torque GREAT WALL HOVER 2006 Service Owners Manual

[x] Cancel search | Manufacturer: GREAT WALL, Model Year: 2006, Model line: HOVER, Model: GREAT WALL HOVER 2006Pages: 425, PDF Size: 26.05 MB

Page 210 of 425

clip

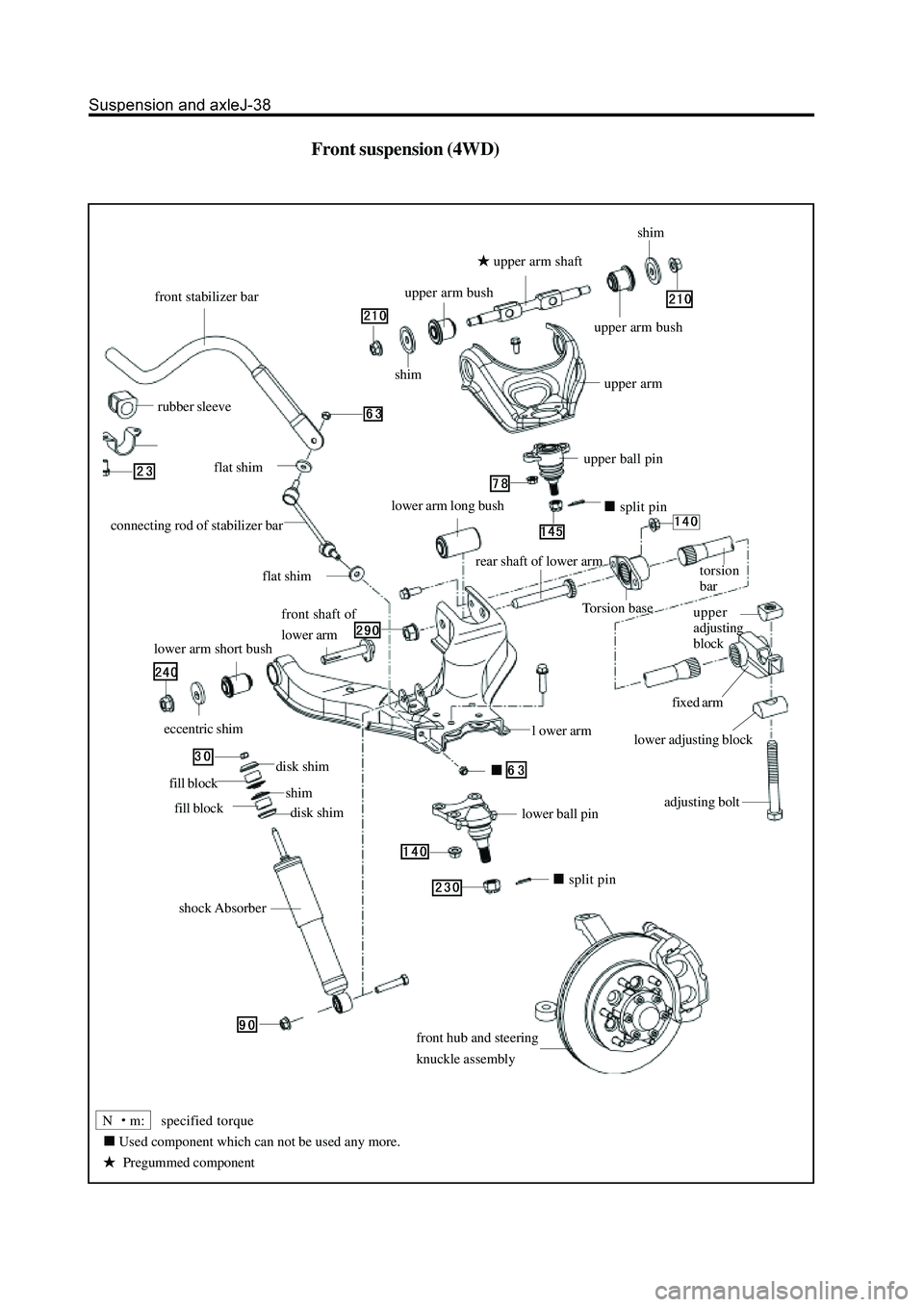

Front suspension (4WD)

N m: specified torque

Used component which can not be used any more.

Pregummed component

rubber sleeve

front shaft of

lower arm

disk shim

fill blockshimfill blockdisk shim

shock Absorber

front hub and steering

knuckle assembly

split pin

lower ball pinadjusting bolt

lower adjusting block

fixed arm

upper

adjusting

block

l ower arm

rear shaft of lower arm

Torsion base

torsion

bar

lower arm long bushsplit pin

upper ball pin

upper arm

shim

upper arm bush

upper arm shaft

upper arm bush

shim

front stabilizer bar

flat shim

connecting rod of stabilizer bar

flat shim

lower arm short bush

eccentric shim

Page 211 of 425

Ball pin

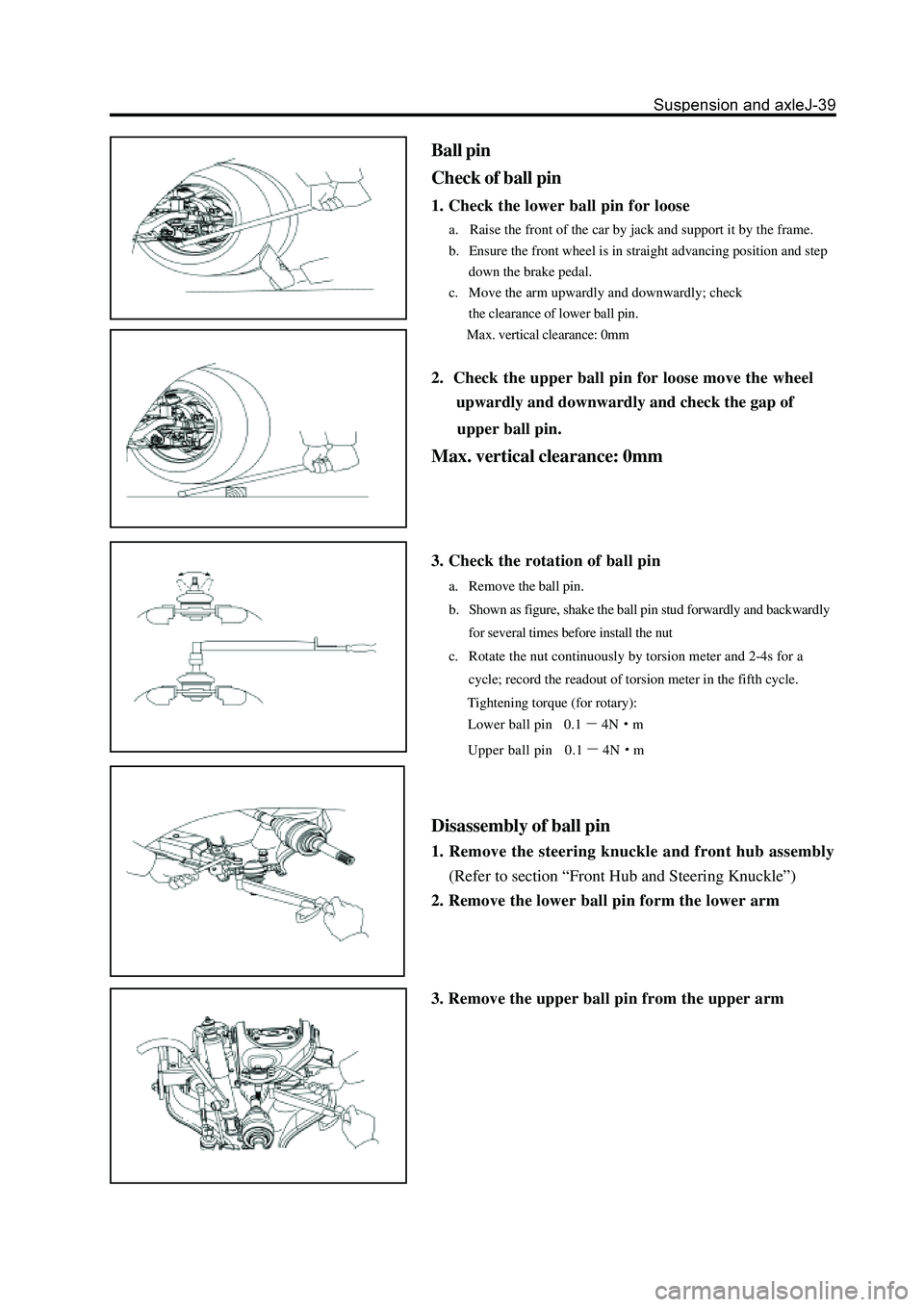

Check of ball pin

1. Check the lower ball pin for loose

a. Raise the front of the car by jack and support it by the frame.

b. Ensure the front wheel is in straight advancing position and step

down the brake pedal.

c. Move the arm upwardly and downwardly; check

the clearance of lower ball pin.

Max. vertical clearance: 0mm

2. Check the upper ball pin for loose move the wheel

upwardly and downwardly and check the gap of

upper ball pin.

Max. vertical clearance: 0mm

3. Check the rotation of ball pin

a. Remove the ball pin.

b. Shown as figure, shake the ball pin stud forwardly and backwardly

for several times before install the nut

c. Rotate the nut continuously by torsion meter and 2-4s for a

cycle; record the readout of torsion meter in the fifth cycle.

Tightening torque (for rotary):

Lower ball pin 0.1

4Nm

Upper ball pin 0.1

4Nm

Disassembly of ball pin

1. Remove the steering knuckle and front hub assembly

(Refer to section “Front Hub and Steering Knuckle”)

2. Remove the lower ball pin form the lower arm

3. Remove the upper ball pin from the upper arm

Page 214 of 425

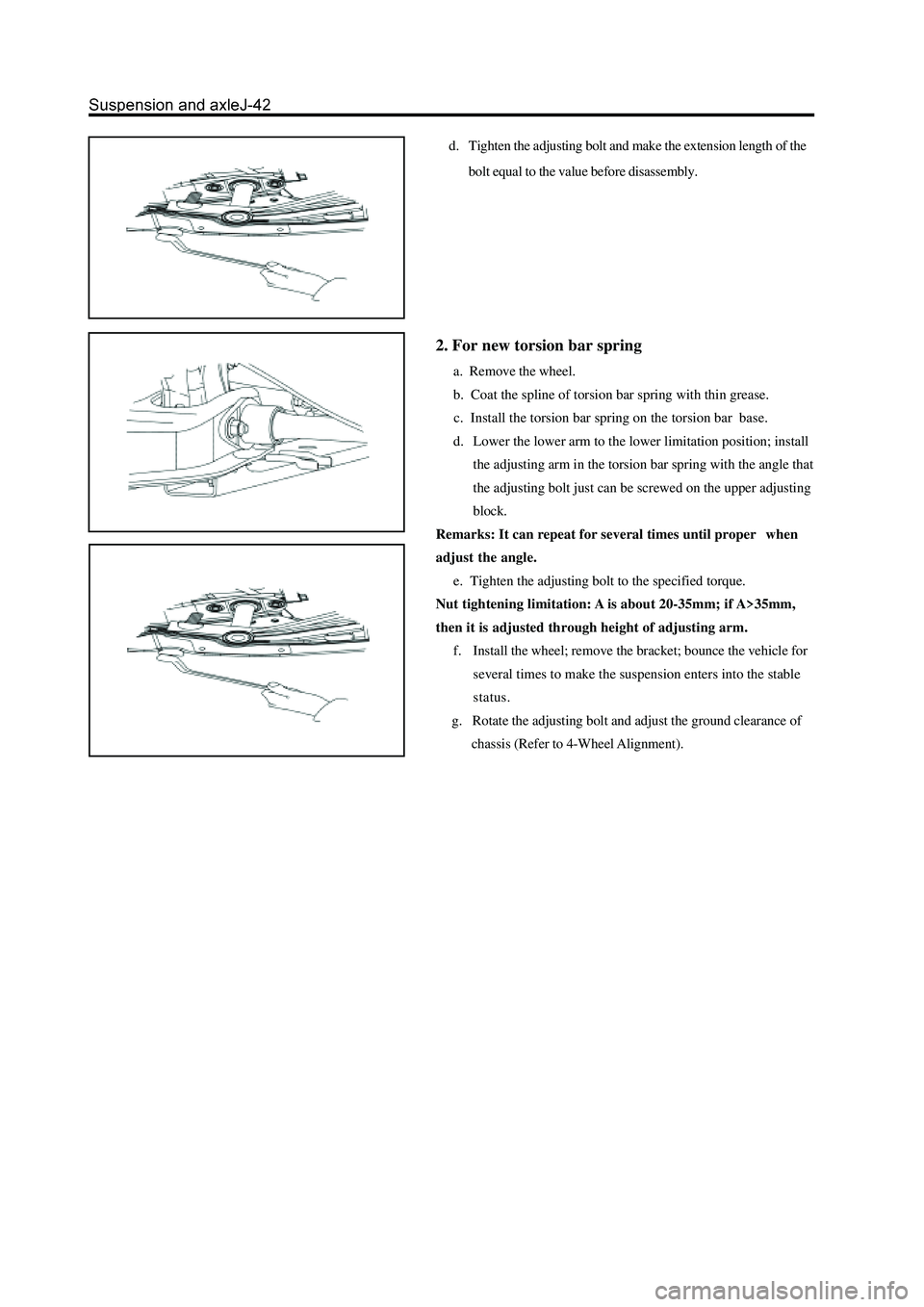

d. Tighten the adjusting bolt and make the extension length of the

bolt equal to the value before disassembly.

2. For new torsion bar spring

a. Remove the wheel.

b. Coat the spline of torsion bar spring with thin grease.

c. Install the torsion bar spring on the torsion bar base.

d. Lower the lower arm to the lower limitation position; install

the adjusting arm in the torsion bar spring with the angle that

the adjusting bolt just can be screwed on the upper adjusting

block.

Remarks: It can repeat for several times until proper when

adjust the angle.

e. Tighten the adjusting bolt to the specified torque.

Nut tightening limitation: A is about 20-35mm; if A>35mm,

then it is adjusted through height of adjusting arm.

f. Install the wheel; remove the bracket; bounce the vehicle for

several times to make the suspension enters into the stable

status.

g. Rotate the adjusting bolt and adjust the ground clearance of

chassis (Refer to 4-Wheel Alignment).

Page 217 of 425

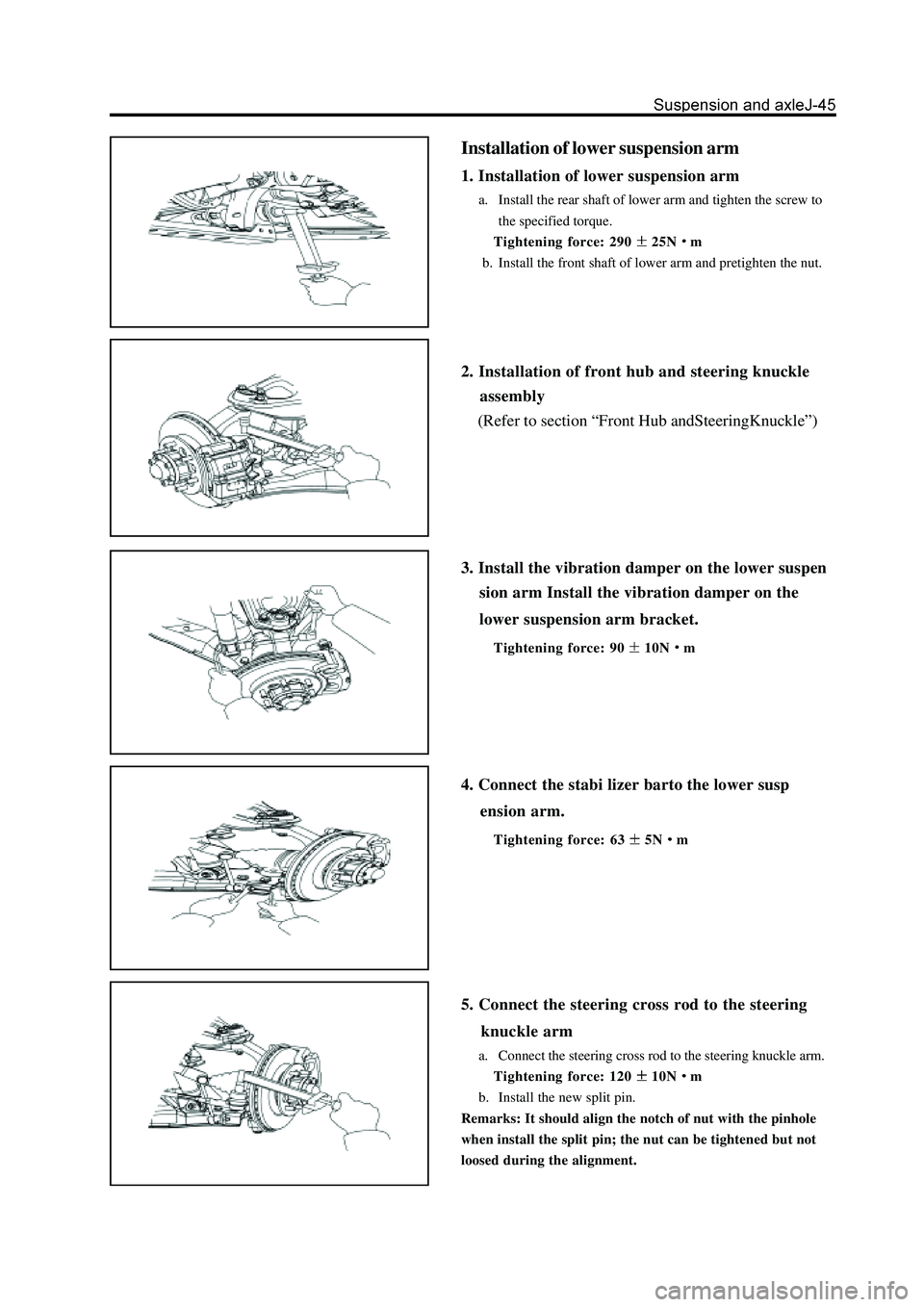

Installation of lower suspension arm

1. Installation of lower suspension arm

a. Install the rear shaft of lower arm and tighten the screw to

the specified torque.

Tightening force: 290

25Nm

b. Install the front shaft of lower arm and pretighten the nut.

2. Installation of front hub and steering knuckle

assembly

(Refer to section “Front Hub andSteeringKnuckle”)

3. Install the vibration damper on the lower suspen

sion arm Install the vibration damper on the

lower suspension arm bracket.

Tightening force: 9010Nm

4. Connect the stabi lizer barto the lower susp

ension arm.

Tightening force: 635Nm

5. Connect the steering cross rod to the steering

knuckle arm

a. Connect the steering cross rod to the steering knuckle arm.

Tightening force: 120

10Nm

b. Install the new split pin.

Remarks: It should align the notch of nut with the pinhole

when install the split pin; the nut can be tightened but not

loosed during the alignment.

Page 218 of 425

6. Install the torsion bar spring

(Refer to the section “Torsion Bar Spring”)

7. Tighten the nut of front shaft of lower arm to the

specified torque

a. Install the wheel, remove the bracket and bounce the vehicle

for several times to make the vibration damper enters into the

stable status.

b. Align the assembly mark and tighten the nut to the specified

torque.

Tightening force: 240

20Nm

8. Check the wheel alignment parameter

(Refer to 4-Wheel Alignment)

Page 220 of 425

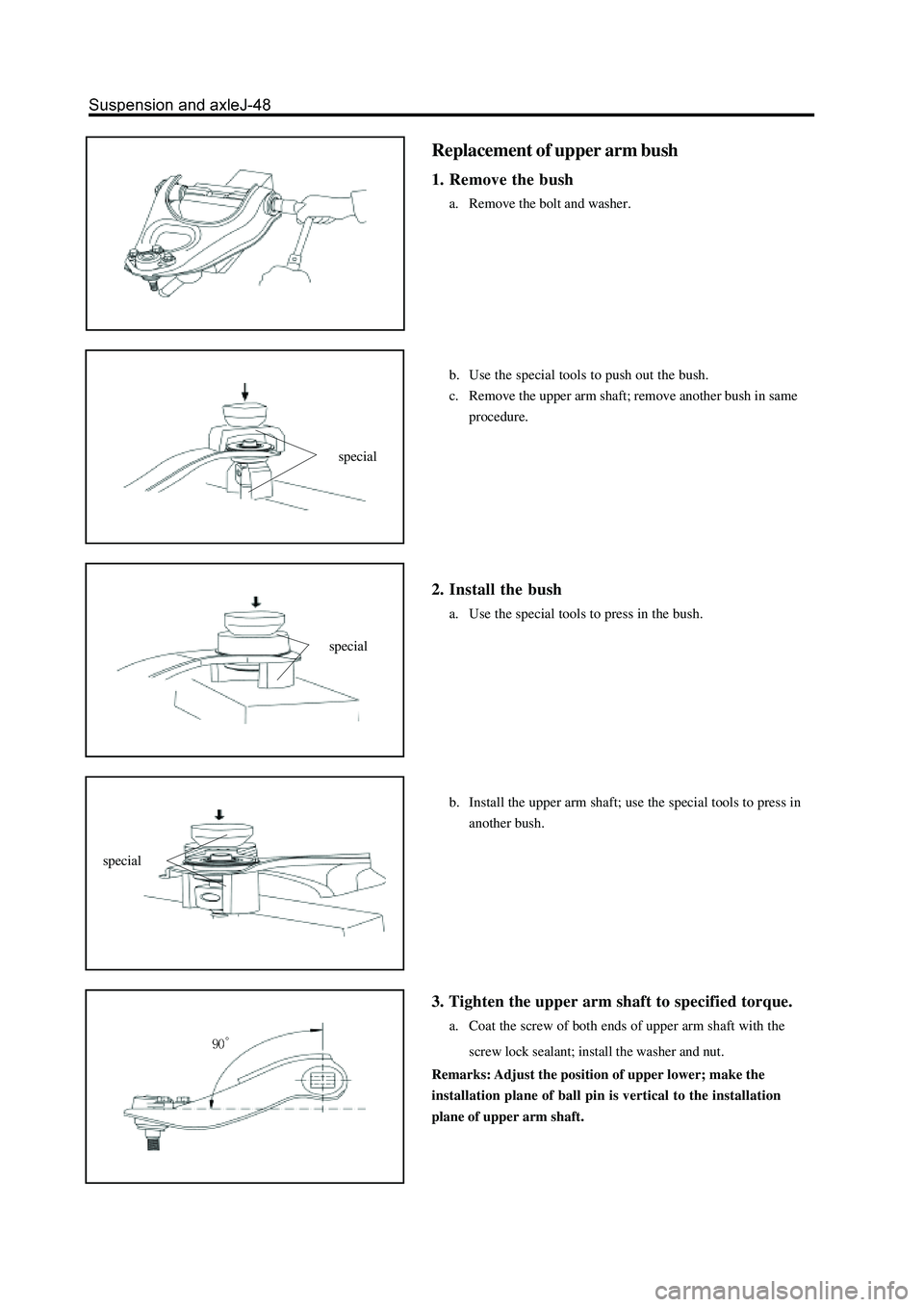

Replacement of upper arm bush

1. Remove the bush

a. Remove the bolt and washer.

b. Use the special tools to push out the bush.

c. Remove the upper arm shaft; remove another bush in same

procedure.

2. Install the bush

a. Use the special tools to press in the bush.

b. Install the upper arm shaft; use the special tools to press in

another bush.

3. Tighten the upper arm shaft to specified torque.

a. Coat the screw of both ends of upper arm shaft with the

screw lock sealant; install the washer and nut.

Remarks: Adjust the position of upper lower; make the

installation plane of ball pin is vertical to the installation

plane of upper arm shaft.

special

special

special

Page 221 of 425

b. Tighten the upper arm shaft nut to specified torque.

Tightening force: 210

10Nm

Installation of upper suspension arm

1. Install the upper suspension arm on the carriage

a. Install the upper suspension arm and camber adjusting shim.

b. Tighten all bolts to the specified torque.

Tightening force: 200

10Nm

Remarks: Install the shim with same quantity and thickness to the

original position.

2. Connect the brake oil pipe of upper arm shaft Tighten

the oil pipe compression nut to specified torque.

Tightening force: 15-17Nm

Remarks: It should tighten four connectors of two two-way valves

to the specified torque if disassemble the right upper arm.

3. Connect the brake hose to the upper arm oil pipe

bracket

a. Thread the brake hose through the hole on upper arm oil pipe

bracket.

b. Insert the sheet steel spring clip by the hammer to fix the brake

hose.

4. Connect the upper ball pin to the steering knuckle.

a. Tighten the slotted nut according to the specified torque.

Tightening force: 145

15Nm

b. Install the new split pin.

Remarks: It should align the notch of nut with the pinhole when

install the split pin; the nut can be tightened but not loosed during

the alignment.

Page 222 of 425

5. Connect the brake hose to the brake caliper.

Install the copper gasket seal and tighten the hollow bolt to the

specified torque.

Tightening force: 50±5N·m

6. Discharge the air in front brake system

(Refer to relevant chapter)

Remarks: It must discharge the air in the rear brake system

i f disassembly the right upper arm.

7. Check the brake fluid for leakage

8. Tighten the upper arm front shaft nut to the

specified torque

a. Install the wheel, remove the bracket and bounce the vehicle for

several times to make the vibration damper enters into the stable

status.

b.Align the assembly mark and tighten the nut to the specified

torque.

Tightening force: 240±20N·m

9. Check the wheel alignment parameter

(Refer to 4-Wheel Alignment)

Page 223 of 425

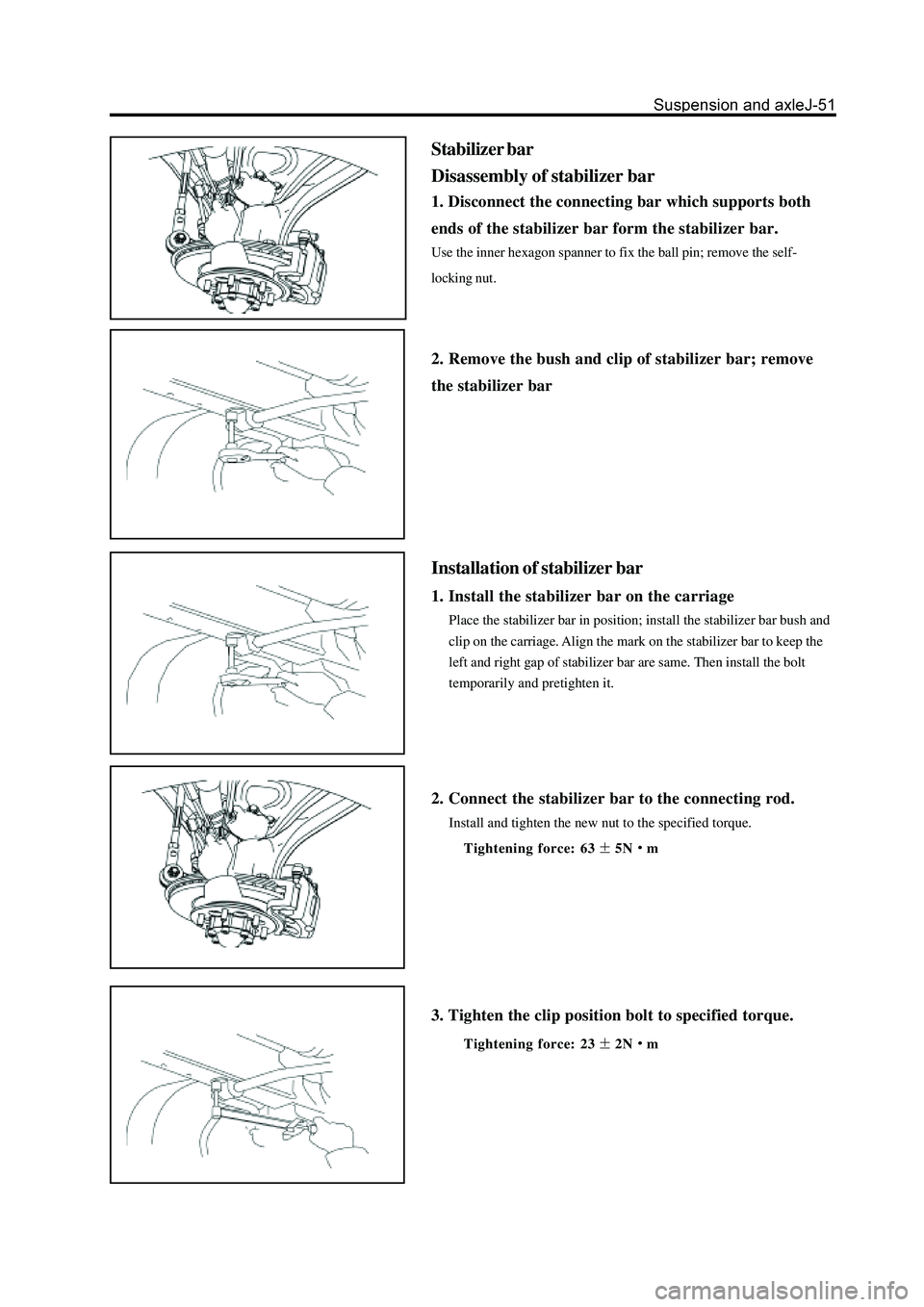

Stabilizer bar

Disassembly of stabilizer bar

1. Disconnect the connecting bar which supports both

ends of the stabilizer bar form the stabilizer bar.

Use the inner hexagon spanner to fix the ball pin; remove the self-

locking nut.

2. Remove the bush and clip of stabilizer bar; remove

the stabilizer bar

Installation of stabilizer bar

1. Install the stabilizer bar on the carriage

Place the stabilizer bar in position; install the stabilizer bar bush and

clip on the carriage. Align the mark on the stabilizer bar to keep the

left and right gap of stabilizer bar are same. Then install the bolt

temporarily and pretighten it.

2. Connect the stabilizer bar to the connecting rod.

Install and tighten the new nut to the specified torque.

Tightening force: 63

5Nm

3. Tighten the clip position bolt to specified torque.

Tightening force: 232Nm

Page 224 of 425

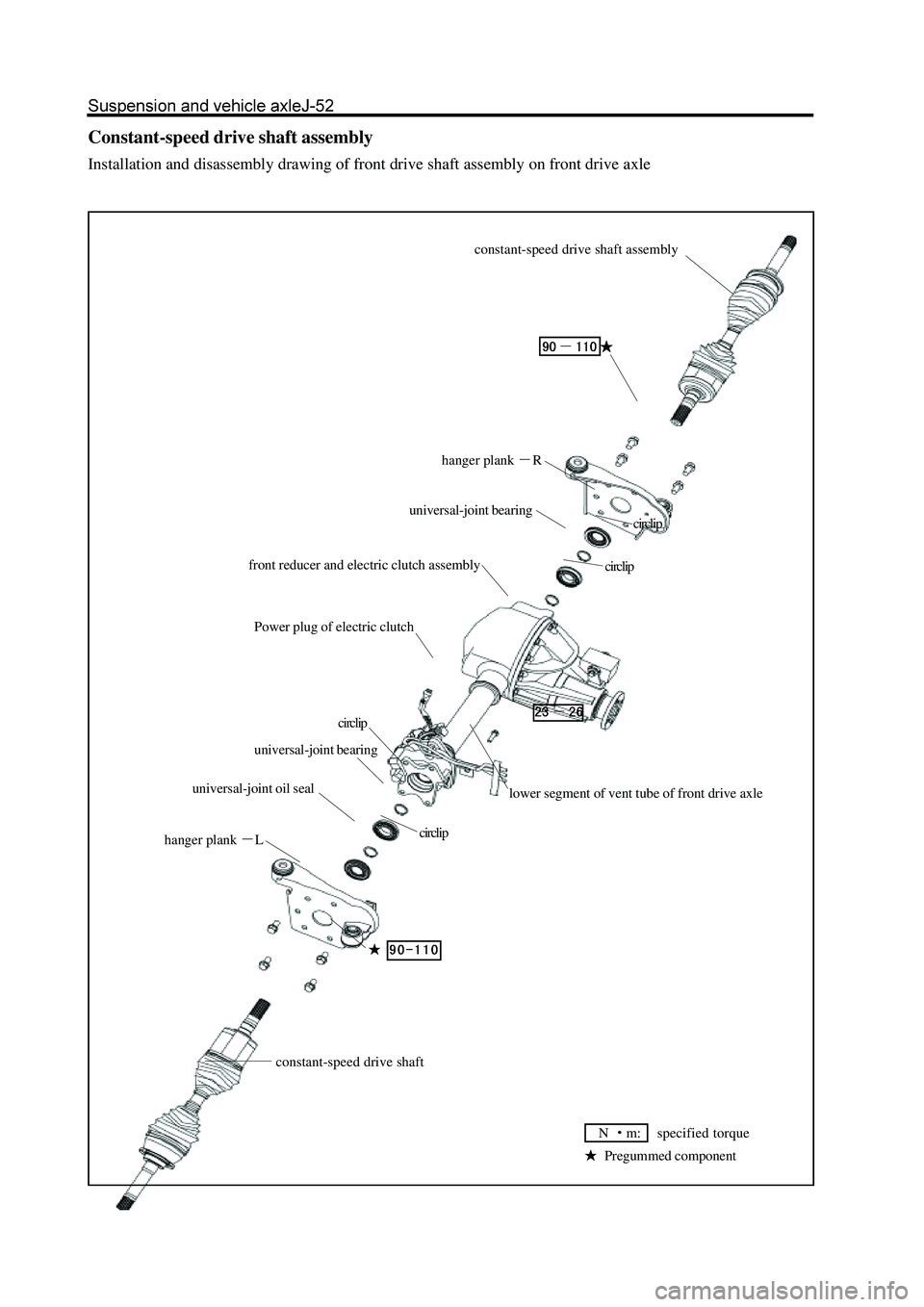

Constant-speed drive shaft assembly

Installation and disassembly drawing of front drive shaft assembly on front drive axle

hanger plank R

universal-joint bearing

front reducer and electric clutch assembly

Power plug of electric clutch

circlip

hanger plank L

constant-speed drive shaft

circlip

lower segment of vent tube of front drive axle

circlip

circlip

Pregummed component

N m: specified torque

universal-joint oil sealuniversal-joint bearingconstant-speed drive shaft assembly