air suspension GREAT WALL HOVER 2006 Service Repair Manual

[x] Cancel search | Manufacturer: GREAT WALL, Model Year: 2006, Model line: HOVER, Model: GREAT WALL HOVER 2006Pages: 425, PDF Size: 26.05 MB

Page 9 of 425

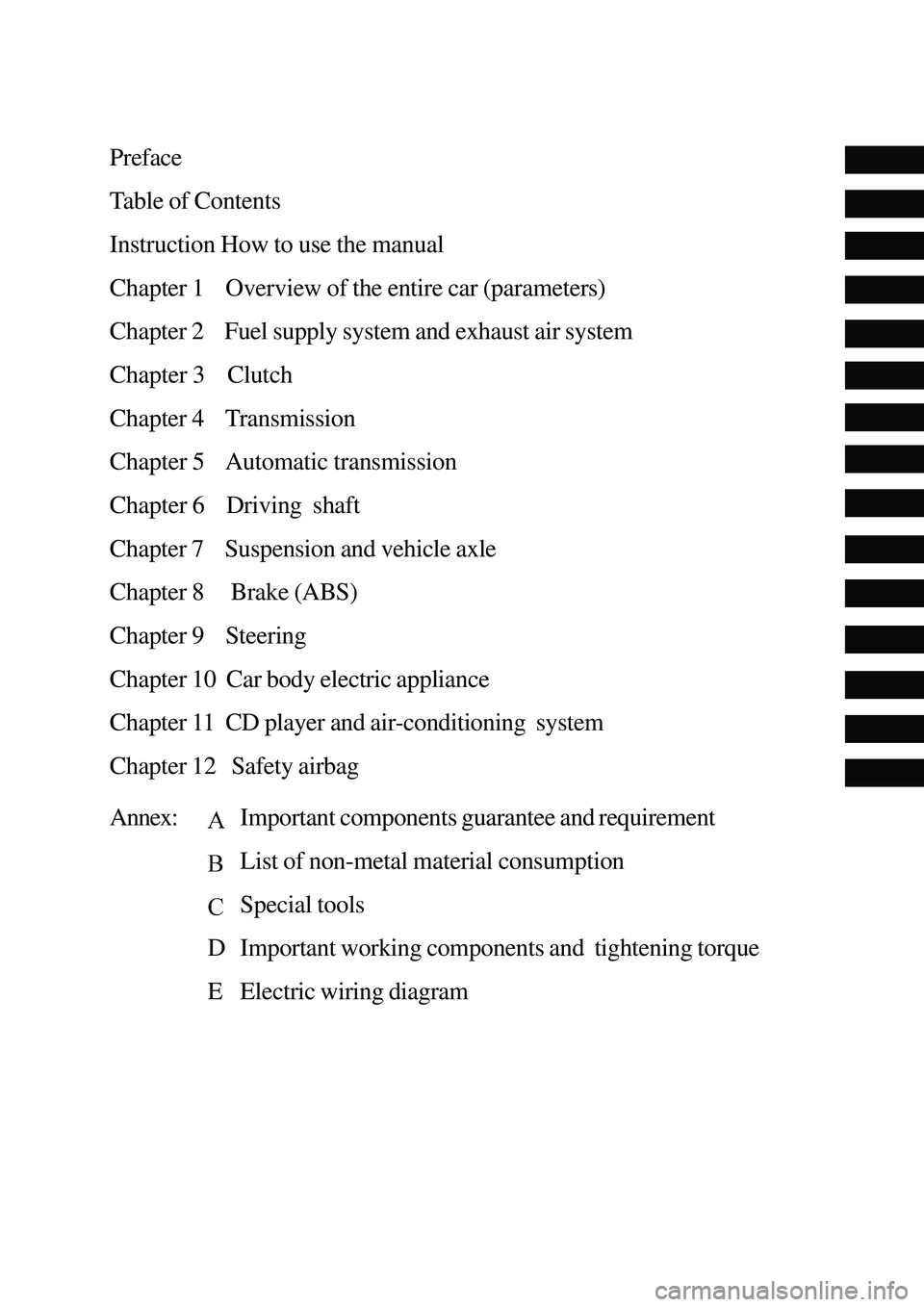

Preface

Table of Contents

Instruction How to use the manual

Chapter 1 Overview of the entire car (parameters)

Chapter 2 Fuel supply system and exhaust air system

Chapter 3 Clutch

Chapter 4 Transmission

Chapter 5 Automatic transmission

Chapter 6 Driving shaft

Chapter 7 Suspension and vehicle axle

Chapter 8 Brake (ABS)

Chapter 9 Steering

Chapter 10 Car body electric appliance

Chapter 11 CD player and air-conditioning system

Chapter 12 Safety airbag

Annex:

Important components guarantee and requirement

List of non-metal material consumption

Special tools

D Important working components and tightening torque

E Electric wiring diagram

Page 10 of 425

Overview of the entire car-1

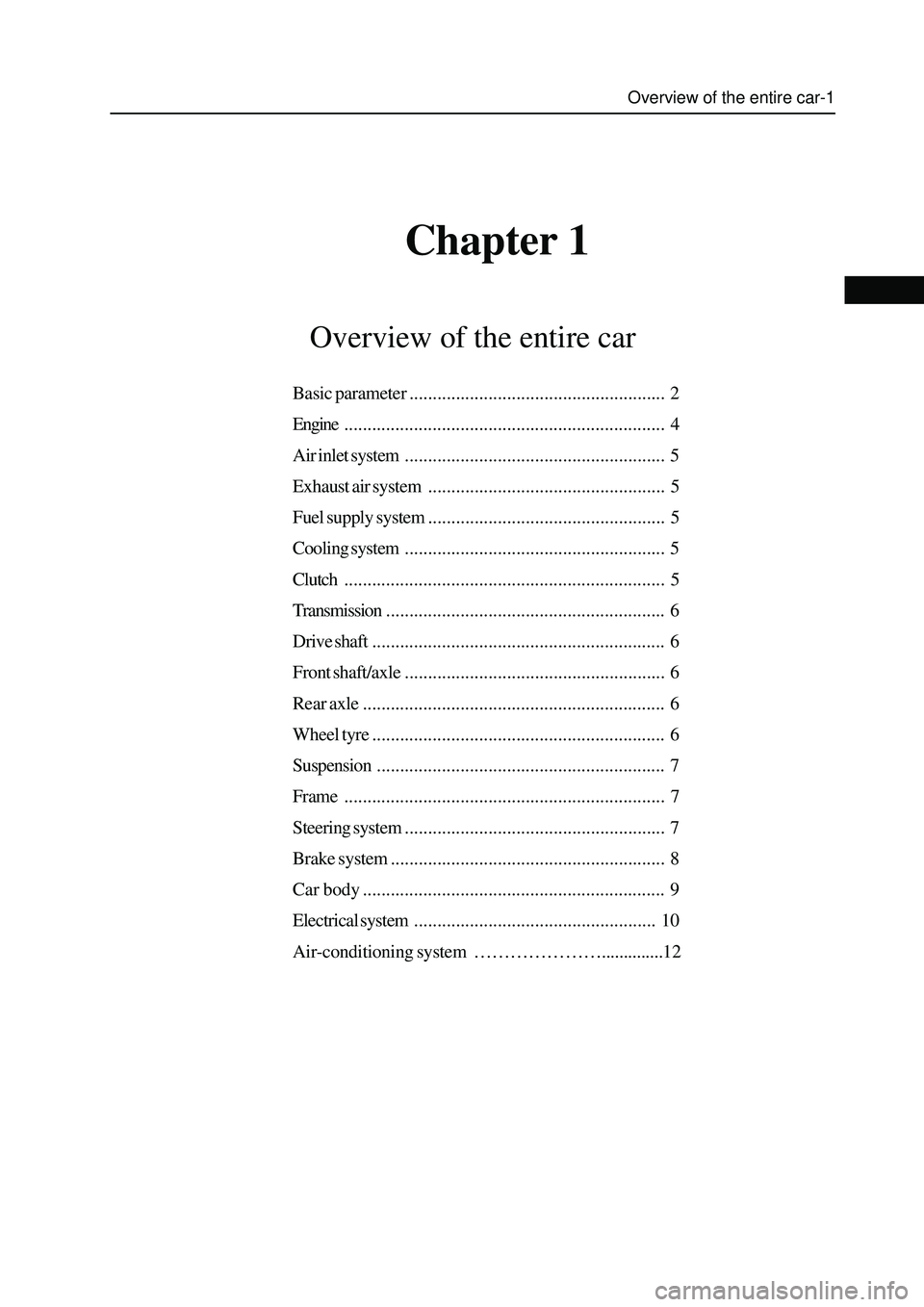

Chapter 1

Overview of the entire car

Basic parameter....................................................... 2

Engine..................................................................... 4

Air inlet system........................................................ 5

Exhaust air system................................................... 5

Fuel supply system................................................... 5

Cooling system........................................................ 5

Clutch..................................................................... 5

Transmission............................................................ 6

Drive shaft............................................................... 6

Front shaft/axle........................................................ 6

Rear axle................................................................. 6

Wheel tyre............................................................... 6

Suspension.............................................................. 7

Frame..................................................................... 7

Steering system........................................................ 7

Brake system........................................................... 8

Car body................................................................. 9

Electrical system.................................................... 10

Air-conditioning system …………………..............12

Page 15 of 425

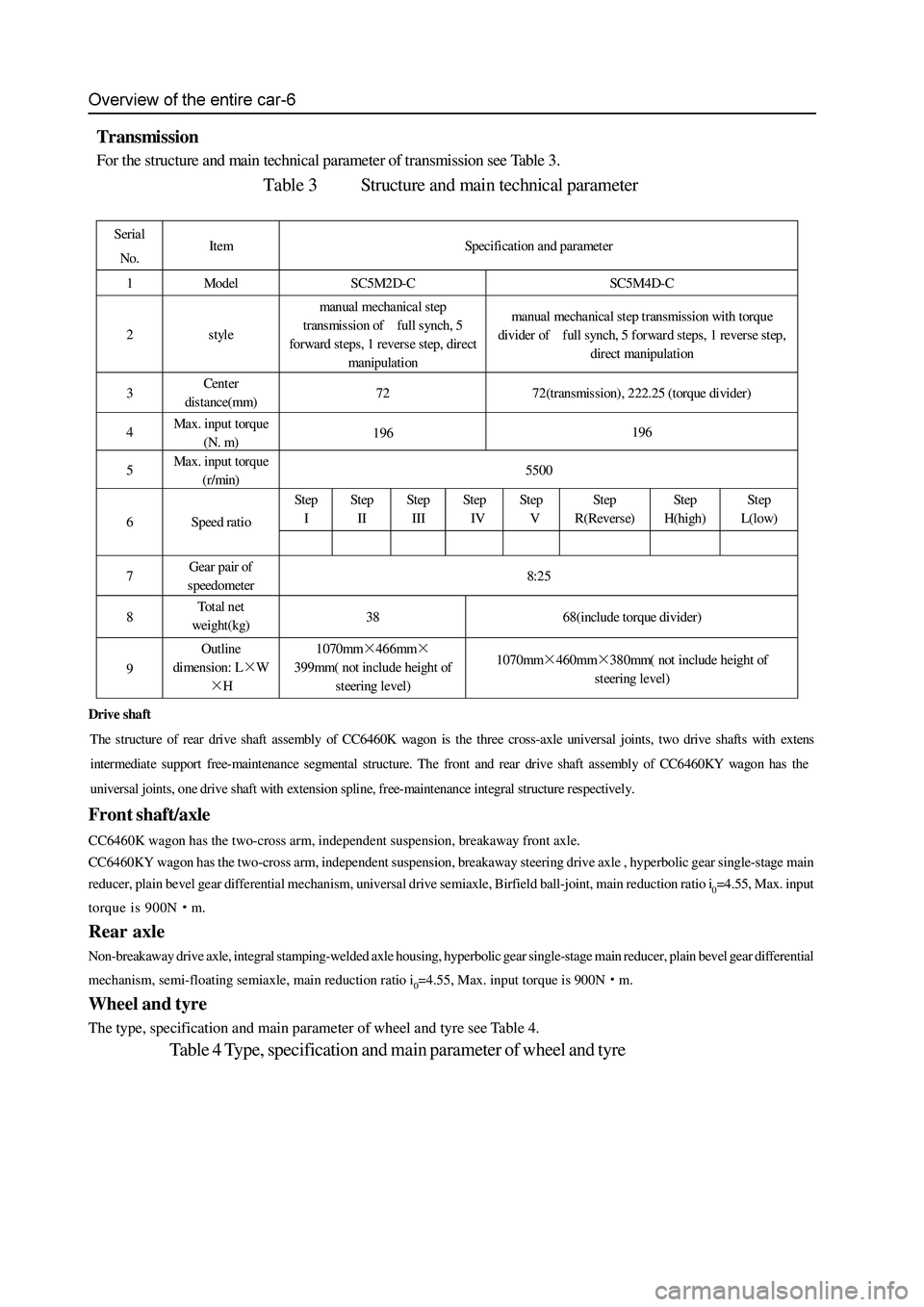

Front shaft/axle

CC6460K wagon has the two-cross arm, independent suspension, breakaway front axle.

CC6460KY wagon has the two-cross arm, independent suspension, breakaway steering drive axle , hyperbolic gear single-stage main

reducer, plain bevel gear differential mechanism, universal drive semiaxle, Birfield ball-joint, main reduction ratio i

0=4.55, Max. input

torque is 900N

m.

Rear axle

Non-breakaway drive axle, integral stamping-welded axle housing, hyperbolic gear single-stage main reducer, plain bevel gear differential

mechanism, semi-floating semiaxle, main reduction ratio i

0=4.55, Max. input torque is 900Nm.

Wheel and tyre

The type, specification and main parameter of wheel and tyre see Table 4.

Table 4 Type, specification and main parameter of wheel and tyre

Transmission

For the structure and main technical parameter of transmission see Table 3.

Table 3 Structure and main technical parameter

Serial

No. Item Specification and parameter

1 Model SC5M2D-C SC5M4D-C

2 style manual mechanical step

transmission of full synch, 5

forward steps, 1 revers e step, direct

manipulation manual mechanical step transmission with torque

divider of full synch, 5 forward steps, 1 reverse step,

direct manipulation

3 Cent er

distance(mm) 72 72(transmission), 222.25 (torque divider)

4 Max. input torque

(N. m) 196 196

5 Max. input torque

(r/min) 5500

Step

I Step

II Step

III St ep

IV Step

V Step

R(Reverse) Step

H(high) St ep

L(low)

6 Speed ratio

7 Gear pair of

speedometer 8:25

8 To t a l n et

weight(kg) 38 68(include torque divider)

9 Outline

dimension: L×W

×H 1070mm×466mm×

399mm( not include height of

steering level) 1070mm×460mm×380mm( not include height of

steering level)

Drive shaft

The structure of rear drive shaft assembly of CC6460K wagon is the three cross-axle universal joints, two drive shafts with exten

s

intermediat e support free-maint enance segmental structure. The front and rear dr ive shaft assembly of CC6 460KY wa gon has the

universal joints, one drive shaft with extension spline, free-maintenance integral structure respectively.

Page 174 of 425

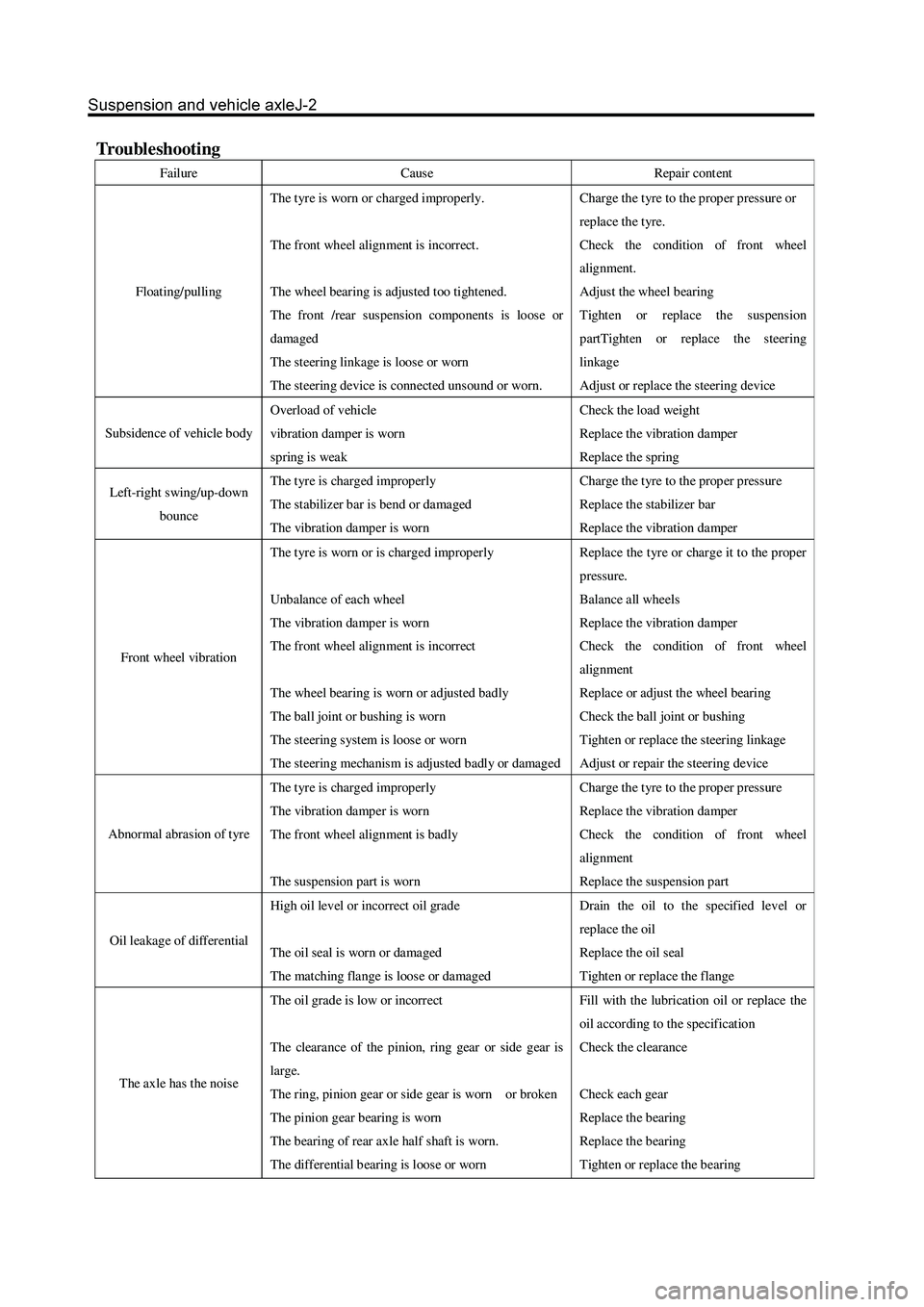

Troubleshooting

Failure Cause Repair cont ent

Floating/pulling The t yre is worn or charged improperly.

The front wheel alignment is incorrect.

The wheel bearing is adjusted too tightened.

The front /rear suspension components is loose or

damaged

The steering linkage is loose or worn

The steering device is connect ed unsound or worn. Charge the t yre to the prop er pressur e or

repla ce the t yre.

Check the condition of front wheel

alignment.

Adjust the wheel bearing

Tighten or replace the suspension

partTighten or replace the steering

linkage

Adjust or replace the steering device

Subsidence of vehicle body Overload of vehicle

vibration damper is worn

spring is weak Check the load weight

Replace the vibration damper

Replace the spring

Left-right swing/up-down

bounce The t yre is charged improperly

The stabilizer bar is bend or damaged

The vibration damper is worn Charge the t yre to the prop er pressur e

Replace the stabilizer bar

Replace the vibration damper

Front wheel vibration The t yre is worn or is charged improperly

Unbalance of each wheel

The vibration damper is worn

The front wheel alignment is incorrect

The wheel bearing is worn or adjusted badly

The ball joint or bushing is worn

The steering system is loose or worn

The steering mechanism is adjusted badly or damaged Repla ce the t yr e or char ge it to the prop er

pressure.

Balance all wheels

Replace the vibration damper

Check the condition of front wheel

alignment

Replace or adjust the wheel bearing

Check the ball joint or bushing

Tighten or replace the steering linkage

Adjust or repair the steering device

Abnormal abrasion of tyre The t yre is charged improperly

The vibration damper is worn

The front wheel alignment is badly

The suspension part is worn Charge the t yre to the prop er pressur e

Replace the vibration damper

Check the condition of front wheel

alignment

Replace the suspension part

Oil leakage of differential High oil level or incorrect oil grade

The oil seal is worn or damaged

The matching flange is loose or damaged Drain the oil to the specified level or

repla ce the oil

Replace the oil seal

Tighten or replace the flange

The axle has the nois e The oil grade is low or incorrect

The clearance of the pinion, ring gear or side gear is

large.

The ring, pinion gear or side gear is worn or broken

The pinion gear bearing is worn

The b earing of rear axle half shaft is worn.

The differential b earing is loos e or worn Fill with the lubrication oil or replace the

oil according to the specification

Check the clearance

Check each gear

Replace the bearing

Replace the bearing

Tighten or replace the bearing

Page 316 of 425

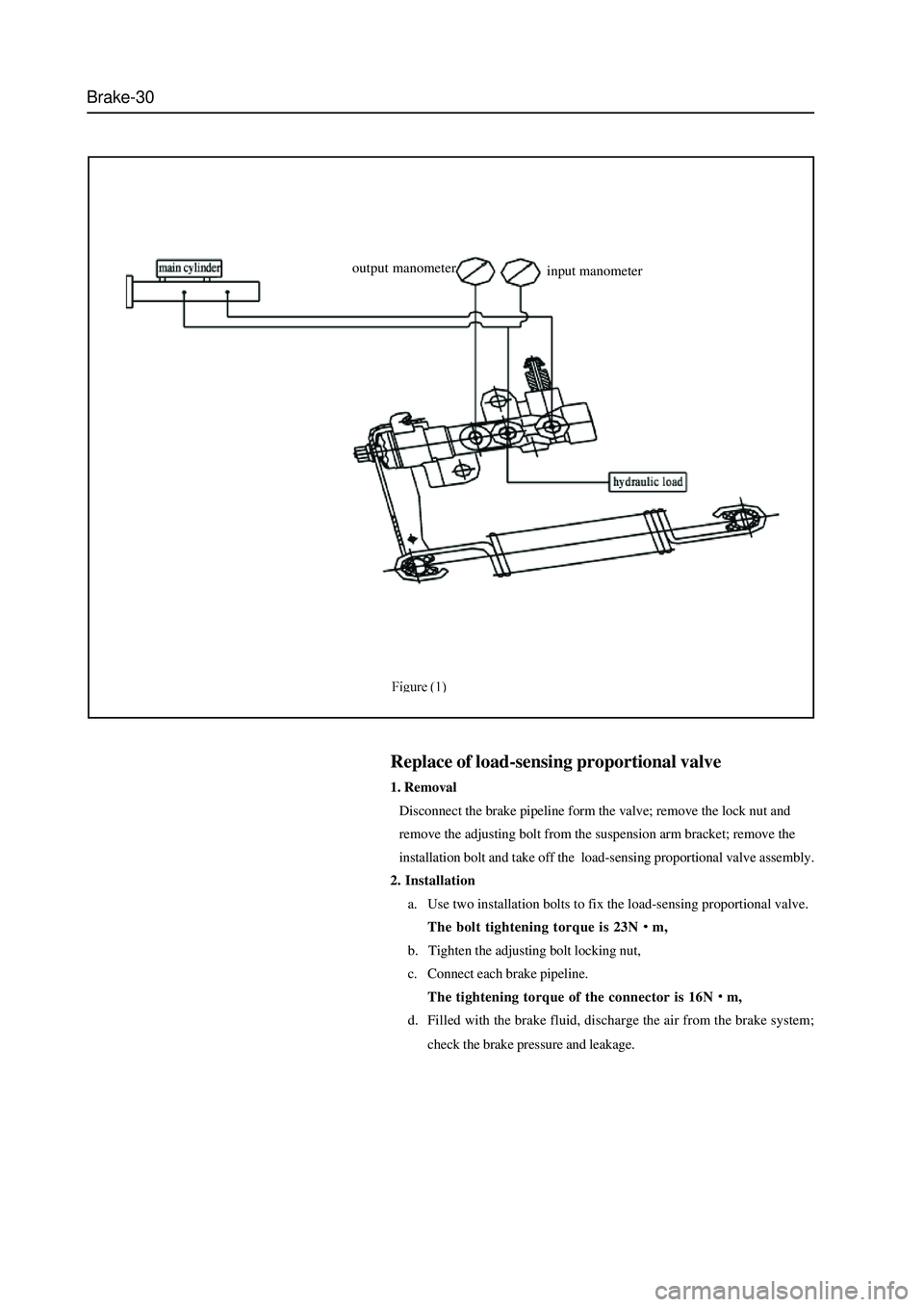

Brake-30

Replace of load-sensing proportional valve

1. Removal

Disconnect the brake pipeline form the valve; remove the lock nut and

remove the adjusting bolt from the suspension arm bracket; remove the

installation bolt and take off the load-sensing proportional valve assembly.

2. Installation

a. Use two installation bolts to fix the load-sensing proportional valve.

The bolt tightening torque is 23N

m,

b. Tighten the adjusting bolt locking nut,

c. Connect each brake pipeline.

The tightening torque of the connector is 16N

m,

d. Filled with the brake fluid, discharge the air from the brake system;

check the brake pressure and leakage. output manometer

input manometer