Back up switch HONDA CIVIC 1996 6.G Service Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1996, Model line: CIVIC, Model: HONDA CIVIC 1996 6.GPages: 2189, PDF Size: 69.39 MB

Page 970 of 2189

Start Clutch Control@

T

Start Clutch Calibration Procedure

NOTE: When the following parts are replaced, the TCM

must memorize the feedback signal for the start clutch

control.

. TCM

. Transmissionassembly

. Stan clutch assembly

. Lower valve bodv assembly

. Engine assembly or overhaul

'96 Model Only

CAUTION: Do not uso this procsdure on'97 - (X) mod-

els or you will damage the transmission. On '97 - 00

models, the TCM or PCM memorizes ths loodback sig'

nals when you drive the vehicle.

1. Engage the parking brake, and block the front

wheels securely.

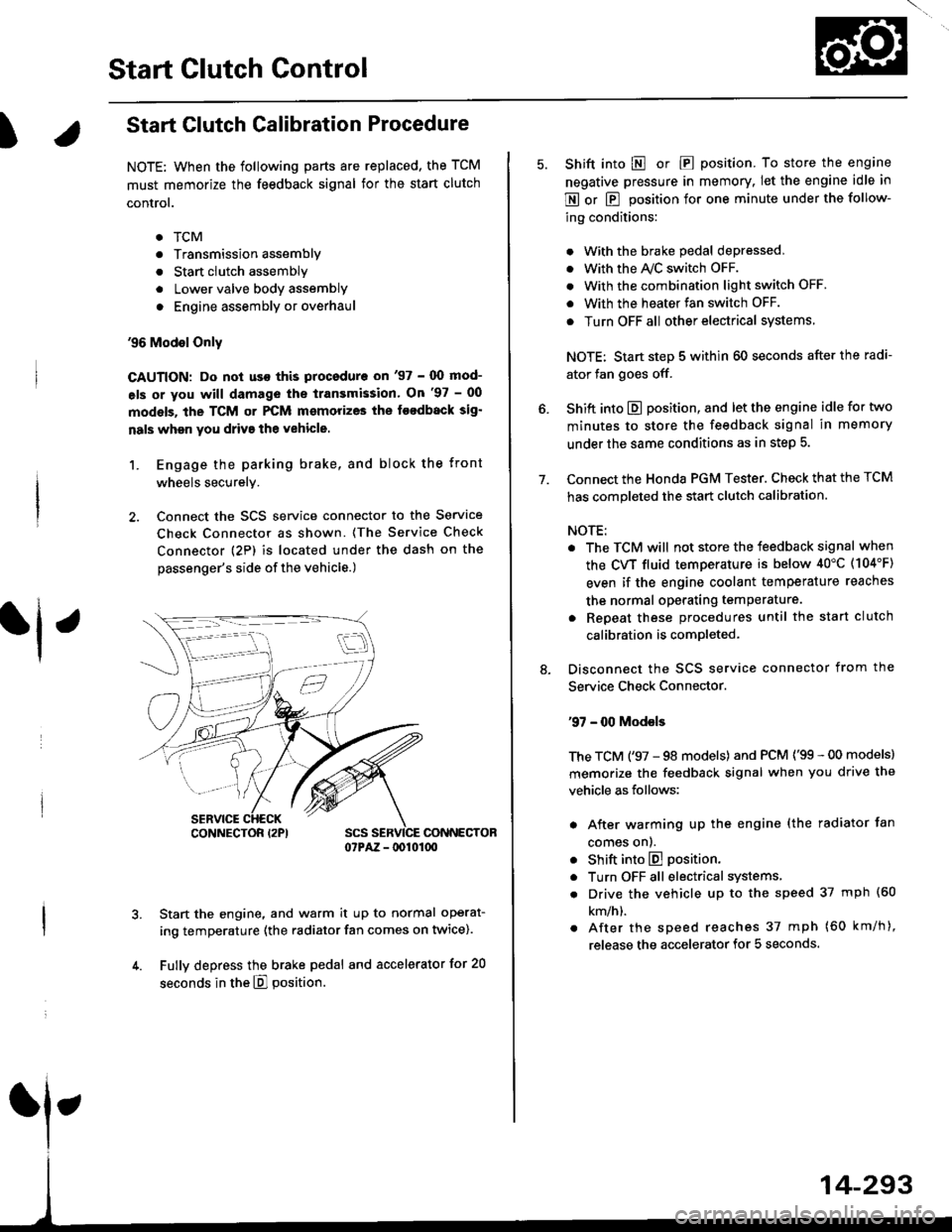

2. Connect the SCS service connector to the Service

Check Connector as shown. (The Service Check

connector (2P) is located under the dash on the

passenger's side of the vehicle.)

CONNECTOR07PAZ - lDl01(xt

Start the engine, and warm it up to normal operat-

ing temperature (the radiator fan comes on twice).

Fully depress the brake pedal and accelerator for 20

seconds in the E] position.

rl ,

CONNECTOR I2PI

14-293

7.

Shift into E o|. E position. To store the engine

negative pressure in memory. Iet the engine idle in

E or E position for one minute under the follow-

ing conditions:

. With the brake pedal depressed,

. with the y'\/c switch oFF.

. With the combination light switch OFF.

. With the heater fan switch OFF.

. Turn OFF all other electrical systems

NOTE: Start step 5 within 60 seconds after the radi-

ator fan goes off.

Shift into E position, and let the engine idle for two

minutes to store the feedback signal in memory

under the same conditions as in step 5.

Connect the Honda PGM Tester. Check that the TCM

has completed the start clutch calibration.

NOTE:

. The TCM will not store the feedback signal when

the CVT fluid temperature is below 40"C (104'F)

even if the engine coolant temperature reaches

the normal operating temperature.

. Repeat these procedures until the start clutch

calibration is completed-

Disconnect the SCS service connector from the

Service Check Connector.

'97 - 00 Models

The TCM ('97 - 98 models) and PCM ('99 - 00 models)

memorize the feedback signal when you drive the

vehicle as follows:

. After warming up the engine (the radiator fan

comes onl.

. Shift into E position.

. Turn OFF all electrical systems,

. Drive the vehicle up to the speed 37 mph (60

km/h).

. After the speed reaches 37 mph (60 km/h),

release the accelerator for 5 seconds.

Page 1159 of 2189

)

Brake Pedal

Pedal Height

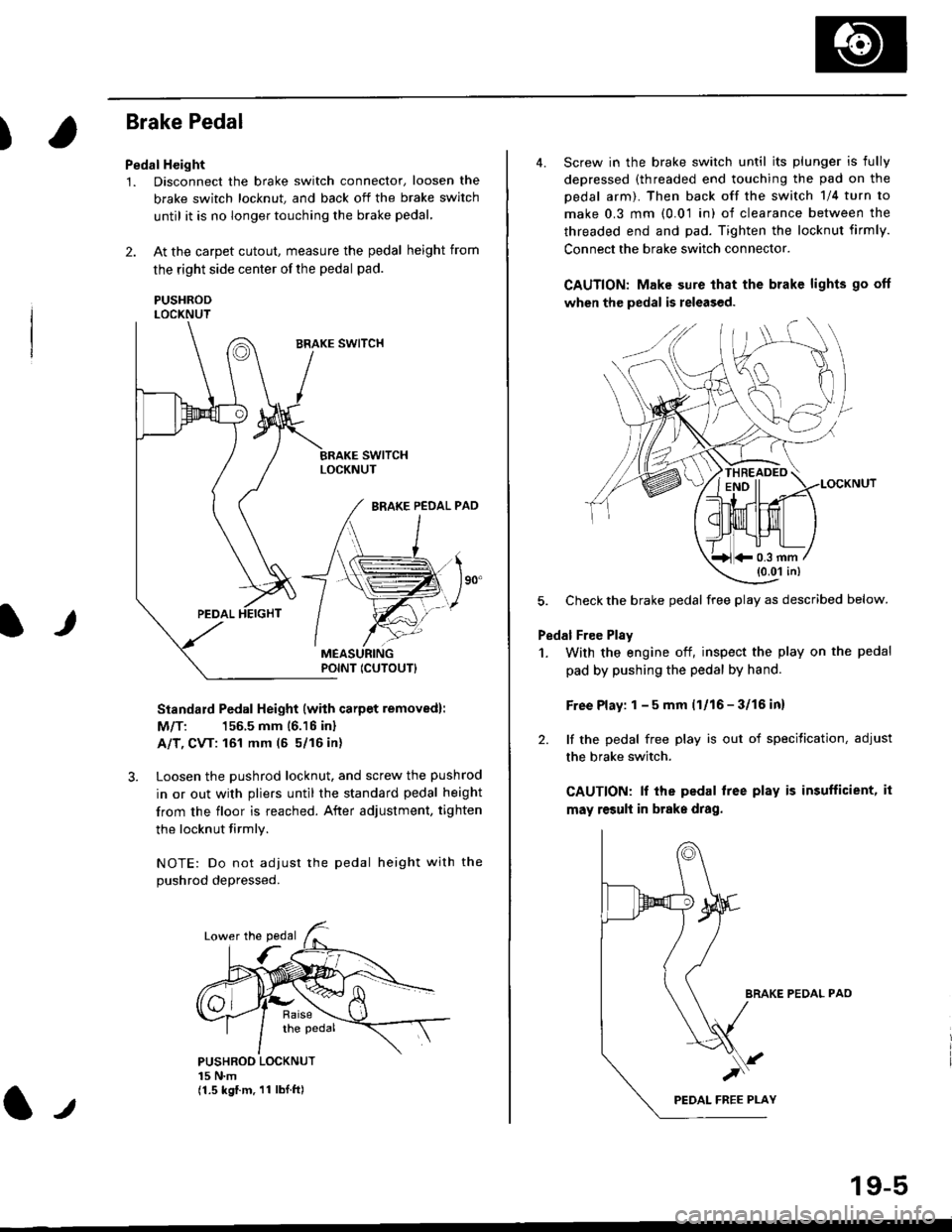

1. Disconnect the brake switch connector, loosen the

brake switch locknut, and back off the brake switch

until it is no longer touching the brake pedal,

2. At the carpet cutout, measure the pedal height from

the right side center of the pedal pad.

PUSHRODLOCKNUT

Standard Pedal Height (with carpet removed):

M/T: 156.5 mm 16.16 inl

A/T, CVT: 161 mm (5 5/16 in)

3. Loosen the pushrod locknut, and screw the pushrod

in or out with pliers until the standard pedal height

from the floor is reached. After adjustment, tighten

the locknut firmly.

NOTE: Do not adiust the pedal height with the

Dushrod depressed.

It

PUSHROO LOCKNUT15 N.m(1.5 kgf.m. 11 lbI.ft)

POINT ICUTOUTI

4. Screw in the brake switch until its plunger is fully

depressed (threaded end touching the pad on the

pedal arm). Then back off the switch 1/4 turn to

make 0.3 mm (0.01 in) of clearance between the

threaded end and pad. Tighten the locknut firmly.

Connect the brake switch connector.

CAUTION: Make sure that the brake lights go off

when the pedal is released.

LOCKNUT

5. Check the brake pedal free play as described below.

Pedal Free Plsy

1. With the engine off, inspect the play on the pedal

pad by pushing the pedal by hand.

Free Play: 1 - 5 mm (1/16 - 3/16 inl

2. lf the pedal free play is out of specitication, adjust

the brake switch.

CAUTION: lf the pedal free play is insufficient, it

may result in brake drag.

BRAKE PEDAL PAO

)

19-5

*0.3 mm(0.01 in)

Page 1195 of 2189

Parking Brake Cable

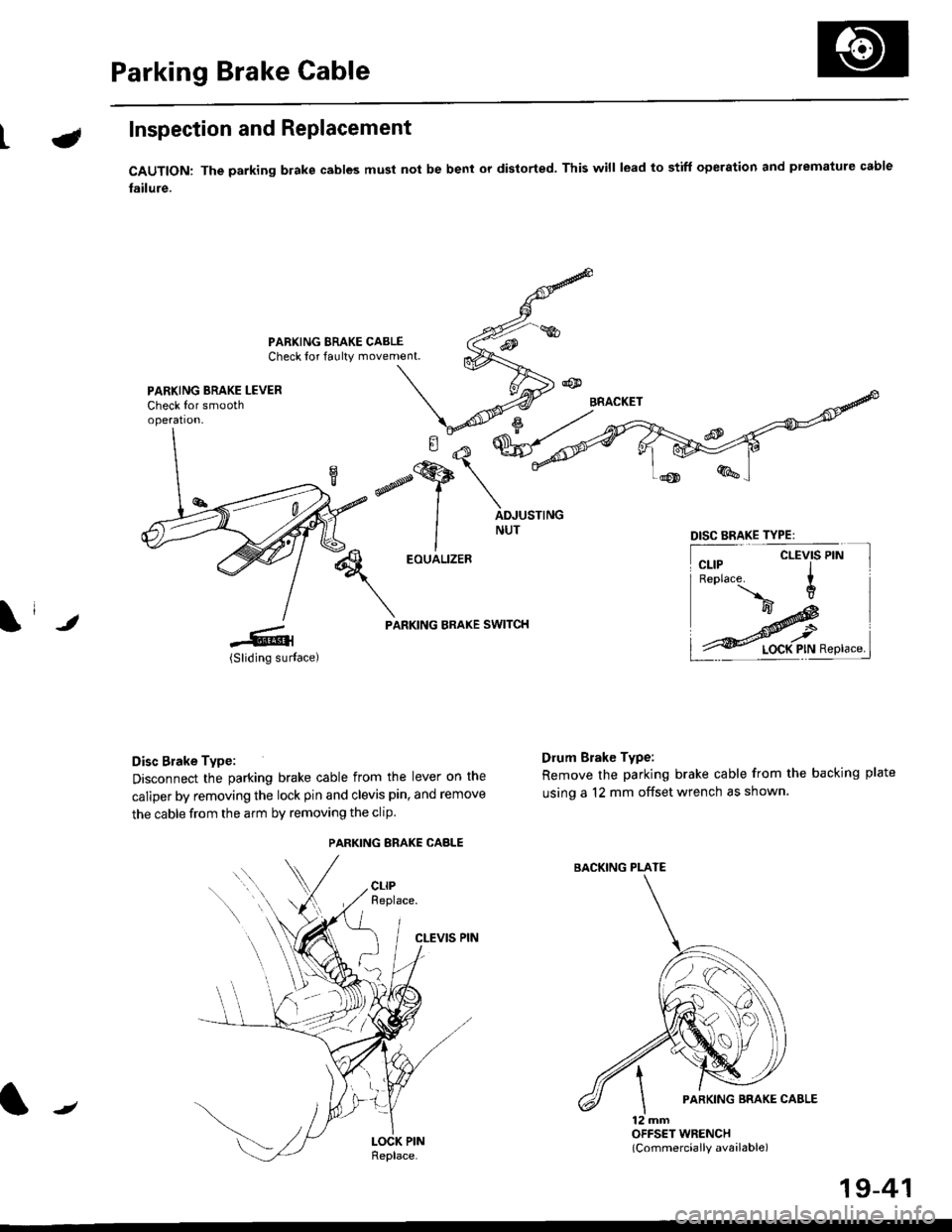

LInspection and Replacement

CAUTION: The parking blake cables must not be bent or distorted. This will lead to stiff operation and premature cable

failure.

PARKING BRAKE CABLECheck for faulty movement.

PARKING BRAKE LEVERCheck for smoothoperation.

\i ,

EOUALIZER

PARKING BRAKE SWITCH

Disc Brake Type:

Disconnect the parking brake cable from the lever on the

caliper by removing the lock pin and clevis pin, and remove

the cable from the arm by removing the clip

CLEVIS PIN

Drum Brake Type:

Remove the parking brake cable from the backing plate

using a 12 mm offset wrench as shown.

12 mmOFFSET WRENCH(Commercially available)

DISC BRAKE TYPE:

CLEVIS PIN

PARKING ERAKE CABLE

{tt

BACKING PLATE

/

19-41

Page 1305 of 2189

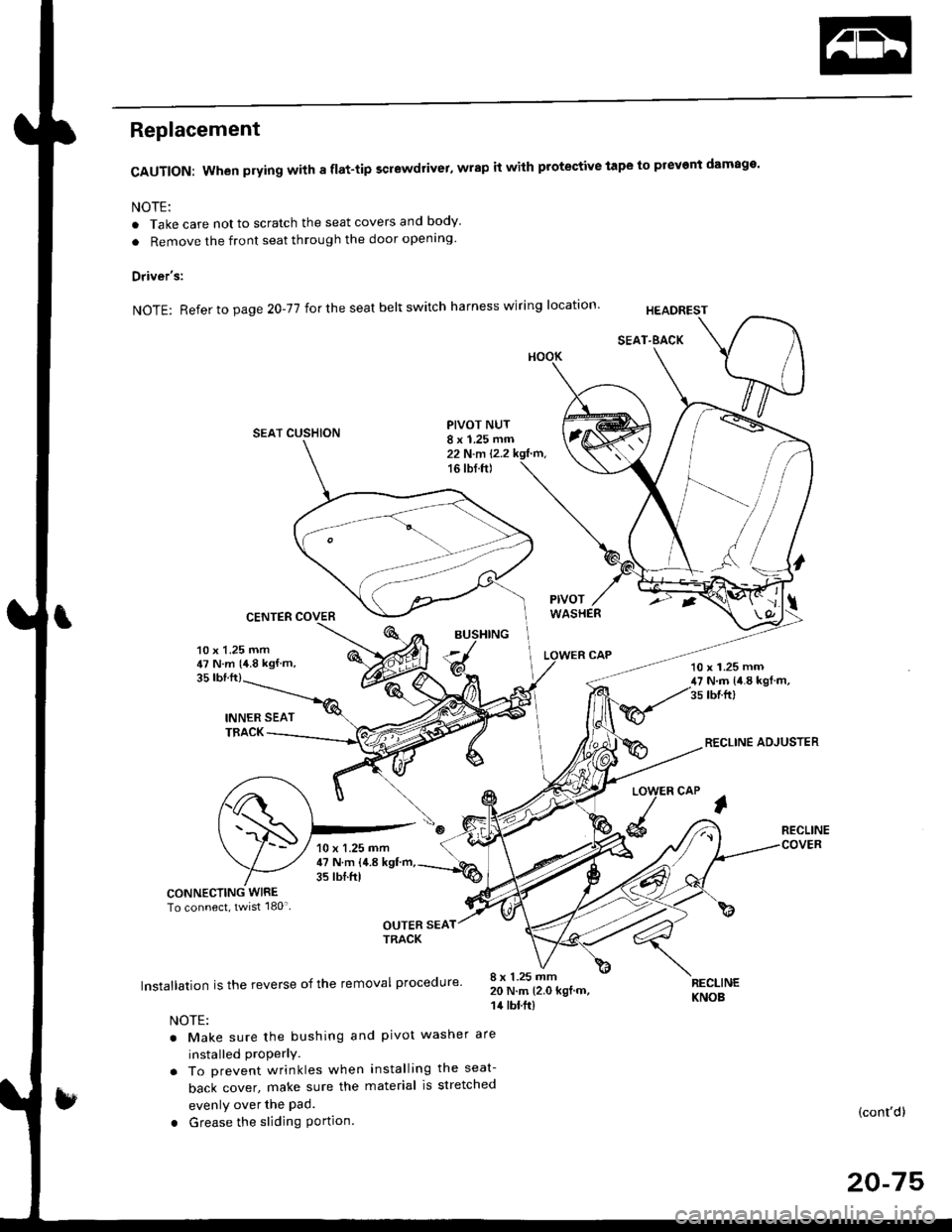

Replacement

CAUTION: When prying with a flat-tip screwdrivet, wrap it with protective tape to prevent damage'

NOTE:

. Take care not to scratch the seat covers and body

. Remove the front seat through the door openlng'

Driver's:

NOTE: Refer to page 2O-77 for the seat belt switch harness wiring location'

SEAT CUSHION

CENTER COVER

INNER SEATTBACK

PIVOT NUT8 x 1.25 mm22 N.m l.2.216 tbf.ft)

v

l

35 tbt.ft)

10 x 1.25 mm47 N.m {4.8 kgf m,10 x 1.25 mm47 N.m {i1.8 kgl m,35 tbr.ft)

RECLINE ADJUSTER

LOW

d

ER CAP

l

RECLINE

CONNECTING WIRETo connect, twist 180'

OUTER SEATTRACK

Installation is the reverse of the removal procedure'

NOTE:

. Make sure the bushing and pivot washer

installed ProPerly.. To prevent wrinkles when installing the seat-

back cover, make sure the material is stretched

evenly over the Pad.

. Grease the sliding Portion

8 x 1.25 mm20 N.m 12.0 kgf.m,14 tbt.ft)

are

RECLINEKNOB

(cont'd)

20-75

10 x 1.25 mm47 N.m {4.8 kgf'm,35 tbtftl

Page 1307 of 2189

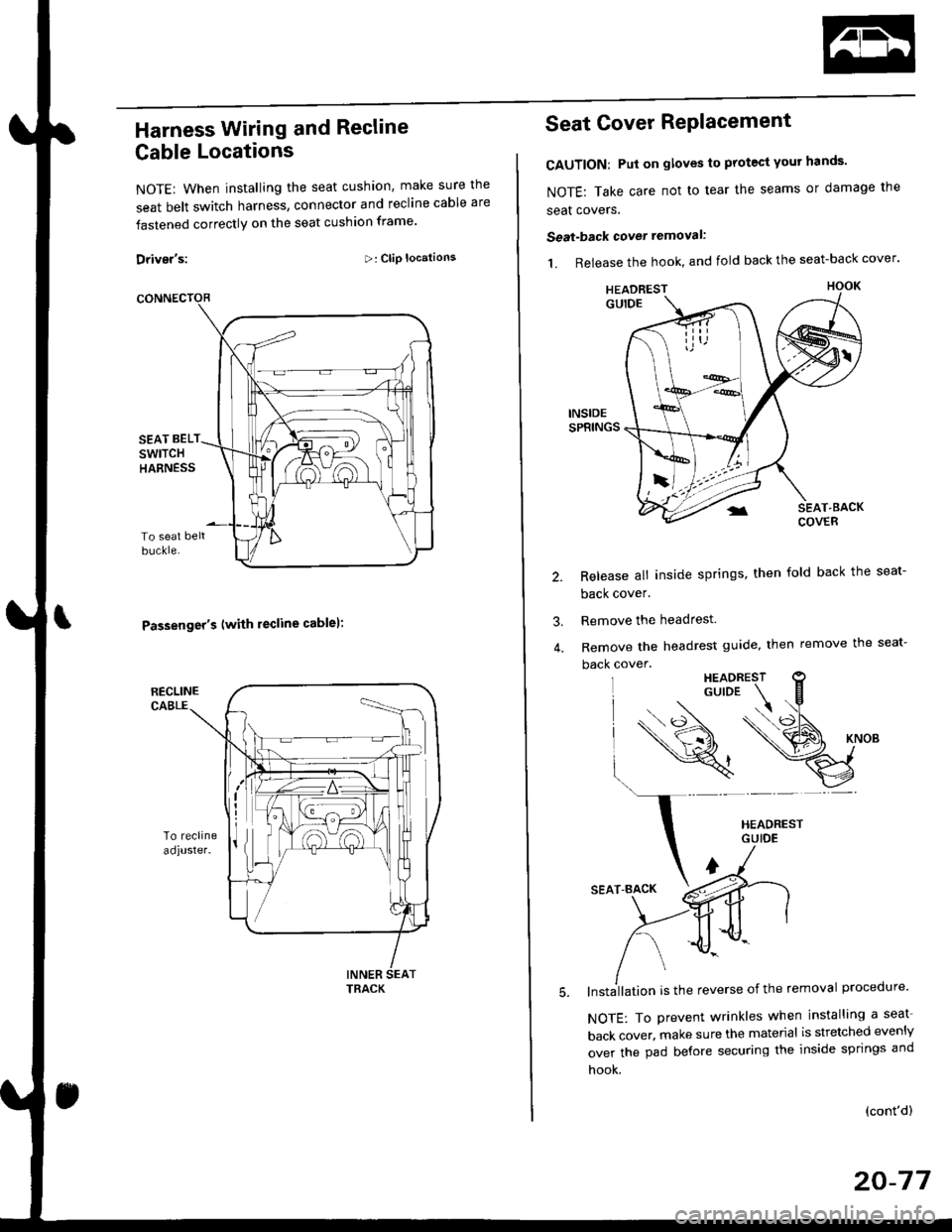

Harness Wiring and Recline

Cable Locations

NOTE: When installing the seat cushion, make sure the

seat belt switch harness, connector and recline cable are

fastened correctly on the seat cushion frame'

Driver's:>: Clip locations

Passenger's (with lecline cablel:

TRACK

Seat Cover RePlacement

CAUTION: Put on gloves to protest yout hands'

NOTE: Take care not to tear the seams or damage the

seat covers.

Seat-back cover removal:

1. Release the hook, and fold back the seat-back cover'

Release all inside springs, then fold back the seat-

back cover.

Remove the headrest.

Remove the headrest guide, then remove the seat-

back cover.

lnst;llation is the reverse of the removal procedure'

NOTE: To prevent wrinkles when installing a seat-

back cover, make sure the material is stretched evenly

over the pad before securing the inside springs and

hook.

3.

(cont'd)

20-77

HEADREST

Page 1410 of 2189

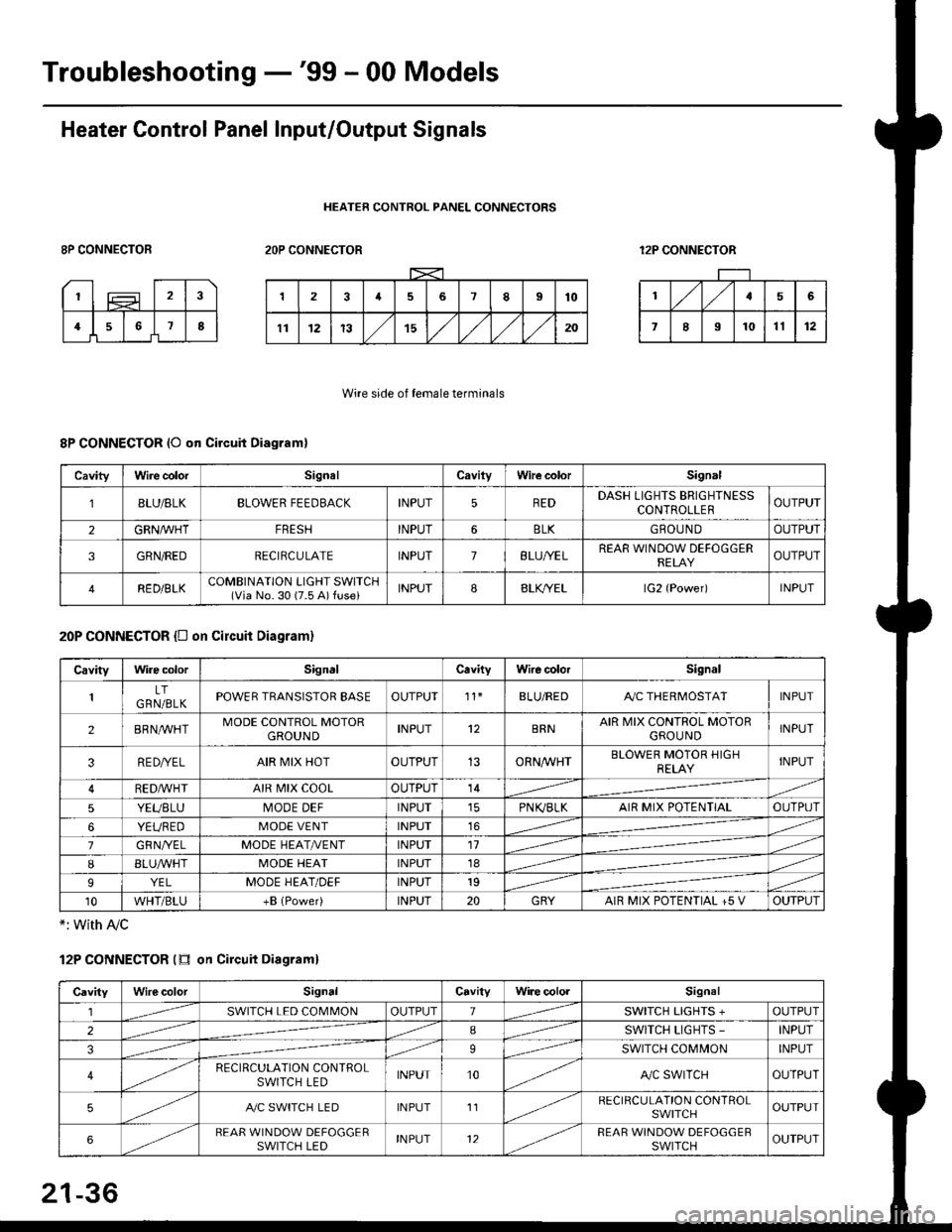

Troubleshooting -'99 - 00 Models

Heater Control Panel Input/Output Signals

HEATER CONTROL PANEL CONNECTORS

8P CONNECTOR2OP CONNECTOR12P CONNECTOR

Wire side of female terminals

8P CONNECTOR (O qn Circuit Diagram)

20P CONNECTOR {D on circuit Diagram}

*: with Ay'c

12P CONNECTOR (tr on Circuit Diagraml

CavityWire colorSignalCavilyWhe colorSignal

BLU/8LKBLOWER FEEDBACKINPUT5REDDASH LIGHTS BRIGHTNESSCONTROLLEROUTPUT

2GRN/lVHTFRESHINPUT6BLKGBOU N DOUTPUT

3GRN/REDRECIRCULATEINPUT7BLU/YELREAR WINDOW DEFOGGERRELAYOUTPUT

4RED/BLKCOMBINATION LIGHT SWITCH(Via No. 30 (7.5 A) fuse)INPUT88LfiELlG2 {Power)INPUT

CavityWire colorSignalCavityWire colorSignal

LTGRN/BLKPOWER TRANSISTOR EASEOUTPUT't1BLU/REDAy'C THERMOSTATINPUT

2BRNMHTMODE CONTROL MOTORGROUNDINPUT12BRNAIR MIX CONTROL MOTORGROU NDINPUT

3RE D/YELAIR MIX HOTOUTPUT13ORNAA/HTBLOWER MOTOR HIGHRELAYINPUT

RED,ryvHIAIR MIX COOLOUTPUT14

5YEUBLUMODE DEFINPUTPN K,/BLKAIR MIX POTENTIALOUTPUT

6YEUREDMODE VENTINPUT16

7GRNI/ELMODE HEAT/r'ENTINPUT11

IBLUAVHTMODE HEATINPUT18

9YELMODE HEAT/DEFINPUT19

10WHT/BLU+B (Power)INPUT20GRYAIR MIX POTENTIAL +5 VOUTPUT

CavityWilecolorSignalCavityWi.e cololSignal

lSWITCH LED COMMONOUTPUT1SWITCH LIGHTS +OUTPUT

2ISWITCH LIGHTS -INPUT

39SWITCH COMMONINPUT

4RECIRCULATION CONTROLSWITCH LEDINPUT10A,/C SWITCHOUTPUT

5A./C SWITCH LEDINPUT11RECIRCULATION CONTROLSWITCHOUTPUT

6REAR WINDOW DEFOGGERSWITCH LEDINPUT12REAR WINDOW DEFOGGEBSWITCHOUTPUT

21-36

Page 1438 of 2189

![HONDA CIVIC 1996 6.G Service Manual Troubleshooting

Compressor lcontdl

COMPRESSOR CLUTCH RELAY4P SOCKET

l--;l

12 |---r--]l.l3 |L-J--J

] BLK/YEL

A(v)

!

ECM/PCM CONNECTOR A I32P}

Wire side of female terminats

*Howto use the backprobe set HONDA CIVIC 1996 6.G Service Manual Troubleshooting

Compressor lcontdl

COMPRESSOR CLUTCH RELAY4P SOCKET

l--;l

12 |---r--]l.l3 |L-J--J

] BLK/YEL

A(v)

!

ECM/PCM CONNECTOR A I32P}

Wire side of female terminats

*Howto use the backprobe set](/img/13/6068/w960_6068-1437.png)

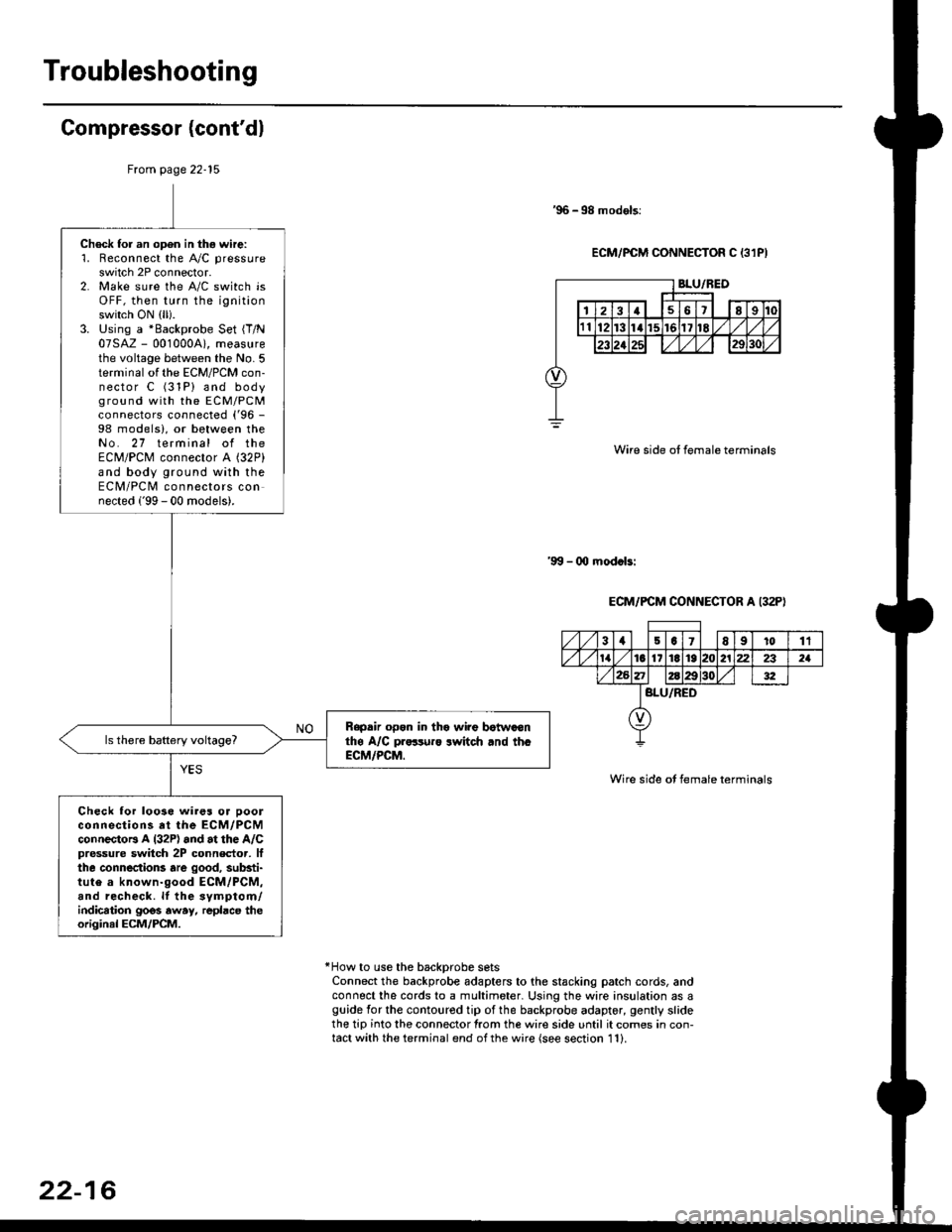

Troubleshooting

Compressor lcont'dl

COMPRESSOR CLUTCH RELAY4P SOCKET

l--;l

12 |---r--]l.l3 |L-J--J

] BLK/YEL

A(v)

!

ECM/PCM CONNECTOR A I32P}

Wire side of female terminats

*Howto use the backprobe setsConnect the backprobe adapters to the stackang patch cords, andconnect the cords to a multimeter. Using the wire insulation as aguide for the contoured tip of the backprobe adapter, gently slidethe tip into the connector from the wire side until it comes in con-tact with the terminalend ofthe wire (see section 11).

Frcm page 22-12

To page 22-15

Check Ior an open in the wire;1. Disconnecl the jumper wire.2. Turn the ignition swatch ON (ll).

3. l\4easure the voltage betweenthe No. 4 terminal of the com-pressor clutch relay 4P socketand body ground.

Repair open in the wire betw€enthe No. 17 fuso and the compres-sor clutch relav.

Check for an open in the wira:1. Turn the ignition switch OFF,then reinstall the compressorclutch relay.2. Make sure the A/C switch isOFF, then turn the ignitionswitch ON (ll).

3. Using a *Backprobe Set (T/N07SAZ 0010004), measurethe voltage between the No.17 terminal oI the ECM/PCMconnector A (32P) and bodyground with the ECM/PCMconnectors connected.

Repair open in the wirc betweonthe compressor clutch relay andthe ECM/PCtvt.

ls there battery voltage?

Page 1440 of 2189

Troubleshooting

Gompressor (cont'dl

'96 -98 models:

ECM/PCM CONNECTOR C 13lPI

Wire side ot female terminals

'9!t - 00 mod.bi

ECM/PCM CONNECTOR A I32P)

Wire side ot female terminals

*How to use the backprobe setsConnect the backprobe adapters to the stacking patch cords, andconnect the cords to a multimeter. Using the wire insulation as aguide for the contoured tip of the backprobe adapter, gently slidethe tip into the connector from the wire side until it comes in con-tact with the terminal end ofthe wire {see section 11}.

From page 22-15

Check for an open in thg wire:'1. Reconnect the A"/C pressure

switch 2P connector.2. Make sure the A/C switch isOFF, then turn the ignitionswitch ON (ll).

3. Using a *Backprobe Set {T/N07SAZ - 001000A), measurethe voltage between the No. 5terminal of the ECM/PCM con-nector C (31P) and bodyground with the EcM/PcMconnectors connected ('96 -

98 models), or between theNo. 27 terminal of theECM/PCM connector A (32P)

and body ground with theECM/PCM connectors connected ('99 - 00 models).

Rapdir open in tho wi?e botwaonthe A/C pr..-ruro lwitch rnd th.ECM/PCM.

Check lor loo3e wires or ooolconnections at the ECM/PCMconnectoB A l32P) and at the A/Cpressure switch 2P connector, lfthe connections are good, substi-tute a known-good ECM/PCM,and recheck. lf the svmptom/indication goos away, repbce theoriginal ECM/PCM.

31501E91011

tat6l11E1921222321

BLU/RED

22-16

Page 1471 of 2189

l'f .

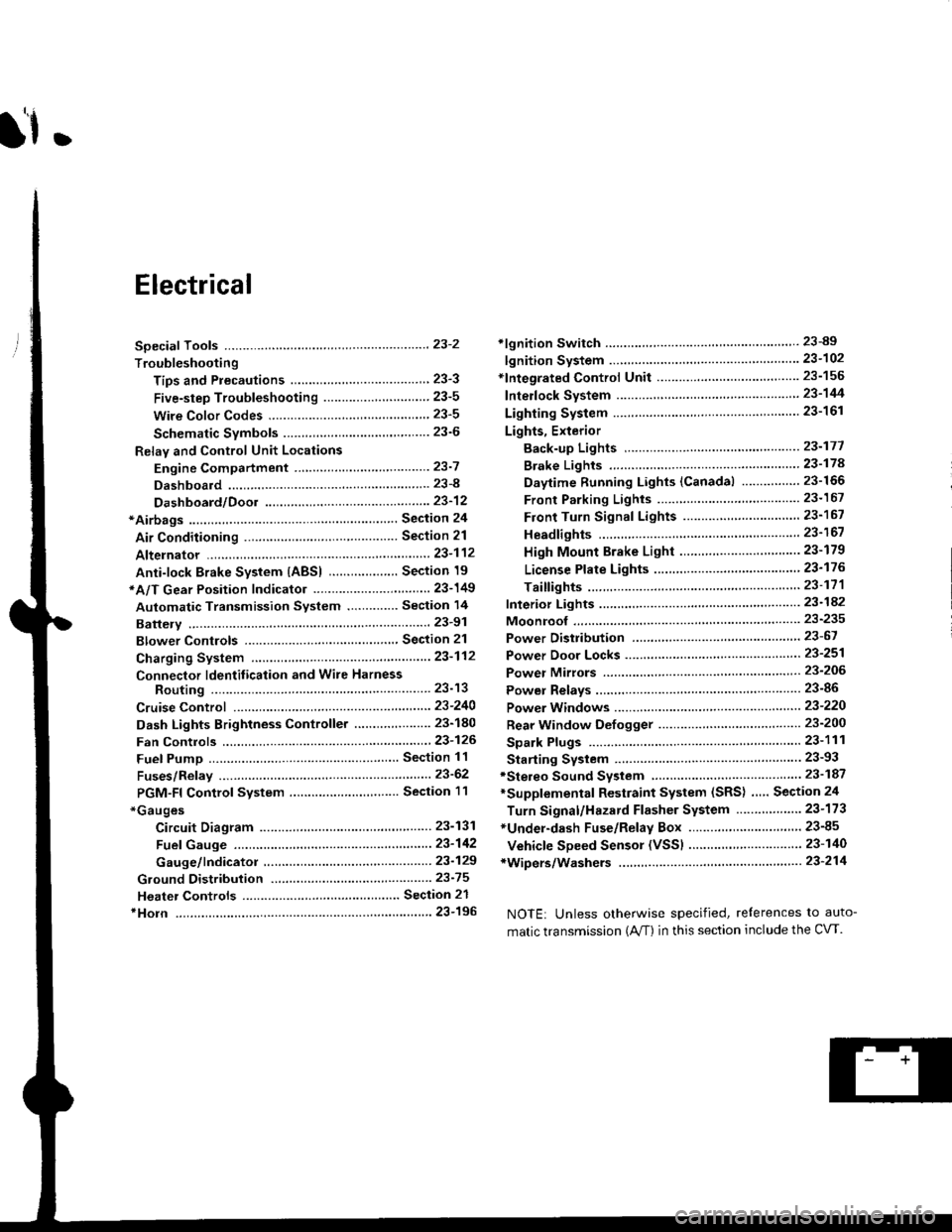

Electrical

Special Toofs .,....................,23-2

Troubleshooting

Tips and Precautions ..............,.................... . 23-3

Five-step Troubleshooting .............. ......... . . 23-5

wire color codes ..........,23-5

Schematic Symbols ........,................... . . .. .... 23-6

Relay and Control Unit Locations

Engine Compartment ...,..................... ... .. . 23'7

Dashboard ......................23-8

Dashboard/Door ......... 23-12*Airbags ................. ....... Section 24

Air Conditioning ......... Section 21

Aftelnator ..........."""" """ 23-112

Anti-lock Brake System {ABS) Section 19*A/T Gear Position Indicator .....................,. .... ... 23-149

Automatic Transmission Svstem .... . ....... Section 14

Batterv ......... . . . ... ...... .......23-91

Blower controls .. . ... Section 2l

Charging System ....'...........23'112

Connector ldentilication and Wire Harness

Routing .................. ......23'13

Cruise Control ............,........23-240

Dash Lights Brightness Controller ............. ....... 23-180

Fan controfs "" 23'126

Fuel PumD ........ . ........ section 11

Fuses/Refay ...............,..,,.. 23'62

PGM-FI Control System ......................,....... Section 1 1

*Gauges

Circuit Diagram ....,.,.......23-131

Fuef Gauge ...........'.'.......23-142

Gauge/lndicator .. . .. 23-129

Ground Distribution .. . 23-75

Heatei controls .. . ..... Section 21*Horn................. ...............23-196

*tgnition Switch ....................23-89

lgnition System .......,.... 23-102

*lntegrated Control Unit ....................................... 23-156

fnterlock System ,........ . . , ,23-144

Lighting System . . . .. ......... 23-161

Lights, Exterior

Back-up Lights ..'............23'171

Brake Lights .................. 23'174

Daytime Bunning Lights (Canadal ............... 23'166

Front Parking Lights ......,................ .'. .......... 23-167

Front Turn Signal Lights .......... . . ............ ..,.23-167

Headtights ....".'....-... ..... 23'167

High Mount Brake Light ...................... ... .23'179

License Plate Lights ...... 23'176

Taitfights ................ .......23'171

lnterior Lights ..-.......,, . 23-142

Moonroof ..,.................,........ 23-235

Power Distribution ....... . . .23-61

Power Door Locks .......,,,. .23'251

Power Mirrors ,..............,.,...23'206

Power Relays ....... . ...... . . .. 23-86

Power Windows ............,,....23-220

Rear Window Defogger .......................... . . ... . . 23-2OO

Spark Plugs . ..... . ........ .....23-111

Slarting System ................23-93*stereo Sound Svstem ,................. ..... ... . ... ,.,.,,23'147'Supplemental Restraint System (SRS) ... . Section 24

Turn Signal/Hazard Flasher System .......'.'....-... 23-173

*Undel-dash Fuse/Relay Box ............,.................. 23-85

vehicfe soeed sensor (VSSI """" ""' 23-140+Wipers/Washers .........,.,.,...23-214

NOTE: Unless otherwise specified, references to auto-

matic transmission (Mf) in this section include the CVT.

Page 1486 of 2189

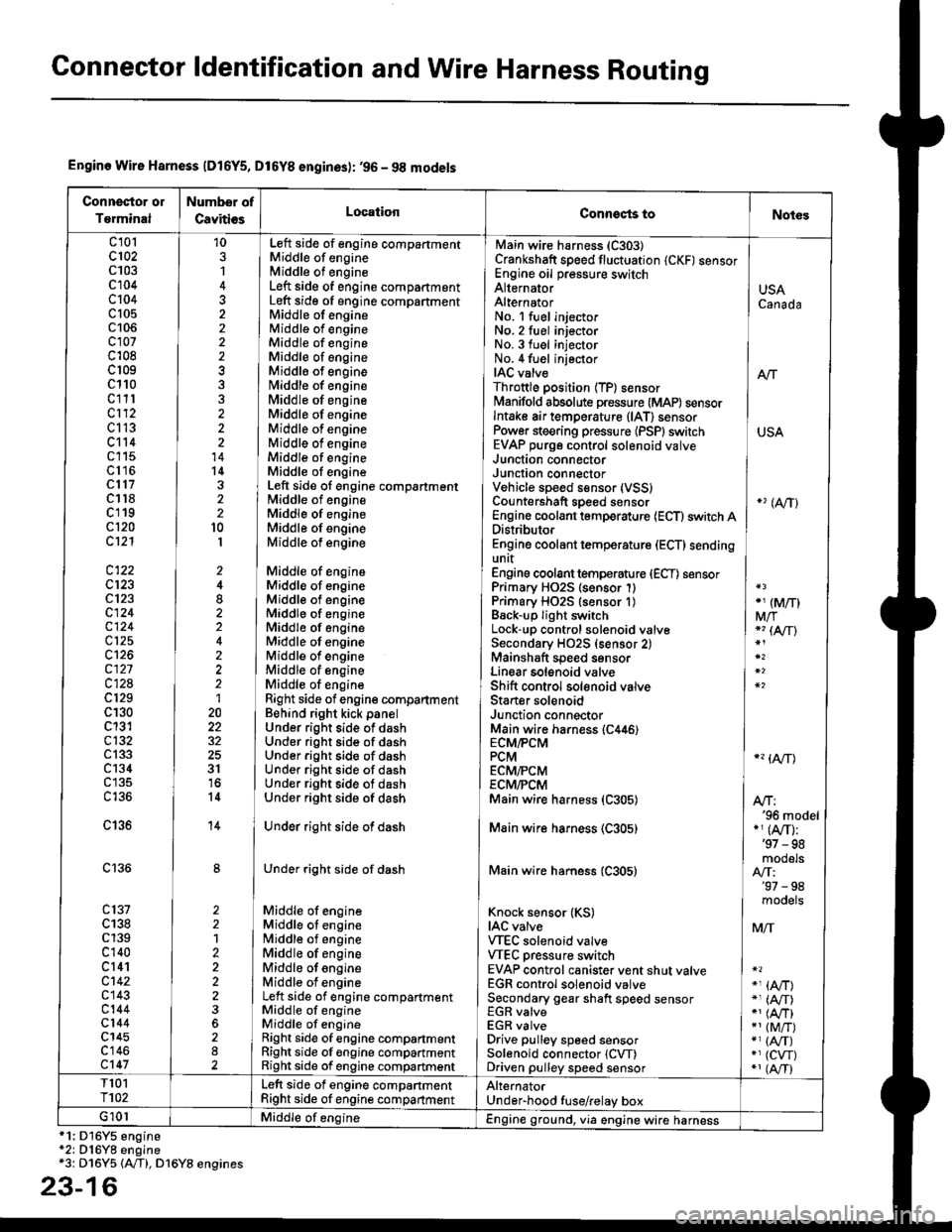

Connector ldentification and Wire Harness Routing

Engine Wire Harness lD16Y5, D16Y8 enginss): '96 - 98 models

Connector or

Torminal

Numbsr of

CavitissLocationConnects toNot€s

c 101c102c103c104c104c105c106c107c108c 109c110c111c112c113c114c115c116cl17c118c119c120cl21

c122c123cl23c124

c125

c127c12Ac129c130c131c132c 133c134c135

c136

c138c139c140c 141c142c 143c144cl44c145c'146cl47

10

1

22

14l4322l0I

2

2

2

2120

3l

14

14

1222

2

2

22

Left side of engine compartmentMiddle of engineMiddle of engineLeft side of engine companmentLeft side of engine compartmentMiddle of engineMiddle of engineMiddle of engineMiddle of engineMiddle of enginefvliddle of engineMiddle of engineMiddle of engineMiddle of engineMiddle of engineMiddle of engineMiddle of engineLeft side of engine compartmentMiddle of engineMiddle of engineMiddle of engineMiddle of engine

Middle of engineMiddle of engineMiddle of engineMiddle of engineMiddle of engineMiddle of engineMiddle of engineMiddle of engineMiddle of engineRight side of engine companmentBehind right kick panelUnder right side of dashUnder riOht side of dashUnder right side of dashUnder right side of dashUnder right side of dashUnder right side of dash

Under right side of dash

Under right side of dash

Middle of engineMiddle ot enginel iddle of engineMiddle of engineMiddle of ongineMiddle of engineLeft side of engine compartmentMiddle of engineMiddle of engineRight side of engine compartmentRight side of engine compartmentRight side of engine compartment

USACanada

Afi

USA

-' (A/r)

Main wire harness (C303)Crankshaft speed fluctuation (CKF) sensorEngine oil pressure switchAlternatorAlternatorNo. 'l fuel injectorNo. 2 fuel injectorNo.3 fuel injectorNo. 4 fuel injectorIAC valveThrottle position (TP) sensorl\4anifold absolute pressure (MAP) sensorIntake air temperature (lAT) sensorPower steering pressure {PSPI switchEVAP purge control solenoid valveJunction connectorJunction conn€ctorVehicle speed sensor {VSS}Countershaft speed sensorEngine coolant temp€rature (ECT) switch ADistributorEngine coolant temperature (ECT) sendingunrtEngine coolant temperature (ECT) sensorPrimary HO2S (sensor'l)Primary HO2S (sensor 1)Back-up light switchLock-up control solenoid valveSecondary HO2S (sensor 2)Mainshaft speed sensorLinear solgnoid valveShift control solsnoid valveStarter solenoidJunction connectorMain wire harnesE (C446)ECM/PCMPCMECMiPCMECM/PCMMain wire harness (C305)

Main wire harness (C305)

Main wire harness (C305)

Knock sensor (KS)IAC valveVTEC solenoid valveVTEC pressure switchEVAP control canister vent shut valveEGR control solenoid valveSecondary gear shaft speed sensorEGR valveEGR valveDrive pulley speed sensorSolenoid connector {CVT)Driven pulley speed sensor

*, (M/T)M/T*" INT\

*, tAtf)

NT:'96 model*,(A,/T):'97 - 98mooets

moqets

M/T

-1 (l,/T)*, (A,/T)-,(4,/T)*1 {M/T)*, (A,/T)*1 (CW)*, (A,T)

T101r102Left side of engine companmentRight side of engine companmentAlternatorUnder-hood fuse/relay boxG 101Middle of engineEngine ground, via engine wire harness

2

*1: Dl6Y5 engine*2: D16Y8 engine*3: D16Y5 (Ay'T), D16Y8 engines

3-16