main fi HONDA CIVIC 1998 6.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CIVIC, Model: HONDA CIVIC 1998 6.GPages: 2189, PDF Size: 69.39 MB

Page 809 of 2189

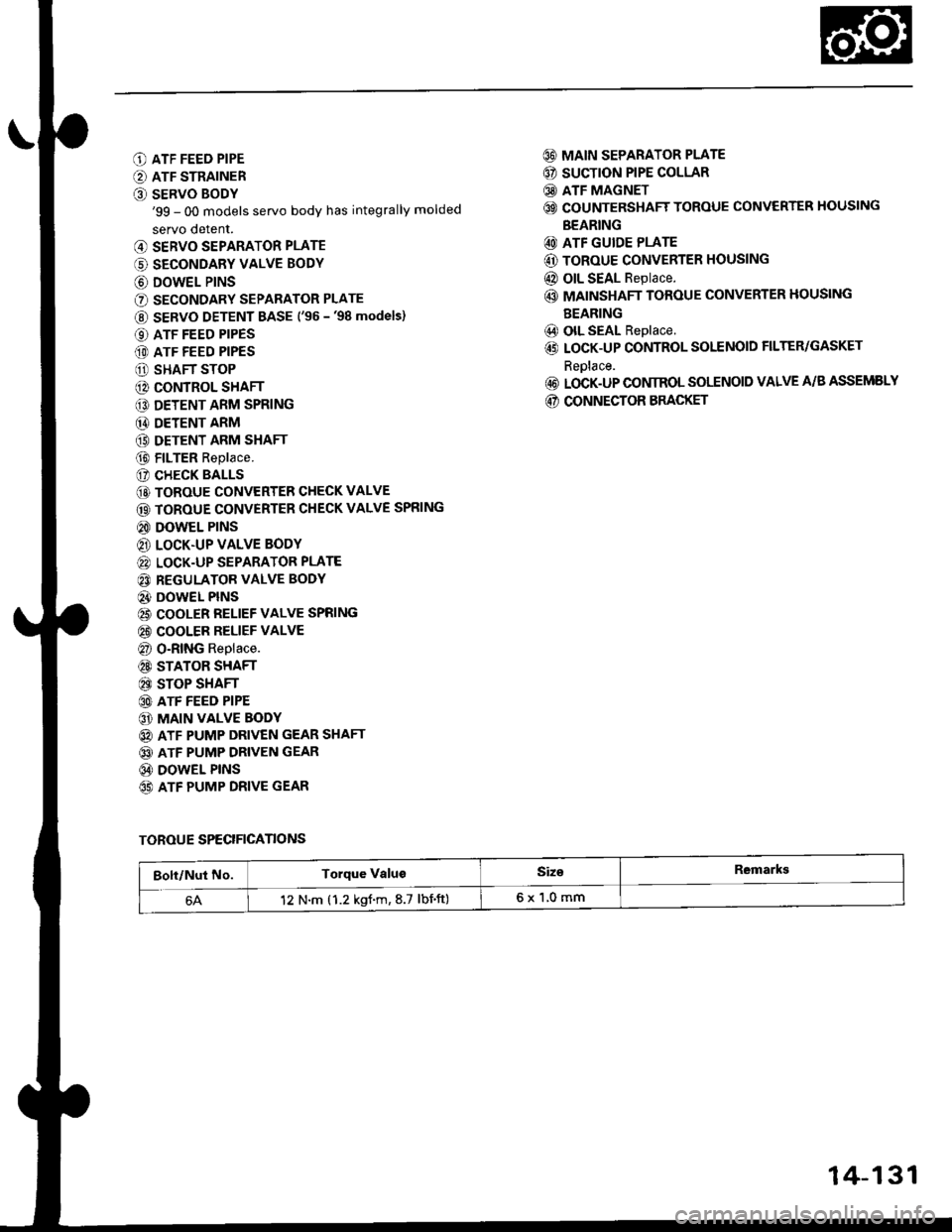

O ATF FEED PIPE

O ATF STRAINER

O SERVO BODY'99 - 00 models servo body has integrally molded

servo detent.

@ SERVO SEPARATOR PLATE

(' SECONDARY VALVE BODY

@ DOWEL P|NS

O SECONDARY SEPARATOR PLATE

@ SERVO DETENT BASE ('�96 -'98 models)

O ATF FEED PIPES

(D ATF FEED PIPES

O SHAFT STOP

@ CONTROL SHAFT

€D DETENT ARM SPRING

@ DETENT ARM

(9 DETENT ARM SHAFT

@ FILTER Replace.

(? CHECK BALLS

@ TOROUE CONVERTER CHECK VALVE

@ TOROUE CONVERTER CHECK VALVE SPRING

@ DOWEL PINS

@ LOCK.UP VALVE BODY

@ LOCK-UP SEPARATOR PLATE

@ REGULATOR VALVE BODY

@} DOWEL PINS

@ COOLER RELIEF VALVE SPRING

@ COOLER RELIEF VALVE

@ O-RING Replace.

@ STATOR SHAFT

@ STOP SHAFT

@ ATF FEED PIPE

@ MAIN VALVE BODY

@ ATF PUMP DRIVEN GEAR SHAFT

@ ATF PUMP DRIVEN GEAR

@ DOWEL PINS

65) ATF PUMP DRIVE GEAR

@ MAIN SEPARATOR PLATE

@ SUCTION PIPE COLLAR

@ ATF MAGNET

@ COUNTERSHAFT TOROUE CONVERTER HOUSING

BEARING

@ ATF GUIDE PLATE

@ ToRoUE CONVERTER HOUSING

@ OIL SEAL Replace.

@ MAINSHAFT TOROUE CONVERTER HOUSING

BEARING

@) olL SEAL Replace.

@ LOCK-UP CONTROL SOLENOID FILTER/GASKET

Reolace.

@ LOCK-UP CONIROL SOLENOID VALVE A/B ASSEMELY

@ CONNECTOR BRACKET

TOROUE SPECIFICANONS

Bolt/Nut No.Torque ValugSiz€Remarkg

12 N.m (1.2 kgf.m,8.7 lbnft)6x1,0mm

14-131

Page 810 of 2189

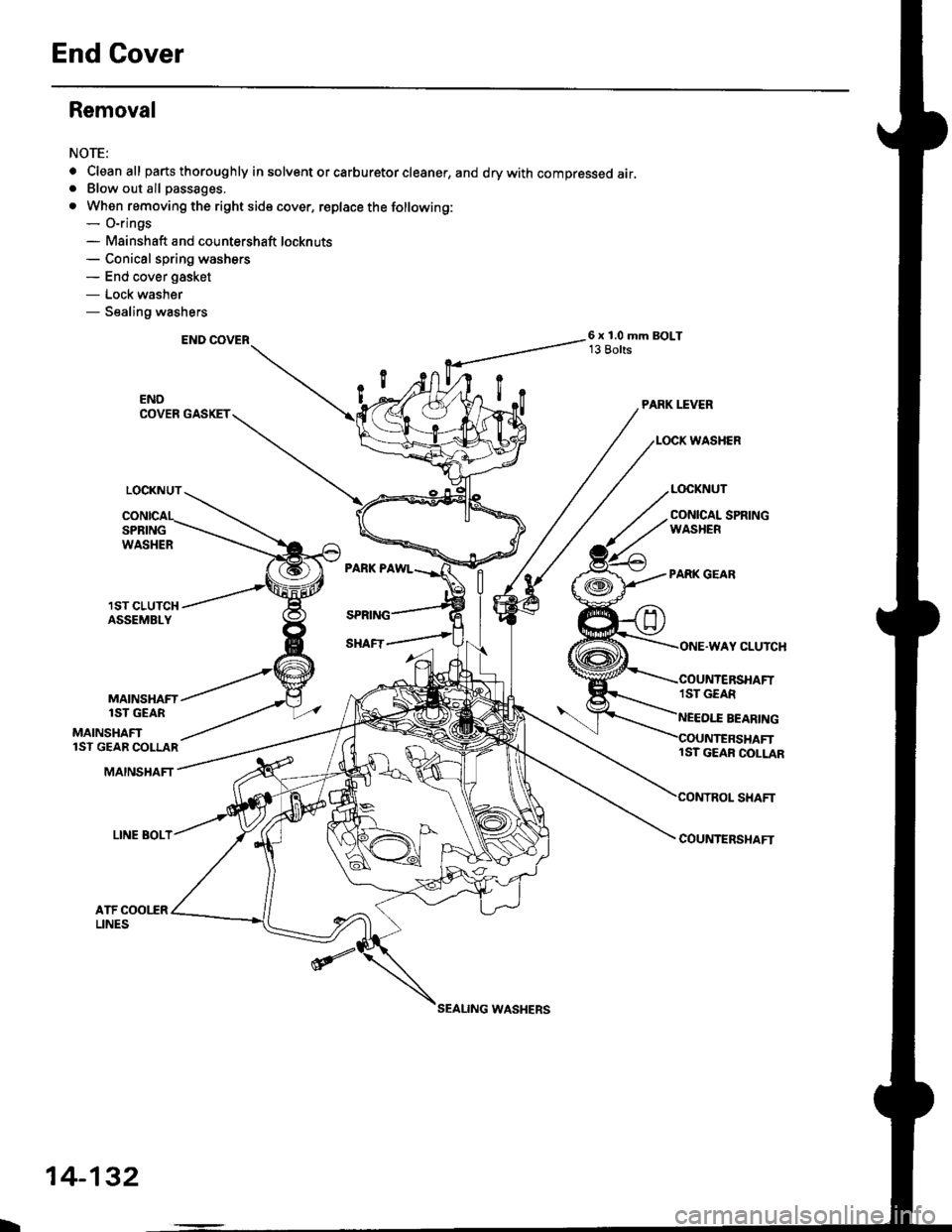

End Cover

Removal

NOTE:

. Cleanall parts thoroughly in solvent or carburetor cleaner, and drywith compressed air,. Blow out all passages,

. When removing the right side cover, replace the following:- O-rings- Mainshaft and countershaft locknuts- Conical spring washgrs- End cover gasket

- Lock washer- Sealing washers

END COVER6 x 1.0 mm BOLT13 Bolts

PARK PAWL

PARK ITVER

LOCK WASHER

COUI{TERSI{AFTLINE AOLT

tST GEAF COLLAR

I

14-132

SEALING WASHERS

Page 811 of 2189

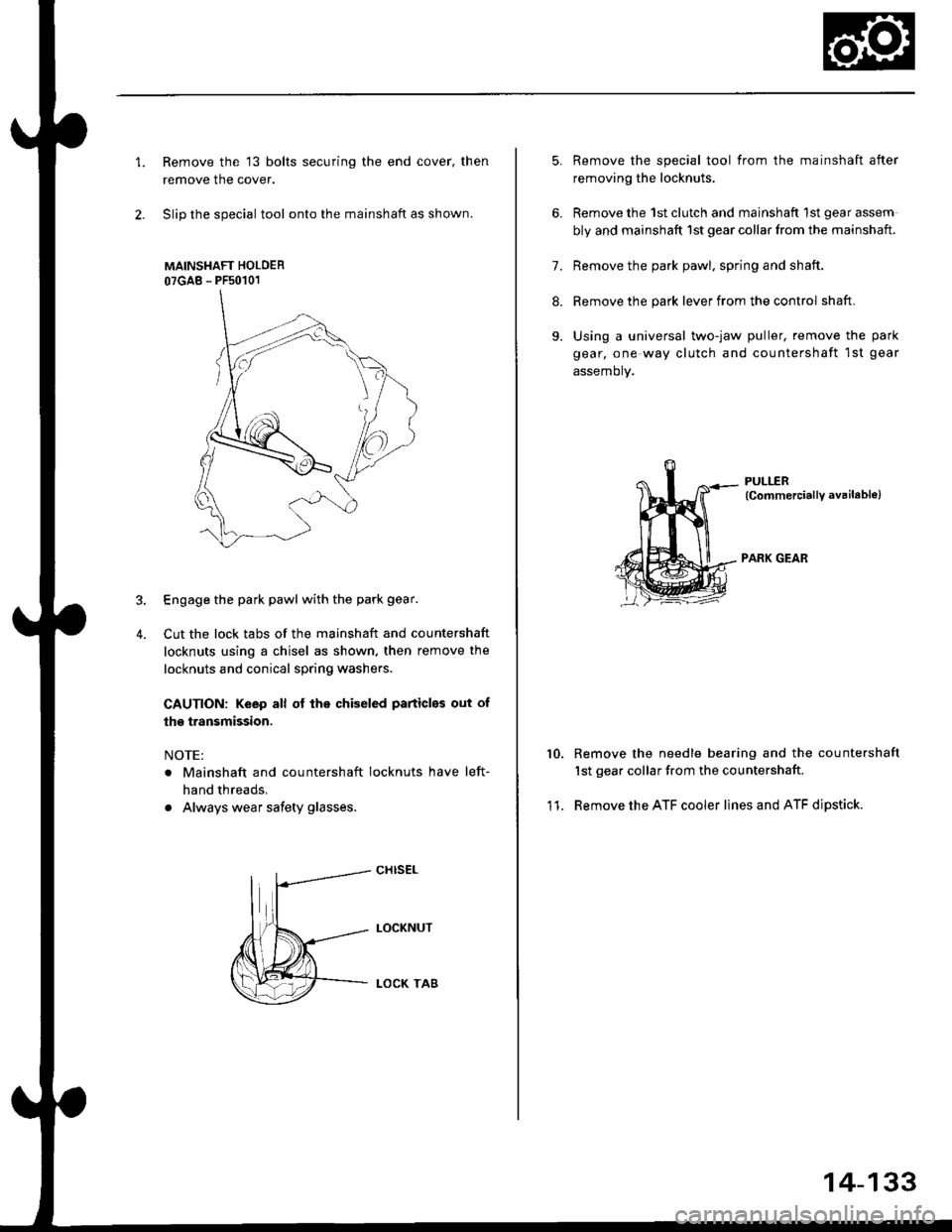

1.Remove the 13 bolts securing the end cover, then

remove the cover.

Slip the special tool onto the mainshaft as shown.

MAINSHAFT HOLOER

07GAB - PFs0101

Engage the park pawl with the park gear.

Cut the lock tabs of the mainshaft and countershaft

locknuts using a chisel as shown. then remove the

locknuts and conical spring washers

CAUTION: Keep all of lhe chiseled particles out of

the transmission.

NOTE:

. Mainshaft and countershaft locknuts have left-

hand threads.

. Always wear safety glasses.

4.

cHrs€L

LOCKNUT

LOCK TA8

5.

6.

11.

Remove the special tool from the mainshaft after

removing the locknuts.

Remove the 1st clutch and mainshaft 1st gear assem

bly and mainshaft 1st gear collar from the mainshaft.

7. Remove the park pawl. spring and shaft.

8. Remove the park lever from the control shaft.

9. Using a universal two-jaw puller, remove the park

gear, one way clutch and countershaft 1st gear

assemory.

PULLER(CommerciallY available)

PARK GEAR

10.Remove the needle bearing and the countershaft

1st gear collar from the countershaft

Remove the ATF cooler lines and ATF dipstick.

14-133

Page 812 of 2189

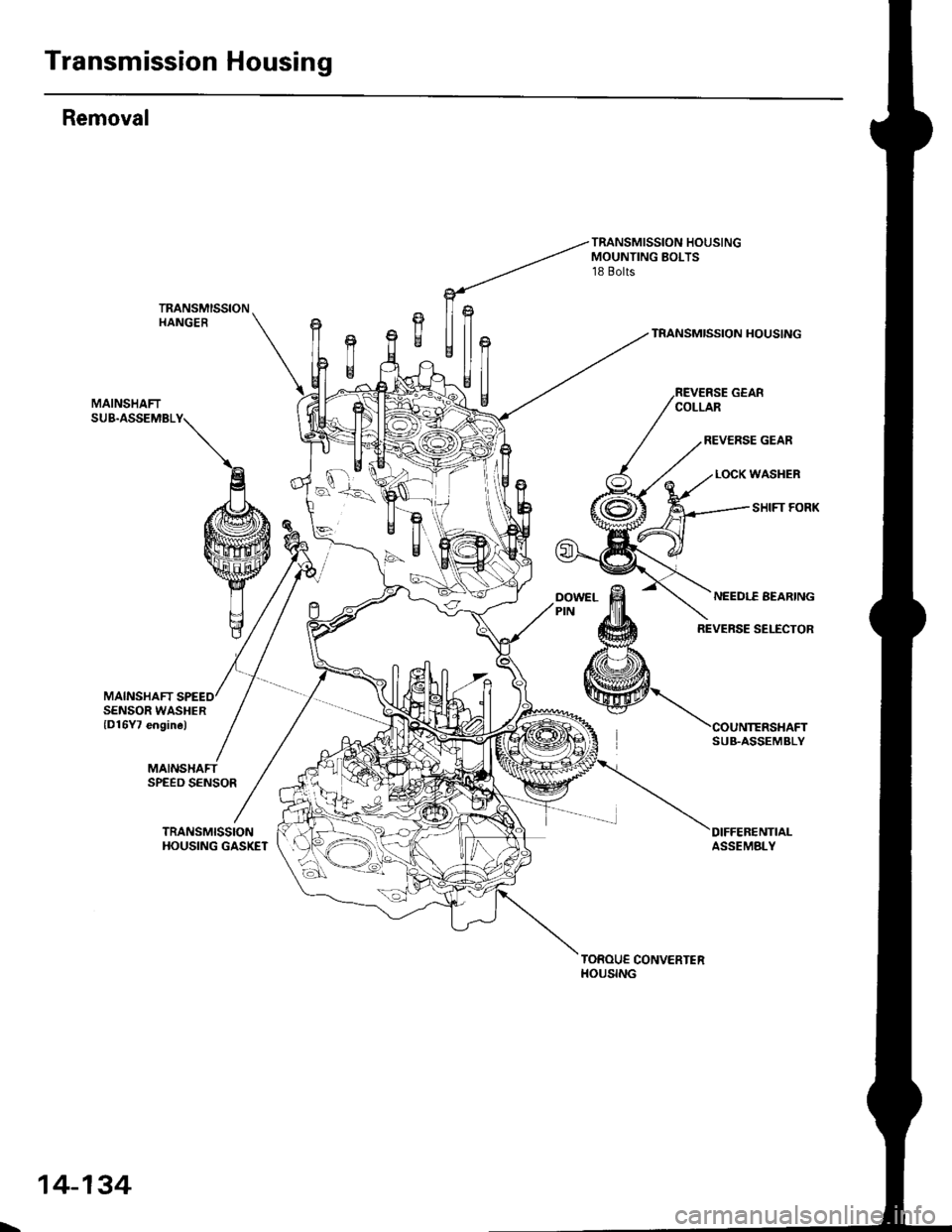

Transmission Housing

Removal

MAINSHAFT

TRANSMISSION HOUSINGMOUNTING BOLTS18 Bolts

TRANSMISSIONHANGERTRANSMISSION HOUSING

MAINSHAFTSUB.ASSEMBLY

SENSOR WASHERlD16Y7 engine)

MAINSHAFTSPEED SENSOR

TRANSMISSIONHOUSING GASKETDIFFEBENTIALASSEMBLY

TOROUE CONVERTERHOUSING

SUB.ASSEMBLY

L,

14-134

Page 814 of 2189

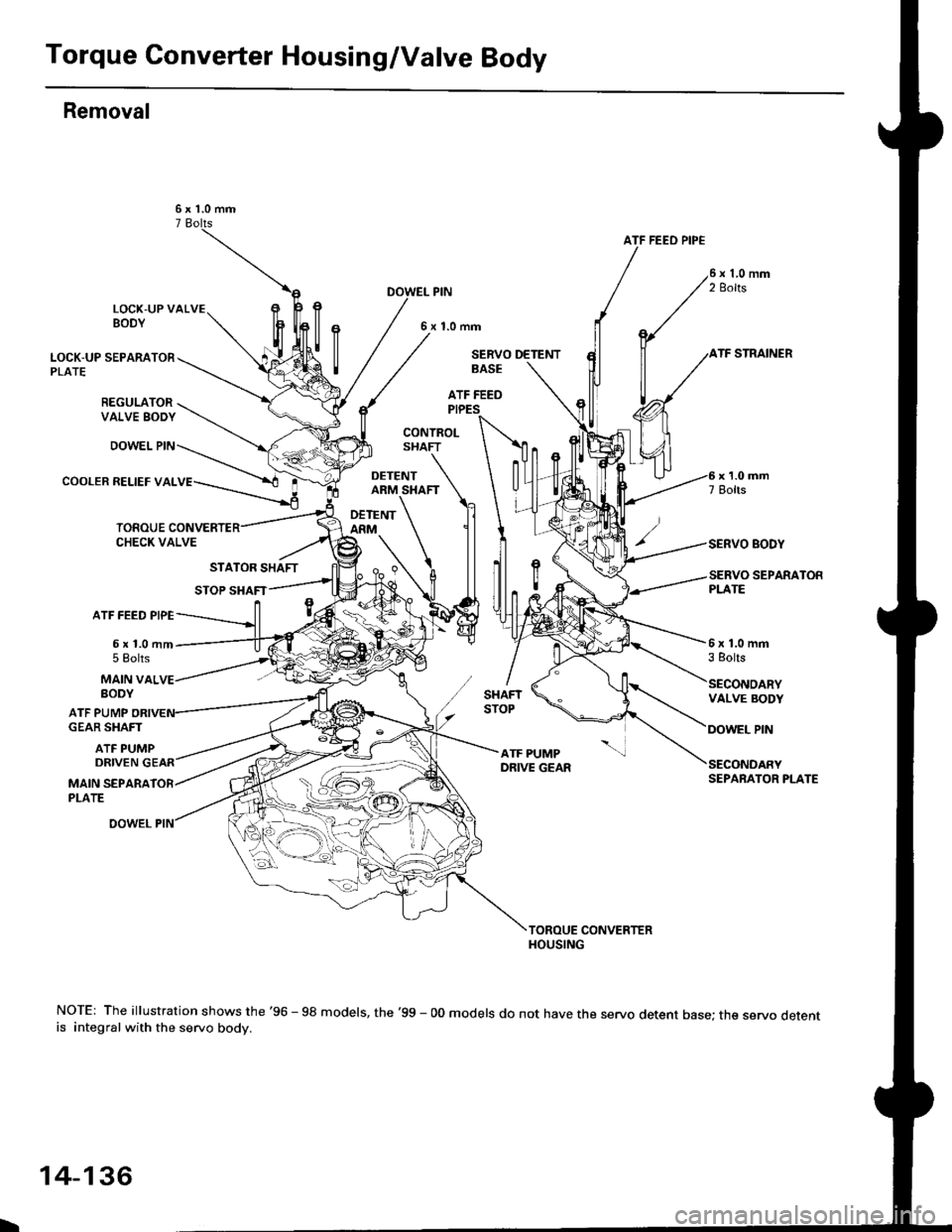

Torque Converter Housing/Valve Body

Removal

ATF FEEO PIP€

LOCK-UP VALVEBODY

PIN

6x1.0mm

LOCK-UP SEPARATORPLATE

REGULATORVALVE SODY

DOWEL PIN

COOLER RELIEF VAL

SERVO DETENTSTRAINER

SERVO EODY

SEPARATON

BASE

ATF FEEDPIPES

CONTROLSHAFT

DETENTARM SHAFT

DETENTARM

ATF FEED PIPE

6x1.0mm5 Eolts6x1.0mm3 Eolts

MAIN VALBODY

ATF PUMP

DRIVEN

VALVE BODY

PINGEAR SHAFT

ATF PUMP

MAIN SEPARAPLATE

SECONDARYSEPARATOR PLATE

NOTE: The illustration shows the '96 - 98 models, the '99 - 00 models do not have the servo detent base; the servo detentis integral with the servo body.

L

14-136

Page 815 of 2189

NOTE;

. Clean all parts thoroughly in solvent or carburetor

cleaner, and dry with compressed air.

. Blow out all passages.

. When removing the valve body, replace the O-ring.

l, Remove the ATF feed pipes from the servo body,

secondary valve body and main valve body.

For'96 - 98 models: Remove the ATF strainer and

servo detent base (two bolts).

For'99 - 00 models: Remove the ATF strainer (one

bolt).

Remove the servo body and servo separator plate

{'96 - 98 models: seven bolts,'99 - 00 models: eight

bolts).

Remove the secondary valve body, shaft stop and

secondary separator plate (three bolts).

Remove the lock-up valve body and separator plate

{seven bolts).

Remove the regulator valve body (one boltl.

Remove the stator shaft and stop shaft.

Remove the detent spring from the detent arm. then

remove the control shaft from the to.que converter

housing.

Remove the detent arm and detent arm shaft from

the main valve body.

Remove the main valve body (five bolts).

NOTE: Do not let the eight check balls fall outofthe

main valve body when removing the main valve

body.

Remove the ATF pump driven gear shaft, then remove

the ATF pump gears.

Remove the main separator plate and two dowel

pins.

7.

't'1.

10.

12.

14.

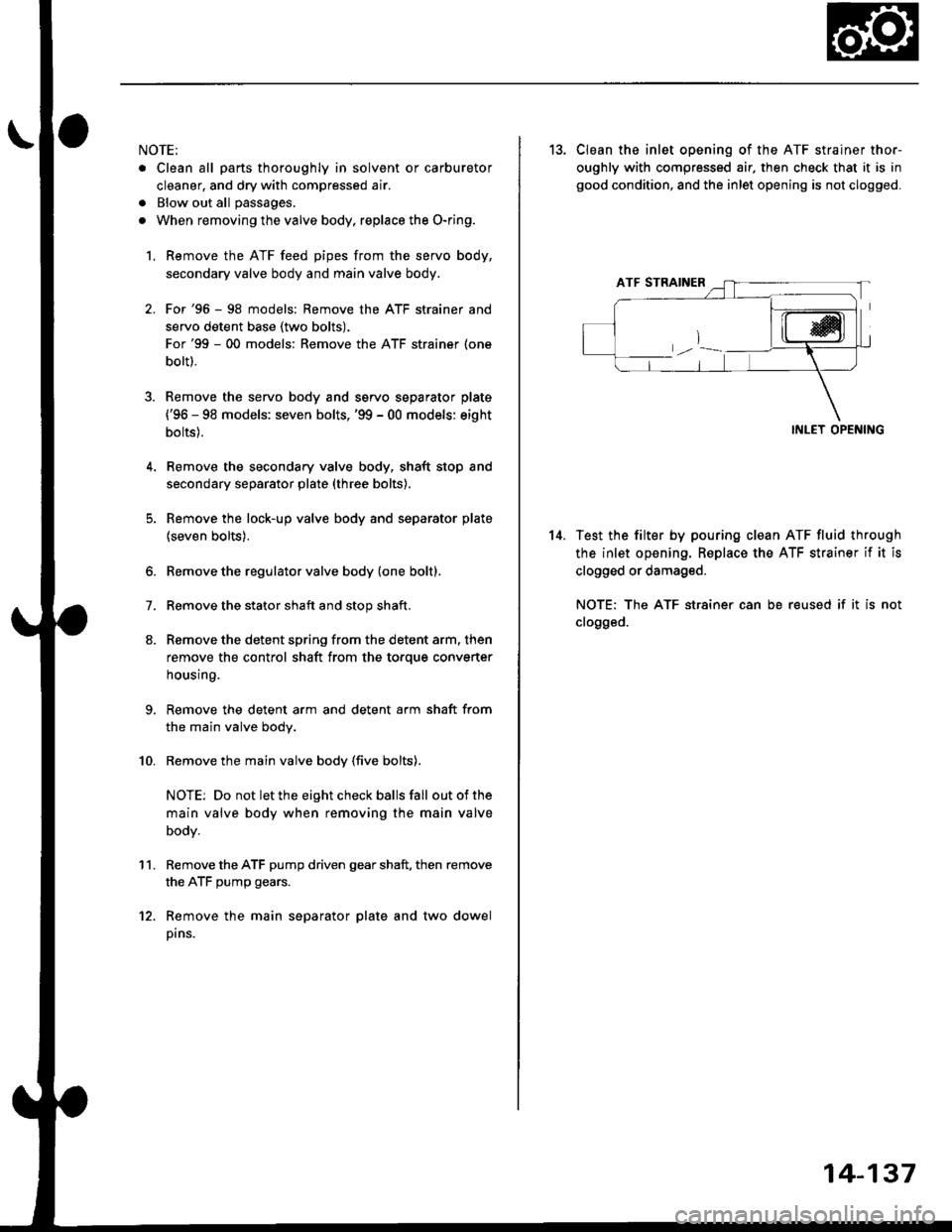

13. CIean the inlet opening of the ATF strainer thor-

oughly with compressed air. then check that it is in

good condition, and the inlet opening is not clogged.

INLET OPENING

Test the filter by pouring clean ATF fluid through

the inlet opening. Beplace the ATF strainer if it is

clogged or damaged.

NOTE: The ATF str8iner can be reused if it is not

clogged.

14-137

Page 819 of 2189

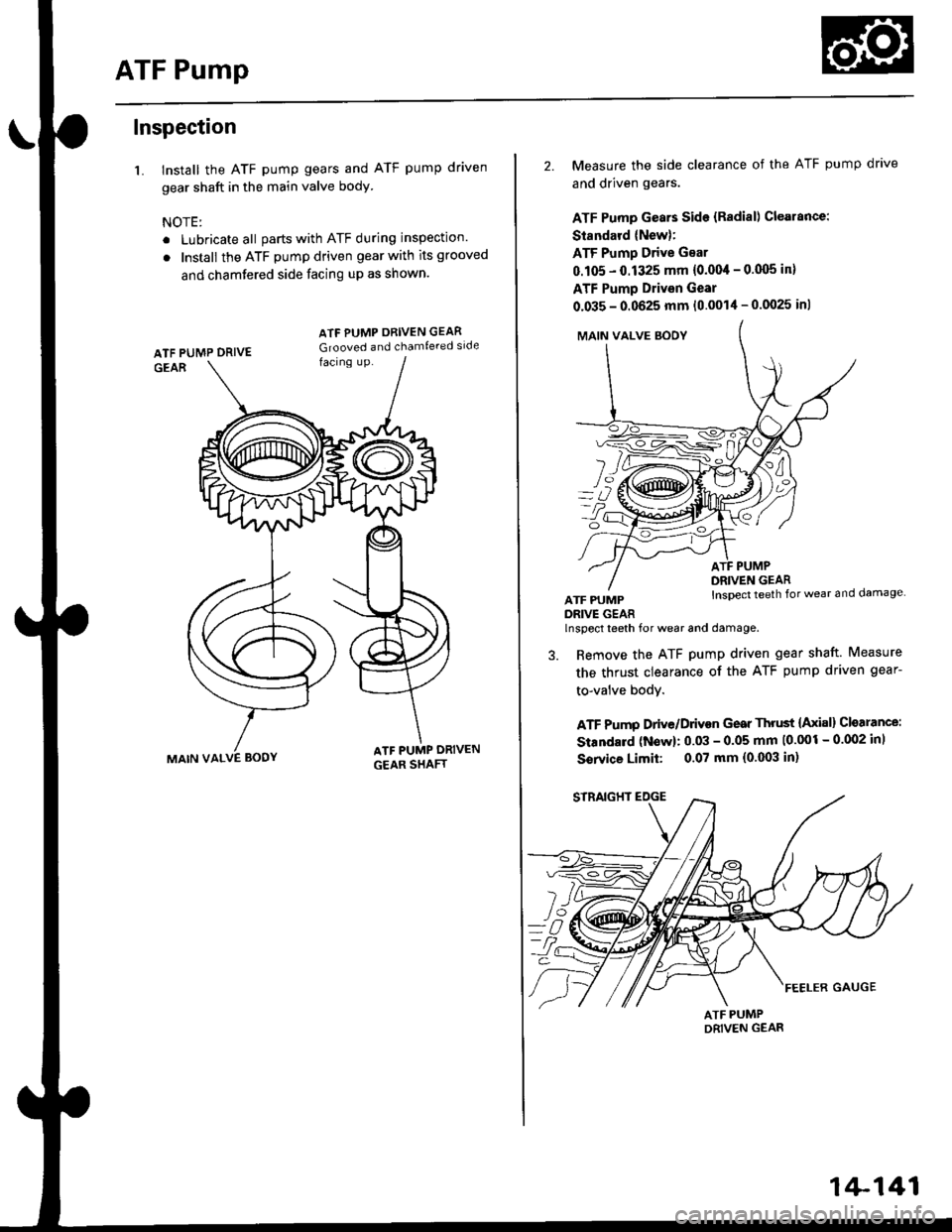

ATF Pump

Inspection

1. Install the ATF pump gears and ATF pump driven

gear shaft in the main valve body

NOTE:

. Lubricate all parts with ATF during inspection.

. Install the ATF pump driven gear with its grooved

and chamfered side facing up as shown.

MAIN VALVE BODY

ATF PUMP ORIVEN GEAR

Grooved and chamfe.ed side

2. Measure the side clearance of the ATF pump drave

and driven gears.

ATF Pump Gears Side {Radial) Clearance:

Standard (New):

ATF Pump Drive Gear

0.105 - 0.1325 mm {0.004 - 0.q)5 in}

ATF Pump Drivsn Gear

0.035 - 0.0625 mm (0.0014 - 0.0025 inl

MAIN VALVE SOOY

YZ]

o?

ATF PUMPDRIVE GEAR

ATF PUMPDRIVEN GEARInspect teeth for wear and damage

lnspect teeth for wear and damage.

3. Remove the ATF pump driven gear shaft. Measure

the thrust clearance of the ATF pump driven gear-

to-valve bodY.

ATF Pump Drive/Drivon Gear Thrust {Axial} Cloarance:

Standard (Now): 0.03 - 0.05 mm 10'001 - 0.002 inl

Sorvice Limit: 0.07 mm (0.003 in)

1+141

Page 820 of 2189

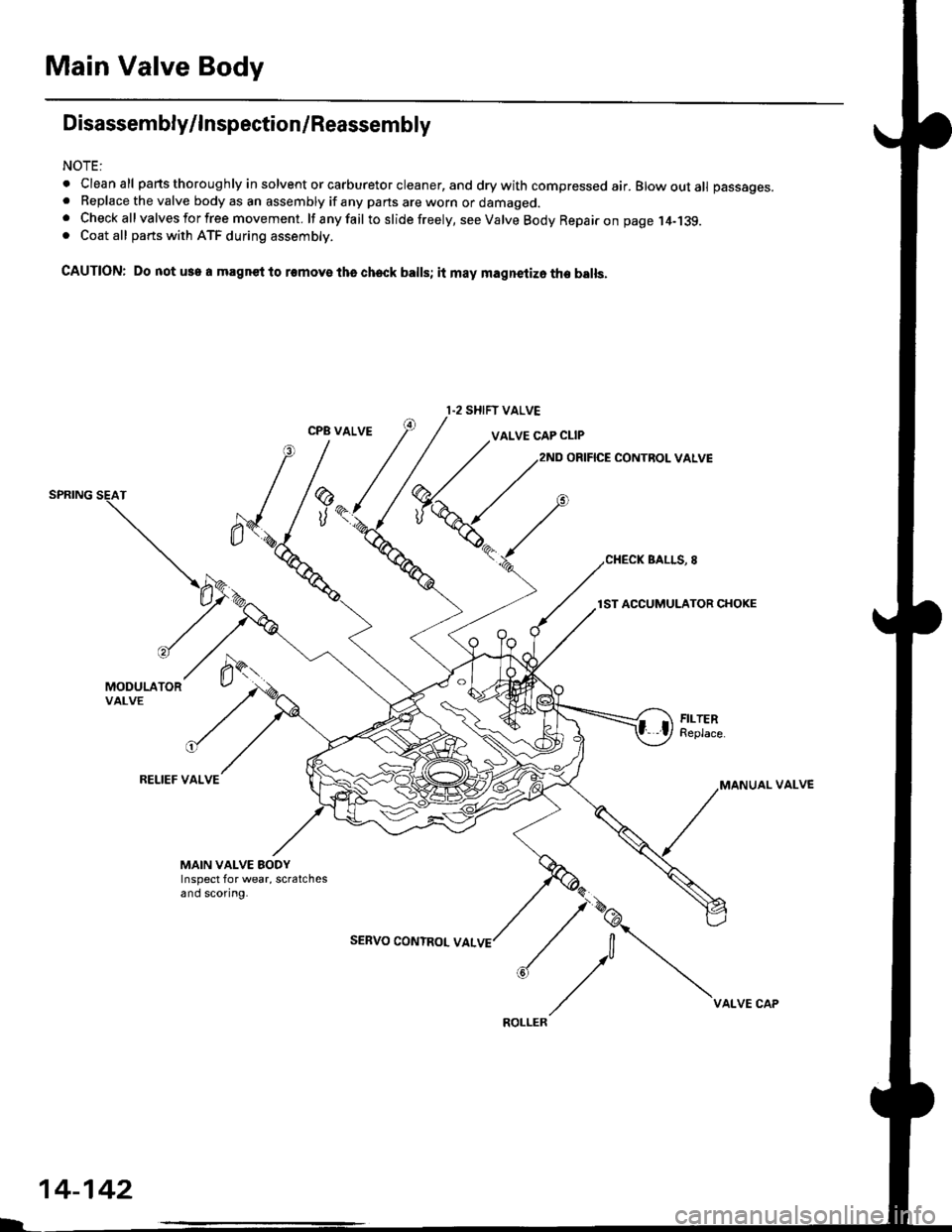

Main Valve Body

Disassembly/lnspection/Reassembly

NOTE:

. Cleanall parts thoroughly in solvent or carburetor cleaner, and drywith compressed air. Blowoutall passages.. Replace the valve body as an assembly if any pans are worn or damaged.. Check all valves for free movement. lf anyfail toslidefreely, see Valve Body Repairon page,l4-139.. Coat all parts with ATF during assembly.

CAUTION: Do not use a magnet to removs tha check balls; it may magnetizo the balls.

CPB VALVEVALVE CAP CLIP

ORIFICE CONTROL VALVE

BALLS, 8

lST ACCUMULATOR CHOKE

MODULATORVALVE

RELIEF VALVEVALVE

MAIN VALVE EODYInspect for wear, scratchesand scoring.

SEBVO CONTROL VAL

I.2 SHIFT VALVE

14-142

VALVE CAP

Page 821 of 2189

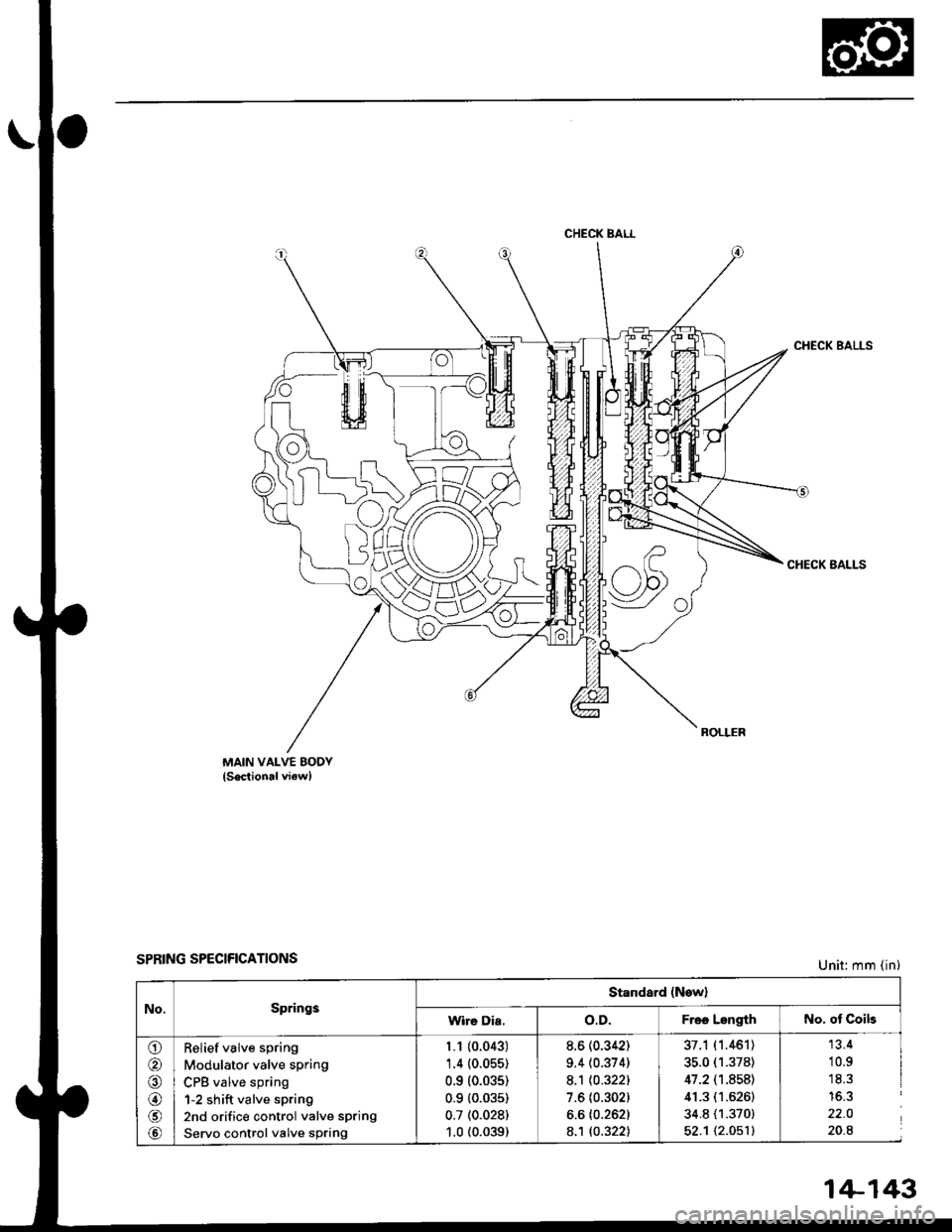

CHECK BALL

w

MAIN VALVE BODY(Sectional viewl

SPRING SPECIFICATIONS

CHECK BALLS

CHECK BALLS

Unit: mm (in)

No.Springs

Standard (New)

Wire Dia.o.D.Free LengthNo. ot Coils

o

@

@

@

@

@

Relief valve spring

Modulator valve spring

CPB valve spring

1-2 shift valve spring

2nd orifice control valve spring

Servo control valve spring

1.1 (0.043)'1.4 (0.055)

0.9 (0.035)

0.9 (0.035)

0.7 (0.028)

1.0 (0.039)

8.6 (0.342)

9.4 (0.374)

8.1 t0.3221

7.6 {0.302)

6.6 (0.262)

8.'t to.322l

37.1 (1.461)

35.0 (1.378)

47.2 (1.8s8)

41.3 (1.6261

34.8 (1.370)

52.1 t2.O51l

13.4

10.91C ?'15.3

22.0

20.8

1+143

Page 826 of 2189

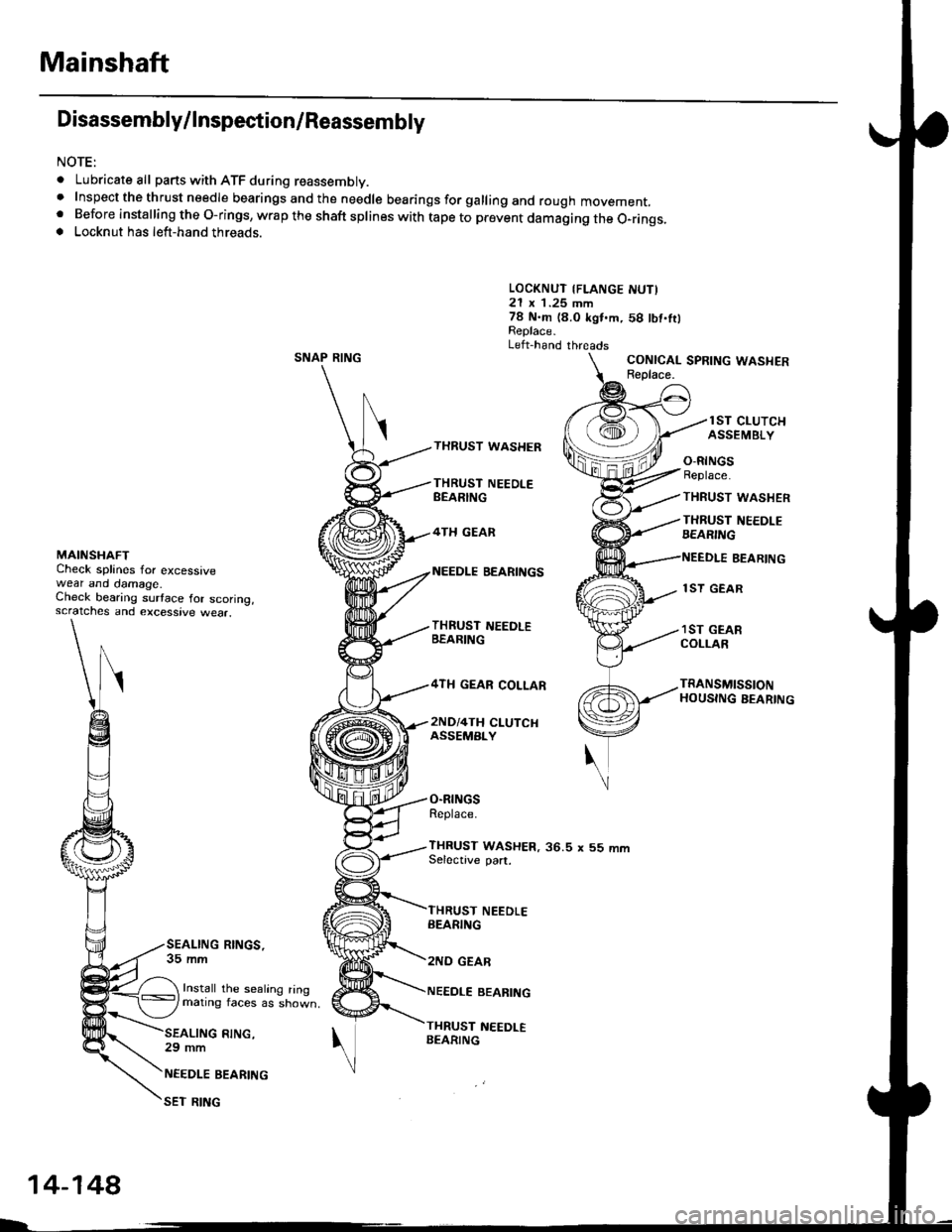

Mainshaft

Disassembly/lnspestion/Reassembly

NOTE:

. Lubricate all parts with ATF during reassembly..Inspectthethrustneedlebearingsandtheneedlebearingsforgallingandroughmovement,

. Before installing the O-rings, wrap the shaft splines with tape to prevent damaging the O_rings.. Locknut has left-hand threads.

LOCKNUT {FLANGE NUTI21 x 1.25 mm78 N.m (8.0 kgl.m,58 lbt.fttReplace.Left-hand threadsSNAP RINGCONICAL SPRING WASHERReolace.

lST CLUTCHASSEMBLYTHRUST WASHER

THRUST NEEOI.EBEARING

4TH GEAN

O-RINGSReplace.

THRUST WASHER

THRUST NEEDLEBEARING

MAINSHAFTCheck splines for excessivewear and oamage.Check bearing surtace for scoring,scratches and excessive wear.

BEARINGBEARINGS

THRUST NEEDLEBEABING

4TH GEAR COLLAR

2ND/4TH CLUTCHASSEMBLY

THRUST NEEDLEEEARING

2NO GEAB

NEEDLE BEABING

THRUST NEEDLEBEARING

1ST GEAR

1ST GEARCOLLAR

TRANSMISSIONHOUSING BEARING

O-RINGSReplace.

THRUST WASHER, 36.5 x 55 mmSelective part.

SEALING RINGS,35 mm

Install the sealing ringmating faces as shown,

RING,29 mm

NEEDLE BEARING

SET RING

14-148