Model HONDA CIVIC 1998 6.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CIVIC, Model: HONDA CIVIC 1998 6.GPages: 2189, PDF Size: 69.39 MB

Page 942 of 2189

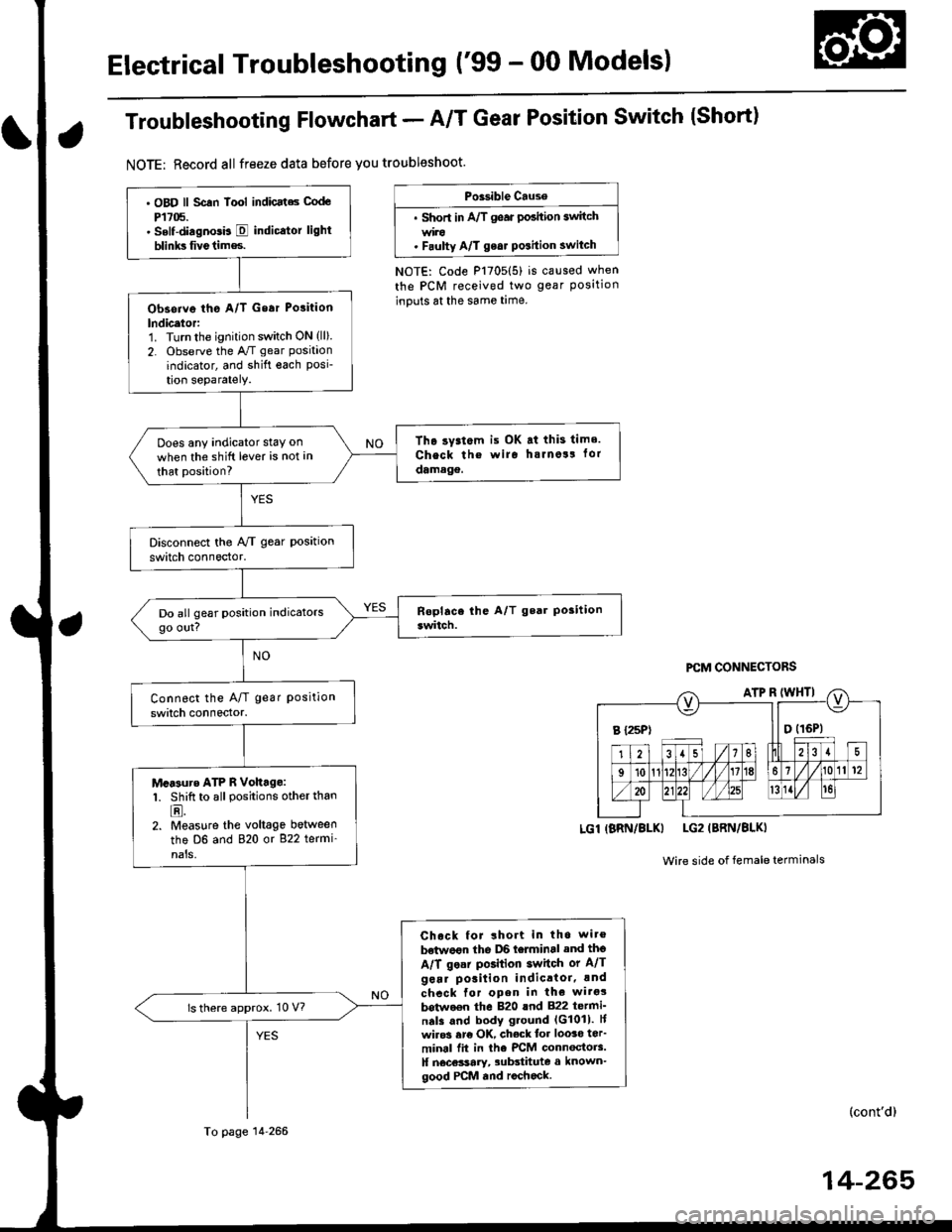

Electrical Troubleshooting ('99 - 00 Models)

Troubleshooting Flowchart - A/T Gear Position Switch (Short)

NOTE: Record all freeze data before you troubleshoot.

Po3sible Cause

. Short in A/T gear po3ition 3witch

. F.ulty A/T ge6r Position switch

NOTE: Code P1705(5) is caused when

the PCM received two gear Positioninputs at the same time.

PCM CONNECTORS

LGl (BRN/8LKI LG2 (BRN/8LKI

Wire side of female terminals

(cont'd)

14-265

B t25Pt llO(16P1

. oBD ll scln lool indicats code

P't705.. Self-diagnosb E indicator light

blinks fivetim€s.

Obseive tho A/T Gear Polition

lndicetor:1. Turn the ignition switch ON (ll).

2. Observe the A,/T gear positaon

indicator, and shift oach Posi-tion separately.

Tho ry3t6m is OK at this tims.

Check th€ wiro hsrno!! tor

damage.

Does any indicator stay on

when the shift lever is not an

that position?

M.Furo ATP R Vohtge:1. Shift to all positions other than

E.2. Measure the voltage between

the D6 and 820 or 822 termi'

nals,

Chock for lhort in tho wit€

betwe€n the D6 telminal and thg

A/T ge.r position 3witch or A/T

gear po3ition indicttoi, !nd

chcck for open in the witgs

botwo€n the 820 lnd 822 tetmi_n.ls and body g.ound (G1011. F

wiro3 ere OK, check tor loo3o ter'

minal fit in the PrCM connoctors.ll n6c€3sary, 3ubstitute a known-good PCM and rochock.

ls there approx. 10 V?

To page 14 266

Page 943 of 2189

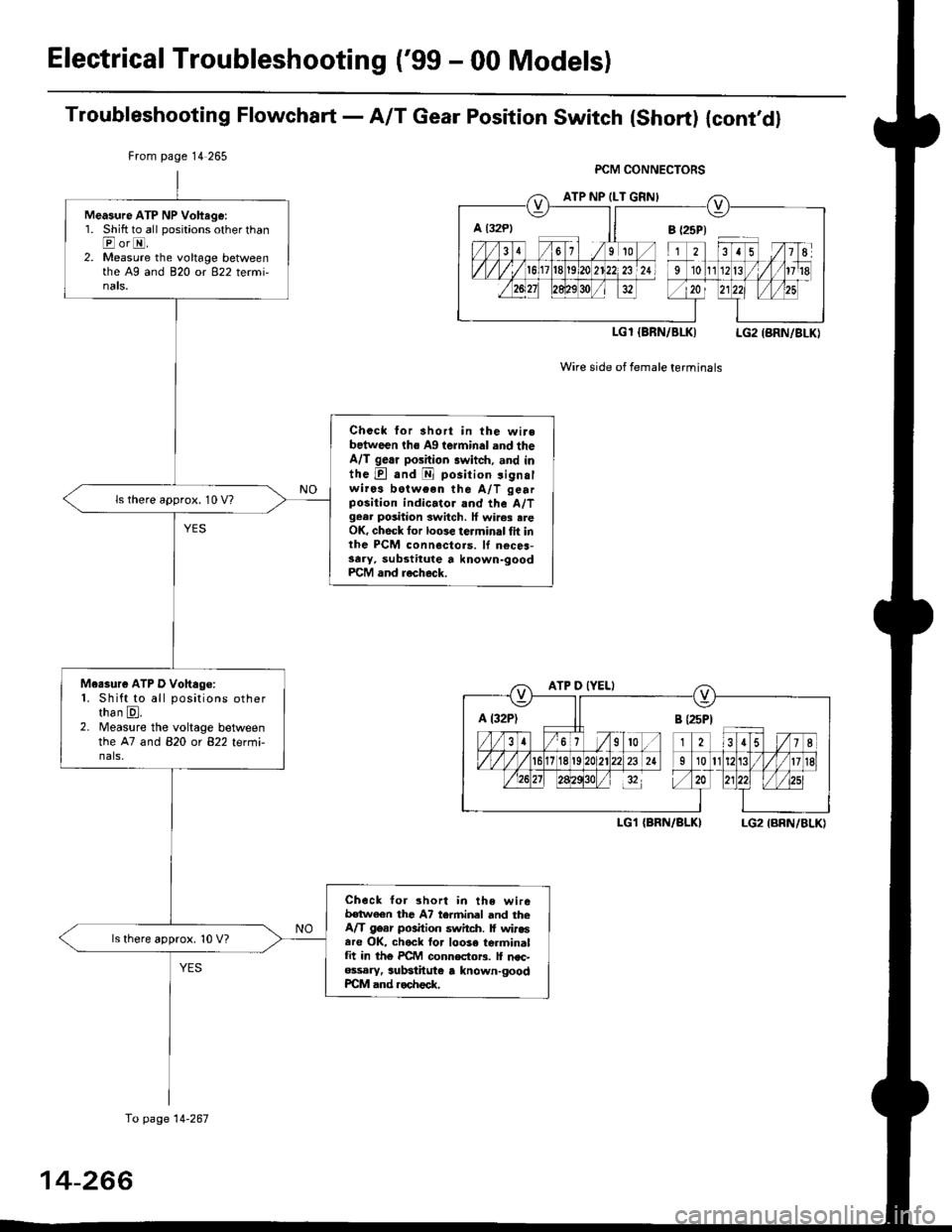

Electrical Troubleshooting ('99 - 00 Models)

Troubf eshooting Flowcharl - AIT Gear Position Switch {Short) {cont,d}

From page 14 265

LGl IBRN/BLK) LG2 {BRN/BLK}

Wire side of female terminals

A t32Pl jl B {25P)

ATP D (YEL)

LG1 {BRN/ALKILG2 IBRN/BLK)

Measure ATP NP Voltage:'1. Shift to all positions other thanEorI2. Measure the voltage betweenthe A9 and 820 or 922 te(mi-nals.

Check for short in the wirebetwoen ths Ag terminal and theA/T gerr position switch, .nd inthe E .nd E position 3ignalwiros botween the A/T gearposition indic.tor and the A/Tgear positaon switch. lf wircs .reOK, check tor loose terminal tit inthe PCM connectols. lf n€ces-3ary, substitute a known-goodPCM and rocheck.

ls there approx. 10 V?

Me.sure ATP D Vohago:1. Shift to all positions otherthan E.2. Measure the voltage betweenthe 47 and 820 ot 822 tet-r'i-nals,

Check tor 3hort in lhe wireb€twaen thc A7 terminel and theA/T g6ar position switch. lf wir.sare OK, ch.rck to. loose terminalfit in th6 PCM connectoF. lf nsc-ossary. substhute a known-goodPCM and ..check.

ls there approx. 10 V?

a l32Pl ll B (25P1

To page 14-267

14-266

Page 945 of 2189

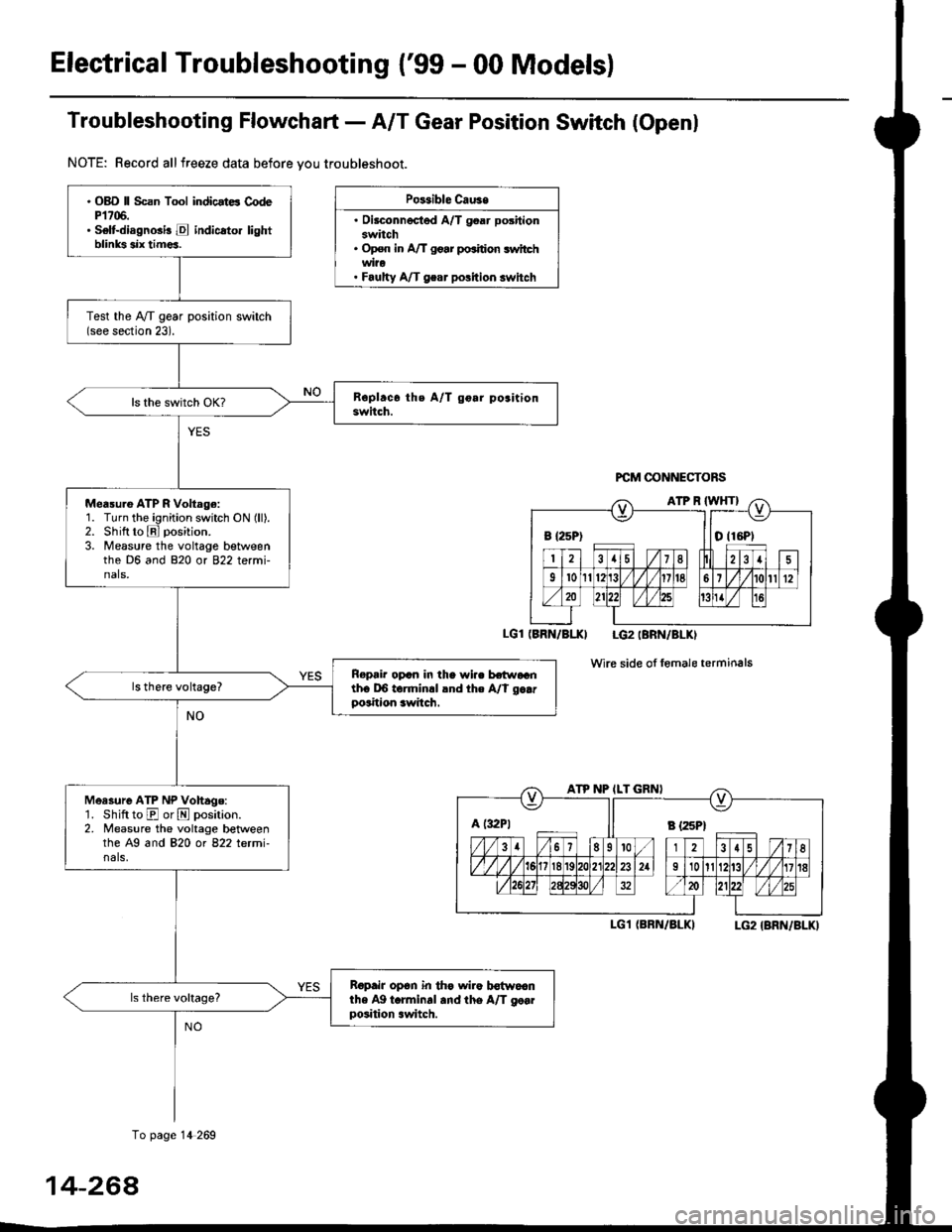

Electrical Troubleshooting {'99 - 00 Models)

Troubfeshooting Flowchaft- AIT Gear Position Switch (Openl

NOTE: Record allfreeze data before vou troubleshoot.

Po$ible Cau3e

. Oilconnected A/T goar positionswitch. Op€n in A/T go.r po.ition switchwi?o. Faulty A/T gear polition switch

PCM @NNECTORS

(BRN/BI.XI LG2IBRN/BLKI

wire side of fomale terminals

I-G1 (BRN/BLKILG2 {BRN/BLK)

B {25P) I tO (16P1

ATP NP ILT GRNI

A t:r2Pt Il s tzspt

. OBD ll Scan Tool indicstE CodeP1706.. Selt-diagnGi! E indicato. lightblinks six tim€a.

Test the IVT gear position switch(see section 23).

Measu.e ATP R Voltage:1. Turn the ignition switch ON (ll).2. Shift to E position.

3. Measure the voltage betweenthe D6 and 820 or 822 termi-nals,

Ropair opcn in the wi.. hr.raGnth6 DO torminrl lnd the A/t g..rposition awitch.

Measure ATP NP Vohage:'1. Shift to E or N position.2. Measure the voltage betweenthe A9 and 820 ot 822 letmi-nals,

Ropair op6n in th€ wiro b€{woanthe Ag t.rminal and the A/T go..position .witch.

To page 14 269

14-264

Page 947 of 2189

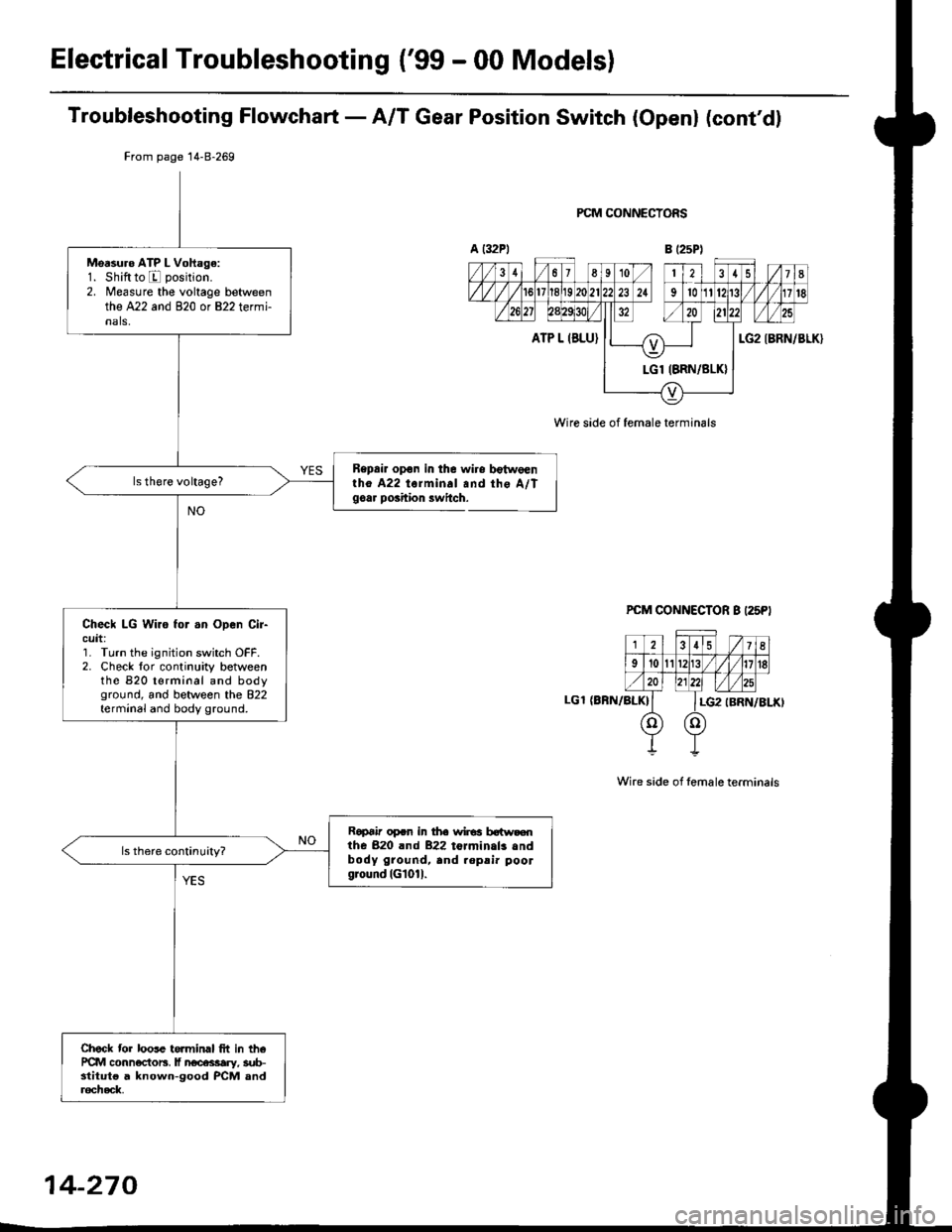

Electrical Troubleshooting {'99 - 00 Models}

Troubleshooting Flowchart - A/T Gear Position Switch (Openl (cont'dl

Bepair opon in the wiro bgtw€enlho A22 torminal and the A/Tgoar poihion lwitch.

PCM CONNECTORS

B (25P1

LGT (BFN/ALK}

PCM CONNECTOR B I25PI

12.15 / 7I

9't0l1Br1/l/41it8

ll lLG2

o) (o)

IBRN/BLKI

Wire side of female terminals

From page 14-8-269

Msasuro ATP L Voftage:1. Shiftto E position.

2. Measure the voltage betweenthe A22 and 820 or 822 termi-nals,

Check LG Wiro for .n Open Cir-cuit:']� Turn the ignition switch OFF.2. Check lor continuity betweenthe 820 t€rminal and bodyground, and between the 822terminal and body ground.

Ropai' op.n in the wir€a botw.€nthe 820 rnd 822 toJminals .ndbody ground, and .opsi. poolground (Gl01l.

Check tor loose te.minal frt in th6PCM conn€ctors, lf n€cessary, sub-stitut€ a knowo-good PCM anda6check,

Wire side of female terminals

14-270

Page 949 of 2189

ElectricalTroubleshooting ('99 - 00 Models)

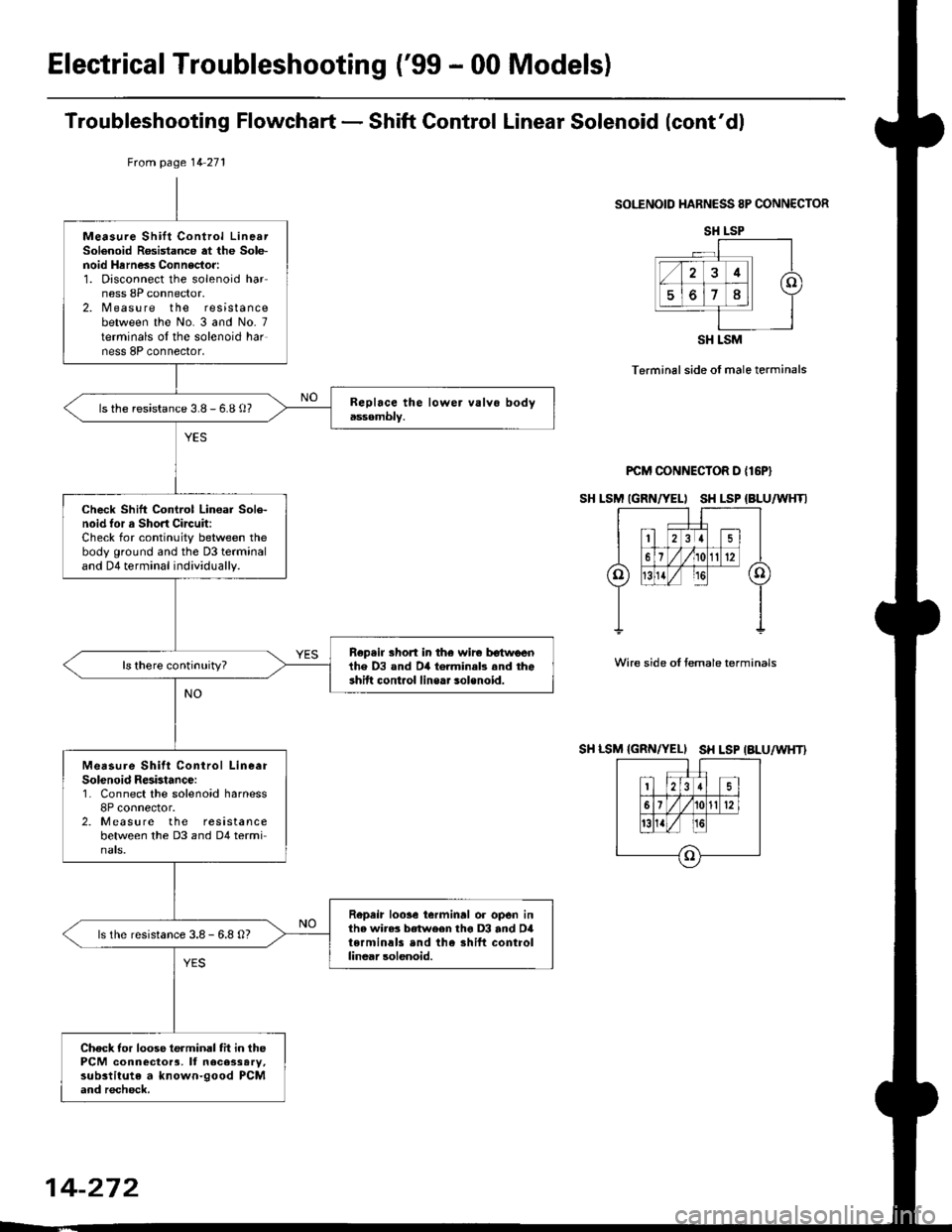

Troubleshooting Flowchart - Shift Gontrol Linear Solenoid (cont'dl

SOI."ENOID HARNESS 8P CONNECTOR

Terminal side of male terminals

PCM CONNECTOR D {16P}

SH LSM IGRN/YELI SH LSP {BLU/WHTI

Wire side oI temale terminals

SH LSM {GRN/YELI SH LSP IALU/WHT}

tuom page 14 271

Measure Shift Control LinearSolenoid R6sistance at the Sole-noid Hrrness Connector:1. Disconnect the solenoid harness 8P connector.2. Measure the resistancebetween the No. 3 and No- 7terminals oI the solenoid harness 8P connector,

ls the resistance 3.8 - 6.8 o?

Check Shift Control Lin€ar Sole-noid tor a Short Circuit:Check for continuity between thebody ground and the D3 terminaland D4 terminal individually.

Rep.ir short in th€ wir€ tr€twlrenihe D3 and D4 torminab .nd theshift cont.ol line.. solenoid.

Measure Shitt Conirol LineerSolenoid Resbtance:1. Connect the solenoid harness8P connector.2. Measure the resistancebetween the D3 and D4 termi-nats.

Repeir loose ierminrl or open inthe wire3 between tho D3 and D4terminals end the shift controllinear solenoid.

ls the resistance 3.8 - 6.8 O?

Check tor loose terminal fit in thePCM connector3, It necessary,substitute a known-good PCMand recheck.

SH LSP

SH LSM

14-272

Page 951 of 2189

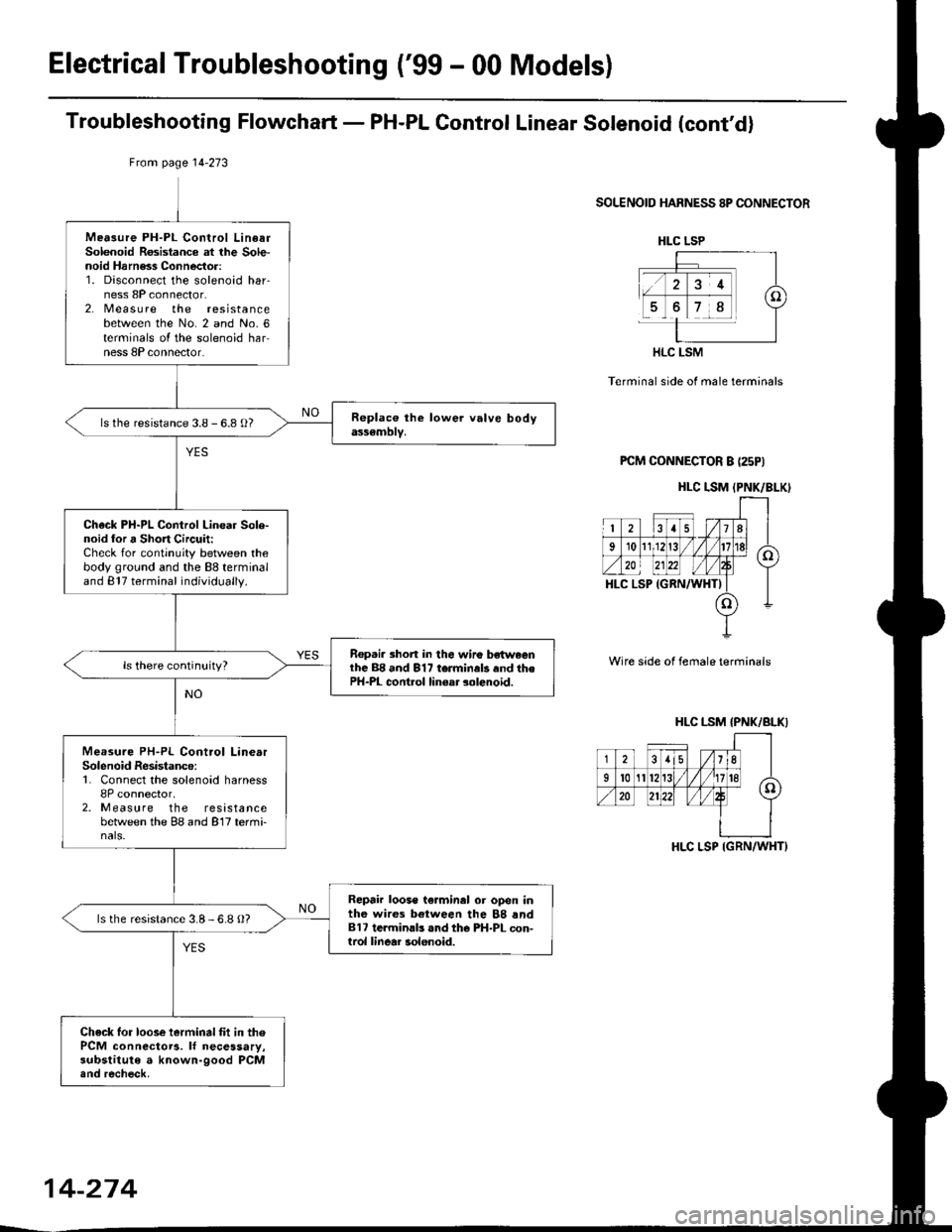

Electrical Troubleshooting ('99 - 00 Models)

Troubleshooting Flowchart - PH-PL Gontrol Linear Solenoid (cont'd)

From page l4-273

SOLENOID HARNESS 8P CONNECTOR

Terminal side of male terminals

PCM CONNECTOR B (25PI

Wire side of female terminals

Mea3ure PH-PL Control LinearSolenoid Rosistance at lhe Sole-noid Harness Connector:1. Disconnect the solenoid har-ness 8P connector.2. Measu re the resistancebetween the No. 2 and No. 6terminals oI the solenoid harness 8P connector.

ls the resistance 3.8 - 6.8 O?

Check PH-PL Control Linear Sole-noid lor a Short Circuit:Check for continuity between thebody ground and the 88 terminaland 817 terminal individually.

Rep.i. 3hort in the wiro bsh^,eenlhc 88 and 817 terminals and thePH-PL cont.ol linear solenoid.

Measure PH-PL Control LinearSolenoid Resistance:1. Connect the solenoid harness8P connector,2. Measure the resistancebetween the 88 and 817 termi-nals.

Repair loose te.minal or open inthe wires between the 88 rnd817 te.minlb .nd the PH-PL con-trol linear solenoid.

ls the resistance 3.8-6.8 O?

Check lor loose ierminal fit in thePCM connectoTa. lf necessary,substitute a known-good PCM.nd recheck.

HLC LSP

HLC LSM

HLC I.SM (PNK/BLK)

HLC LSM {PNK/BLKI

-j-i8lisli.((

35/11

Il0A/'.n20

HLC LSP IGRN/WHT}

14-274

Page 953 of 2189

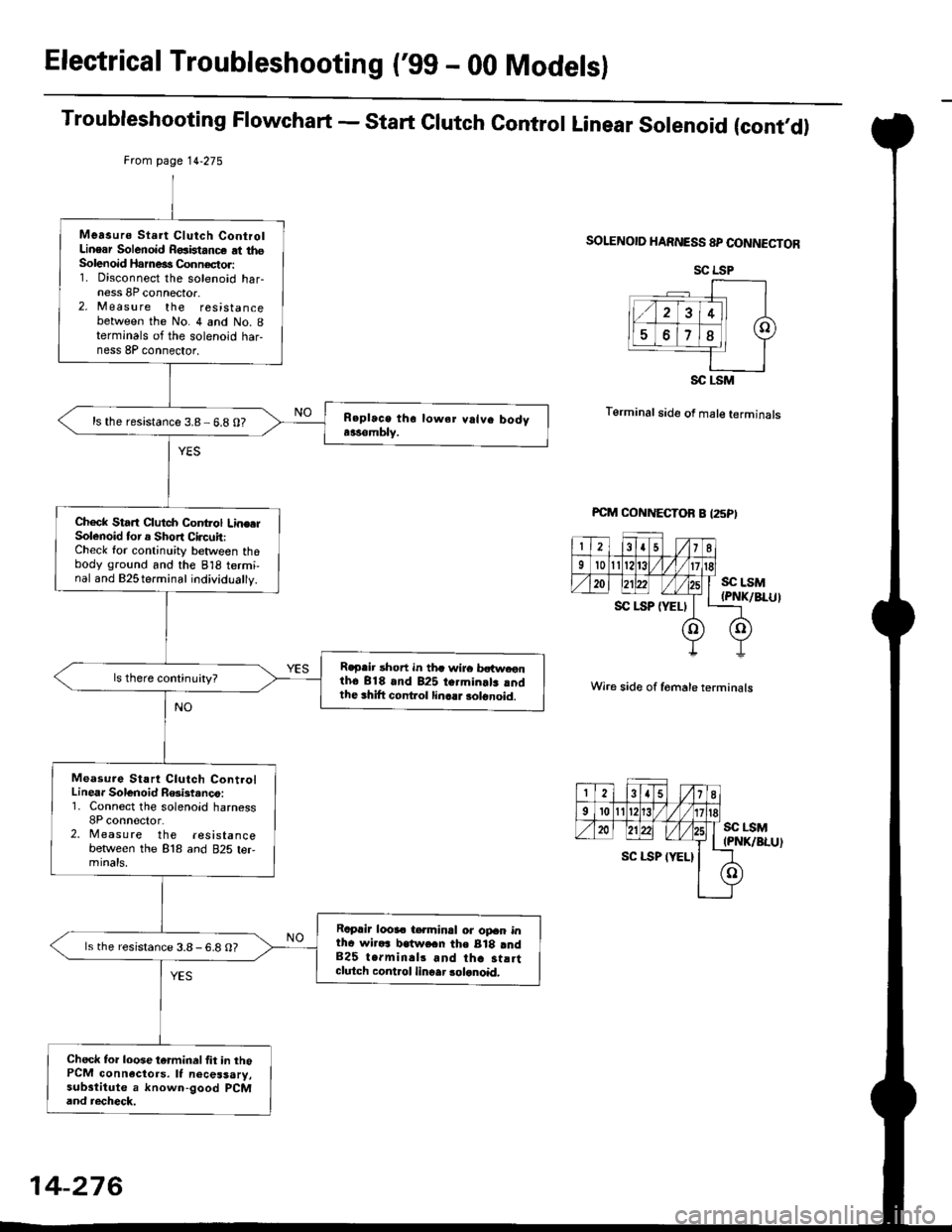

Electrical Troubleshooting ('gg - 00 Modelsl

Troubleshooting Flowchart - start clutch control Linear solenoid (cont,d)

Frcm page 14.275

SOLENOID HARNESS 8P CONNECTOR

T6rminal side of male terminals

Wire side of f6male terminals

SC LSM(PNK/BLU)

Measurs Start Clutch ControlLinear Solenoid R€aistance at thsSolenoid Harne€s Connector:1. Disconnect the solenoid har-ness 8P connector.2, M easu re the resistancebetween the No. 4 and No. Iterminals of the solenoid har-ness 8P connector,

ls the resistance 3.8- 6.8 0?

Check Start Clutch Control Line.rSolenoid tor a Short Circuit:Check for continuity between thobody ground and the 818 termi-nal and B2Sterminal individually.

R€p.ir short in th. wire bctw.onth6 818 and 825 termin.lr rndthe 3hift cont ol linc.r solonoid.

Measure Start Clutch ControlLinear Solenoid R6ist.nco:1. Connect the solenoid harness8P conn€clor.2. Measure the resistancebetlveen the 818 and 825 ter,mtnats,

Raprir looa. t€.minal or opan intha wirars lratwe.n the B18 and825 terminal3 and tha st!rtclutch control linoar 3olanoid,

ls the resistance 3.8-6.8 O?

Check to. loose tarminal fit in thoPCM connactors. It necessary,substitute a known-good PCMand recheck.

SC LSP

SC LSM

14-276

Page 955 of 2189

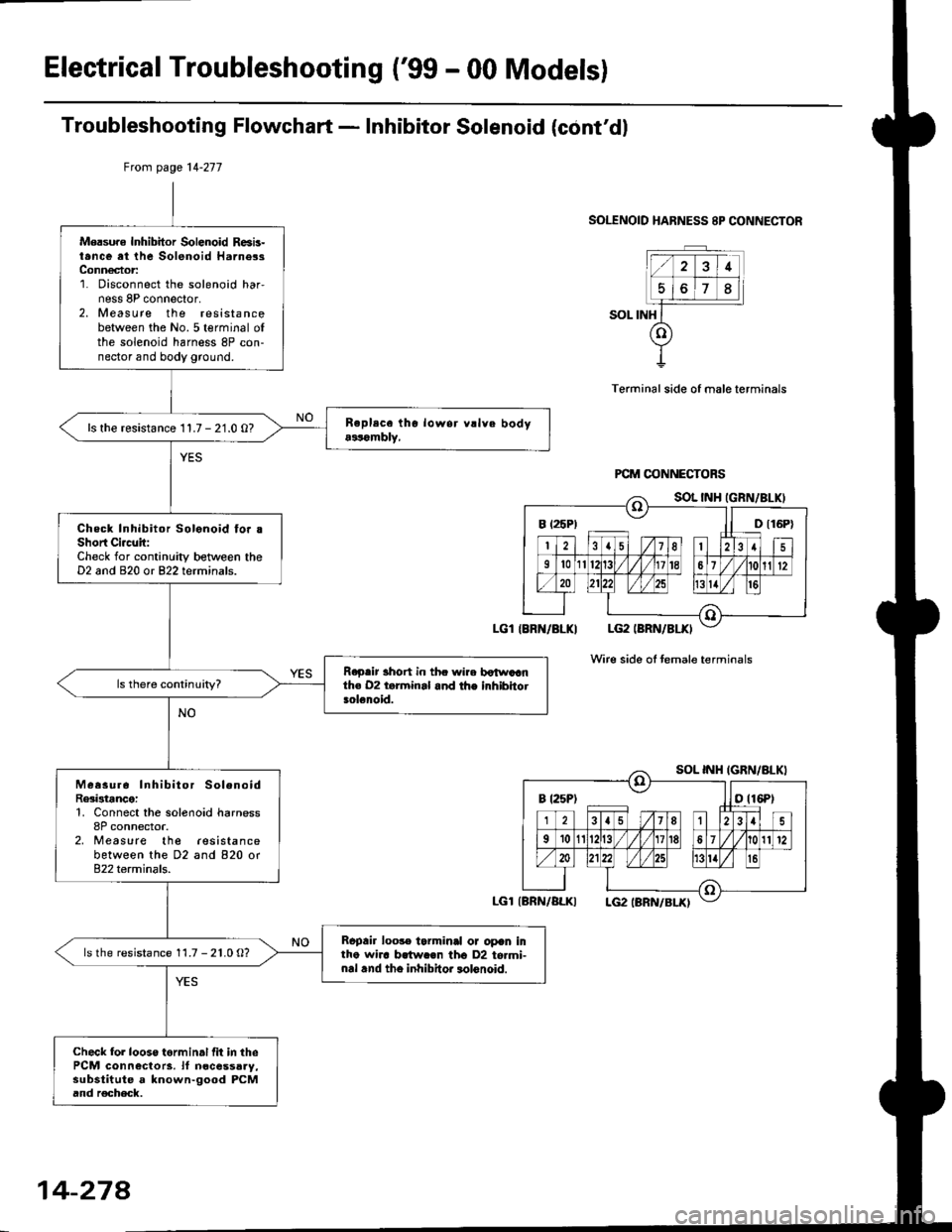

Electrical Troubleshooting ('99 - 00 Models)

Troubleshooting Flowchart - Inhibitor Solenoid (cont'dl

SOLENOID HARNESS 8P CONNECTOR

SOL INH

Terminal side of male terminals

Wire side oI temale terminals

Mersure Inhibitor Solenoid R6b-t.nce at the Solenoid Harne3sConn€ctor:1. Disconnect the solenoid har,ness 8P connector,2. Measure the resistancebetween the No.5 terminal ofthe solenoid harness 8P con-nector and body ground.

ls the resistance 11.7 - 21.0 O?

Check Inhibitor Solonoid fo. .Short Ci.c!it:Check for continuity between theD2 and 820 or 822 terminals.

R.p.ir 3hort in thc wire botwaanth€ 02 t.rminal and the inhibhotsolenoid.

Measur6 Inhibitor SolenoidRe3istance:1, Connect the solenoid harness8P connector.2, Measure the lesistancebetween the D2 and 820 or822 terminals.

Rcpair loo3. tarminal or opan intho wha brtw.€n tho D2 to.mi-nal .nd tho inhibitor lolonoid.

ls the resistance 11.7 - 21.0 O?

Check fol looso torminal fit in thePCM connectors. lf n€cessaay,substitute a known-good PCMand r€check.

Ftom page 14-277

LGl IBRN/BLKI

LGl{BRN/ALKI

B t25P) ll D t16P)

B t25Pt otl6Pt

14-274

Page 957 of 2189

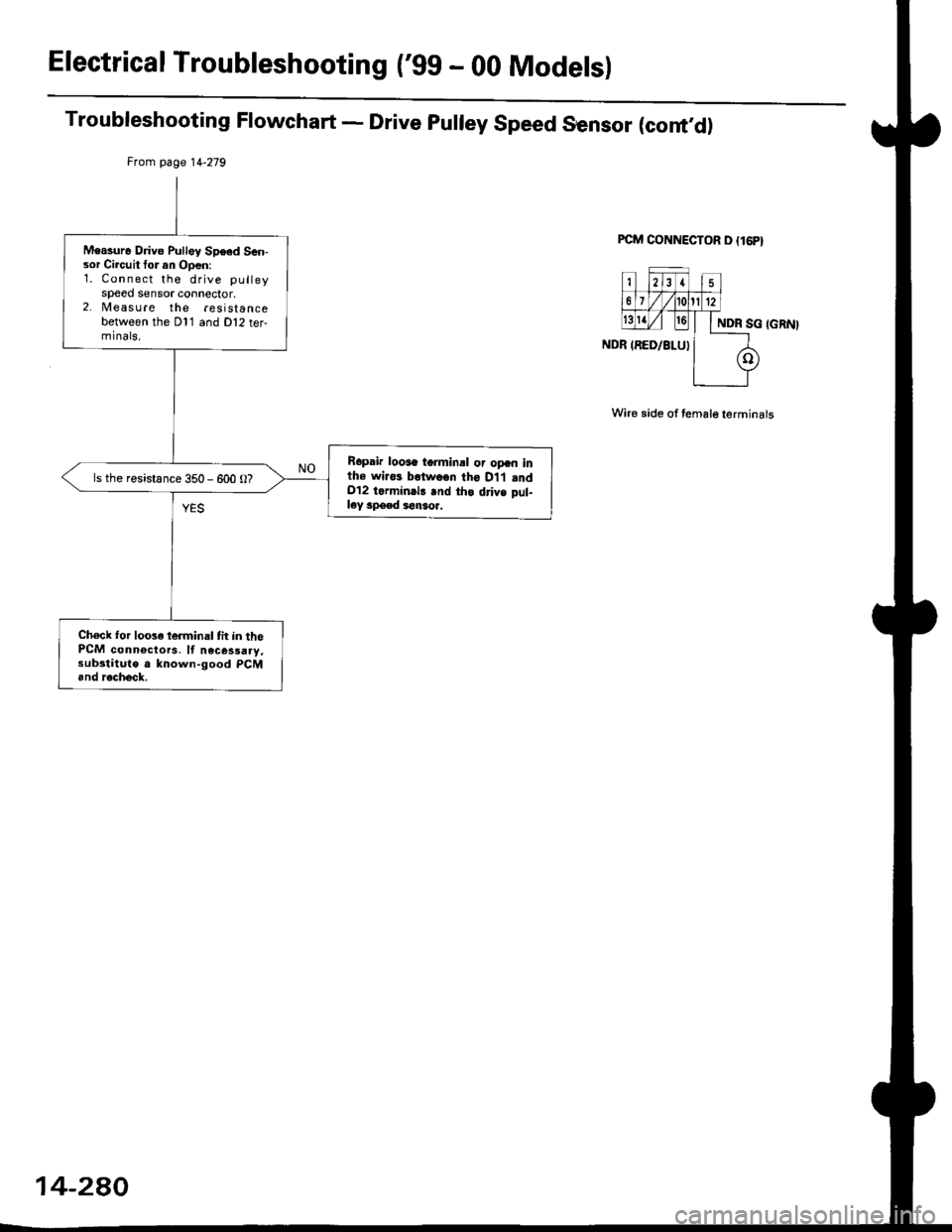

Electrical Troubleshooting ('gg - 00 Models)

Troubleshooting Flowchart - Drive pulley Speed Sensor (cont,d)

PCM CONNECTOR D {16P}

Wire side of temale terminals

From page 14-279

Measure Drivo Pulley Speed Sen-sor Circuit tor an Open:1. Connect the drive pulleyspeed sensor connector,2. lvleasu re the resistancebetween the Dl1 and Dl2 ter-minals.

R6pair loose tgrminal or opan inthe wiros betwo€n tho D1,l .ndOl2 tarminrl! .nd th. drivs pul-ley speed *n3or.

ls the resistance 350 - 600 O?

Ch6ck for loose lerminal tit in thePCM connectors, ll nece3saay,substituto a known-good PCM6nd r€check.

14-280

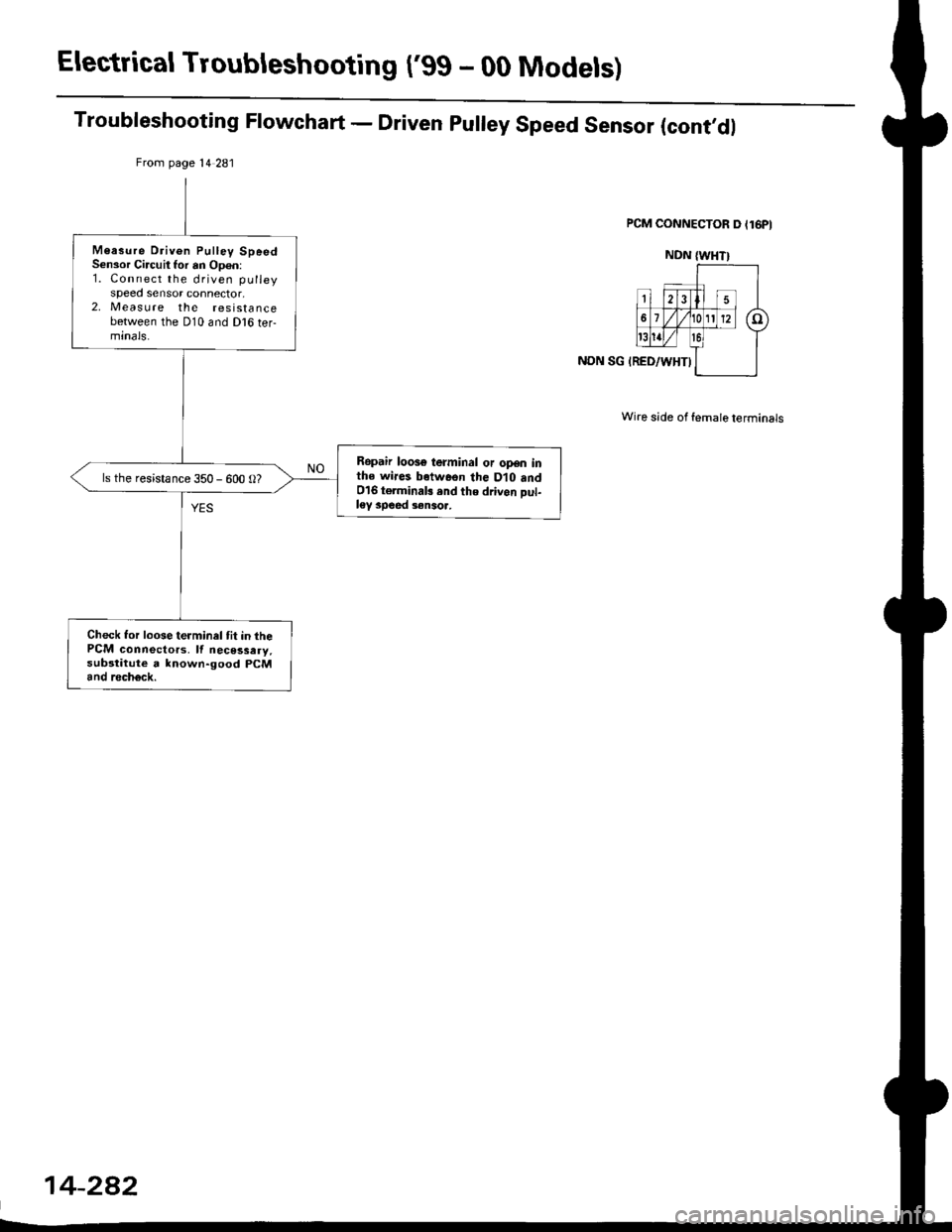

Page 959 of 2189

Electrical Troubleshooting ['gg - 00 Models)

Troubleshooting Flowchart - Driven pulley Speed Sensor (cont,dl

NON SG IRED/WHTI

Wire side of female terminals

From page l4 281

M6asure Driven Pulley SpeedSensor Circuit Ior an Op€n:1. Connect the driven pulleyspeed sensor connector,2, Measure the resistancebetween the D10 and Dl6 ter-minals.

Rgpair loose terminal or open inthe wires botwosn the Dlo and016 torminab rnd the drivon Dul-ley speed 3ensoa,

ls the resistance 350 - 600 O?

Check tor loose terminal tit in thePCM connectors, lf necessary,sub3titute a lnown-good PCMand rech6ck.

14-282