Replacement part HONDA CIVIC 1997 6.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1997, Model line: CIVIC, Model: HONDA CIVIC 1997 6.GPages: 2189, PDF Size: 69.39 MB

Page 1089 of 2189

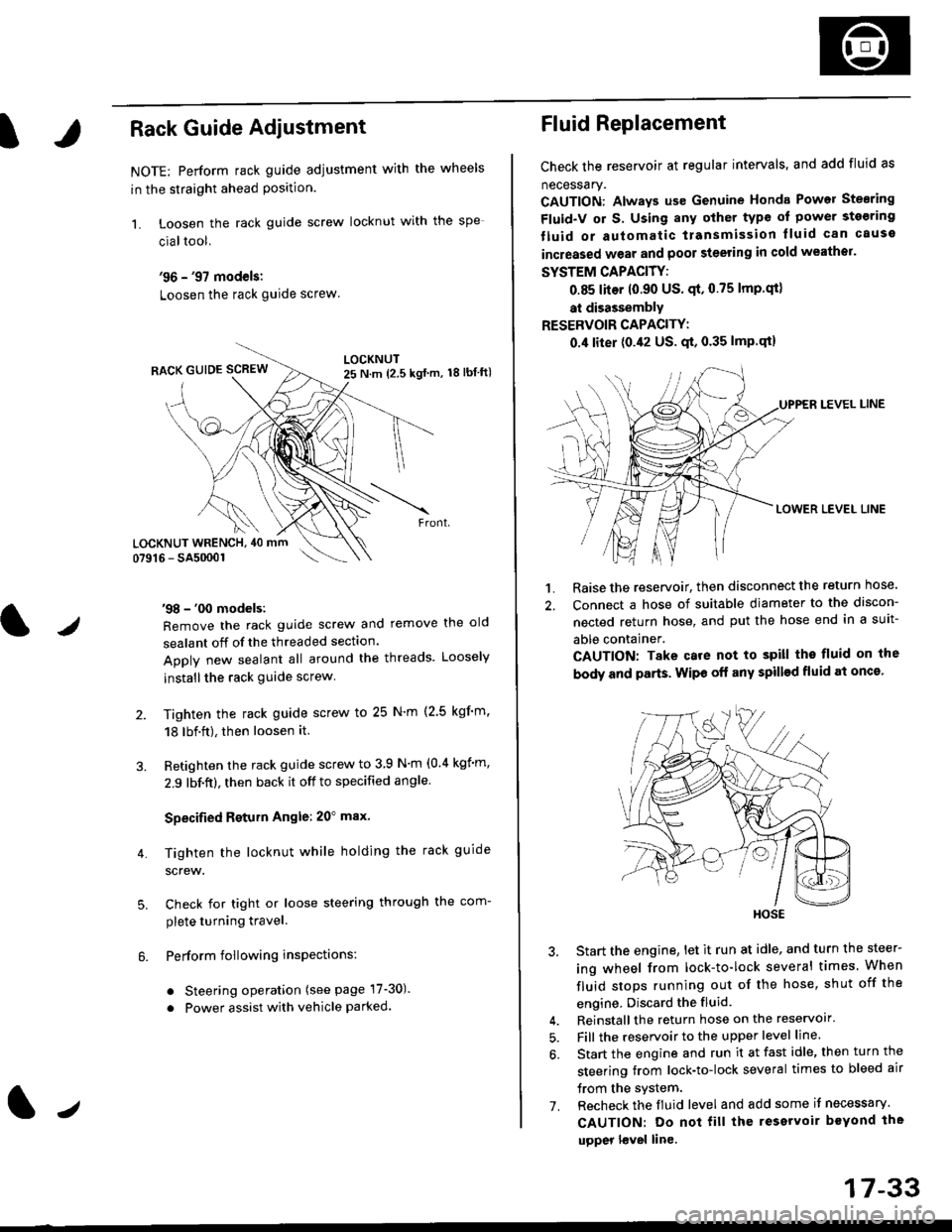

IRack Guide Adjustment

NOTE: Perform rack guide adjustment with the wheels

in the straight ahead Position.

1. Loosen the rack guide screw locknut with the

cialtool.

'96 - '97 models:

Loosen the rack guide screw

'98 - '00 models:

Remove the rack guide screw and remove the old

sealant off of the threaded section.

Apply new sealant all around the threads. Loosely

installthe rack guide screw

Tighten the rack guide screw to 25 N'm (2.5 kgf'm.

18 lbf.ft), then loosen it.

Retighten the rack guide screw to 3 9 N'm (0.4 kgim,

2.9 lbf.ft), then back it off to specified angle.

Specified Return Angle: 20" max.

Tighten the locknut while holding the rack guide

screw.

Check for tight or loose steering through the com-

plete turning travel.

Perform following insPections:

. Steering operation (see page 17-30).

. Power assist with vehicle parked.

4.

LOCKNUT WRENCH, 40 mm

lr

17-33

Fluid Replacement

Check the reservoir at regular intervals, and add fluid as

necessary.

CAUTION: Always us€ Genuine Honda Power Stearing

Fluid-V or S. Using any other type of power sto€ring

tluid or automatic transmission lluid can cause

increased wear and poor steering in cold weathor.

SYSTEM CAPACITY:

0.85 liter 10.90 US' qt,0.75 lmp'qt)

at disassembly

RESERVOIR CAPACITY:

0.4 liter (0.42 US. qt, 0.35 lmP.qt)

LEVEL LINE

LOWER LEVEL LINE

1. Raise the reservoir, then disconnect the return nose.

2. Connect a hose of suitable diameter to the discon-

nected return hose, and put the hose end in a suit-

able container.

CAUTION: Take care not to spill tho fluid on the

body and parts. Wipe off any spill€d fluid at oncs'

3. Start the engine, let it run at idle, and turn the steer-

ing wheel from lock-to-lock several times When

fluid stops running out of the hose, shut off the

engine, Discard the fluid.

4. Reinstall the return hose on the reservoir'

5. Fill the reservoir to the upper level line.

6. Start the engine and run it at fast idle, then turn the

steering trom lock-to-lock several times to bleed air

trom the system.

7. Recheck the fluid level and add some it necessary.

CAUTION: Do not fill the reservoir beYond the

upper l€vel line.

HOSE

Page 1097 of 2189

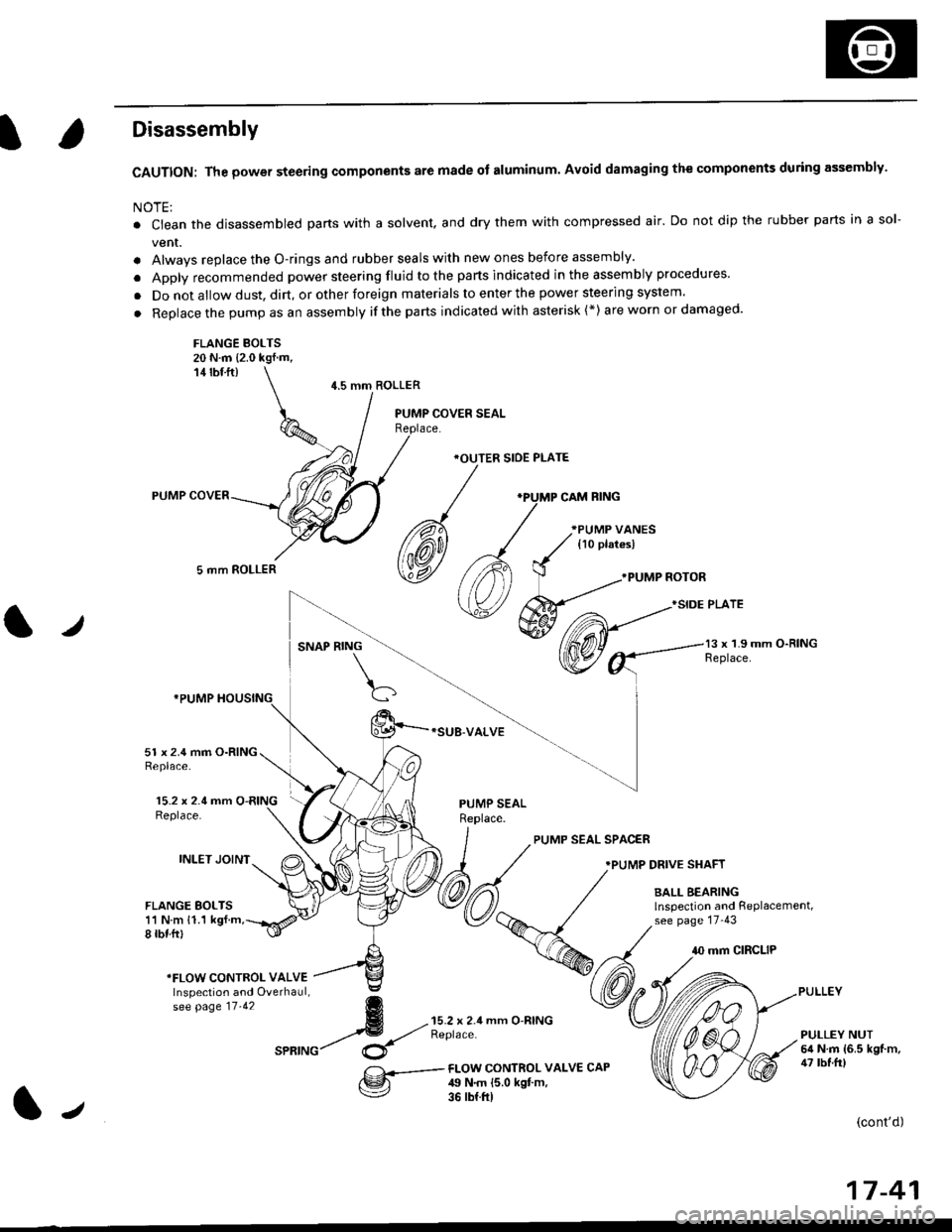

Disassembly

CAUTION: The power steering components are made of aluminum. Avoid damaging the components during assembly.

NOTE:

. Ctean the disassembled parts with a solvent, and dry them with compressed air. Do not dip the rubber parts in a sol-

vent.

. Alwavs replace the O-rings and rubber seals with new ones before assembly.

. Apply recommended power steering fluid to the parts indicated in the assembly procedures'

. Do not allow dust, dirt, or other foreign materials to enter the power steering system.

. Replace the pump as an assembly ifthe parts indicated with asterisk (*) are worn or damaged'

FLANGE BOLTS20 N.m {2.0 kgf.m,14 rbf ft)

5 mm ROLLER

4.5 mm ROLLER

*OUTER SIOE PLATE

*SUB-VALVE

.PUMP NOTOR

}SIDE PLATE

l,/SNAP RING13 x 1.9 mm O-RINGReplace.

15.2 x 2.4 mm O-RINGReplace.

INLET JOINT

51 x 2.4 mm O-RINGReplace.

FLANGE BOLTS11 N m 11.1 kgf.m,8 rbf.ftl

PUMP SEALReplace.

PUMP SEAL SPAC€R

.PUMP DRIVE SHAFT

BALL BEARINGlnspection and RePlacement,see page 17-43

10 mm CIRCLIP

*FLOW CONTROI- VALVEInspection and Overhaul,se[ pase tt.tz g

4 --{;'rX!;'seatuc/ $

mm O-RINGPULLEY NUT6il N.m {6.5 kgf.m,47 tbf.frlFI-OW CONTROL VALV€ CAP49 N.m {5.0 kgt m,36 rb{.ft)

(cont'd)

17-41

J

Page 1140 of 2189

Front Suspension

L

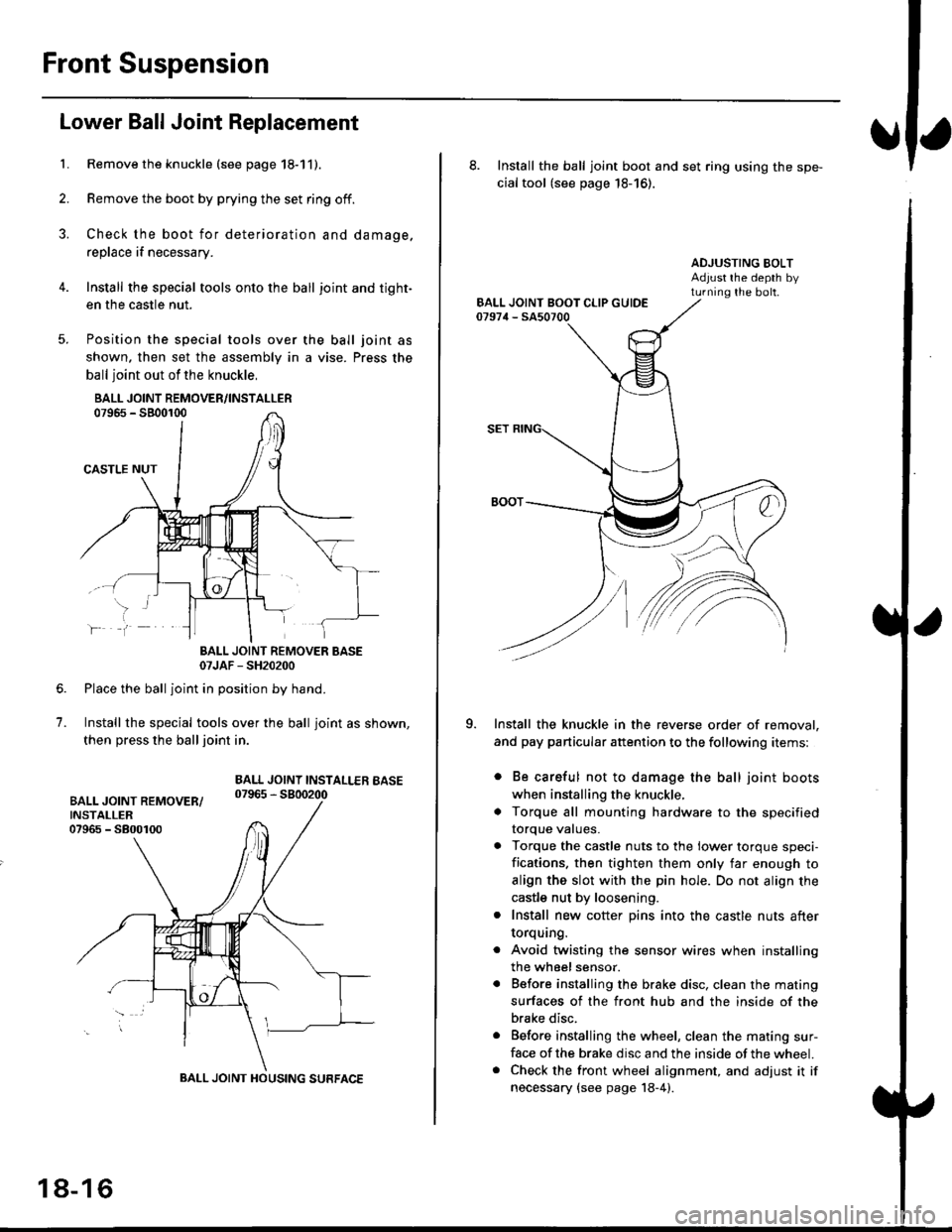

Lower Ball Joint Replacement

Remove the knuckle (see page 18-11).

Remove the boot by prying the set ring off.

Check the boot for deterioration and damage.

replace if necessary.

Install the special tools onto the ball joint and tight-

en the casfle nut.

Position the special tools over

shown. then set the assembly in

ball joint out of the knuckle,

BALL JOINT REMOVER/INSTALLER07965 - SB00r00

CASTLE NUT

the ball joint as

a vise. Press the

lf

7.

BALL JOINT REMOVER BASE07JAF - SH20200

Place the ball joint in position by hand.

Install the special tools over the ball joint as shown,

then press the ball joint in.

BALL JOINT INSTALLEB BASE07965 - 5800200

BALL JOINT HOUSING SURFACE

18-16

8. Install the ball joint boot and set ring using the spe-

cial tool (see page 18-16).

ADJUSTING BOLTAdjust rhe depth byturning the bolt.

Install the knuckle in the reverse order of removal,

and pay particular attention to the following items:

. Be careful not to damage the ball joint boots

when installing the knuckle,

. Torque all mounting hardware to the specified

torque values.

. Torque the castle nuts to the lower torque speci-

fications. then tighten them only far enough to

align the slot with the pin hole. Do not align the

castle nut by loosening.

. Install new cotter pins into the castle nuts after

torquang.

. Avoid twisting the sensor wires when installing

the wheel sensor.

. Before installing the brake disc. clean the mating

surfaces of the front hub and the inside of the

brake disc.

. Before installing the wheel, clean the mating sur-

face of the brake disc and the inside of the wheel.. Check the front wheel alignment, and adjust it if

necessary {see page 18-4).

Page 1155 of 2189

t

Conventional Brake

Speciaf Tools .............19'2

Component Locations

lndex ................ ...... 19-3

Inspection and Adiustment

Brake System Rubber Parts

and Brake Booster ...........,.,............. 19-4

Brake Pedal ............ 19-5

Parking Brake ........ 19-6

Bleeding ................. 19-7

Front Brake Pads

Inspection and Replacement .......... 19-8

Front Erake Disc

Disc Runout Inspection ................... 19-12

Disc Thickness and Parallelism

Inspection .......... 19-12

Front Brake Caliper

Disassembly .......... 19'13

Reassembly ........... 19-16

Master Cylinder/Brake Booster

Removal/lnstallation ....................... 19-21

Pushrod Clearance Adiustment ...... 19-22

Brake Booster Inspection ................ 19-23

Rear Brake Pads

Inspection and Replacement ,,........ 19-24

Rear Brake Disc

Disc Runout lnspection ................... 19-26

Disc Thickness and Parallelism

Inspection .......... 19-26

Rear Brake Caliper

Disassembly ...........19-27

Reassembly ........." 19-31

Rear Drum Brake

Index/lnspection .............................. 19-35

Inspection ....,.,....... 19-36

Brake Shoe Disassembly ..............." 19-37

Brake Shoe Reassembly ...............'.. 19-37

Brake Hoses/Lines

Inspection/Torque Specifications ..... 19-39

Hose Replacement ........................... 19-40

Parking Brake Cable

lnspection and Replacement ........,. 19-41

l-l

Page 1180 of 2189

Rear Brake Disc

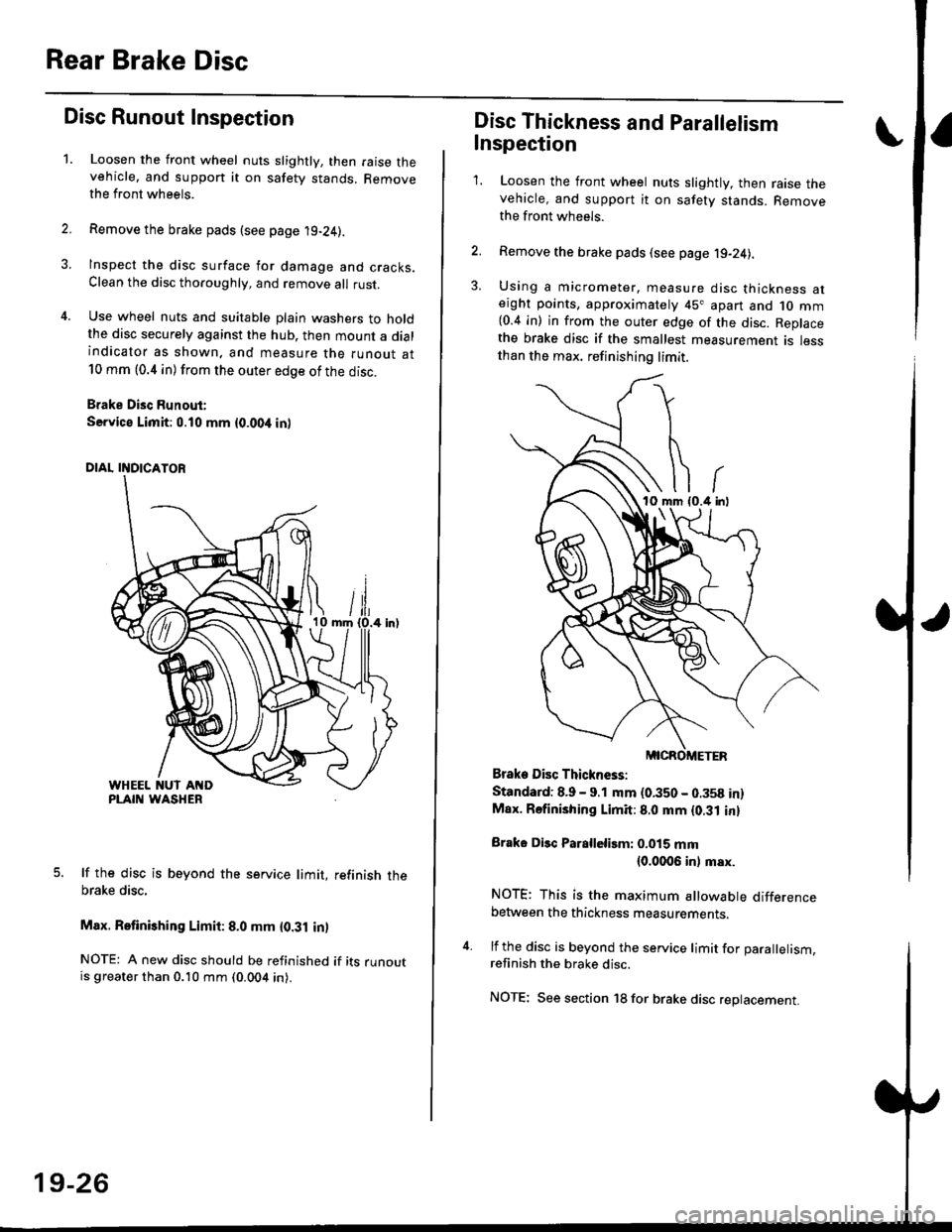

Disc Runout Inspection

1.Loosen the front wheel nuts slightly, then raise thevehicle, and suppon it on safety stands. Removethe front wheels.

Remove the brake pads (see page 19-24).

Inspect the disc surface for damage and cracks.Clean the disc thoaoughly, and remove a

rust.

Use wheel nuts and suitable plain washers to holdthe disc securely against the hub. then mount a dialindicator as shown. and measure the runout at10 mm (0.4 in) from the outer edge of the disc.

Brake Disc Runout:

Service Limit:0.10 mm {0.00,t in)

5. lf the disc is beyond the service limit, refinish thebrake disc,

Max. Retinishing Limit: 8.0 mm {0.31 in)

NOTE: A new disc should be refinished if its runoutis greater than 0.10 mm (0.004 in).

19-26

Disc Thickness and Parallelism

Inspection

1. Loosen the front wheel nuts slightly, then raise thevehicle, and support it on safety stands. Removethe front wh6els.

2. Remove the brake pads (see page j9-24).

3. Using a micrometer. measure disc thickness aterght points, approximately 45" apart and 1o mm{0.4 in) in from the outer edge of the disc. Replacethe brake disc if the smallest measurement is lessthan the max. refinishing limit.

Brake Disc Thickness:

Standard: 8.9 - 9.1 mm (0.350 - 0.358 in)Max. Rsfinishing Limit: 8.0 mm {0.31 in}

Brake Disc Parallelirm: 0.015 mm(0.0006 inl msx.

NOTE; This is the maximum allowable differencebetween the thickness measurements.

4. lf the disc is beyond the service limit for Darallelism.refinish the brake disc.

NOTE; See section 18 for brake disc replacement.

Page 1194 of 2189

Brake Hoses/Lines

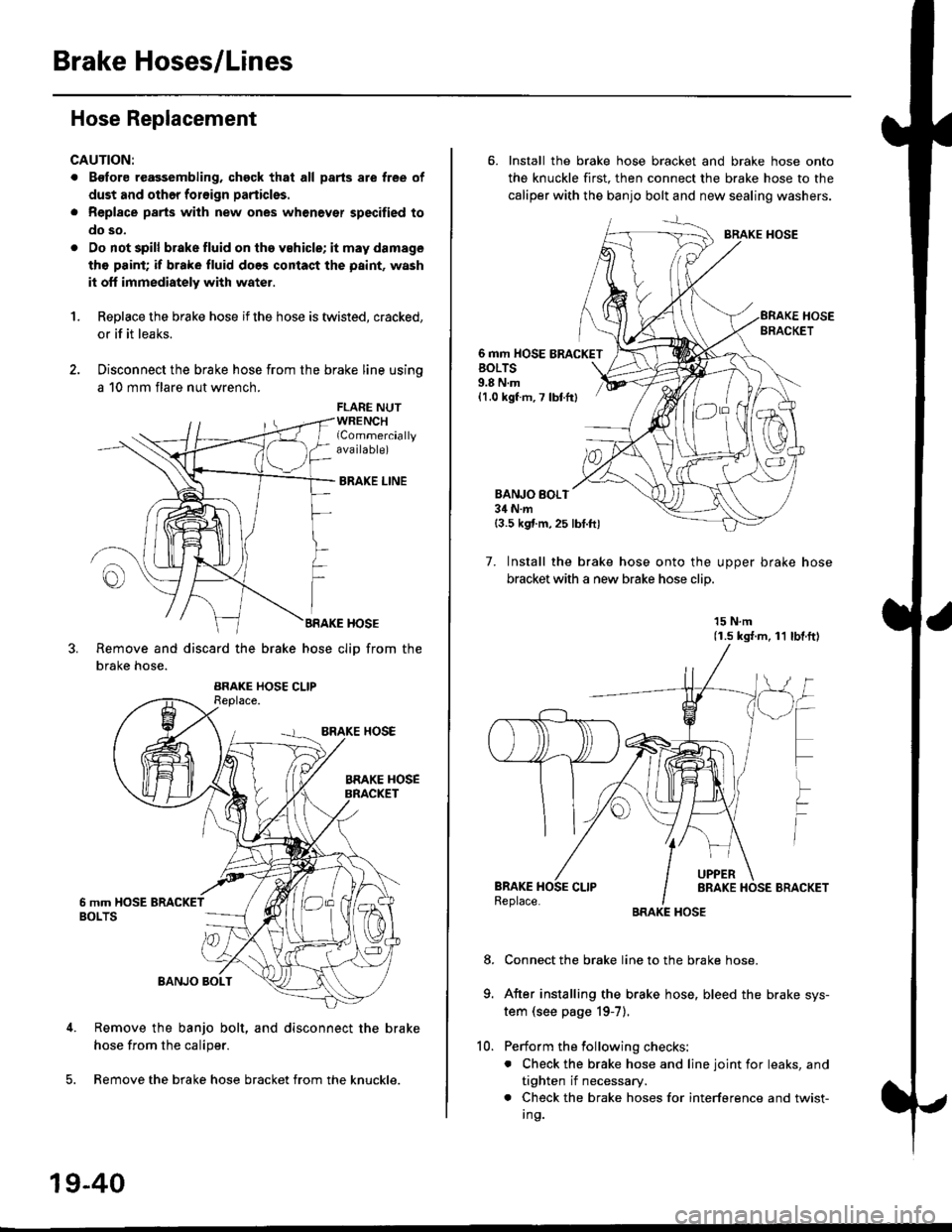

Hose Replacement

CAUTION:

. Bgfore reagsembling, chgck that all parts are free of

dust and othor foroign particles.

. Repl8ce parts with new ones whenever specified to

do so,

. Do not spill brake fluid on th6 vehicle; it may damage

tho paint; if brake fluid does contact the paint, wash

it off immediately with water.

1.Replace the brake hose if the hose is twisted, cracked,

or if it leaks.

Disconnect the brake hose from the brake line using

a 10 mm flare nut wrench.

FLARE NUTWRENCHlCommerciallyava ilable)

BRAKE LINE

BRAKE HOSE

Remove and discard the brake hose cliD from the

brake hose.

Remove the banjo bolt, and disconnect the brake

hose from the caliper.

Remove the brake hose bracket from the knuckle.

19-40

10.

6. Install the brake hose bracket and brake hose onto

the knuckle first. then connect the brake hose to the

caliper with the banjo bolt and new sealing washers.

BRAKE HOSE

6 mm HOSE BRACKETBOLTS9.8 N.m{1.0 kgf m, 7 lbtfr}

BANJO BOI.T34 N.m{3.5 kgf.m,25 lbt.ftl

7. Install the brake hose onto the uooer brake hose

bracket with a new brake hose clip

15 N.m(1.s ks{.m, 11 lbl.ftl

Connect the brake line to the brake hose.

After installing the brake hose, bleed the brake sys-

tem (see page 19-7).

Perform the following checks:

. Check the brake hose and line joint for leaks, and

tighten if necessary.

. Check the brake hoses for interference and twist-

I ng.

8.

Page 1240 of 2189

Doors

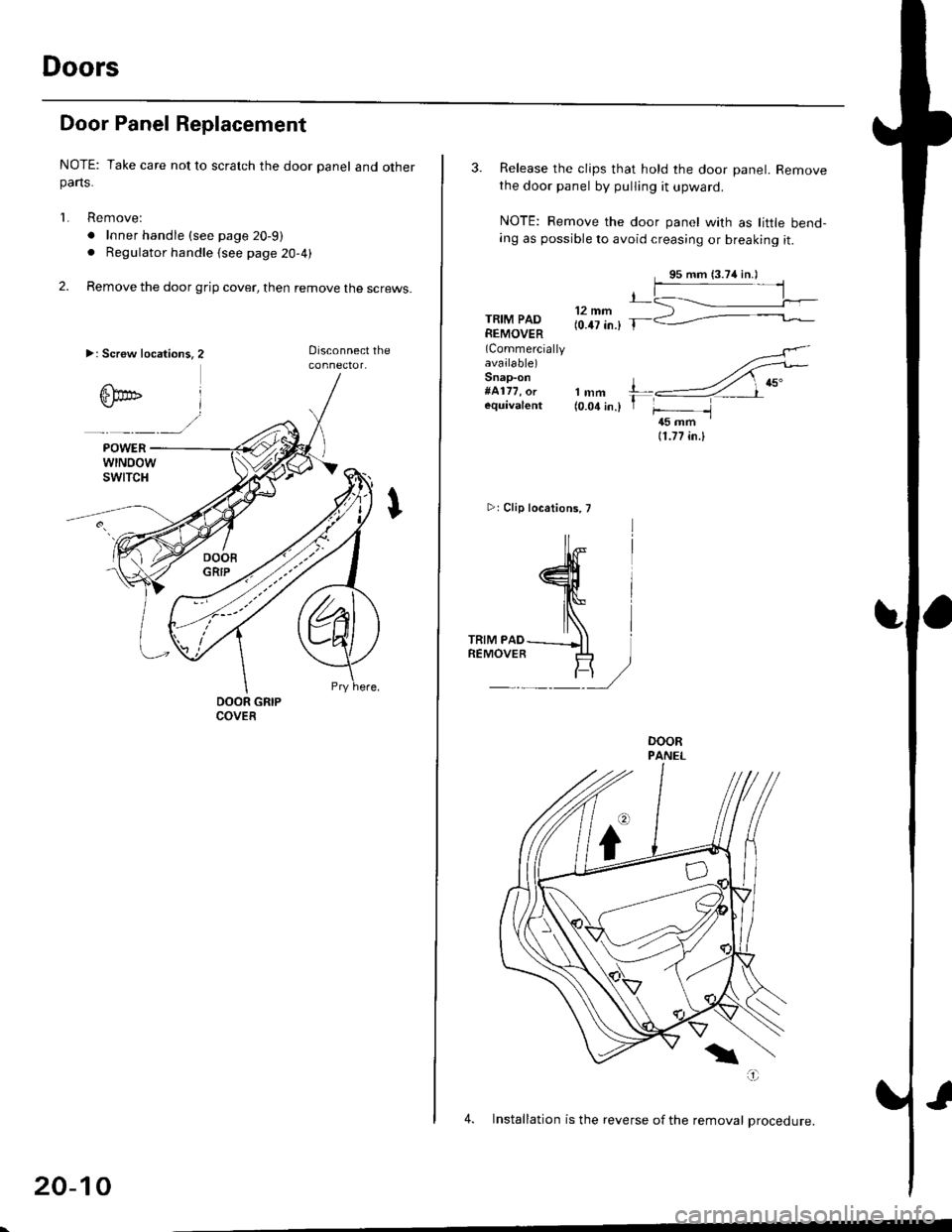

Door Panel Replacement

NOTE: Take care not to scratch the door panel and otherparts.

1. Remove:

. Inner handle (see page 20-9)

. Regulator handle (see page 20-4)

2. Remove the door grip cover, then remove the screws.

>: Screw location3.2

20-10

3. Release the clips that hold the door panel. Removethe door panel by pulling it upward.

NOTE: Remove the door panel with as little bend-ang as possible to avoid creasing or breaking it.

,L12 mm(0.47 in.) T-TRIM PADREMOVER(Commercially

available)Snap-on#4177, orequival€nt

4

lNlrRrM PAD---_Jl iREMOVER .I+ ]

F/

rt{-

lmm l---4 ,nu"(o.o1in.l 1 f- -l45 mm '

11.77 in.l

>rClip locations, T

4. Installation is the reverse of the removal Drocedure.

Page 1285 of 2189

L

L

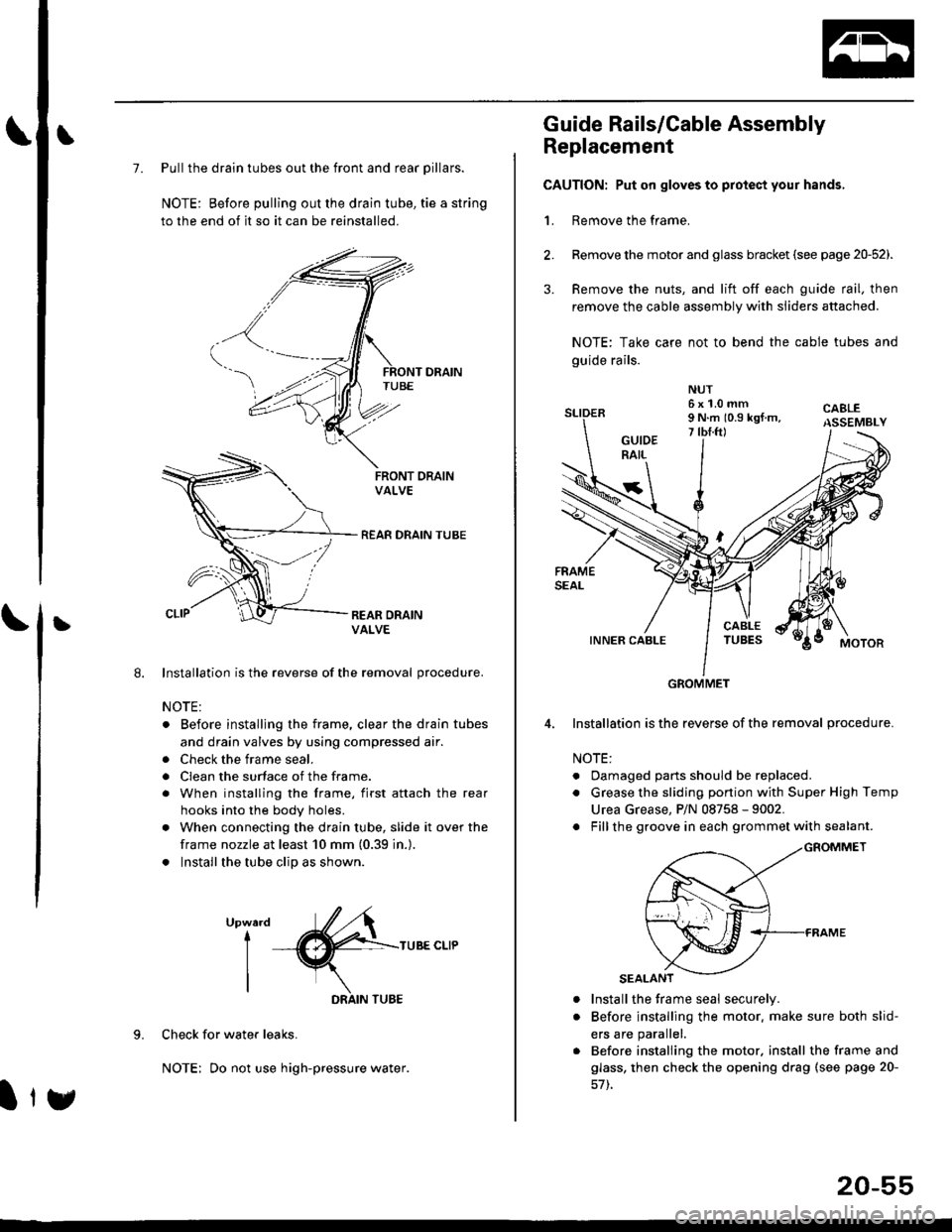

7. Pull the drain tubes out the front and rear pillars.

NOTE: Before pulling out the drain tube, tie a string

to the end of it so it can be reinstalled.

Installation is the reverse of the removal procedure.

NOTE:

. Before installjng the frame, clear the drain tubes

and drain valves by using compressed air.

. Check the frame seal.

. Clean the surface of the frame.

. When installing the frame, first attach the rear

hooks into the body holes.

. When connecting the drain tube, slide it over the

frame nozzle at least 10 mm (0.39 in.).

. Install the tube clip as shown.

UpwardI

I

I

TUBE CLIP

Check for water leaks.

NOTE: Do not use high-pressure water.

DRAIN TUBE

Ity

20-55

Guide Rails/Cable Assembly

Replacement

CAUTION: Put on gloves to protect your hands,

1. Remove the frame.

Remove the motor and glass bracket (see page 20-52).

Remove the nuts, and lift off each guide rail, then

remove the cable assembly with sliders attached.

NOTE: Take care not to bend the cable tubes and

guide rails.

Installation is the reverse of the removal procedure.

NOTE:

. Oamaged parts should be replaced.

. Grease the sliding portion with Super High Temp

Urea Grease, P/N 08758 - 9002.

. Fillthe groove in each grommet with sealant.

a

a

Install the frame seal securely.

Before installing the motor. make sure both slid-

ers are parallel.

Before installing the motor. install the frame and

glass, then check the opening drag (see page 20-

GROMMET

Page 1288 of 2189

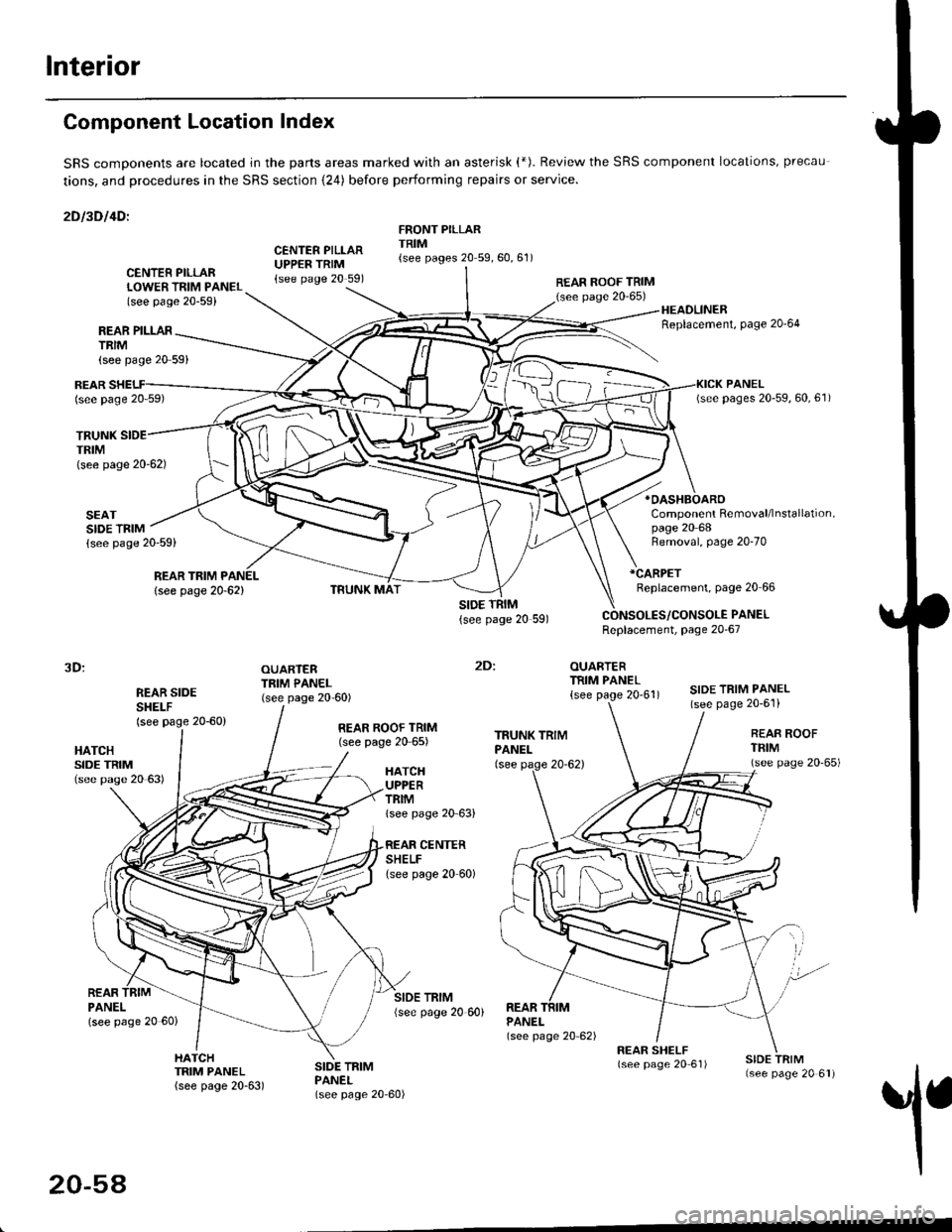

Interior

Component Location Index

SRS comDonents are located jn the parts areas marked with an asterisk (*). Review the SRS component locations, precau

tions, and procedures in the SRS section {24) before performing repairs or service.

2Dl3Dl4Dl

CENTER PILLARUPPER TRIM{see page 20 591

FRONT PILLARTRIM{see pages 20 59,60,61)

REAR PILLARTRIM

TRUNKTRIM(see page 20-62)

SEATSIDE TRIM{see page 20-59)

{see page 20 59}

CENTER PILLARLOWER TRIM PANEL(see page 20-59)

REAR ROOF TRIM(see page 20-65)

:

OUARTERTRIM PANEL

{see page 20'61)

HEADLINERReplacement, Page 20'64

*OASHBOARO

Component Removal/lnstallation,page 20 68

REARlsee page 20 59)

REAR TRIM PANEL

lsee page 20-62)

Removal, page 20-70

*CARPET

Replacement, page 20 66

PANELReplacement, page 20-67

3D:

REAR SIDESHEI-F(see page 20-60)

OUARTERTRIM PANEL(see page 20-60)SIDE TRIM PANEL(see page 20-6'l)

2Dl

HATCHSIDE TRIM(see pase 20 63)

REAR ROOF TRIM(see page 20 65)REAR ROOFTFIM(see page 20'65)HATCHUPPERTRIMlsee page 20 63)

CENTERSHELFlsee page 20 60)

REARPANELlsee page 20 60)

SIDE TRIM{see page 20 60)REARPANEL(see page 20 62)

1

HATCHTRIM PANEL(see page 20-63)

SIDE TRIMPANEL(see page 20-60)

20-54

Page 1297 of 2189

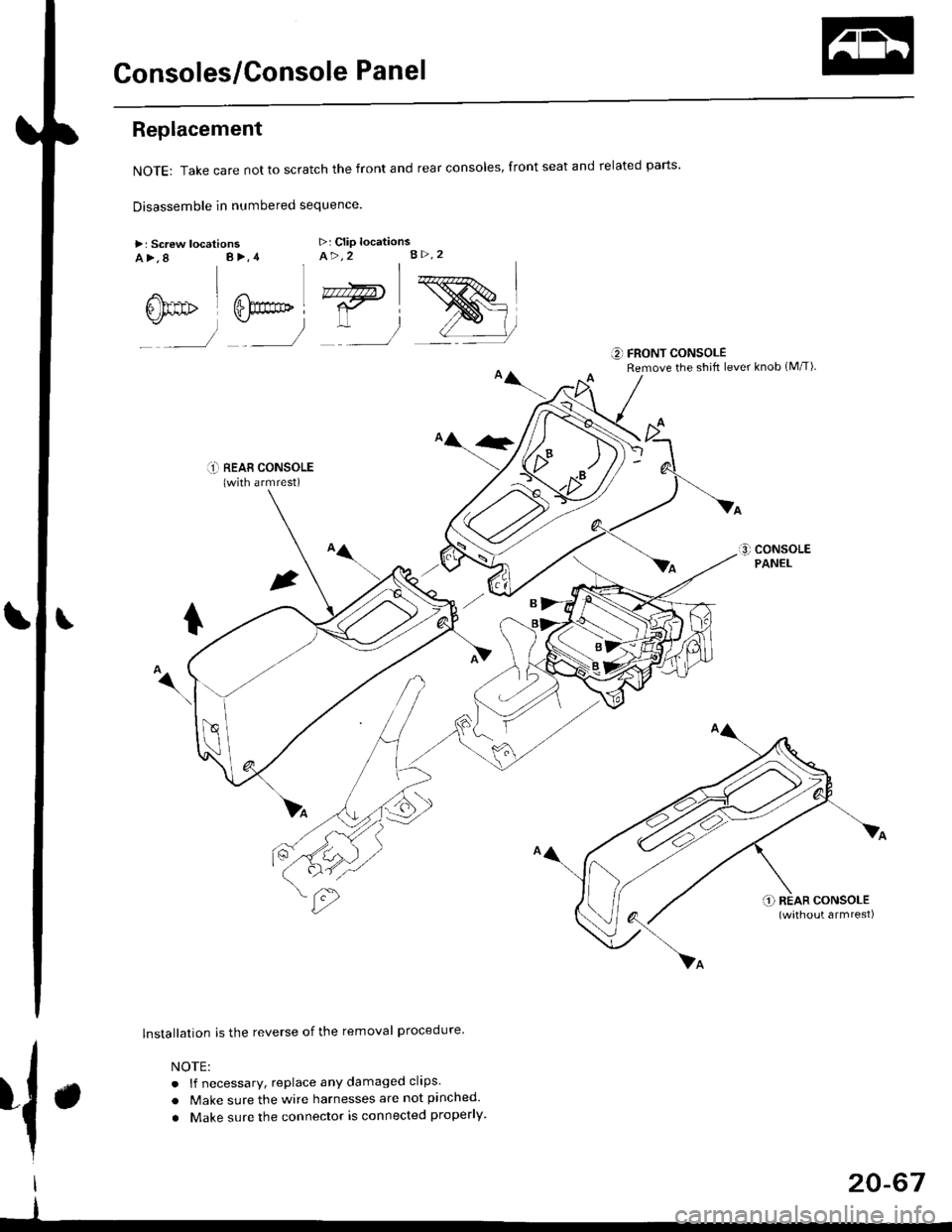

Consoles/Console Panel

Replacement

NoTE:Takecarenottoscratchthefrontandrealconso|es,frontseatandre|atedparts.

Disassemble in numbered sequence

>: Screw locationsa>,8 B>,4>: Clip locationsA>,2 B>.2

' nnffir

:__)

"=)

:)

::r_l REAB CONSoLE(with armrest)

lnstallation is the reverse of the removal procedure

NOTE:

. lf necessary, replace any damaged clips.

. Make sure the wire harnesses are not pinched.

. Make sure the connector is connected properly.

€] FRONT CONSOLERemove the shift lever knob (M/T)

{.

I

I

20-67