Face HONDA CIVIC 1997 6.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1997, Model line: CIVIC, Model: HONDA CIVIC 1997 6.GPages: 2189, PDF Size: 69.39 MB

Page 1107 of 2189

t

t5.

16.

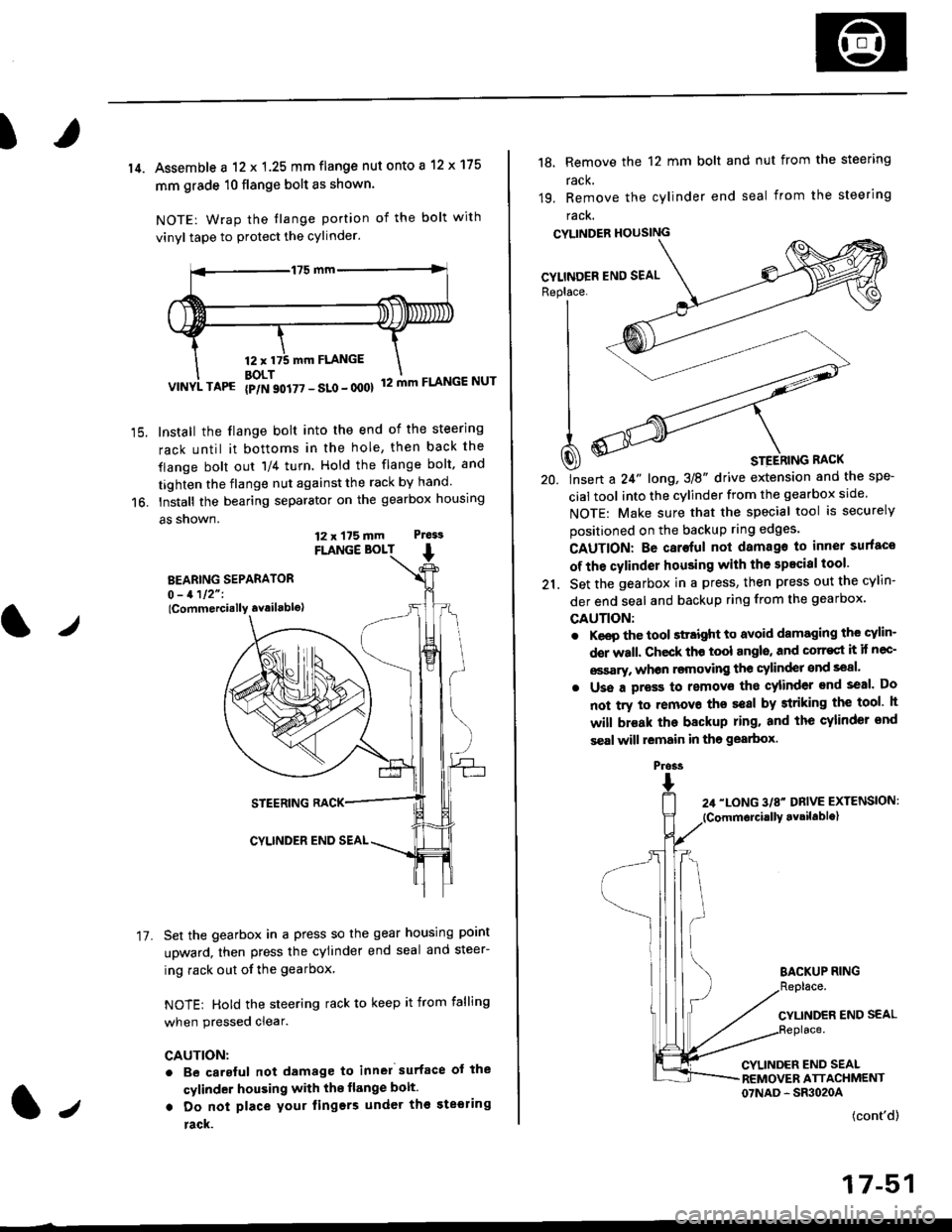

14. Assemble a 12 x 1.25 mm flange nut onto a 12 x 175

mm grade 10 flange bolt as shown.

NOTE: Wrap the tlange portion of the bolt with

vinyl tape to protect the cylinder.

12,mm FLANGE

BOLT12 mm FLANGE NUTVINYL TAPG {p/N 90i77 - SLo - 000}

Install the flange bolt into the end of the steering

rack until it bottoms in the hole, then back the

flange bolt out 'll4 turn. Hold the flange bolt, and

tighten the flange nut against the rack by hand.

Install the bearing separator on the gearbox housing

a5 snown.

FLANGE BOLT

BEARING SEPARATOR0 - 1112" I

lCommercially availablo)

STEERING RACK

CYLINDER END SEAL

Set the gearbox in a press so the gear housing point

upward, then press the cylinder end seal and steer-

ing rack out of the gearbox

NOTE: Hold the steering rack to keep it from falling

when pressed clear.

CAUTION:

. Be carsful not damage to inn6l surface ot the

cylinder housing with the flange bolt.

. Do not place your lingers under th€ ste€ring

rack.

t./

17.

12 x 175 mm Ptess

1.,

the spe-

srcle.

securely

Replace. J__--'- ,----)t'| ,-----'" ,-,-'-'| fiN ----'

| .Wl'----

I

t

-'4a

| ^--.'--4

A ooY----- \

Q) * srerhtnc nact

20. lnsert a 24" long,3E" drive extension and

cial tool into the cylinder from the gearbox

NOTE: Make sure that the special tool is

positioned on the backup ring edges'

18, Remove the 12 mm bolt and nut from the steering

rack,

19. Remove the cylinder end seal from the steering

racK.

CYLINDER HOUSING

CAUTION: Be caroful not damago to inner surfaco

of the cylinder housing with the specisl tool'

21. Set the gearbox in a press, then press out the cYlin-

der end seal and backup ring from the gearbox,

GAUTION:

. Keep the tool sttaight to avoid damaging the cylin'

der wall. Check th€ tool angls, and corr€st it if nec-

€ssary, whon rsmoving the cylinder snd seal.

. Uss a pross to removs tho cylinder end seal. Do

not try to removo ths seal by striking the tool h

will br€ak the backup ring. and the cylinder snd

s€al will lemain in tho gearbox.

BACKUP RING

CYLINDER END SEAL

CYLINDER END SEALREMOVER ATTACHMENT07NAD - SR3020A

(cont'd)

17-51

Pross

Page 1108 of 2189

Steering Gearbox

Disassembly (cont'dl

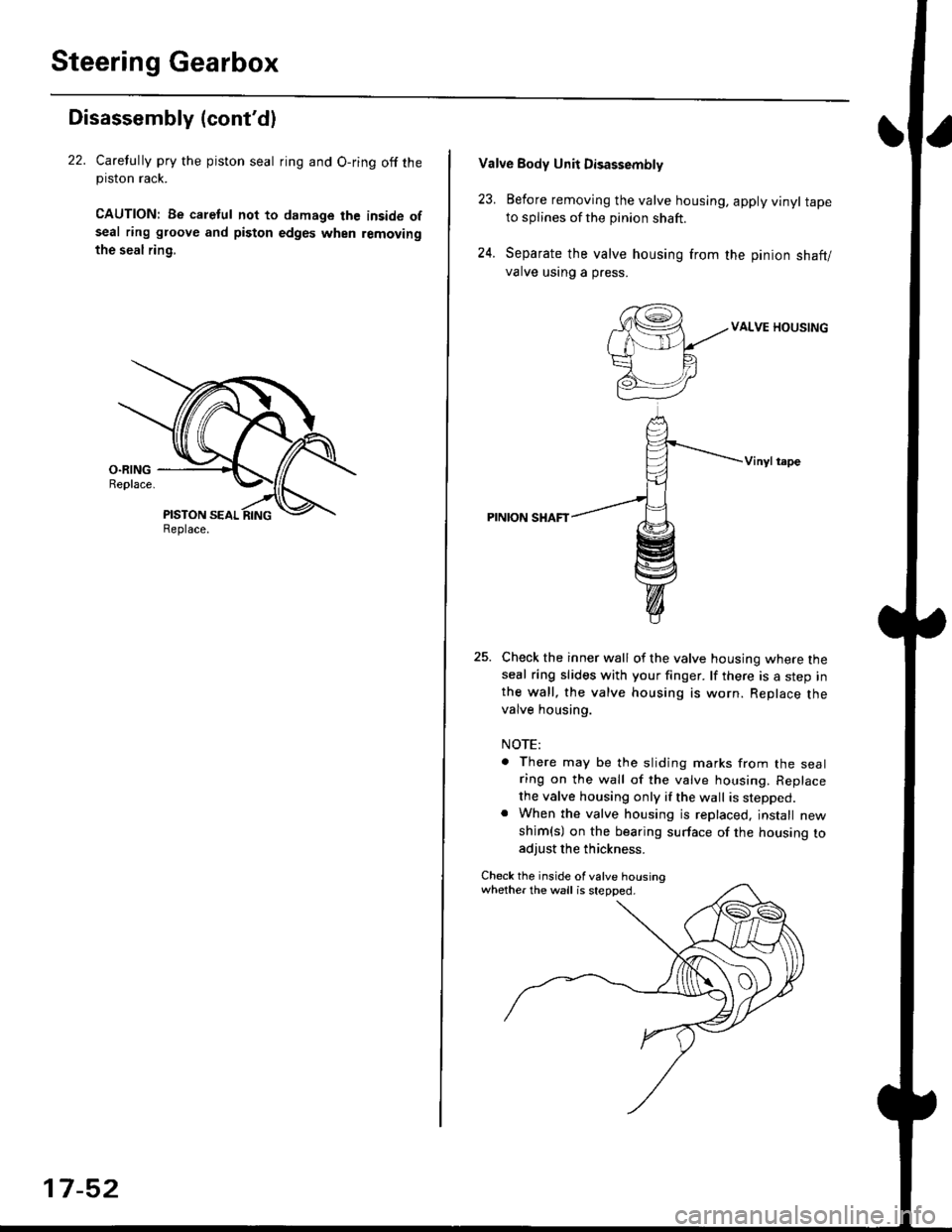

22. Carelully pry the piston seal ring and O-ring off theprslon rack.

CAUTION| Be caletul not to damage the inside ofseal ring groove and piston edges when removing

the seal rin9,

Replace.

17-52

Valve Body Unii Disassembly

23. Eefore removing the valve housing, apply vinyl tapeto splines of the pinion shaft.

24. Separate the valve housing from the pinion shaft/

valve using a press.

VALVE HOUSING

Vinylt.pe

PINION SHAFT

Check the inner wall of the valve housing where theseal ring slides with your finger. lf there is a step inthe wall, the valve housing is worn. Replace thevalve housing.

NOTE:

There may be the sliding marks from the sealring on the wall of the valve housing. Replace

the valve housing only if the wall is stepped.When the valve housing is replaced, jnstall new

shim(s) on the bearing surface of the housing toadjust the thickness.

Check the inside of valve housingwhether the wall is stepped.

Page 1109 of 2189

I

l./

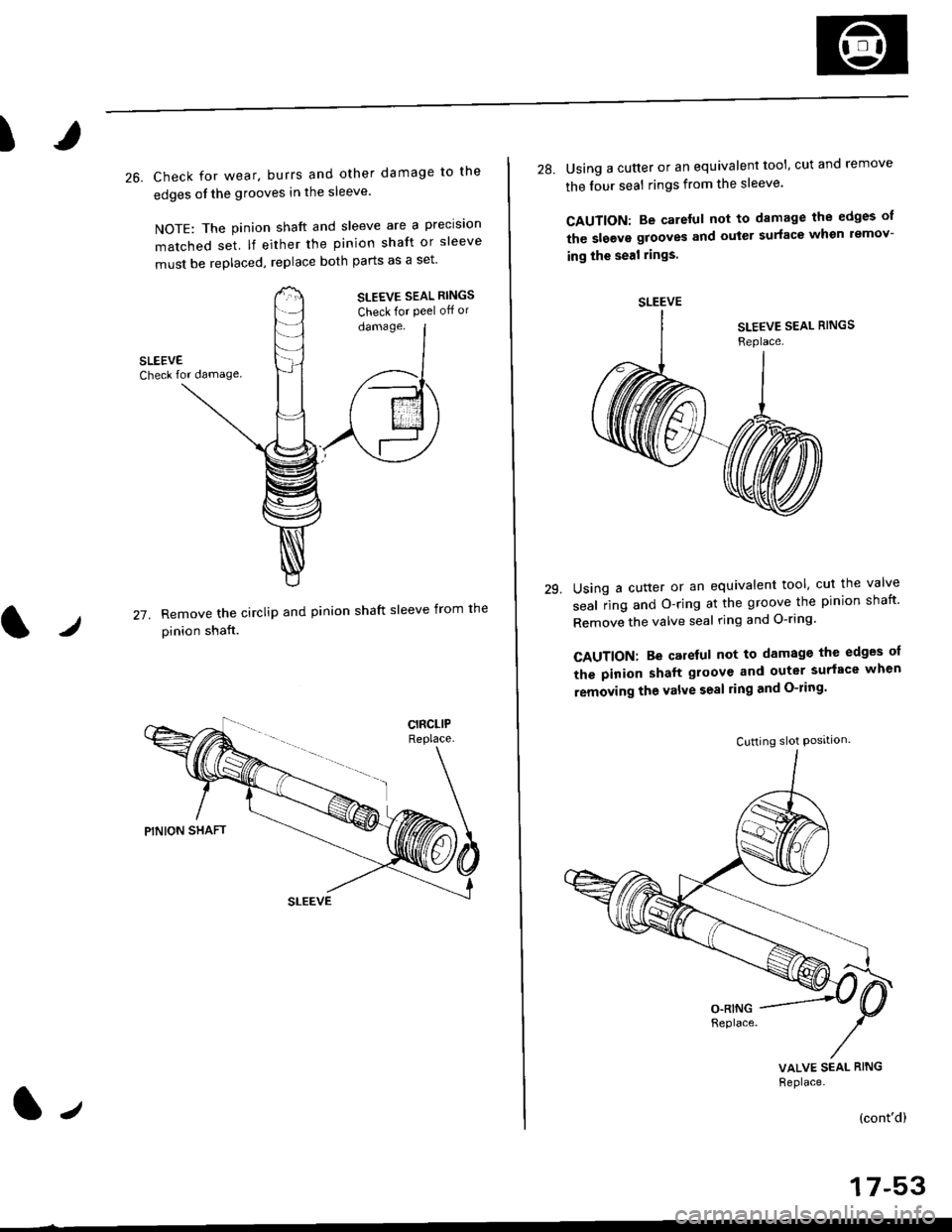

26. Check for wear. burrs and other damage to the

edges of the grooves in the sleeve'

NOTE: The pinion shaft and sleeve are a precision

matched set lf either the pinion shaft or sleeve

must be replaced, replace both parts as a set'

SLEEVE SEAL RINGS

Check for Peel off or

damage.

27. Remove the circliP and Pi

pinion shaft.

nion shaft sleeve from the

1.,

-r t rt .

the lour seal rings from the sleeve'

CAUTION: Be careful not to damage the edges of

the slgevs grooves and outer surface whsn lemov-

ing the seal rings.

29.Using a cutter or an equivalent tool, cut the valve

seal iing and O-ring at the groove the pinion shaft'

Remove the valve seal ring and O-ring'

CAUTION: Be careful not to damage the edges oI

the pinion shaft gloove and outer surface when

removing the valve seal ling and O-ring'

VALVE SEAL RING

Replace.

(cont'd)

SLEEVE

Cutting slot Posrtlon.

Page 1112 of 2189

Steering Gearbox

Reassembly (cont'd)

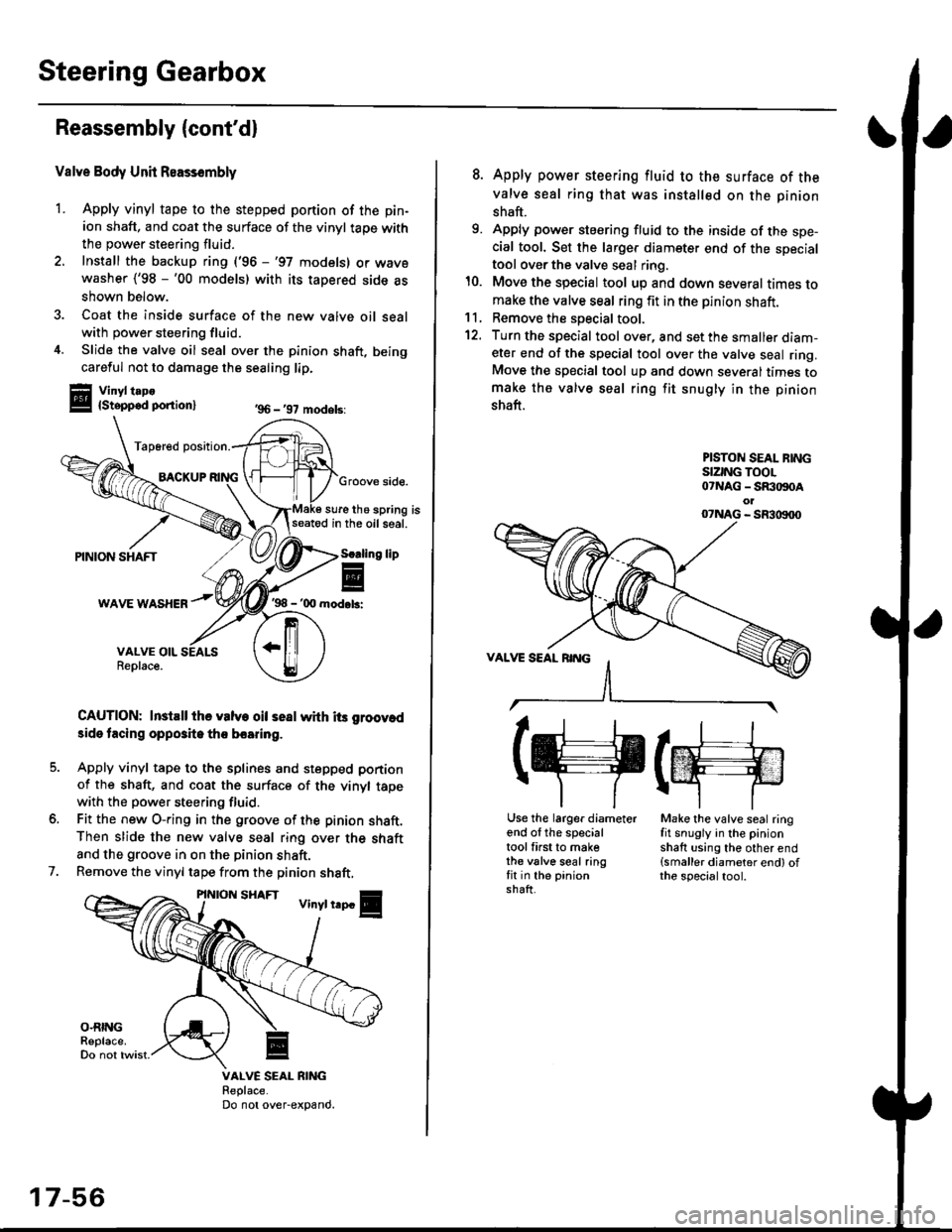

Valve Body Unit Reassembly

1. Apply vinyl tape to the stepped portion of the pin-

ion shaft, and coat the surface of the vinyl taoe with

the power steering fluid.

2. Install the backup ring ('96 -'97 models) or wavewasher ('98 -'00 models) with its tapered side as

shown below.

3. Coat the inside surface of the new valve oil sealwith power steering fluid.

4. Slide the valve oil seal over the pinion shaft, being

careful not to damage the sealing lip.

Vinyl t.po{Stepped ponion}

Tap6red position.

BACKUPGroove side.

sure the spring isseatod in the oil seal.

'98 - '00 mod.b:

CAUTION: InstEll ihe valve oil seal whh its groov.d

3ide tacing opposite tho boaring.

Apply vinyl tape to the splines and stepped portion

of the shaft, and coat the surface of the vinyl tapewith the power steering fluid.

Fit the new O-ring in the groove of the pinion shaft.Then slide the new valve seal ring over the shaft

and the groove in on the pinion shaft.

Remove the vinyl tape from the pinion shaft,

'96 - '97 models:

lip

7.

VALVE SEAL RIiIGReplace.Do not over-expand.

17-56

8. Apply power steering fluid to the surface of the

valve seal ring that was installed on the pinion

shaft.

9. Apply power steering fluid to the inside of the spe-cial tool. Set the larger diameter end of the specialtool over the valve seal ring.

10. Move the special tool up and down several times tomake the valve seal ring fit in the pinion shaft.11, Remove the soecial tool.

12. Turn the special tool over, and set the smaller diam-eter end of the special tool over the valve seal ring.Move the special tool up and down several times tomake the valve seal ring fit snugly in the pinion

shaft.

PISTON SEAL BINGSIZING TOOL07NAG - SR:togoAol07NAG - SR3|X)00

(g(m

Use the larger diameterend of the specialtool first to makethe valve seal ringfit in the pinionshaft.

Make the valve seal ringfit snugly in the pinionshaft using the other end(smaller diameter end) ofthe specialtool.

Page 1113 of 2189

I

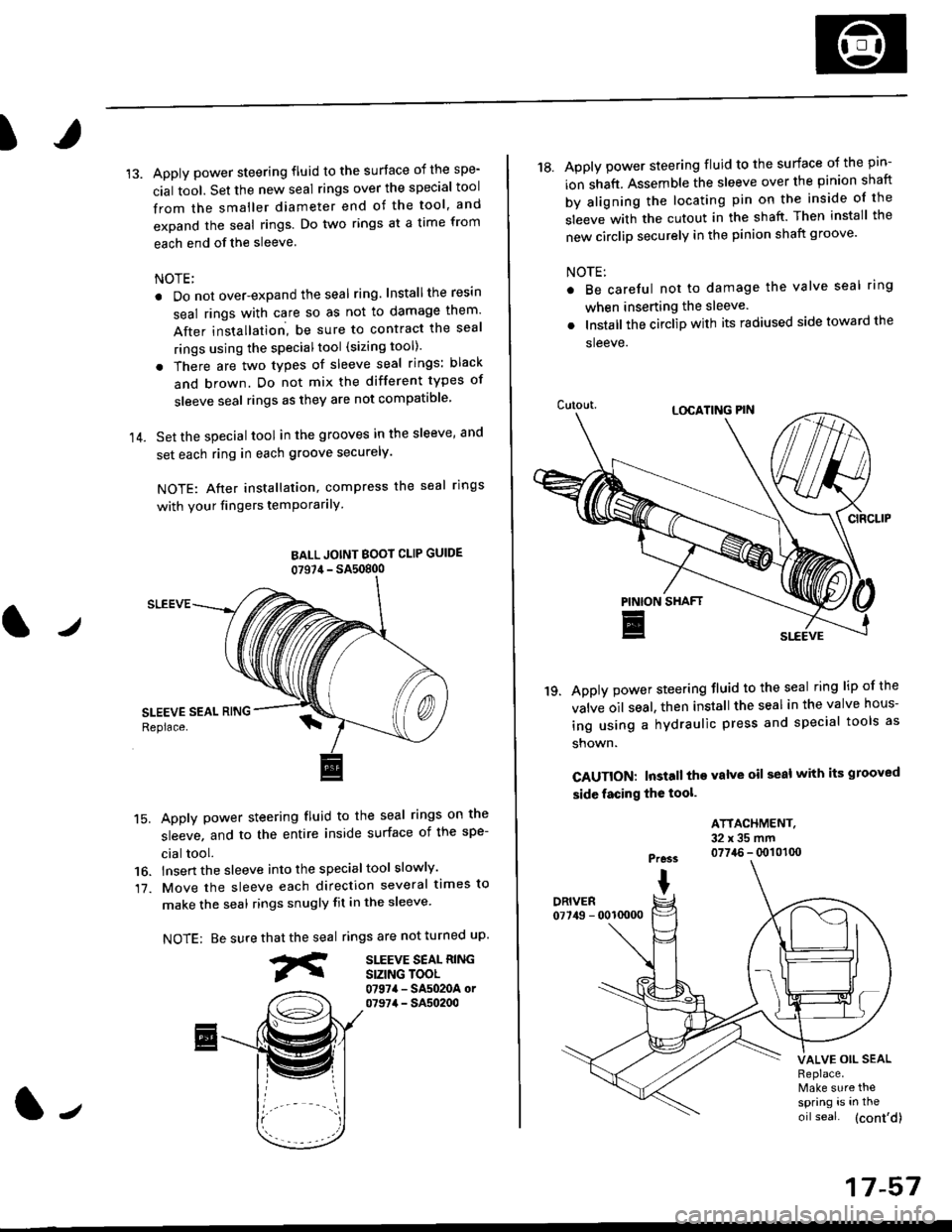

14.

Apply power steering fluid to the surface of the spe-

cial tool. Set the new seal rings over the special tool

from the smaller diameter end of the tool, and

expand the seal rings. Do two rings at a time from

each end of the sleeve.

NOTE;

. Do not over-expand the seal ring. Installthe resin

seal rings with care so as not to damage them'

After installation, be sure to contract the seal

rings using the specialtool (sizing tool).

. There are two types of sleeve seal rings: black

and brown. Do not mix the different types of

sleeve seal rings as they are not compatible

Set the special tool in the grooves in the sleeve, and

set each ring in each groove securely.

NOTE: After installation, compress the seal rings

with your fingers temPorarilY

BALL JOINT BOOI CLIP GUIDE

07S7,1- SA50800

SLEEVE

15. Apply power steering fluid to the seal rings on the

sleeve, and to the entire inside surface of the spe-

cial tool.

16. lnsert the sleeve into the specialtool slowly'

17. Move the sleeve each direction several times to

make the seal rings snugly fit in the sleeve'

NOTE: Be surerings are not turned uP.

SITEVE SEAL RINGSIZING TOOL0797a - SA5020A or07974 - SA50200

that the seal

fr

J

17-57

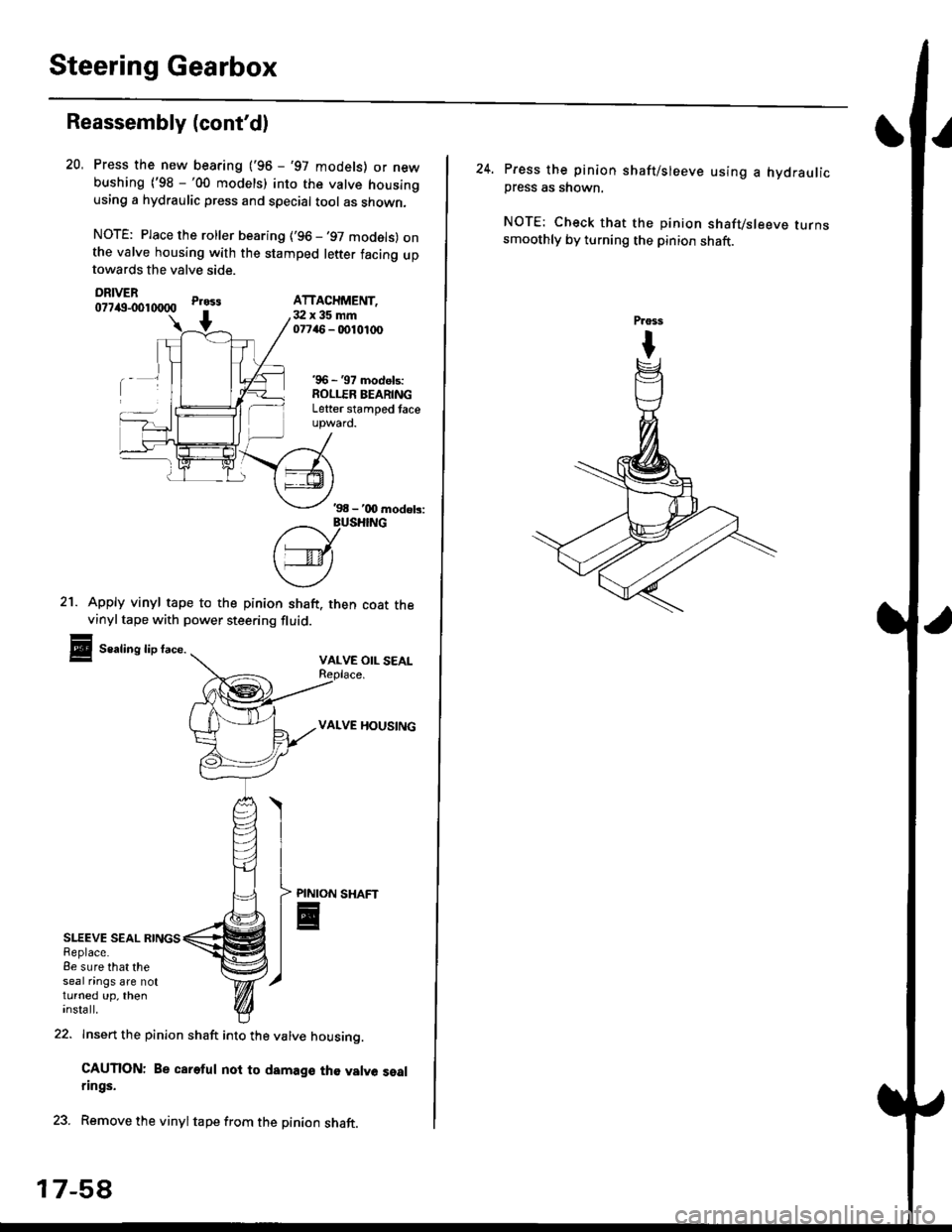

18. Apply power steering fluid to the surface o{ the pin-

ion shaft. Assemble the sleeve over the pinion shaft

by aligning the locating pin on the inside of the

sleeve with the cutout in the shaft. Then install the

new circlip securely in the pinion shaft groove'

NOTE:

Be careful not to damage the valve seal ring

when inserting the sleeve.

Installthe circlip with its radiused side toward the

sleeve.

Apply power steering fluid to the seal ring lip of the

valve oil seal. then install the seal in the valve hous-

ing using a hydraulic press and special tools as

shown.

CAUTION: Install the valve oil seal with its grooved

side facing the tool.

'19.

ATTACHMENT.32x35mm0774.6 - q)101(x)Pre3s

IDRIVER07749 - 0010000

VALVE OIL SEALReplace.Make sure thespring is in the

oil seal. (cont'd)

Page 1114 of 2189

Steering Gearbox

Reassembly (cont'd)

SLEEVE SEAL RINGSReplace.8e sure that theseal nngs are notturned up, theninsta ll.

21. Apply vinyl tape to the pinion shaft. then coat thevinyltape with power steering fluid.

Sealing lip face.VALVE OIL SEAL

VALVE HOUSING

Press the new bearing ('96 - '97 models) or newbushing ('98 -'00 models) into the valve housingusing a hydraulic press and special tool as shown,

NOTE: Place the roller bearing ('96 -'97 models) onthe valve housing with the stamped letter facing uptowards the valve side.

DRIVER077itg-001tXlOO

22. Insert the pinion shaft into the valve housino.

CAUTION: Be careful noi to damage th€ valve sealrings.

23. Remove the vinyltape from the pinion shaft.

20.

Pr033

+3:Ix35mm07746 - 0010,t(x)

'96 - '97 models:ROLLER BEARINGLetter stamped taceupward.

ATTACHMENT,

'98 - '00 modob:

?/_vusHrNG

['---v-lt

\4)

PINION

E

17-5A

24. Press the pinion shaft/sleeve using a hydraulicpress as shown.

NOTE: Check that the pinion shafvsleeve turnssmoothly by turning the pinion shaft.

Page 1115 of 2189

)

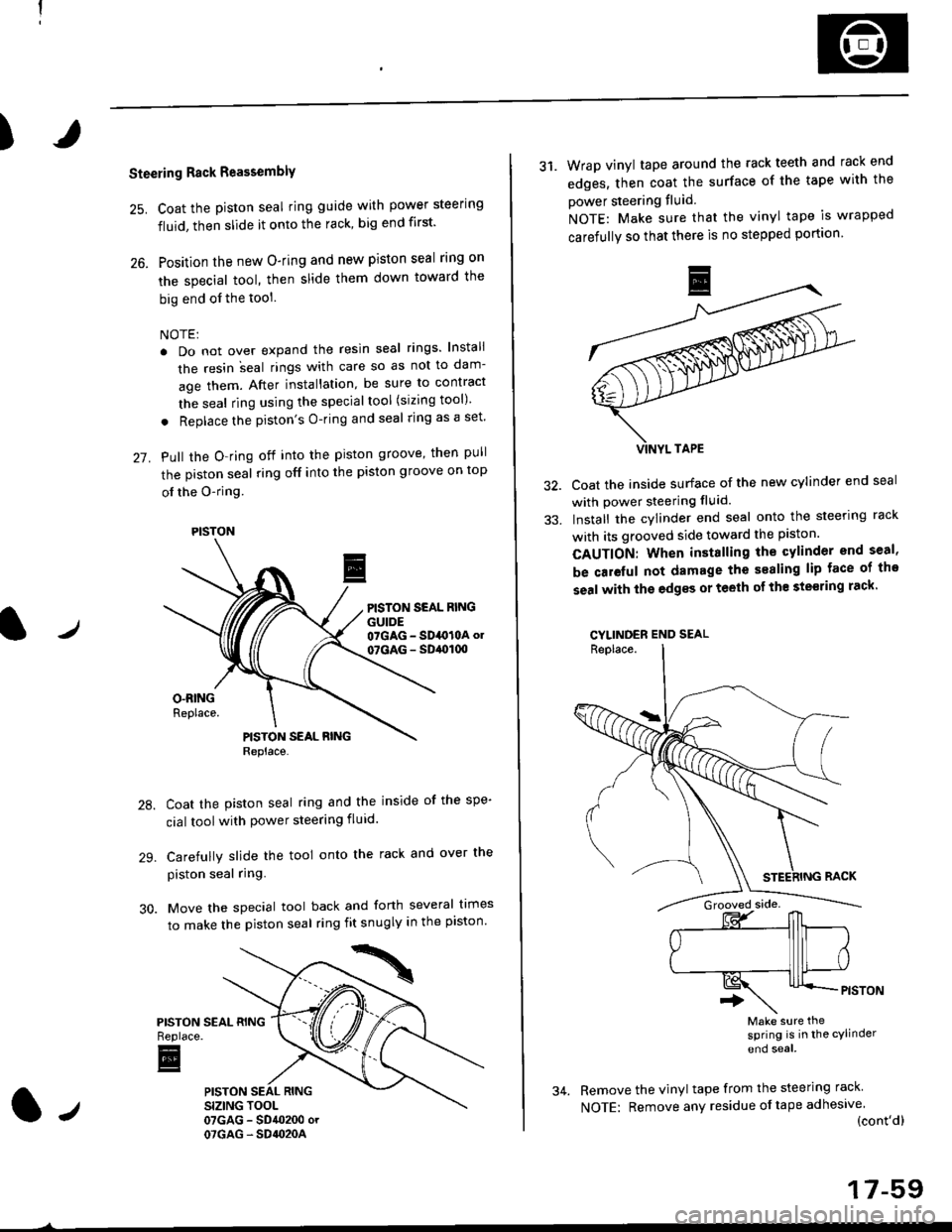

Steering Rack Reassembly

25. Coat the piston seal ring guide with power steering

fluid, then slide it onto the rack, big end first'

26. Position the new O-ring and new piston seal rlng on

the special tool, then slide them down toward the

big end of the tool

NOTE:

. Do not over expand the resin seal rings lnstali

the resin ;eal rings with care so as not to dam-

age them. After installation, be sure to contract

the seal ring using the specialtool (sizing tool)

. Replace the piston's O-ring and seal ring as a set'

27. Pull the O-ring off into the piston groove, then pull

the piston seal ring off into the piston groove on top

ol the O-ring

PISTON SEAL RINGGUIDE07GAG - SD4O10A ol

07GAG - SD,ol(xt

Coat the piston seal ring and the inside of the spe-

cial toolwith power steering fluid.

Carefully slide the tool onto the rack and over the

piston seal ring.

Move the special tool back and forth several times

to make the piston seal ring fit snugly in the piston'

PISTONReplace.

E

PISTON

31. Wrap vinyl tape around the rack teeth and rack end

edges, then coat the surface of the tape with the

power steering fluid

NOTE: Make sure that the vinyl tape is wrapped

carefully so that there is no stepped portion

Coat the inside surface of the new cylinder end seal

with power steering fluid.

Install the cylinder end seal onto the steering rack

with its grooved side toward the piston.

CAUTION: When installing the cylinder end seal,

be caieful not damage the sealing lip face of tho

seal with the edgss or teeth of th€ ste€ring rack'

CYLINDER END SEAL

Make sure thesPring is in the cylinder

end soal

Remove the vinyl tape from the steering rack

NOTE: Remove any residue oftape adhesive(cont'dl

17-59

Page 1116 of 2189

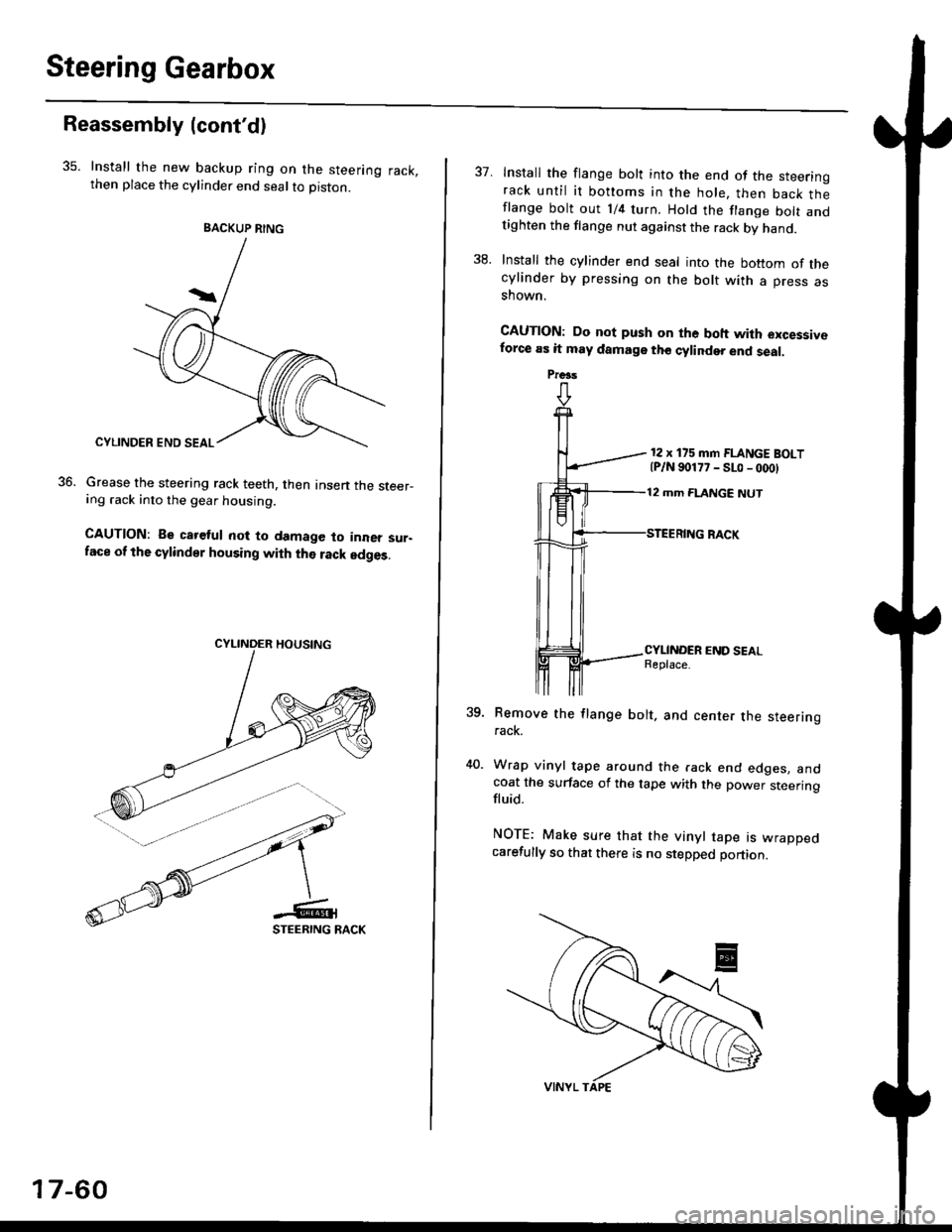

Steering Gearbox

Reassembly {cont'd)

35. Install the new backup ring on the steering rack,then place the cylinder end seal to piston.

Grease the steering rack teeth, then Insen the steer-ing .ack into the gear housing.

CAUTION: Be careful not to damage to inner sur-face of the cylindsr housing with the rack edges.

36.

BACKUP RING

17-60

37. Install the flange bolt into the end of the steerinorack until it bottoms in the hole, then back thlflange bolt out 1/4 turn. Hold the flange bolt andtighten the flange nut against the rack by hand.

38. Install the cylinder end seal into the bottom of thecylinder by pressing on the bolt with a press asshown.

CAUTION: Do not push on the boh with excessiveforce as it may damage tho cylinder end seal.

12 x 175 mm FLANGE BOLT{P/N 90177 - SLo - 000}

12 mm FLANGE NUT

?qRemove the flange bolt. and center the steeringrack.

Wrap vinyl tape around the rack end edges. andcoat the surface of the tape with the power steeringfluid.

NOTE: Make sure that the vinyl tape rs wrappedcarefully so that there is no stepped portion.

Preas

Page 1117 of 2189

)

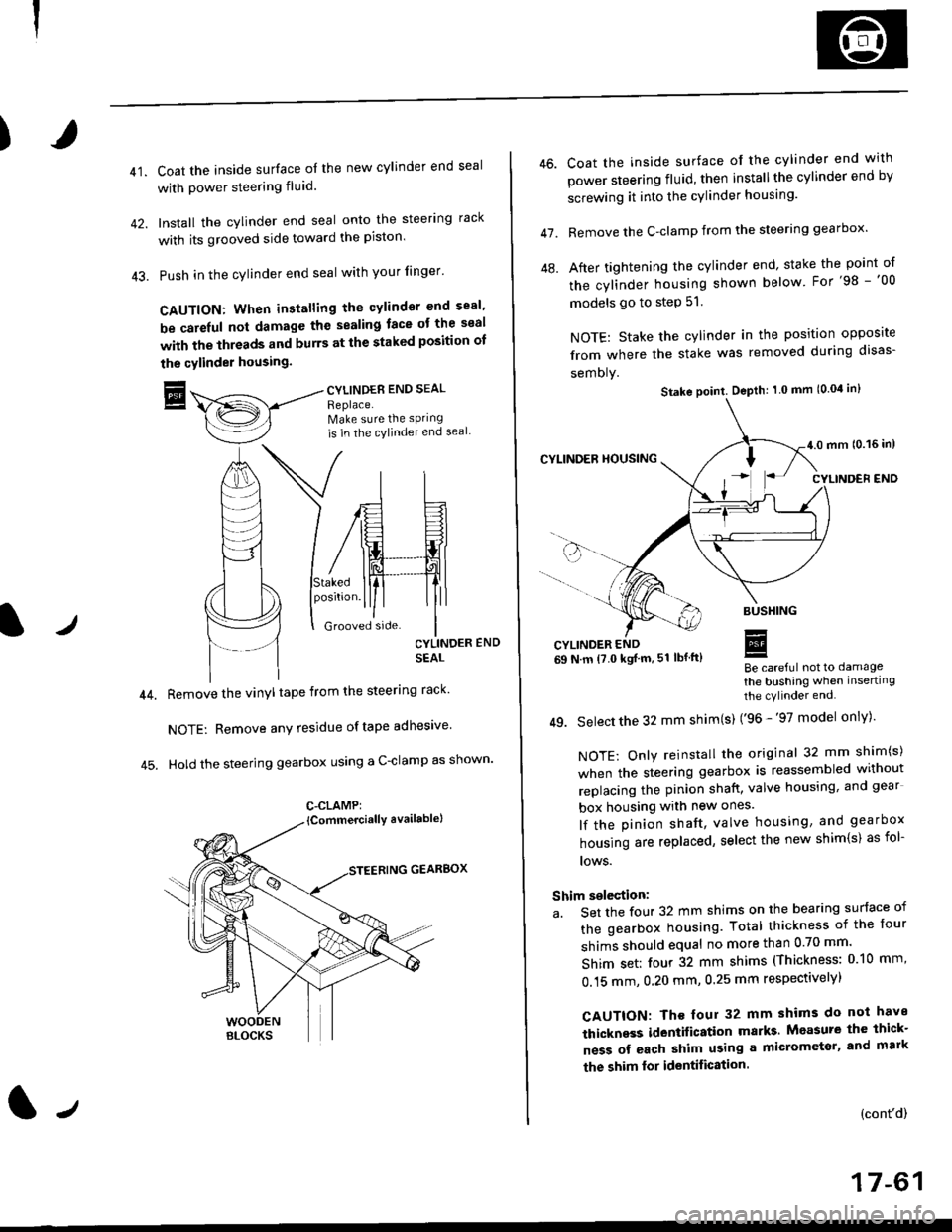

41.Coat the inside surface of the new cylinder end seal

with power steering fluid.

Install the cylinder end seal onto the steering rack

with its grooved side toward the piston'

Push in the cylinder end seal with your finger'

CAUTION: When installing the cylinder end sesl'

be carelul not damage the sealing face ot the seal

with the threads and burrs at the staked position oI

the cylinder housing.

trCYLINDES END SEAL

Replace.Make sure the sPring

is in the cylincler end seal

CYLINDER END

SEAL

Remove the vinyl tape from the steering rack'

NOTE: Remove any residue oftape adhesive

Hold the steering gearbox using a C-clamp as shown'

GEARBOX

C-CLAMP:

l-,

46.

47.

Coat the inside surface of the cylinder end with

power steering fluid, then installthe cylinder end by

screwing it into the cylinder housang.

Remove the C-clamp from the steering gearbox'

After tightening the cylinder end' stake the point of

the cylinder housing shown below For'98 -'00

models go to step 51.

NOTE: Stake the cylinder in the position opposite

from where the stake was removed during disas-

semoly.

Be careful not to damage

the bushing when inserting

the cylinder end.

49. Select the 32 mm shim(s) ('96 -'97 model only)'

NOTE: Only reinstall the original 32 mm shim(s)

when the steering gearbox is reassembled without

replacing the pinion shatt, valve housing, and gear

box housing with new ones.

lf the pinion shaft, valve housing, and gearbox

housing are replaced, select the new shim{s) as fol-

lows.

Shim selection:

a. Set the four 32 mm shims on the bearing surface of

the gearbox housing. Total thickness of the four

shims should equal no more than 0 70 mm'

Shim set: four 32 mm shims (Thickness: 010 mm'

0.15 mm, 0.20 mm, 0.25 mm respectivelyl

CAUTION: Th€ four 32 mm shims do not have

thickness identification marks Measure the thick-

ness of each shim using a micrometsr, and mark

the shim lor identification.

(cont'd)

17-61

Stake point. Depth: 1 0 mm (0.04 in)

Page 1118 of 2189

Steering Gearbox

Reassembly (cont'd)

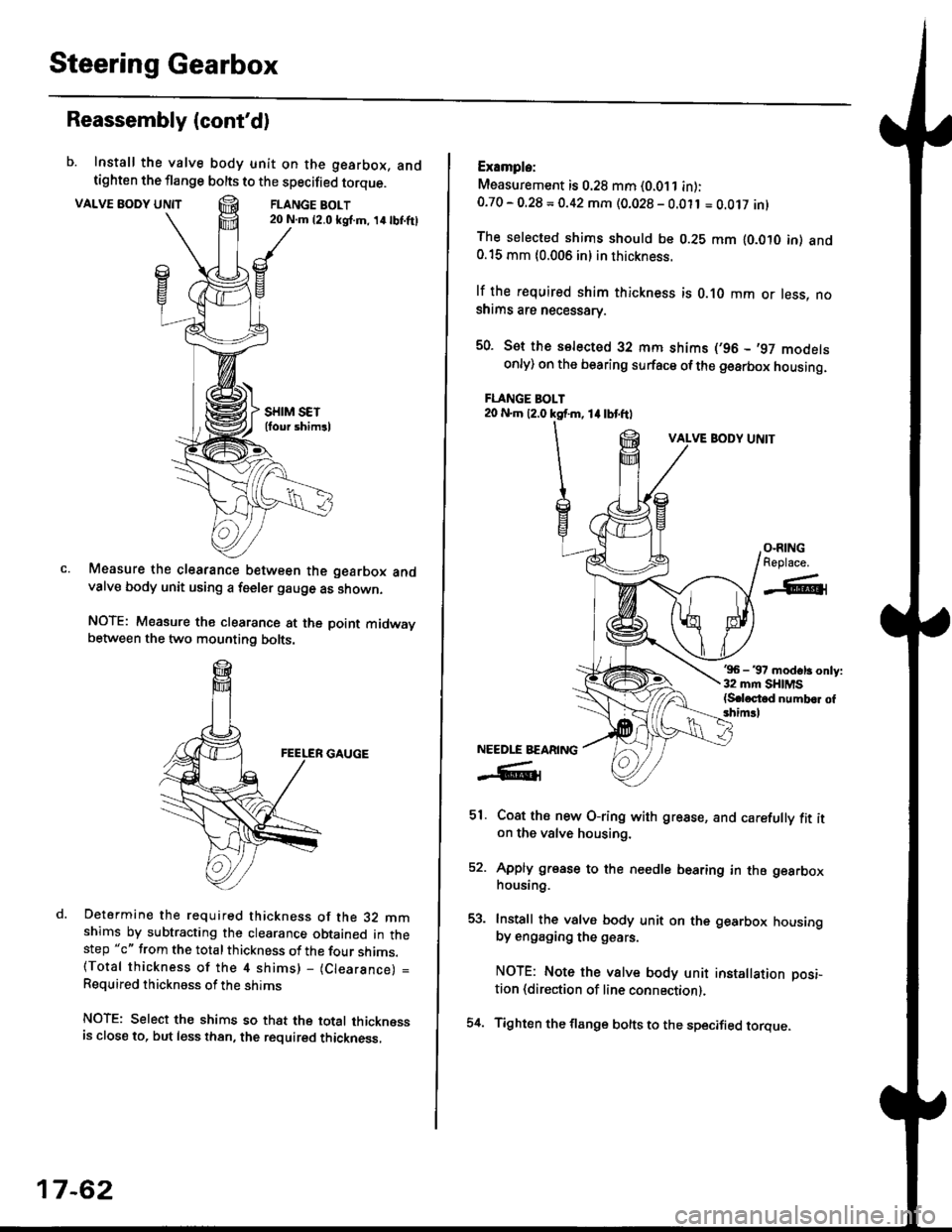

b. Install the valve body unit on the gearbox, andtighten the flange bolts to the specified torque.

VALVE BODY UNTTFLANGE BOLT20 N.m {2.0 ksl.m, 14lbI.ftl

Measure the clearance between the gearbox andvalve body unit using a feeler gauge as shown.

NOTE: Measure the clearance at the point midwaybetween the two mounting bolts.

Determine the required thickness of the 32 mmshims by subtracting the clearance obtained in thestep "c" from the total thickness of the four shims.(Total thickness of the 4 shims) - (Clearance) =

Required thickness of the shims

NOTE: Select the shims so that the total thicknessis close to. but less than, the required thickness,

17-62

54.

Example:

Measurement is 0.28 mm (0.011 in):0.70 - O.28 = 0.42 mm (0.028 - 0.011 = O.Ot7 inl

The selected shims should be 0.28 mm lO.OtO in) and0.15 mm {0.006 in} in thickness.

lf the r€quired shim thickness is 0.10 mm or less, noshims are necessarv.

50. Sot the selected 32 mm shims (,96 - ,97 modelsonly) on the bearing surface ofthe gearbox housing.

FLANGE BOLT20 N.m 12.0 ksf.m, 1l lbtftl

VALVE BODY UNIT

'96 - 37 modsl3 only:32 mm SHIMS{S.loctod numb.r of3him!l

Coat ths new O-ring with grease, and carefully fit iton the valve housing.

Apply grease to the needle bearing in the gearboxhousing.

Install the valve body unit on the gearbox housingby engaging the g€ars.

NOTE: Note the valve body unit installation posi-

tion (direction of line connection).

Tighten the flange bolts to the specified torque.

O-RINGReplace.

-A-l

NEEDLE BEARING

-R1

51.

EA