Model HONDA CIVIC 1998 6.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CIVIC, Model: HONDA CIVIC 1998 6.GPages: 2189, PDF Size: 69.39 MB

Page 854 of 2189

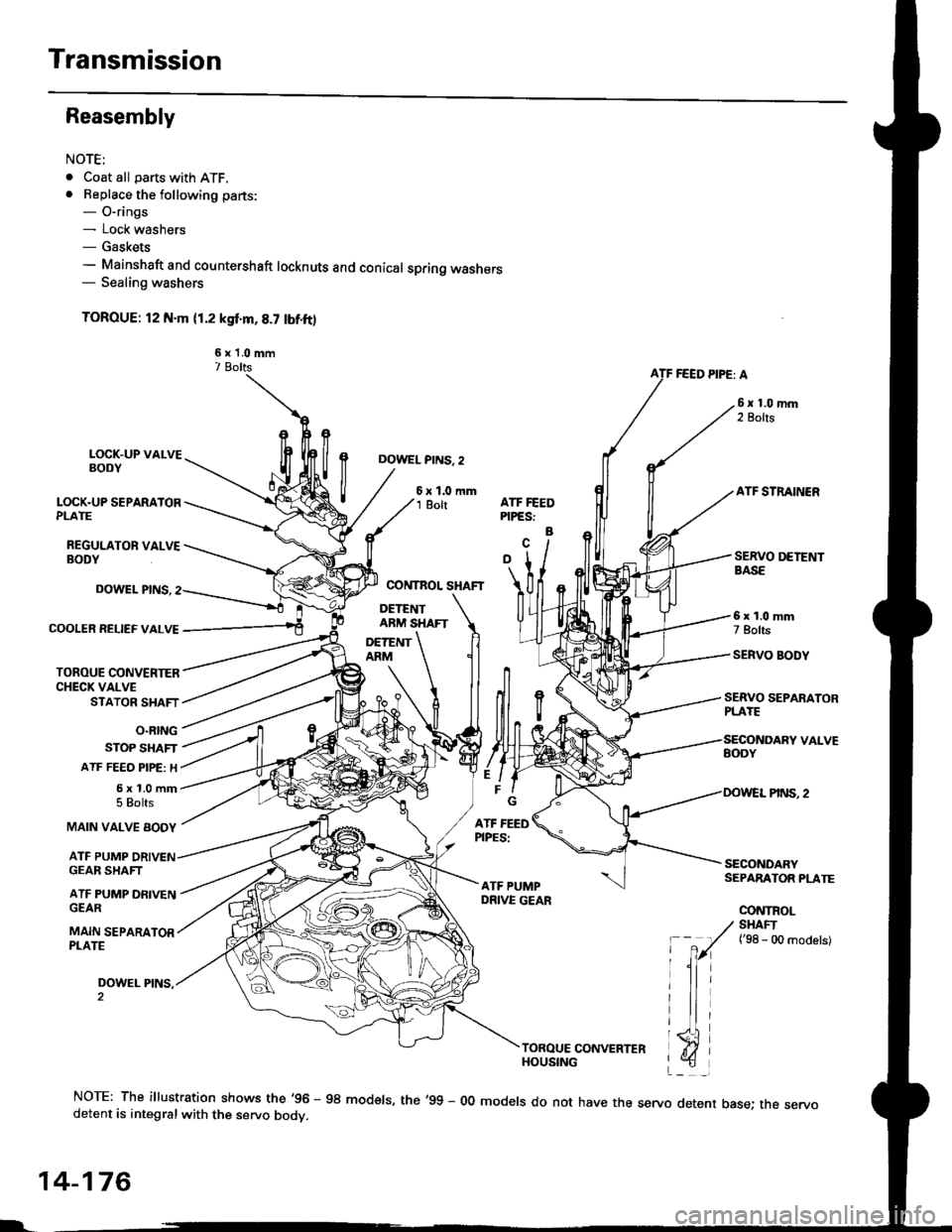

Transmission

Reasembly

NOTE;

. Coat all parts with ATF.. Beplace the following parts:- O-rings- Lock washers- Gaskets- Mainshaft and countershaft locknuts and conical spring washers- Sealing washers

TOROUE: l2 N.m (1.2 ksf'm,8.7 lbf.ft)

6 x 'l.0 mm7 BoltsFEED PIPE: A

LOCK.UP VALVEBODY

LOCK.UP SEPARATORPLATE

REGULATOR VALVEBODY

DOWEL PINS. 2

6xl.0mm1 BoltATF STRAINERATF FEEDPIPES:

a

COOIER RELIEF VALVE

TOROUE CONVENIERCHECK VALVESTATOR SHAFT

O.RING

STOP SHAFT

ATF FEEO PIPE: H

5x1.0mm5 Bolts

DOWEL PINS.

MAIN VALVE BODY

ATF PUMP

SERVO SEPARATORPLAYE

6x1.0mm7 Bolts

SERVO BODY

SECONOARYSEPARATOR PLATE

CONTROL

GEAR SHAFT

ATF PUMP DFIVENGEAR

MAIN SEPARATORPLATE

DOWEL PINS,

/ SHAFI

' -

7r(

t'se - oo ^od"t"t

lli

triTOROUE CONVERTERHOUSING

NOTE: The illustration shows the'96 - 98 modsls, the'99 - 00 models do not have the servo detent base; the servodetent is integralwith the servo bodv.

14-176

L-

Page 855 of 2189

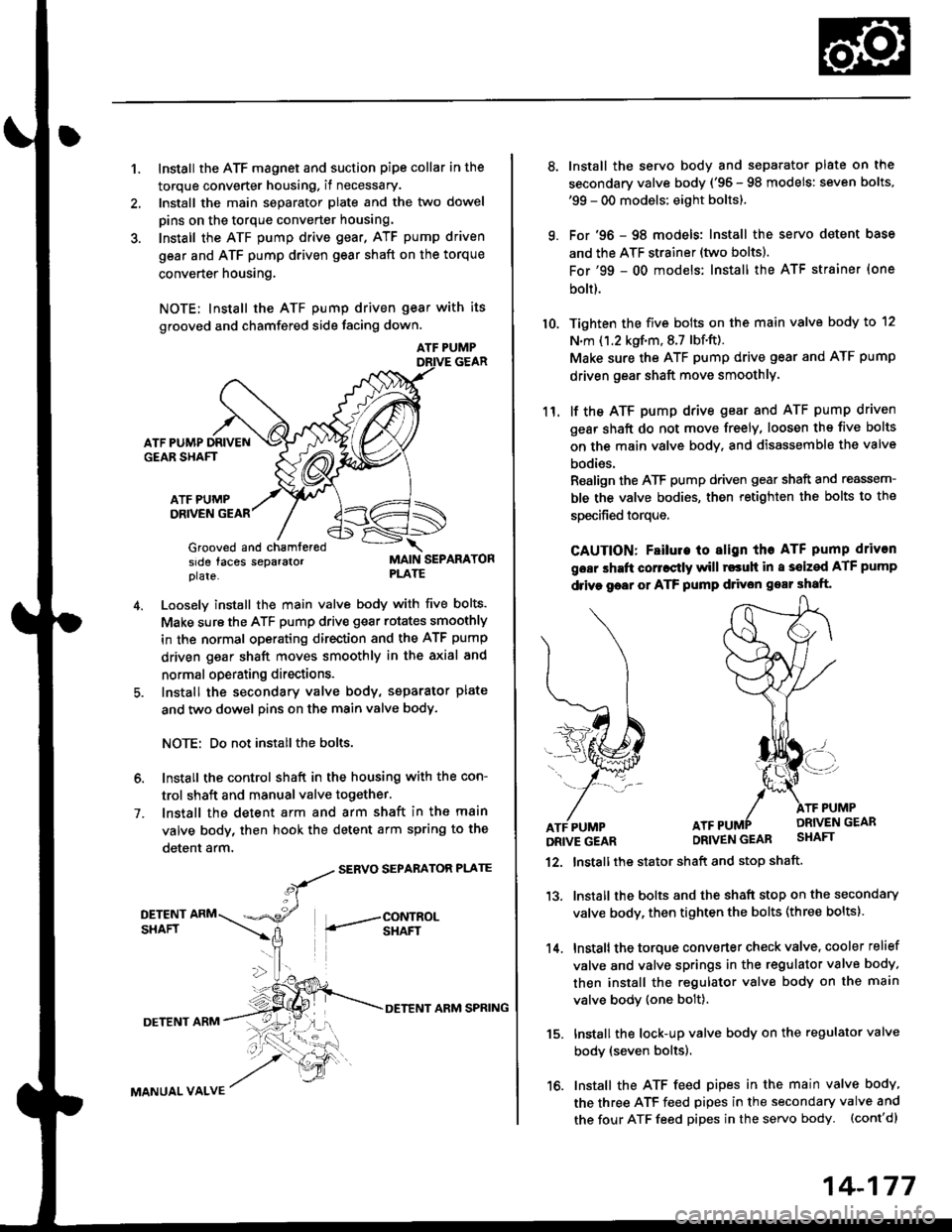

1.Install the ATF magnet and suction pipe collar in the

torque converter housing. if necessary.

lnstall the main seDarator plate and the two dowel

pins on the torque converter housang.

Install the ATF pump drive gear, ATF pump driven

gear and ATF pump driven gear shaft on the torque

converter housing.

NOTE; Install the ATF pump driven gear with its

grooved and chamfered side tacing down.

ATF PUMP

ATF PUMP DRIVENGEAR SHAFT

ATF PUMPDRIVEN GEAR

Grooved and chamferedside taces separalorplate.MAIN SEPARATORPLATE

4.Loosely install the main valve body with five bolts.

Make sure the ATF pump drive gear rotates smoothly

in the normal operating direction and the ATF pump

driven gear shaft moves smoothly in the axial and

normal operating directions.

Install the secondary valve body, separator plate

and two dowel pins on the main valve body.

NOTE: Do not installthe bolts.

6. Install the control shaft in the housing with the con-

trol shaft and manual valve together.

7. lnstall the detent arm and arm shaft in the main

valve body, then hook the detent arm spring to the

detent arm,

SERVO SEPARATOR PLATE

DETENT

MANUAL VALVE

DETENT ARM SPRING

15.

14-177

a

10.

11.

Install the servo body and separator plate on the

secondary valve body ('95 - 98 models: seven bolts.'99 - 00 models: eight boltsl.

For '96 - 98 models: Install the servo detent base

and the ATF strainer (two boltsl.

For'99 - 00 models: Install the ATF strainer (one

bolt).

Tighten the five bolts on the main valve body to 12

N.m ('1.2 kgf.m,8.7 lbf.ft).

Make sure the ATF pump drive gear and ATF pump

driven gear shaft move smoothlY'

lf the ATF pump drive gsar and ATF pump driven

gear shaft do not move freely, loosen ths five bolts

on the main valve body, and disassemble the valve

bodies.

Realign the ATF pump driven gear shaft and reassem-

ble the valve bodies, then retighten the bolts to the

specified torque,

CAUTION: Fsilule to align tho ATF pump driven

goar shaft corr.ctly will rscuh in a s€ized ATF pump

drive goar or ATF pump d ven gear shaft.

Install the stator shaft and stop shaft.

Install the bolts and the shaft stop on the secondary

valve body, then tighten the bolts (three boltsl.

Install the torque converter check valve, cooler relief

valve and valve springs in the regulator valve body.

then install the regulator valve body on the main

valve bodv (one bolt).

Install the lock-up valve body on the regulator valve

bodv (seven bolts).

Install the ATF feed pipes in the main valve bodY,

the three ATF feed pipes in the secondary valve and

the four ATF feed pipes in the servo body. (cont'dl

12.

't 3.

14.

PUMP

Page 871 of 2189

Continuously Variable Transmission (CVTI

Special Tools ................ 14-194

Description .................... 14-195

Clutches/Reverse Brake/Planetary

Gear/Pulleys .......... 14-198

power Flow ..............,..... 14-200

Electronic Control SYstem(,96 - 98 Modets) ......14-203

Electronic Control System

('99 - oo Models) " 14-205

Hydraulic Control '....... 14-208

Hydraulic Flow .'..-.....'... '14-212

Park Mechanism .....-...'.' 14-222

Eleqtrical Systom

Component Locations'96 - 98 Models """"""' 14-224,99 - 00 Modets ............. 14-225

TCM Circuit Diagram ('96 - 98 Models) ............. 14-226

TCM Terminal Voltage/Measuring Condiiions ('96 - 98 Models) '.... 14-228

PcM Circuit Oiaqram{A/T Control System: '99 - 00 Models} ...--.... 14-230

PCM Terminal Voltage/Measuring Conditions('99 - 00 Models)

A/4 Control System .'.'...14-232

Troubleshooting Procedures ... . .... .....',........."' '14-234

Symptom-to-ComPonent Chart

Electrical System - '96 - 98 Models ......'..... '14-234

Electrical System -'99 - 00 Models ..'....-..-. '11-210

Electrical Troubleshooting

Troubleshooting Flowcharts('96 - 98 Models) """'11-242

Troubleshooting Flowchart

('99 - 0O Modets) ...... 14-265

Linear Solenoids/lnhibitor Solenoid

Test ......................... . ...... 14-29f

Drive Pulley/Driven Pulley/Secondary Gear

Shaft Speed Sensors

Replacement .........'...... .14-292

Start Clutch Control

Start Clutch Calibration Procedure ....... ....,. 14-293

Hydraulic SYstem

Symptom-to-ComPonent Chart

Hydraulic System '.'.......14-294

Road Test ............................ 14-296

Stall Speed

Test......................... ...... 14-294

Fluid Level

Checking/Changing ....... 14-299

Pressure Testing ................. 14-300

Lower Valve BodY AssemblY

Replacement ..........,... 14-302

ATF Filter

Removal/lnstallation ..... 14-303

Transmission

Transmission

Removal ........... . 14-304

lllustrated Index

Transmission/Lower Valve BodY

Assembly ................. 14-308

Transmission Housing/Flywheel Housing ... 14-310

End Cover/f ntermediate Housing ..........'.'.... 14-312

Transmission Housing/Lower Valve Body Assembly

Removal ..........'.... .. " 14-314

Transmission Housing/Flywhesl Housing

Removal ................. ........ 1+316

End Cover/lntermediate Housing

14-318Removal .........,...............

Manual Valve Body

Disassembly/lnspection/Reassemblv .'.'.'..... 1 4-320

Forward Clutch

lltustrated Index ........................................ 14-321

Disassemblv .................. 14-322

Reassemblv , ,, . ',','......14-324

Secondary Gear Shaft

25 x 35 mm Thrust Shim Selection ..'.'....-... 14-324

Differential

lllustrated lndex ...,.....................,.,...-.-.-...'... 14-329

Backlash Inspection .-....14-329

Bearing Replacement ......'........'....'... ....'... 14-330

Differential Carrier Replacement ........'........ 14-330

Oil Seal Removal ........... 14-331

Oil Seal Installation/Side Clearance ....... . . 14-331

Flywheel Housing Input Shaft Oil Seal

Replacement .....,.... ...'.'.. 14-333

Transmission Housing Bearings

Driven Pulley Shaft Bearing

Replacenient ...................'. . ...................'.. 14-334

Secondary Gear Shaft Bearing

Reolacbment ...................... . .......... . ........ 14-335

Flywheel Housing Beating

Secondary Gear Shaft BearingReo1acement..................,........................... 14-335

Ring Gear Bearing

Replacement......... ........ 14-336

Control Shaft Assembly

Removal/lnstallation ....................'........... 14-336

Transmission

Reassembly .................. 14-338

Flywheel/Drive Plate .. . ...... . ...... ... . ....-.....'.'...14-341

Transmission

lnstalation ..................... 14-348

Cooler Flushing .'......... 14-352

shift cable

Removal/lnstallation....'........." """ 14-354

Adjustment .......'........ 14-355

Shift Lever ........................,. 14'356

Shift Indicator Panel

Adjustment ................ 14-357

ATF Cooler/Hoses

lnsta llation ......,,...... .... 14-357

Page 873 of 2189

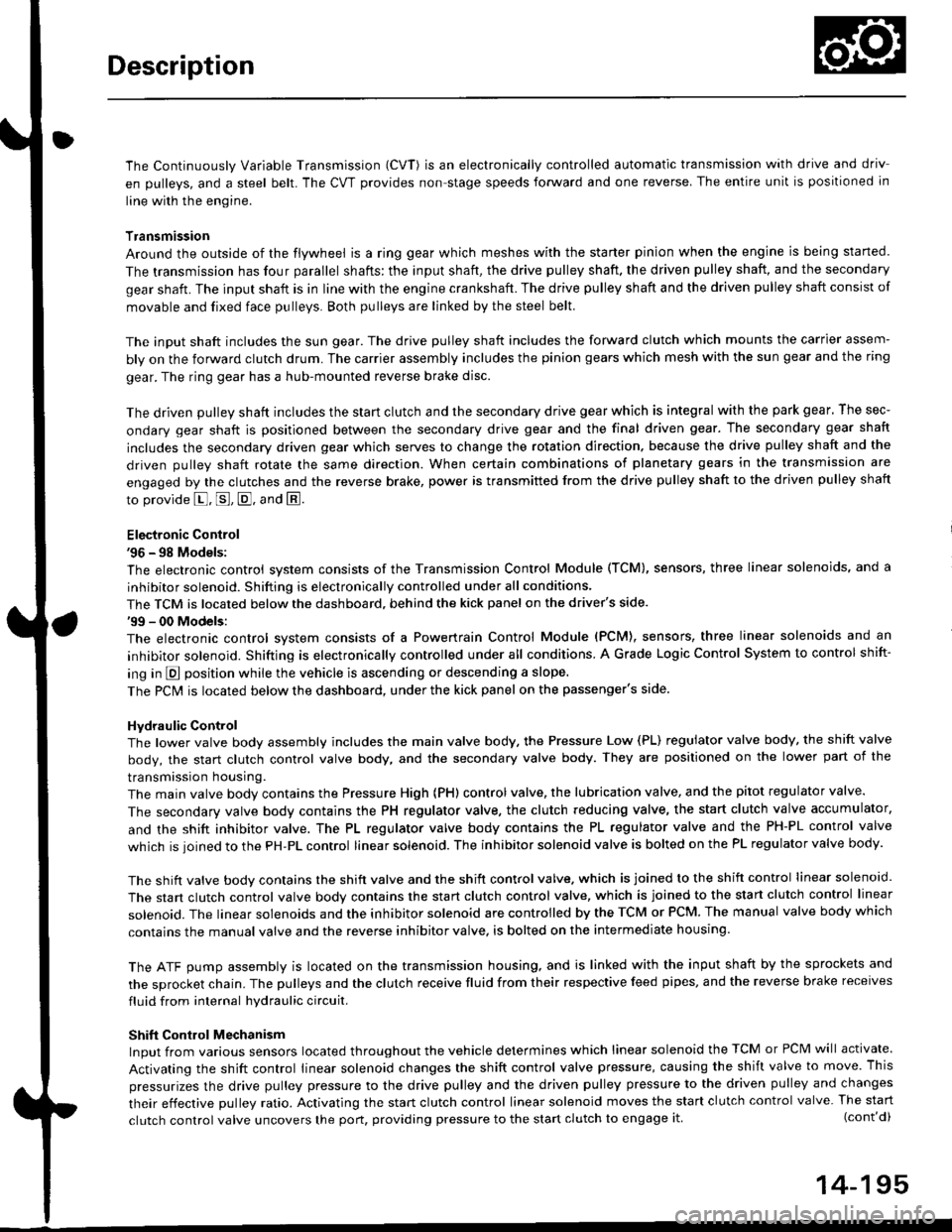

Description

The Continuously Variable Transmission (CVT) is an electronically controlled automatic transmission with drive and driv

en Oullevs, and a steel belt. The CVT provides non stage speeds forward and one reverse. The entire unit is positioned in

line with the engine.

Transmission

Around the outside of the flywheel is a ring gear which meshes with the starter pinion when the engine is being staned.

The transmission has four parallel shafts: the input shaft, the drive pulley shaft. the driven pulley shaft, and the secondary

gear shaft. The input shaft is in line with the engine crankshaft. The drive pulley shaft and the driven pulley shaft consist of

movable and fixed face pulleys. Both pulleys are linked by the steel belt.

The input shaft includes the sun gear. The drive pulley shaft includes the forward clutch which mounts the carrier assem-

bly on the forward clutch drum. The carrier assembly includes the pinion gears which mesh with the sun gear and the ring

gear. The ring gear has a hub-mounted reverse brake disc.

The driven pulley shaft includes the start clutch and the secondary drive gear which is integral with the park gear' The sec-

ondary gear shaft is positioned between the secondary drive gear and the final driven gear. The secondary gear shaft

includes the secondary driven gear which serves to change the rotation direction. because the drive pulley shaft and the

driven oullev shaft rotate the same direction. When certain combinations of planetary gears in the transmission are

engaged by the clutches and the reverse brake, power is transmitted from the drive pulley shaft to the driven pulley shaft

to provide E, E, E, and El.

Electronic Control'96 - 98 Models:

The electronic control system consists of the Transmission Control Module (TCM), sensors, three linear solenoids, and a

inhibitor solenoid. Shifting is electronically controlled under all conditions'

The TCM is located below the dashboard, behind the kick panel on the driver's side.'99 - 00 Models:

The electronic control svstem consists of a Powertrain Control Module (PCM), sensors, three linear solenoids and an

inhibitor solenoid. Shifting is electronically controlled under all conditions. A Grade Logic Control System to control shift-

ing in E position while the vehicle is ascending or descending a slope.

The PCM is located below the dashboard, under the kick panel on the passenger's side.

Hydraulic Control

The lower valve body assembly includes the main valve body, the Pressure Low (PL) reguiator valve body, the shift valve

body, the start clutch control valve body, and the secondary valve body. They are positioned on the lower part of the

transmission housing.

The main valve body contains the Pressure High (PH) control valve, the lubrication valve, and the pitot regulator valve.

The secondary valve body contains the PH regulator valve, the clutch reducing valve, the start clutch valve accumulator,

and the shift inhibitor valve. The PL regulator valve body contains the PL regulator valve and the PH-PL control valve

which is ioined to the PH,PL control linear solenoid. The inhibitor solenoid valve is bolted on the PL regulator valve body.

The shift valve body contains the shift valve and the shift control valve. which is joined to the shift control linear solenoid.

The start clutch control valve body contains the start clutch control valve, which is joined to the start clutch control linear

solenoid. The linear solenoids and the inhibitor solenoid are controlled by the TCM or PCM. The manual valve body which

contains the manual valve and the reverse inhibitor valve, is bolted on the intermediate housing.

The ATF pump assembly is located on the transmission housing, and is linked with the input shaft by the sprockets and

the sprocket chain. The pulleys and the clutch receive fluid from their respective feed pipes, and the reverse brake receives

fluid from internal hydraulic circuit.

Shift Control Mechanism

Input from various sensors located throughout the vehicle determines which linear solenoid the TCM or PCM will activate.

Activating the shift control linear solenoid changes the shift control valve pressure, causing the shift valve to move. This

pressurizes the drive pulley pressure to the drive pulley and the driven pulley pressure to the driven pulley and changes

their effective pulley ratio. Activating the start clutch control linear solenoid moves the start clutch control valve. The start

clutch control valve uncovers the port, providing pressure to the start clutch to engage it(cont'd)

14-195

,!

Page 881 of 2189

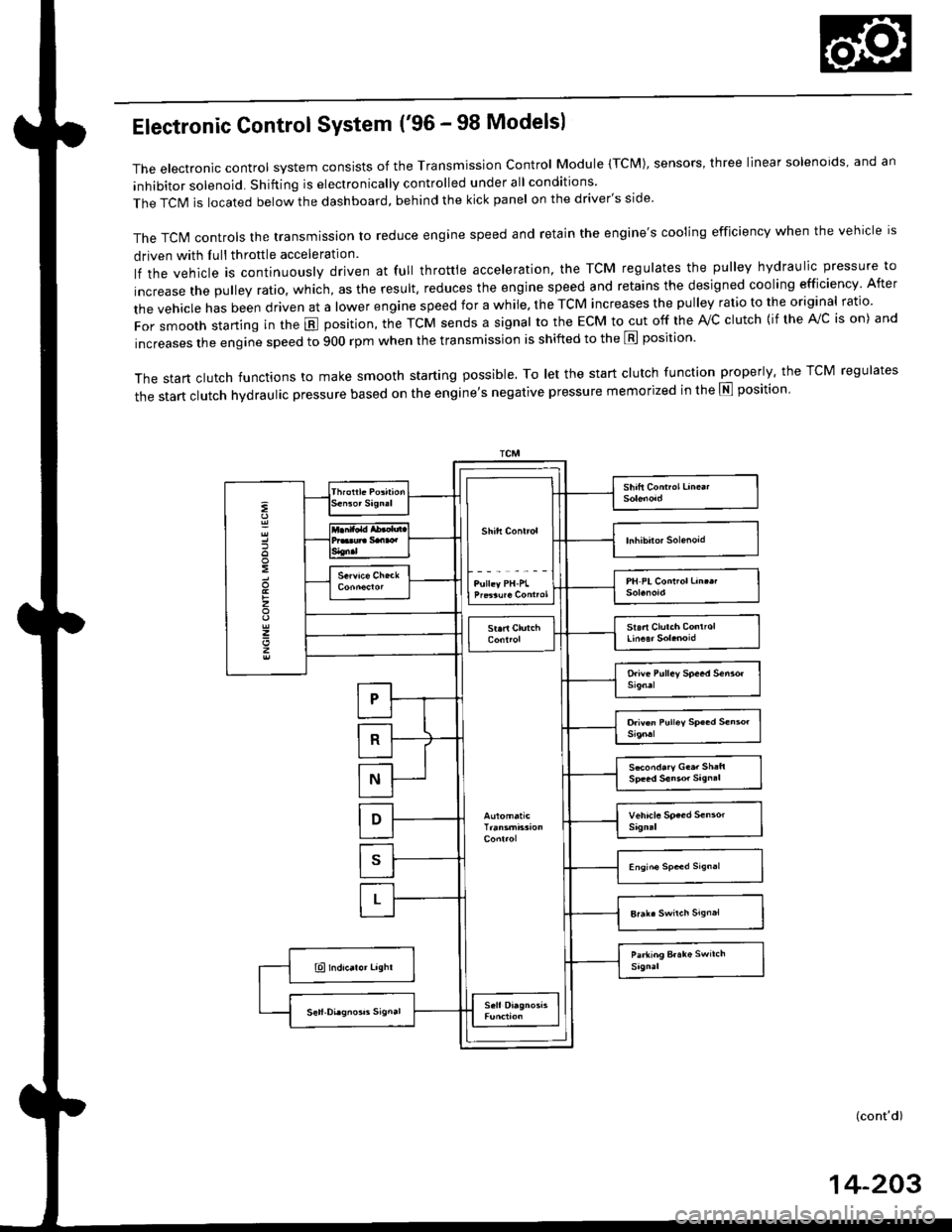

Electronic Control System ('96 - 98 Modelsl

The electronic control system consists of the Transmission control Module (TcM), sensors, three linear solenoids, and an

inhibitor solenoid. Shifting is electronically controlled under all conditions

The TCIM is located below the dashboard, behind the kick panel on the driver's side'

The TcN4 controls the transmission to reduce engine speed and retain the engine's cooling efficiency when the vehicle is

driven with Iull throttle acceleration

lf the vehicle is continuously driven at full throttle acceleration, the TCM regulates the pulley hydraulic pressure to

increase the pulley ratio, which, as the result. reduces the engine speed and retains the designed cooling efficiency After

the vehicle has been driven at a lower engine speed for a while, the TCM increases the pulley ratio to the original ratio.

For smooth starting in the E position, the TcM sends a signal to the EcM to cut off the rvc clutch {if the A!/c is on) and

increases the engine speed to 900 rpm when the transmission is shifted to the E position'

The start clutch functions to make smooth starting possible. To let the start clutch function properly. the TCM regulates

the start clutch hydraulic pressure based on the entine's negative pressure memorized in the E position'

:

:

z

z

z

S*ond.ry G..r Sh:ft

(cont'd)

14-203

Page 882 of 2189

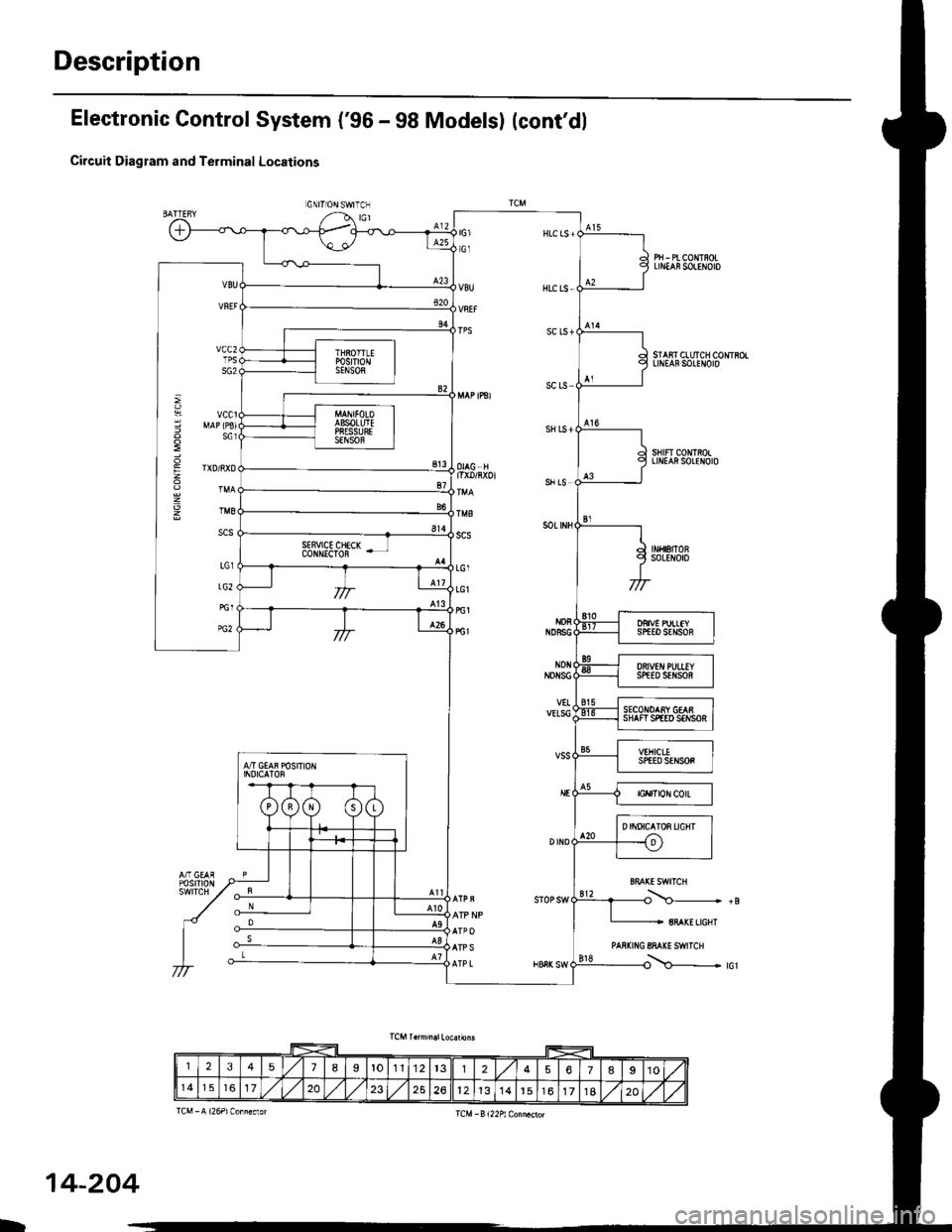

Description

Electronic Control System ('gG - 98 Modelsl (cont'dl

Circuit Diagram and Terminal Locations

GNITIONSWITCN

Pri - Pt coNTnoLLrN ns0LtN0t0

SIAiT CLUTCH CONTSOLLINEAFSOLENOID

sHtFT CONmOILINIAftSOLENOID

BFAXELIGHT

PAS|(ING 8MI(E SWITCH

i\c-...............- +B

i\--------.--_ rcr

: MAP(PBIg s61

E rtDiRxo

g TM8

scs

123518I1011't22578910

14172023261213t4t6171820

D

14-204

Page 883 of 2189

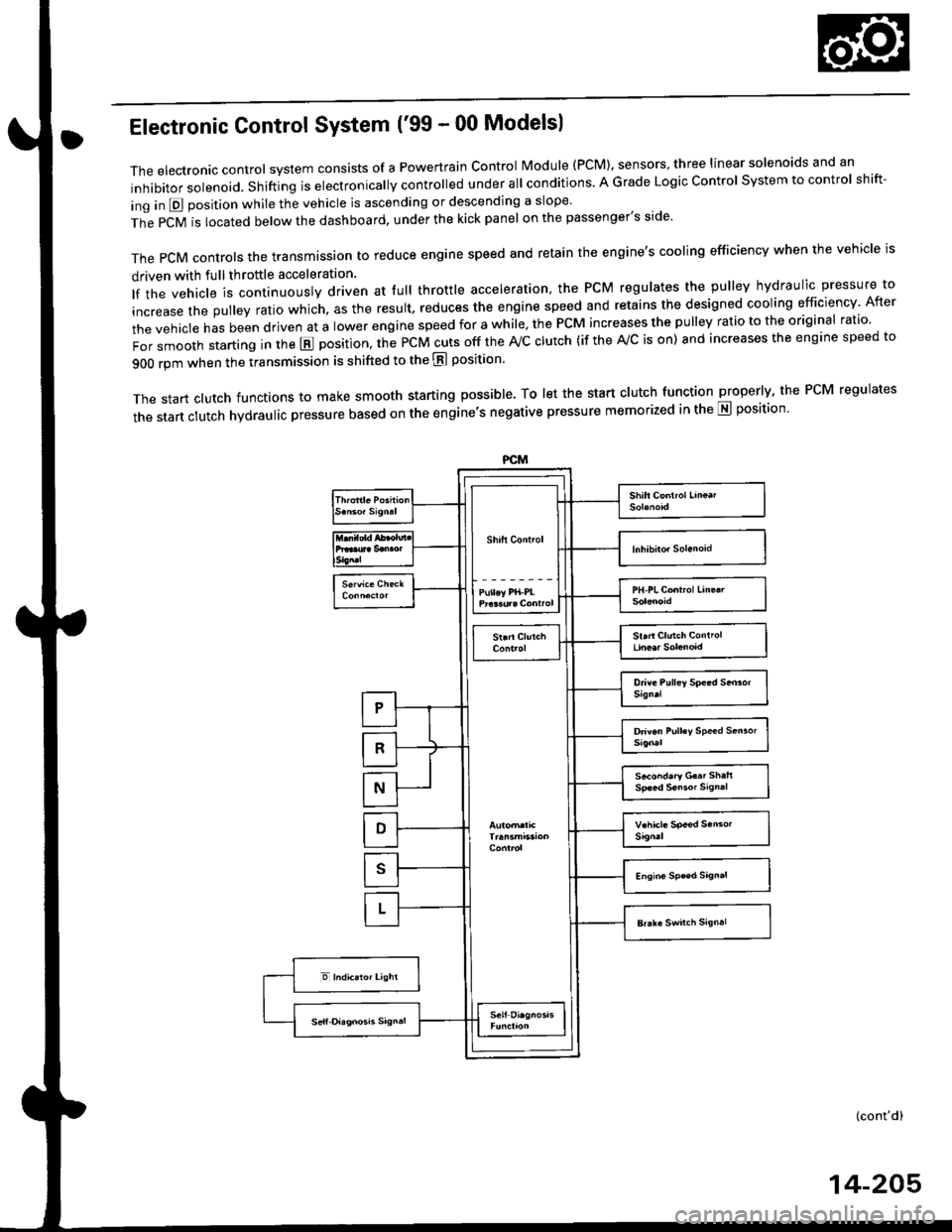

Electronic Gontrol System ('99 - 00 Modelsl

The electronic controt system conststs of a Powertrain control Module (PCM). sensors, three linear solenoids and an

inhibitor solenoid. shifting is electronically controlled under all conditions A Grade Logic control system to control shift-

ing in E position while the vehicle is ascending or descending a slope'

fn"pCVirlocatedbelowthedashboard,underthekickpanelonthepassenger'sside'

The pCM controls the transmassion to reduce engine speed and retain the engine's cooling efficiency when the vehicle is

driven with full throftle acceleration

lf the vehicle is continuously driven at lull throttle acceleration, the PCM regulates the pulley hydraulic pressure to

increase the pulley ratio which. as the result, reduces the engine speed and retains the designed cooling efficiency After

the vehicle has been driven at a lower engine speed for a while, the PCM increases the pulley ratio to the original ratio'

i"i ".nl",rr starting in the E position, the PcM cuts off the ,Vc clutch (if the A/c is on) and increases the engine speed to

900 rpm when the transmission is shifted to the E position'

The start clutch functions to make smooth starting possible. To let the start clutch function properly, the PcM regulates

the start clutch hydraulic pressure based on the engine's negative pressure memorized in the E position'

FCM

s*o.d.ry G..t Sh.h

(cont'd)

14-205

Page 884 of 2189

Description

Electronic Control System ('99 - 00 Modelsl (cont'dl

Grade Logic Control System

How it works:

The PcM compares actual driving conditions with memorized driving conditions. based on the input from the vehiclespeed sensor, the throttle position sensor, the manifold absolute pressure sensor, the engine coolant temperature sensor,the brake switch signal, and the shift lever position signal, to control shifting while the vehicle is ascending or descendinga slope.

Ascending Control

When the PCM determines that the vehicle is climbing a hill in E position, the system selects the most suitable shiftschedule (pulley ratio) according to the magnitude of a gradient. so the vehicle can run smooth and have more powerwhen needed. There are three ascending modes with different shift schedules according to the magnitude ot a gradient inthe PCM.

Descending Control

when the PCM determines that the vehicle is going down a hill in E position. the system selects the most suitable shiftschedule (pulley ratio) according to the magnitude of a gradient. This, in combinstion with engine braking, achievessmooth driving when the vehicle is descending, There are three descending modes with different shift schedules accord-ing to the magnitude of a gradient in the PCM.

L

14-206

Page 885 of 2189

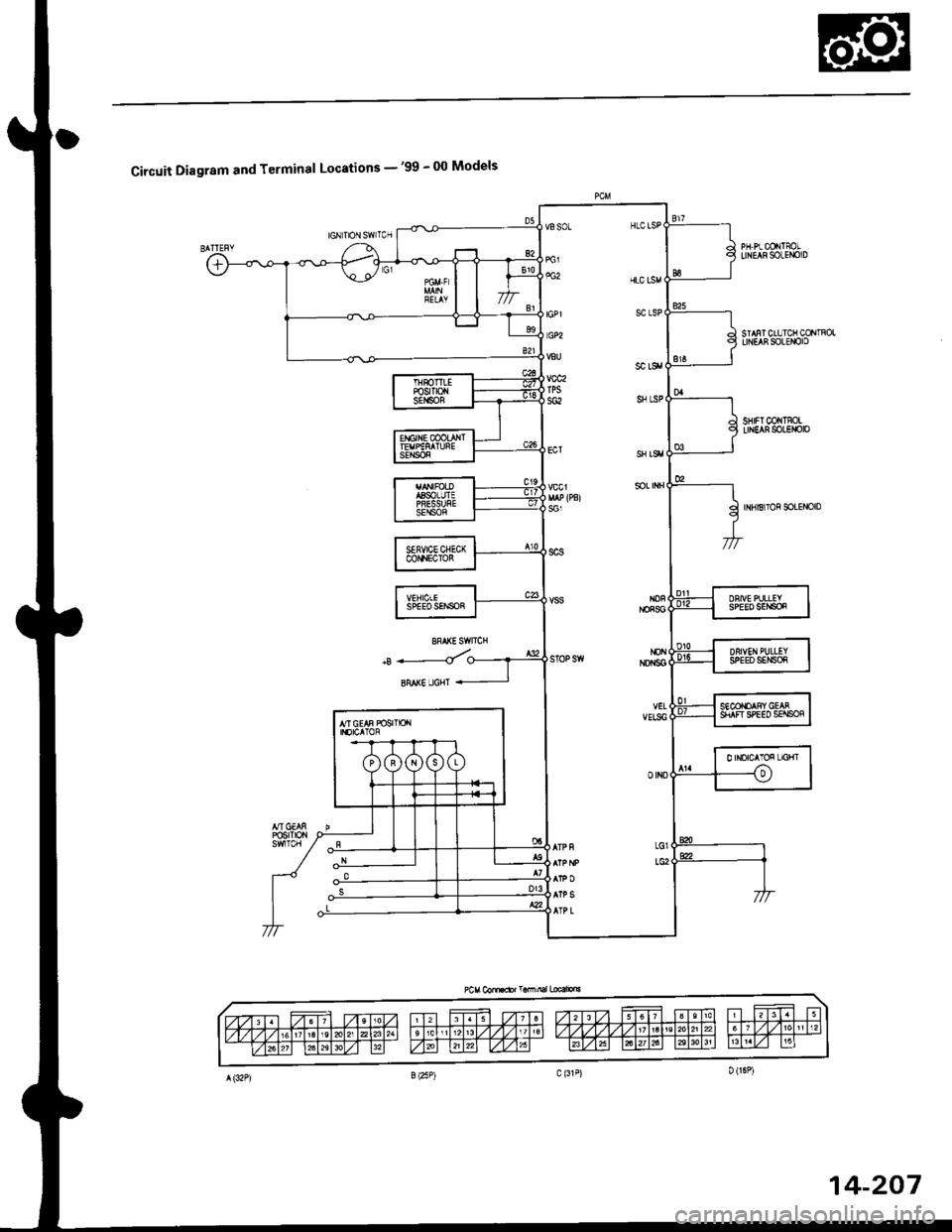

Circuit Diagram and Terminal Locations -'99 - 00 Models

IGN1TIONSWTCHPH.PLCOiTSOLLINEAF SOLEI€ID

SIAFT CLIJICH COTITROLLINEiF SOLET€IO

SHIFI CONTNOTLINEAR SOLEI{OIO

INNIB TOF SOLETIOIO

IGPl

vcc2TPS

14-207

Page 901 of 2189

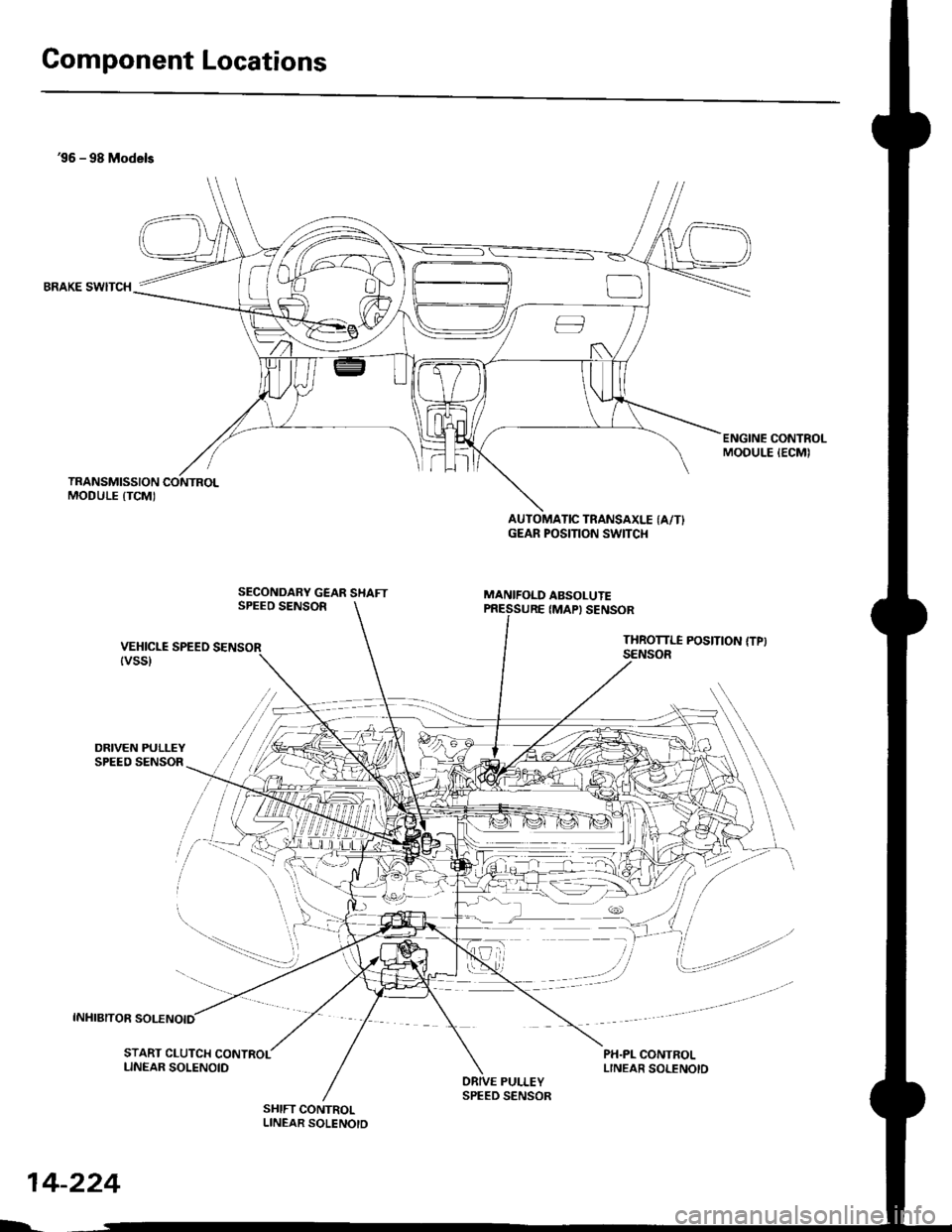

Component Locations

36 - 98 Models

BRAKE SWITCH

DRIVEN PULLEYSPEED SENSOR

INHIBITOR SOLENOID

ENGINE CONTROLMODULE IECMI

SECONDARY GEAR SHAFTSPEEO SENSOR

AUTOMATIC TRANSAXLE (A/T}GEAR POSITION SWITCI{

MANIFOLD ABSOLUTE

VEHICLE SPEEO SENSOR{vss}

IMAPI SENSOR

THROTTI.I POSITION {TPISENSOR

PH.PL CONTROLLINEAR SOLENOID

/i/ i,' / ,','4

,i/:1

t"--.---.- i,,

-_,-:-_a.--:

il

START CLUTCH CONTROLLINEAR SOLENOIDPULLEY

SHIFT CONTROLLINEAR SOLENOTD

$r,

14-224

h

SPEED SENSOR