Oil leak HONDA CIVIC 1997 6.G Owner's Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1997, Model line: CIVIC, Model: HONDA CIVIC 1997 6.GPages: 2189, PDF Size: 69.39 MB

Page 1151 of 2189

IDisassembly/lnsPection

lr

Disassembly

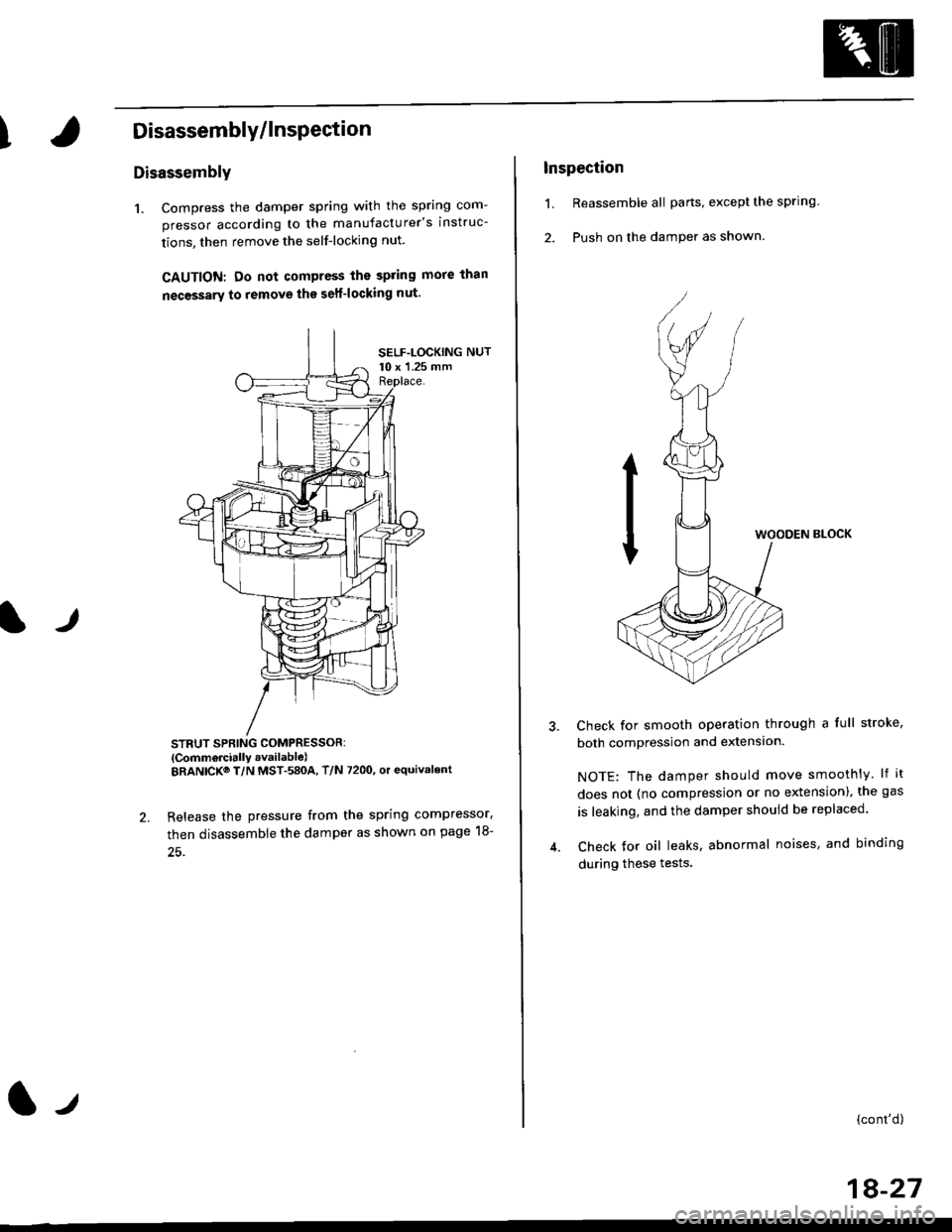

1. Compress the damper spring with the spring com-

pressor according to the manufacturer's instruc-

tions, then remove the self-locking nut.

GAUTION: Do not compress the spring more than

necessary to remove the sell-locking nut.

STNUT SPRING COMPRESSOR:

lComm6rcially .vailablelERANICKo T/N MST-580A, T/N 7200, or equivalent

Release the pressure from the spring compressor.

then disassemble the damper as shown on page 18-

(|-r

lnspection

1. Reassemble all parts, except the sprlng.

2. Push on the damPer as shown.

WOODEN BLOCK

Check for smooth operation through a full stroke,

both compression and extension.

NOTE: The damper should move smoothly lf it

does not (no compression or no extension), the gas

is leaking, and the damper should be replaced.

Check Jor oil leaks, abnormal noises, and binding

during these tests.

{cont'd)

18-27

Page 1192 of 2189

Rear Drum Brake

Brake Shoe Reassembly {cont'dl

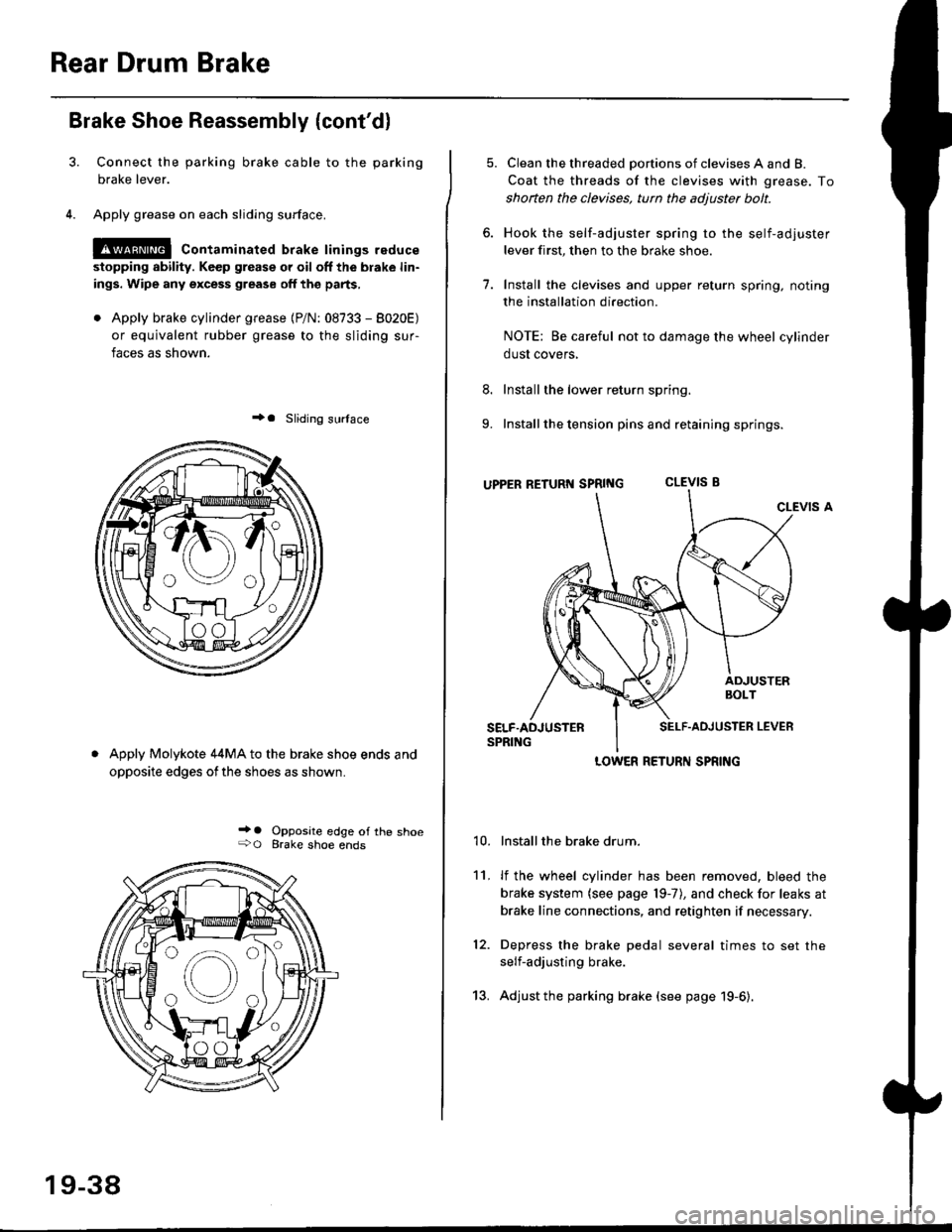

Connect the parking brake cable to the parking

brake lever.

Apply grease on each sliding surface.

!@ contaminated brake linings reduce

stopping ability. Keep grease or oil off the blake lin-

ings. Wipe any excess grease off the parts,

. Apply brake cylinder grease {P/N: 08733 - 8020E)

or equivalent rubber grease to the sliding sur-

faces as shown.

+a Sliding surlace

Apply Molykote 44MA to the brake shoe ends and

opposite edges ofthe shoes as shown.

_' o Opposite edge of the shoe+O Brake shoe ends

19-38

13.

5. Clean the threaded portions of clevises A and B.

Coat the threads of the clevises with grease. To

shoften the clevises, tun the adjuster bolt.

6. Hook the self-adjuster spring to the self-adjuster

lever first, then to the brake shoe

7. Install the clevises and upper return spring. noting

the installation direction.

NOTE: Be careful not to damage the wheel cylinder

dust covers,

8. Install the lower return spring.

9. Install the tension pins and retaining springs.

uppER RETURT{ SpRtNG CLEVIS B

CLEVIS A

Installthe brake drum.

lf the wheel cylinder has been removed, bleed the

brake system (see page 19-7), and check for leaks at

brake line connections, and retighten if necessary.

Depress the brake pedal several times to set the

self-adjusting brake.

Adjust the parking brake (see page 19-6).

't0.

11.

12.

LOWER RETURN SPRING

Page 1429 of 2189

Description

Outline

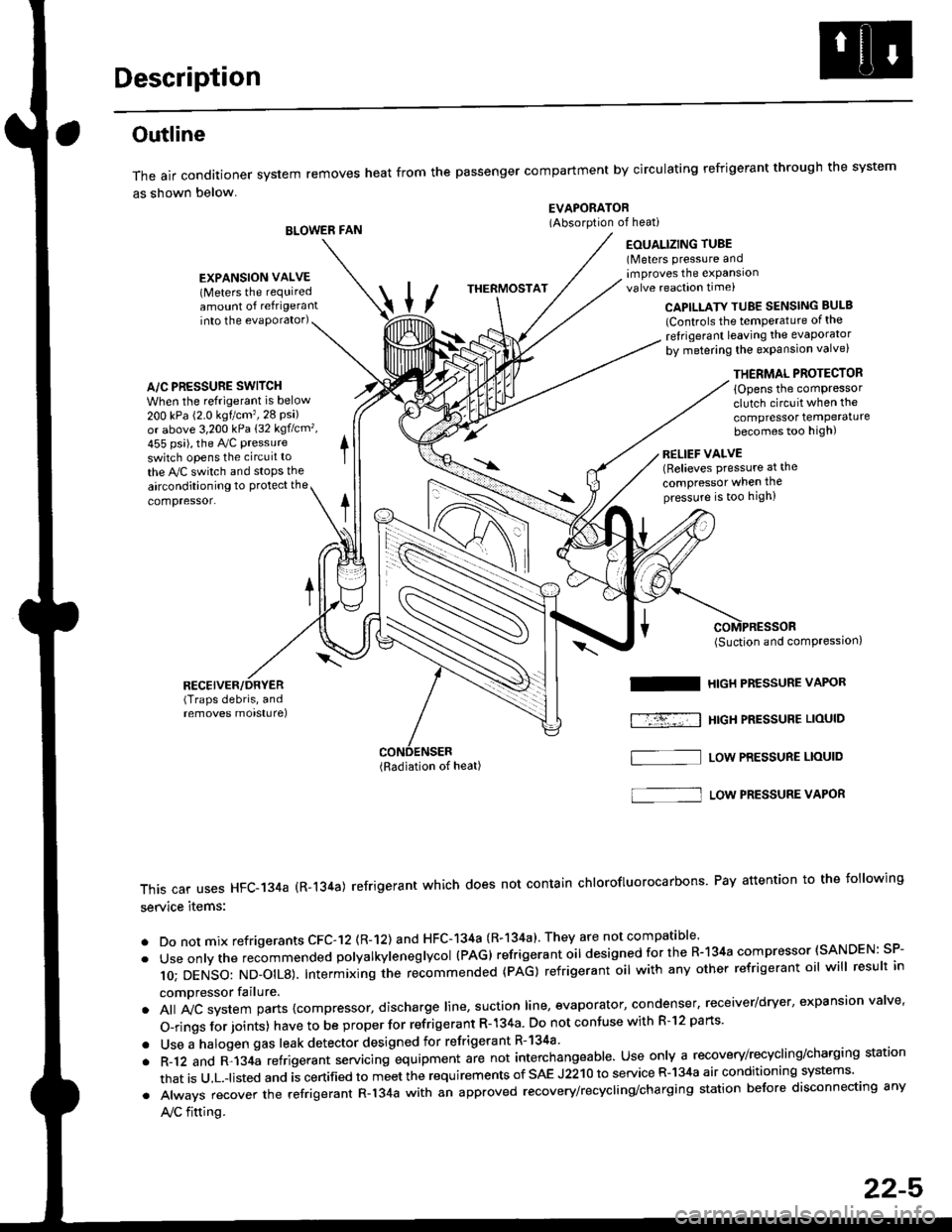

The air conditioner system removes heat from the passenger compartment by circulating refrigerant through the system

as shown below.

BLOWER FAN

EVAPORATOR(Absorption of heati

EOUALIZING TUBE(Meters pressure andimproves the expansionvalve reaction time)

into the evaporator)CAPILLATY TUBE SENSING BULB

lControls the temPerature of the

ref rigerant leaving the evaporator

by metering the expansion valve)

/\

THERMOSTAT

A/C PRESSURE SWITCH

When the refrigerant is below

200 kPa (2.0 kgtcm'�,28 Psi)or above 3,200 kPa 132 kgflcm',

455 psi), the Ay'C pressure

switch opens the circuit to

the A,/C switch and stops the

EXPANSION VALVE(Meters the requiredamount of refrigerant

airconditioning to Protect the

compressor.

RECEIVER/DRYER(Traps debris, andremoves morsturel

THERMAL PROTECTOR

{Opens the comPressorclutch circuit when the

compressor temPeraturebecomes too high)

RELIEF VALVE(Relieves pressure at the

compressor when thepressure is too high)

(Radiation of heat)

I

f-r-�-; I

(Suction and comPression,

HIGH PRESSURE VAPOR

HtGH PRESSUBE LIOUID

LOW PRESSURE LIOUID

This car uses HFC-134a (R-134a) refrigerant which does not contain chlorofluorocarbons Pay attention to the following

service items:

. Do not mix refrigerants CFC-12 (R-12) and HFC-134a (R-134a)' They are not compatible'

. Useonlythe recommended polyalkyieneglycol (PAG) refrigerant oil designedforthe R-134a compressor (SANDEN: SP-

10; DENSO: ND_OIL8). Intermixing ihe re-commended (pAG) refrigerant oil with any other refrigerant oil will result in

compressor failure.

. All A,,ic system parts {compressor, discharge line, suction line, evaporator, condenser, receiver/dryer, expansion valve'

O-rings for joints) have to be proper for refrigerant R- 134a Do not confuse with R-l2 parts'

. Use a halogen gas leak detector designed for refrigerant R-134a

. R-12 and R-134a refrigerant servacing equipment are not interchangeable. Use only a recovery/recycling/charging station

that is u,L.-listed and is certified to meet the requirements of sAE J2210 to service R-134a air conditioning systems'

. Always recover the refrigerant R-134a with an approved recovery/recycling/charging station before disconnecting any

A,/C fitting.

S]

22-5

Page 1446 of 2189

A/C Service Tips and Precautions

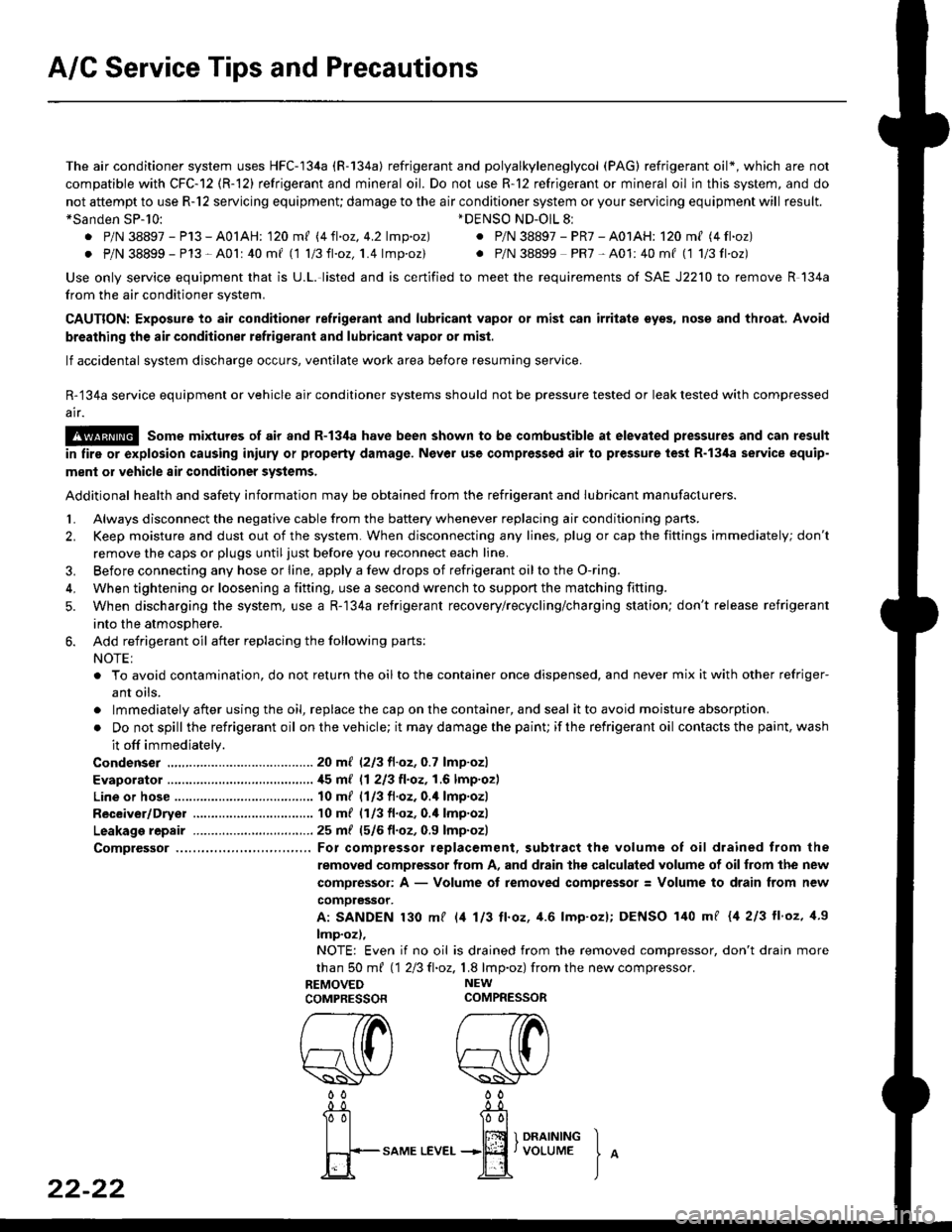

The air conditioner system uses HFC-134a (R-134a) refrigerant and polyalkyleneglycol (PAG) refrigerant oil*, which are not

compatible with CFC-12 (R-12) refrigerant and mineral oil. Do not use R-12 refrigerant or mineral oil in this system, and do

not attempt to use R-12 servicing equipmenU damage to the air conditioner system or your servicing equipment will result.*Sanden SP-10:

. P/N 38897 - P13 - A0lAH: 120 ml 14ll.oz, 4.2lmp.oz)

. P/N 38899 - P13 - A0l | 40 mf 11 1/3ll.oz,1.4 lmp'oz)

Use only service equipment that is U.L. listed and is certified to meet the requirements of SAE J2210 to remove R 134a

from the air conditioner system.

CAUTION: Exposure to air conditioner ref;ige;ant and lubricant vapol or mist can irritate syes, nose and throat, Avoid

breathing the air conditioner refrigerant and lubricant vapor or misl.

lf accidental system discharge occurs, ventilate work area before resuming service.

R-'134a service equipment or vehicle air conditioner systems should not be pressure tested or leak tested with compressed

ai.

!@@ some mixtures of air and R-t3ila have been shown to be combustible at elevated pressures and can result

in tire or explosion causing iniury or property damage. Never use compressed air lo pressure tesl R-134a service equip-

ment or vehicle 8ir conditioner systoms.

Additional health and safety information may be obtained from the refrigerant and Iubricant manufacturers.

L Always disconnect the negative cable from the battery whenever replacing air conditioning pans.

2. Keep moisture and dust out of the system. When disconnecting any lines, plug or cap the fittings immediately; don't

remove the caps or plugs until just before you reconnect each line.

3. Before connecting any hose or line, apply a few drops of refrigerant oilto the O-ring.

4, When tightening o. loosening a fitting, use a second wrench to support the matching fitting.

5. When discharging the system, use a R-134a refrigerant recovery/recycling/charging station; don't release refrigerant

into the atmosphere,

6. Add refrigerant oil after replacing the following parts:

NOTE:

. To avoid contamination, do not return the oil to the container once dispensed, and never mix it with other refriger-

ant oils.

. lmmediately after using the oil, replace the cap on the container, and seal it to avoid moisture absorption.

. Do not spill the refrigerant oil on the vehicle; it may damage the paint; if the refrigerant oil contacts the paint, wash

it off immediately.

Condenser .......2o ml (2/3 fl.oz, 0.7 lmp.ozl

Evaporator .,.,.,. i[5 m{ 11 213 tl.oz,1,6lmp.ozl

Line or hose ..... 10 mf (1/3 fl.oz, 0.4 lmp.ozl

Receiver/Dryer 10 m{ (1/3 fl.oz,0.'l lmp.ozl

Leakage repair 25 m{ (5/6 fl.oz, 0.9 lmp.ozl

Comptessor ... For compressor replacement. subtract the volume of oil drained trom the

removed compressor from A, and drain the calculated volume of oilfrom the new

compressor: A - Volume of removed compressor: Volume to drain from new

comoressor.

A: SANDEN 130 mf l/t 113 ll.oz, 4.6 lmp'ozl; DENSO 140 mf {4 213 ll'oz, 1.9

lmp.oz),

NOTE: Even if no oil is drained from the removed compressor, don't drain more

than S0 m{ 112Ell.oz,1.8 lmp.oz) fromthe new compressor.

REMOVED NEW

COMPRESSORCOMPRESSOR

*DENSO ND-OlL 8l

. P/N 38897 - PR7 - A01AH: 120 ml (4 fl.oz)

. P/N 38899 PR7-A01:40mf (1 1/3fl'oz)

rereW W0000

22-22

-0_!- -0_a

Tol l00l

| | lffi 1 onrrrutrc I

fi+-sAME

LEvEr...+jEf,voLUME

J

^

Page 1450 of 2189

A/C System Service

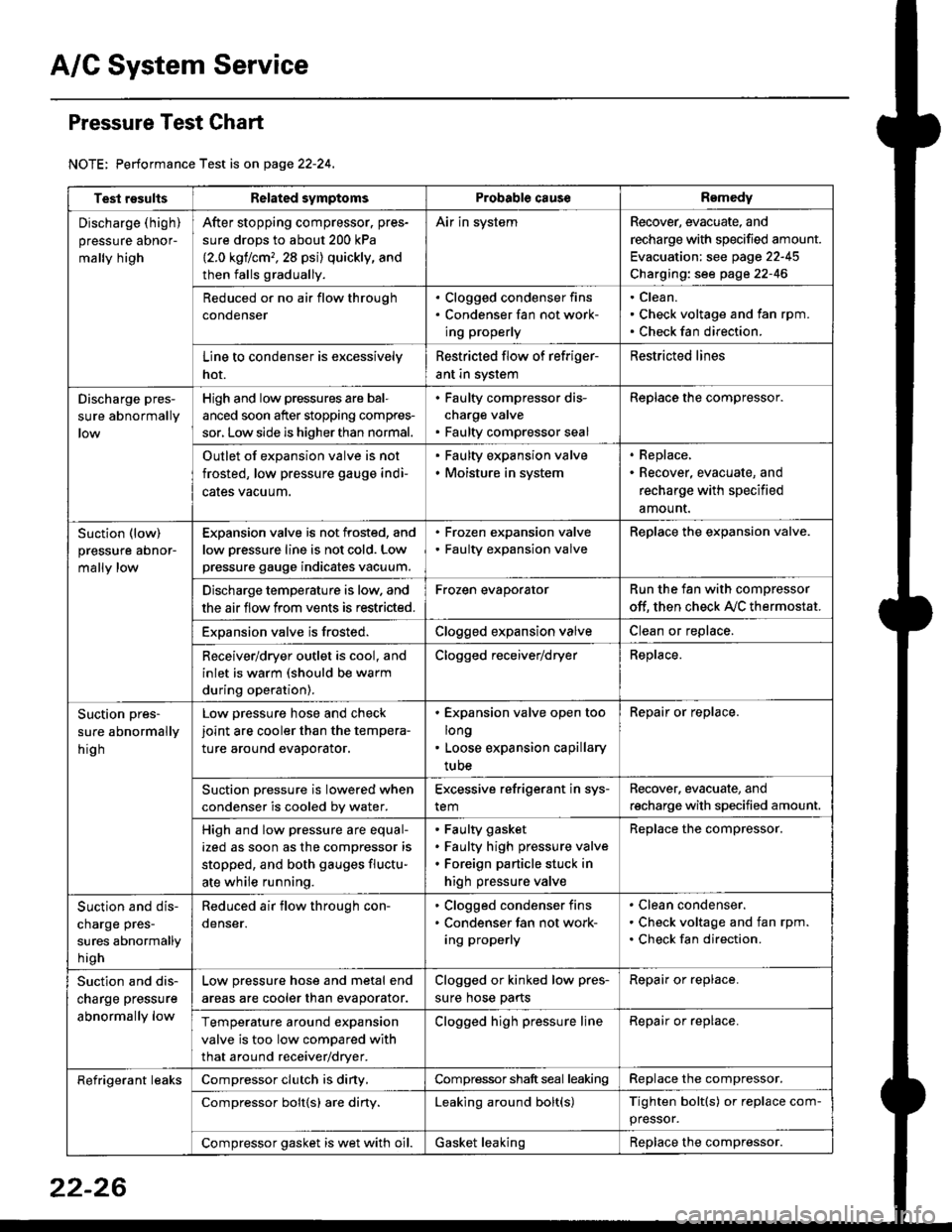

Pressure Test Chart

NOTE: Performance Test is on page 22-24,

Test resultsRelated symptomsProbabl€ causeRemedy

Discharge (high)

pressure aDnor-

mally high

After stopping compressor. pres-

sure drops to about 200 kPa

{2.0 kgflcm,,28 psi) quickly, and

then falls gradually.

Air in systemRecover, evacuate, and

recharge with specified amount.

Evacuation: see page 22-45

Charging: see page 22-46

Reduced or no air flow through

condenser

. Clogged condenser fins. Condenser fan not work-

ing properly

Clean.

Check voltage and fan rpm.

Check fan direction.

Line to condenser is excessively

hot.

Restricted flow of refriger-

ant in system

Restricted lines

Discharge pres-

sure abnormally

High and low pressures are bal-

anced soon after stopping compres-

sor, Low side is higher than normal.

. Faulty compressor dis-

charge valve. Faulty compressor seal

Replace the compressor.

Outlet of expansion valve is not

frosted, low pressure gauge indi-

cales vacuum.

. Faulty expansion valve. Moisture in system

. Replace,. Recover, evacuate, and

recharge with specified

amount.

Suction (low)

pressure abnor-

mally low

Expansion valve is not frosted, and

low oressure line is not cold. Low

pressure gauge indicates vacuum.

. Frozen expansion valve. Faulty expansion valve

ReDlace the exoansion valve.

Discharge temperature is low. and

the air flow from vents is restricted.

Frozen evaporatorRun the fan with compressor

off. then check A,/C thermostat.

Exoansion valve is frosted.Clogged expansion valveClean or replace.

Receiver/dryer outlet is cool, and

inlet is warm (should be warm

during operation).

Clogged receiver/dryerReplace.

Suction pres-

sure abnormally

hig h

Low pressure hose and check

joint are cooler than the tempera-

ture around evaporator.

. Expansion valve open too

long. Loose expansion capillary

tube

Repair or replace.

Suction oressure is lowered when

condenser is cooled bv water.

Excessive refrigerant in sys-

tem

Recover. evacuate, and

recharge with specified amount.

High and low pressure are equal-

ized as soon as the compressor is

stopped, and both gauges fluctu-

ate while running.

Faulty gasket

Faulty high pressure valve

Foreign particle stuck in

high pressure valve

Replace the compressor.

Suction and dis-

charge pres-

sures abnormally

h igh

Reduced air flow through con-

denser.

. Clogged condenser fins. Condenser fan not work-

ing properly

Clean condenser.

Check voltage and fan rpm.

Check fan direction.

Suction and dis-

charge pressure

abnormally low

Low pressure hose and metal end

areas are cooler than evaporator.

Clogged or kinked low pres-

sure hose parts

Repair or replace.

Temperature around expansion

valve is too low compared with

that around receiver/dryer.

Clogged high pressure lineRepair or replace.

Refrigerant leaksCompressor clutch is diny,Compressor shaft seal leakingReplace the compressor.

Compressor bolt{s) are diny.Leaking around bolt(s)Tighten bolt(s) or replace com-

pressor.

Compressor gasket is wet with oil.Gasket leakingReplace the compressor.

22-26

Page 1451 of 2189

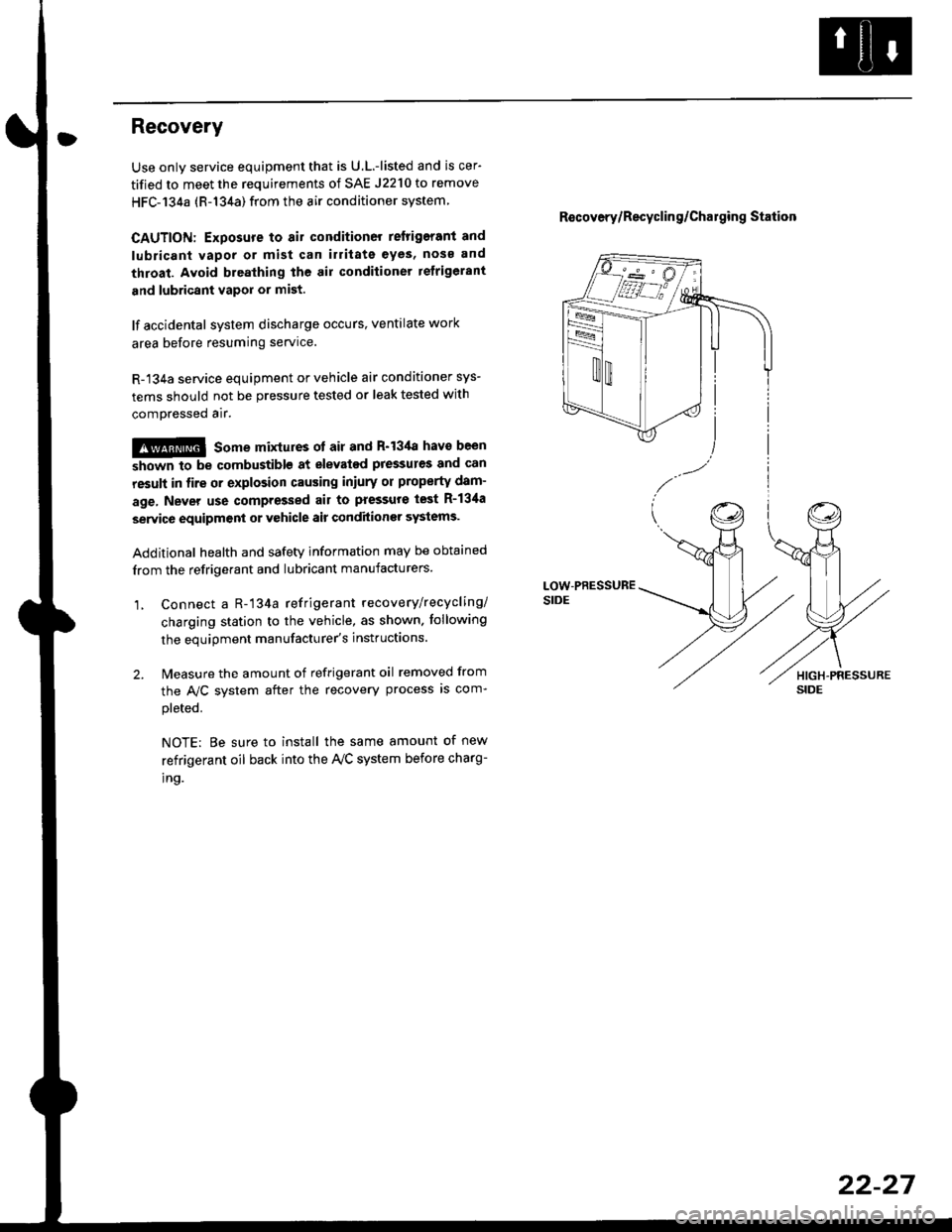

Recovery

Use only service equipment that is U.L.-listed and is cer-

tified to meet the requirements of SAE J2210 to remove

HFC-134a (R-134a) from the air conditioner system

CAUTION: Exposure to air conditioner relrigerant and

lubricant vapor or mist can illitate eyes, noss and

throat. Avoid breathing the ail conditioner refrigerant

and lubricant vapor or mist.

lf accidental system discharge occurs, ventilate work

area before resuming service.

R-134a service equipment or vehicle air conditioner sys-

tems should not be pressure tested or leak tested with

compressed air.

!@@ some mixtures ot air and R'13'[a havo been

strown to be combustiblg at elevated pressures and Gan

resuh in fire or explosion causing iniury or property dam-

age, Never use compressed air to pressure test R-134a

service equipment or vehicle air conditioner systems.

Additional health and safetv information may be obtained

from the refrigerant and lubricant manufacturers.

1, Connect a R-'134a refrigerant recove rylrecycling/

charging station to the vehicle, as shown. tollowing

the equipment manufacturer's instluctions.

2. Measure the amount of refrigerant oil removed from

the A/C svstem after the recovery process is com-

pleted.

NOTE: Be sure to install the same amount of new

refrigerant oil back into the Iy'C system before charg-

tno.

R€covery/Recyclin g/Cha19ing Station

22-27

Page 1452 of 2189

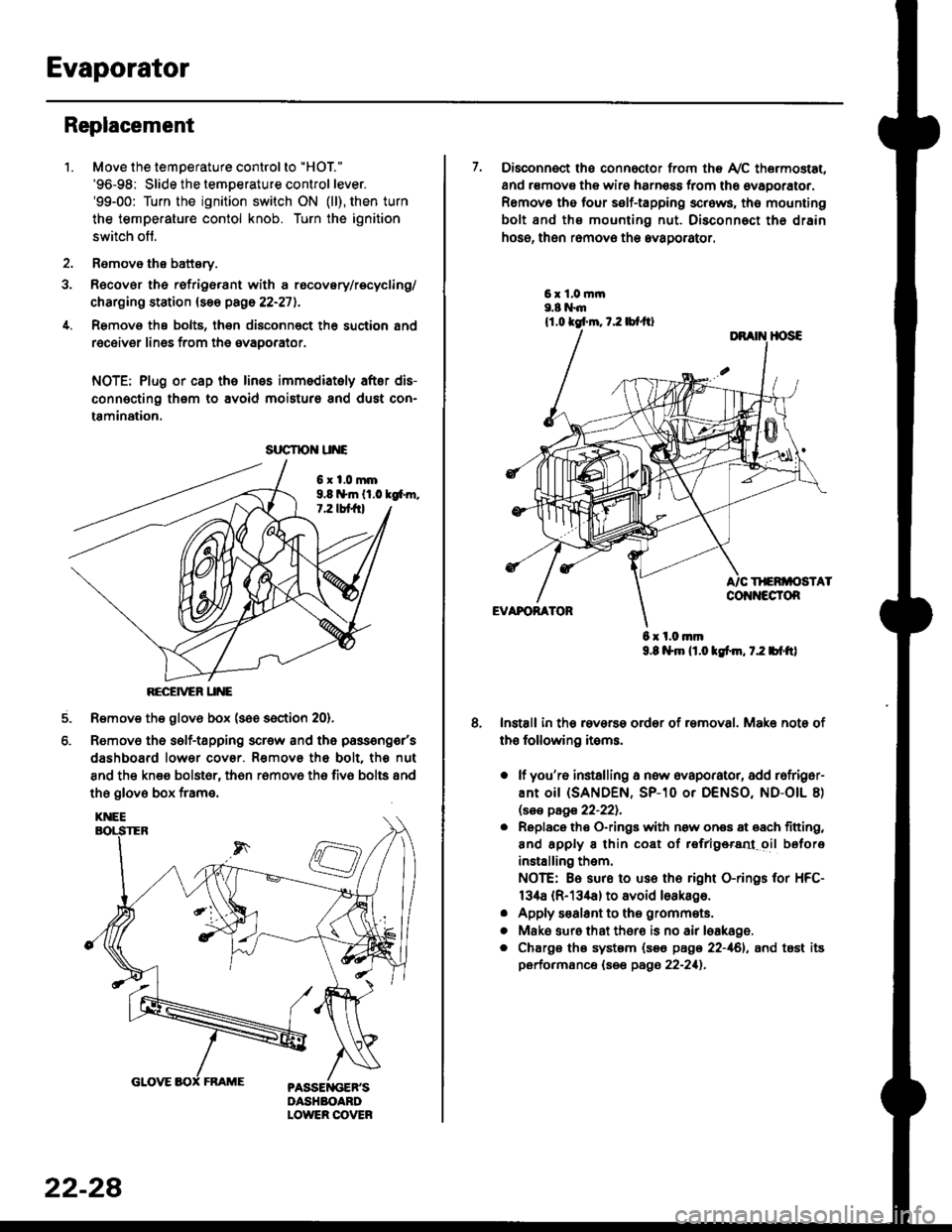

Evaporator

1.

Replacement

4.

Move the temperature control to "HOl"

'96-98: Slide the temoerature control lever.'99-00: Turn the ignition switch ON (ll), then turn

the temperature contol knob. Turn the ignition

switch off.

Remove the battsry.

Rgcover the refrigerant with a rocovery/recycling/

charging station (see page 22-271.

Remove the bolts, then disconnect th6 suction 8nd

receiver lines from th6 evaoorator.

NOTE: Plug or cap the lines imm€diatoly after dis-

connecting them to avoid moisture and dust con-

tamination.

6xl.0mm9.8 n*ln ll.0 tg6m.7.2 lbt frl

RECEiVER UNE

Remove the glov6 box (see section 20).

Removo the self-tapping scr€w and the passeng€r's

dashboard lower cover. Removs the bolt. the nut

8nd the kn€e bolst6r, th6n r6mov6 th6 fiv6 bolts and

the glove box frame.

6.

srrcrrc u E

22-28

7. Disconnect the connector from th€ Ay'C thermostat,

and r€movs the wire harness from the ovaporator.

Remov6 tho four self-tapping screws, tho mounting

bolt and ths mounting nut. Disconnect th€ drain

hose, then remov€ th6 avagorator.

6 x l.0.nm9.8 l$m lt.o ldm, 7.2 bl.tt)

Install in the reverse order of removal. Make note of

th€ following items.

o lf you'r6 installing a new evaporator, add rofriger-

ANt OiI {SANDEN, SP-10 Or DENSO, ND-OIL 8)

lsas page 22-221.

. Replace the O-rings with now ones 8t 68ch titting,

and apply 8 thin coat of r€frlgersd oil before

installing them.

NOTE: Be sure to use the right O-rings for HFC-

134a (R-134a) to avoid loakago.

. Apply s€alant to tha grommets.

. Mske sure that ther€ is no air leakage.

. Chargs ths system {s€€ page 22-161, and tost its

performance (see pags 22-211.

Page 1453 of 2189

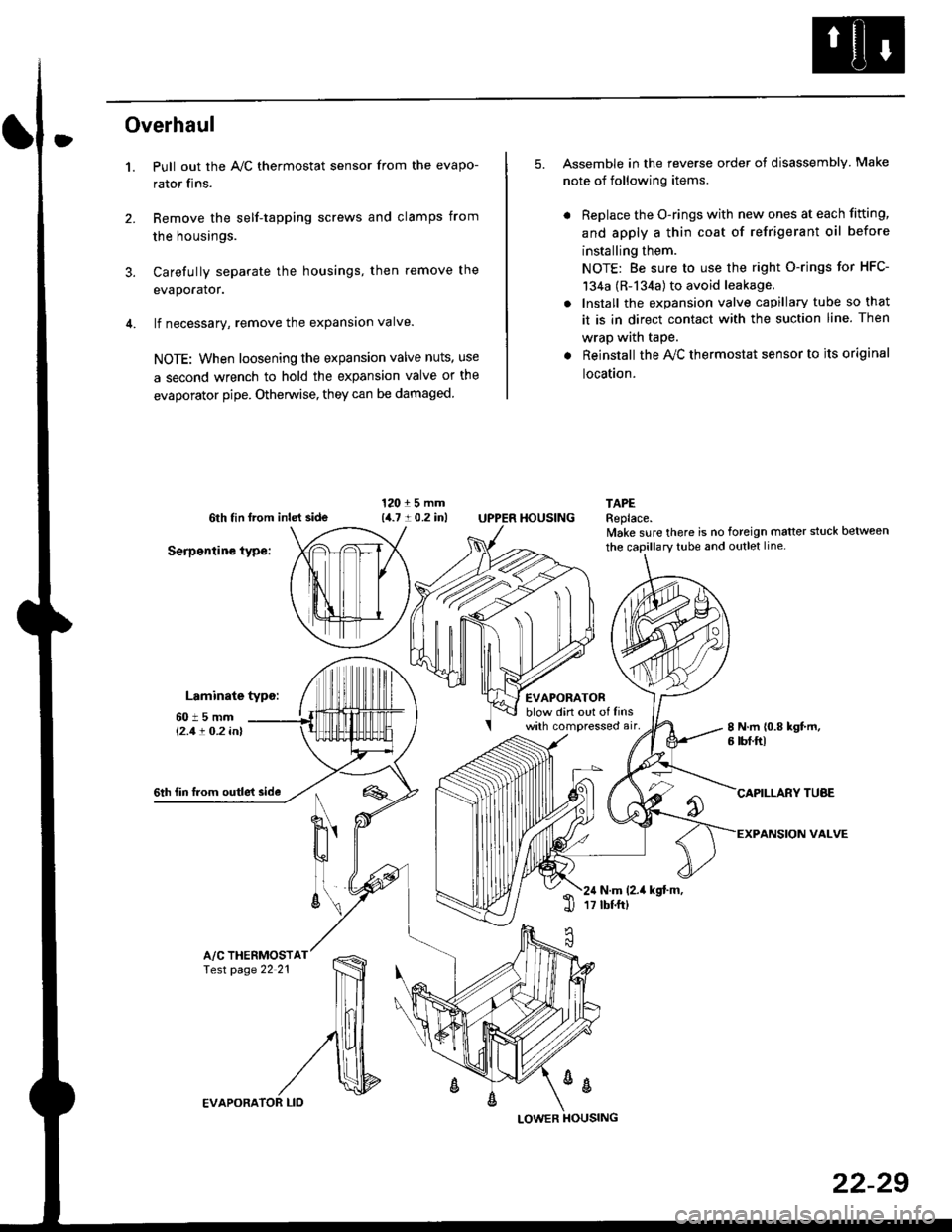

Overhaul

1.

3.

Pull out the A,/C thermostat sensor from the evapo-

rator fins.

Remove the self-tapping screws and clamps from

the housings.

Carefully separate the housings, then remove the

evaporator.

lf necessary, remove the expansion valve.

NOTE: When loosening the expansion valve nuts, use

a second wrench to hold the expansion valve or the

evaporator pipe. Otherwise, they can be damaged

5. Assemble in the reverse order of disassembly Make

note of following items.

. Replace the O-rings with new ones at each fitting,

and apply a thin coat of refrigerant oil before

installing them.

NOTE: Be sure to use the right O-rings for HFC-

134a (R-134a) to avoid leakage.

. Install the expansion valve capillary tube so that

it is in direct contact with the suction line. Then

wrap wath taPe.

. Reinstall the Ay'C thermostat sensor to its original

location.

6th tin lrom inld side

Serpentine type:

Laminate typo:

TAPEReplace.lvake sure there is no foreign matter stuck between

60t5mml'2.1! O.2 inl

EVAPORATORblow din out of linswith compressed air,

HOUSING

8 N.m 10.8 kgt m,6 tbf.ftl

6th fin lrom outle't sideCAPILLARY TUAE

VALVEN

u'

ll

6\N.m (2.it kgt.m,17 tbtftl1l

A/C THERMOSTfesr page 22 21

%

EVAPORA

LOWER

22-29

Page 1455 of 2189

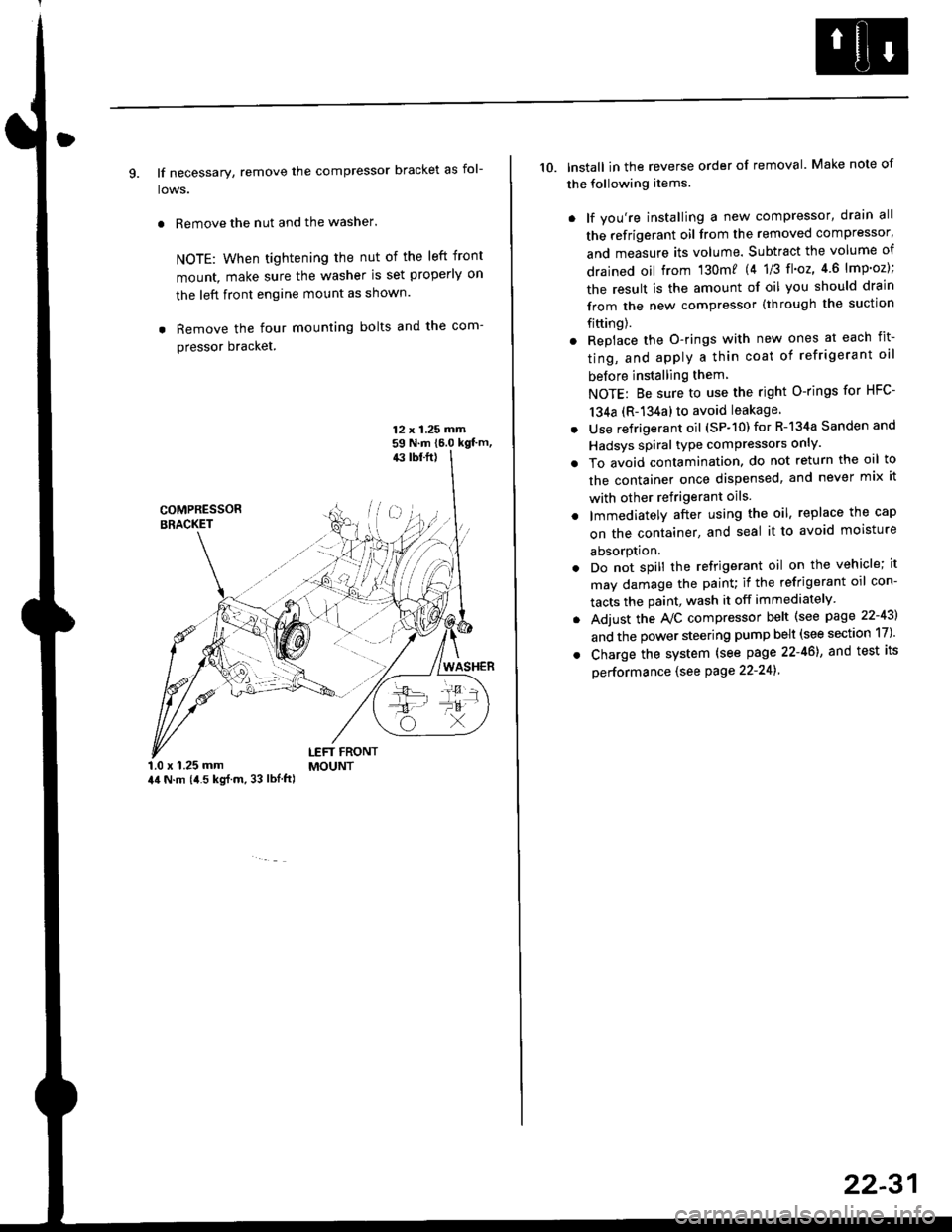

9. lf necessary, remove the compressor bracket as fol-

lows.

. Remove the nut and the washer.

NOTE: When tightening the nut of the left front

mount, make sure the washer is set properly on

the left front engine mount as shown.

. Remove the four mounting bolts and the com-

pressor bracket.

12 x 1.25 rrirn59 N.m 16.0 kgt'm,43 tbf.ft)

COMPRESSORBRACKET

WASHER

1.0 x 1.25 mm44 N.m (i1.5 kg{.m, 33 lbl.ft)

LEFT FRONTMOUNT

10. lnstall in the reverse order of removal. Make note of

the following items.

. lf you're installing a new compressor, drain all

the refrigerant oil from the removed compressor,

and measure its volume. Subtract the volume of

drained oil from '130m? 14 1/3 tl'o2,4 6 lmp'oz);

the result is the amount of oil you should drain

from the new compressor (through the suction

fifting).

. Replace the O-rings with new ones at each fit-

ting, and apply a thin coat of refrigerant oil

before installing them

NOTE: Be sure to use the right O-rings for HFC-

134a (R-134a) to avoid leakage

. Use refrigerant oil (SP-10) for R-134a Sanden and

Hadsys spiral type compressors only'

o To avoid contamination, do not return the oil to

the container once dispensed, and never mix it

with other refrigerant oils.

. lmmediatelY after using the oil, replace the cap

on the container, and seal it to avoid moisture

absorption.

. Do not spill the refrigerant oil on the vehicle; it

may damage the painu if the refrigerant oil con-

tacts the paint, wash it off immediately

. Adjust the Ay'C compressor belt (see page 22-43)

and the power steering pump belt (see section 17)'

. Charge the system (see page 22-46), and test its

oerformance (see Page 22-241

22-31

Page 1462 of 2189

Compressor (DENSOI

Replacement (cont'd)

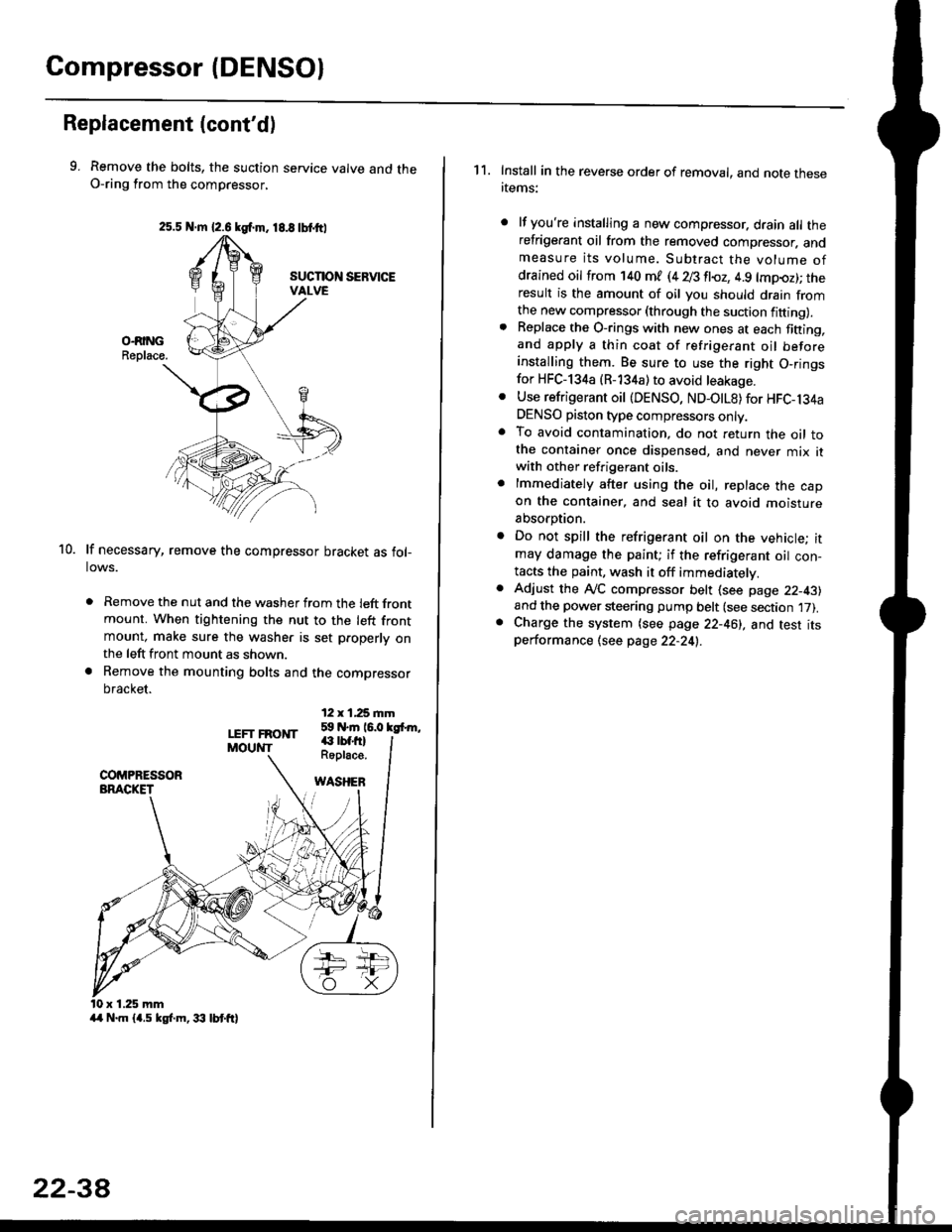

9. Remove the bolts, the suction service valve and theO-ring from the compressor,

lf necessary, remove the compressor bracket as fol-lows.

. Remove the nut and the washer from the left frontmount. When tightening the nut to the left frontmount, make sure the washer is set p.operly onthe left front mount as shown.

a Remove the mounting bolts and the compressor

bracket.

12 x 1,25 rnm59 N.m 16.0 kgfrm,

10.

LEFT FRONTMOUNT€ rbf.fi)Roplace.

WASHEB

x 1.25 mm

2s.5 N.m {2.6 kgf.m. 18.8 tbtttl

4/r N.m {4.5 kgf.m, 33 lbt ft}

22-3A

1 1. Install in the reverse order of removal, and note thesertems:

lf you're installing a new compressor. drain all therefrigerant oil from the removed compressor. andmeasure its volume. Subtract the volume ofdrained oil from '140 ml (4 28 fl{,z, 4.9 lmpoz); theresult is the amount of oil you should drain fromthe new compressor (through the suction fifting).Replace the O-rings with new ones at each fining,and apply a thin coat of refrigerant oil beforeinstalling them. Be sure to use the right O,ringsfor HFC-134a (R-134a) to avoid leakage.

Use refrigerant oil {DENSO, ND-OtL8) for HFC-134aDENSO piston type compressors only.To avoid contamination, do not return the oil tothe container once dispensed, and never mix itwith other refrigerant oils.

lmmediately after using the oil, replace the capon the container, and seal it to avoid moisture

absorption.

Do not spill the refrigerant oil on the vehicle; itmay damage the paint; if the refrigerant oil con-tacts the paint, wash it off immediatelv.

Adjust the ly'C compressor belt (see page 22-43)and the power steering pump belt (see section 17).Charge the system (see page 22-46), and test itsperformance (see page 22-24!..