MAIN BEARING HONDA CIVIC 1996 6.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1996, Model line: CIVIC, Model: HONDA CIVIC 1996 6.GPages: 2189, PDF Size: 69.39 MB

Page 206 of 2189

Main Bearings

4.

Glearance

1.To check main bearing-to-journal oil clearance.

remove the main caps and bearing halves.

Clean each main journal and bearing half with a

clean shop towel.

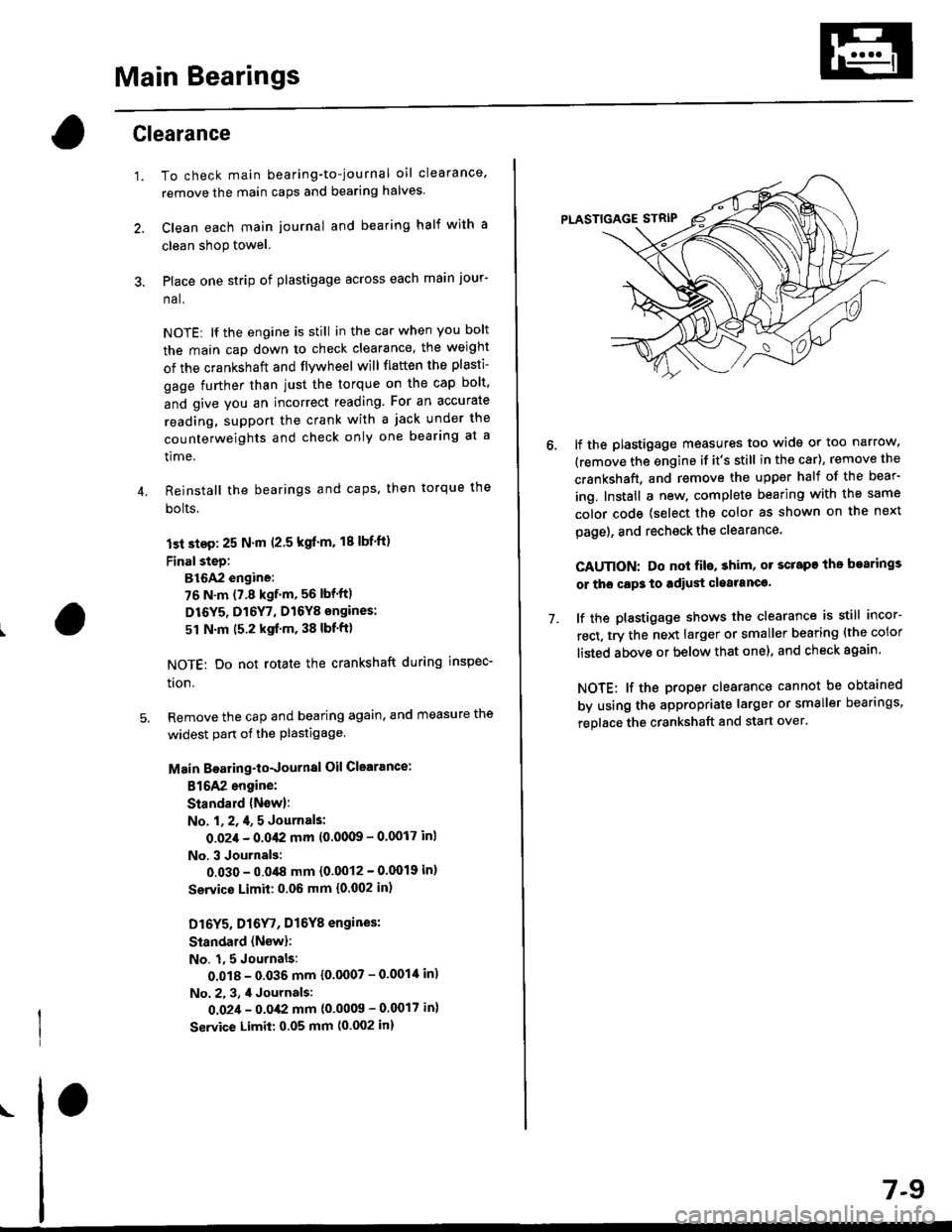

Place one strip of plastigage across each main jour-

na l.

NOTE: lf the engine is still in the car when you bolt

the main cap down to check clearance, the weight

of the crankshaft and flvwheel will flaften the plasti-

gage further than just the torque on the cap bolt.

and give you an incorrect reading. For an accurate

reading, support the crank with a jack under the

counterweights and check only one bearing at a

time,

Reinstall the bearings and caps, then torque the

bolts.

lst step: 25 N'm (2.5 kgl'm. 18 lbf'ft)

FinalsteD:

B16A2 engine:

76 N.m (7.8 kgf.m, 56 lbf'ft)

D16Y5, Dl6Y7, D16Y8 engines:

51 N.m (5.2 kgf'm, 38 lbf'ft)

NOTE: Do not rotate the crankshaft during inspec-

tron.

Remove the cap and bearing again, and measure the

widest part ot the plastigage.

Main Boaring-toJournal Oil Clearance:

816A2 engine:

Standald {New}:

No. l, 2, 4, 5 Journals:

O.O2,l - 0.042 mm 10'00(B - 0.0017 in)

No. 3 Journals:

0.030 - 0.048 mm {0'0012 - 0'0019 in)

Servico Limit: 0.06 mm {0.002 in,

Dl6Y5, Dl6

r, Dl6Y8 engines:

Standard (Nsw):

No. 1,5 Journals:

0.018 - 0.035 mm {0.0007 - 0'001'[ in)

No. 2. 3, 4 Journals:

0.02,1 - 0.0,(2 mm {0'0009 - 0.0017 in}

Service Limit: 0.05 mm (0.002 in)

\

7-9

7.

lf the plastigage measures too wide or too narrow,

(remove the engine if it's still in the car), remove the

crankshaft, and remove the upper half of the bear-

ing. Install a new. complete bearing with the same

color code {select the color as shown on the next

page), and rechsck the clearance.

CAUTION: Do nol fil€, shim, or scrape the bearings

or tho cap3 to adiust cleatanc€.

lf the plastigage shows the clearance is still incor-

rect, try the next larger or smaller bearing (the color

listed above or below that one), and check again

NOTE: lf the proper clearance cannot be obtained

by using the appropriate larger or smaller bearings,

replace the crankshaft and start over.

Page 207 of 2189

Main Bearing

Selection

CAUTION: lf the codes are indecipherable because of anaccumulation of dirt and dust, do not scrub them with a

wire brush or scraper. Clean them only with solvent ol

deiergent.

Crankshaft Bore Code Location

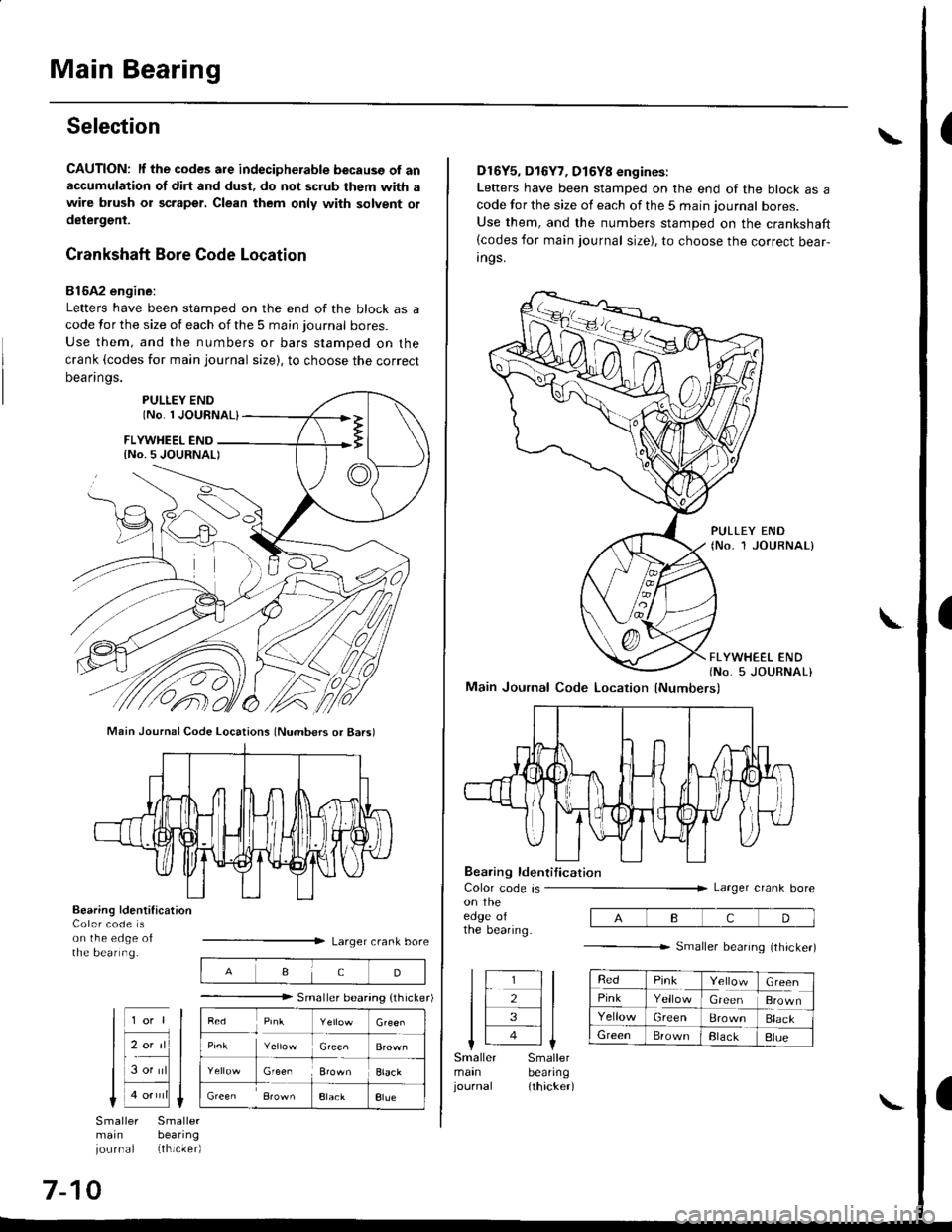

81642 engine:

Letters have been stamped on the end of the block as acode for the size of each of the 5 main journal bores.

Use them, and the numbers or bars stamped on the

crank {codes for main journal size), to choose the correct

beaflngs.

Main JournalCode Locations {Nombers or Barc)

Eearing ldentificationColor code rson lhe edge ofthe bear ng.Larger crank bore

acD

-----------""' Smallerbeanngtlhrcker)

9""1B':""

Alack

Black

Alue

7-10

\

D16Y5, D16Y7, D16Y8 engines:

Letters have been stamped on the end of the block as acode for the size of each of the 5 main journal bores.

Use them, and the numbers stamped on the crankshaft(codes for main journal size), to choose the correct bear-

Ings.

Main Journal Code Location (Numbers)

\

Color codeon theedge ofthe bearing-

Ldrger crank bore

Smaller bea ng {th'cker)

lr-l

t#lt+,tlf l 4 tlf '- 't

Smaller Smallermaan bearingjournal {thicker)

RedPinkGreen

PinkGreenBrown

GreenBrownBlack

GreenBrownBlackElue

I

Bearing ldentification

BcD

Page 210 of 2189

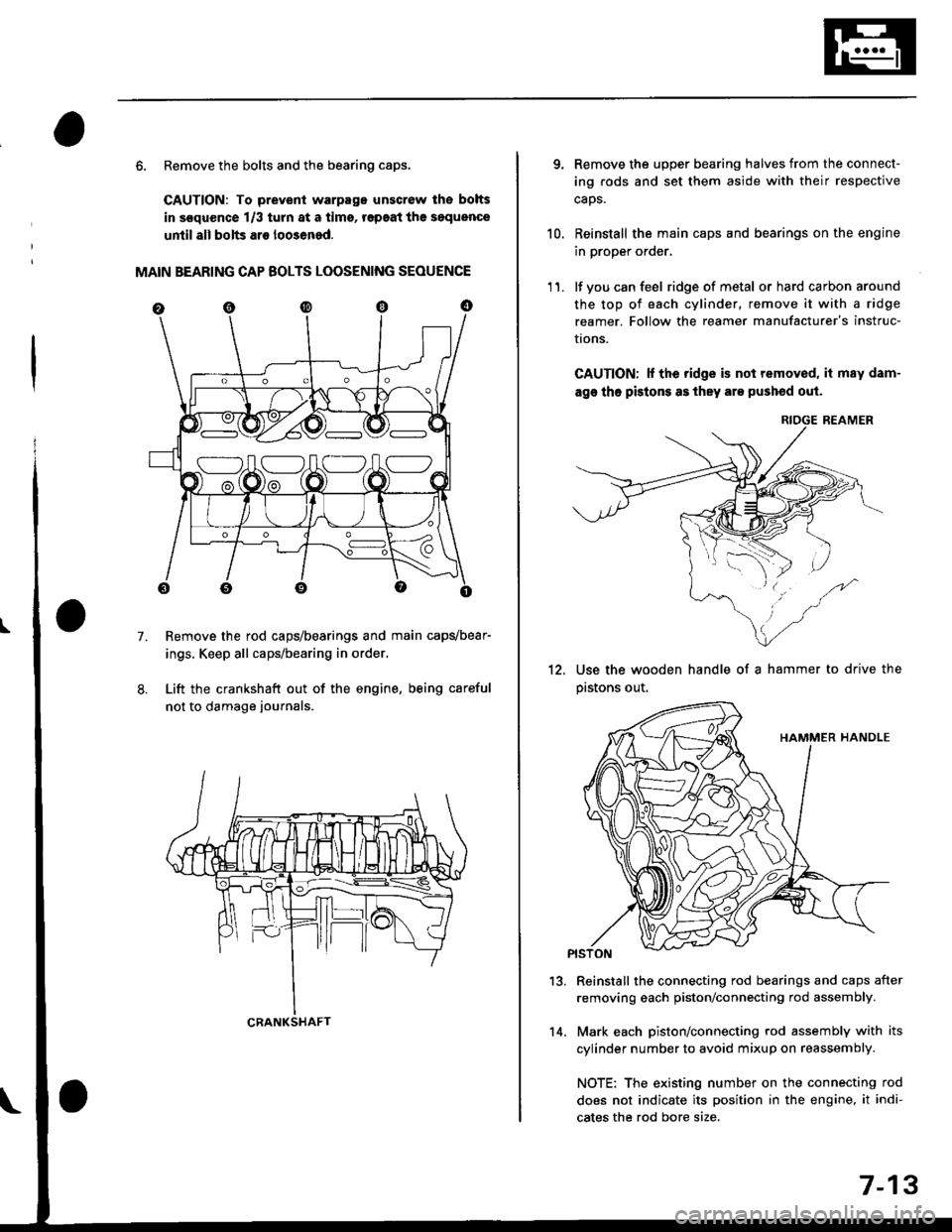

6. Remove the bolts and the bearing caps.

CAUTION: To prevenl warpago unscrow lhe bolts

in s€quence 1/3 turn at a tims, r€paat the soquence

until all bolts ar€ loo3ened.

MAIN BEARING CAP BOLTS LOOSENING SEOUENCE

Remove the rod caps/bearings and main capvbear-

ings. Keep all caps/bearing in order.

Lift the crankshaft out of the engine, being careful

not to damage journals.

7.

S:_]ILOJLOAO

CRANKSHAFT14.

7-13

qRemove the upper bearing halves from the connect-

ing rods and set them aside with their respective

caos.

Reinstall the main caps and bearings on the engine

in proper order,

lf you can feel ridge of metal or hard carbon around

the top of each cylinder, remove it with a ridge

reamer. Follow the reamer manufacturer's instruc-

I|ons.

CAUTION; lf the ridge is not removed, it may dam-

age tho pistons as they are pushod out.

RIOGE REAMER

10.

11.

12.Use the wooden handle of a hammer to drive the

pastons out.

13.Reinstall the connecting rod bearings and caps after

removing each piston/connecting rod assembly.

Mark each piston/connecting rod assembly with its

cylinder number to avoid mixup on reassembly.

NOTE: The existing number on the connecting rod

does not indicate its position in the engine, it indi-

cates the rod bore size.

Page 220 of 2189

PistonsGrankshaft

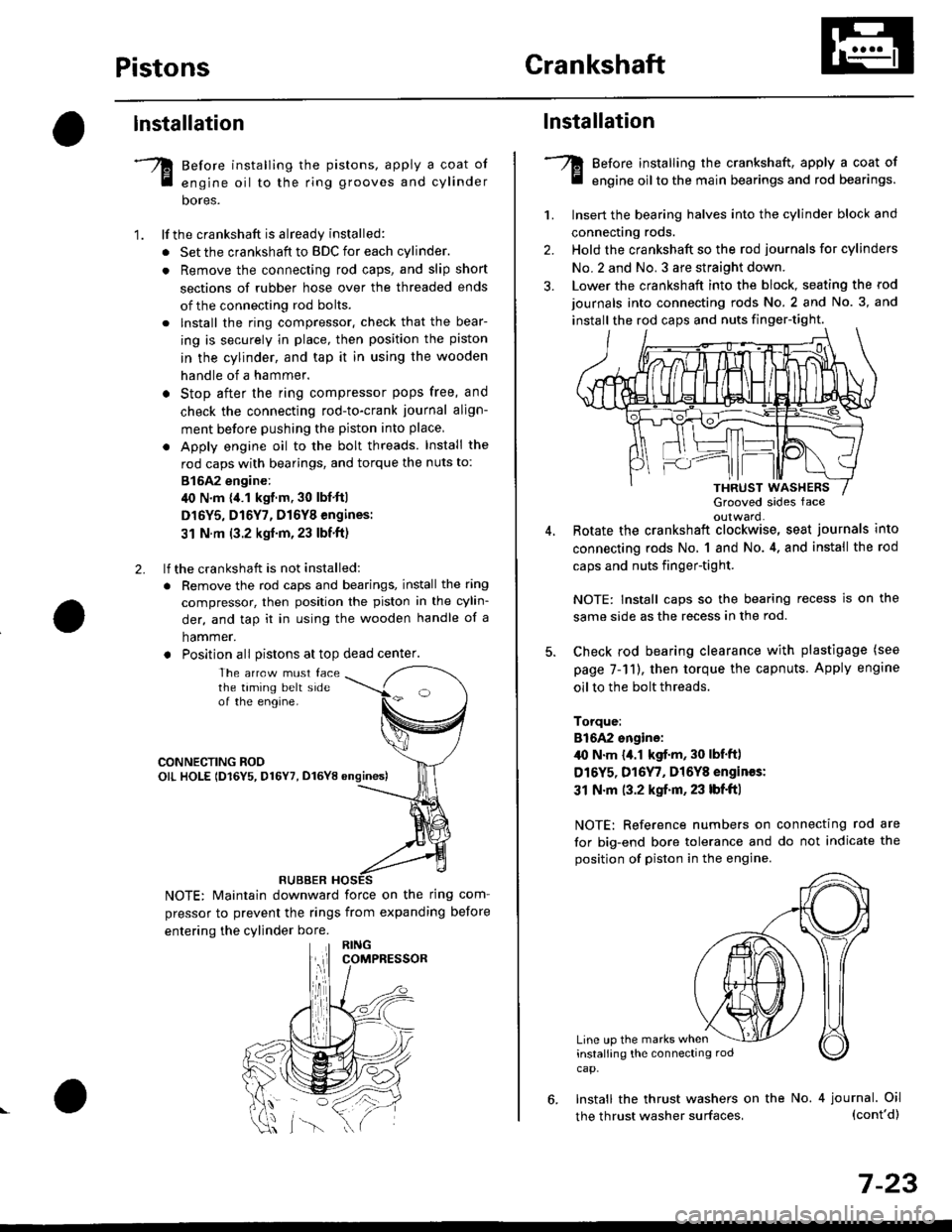

lnstallation

Before installing the pistons, apply a coat of

engine oil to the ring grooves and cylinder

bores.

lf the crankshaft is already installed:

. Set the crankshaft to BDC for each cylinder.

. Remove the connecting rod caps, and slip short

sections of rubber hose over the threaded ends

of the connecting rod bolts.

. lnstall the ring compressor. check that the bear-

ing is securely in place, then position the piston

in the cylinder, and tap it in using the wooden

handle of a hammer.

o Stop after the ring compressor pops free, and

check the connecting rod-to-crank journal align-

ment before pushing the piston into place

. Apply engine oil to the bolt threads. Install the

rod caps with bearings, and torque the nuts to:

815A2 engine:

40 N.m {,1.1 kgf.m, 30 lbf'ft|

D16Y5, D16Y7, D16Y8 engines:

31 N.m (3.2 kgf'm,23 lbf'ft)

lf the crankshaft is not installed:

. Remove the rod caps and bearings, install the ring

compressor, then position the piston in the cylin-

der, and tap it in using the wooden handle of a

hammer.

. Position all Distons at top dead center.

1.

2.

The arrcw must facethe taming belt sideof the engine.

CONNECTING ROOOIL HOLE lD16Y5, D16Y7, D16YB ongines)

NOTE: Maintain downward force on the ring com-

pressor to prevent the rings from expanding before

entering the cylinder bore.

RUBBER

,lll

lnstallation

Before installing the crankshaft, apply a coat of

engine oil to the main bearings and rod bearings.

Insert the bearing halves into the cylinder block and

connecting rods.

Hold the crankshaft so the rod journals for cylinders

No.2 and No. 3 are straight down.

Lower the crankshaft into the block, seating the rod

journals into connecting rods No. 2 and No. 3, and

install the rod caps and nuts finger-tight.

1.

2.

3.

5.

Grooved sides faceoulward.Botate the crankshaft clockwise, seat journals into

connecting rods No, 1 and No.4, and install the rod

caps and nuts finger-tight.

NOTE: Install caps so the bearing recess is on the

same side as the recess in the rod.

Check rod bearing clearance with plastigage (see

page 7-11), then torque the capnuts. Apply engine

oil to the bolt threads.

Torque:

816A2 sngine:/l{, N.m {a.l kgf.m, 30 lbf'ftl

D16Y5, D16Y7, Dl6Y8 engines:

31 N.m (3.2 kgf.m, 23 lbf'ft|

NOTE: Reference numbers on connecting rod are

for big-end bore tolerance and do not indicate the

position of piston in the engine.

Line up the marks wheninstalling the connectrng rod

cap.

6. Install the thrust washers on the No. 4 journal. Oil(cont'd)

7-23

the thrust washer surfaces,

Page 221 of 2189

Crankshaft

Installation (cont'd)

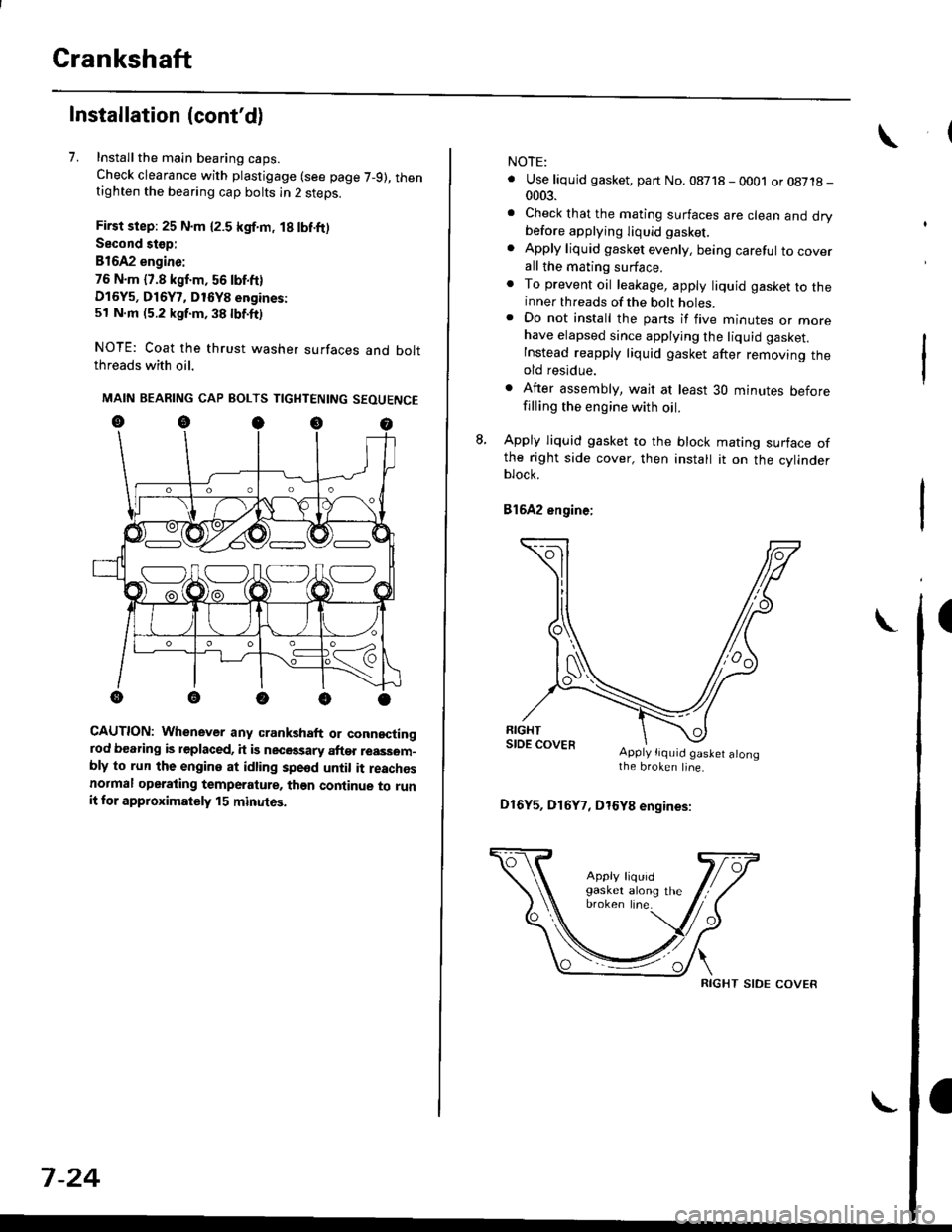

7. Installthe main bearing caps.

Check clearance with plastigage (see page 7-9), thentighten the bearing cap bolts in 2 steps.

First step: 25 N.m {2.5 kgf.m, 18 lbf.ft)

Second stop:

B1642 engine:

76 N.m {7.8 kgf.m, 56 lbf.ft)

D16Y5, D16Y7, D16Y8 engines:

51 N.m (5.2 kgf.m, 38 lbf.ft)

NOTE: Coat the thrust washer surfaces and boltthreads with oil.

MAIN BEARING CAP BOLTS TIGHTENING SEOUENCE

oocoo

CAUTION: Whenever any crankshaft or connectingrod bearing is replaced, it is necGssary after reassom-bly to run the engine at idling spe6d until it reachesnormal operating temperature, than continue to runit for approximately 15 minutos.

:V fr\-/.---\-/.-

7-24

NOTE:

. Use liquid gasket, part No. 08718 - 0001 or08718-0003.

. Check that the mating surfaces are clean and drybefore apptying liquid gasket.

. Apply liquid gasket evenly, being careful to coverall the mating surface.. To prevent oil leakage, apply liquid gasket to theinner threads of the bolt holes.. Do not install the parts if five minutes or morehave elapsed since applying the liquid gasket.

Instead reapply liquid gasket after removing theold residue.

. After assembly, wait at least 30 minutes beforefilling the engine with oil.

L Apply liquid gasket to the block mating surface ofthe right side cover, then install it on the cylinderblock.

Bl6A2 engine;

Apply tiquid gaslet alongthe broken line.

D16Y5, D16Y7, D16Y8 engines:

RIGHT SIDE COVER

Page 579 of 2189

Release Bearing

Installation

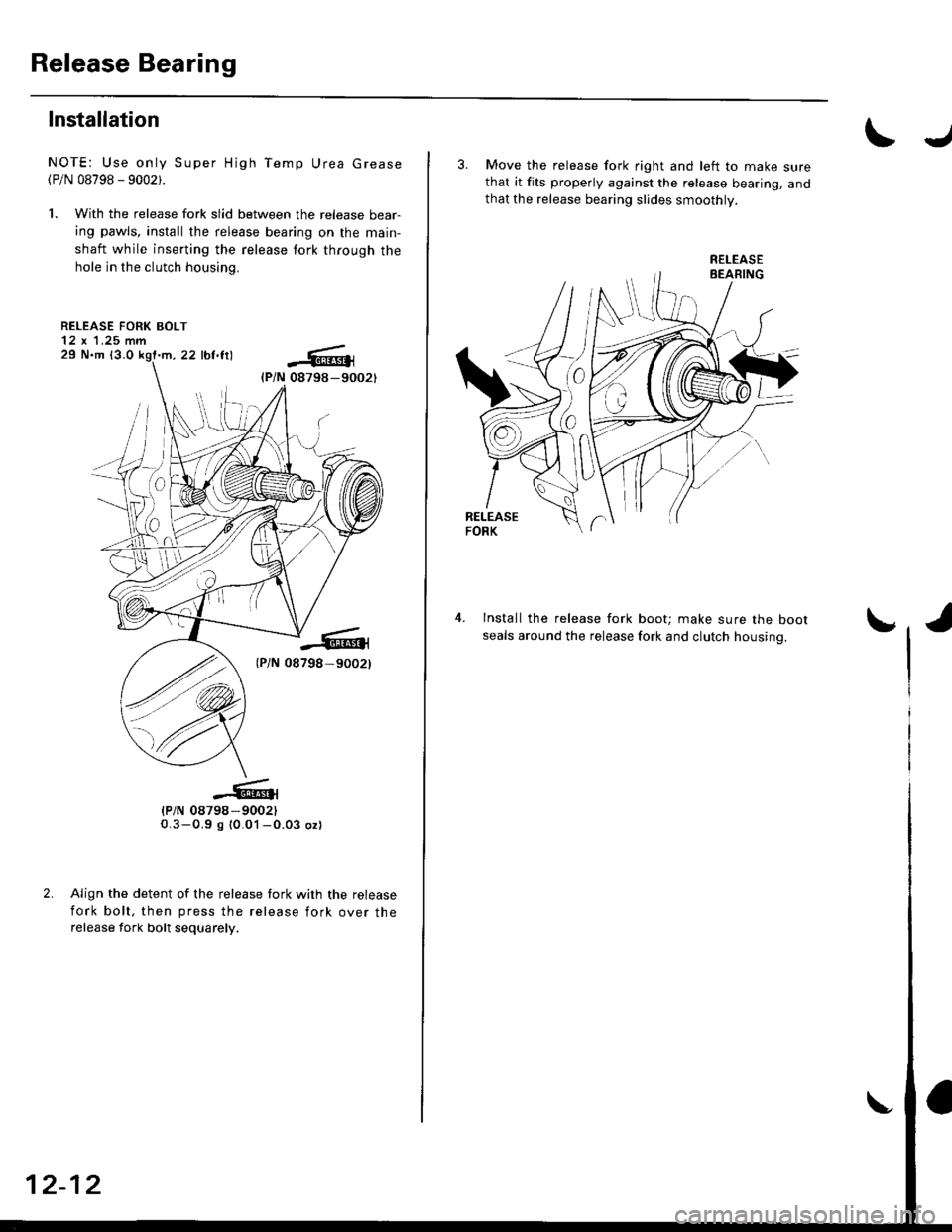

NOTE: Use only Super High Temp Urea Grease(P/N 08798 - 9002).

1. With the release fork slid between the release bear-

ing pawls, install the release bearing on the main-

shaft while inserting the release fork through the

hole in the clutch housing.

RELEASE FORK BOLT12 x 'l .25 mm

tP/N 0a79a-90021O.3-0.9 s 10.01 -O.03 ozl

Align the detent of the release fork with the release

fork bolt, then press the release fork over the

release fork bolt sequarely.

-Gr08798-9002)

2.

12-12

IJ

3. Move the release fork right and left to make surethat it fits properly against the release bearing, and

that the release bearing slides smoothly.

4. Install the release fork boot; make sure the bootseals around the release fork and clutch housino.

Page 581 of 2189

\

S40 Model (All except'99 - 00 2-door Si' SiR)

Manual Transmission

Special Tools ..'.......... 13-2

Maintenance

Transmission Oil .............................. 13-3

Back-up Light Switch

Replacement ......... 13-3

Troubleshooting '....... 13-4

Transmission AssemblY

Removal ................. 13-5

lnstallation ............. 13-8

lllustrated Index ...............'........."........ 13-10

Transmission Housing

I Removaf .."""""""' 13-12

J R"rr"r"" Shift Holder

Clearance lnspection ....................... 13-13

Reverse ldler Gear

Removal ....'.........." 13-14

Mainshaft, Countershaft, Shift Fork

Disassembly ......'... 13-14

Mainshaft AcsemblY

Index ............... ....... 13-15

Clearance Inspection ..'.................... 13-16

Disassembly .......... 13-17

Inspection ....'......... 13-18

Reassembly ........... 13-19

Countershaft AssemblY

lndex ................ ...... 13-20

Clearance lnspection ."..........'......." 13-21

Disassembly ..."""' 13-22

Inspection .............. 13-23

Reassembly ..'.""... 13-23

Shift Fork AssemblY

lndex ............... ."'... 13-25

Clearance lnspection ."......."........'.. 13'26

MBS Shift Piece Inspection ....-.....'.. 13'27

Synchro Sleeve, Synchro Hub

f nspection/lnstallation .......'...... ".... 13'27

Synchro Ring, Gear

Inspection '....'..".... 13'28

Shift Rod

Removal .'......".""" 13'29

Differential

lndex ......."'...... .'."' 13-30

Backlash Inspection ..........."......."... 13-30

Bearing Beplacement'.............'.".... 13'31

Final Driven Gear Replacement '..... 13-31

Thrust Shim Adiustment ..."........... 13-32

Clutch Housing Bearing

Replacement .......'. 13-34

Mainshaft Thrust Shim

Adiustment '....'..".. 13-36

Transmission

Reassembly ........... 13-39

Oil Seals

Replacement ......... 13-43

Gearshift Mechanism

Overhaul ................ 13-44

\

Page 582 of 2189

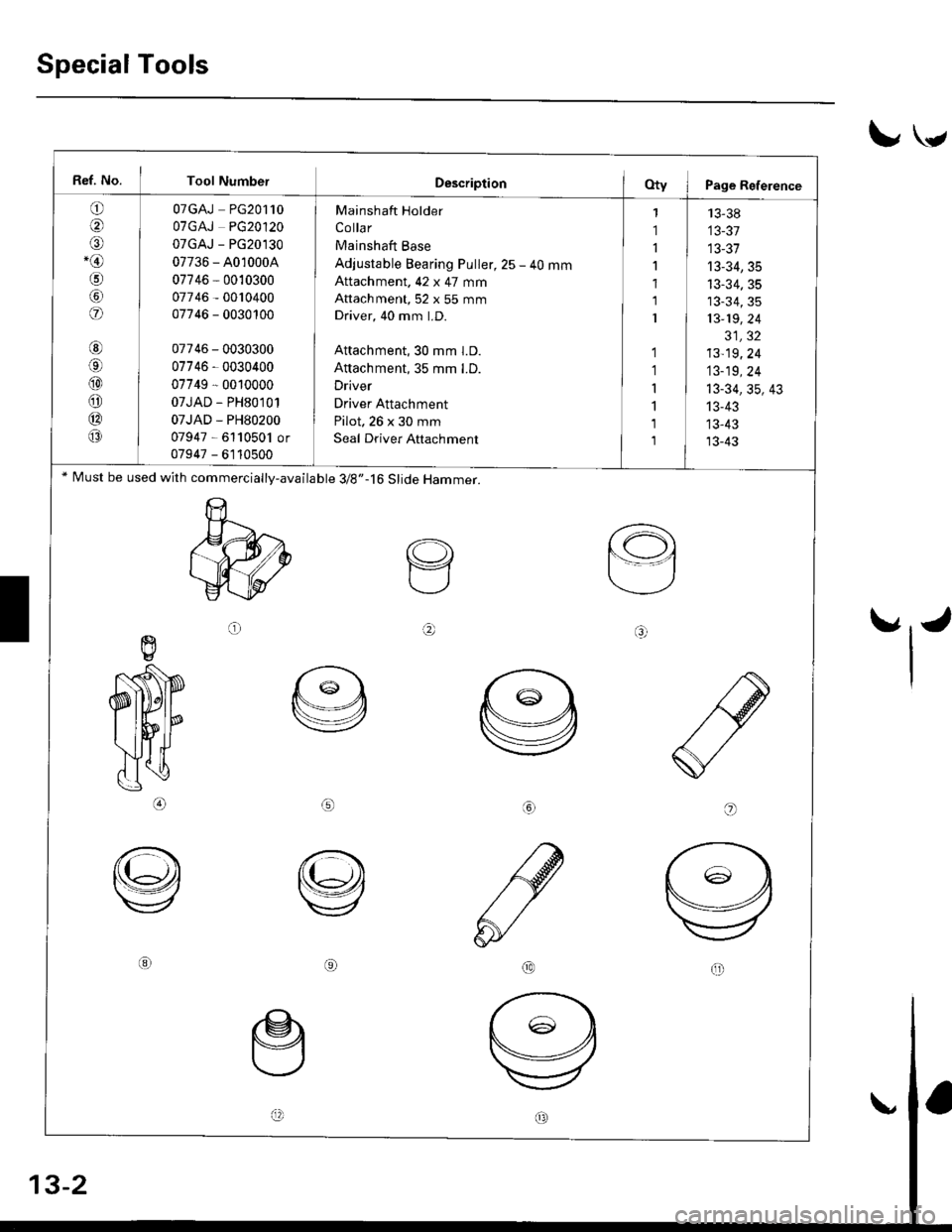

Special Tools

Ref. No. I Tool NumbetDescription(Xy I Page Reference

o

@

o.@

!'5,

@

o

@6

@

@

@(3

OTGAJ PG2O11O

OTGAJ PG2012O

07GAJ - PG20130

07736 - A010004

07746 - 0010300

07746 - 0010400

07746 - 0030100

07746 - 0030300

07746 - 0030400

07749 - 0010000

07JAD - PH80101

07JAD - PH80200

07947 - 6110501 or

07947 - 6110500

Mainshaft Holder

Co lla r

Mainshaft Base

Adjustable Bearing Puller, 25 - 40 mm

Attachment. 42 x 47 mm

Attachment,52 x 55 mm

Driver, 40 mm LD.

Attachment, 30 mm I.D.

Attachment, 3S mm LD.

Driver

Driver Attachment

Pilot. 26 x 30 mm

Seal Driver Attachment

1 13-38

1 13-37

1 I 13-37

1 13-34,35

1 13-34.35

1 13-34,35

1 | 13-19,24

31,32

1 13-19,24

1 13-19,24

r I t3-34,35, 43

1 13-43

1 13,43

1 I 13-43

* Must be used with commercially-available 3/8"-j6 Slide Hammer.

oaaal

\91o

aif!

o

ly tr

IvI

Page 588 of 2189

Transmission Assembly

Removal(cont'd)

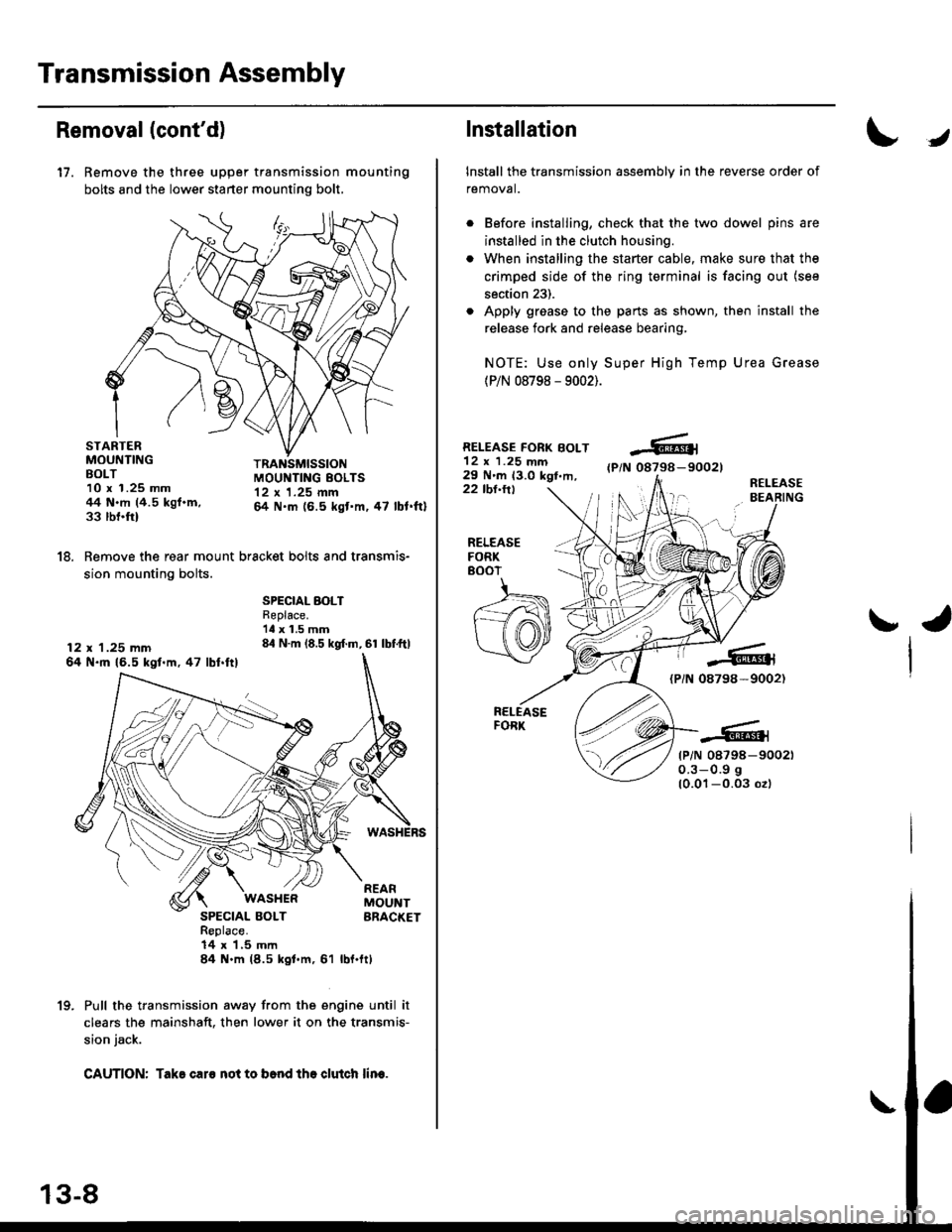

17. Remove the three upper transmission mounting

bolts and the lower starter mounting bolt,

STARTERMOUNTINGBOLT10 x 1.25 mm44 N.m (4.5 kgf.m,33 rbnftl

TRANSMISSIONMOUI{TING EOLTS12 x 1.25 mm& N.m (6.5 kgt'm,47 lbl.ftl

18. Remove the rear mount bracket bolts and transmis-

sion mounting bolts.

12 x 1.25 mm64 N.ft 16.5 kgl.m,47 lbl.ftl

SPECIAL BOLTReplace.'ll x 1.5 mm84 N.m (8.5 kgf.m, 61 lbf.ftl

SPECIAL BOLTReplace.14 x 1,5 mln84 N.m (8.5 kgl.m, 61

WASI{ERREARMOUNTBRACKET

rbl.ftt

Pull the transmission away from the engine until it

clears the mainshaft. then lower it on the transmis-

sion jack.

CAUTION: Take caro not to b6nd tho clutch lin€.

1(|

Installation

Install the transmission assembly in the reverse order of

removal.

Before installing, check that the two dowel pins are

installed in the clutch housing.

When installing the starter cable, make sure that the

crimped side of the ring terminal is facing out (see

section 23).

Apply grease to the parts as shown, then install the

release fork and release bearing,

NOTE: Use only Super High Temp Urea Grease

(P/N 08798 - 9002).

RELEASE FORK BOLT12 x 1.25 mm29 N'm 13.0 kgt,m,(P/N 08798-90021

22 tbl.ttlR€LEASEBEARING

J

RELEASEFORK8()07

ra

{PiN 08798-9002)

tP/N 08798-900210.3-0.9 g

10.01-0.03 ozl

Page 591 of 2189

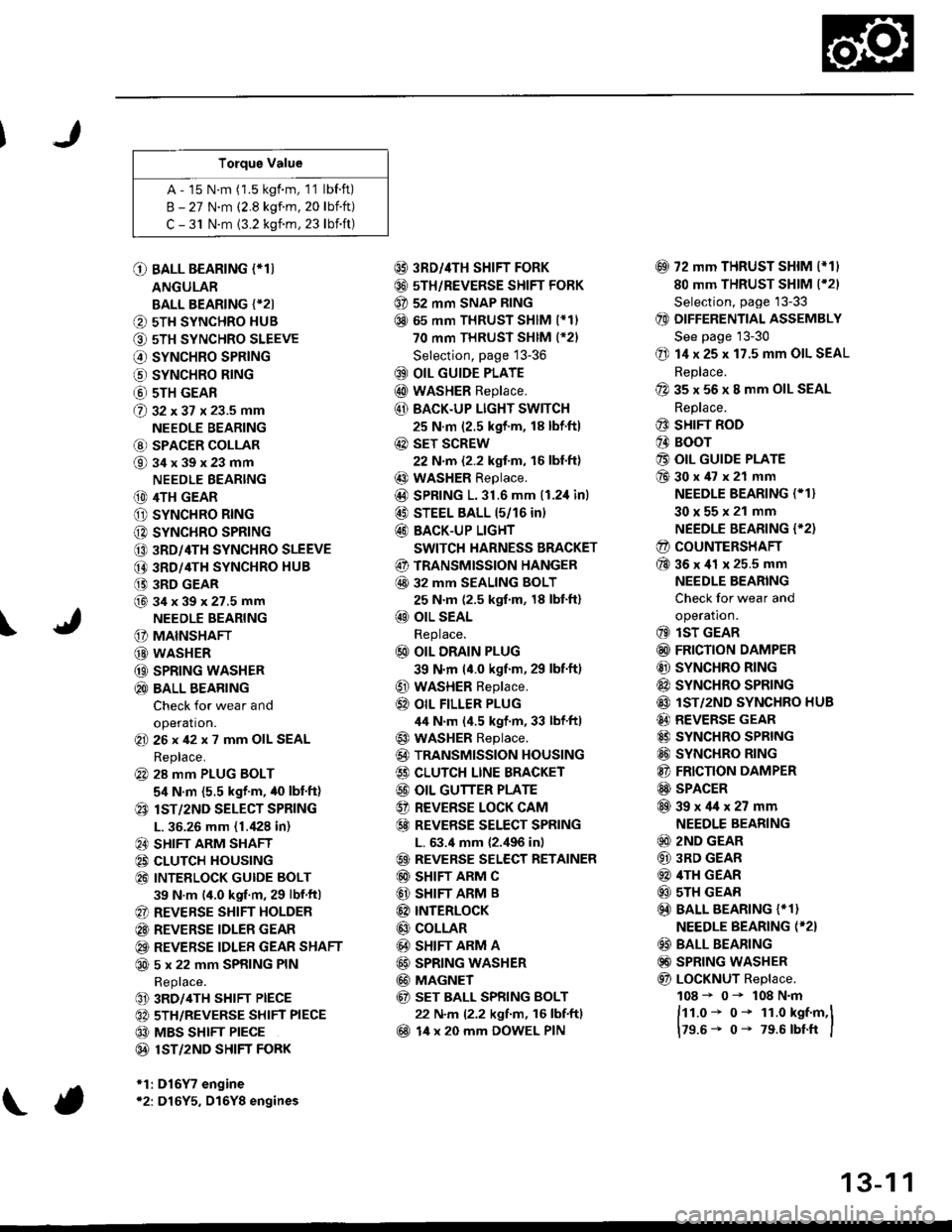

Torque Value

A - 15 N.m (1.5 kgf.m, 1'1 lbf.ft)

B - 27 N.m (2.8 kgf.m. 20 lbift)

C - 31 N.m {3.2 kgnm, 23 lbift)

\

O BALL BEARING (*T)

ANGULAR

BALL BEARING {*2I

O 5TH SYNCHRO HUB

O 5TH SYNCHRO SLEEVE

€) SYNCHRO SPRING

o SYNCHRO B|NG

@ 5TH GEAR

@ gz xgt x 23.5 mm

NEEDLE BEARING

@ SPACER COLLAR

@34x39x23mm

NEEDLE BEARING

(D 4TH GEAR

O SYNCHRO RING

C) SYNCHRO SPRING

CO 3RD/4TH SYNCHRO SLEEVE

@ 3RD/4TH SYNCHRO HUB

(} 3RD GEAR

@34x39x27.5mmNEEDLE BEARING

G) MAINSHAFT

G) WASHER

@ SPRING WASHER

@ BALL BEARING

Check for wear and

operation.(E 26x42x7 mm OIL SEAL

Replace.

@ 28 mm PLUG BOLT

5,1 N.m {5.5 kgf'm, /t0 lbt'ft)

@ lsT/zND SELECT SPRING

L. 36.26 mm (1./P8 in)

@ SHIFT ARM SHAFT

@ CLUTCH HOUSING

@ INTEELOCK GUIDE BOLT

39 N.m (4.0 kgf.m, 29 lbf.ftl

@ REVERSE SHIFT HOLDER

@ REVERSE IDLER GEAR

@ REVERSE IDLER GEAR SHAFT

@ 5 x 22 mm SPRING PIN

Replace.

@ 3RD/4TH SHIFT PIECE

@ 5TH/REVERSE SHIFT PIECE

@ MBS SHIFT PIECE

@ 1ST/2ND SHIFI FORK

*1:D16Y7 engine*2: D16Y5, D16Y8 engines

@ 3RD//|TH SHIFT FORK

@ 5TH/REVERSE SHIFT FORK

@ 52 mm SNAP RING

@ 65 mm THRUST SHIM (*11

70 mm THRUST SHIM (*21

Selection, page 13-36

@ OIL GUIDE PLATE

@ wASHER Replace.

@ BACK.UP LIGHT SWITCH

25 N.m (2.5 kgf'm, 18 lbf'ft)

@ sET SCREW

22 N.m {2.2 kgf.m, 16 lbl.ft}

@ WASHER Replace.

@D SPRING 1.31.6 mm (1.2,1inl

@ STEEL BALL 15/16 in)

@ BACK-UP LIGHT

SWITCH HARNESS BRACKET

@ TRANSMISSION HANGER

@ 32 MM SEALING BOLT

25 N.m (2.5 kgf.m, 18 lbt'ft)

@ OIL SEAL

Replace.

@ OIL DRAIN PLUG

39 N.m (4.0 kgf.m, 29 lbf.ft)

@ WASHER Replace.

@} OIL FILLER PLUG

44 N.m (4.5 kgf.m, 33 lbf'ftl

@ WASHER Replace.

@) TRANSMISSION HOUSING

€) CLUTCH LINE BRACKET

@ OIL GUTTER PLATE

@ REVERSE LOCK CAM

@ REVEBSE SELECT SPRING

L. 63.4 mm {2.,196 in)

@ REVERSE SELECT RETAINER

@ SHIFT ARM C

@ SHIFT ARM B

@ INTERLoCK

@ COLLAR

@ SHIFT ARM A

@ SPRING WASHER

@ MAGNET

@ sET BALL SPRING BOLT

22 N.m (2.2 kgf.m, 16 lbf.ftl

@ 14 x 20 mm DOWEL PIN

@ 72 mm THRUST SHIM l*11

80 mm THRUST SHIM (*21

Selection, page '13-33

@ DIFFERENTIAL ASSEMBLY

See page 13-30

@ 14 x 25 x 17.5 mm OIL SEAL

Replace.

@ 35 x 56 x 8 mm OIL SEAL

Replace.

@ SHIFT ROD

@ BOOr

@ OIL GUIDE PLATE

@30x47x21 mm

NEEDLE BEARING (* 1}

30x55x21 mm

NEEDLE BEARING {'2)

@ COUNTERSHAFT

@36x41 x 25.5 mm

NEEDLE BEARING

Check for wear and

operatron.

@ lsT GEAR

@ FRICTION DAMPER

@ SYNCHRO RING

@ SYNCHRO SPRTNG

@ lST/2ND SYNCHRO HUB

@ REVERSE GEAR

@ SYNCHRO SPRING

@ SYNCHRO RING

@ FRICTION DAMPER

@ SPACER

@39x4lx27mm

NEEDLE BEARING

@ 2ND GEAR

@ 3RD GEAR

@ 4TH GEAR

@ sTH GEAR

@) BALL BEARING {* 1}

NEEDLE BEARING (*2}

@ BALL BEARING

@) SPRING WASHER

@ LoCKNUT Replace.

108 - 0- 108 N.m

ftt.o* o- 1r.o kst.m,l

179.6- 0- 79.6 rbtft I

13-1 1