torque GREAT WALL HOVER 2006 Service Manual PDF

[x] Cancel search | Manufacturer: GREAT WALL, Model Year: 2006, Model line: HOVER, Model: GREAT WALL HOVER 2006Pages: 425, PDF Size: 26.05 MB

Page 139 of 425

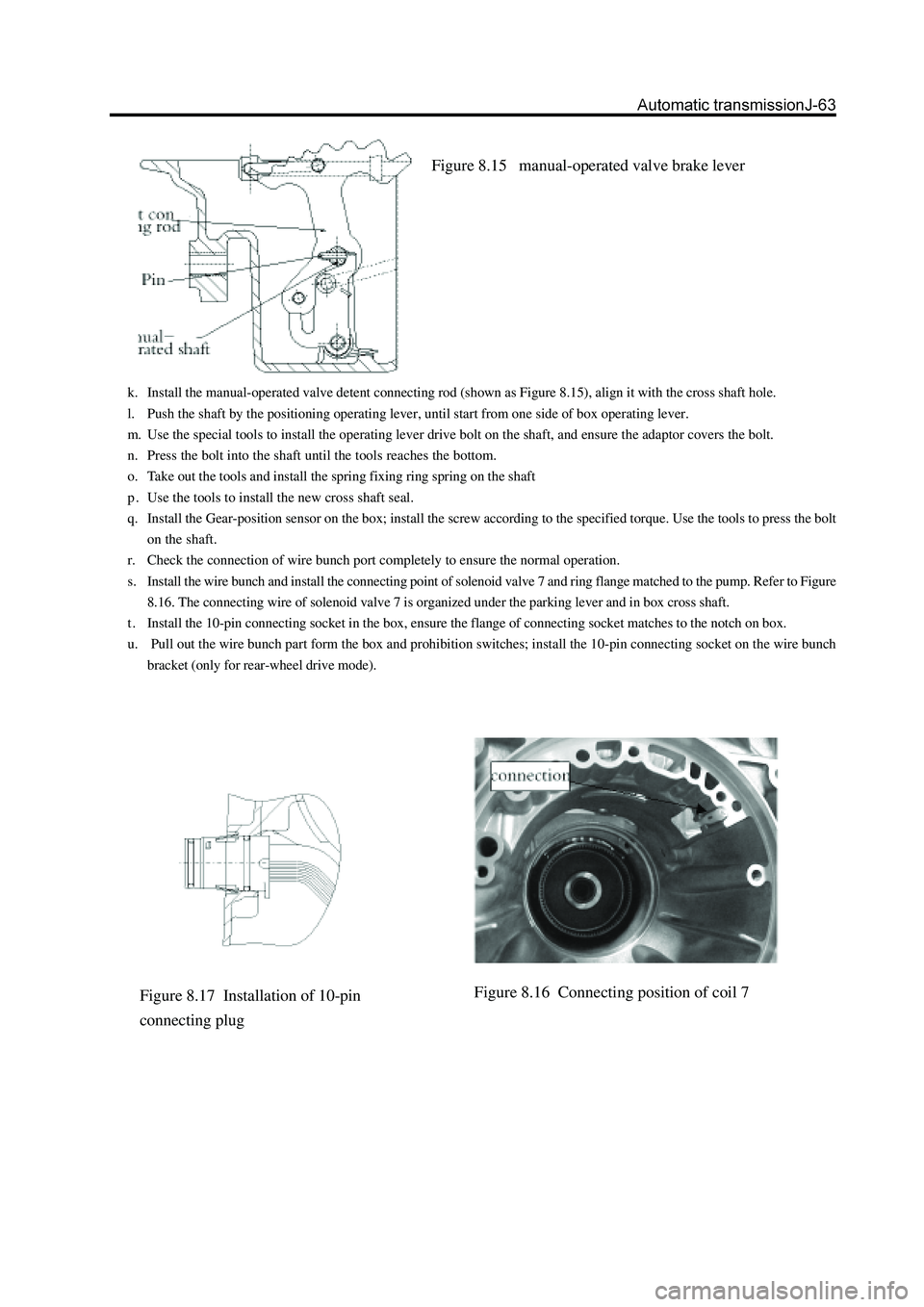

Figure 8.15 manual-operated valve brake lever

k. Install the manual-operated valve detent connecting rod (shown as Figure 8.15), align it with the cross shaft hole.

l. Push the shaft by the positioning operating lever, until start from one side of box operating lever.

m. Use the special tools to install the operating lever drive bolt on the shaft, and ensure the adaptor covers the bolt.

n. Press the bolt into the shaft until the tools reaches the bottom.

o. Take out the tools and install the spring fixing ring spring on the shaft

p . Use the tools to install the new cross shaft seal.

q. Install the Gear-position sensor on the box; install the screw according to the specified torque. Use the tools to press the bolt

on the shaft.

r. Check the connection of wire bunch port completely to ensure the normal operation.

s. Install the wire bunch and install the connecting point of solenoid valve 7 and ring flange matched to the pump. Refer to Figure

8.16. The connecting wire of solenoid valve 7 is organized under the parking lever and in box cross shaft.

t . Install the 10-pin connecting socket in the box, ensure the flange of connecting socket matches to the notch on box.

u. Pull out the wire bunch part form the box and prohibition switches; install the 10-pin connecting socket on the wire bunch

bracket (only for rear-wheel drive mode).

Figure 8.16 Connecting position of coil 7Figure 8.17 Installation of 10-pin

connecting plug

Page 151 of 425

e. If need to install the new friction disk, please remove the clutch assembly and immerse the friction assembly into the

transmission fluid for 5 minutes at least before the installation.

f. Check whether the clutch C1 wheel axle is matched with the overspeed shaft. It should replace the wheel axle and wheel axle

assembly if loose.

g. Coat the small nylon thrust insulation plate with the Vaseline and installs it on the overspeed shaft. Refer to Figure 8.19.

h. It should be carefully when install the overspeed shaft on the C1 cylinder to avoid the damage of sealing ring.

i. Use the Vaseline to install the small copper C1 wheel axle thrust washer, shown as Figure 8.19.

j. Check the input shaft for problem. Install the input shaft on the cylinder and use the ring spring to install the wire safety of

input shaft and cylinder. Ensure the coil is in groove completely.

k. Use the petroleum jelly to install the gasket and place it on the input shaft.

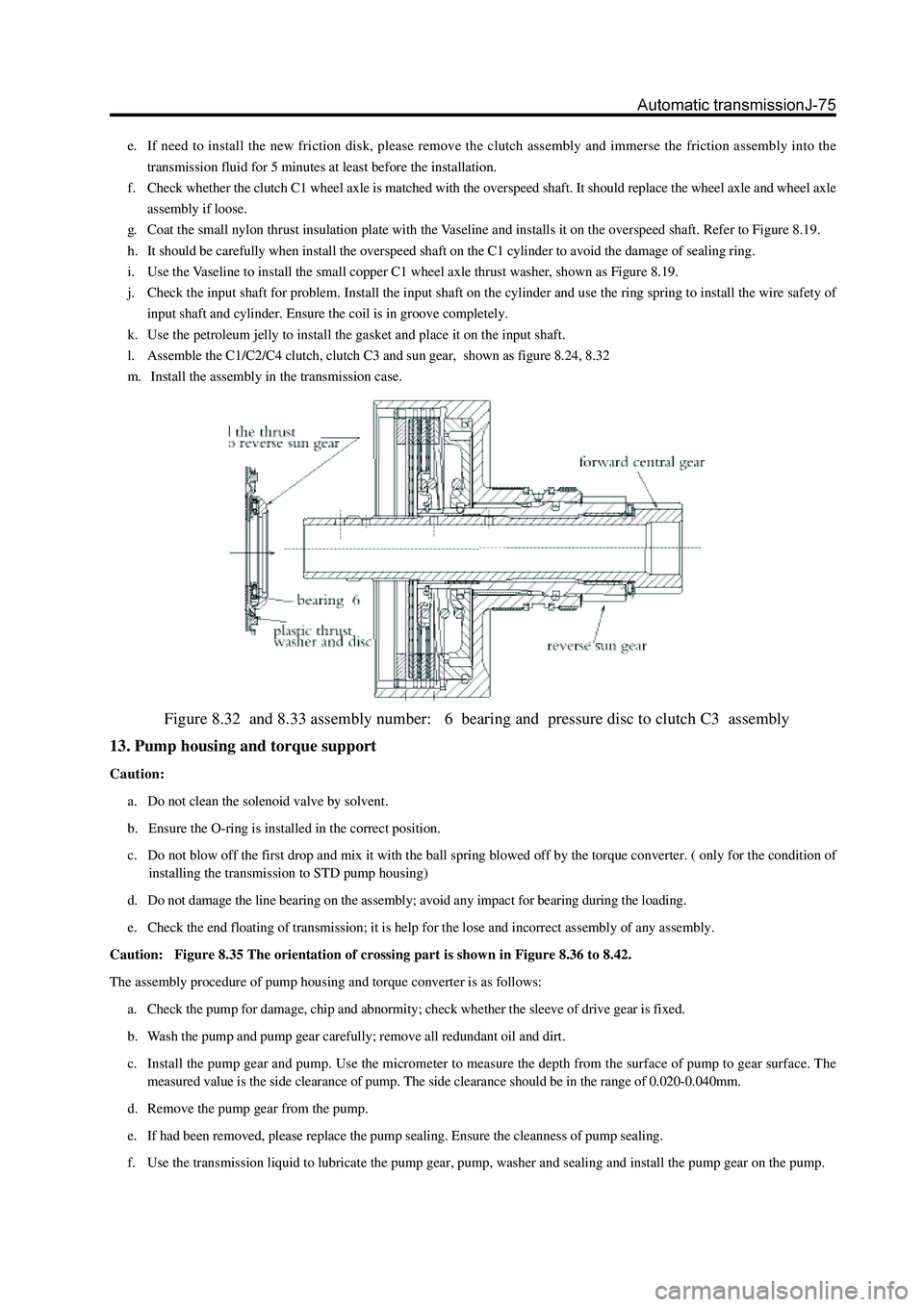

l. Assemble the C1/C2/C4 clutch, clutch C3 and sun gear, shown as figure 8.24, 8.32

m. Install the assembly in the transmission case.

Figure 8.32 and 8.33 assembly number: 6 bearing and pressure disc to clutch C3 assembly

13. Pump housing and torque support

Caution:

a. Do not clean the solenoid valve by solvent.

b. Ensure the O-ring is installed in the correct position.

c. Do not blow off the first drop and mix it with the ball spring blowed off by the torque converter. ( only for the condition of

installing the transmission to STD pump housing)

d. Do not damage the line bearing on the assembly; avoid any impact for bearing during the loading.

e. Check the end floating of transmission; it is help for the lose and incorrect assembly of any assembly.

Caution: Figure 8.35 The orientation of crossing part is shown in Figure 8.36 to 8.42.

The assembly procedure of pump housing and torque converter is as follows:

a. Check the pump for damage, chip and abnormity; check whether the sleeve of drive gear is fixed.

b. Wash the pump and pump gear carefully; remove all redundant oil and dirt.

c. Install the pump gear and pump. Use the micrometer to measure the depth from the surface of pump to gear surface. The

measured value is the side clearance of pump. The side clearance should be in the range of 0.020-0.040mm.

d. Remove the pump gear from the pump.

e. If had been removed, please replace the pump sealing. Ensure the cleanness of pump sealing.

f. Use the transmission liquid to lubricate the pump gear, pump, washer and sealing and install the pump gear on the pump.

Page 152 of 425

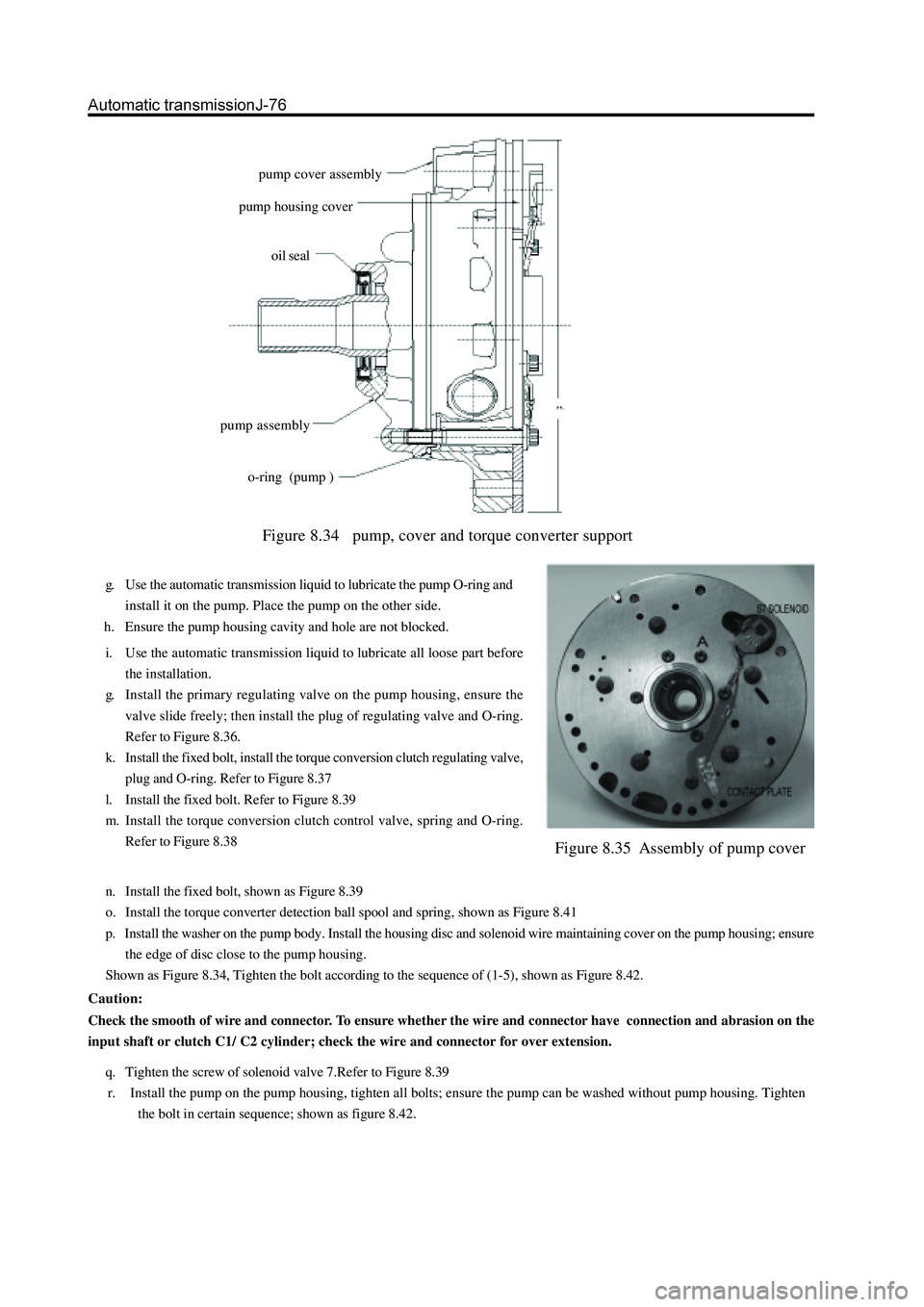

Figure 8.34 pump, cover and torque converter support

g. Use the automatic transmission liquid to lubricate the pump O-ring and

install it on the pump. Place the pump on the other side.

h. Ensure the pump housing cavity and hole are not blocked.

Figure 8.35 Assembly of pump cover

i. Use the automatic transmission liquid to lubricate all loose part before

the installation.

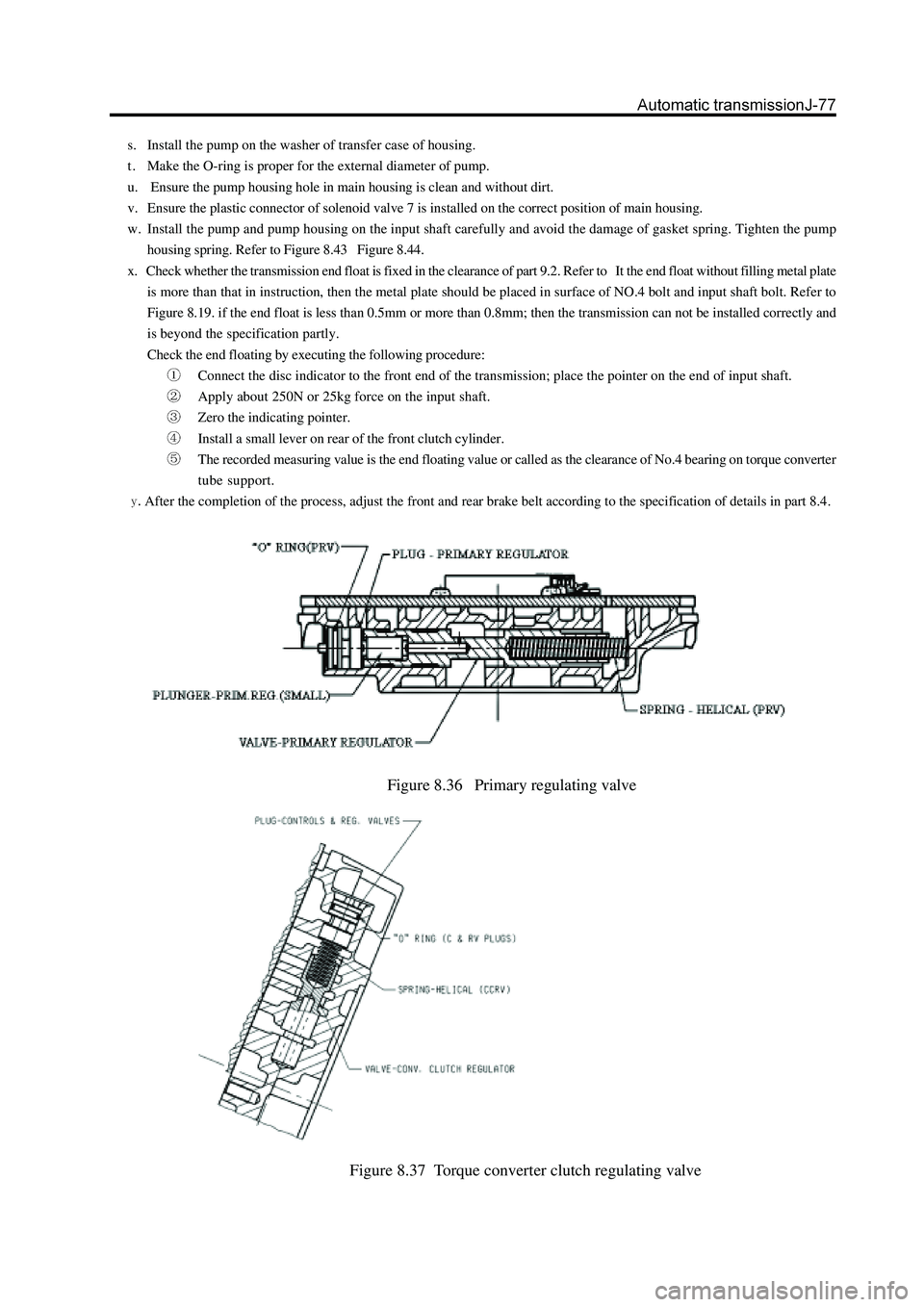

g. Install the primary regulating valve on the pump housing, ensure the

valve slide freely; then install the plug of regulating valve and O-ring.

Refer to Figure 8.36.

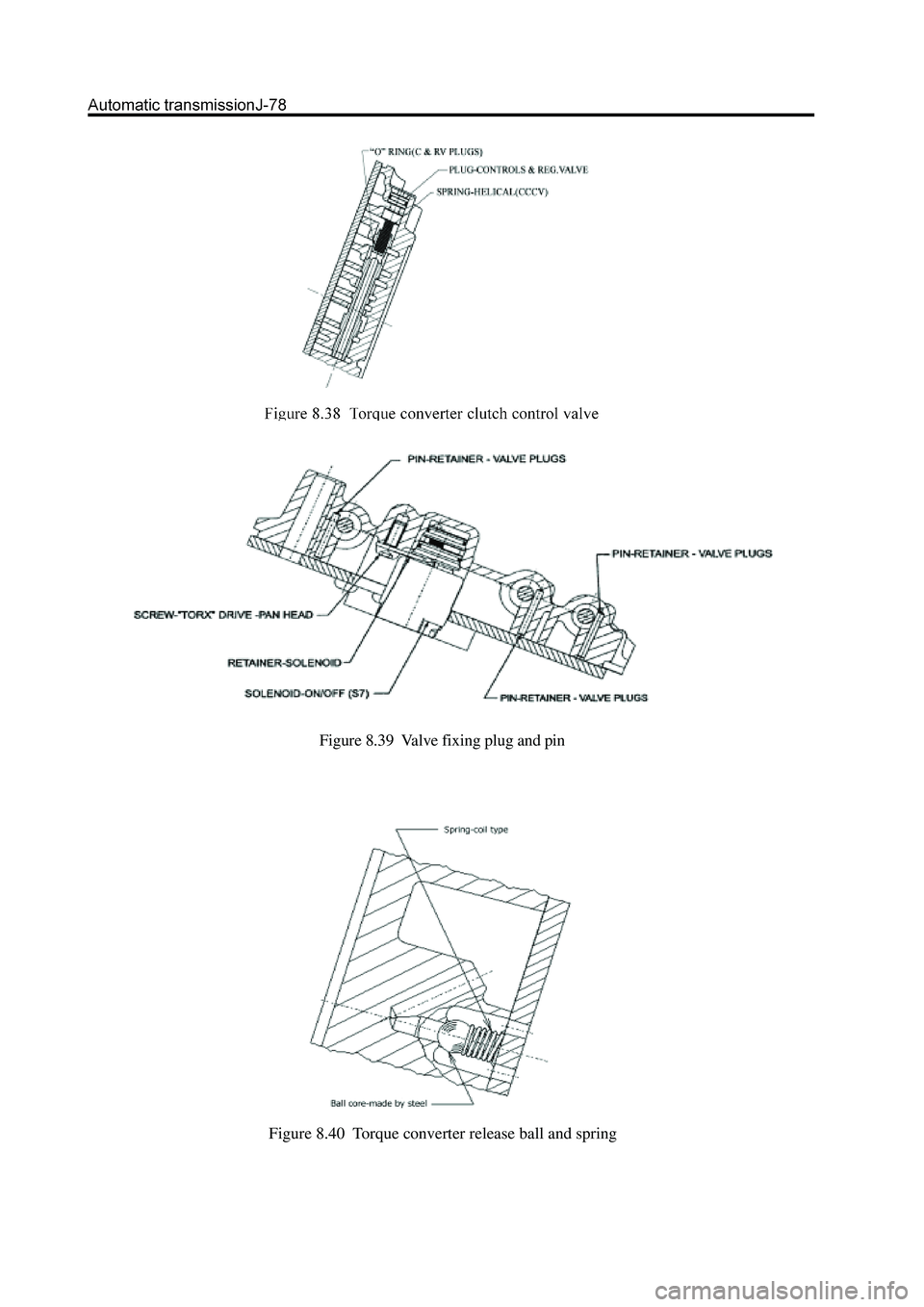

k. Install the fixed bolt, install the torque conversion clutch regulating valve,

plug and O-ring. Refer to Figure 8.37

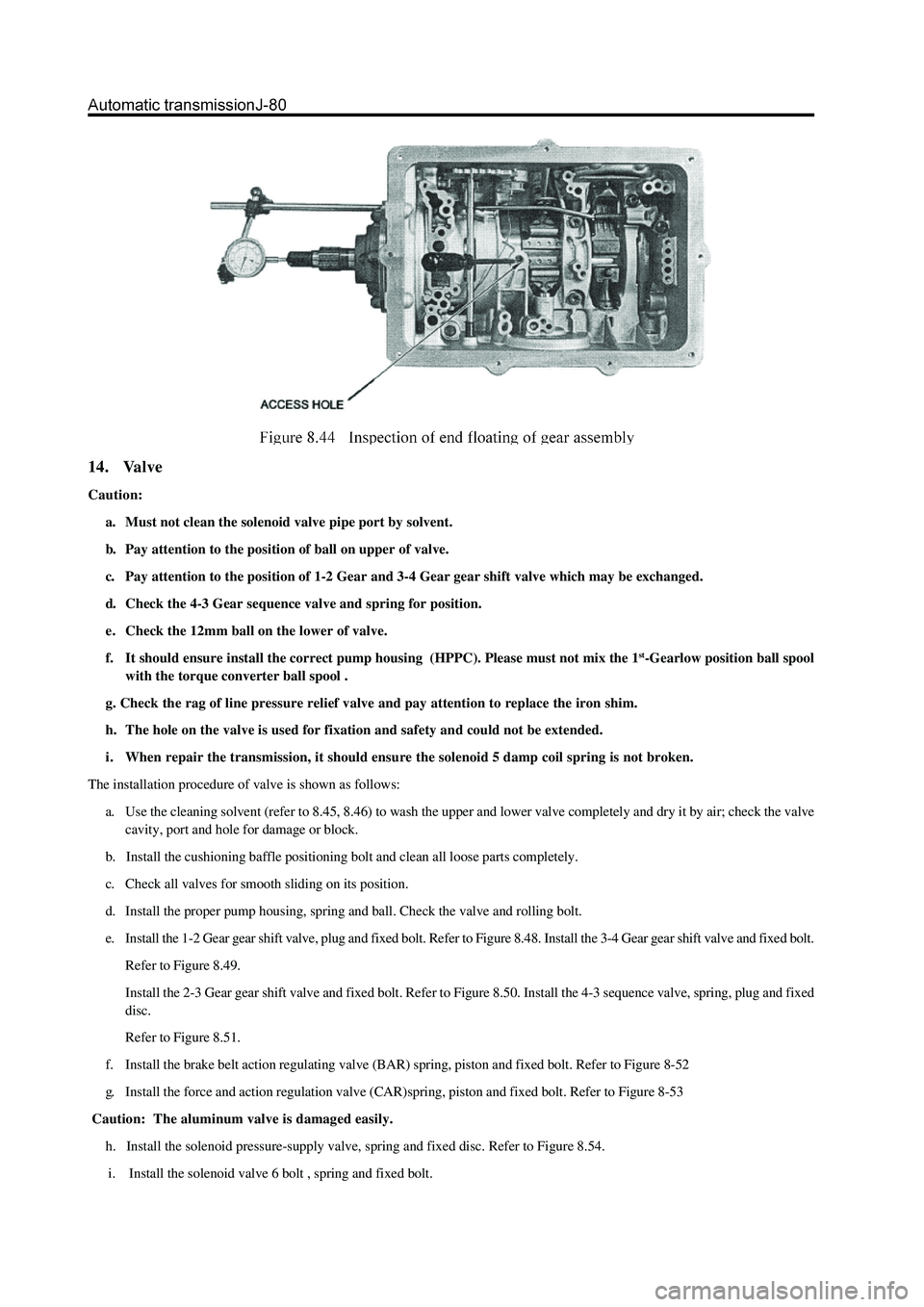

l. Install the fixed bolt. Refer to Figure 8.39

m. Install the torque conversion clutch control valve, spring and O-ring.

Refer to Figure 8.38pump cover assembly

pump housing cover

oil seal

pump assembly

o-ring (pump )

n. Install the fixed bolt, shown as Figure 8.39

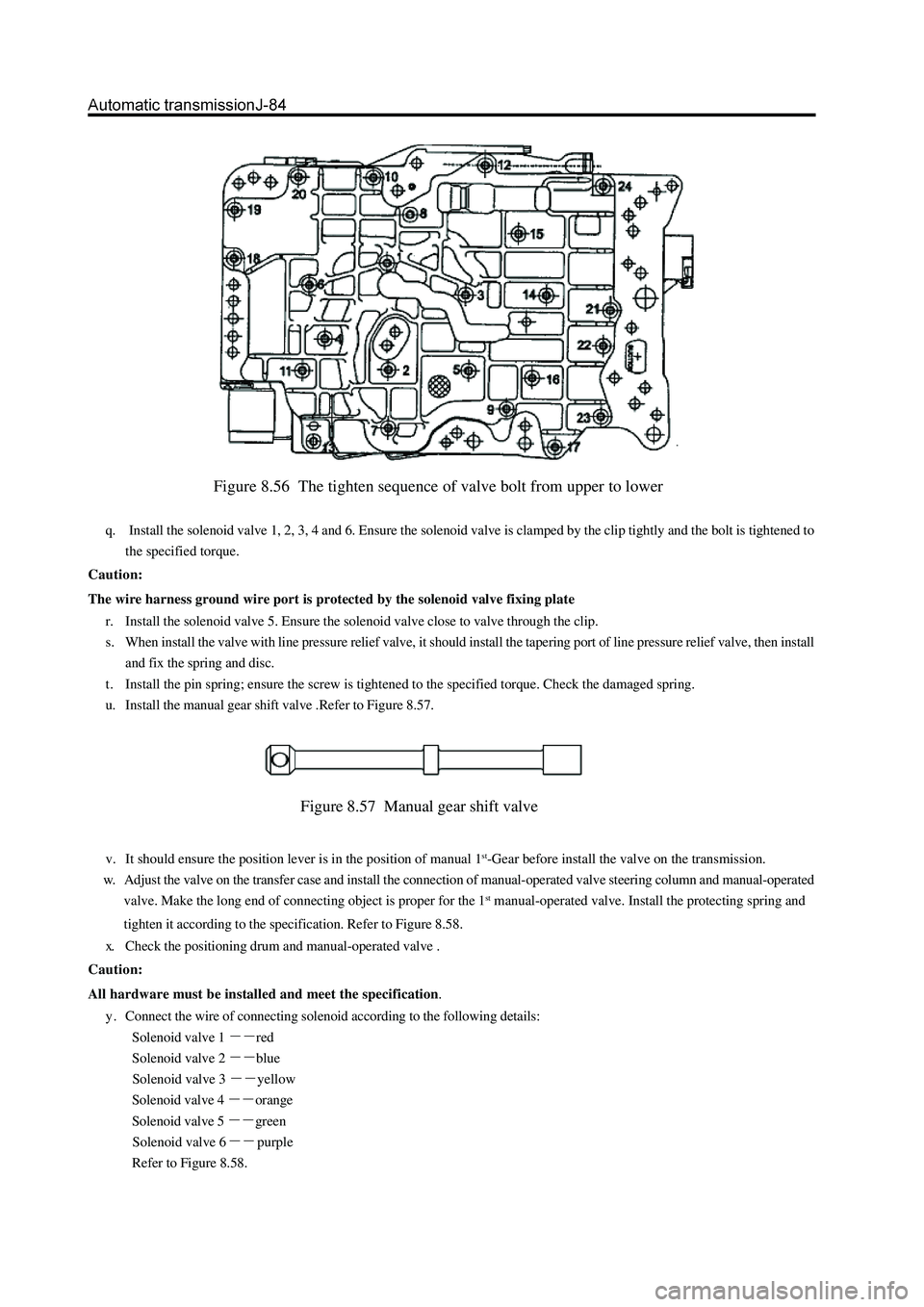

o. Install the torque converter detection ball spool and spring, shown as Figure 8.41

p. Install the washer on the pump body. Install the housing disc and solenoid wire maintaining cover on the pump housing; ensure

the edge of disc close to the pump housing.

Shown as Figure 8.34, Tighten the bolt according to the sequence of (1-5), shown as Figure 8.42.

Caution:

Check the smooth of wire and connector. To ensure whether the wire and connector have connection and abrasion on the

input shaft or clutch C1/ C2 cylinder; check the wire and connector for over extension.

q. Tighten the screw of solenoid valve 7.Refer to Figure 8.39

r. Install the pump on the pump housing, tighten all bolts; ensure the pump can be washed without pump housing. Tighten

the bolt in certain sequence; shown as figure 8.42.

Page 153 of 425

Figure 8.36 Primary regulating valve

Figure 8.37 Torque converter clutch regulating valve

s. Install the pump on the washer of transfer case of housing.

t . Make the O-ring is proper for the external diameter of pump.

u. Ensure the pump housing hole in main housing is clean and without dirt.

v. Ensure the plastic connector of solenoid valve 7 is installed on the correct position of main housing.

w. Install the pump and pump housing on the input shaft carefully and avoid the damage of gasket spring. Tighten the pump

housing spring. Refer to Figure 8.43 Figure 8.44.

x. Check whether the transmission end float is fixed in the clearance of part 9.2. Refer to It the end float without filling metal plate

is more than that in instruction, then the metal plate should be placed in surface of NO.4 bolt and input shaft bolt. Refer to

Figure 8.19. if the end float is less than 0.5mm or more than 0.8mm; then the transmission can not be installed correctly and

is beyond the specification partly.

Check the end floating by executing the following procedure:

Connect the disc indicator to the front end of the transmission; place the pointer on the end of input shaft.

Apply about 250N or 25kg force on the input shaft.

Zero the indicating pointer.

Install a small lever on rear of the front clutch cylinder.

The recorded measuring value is the end floating value or called as the clearance of No.4 bearing on torque converter

tube support.

After the completion of the process, adjust the front and rear brake belt according to the specification of details in part 8.4.

Page 154 of 425

Figure 8.39 Valve fixing plug and pin

Figure 8.40 Torque converter release ball and spring

Page 156 of 425

14. Valve

Caution:

a. Must not clean the solenoid valve pipe port by solvent.

b. Pay attention to the position of ball on upper of valve.

c. Pay attention to the position of 1-2 Gear and 3-4 Gear gear shift valve which may be exchanged.

d. Check the 4-3 Gear sequence valve and spring for position.

e. Check the 12mm ball on the lower of valve.

f. It should ensure install the correct pump housing (HPPC). Please must not mix the 1

st-Gearlow position ball spool

with the torque converter ball spool .

g. Check the rag of line pressure relief valve and pay attention to replace the iron shim.

h. The hole on the valve is used for fixation and safety and could not be extended.

i . When repair the transmission, it should ensure the solenoid 5 damp coil spring is not broken.

The installation procedure of valve is shown as follows:

a. Use the cleaning solvent (refer to 8.45, 8.46) to wash the upper and lower valve completely and dry it by air; check the valve

cavity, port and hole for damage or block.

b. Install the cushioning baffle positioning bolt and clean all loose parts completely.

c. Check all valves for smooth sliding on its position.

d. Install the proper pump housing, spring and ball. Check the valve and rolling bolt.

e. Install the 1-2 Gear gear shift valve, plug and fixed bolt. Refer to Figure 8.48. Install the 3-4 Gear gear shift valve and fixed bolt.

Refer to Figure 8.49.

Install the 2-3 Gear gear shift valve and fixed bolt. Refer to Figure 8.50. Install the 4-3 sequence valve, spring, plug and fixed

disc.

Refer to Figure 8.51.

f. Install the brake belt action regulating valve (BAR) spring, piston and fixed bolt. Refer to Figure 8-52

g. Install the force and action regulation valve (CAR)spring, piston and fixed bolt. Refer to Figure 8-53

Caution: The aluminum valve is damaged easily.

h. Install the solenoid pressure-supply valve, spring and fixed disc. Refer to Figure 8.54.

i. Install the solenoid valve 6 bolt , spring and fixed bolt.

Page 160 of 425

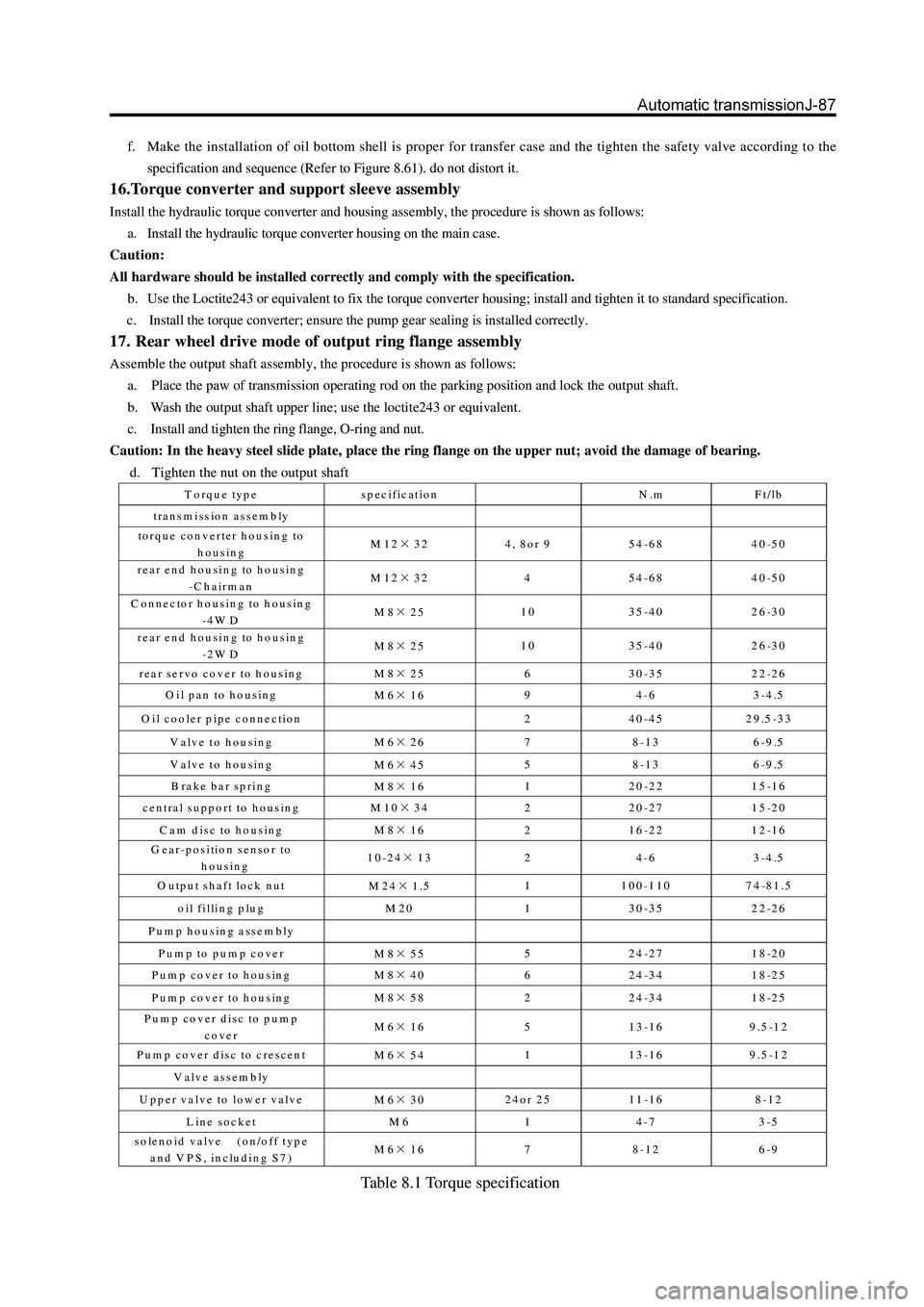

Figure 8.56 The tighten sequence of valve bolt from upper to lower

q. Install the solenoid valve 1, 2, 3, 4 and 6. Ensure the solenoid valve is clamped by the clip tightly and the bolt is tightened to

the specified torque.

Caution:

The wire harness ground wire port is protected by the solenoid valve fixing plate

r. Install the solenoid valve 5. Ensure the solenoid valve close to valve through the clip.

s. When install the valve with line pressure relief valve, it should install the tapering port of line pressure relief valve, then install

and fix the spring and disc.

t . Install the pin spring; ensure the screw is tightened to the specified torque. Check the damaged spring.

u. Install the manual gear shift valve .Refer to Figure 8.57.

Figure 8.57 Manual gear shift valve

v. It should ensure the position lever is in the position of manual 1st-Gear before install the valve on the transmission.

w. Adjust the valve on the transfer case and install the connection of manual-operated valve steering column and manual-operated

valve. Make the long end of connecting object is proper for the 1

st manual-operated valve. Install the protecting spring and

tighten it according to the specification. Refer to Figure 8.58.

x. Check the positioning drum and manual-operated valve .

Caution:

All hardware must be installed and meet the specification.

y . Connect the wire of connecting solenoid according to the following details:

Solenoid valve 1

red

Solenoid valve 2

blue

Solenoid valve 3

yellow

Solenoid valve 4

orange

Solenoid valve 5

green

Solenoid valve 6

purple

Refer to Figure 8.58.

Page 163 of 425

f. Make the installation of oil bottom shell is proper for transfer case and the tighten the safety valve according to the

specification and sequence (Refer to Figure 8.61). do not distort it.

16.Torque converter and support sleeve assembly

Install the hydraulic torque converter and housing assembly, the procedure is shown as follows:

a. Install the hydraulic torque converter housing on the main case.

Caution:

All hardware should be installed correctly and comply with the specification.

b. Use the Loctite243 or equivalent to fix the torque converter housing; install and tighten it to standard specification.

c. Install the torque converter; ensure the pump gear sealing is installed correctly.

17. Rear wheel drive mode of output ring flange assembly

Assemble the output shaft assembly, the procedure is shown as follows:

a. Place the paw of transmission operating rod on the parking position and lock the output shaft.

b. Wash the output shaft upper line; use the loctite243 or equivalent.

c. Install and tighten the ring flange, O-ring and nut.

Caution: In the heavy steel slide plate, place the ring flange on the upper nut; avoid the damage of bearing.

d. Tighten the nut on the output shaft

Torque type specification N.m Ft/lb

tra n s m iss io n as se m b ly

torque converter housing to

housing M12×32 4, 8or 9 54-68 40-50

rear end housing to housing

-C h a irm a n M12×32 4 54-68 40-50

C onnector housing to housing

-4 W D M8×25 10 35-40 26-30

rear end housing to housing

-2 W D M8×25 10 35-40 26-30

rear servo cover to housing

M8×25 6 30-35 22-26

O il pan to housing

M6×16 9 4-6 3-4.5

O il cooler pipe connection

2 40-45 29.5-33

V alve to housing

M6×26 7 8-13 6-9.5

V alve to housing

M6×45 5 8-13 6-9.5

B rake bar spring

M8×16 1 20-22 15-16

central support to housing

M10×34 2 20-27 15-20

C am disc to housing

M8×16 2 16-22 12-16

G ear-position sensor to

housing 10-24×13 2 4-6 3-4.5

O utput shaft lock nut

M24×1.5 1 100-110 74-81.5

oil filling plug M 20 1 30-35 22-26

Pump housing assembly

Pump to pump cover

M8×55 5 24-27 18-20

Pum p cover to housing

M8×40 6 24-34 18-25

Pum p cover to housing

M8×58 2 24-34 18-25

Pum p cover disc to pum p

cover M6×16 5 13-16 9.5-12

Pum p cover disc to crescent

M6×54 1 13-16 9.5-12

Valve assem bly

U p p e r v a lv e to lo w e r v a lv e

M6×30 24or 25 11-16 8-12

Line socket M 6 1 4-7 3-5

solenoid valve (on/off type

and VPS, including S7) M6×16 7 8-12 6-9

Table 8.1 Torque specification

Page 166 of 425

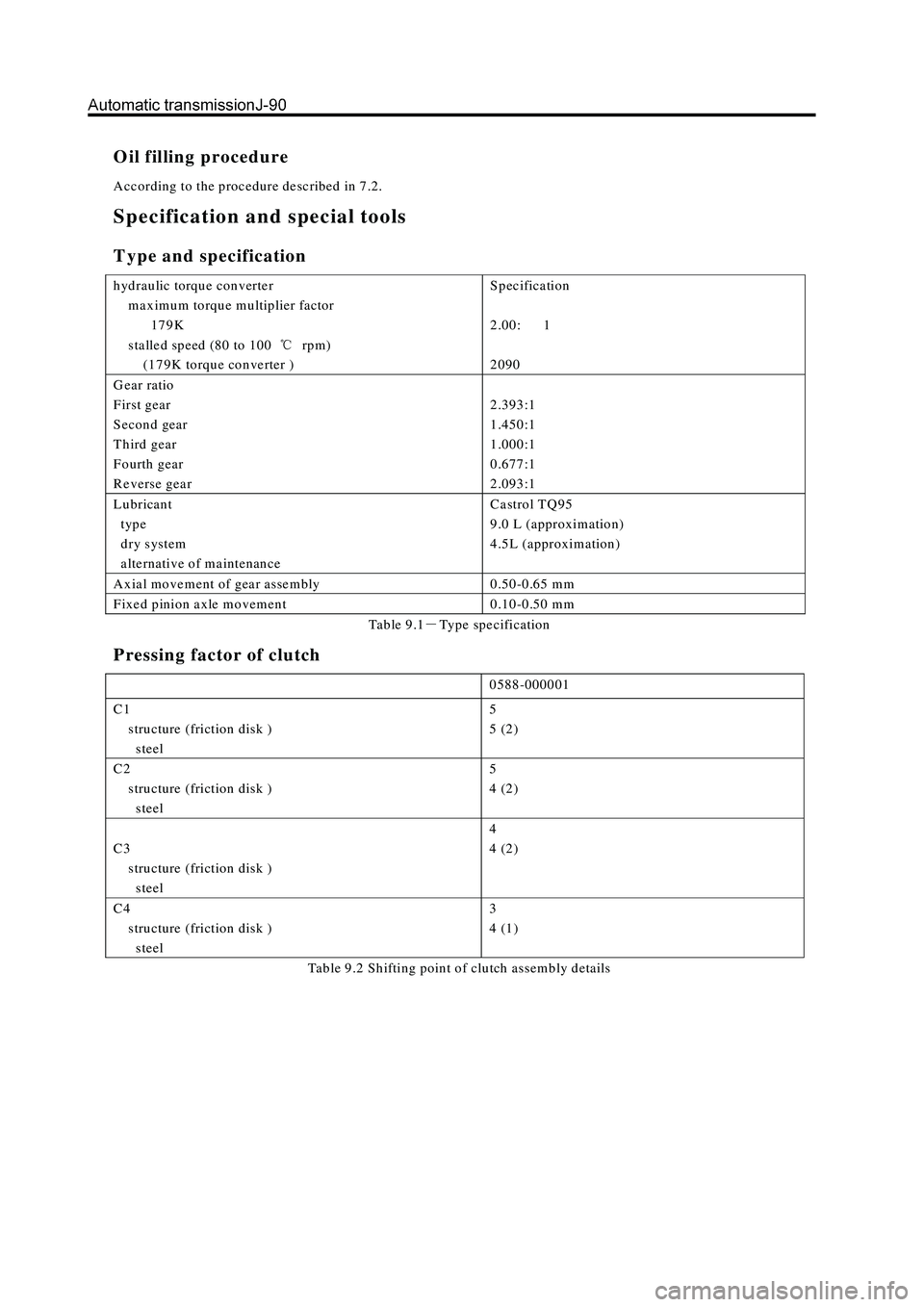

O il fillin g procedure

According to the procedure described in 7.2.

Specification and special tools

Type and specification

hydraulic torque converter

maximum torque multiplier factor

179K

stalled speed (80 to 100 ℃ rp m)

(179K torque converter ) Specification

2.00: 1

2090

Gear ratio

First gear

Second gear

Third gear

Fourth gear

Reverse gear

2.393:1

1.450:1

1.000:1

0.677:1

2.093:1

Lubricant

type

dry system

alternative of maintenance Castrol TQ95

9.0 L (approximation)

4.5L (approximation)

Axial movement of gear assembly 0.50-0.65 mm

Fixed pinion axle movement 0.10-0.50 mm

Tab le 9 .1-Type specification

Pressing factor of clutch

0588-000001

C1

structure (friction disk )

steel 5

5 (2)

C2

structure (friction disk )

steel 5

4 (2)

C3

structure (friction disk )

steel 4

4 (2)

C4

structure (friction disk )

steel 3

4 (1)

Table 9.2 Shifting point of clutch assembly details

Page 171 of 425

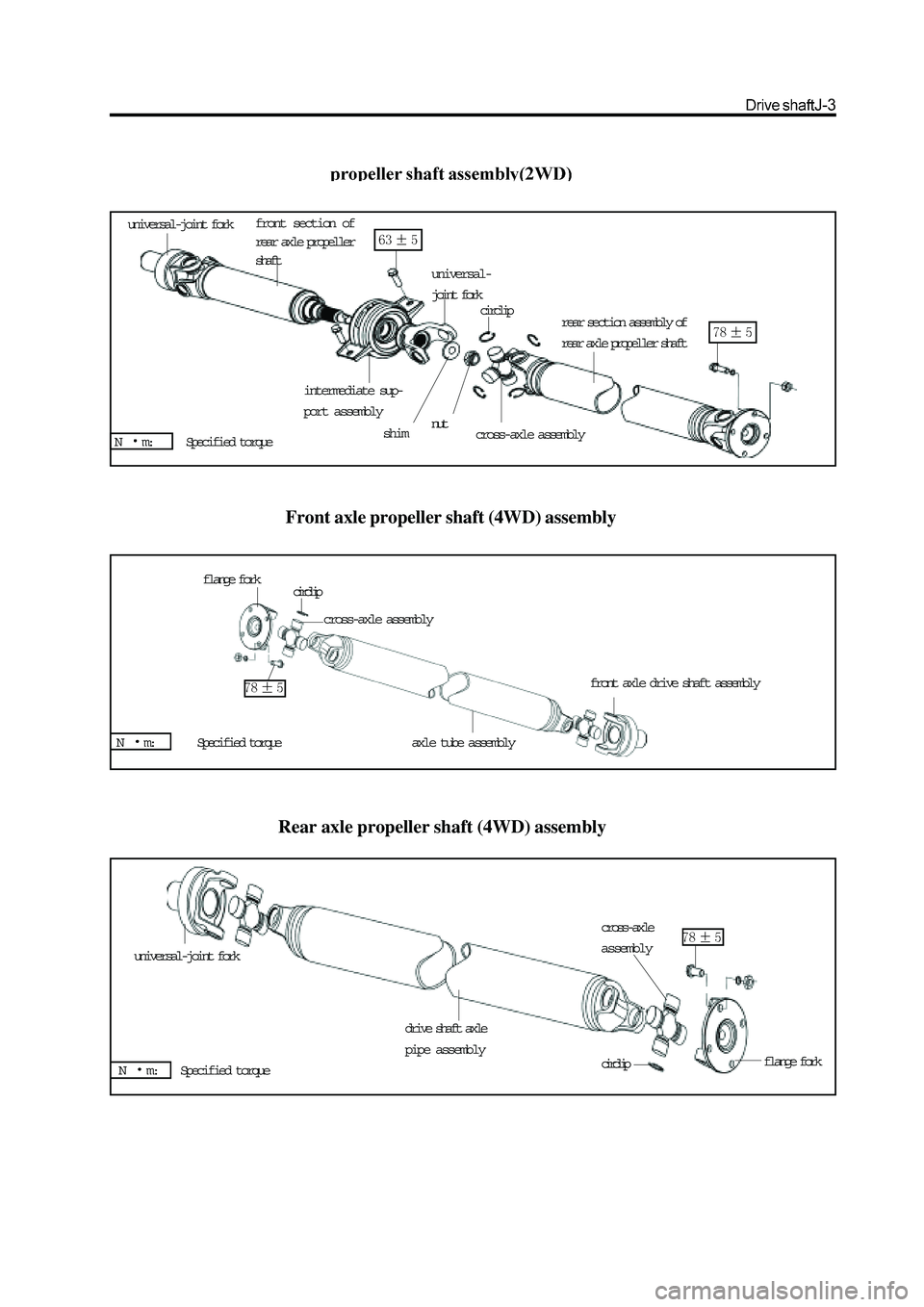

Front axle propeller shaft (4WD) assembly

Rear axle propeller shaft (4WD) assembly

N m: Specified torque

universal-joint forkfront section of

rear axle propeller

shaft

intermediate sup-

port assembly

universal-

joint fork

shimnut

circlip

cross-axle assembly

rear section assembly of

rear axle propeller shaft

flange forkcirclip

cross-axle assembly

axle tube assembly

front axle drive shaft assembly

N

m: Specified torque

universal-joint fork

circlip

cross-axle

assembly

drive shaft axle

pipe assembly

N

m: Specified torqueflange fork