. The lower end must not slide out.

3. Use the circlip pliers to install the outer circlip on

the front drive shaft assembly.

4. Repeat the previous method to install the hanger

plank, oil seal, circlip, bearing and circlip on another

end.

5. Insert the spline of connecting end of drive shaft

and reducer into the differential halfaxle gear spline

hole of electric clutch and reducer slowly.

6. Drip 1-2 drop of screw lock agent on the middle of

screw of connecting bolt of hanger plank andreducer.

7. Use the wrench to tighten the connecting bolt of

hanger plank and drive axle to specified torque.

specified torque : 90-110N

m

Caution: It should screw on all bolts before tighten

them, then tighten them in diagonal direction.

Check the hanger plank for levelness after tightened

the bolt to the specified torque. Remove the hanger

plank and reinstall it if is not planished.

8. Install the vent tube connector assembly; connect

all ports to front drive axle.

(Refer to “Assembly of Front Reducer Assembly”)

special tools

support the lower end