Valve spring HONDA CIVIC 1996 6.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1996, Model line: CIVIC, Model: HONDA CIVIC 1996 6.GPages: 2189, PDF Size: 69.39 MB

Page 141 of 2189

Cylinder HeadRocker Arms

18.

19.

21.

22.

Removal (cont'd)

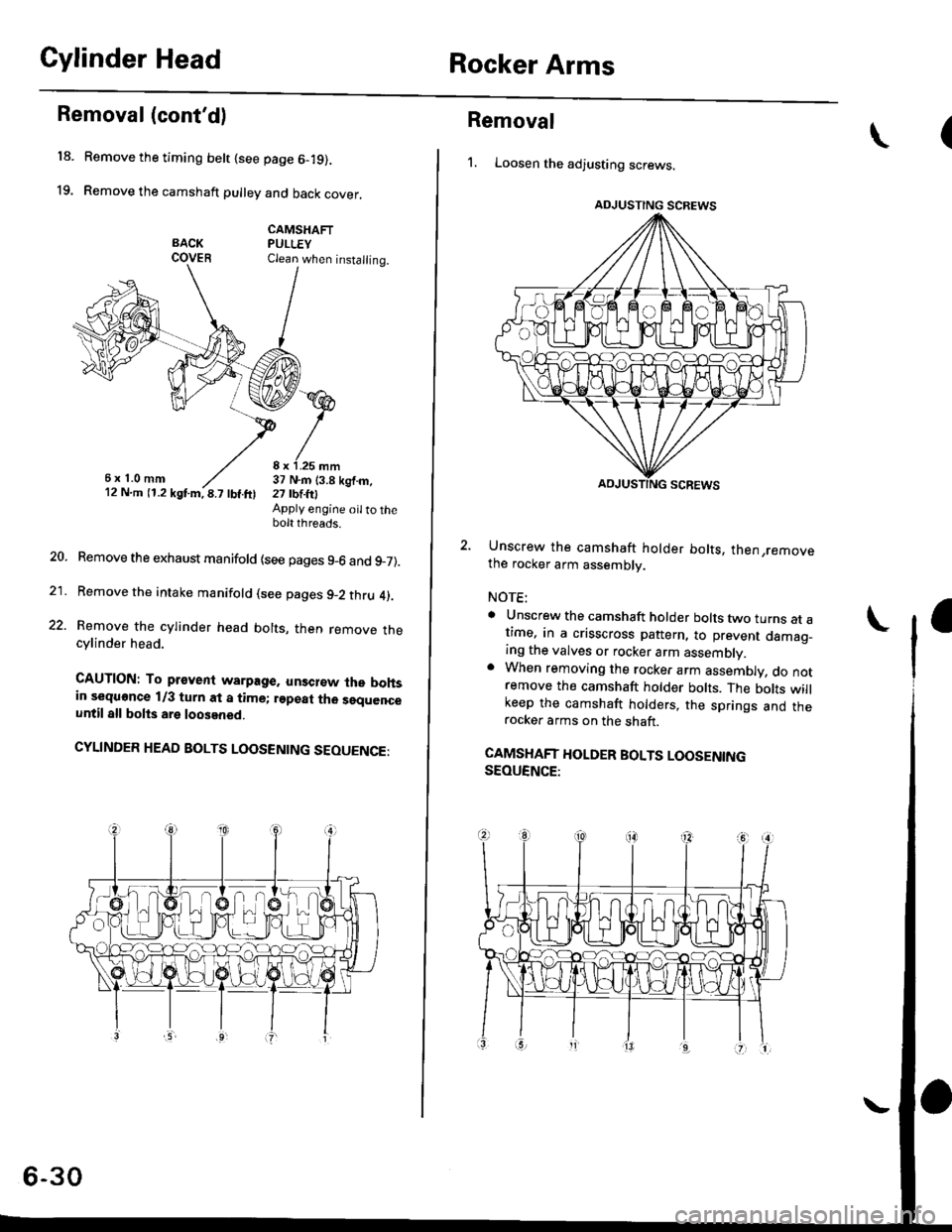

Remove the timing belt {see page 6-19).

Remove the camshaft pulley and back cover,

CAMSHAFTPULLEYClean when installing.

6x1.0mm8 x 1.25 mm37 N.m (3.8 kgf.m,21 tbtlrlApply engine oilto thebolt threads.

Remove the exhaust manifold {see pages 9-6 and 9_7).

Remove the intake manifold (see pages 9-2 thru 4).

Remove the cylinder head bolts, then remove thecylinder head.

CAUTION: To pr€vent warpage, unsclew lhe bohsin sequonce 1/3 turn at a time; rgpeat tho sequenceuntil all bolts are loosened.

CYLINDER HEAD BOLTS LOOSENING SEOUENGE:

6-30

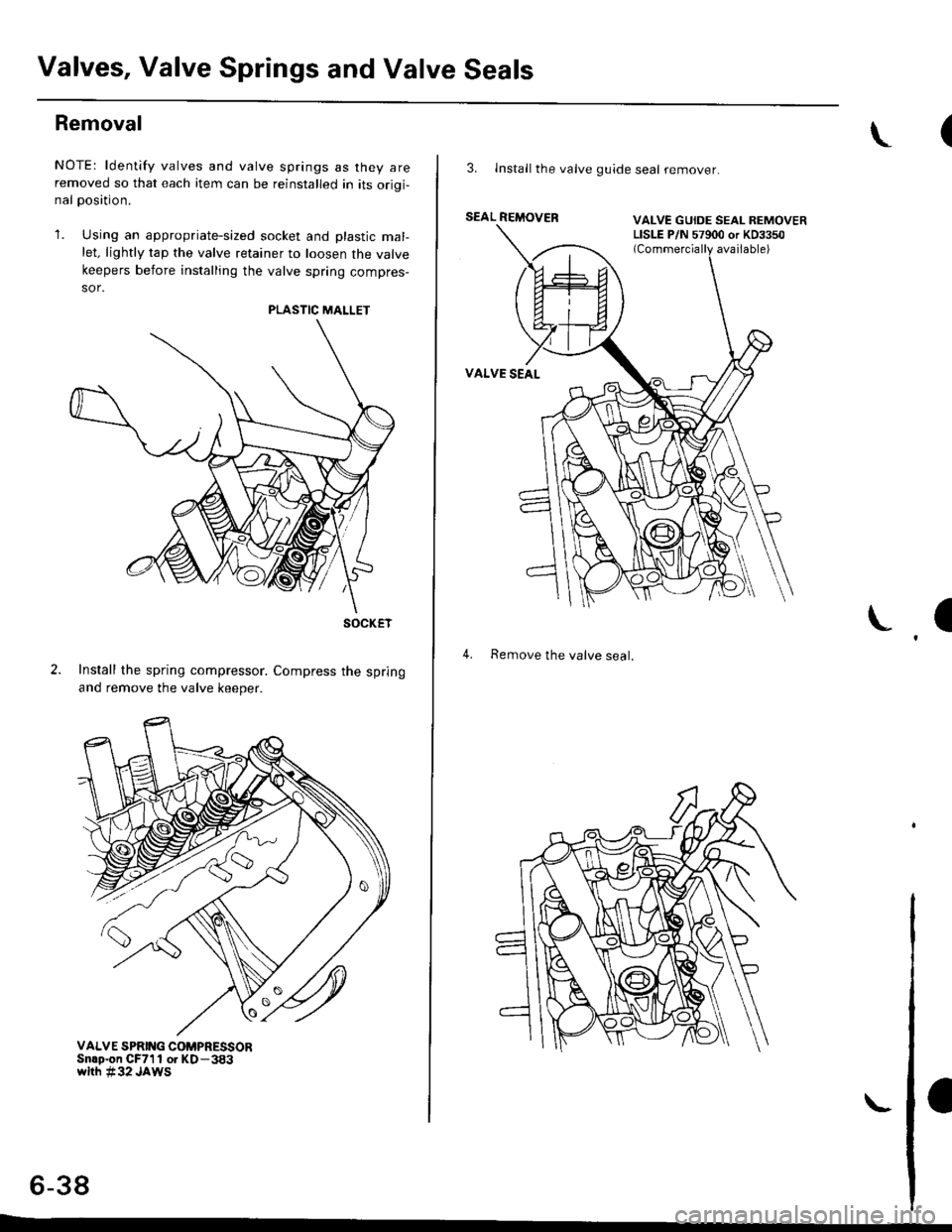

Removal

1. Loosen the adjusting screws.

2. Unscrew the camshaft holder bolts, then,removethe rocker arm assembly.

NOTE:

a Unscrew the camshaft holder bolts two turns at at,me, in a crisscross pattern, to prevent damao_ing the valves or rocker arm assembly.. When removing the rocker arm assembly, do notremove the camshaft holder bolts. The bolts willkeep the camshaft holders, the springs and therocker arms on the shaft.

CAMSHAFT HOLDER BOLTS LOOSENINGSEOUENCE:

\(

ADJUSTING SCREWS

Page 149 of 2189

Valves, Valve Springs and Valve Seals

Removal

NOTE: ldentify valves and valve springs as they areremoved so that each item can be reinstalled in its orioi-nal oosition.

'1. Using an appropriate-sized socket and plastic mal-let. lightly tap the valve retainer to loosen the valve

keepers before installing the valve spring compres-

sor.

Install the spring compressor. Compress the spring

and remove the valve keeper.

PLASTIC MALLET

SOCKET

VALVE SPRII{G COMPRESSORSnlp-on CF711 or KD-383whh #32 JAWS

6-38

L

(

3. Install the valve guide seal remover.

SEAL REMOVER vat vF GI nF !

4. Remove the valve seal.

I

VALVE GUIDE SEAL REMOVERLISLE P/N 57900 or KD3350

Page 154 of 2189

Valves

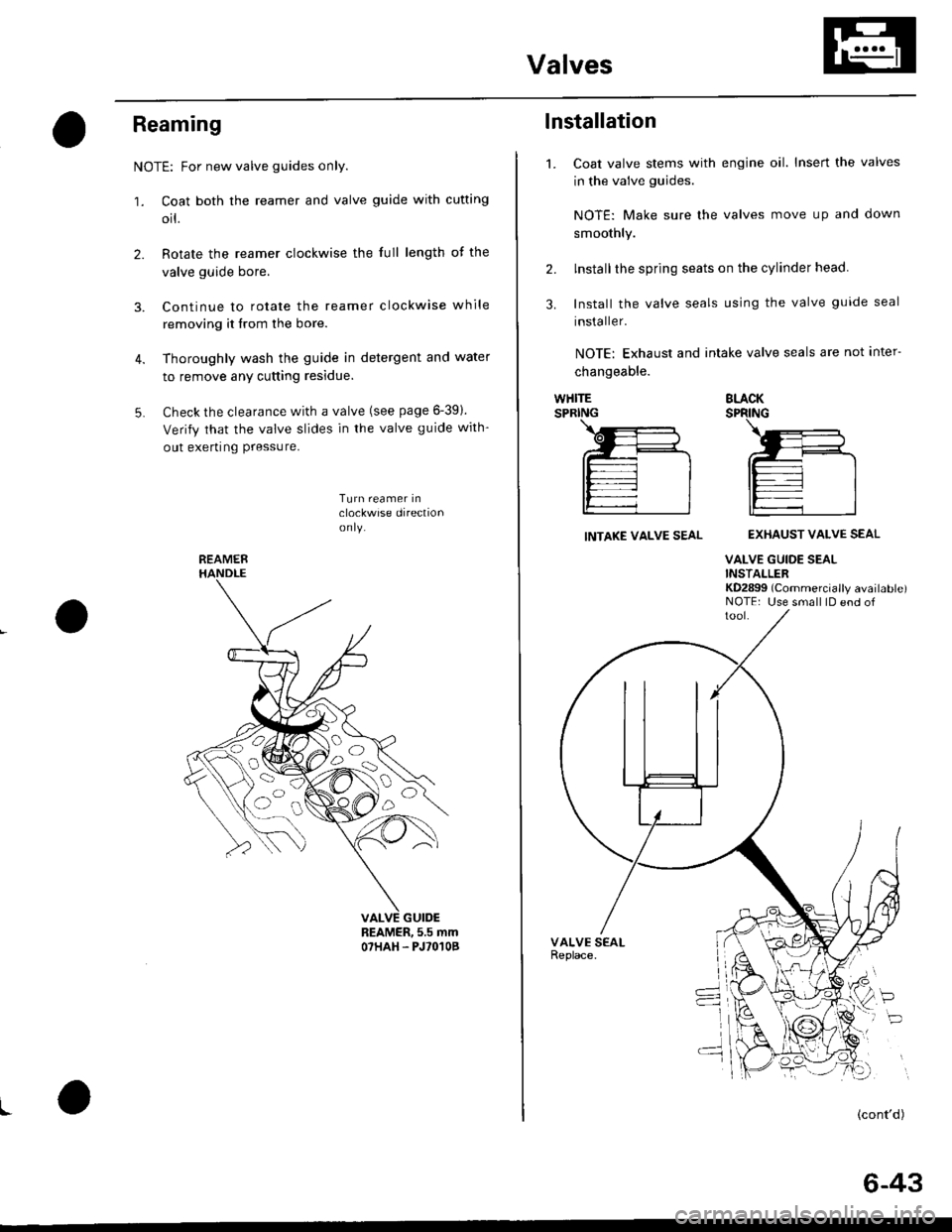

Reaming

NOTE: For new valve guides only.

1. Coat both the reamer and valve guide with cufting

orl.

2. Rotate the reamer clockwise the full length of the

valve guide bore.

3. Continue to rotate the reamer clockwise while

removing it from the bore.

4. Thoroughly wash the guide in detergent and water

to remove any cutting residue.

5. Check the clearance with a valve (see page 6-391.

Verify that the valve slides in the valve guide with-

out exerting Pressure.

Turn reamer inclockwise direclionon ly.

REAMER, 5.5 mmO7HAH. PJ'O'IOB

I

REAMER

oa)o,

o

o

1.

lnstallation

Coat valve stems with engine oil. Insert the valves

in the valve guides.

NOTE: Make sure lhe valves move up and clown

smoothly.

lnstallthe spring seats on the cylinder head.

Install the valve seals using the valve guide seal

installer.

NOTE: Exhaust and intake valve seals are not inter-

changeable.

2.

3.

WHITESPRINGBLACKSPRING

INTAKE VALVE SEALEXHAUST VALVE SEAL

VALVE GUIDE SEALINSTALLERKD2899 (Commercially available)NOTE: Use small lD end of

P

(cont'd)

6-43

Page 155 of 2189

Valves

Camshaft/Rocker Arms and

Camshaft Seal/Pulley

Installation (cont'd)

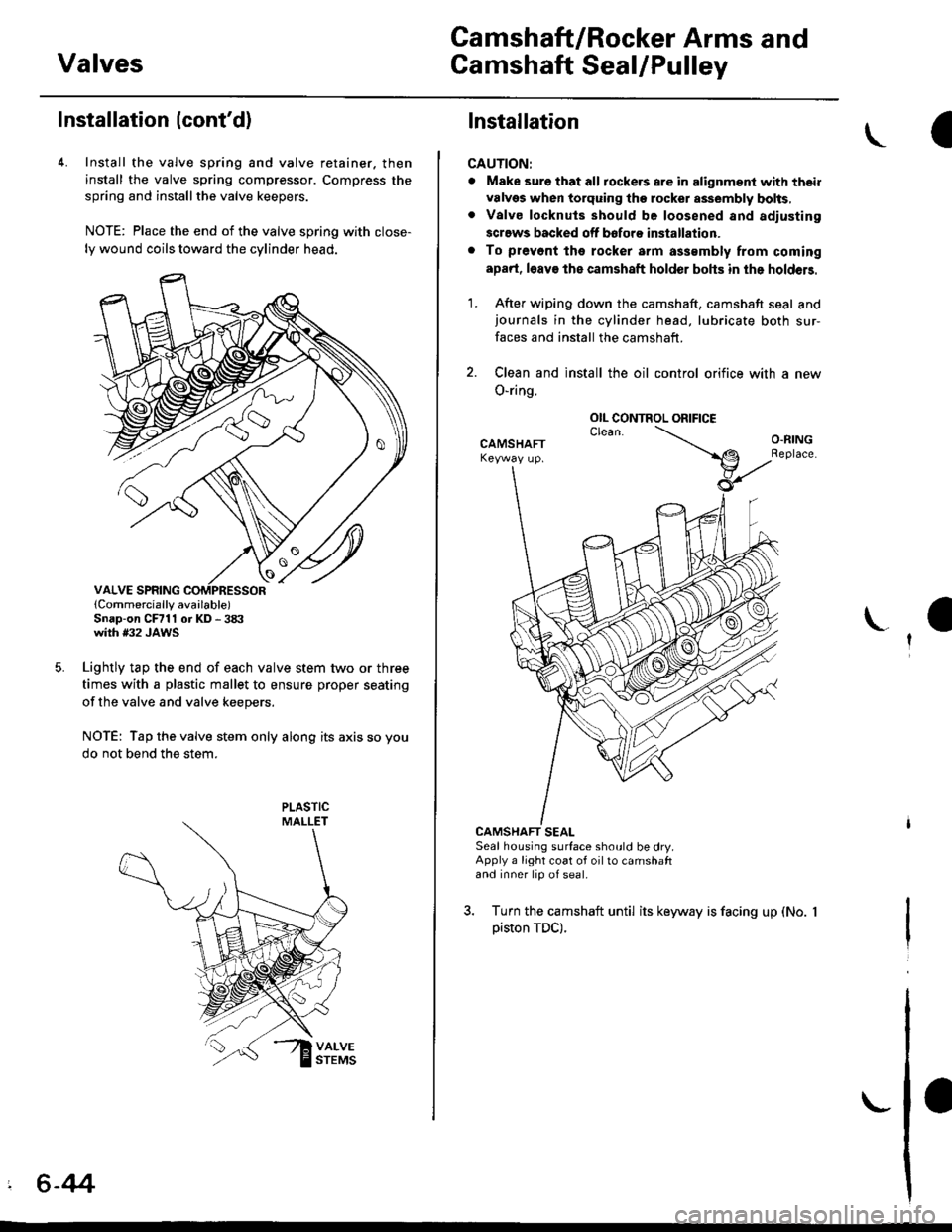

4. Install the valve spring and valve retainer. then

install the valve spring compressor. Compress the

spring and installthe valve keepers.

NOTE: Place the end of the valve spring with close-

ly wound coils toward the cylinder head.

lCornmercially available)Snap-on CFrll or KD - 3tX'with #32 JAWS

Lightly tap the end of each valve stem two or three

times with a plastic mallet to ensure proper seating

of the valve and valve keepers.

NOTE: Tap the valve stem only along its axis so you

do not bend the stem.

' 6-44

Installation

CAUTION:

. Make sure that all tockers are in alignment with their

valvgs when torquing the rocket assembly bolts,. Valve locknuls should be loosened and adiusting

screws backed off bofore installation.

. To prevont tho rocker arm a$smbly from coming

apad, l6av€ the camshaft holder bohs in the holdeB.

1. After wiping down the camshaft, camshaft seal andjournals in the cylinder head, lubricate both sur-

faces and install the camshaft.

2. Clean and install the oil control orifice with a new

O-ring.

CAMSHAFT SEALSeal housing surface should be dry.Apply a light coat of oil to camshaftand inner lip of seal.

3. Turn the camshaft until its keyway is facing up (No.

piston TDC).

OIL CONTROL ORIFICE

Page 159 of 2189

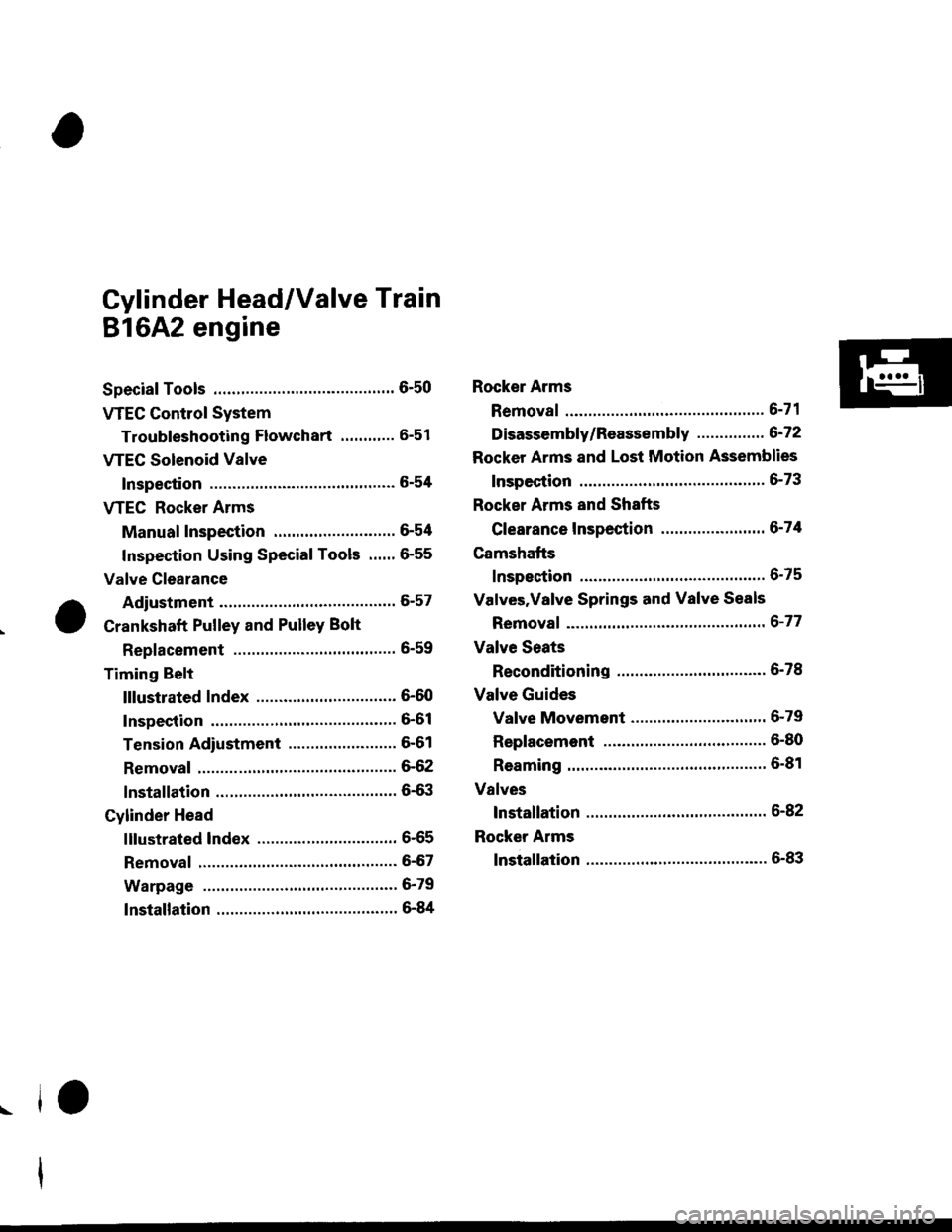

Gylinder Head/Valve Train

816A2 engine

Special Tools ............. 6'50 Rocker Arms

VTEC Contlol System

Troubfeshooting Flowchart ............ 6-51 Disassembly/Reassembly ...............6'72

VTEC Solenoid ValveRocker Arms and Lost Motion Assemblies

Inspection ...""'...... 5-54 Inspection .........""' 6-73

VTEC Rocker ArmsRocker Arms and Shafts

Manual Inspection ........................... 6-54 Clearance Inspection ..'..."'.............. 6-74

Inspection Using Special Tools .....' 6-55 Camshafts

Valve Clearance

.^ Adiustment .........." 6-57 Valves'Valve Springs and Valve Seals

. t Crankshaft Pulley and Pulley Bolt Removal """"""""' 6-77

Replacement ..".....6-59 Valve Seats

Timing BeltReconditioning ......6'78

Cylinder Headlnstallation '............ 6-82

Page 160 of 2189

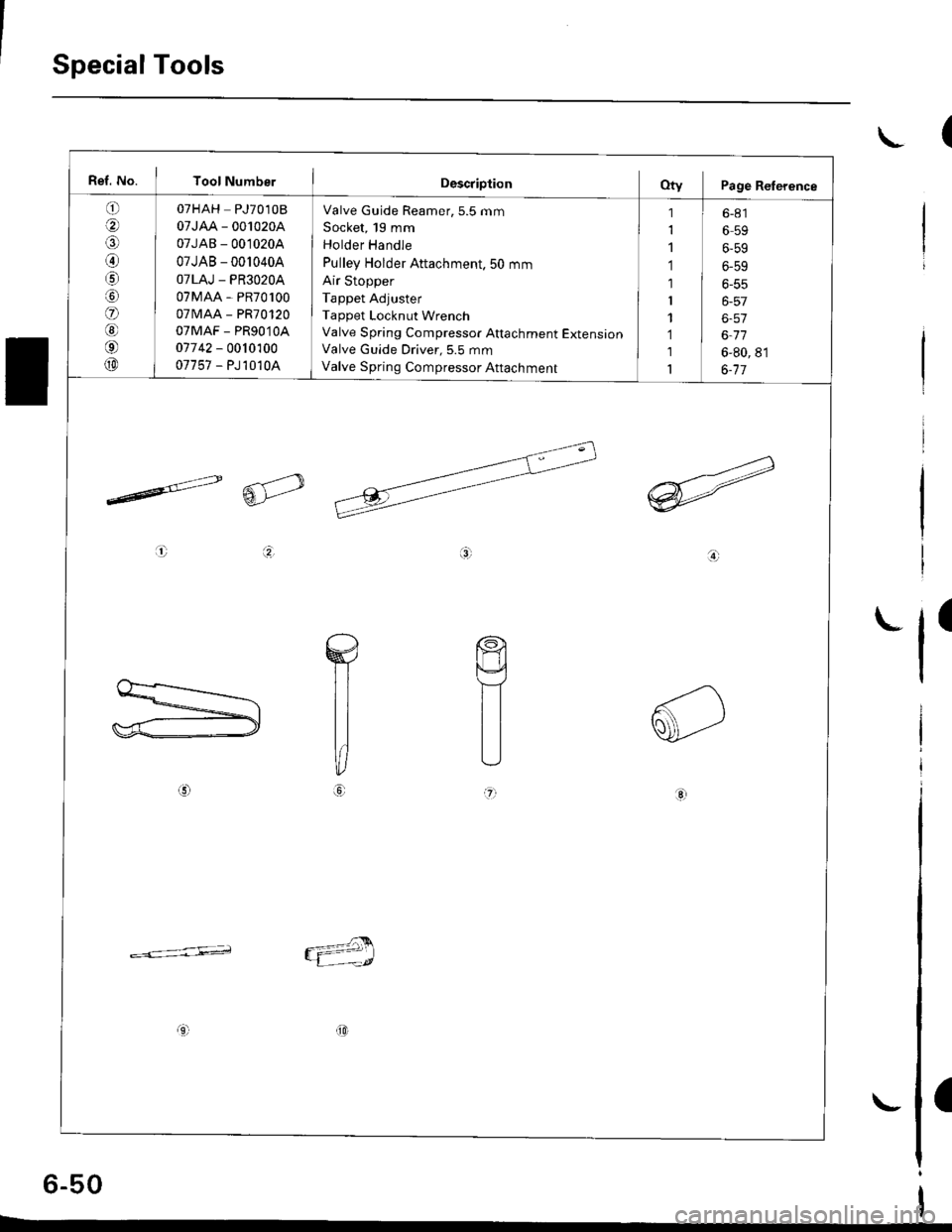

Special Tools

(\

Ref. No. I Tool NumberDescriptionOty Page Relerence

q oTHAH PJ7010B

g I 07JAA-001020A

g I 07JAB-0010204

I 07JAB - 0010404

g 07LAJ - PR3020A

|6) 07MAA - PR70100

g I ozvu,r - enu orzo

g 07MAF - PR9010A

g 07742 - 0010100(!D I 07757-PJ10104

Valve Guide Reamer,5.5 mm

Socket, 19 mm

Holder Handle

Pulley Holder Attachment. 50 mm

Air Stopper

Tappet Adjuster

Tappet Locknut Wrench

Valve Spring Compressor Attachment ExtensionValve Guide Driver, 5.5 mm

Valve Spring Compressor Attachment

1 I 6-81

1 659

1 6-59

1 ] 6-5s

1 I 6-55

1 6-57

1 6-57

1 J 6-77

1 6-80, 81

1 6-71

ta;

aL)'n

-=<-,,LE;;

(D

a

6-50

\-

Page 176 of 2189

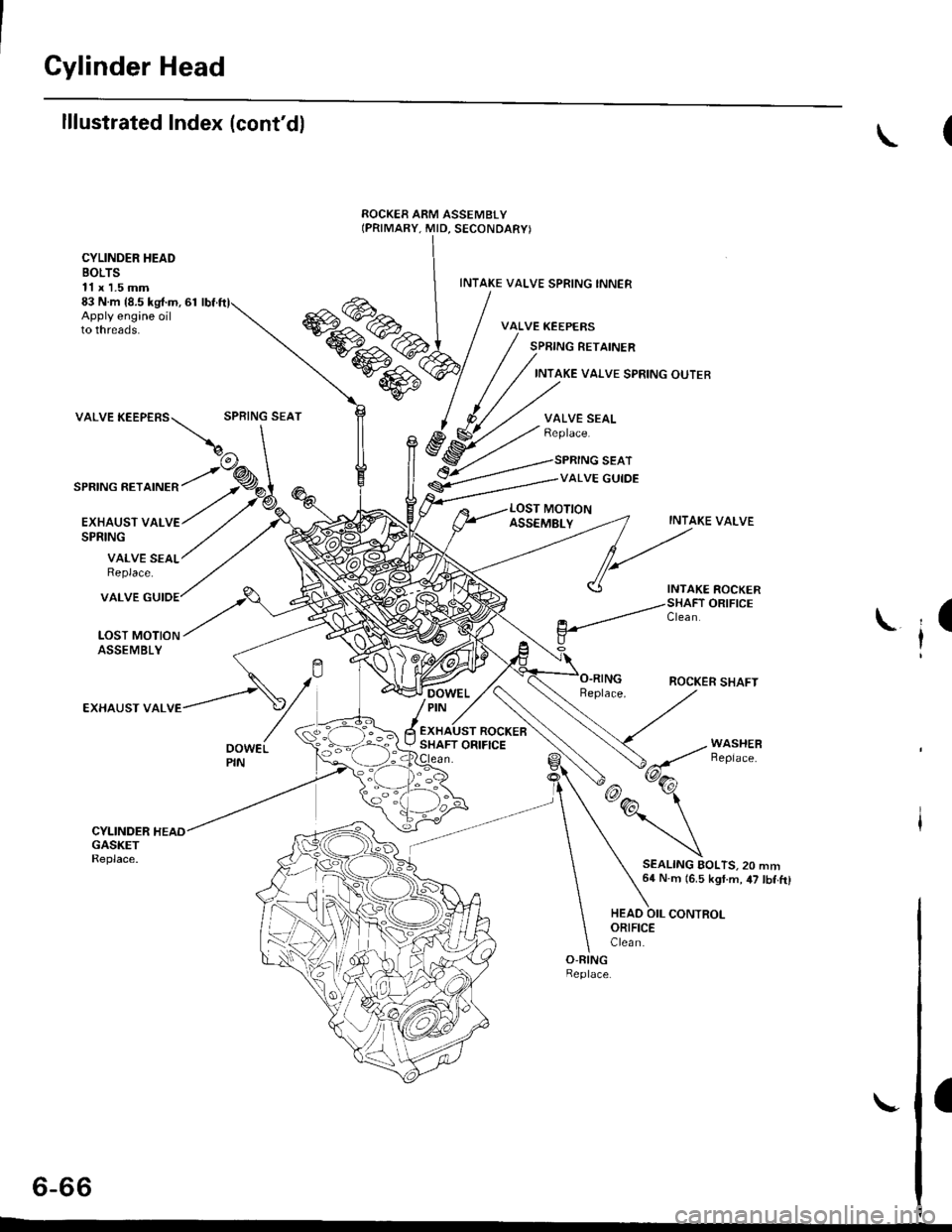

Cylinder Head

lllustrated Index (cont'dl

CYLINDER HEADBOLTS11 x 1.5 mm83 N.m {8.5 kg{.m, 61Apply engine oilto threads.

INTAKE VALVE SPRING INNER

VALVE KEEPERS

SPRING RETAINER

INTAKE VAI.VE SPRING OUTER

valvEKEEPEBS\:""j"*'

SPRING RETAINER

EXHAUST VALVESPRING

VALVE SEALReplace.

VALVE

LOST MOTIONASSEMBLY

EXHAUST VAL

VALVE SEALReplace.

SPRING SEAT

VALVE GUIDE

INTAKE VALVE

ROCKER SHAFT

SEALING AOLTS.20 mm64 N.m (6.5 kgt.m, 47 tbf.ft)

t

il

HEAO OIL CONTROLORIFICEClea n.

a

6-66

Page 187 of 2189

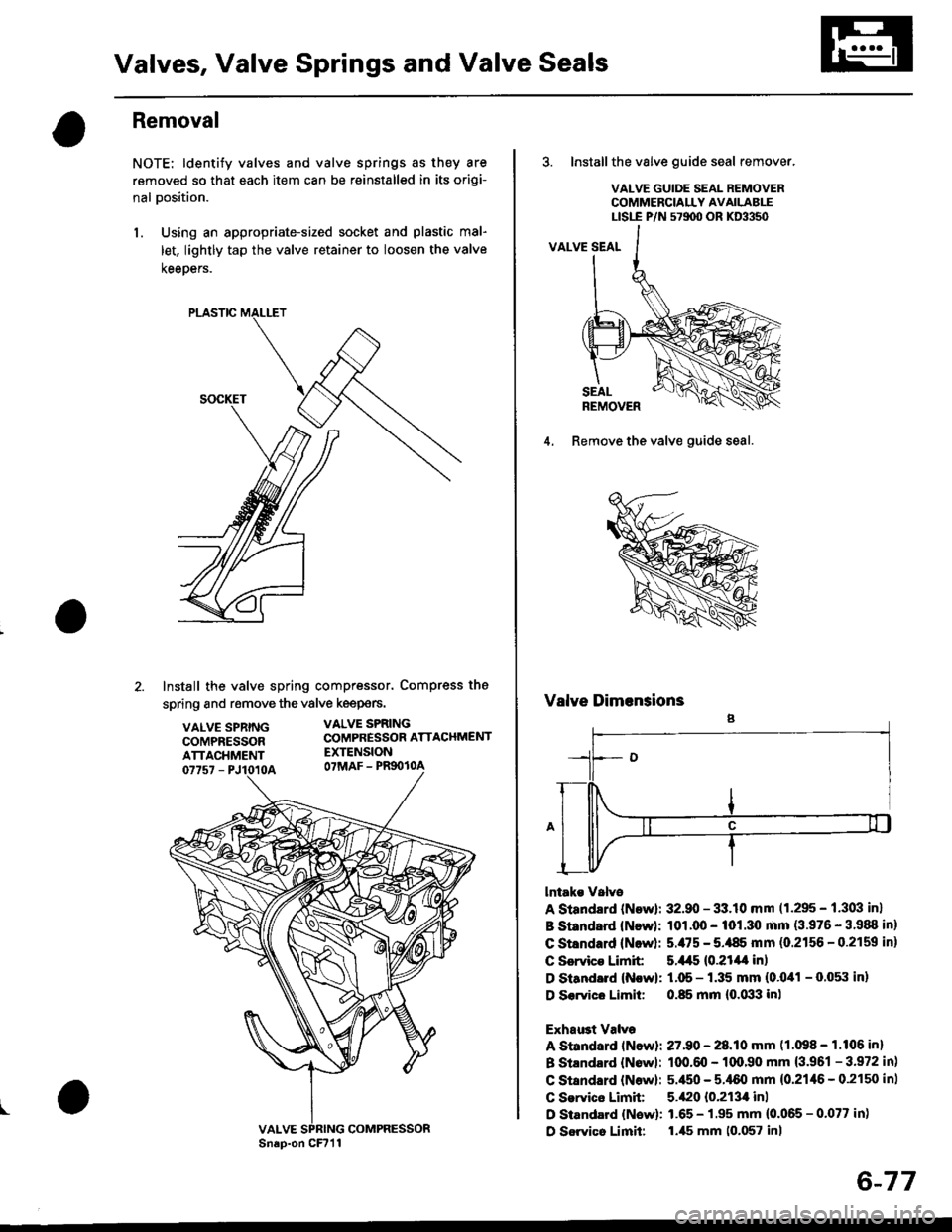

Valves, Valve Springs and Valve Seals

Removal

NOTE: ldentify valves and valve springs as they are

removed so that each item can be reinstalled in its origi-

nal Dosition.

l. Using an appropriate-sized socket and plastic mal-

let, lightly tap the valve retainer to loosen the valve

keeoers.

PLASTIC

Install the valve spring compressor. Compress the

spring and remove the vSlve keepers.

VALVE SPRINGCOMPRESSORATTACHMENT07757 - PJ1010A

VALVE SPRINGCOMPRESSOR ATTACHMENTEXTENSIONOTMAF - PRgOIOA

I

Sn.p-on CFr1lCOMPRESSOR

6-77

3. Installthe valve guide seal remover.

VALVE GUIDE SEAL REMOVERCOMMERCIALLY AVAILABLELtst-E P/N 571100 ()R KD3350

4. Remove the valve guide seal.

Valve Dimensions

lntake Valvo

A Standsrd {Newl; 32.90 - 33.10 mm (1.295 - 1.303 in}

B St ndard {New}: 101.00 - 101.30 mm (3.976 - 3'988 in}

C Stsndard (Nowl: 5./t5 - 5.,185 mm (0.2156 - 0.2159 in)

C Servico Limit 5.445 {0.21/l| in)

D Siandard (N!w): 1.05 - 1.35 mm (0.041 - O.05il inl

D S€.vice Limit: 0.85 mm {0.033 inl

Exhaust Valve

A Standard lNewli 27.90 - 28.10 mm (1.098 - 1.106 in)

B Stlndard {Nowl: 100.m - 1qr,90 mm {3.961 - 3.972 in)

C Stsndard {Now}: 5.450 - 5.,[60 mm {0.21,16 - 0.2150 in)

C Service Limit 5.420 10.213,0 inl

D Standard {New): 1.65 - 1.95 mm (0.065 - 0.077 in)

D Sorvico Limit: l.ils mm 10.057 inl

Page 192 of 2189

Valves

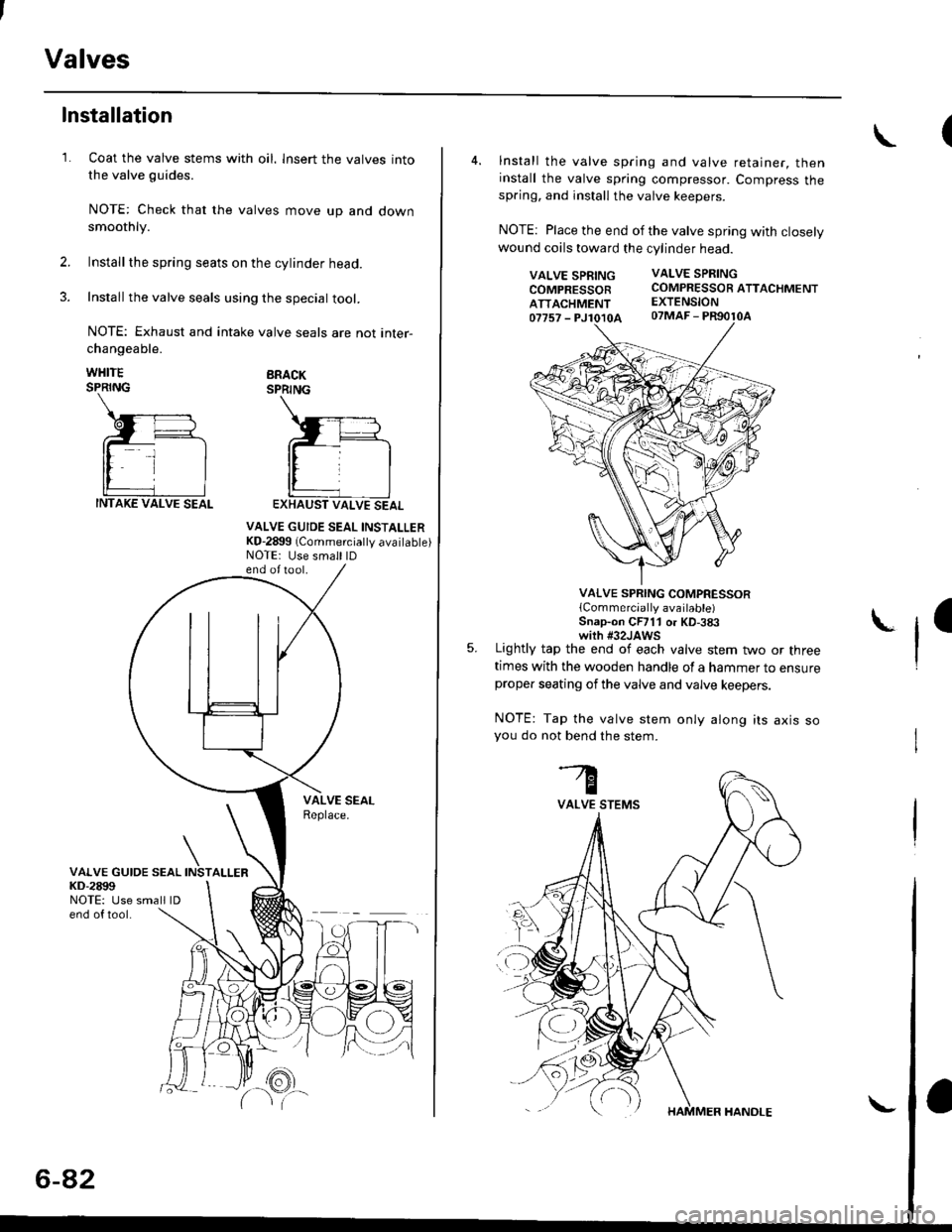

1.

Installation

Coat the valve stems with oil. lnsert the valves into

the valve guides.

NOTE: Check that the valves move up and downsmoothly.

Installthe spring seats on the cylinder head.

Install the valve seals using the special tool.

NOTE: Exhaust and intake valve seals are not inter-

changeable.

WHITESPRING

VALVE GUIDE SEAL INSTALLERKD-28)g (Commercially available)NOTE: Use small lDend of tool,

2.

BRACKSPRING

VALVE SEALReplace.

tNsTALLERVALVE GUIDE SEALKD-2899NOTE: Use small lDend of tool

(

4. lnstall the valve spring and valve retainer, theninstall the valve spring compressor. Compress thespring, and install the valve keepers.

NOTE: Place the end of the valve spring with closely

wound coils toward the cylinder head.

VALVE SpRtNG VALVE SPRTNG

COMpRESSOR COMPRESSORATTACHMENT

ATTACHMENT EXTENSTON

0775? _ pJlOl0A o?MAF - PR9010A

VALVE SPRING COMPRESSORlCommercially available)Snap-on CF711 or KD-3tXlwith #32JAWSLightly tap the end of each valve stem two or threetimes with the wooden handle of a hammer to ensureproper seating of the valve and valve keepers.

NOTE: Tap the valve stem only along its axis soyou do not bend the stem.

I

5.

Page 237 of 2189

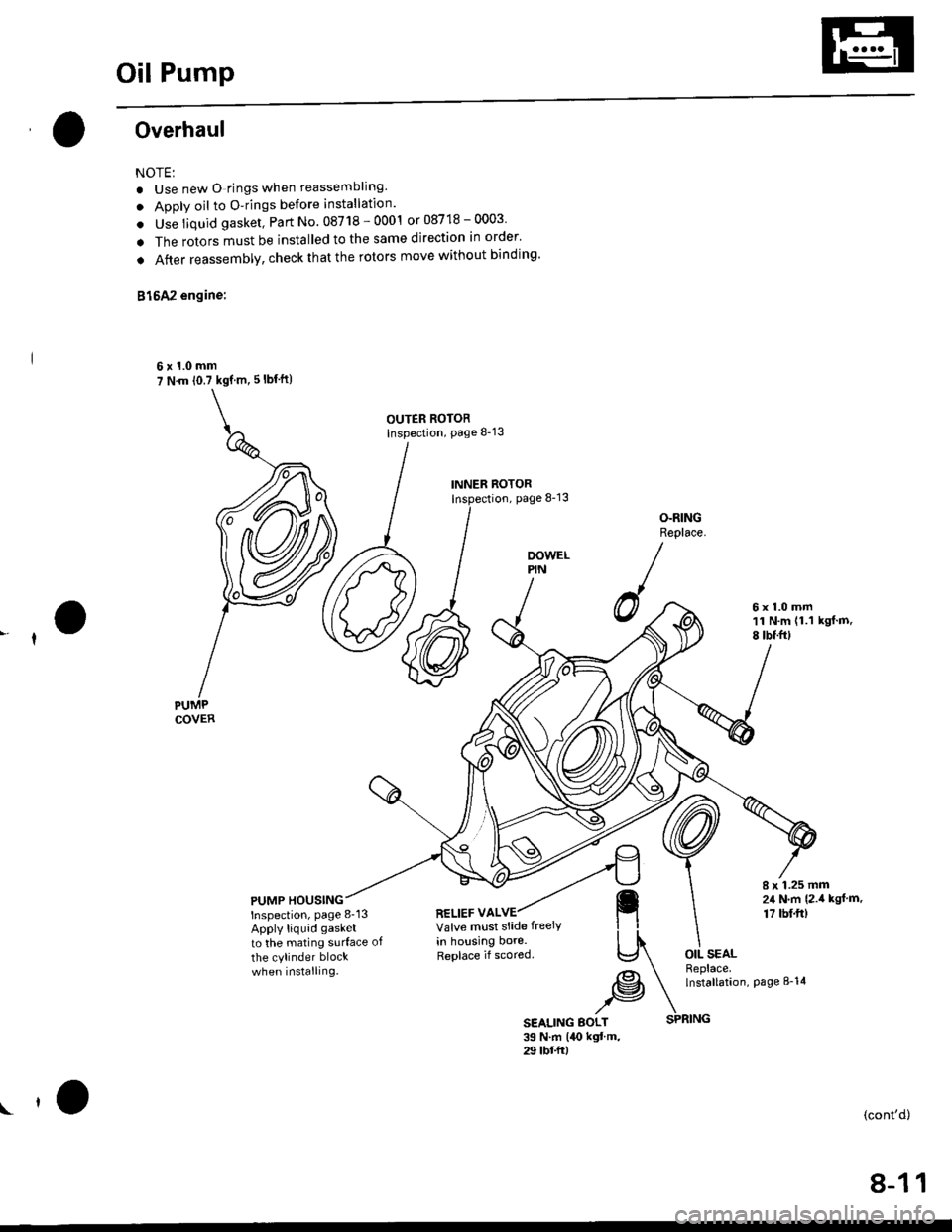

Oil Pump

Overhaul

NOTE:

. Use new O rings when reassembllng.

. Apply oil to O-rings before installation.

. Use liquid gasket, Part No. 08718 - 0001 or 08718 - 0003

. The rotors must be installed to the same direction in order'

o After reassembly, check that the rolors move without binding'

B15A2 engine:

6x1.0mm7 N.m (0.7 kgf m, 5 lbf ft)

OUTER ROTORInspection, page 8-13

INNER ROTORpage 8-13

OOWELPIN

O-RINGReplace.

6x1.0mm11 N.m (1.1

8 tbtfrlkgf.m,

PUMP HOUSINGInspection, page 8-13

Apply liquid gasket

to the mating surface of

the cylinder blockwhen installing.

8 x 1.25 mm24 N,m {2.i1 kgl.m.

17 tbf.ft)RELIEF VALVEValve mlst slide freeiy

in housing bore.Replace if scored.OIL SEALReplace.lnstallation,page 8-14

SEALING BOLT39 N.m l4O kgt'm,29 tbt frl

\(cont'd)

SPRING

8-11