Mount HONDA CIVIC 1998 6.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CIVIC, Model: HONDA CIVIC 1998 6.GPages: 2189, PDF Size: 69.39 MB

Page 1371 of 2189

Seat Belts

Child Seat Anchor Plate Removal/lnstallation

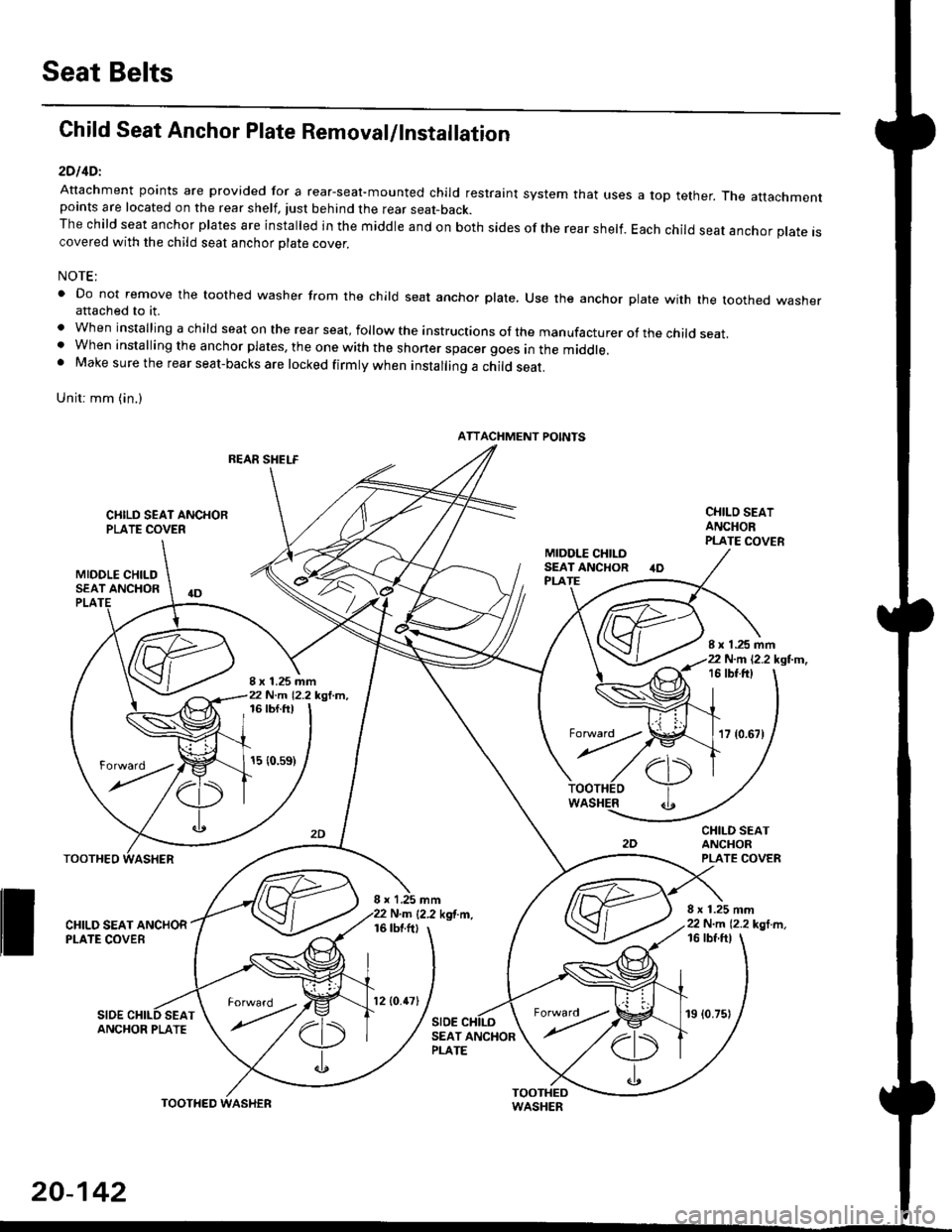

2DllDl

Attachment points are provided for a rear-seal-mounted child restraint system that usespoints are located on the rear shelf, tust behind the rear seat-back.The child seat anchor plates are installed in the middle and on both sides of the rear shelf.covered with the child seat anchor olate cover.

a top tether. The attachment

Each child seat anchor plate is

NOTE:

' Do not remove the toothed washer from the child seat anchor plate, Use the anchor plate with the toothed washerattached to it.

. When installing a child seat on the rear seat, follow the instructions of the manufacturer of the child seat.. When installing the anchor plates, the one with the shoner spacer goes in the middle.. Make sure the rear seat-backs are locked firmly when installing a child seat.

Unit: mm (in.)

REAR SHELF

CIIILD SEAT ANCHORPLATE COVER

MIDOLE CHILDSEAT ANCHOR

CHILO SEATANCHORPLATE COVER

CHILD SEATANCHORPLATE COVER

8 x 1.25 mm22 N.m 12.2 kgl m,

PLA

8 x 1.25 mm22 N.m 12.2 kgl.m,

I x 1.25 mm22 N.m 12.2 kgl.m,16 tbt.ftt

17 {0.67)

16 tbf.ft)

15 {0.s9)

WASHER

rl)

.t

TOOTHEO

ll ff*,".rd,',i"'"o*

SIDESEAT

I x 1,25 mmN.m {2.2 kgf.m.16 tbtftl

SIDE

16 tbf ftl

ANCHOR PLATESEAT ANCHORPLATE

ATTACHMENT POINTS

torward .

20-142

TOOTHED

12lO.47l19 (0.75)

Page 1372 of 2189

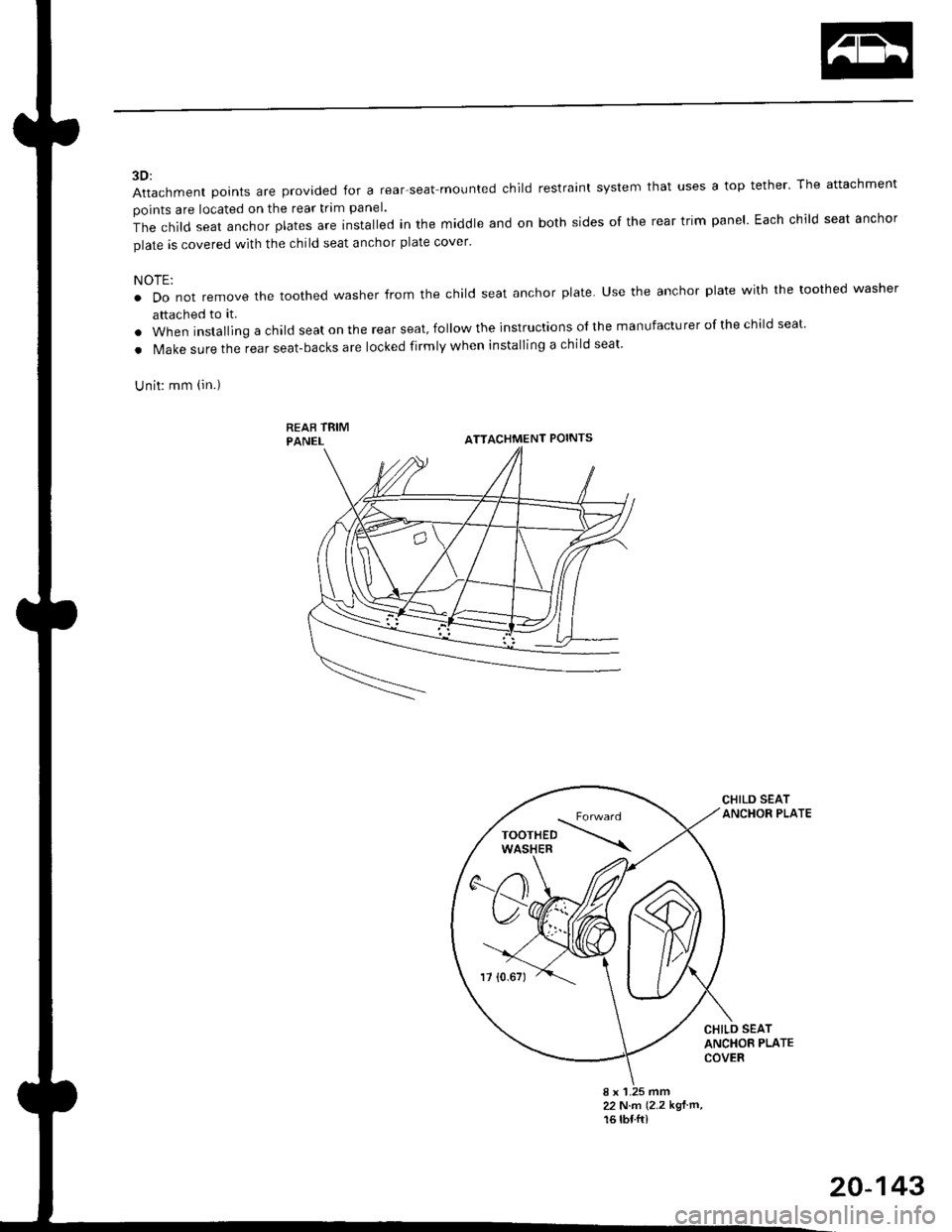

3D:

Attachment points are provided for a rear-seat mounted child restraint system that uses a top tether' The attachment

points are located on the rear trim panel.

The child seat anchor plates are rnstalled in the middle and on both sides of the rear trim panel Each child seat anchor

plale is covered with the child seat anchor plate cover'

NOTE:

. Do not remove the toothed washer from the child seat anchor plate. use the anchor plate with the toothed washer

attached to it.

. when installing a child seat on the rear seat, follow the instructions ol the manufacturer of the child seat'

. Make sure the rear seat-backs are locked firmly when installing a child seat'

gn;1 6rn (in.)

ATTACHMENT POINTS

CHILO SEATANCHOR PLATE

CHILD SEATANCHOB PLATECOVER

8 x 1.25 mm22 N..n (2.2 kgl'm.16 tbfft)

;x?',rff{-*.

20-143

Page 1411 of 2189

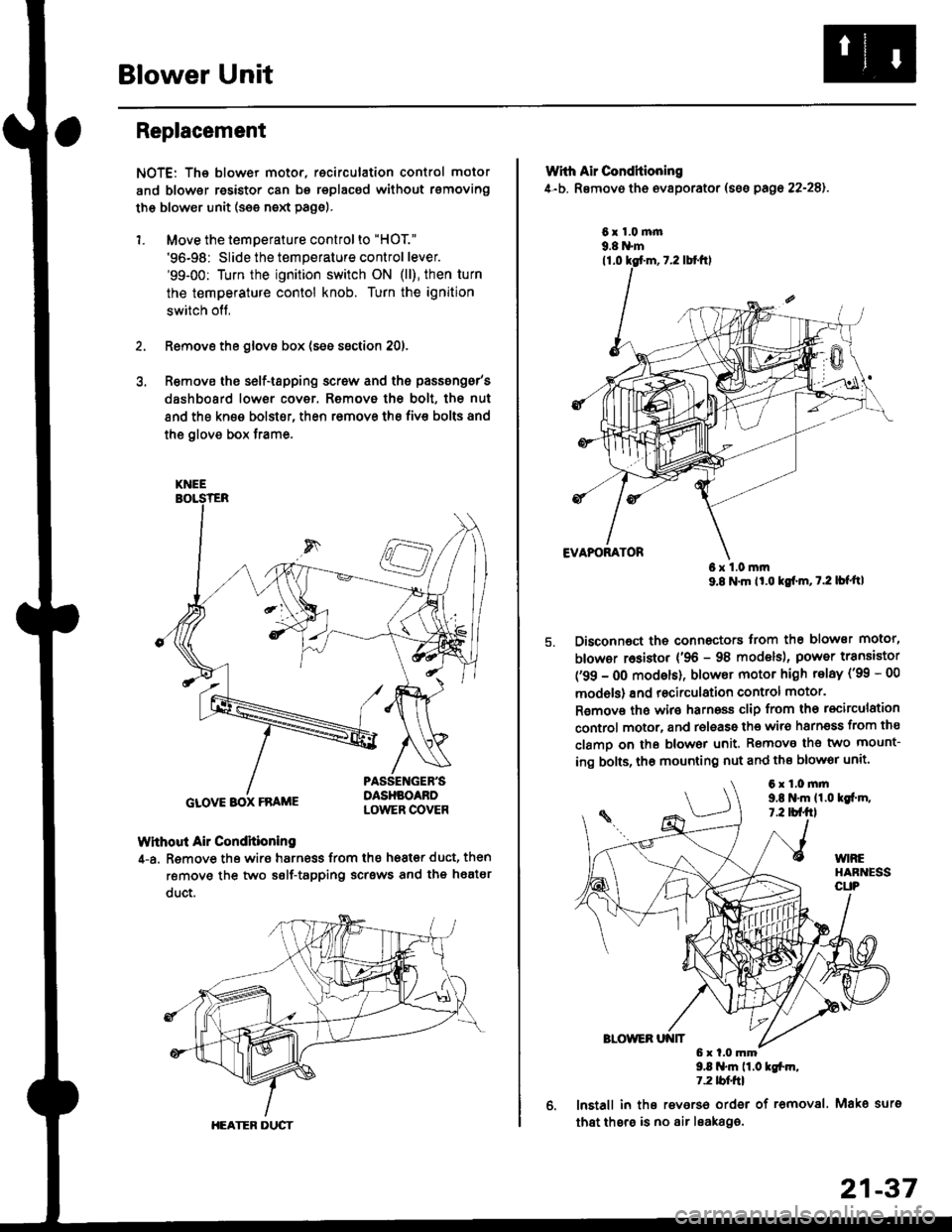

Blower Unit

Replacement

NOTE: The blower motor, recirculation control motor

and blower resistor can bs replacsd without rsmoving

th€ blower unit (see neld Page).

1. Move the temperature control to "HOT."

'96-98: Slide the temperature control lever.'99-00: Turn the ignition switch ON (ll), then turn

the temperature contol knob. Turn the ignition

switch off,

Remove the glovs box (ses ssction 20),

R€move ths s6lf-tapping screw and ths passsng6r's

dashboard low€r cover. Removo the bolt, the nut

and the kn€e bolst€r, then remove the fiv€ bolts and

the glove box trame,

Without Air Condhioning

4-a. Remove the wiro harness from the h68t€r duct, then

remove the two self-tapping scrsws and the heatsr

duct.

KNEE

GLOVE BOX FRAME

HEATER DUCT

21-37

Wrth Air Conditioning

4-b. Removo th6 ev8porator (sss pago 22-28).

6x1.0m|n9.8 N'm

6x1.0mm9.8 N'm lt'o tgf'm, t.2 lb{'ttl

Disconnoct the connectors trom th€ blower motor,

blowor r6sistor {'96 - 98 models), power transiator

('99 - 0O modsls), blowor motor high telay ('99 - 00

models) and recirculation control motor.

R€mov€ ths wiro harnoss clip from tho recirculation

control motor, and release the wir6 harnsss from ths

clamo on the blowor unit. Remove the two mount-

ing bolts, tho mounting nut and ths blowor unit'

9.8 .m 11.0 tgfm,1.2 tblfrl

lnstall in ths reverso order of removal. Mako surs

that thsre is no air leaka96.

6x1.0mm9,t N'm 11.0lgi.m,7.2 tbf.fil

Page 1413 of 2189

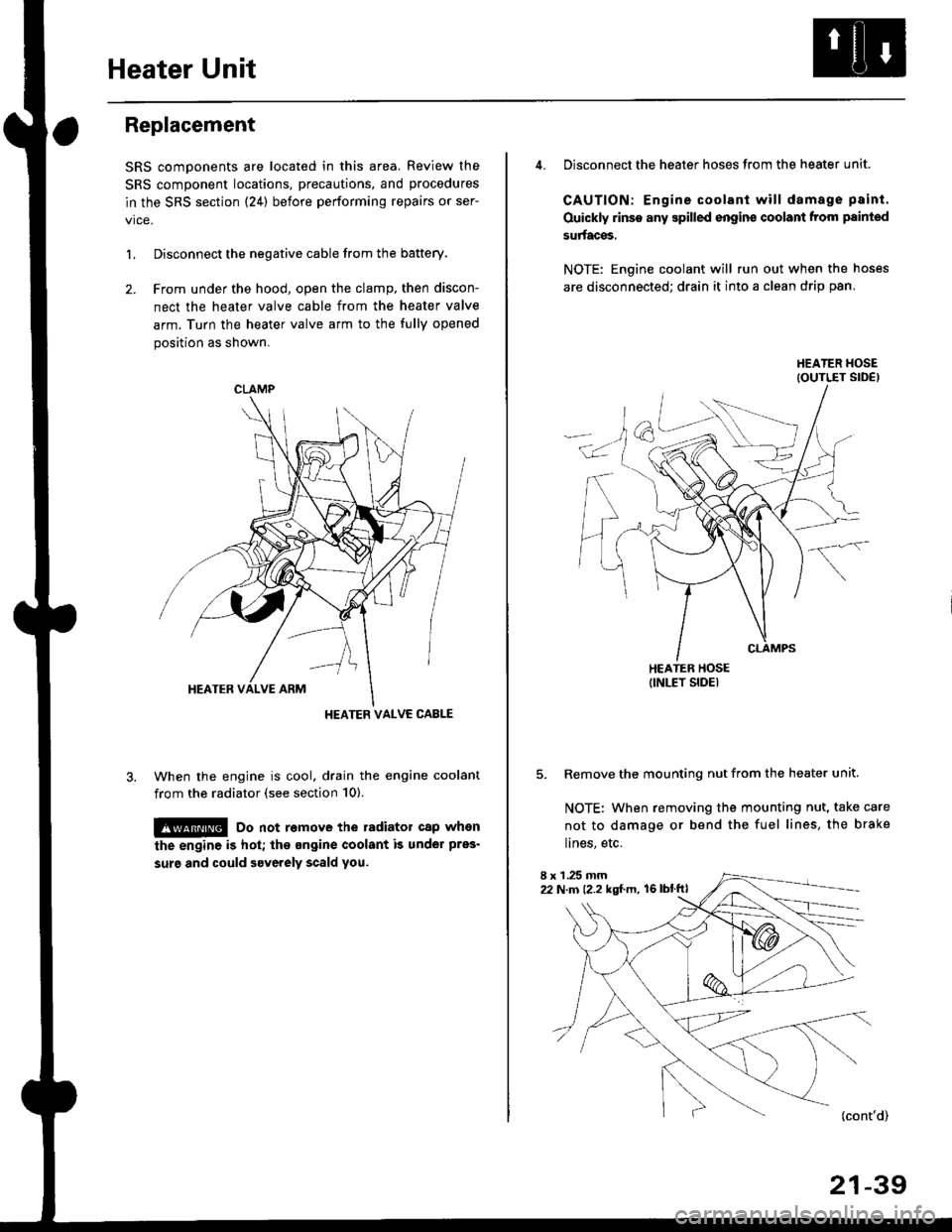

Heater Unit

Replacement

SRS components are located in this area. Review the

SRS component locations, precautions, and procedures

in the SRS section {24} before performing repairs or ser-

L Disconnect the negative cable from the battery.

2. Frcm under the hood, open the clamp, then discon-

nect the heater valve cable from the heater valve

arm. Turn the heater valve arm to the fully opened

position as shown.

When the engine is cool. drain the engine coolant

from the radiator (see section 10).

!@ Do not remove the radiator cap when

the engine is hot; the ongine coolant is under pres'

surg and could severely scald you.

CLAMP

HEATER VALVC CABLE

4. Disconnect the heater hoses from the heater unit.

CAUTION: Engine coolant will damage p8int.

Ouickly rinse any spilled engins coolant from painted

su aces,

NOTE: Engine coolant will run out when the hoses

are disconnected; drain it into a clean drip pan.

5. Remove the mounting nut from the heater unit.

NOTE: When removing the mounting nut, take care

not to damage or bend the fuel lines, the brake

lines, etc.

I x 1 .25 mm22 N.m {2.2 kgl.m, 16lblftl

21-39

Page 1414 of 2189

Heater Unit

Replacement (cont'dl

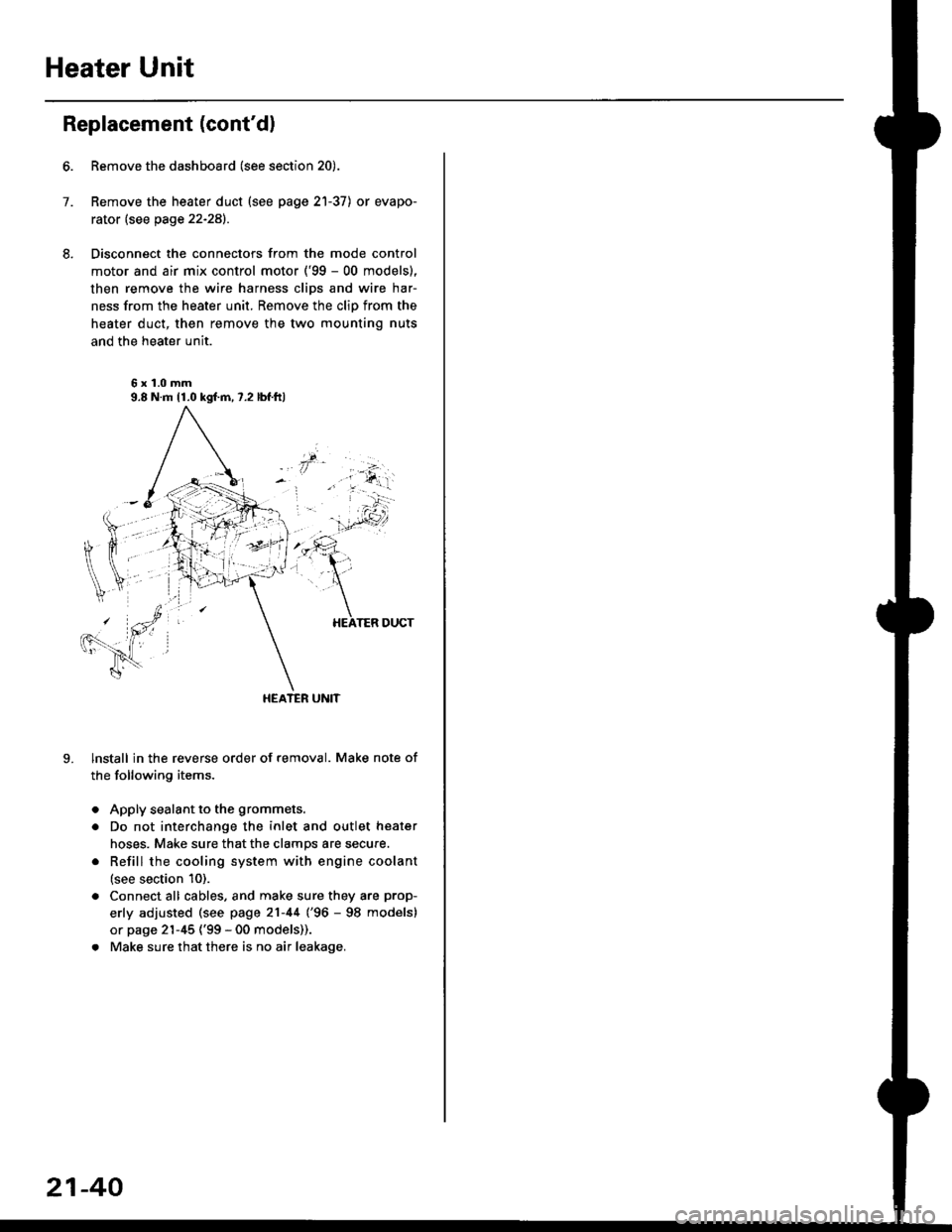

6.

7.

8.

9.

Remove the dashboard (see section 20).

Remove the heater duct (see page 21-37) or evapo-

rator (see page 22-28).

Disconnect the connectors from the mode control

motor and air mix control motor ('99 - 00 models),

then remove the wire harness clips and wire har-

ness from the heater unit. Remove the clip from the

heater duct, then remove the two mounting nuts

and the heater unit.

6x1.0mm9.8 N.m 11.0 kgl.m,7.2 lbf.ftl

HEATER UNIT

lnstall in the reverse order of removal. Make note of

the following items.

Apply sealant to the grommets.

Do not interchange the inlet and outlet heater

hoses. Make sure that the clamps are secure.

Refill the cooling system with engine coolant

(see section 10).

Connect all cables, and make sure they are prop-

erly adjusted (see page 21-44 (96 - 98 models)

or page 21-45 ('99 - 00 models)).

Make sure that there is no air leakage.

21-40

Page 1429 of 2189

Description

Outline

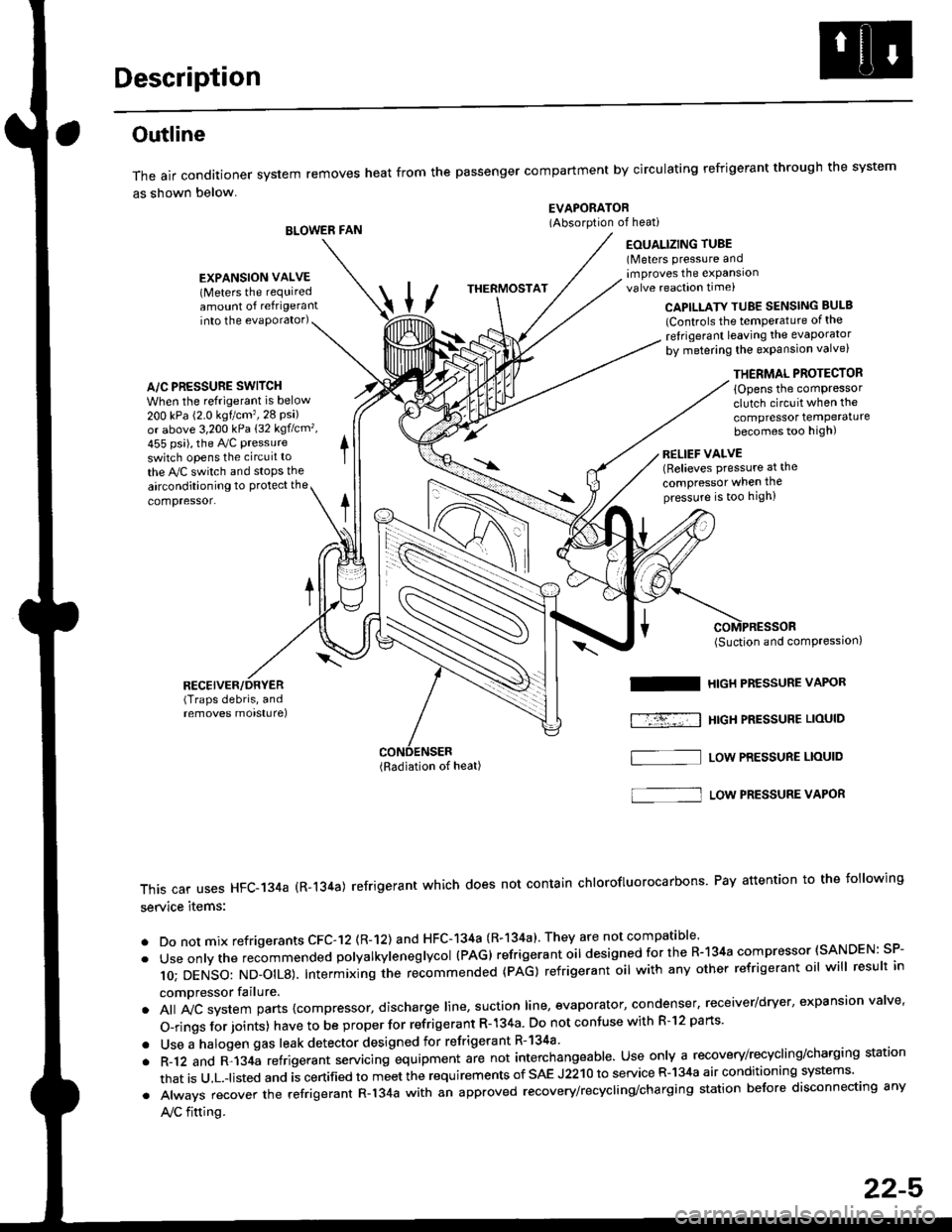

The air conditioner system removes heat from the passenger compartment by circulating refrigerant through the system

as shown below.

BLOWER FAN

EVAPORATOR(Absorption of heati

EOUALIZING TUBE(Meters pressure andimproves the expansionvalve reaction time)

into the evaporator)CAPILLATY TUBE SENSING BULB

lControls the temPerature of the

ref rigerant leaving the evaporator

by metering the expansion valve)

/\

THERMOSTAT

A/C PRESSURE SWITCH

When the refrigerant is below

200 kPa (2.0 kgtcm'�,28 Psi)or above 3,200 kPa 132 kgflcm',

455 psi), the Ay'C pressure

switch opens the circuit to

the A,/C switch and stops the

EXPANSION VALVE(Meters the requiredamount of refrigerant

airconditioning to Protect the

compressor.

RECEIVER/DRYER(Traps debris, andremoves morsturel

THERMAL PROTECTOR

{Opens the comPressorclutch circuit when the

compressor temPeraturebecomes too high)

RELIEF VALVE(Relieves pressure at the

compressor when thepressure is too high)

(Radiation of heat)

I

f-r-�-; I

(Suction and comPression,

HIGH PRESSURE VAPOR

HtGH PRESSUBE LIOUID

LOW PRESSURE LIOUID

This car uses HFC-134a (R-134a) refrigerant which does not contain chlorofluorocarbons Pay attention to the following

service items:

. Do not mix refrigerants CFC-12 (R-12) and HFC-134a (R-134a)' They are not compatible'

. Useonlythe recommended polyalkyieneglycol (PAG) refrigerant oil designedforthe R-134a compressor (SANDEN: SP-

10; DENSO: ND_OIL8). Intermixing ihe re-commended (pAG) refrigerant oil with any other refrigerant oil will result in

compressor failure.

. All A,,ic system parts {compressor, discharge line, suction line, evaporator, condenser, receiver/dryer, expansion valve'

O-rings for joints) have to be proper for refrigerant R- 134a Do not confuse with R-l2 parts'

. Use a halogen gas leak detector designed for refrigerant R-134a

. R-12 and R-134a refrigerant servacing equipment are not interchangeable. Use only a recovery/recycling/charging station

that is u,L.-listed and is certified to meet the requirements of sAE J2210 to service R-134a air conditioning systems'

. Always recover the refrigerant R-134a with an approved recovery/recycling/charging station before disconnecting any

A,/C fitting.

S]

22-5

Page 1450 of 2189

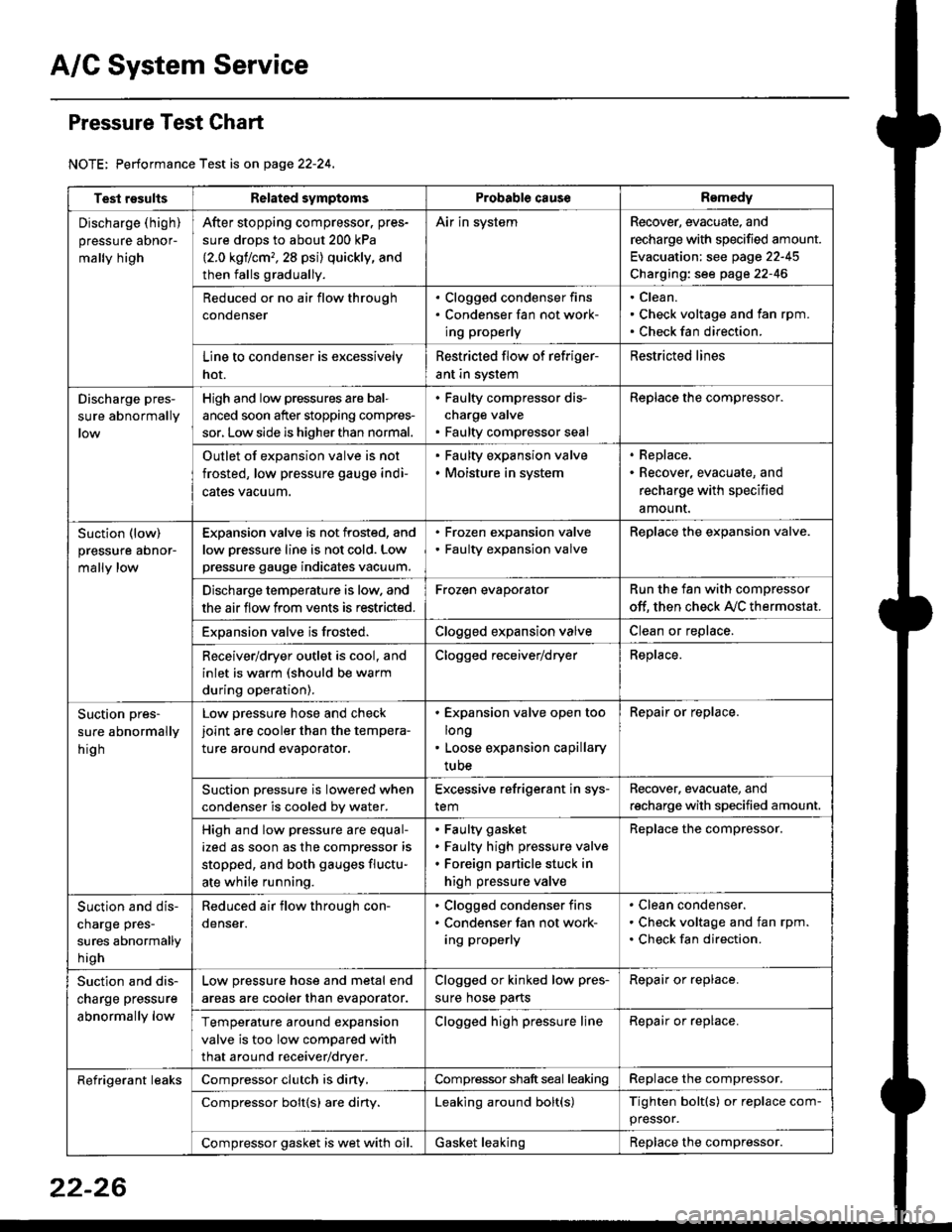

A/C System Service

Pressure Test Chart

NOTE: Performance Test is on page 22-24,

Test resultsRelated symptomsProbabl€ causeRemedy

Discharge (high)

pressure aDnor-

mally high

After stopping compressor. pres-

sure drops to about 200 kPa

{2.0 kgflcm,,28 psi) quickly, and

then falls gradually.

Air in systemRecover, evacuate, and

recharge with specified amount.

Evacuation: see page 22-45

Charging: see page 22-46

Reduced or no air flow through

condenser

. Clogged condenser fins. Condenser fan not work-

ing properly

Clean.

Check voltage and fan rpm.

Check fan direction.

Line to condenser is excessively

hot.

Restricted flow of refriger-

ant in system

Restricted lines

Discharge pres-

sure abnormally

High and low pressures are bal-

anced soon after stopping compres-

sor, Low side is higher than normal.

. Faulty compressor dis-

charge valve. Faulty compressor seal

Replace the compressor.

Outlet of expansion valve is not

frosted, low pressure gauge indi-

cales vacuum.

. Faulty expansion valve. Moisture in system

. Replace,. Recover, evacuate, and

recharge with specified

amount.

Suction (low)

pressure abnor-

mally low

Expansion valve is not frosted, and

low oressure line is not cold. Low

pressure gauge indicates vacuum.

. Frozen expansion valve. Faulty expansion valve

ReDlace the exoansion valve.

Discharge temperature is low. and

the air flow from vents is restricted.

Frozen evaporatorRun the fan with compressor

off. then check A,/C thermostat.

Exoansion valve is frosted.Clogged expansion valveClean or replace.

Receiver/dryer outlet is cool, and

inlet is warm (should be warm

during operation).

Clogged receiver/dryerReplace.

Suction pres-

sure abnormally

hig h

Low pressure hose and check

joint are cooler than the tempera-

ture around evaporator.

. Expansion valve open too

long. Loose expansion capillary

tube

Repair or replace.

Suction oressure is lowered when

condenser is cooled bv water.

Excessive refrigerant in sys-

tem

Recover. evacuate, and

recharge with specified amount.

High and low pressure are equal-

ized as soon as the compressor is

stopped, and both gauges fluctu-

ate while running.

Faulty gasket

Faulty high pressure valve

Foreign particle stuck in

high pressure valve

Replace the compressor.

Suction and dis-

charge pres-

sures abnormally

h igh

Reduced air flow through con-

denser.

. Clogged condenser fins. Condenser fan not work-

ing properly

Clean condenser.

Check voltage and fan rpm.

Check fan direction.

Suction and dis-

charge pressure

abnormally low

Low pressure hose and metal end

areas are cooler than evaporator.

Clogged or kinked low pres-

sure hose parts

Repair or replace.

Temperature around expansion

valve is too low compared with

that around receiver/dryer.

Clogged high pressure lineRepair or replace.

Refrigerant leaksCompressor clutch is diny,Compressor shaft seal leakingReplace the compressor.

Compressor bolt{s) are diny.Leaking around bolt(s)Tighten bolt(s) or replace com-

pressor.

Compressor gasket is wet with oil.Gasket leakingReplace the compressor.

22-26

Page 1451 of 2189

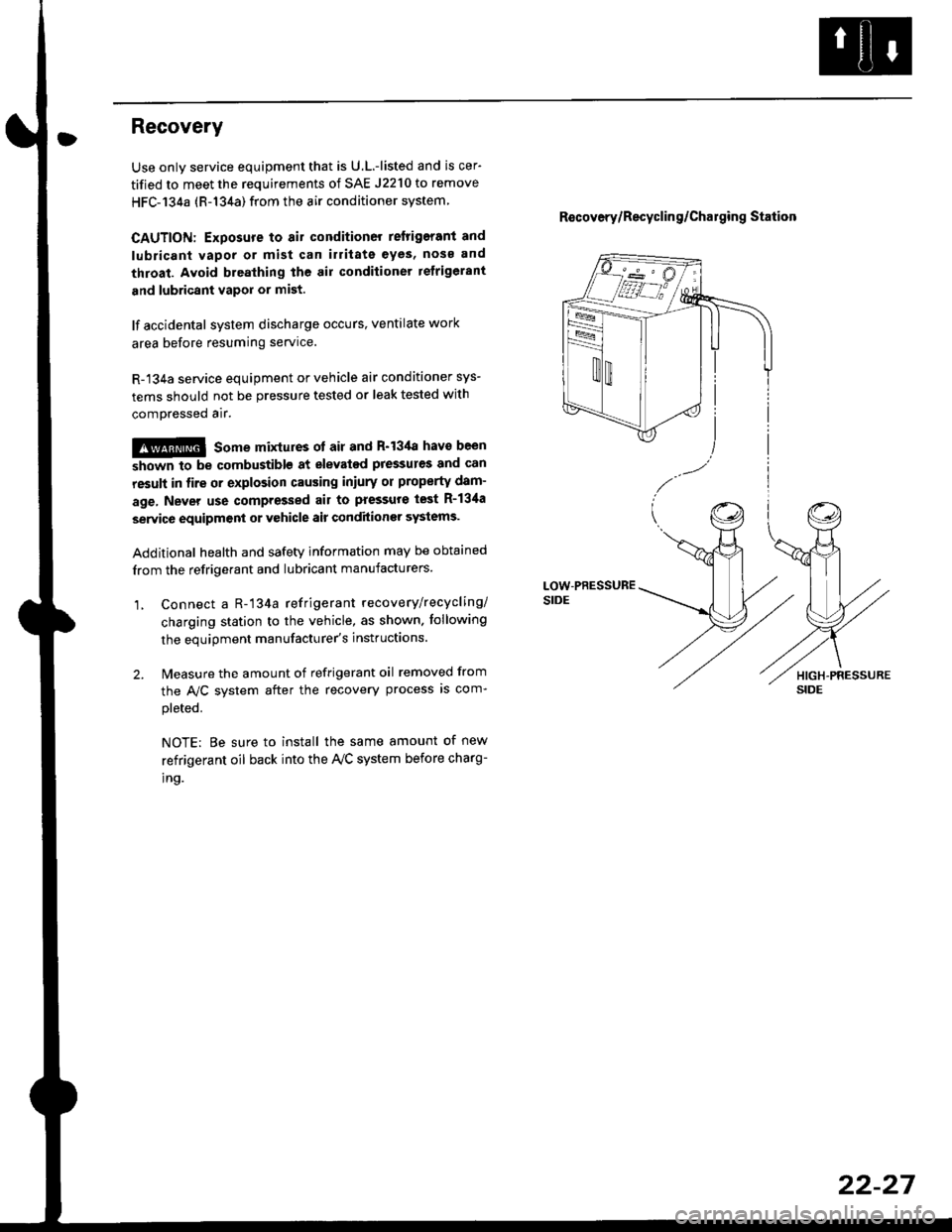

Recovery

Use only service equipment that is U.L.-listed and is cer-

tified to meet the requirements of SAE J2210 to remove

HFC-134a (R-134a) from the air conditioner system

CAUTION: Exposure to air conditioner relrigerant and

lubricant vapor or mist can illitate eyes, noss and

throat. Avoid breathing the ail conditioner refrigerant

and lubricant vapor or mist.

lf accidental system discharge occurs, ventilate work

area before resuming service.

R-134a service equipment or vehicle air conditioner sys-

tems should not be pressure tested or leak tested with

compressed air.

!@@ some mixtures ot air and R'13'[a havo been

strown to be combustiblg at elevated pressures and Gan

resuh in fire or explosion causing iniury or property dam-

age, Never use compressed air to pressure test R-134a

service equipment or vehicle air conditioner systems.

Additional health and safetv information may be obtained

from the refrigerant and lubricant manufacturers.

1, Connect a R-'134a refrigerant recove rylrecycling/

charging station to the vehicle, as shown. tollowing

the equipment manufacturer's instluctions.

2. Measure the amount of refrigerant oil removed from

the A/C svstem after the recovery process is com-

pleted.

NOTE: Be sure to install the same amount of new

refrigerant oil back into the Iy'C system before charg-

tno.

R€covery/Recyclin g/Cha19ing Station

22-27

Page 1452 of 2189

Evaporator

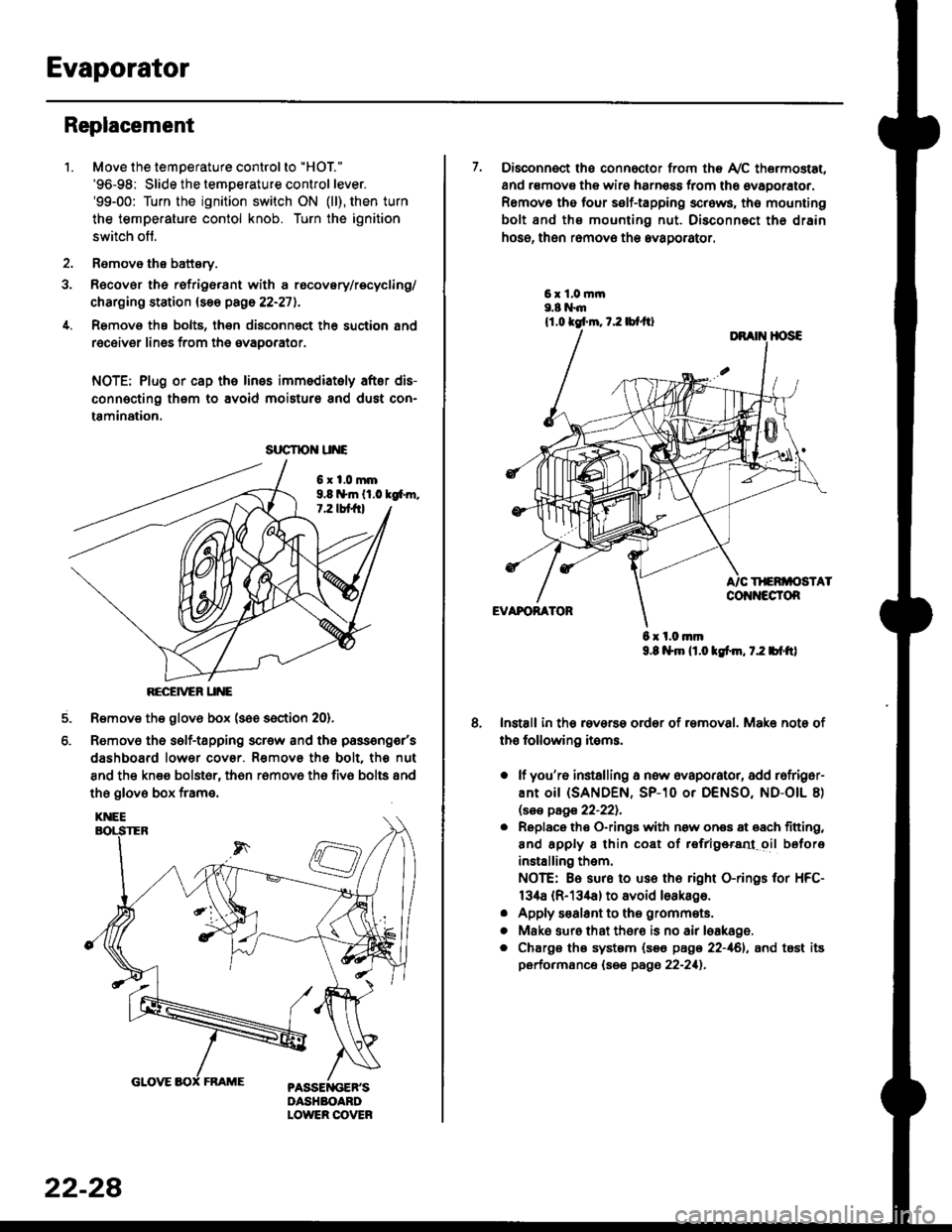

1.

Replacement

4.

Move the temperature control to "HOl"

'96-98: Slide the temoerature control lever.'99-00: Turn the ignition switch ON (ll), then turn

the temperature contol knob. Turn the ignition

switch off.

Remove the battsry.

Rgcover the refrigerant with a rocovery/recycling/

charging station (see page 22-271.

Remove the bolts, then disconnect th6 suction 8nd

receiver lines from th6 evaoorator.

NOTE: Plug or cap the lines imm€diatoly after dis-

connecting them to avoid moisture and dust con-

tamination.

6xl.0mm9.8 n*ln ll.0 tg6m.7.2 lbt frl

RECEiVER UNE

Remove the glov6 box (see section 20).

Removo the self-tapping scr€w and the passeng€r's

dashboard lower cover. Removs the bolt. the nut

8nd the kn€e bolst6r, th6n r6mov6 th6 fiv6 bolts and

the glove box frame.

6.

srrcrrc u E

22-28

7. Disconnect the connector from th€ Ay'C thermostat,

and r€movs the wire harness from the ovaporator.

Remov6 tho four self-tapping screws, tho mounting

bolt and ths mounting nut. Disconnect th€ drain

hose, then remov€ th6 avagorator.

6 x l.0.nm9.8 l$m lt.o ldm, 7.2 bl.tt)

Install in the reverse order of removal. Make note of

th€ following items.

o lf you'r6 installing a new evaporator, add rofriger-

ANt OiI {SANDEN, SP-10 Or DENSO, ND-OIL 8)

lsas page 22-221.

. Replace the O-rings with now ones 8t 68ch titting,

and apply 8 thin coat of r€frlgersd oil before

installing them.

NOTE: Be sure to use the right O-rings for HFC-

134a (R-134a) to avoid loakago.

. Apply s€alant to tha grommets.

. Mske sure that ther€ is no air leakage.

. Chargs ths system {s€€ page 22-161, and tost its

performance (see pags 22-211.

Page 1454 of 2189

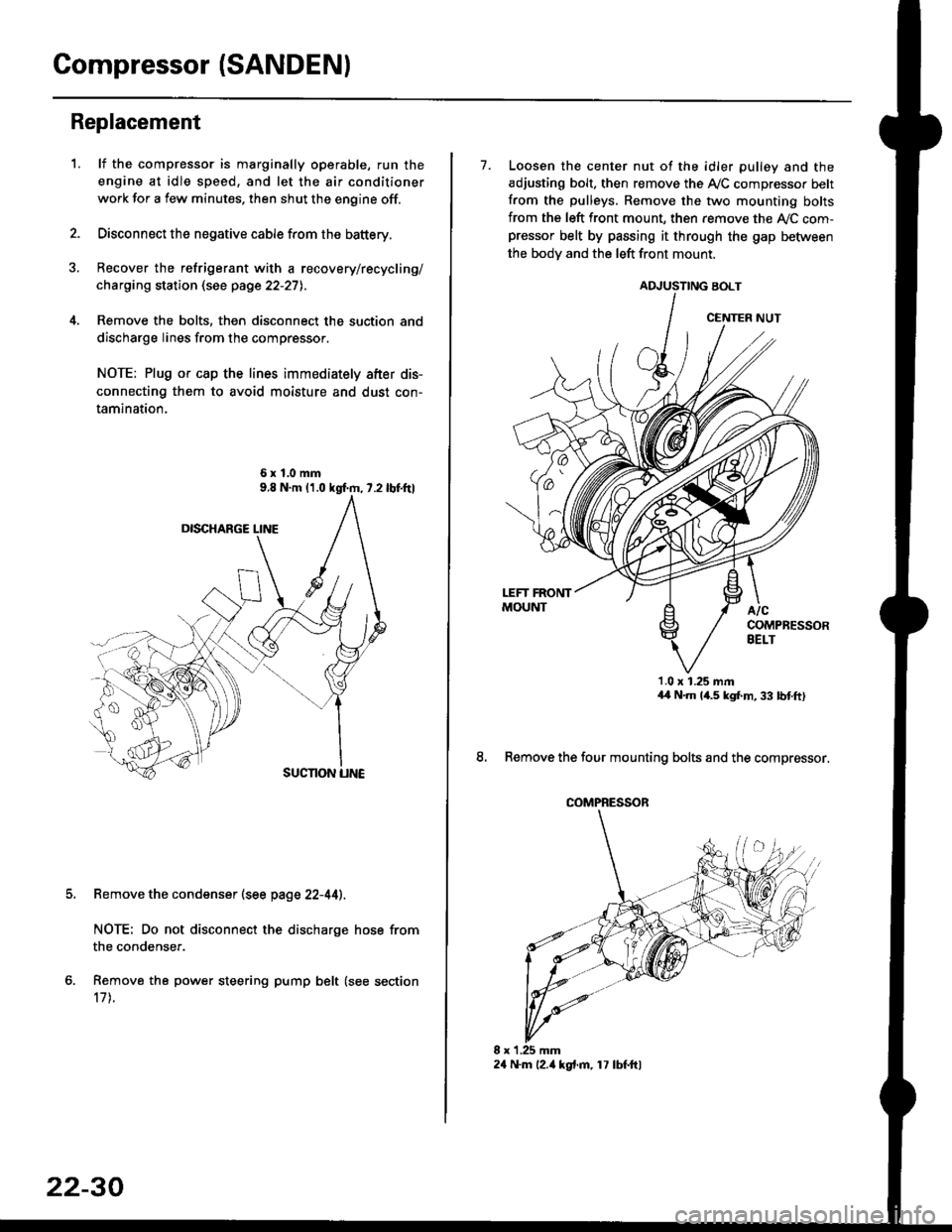

Compressor (SANDENI

Replacement

1.lf the compressor is marginally operable, run the

engine at idle speed, and let the air conditioner

work for a few minutes. then shut the engine off.

Disconnect the negative cable from the battery.

Recover the refrigerant with a recovery/recycling/

charging station (see page 22-27l..

Remove the bolts, then disconnect the suction and

discharge lines from the compressor.

NOTE: Plug or cap the lines immediately after dis-

connecting them to avoid moisture and dust con-

tamination.

6xl.0mm

Remove the condenser (see page 22-44).

NOTE: Do not disconnect the discharge hose from

the condenser.

Remove the power steering pump belt (see section

17 t.

22-30

24 N.m l2.ia kgt.m, 17 lbf.ftl

7. Loosen the center nut of the idler pulley and the

adjusting bolt. then remove the A,/C compressor belt

from the pulleys. Remove the two mounting bolts

from the left front mount, then remove the ly'C com-pressor belt by passing it through the gap befiiveen

the bodv and the left front mount.

ADJUSTING BOLT

1.0 x 1.25 mmaa N.m 14.5 kgf,m, 33 bnft)

8. Remove the four mounting bolts and the compressor.

CENTER NUT

COMPRESSOR