Thrust HONDA CIVIC 1998 6.G Owner's Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CIVIC, Model: HONDA CIVIC 1998 6.GPages: 2189, PDF Size: 69.39 MB

Page 616 of 2189

Mainshaft Thrust Shim

Adjustment

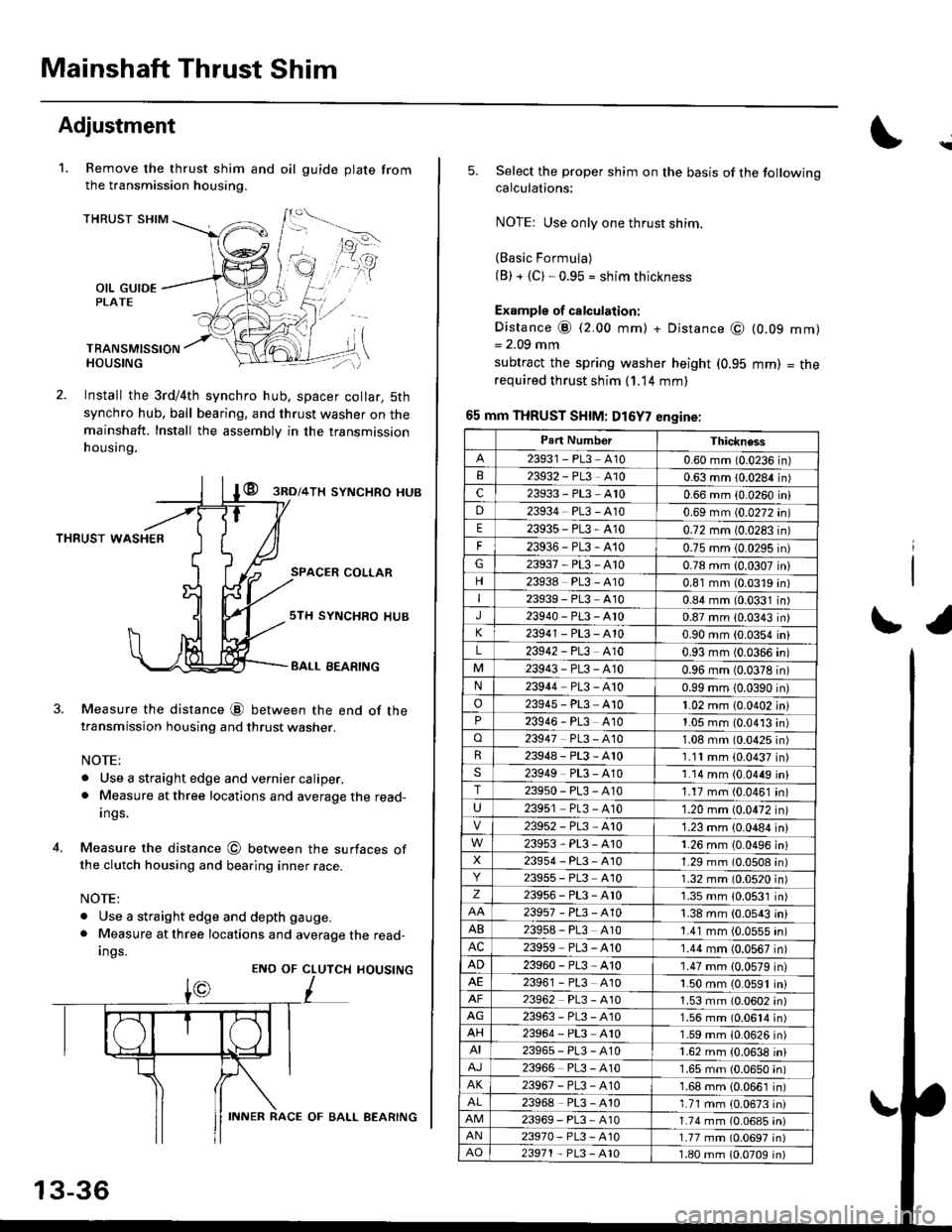

Remove the thrust shim and oil

the transmission housing.

1.gu ide plate from

THRUST SHIM

OIL GUIDEPLATE

TBANSMISSIONHOUSING

Install the 3rd/4th synchro hub, spacer collar, 5th

synchro hub, ball bearing, and thrust washer on themainshaft. Install the assembly in the transmission

h ousing.

@ gnol+lx syNcHRo HUB

THRUST WASHER

SPACER COLLAR

4.

Measure the distance @ between the end of thetransmission housing and thrust washer.

NOTE:

. Use a straight edge and vernier caliper.. Measure at three locations and average the read-

Ings.

Measure the distance @ between the surfaces ofthe clutch housing and bearing inner race.

NOTE:

. Use a straight edge and depth gauge.

. Measure at three locations and average the read-

Ings.

sTH SYNCHRO IIUB

BALL EEARING

CLUTCH

L

HOUSINGENO OF

13-36

INNER RACE OF BALL AEARING

\

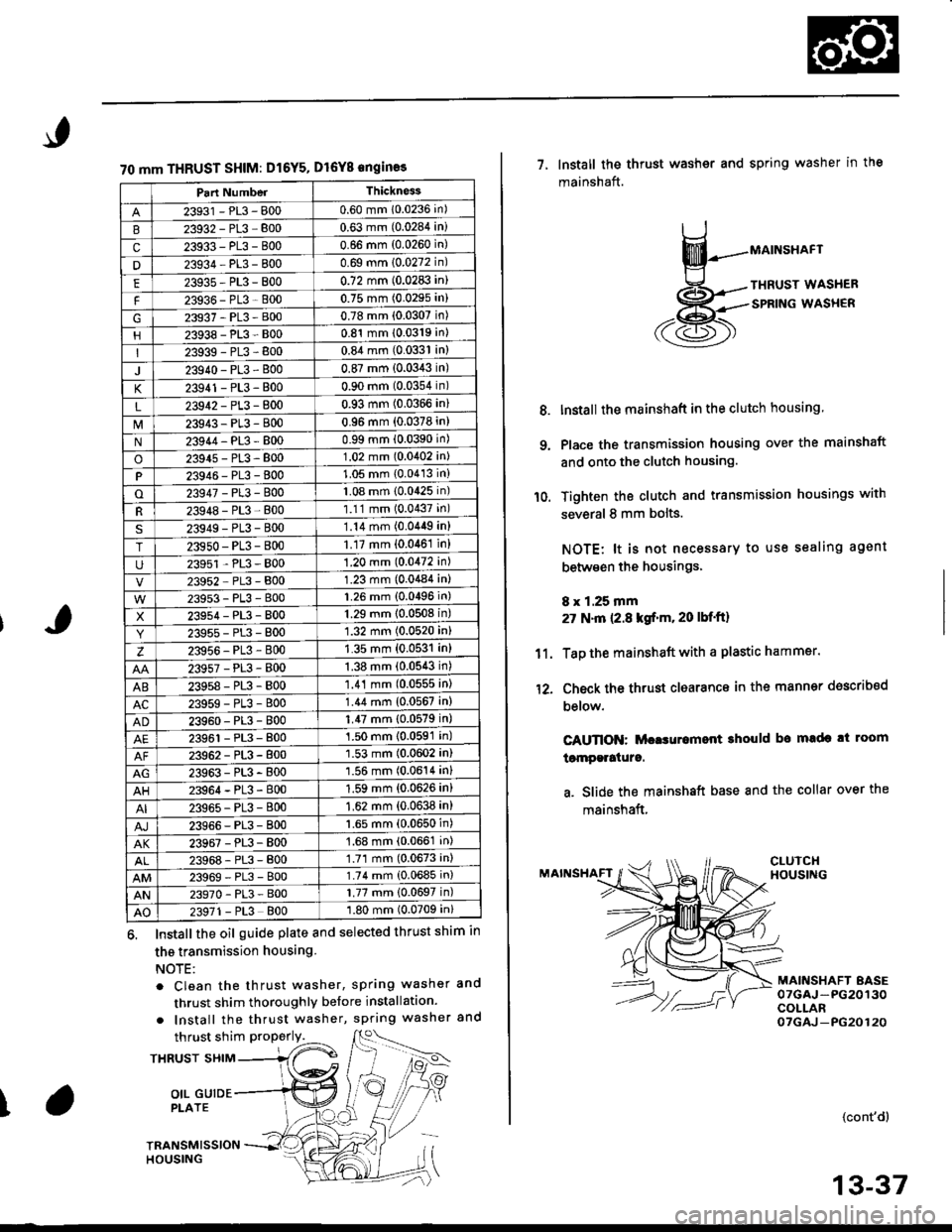

5.Select the proper shim on the basis of the followingcalculations:

NOTE: Use only one thrust shim.

(Basic Formula)(B) + {C). 0.95 = shim thickness

Example of calculation:

Distance @ (2.00 mm) + Distance @= 2.09 mm

subtract the spring washer height (0.95

required thrust shim (1.14 mm)

65 mm THRUST SHIM: D16Y7 engine:

(0.09

mm)

mm)

= tne

r1

Part NumborThickness

23931 - PL3 A100.60 mm (0.0236 in)23932 - PL3 A100.63 mm 10.0284 in)c23933 - PL3 A100.66 mm {0.0260 iniD23934 PL3 - A100.69 mm (0.0272 in)

E23935-PL3-4100.72 mm 10.0283 in)

F23936-PL3-4100.75 mm 10.0295 in)G23937-PL3-A100.78 mm {0.0307 in}

23938 PL3 - A100.81 mm (0.0319 in)I23939 - PL3 At00.84 mm (0.0331 in)J23940-PL3-Ar00.87 mm (0.0343 in)

23941 - PL3 - A100.90 mm (0.0354 in)

L23942 - PL3 A100.93 mm (0.0366 in)

23943-PL3-A100.96 mm (0.0378 in)N23944 PL3 - A100.99 mm 10.0390 in)

o23945-PL3-A101.02 mm {0.0402 in}23946 - PL3 A101.05 mm (0.0413 in)o23947 PL3 - 4101.08 mm (0.0425 in)R23948-PL3-A101.11mm (0.0437 in)s23949 PL3 - A101.14 mm {0.0449 in}T23950-PL3-A101.17 mm (0.0461 in)

U23951 PL3 - A101.20 mm (0.0472 in)

23952-PL3-Ar01.23 mm {0.0484 in)

23953-PL3-A101.26 mm {0.0496 in}X23954 - P13, A101.29 mm (0.0508 in)23955 - PL3 A101.32 mm (0.0520 in)z23956-PL3-Ar01.35 mm {0.0531 in)

23957-PL3-A101.38 mm (0.0543 in)

AB239s8 - PL3 A101.41 mm (0.0555 in)AC23959 PL3 - A101.44 mm (0.0567 in)

AD23960 - PL3 A101.47 mm (0.0579 in)23961 - PL3 4101.50 mm (0.0591 in)23962 PL3 - A101.53 mm (0.0602 in)AG23963-PL3-4101.56 mm (0.0614 in)AH23964 - PL3 A101.59 mm (0.0626 in)AI23965-PL3-A101.62 mm {0.0638 in)

23966 PL3 - A101.65 mm (0.0650 in)AK23967-PL3-A101.68 mm {0.0661 in)

23968 PL3 - A101.71 mm {0.0673 in)23969-PL3-A101.74 mm (0.06a5 iniAN23970- PL3 -A101.77 mm (0.0697 in)AO23971 - PL3 - A101.80 mm 10.0709 in)

Page 617 of 2189

70 mm THRUST SHIM: Dl6Y5, Dl6Y8 engin€s

Part NumberThickness

23931 - PL3 - 8000.60 mm 10.0236 in)

23932-PL3-8000.63 mm (0.0284 in)

c23933-PL3-8000.66 mm (0.0260 in)

D23334-PL3-8000.69 mm 10.0272 in)

E23935-PL3-8000.72 mm (0.0283 in)

F23936 - PL3 8000.75 mm (0.0295 in)

23937-PL3-B000.78 mm (0.0307 in)

23938-PL3-8000.81 mm (0.0319 inl

23939-PL3-8000.84 mm (0.0331 in)

23940-PL3-8000.87 mm {0.0343 in)

23941 - PL3 - 8000.90 mm (0.0354 in)

L23942-PL3-8000.93 mm (0.0366 in)

23943-PL3-8000.96 mm (0.0378 in)

N23944-PL3-8000.99 mm i0.0390 in)

o2394s-PL3-8001.02 mm (0.0102 in)

P23946-PL3-8001.05 mm {0.0413 in}

o23947-PL3-8001.08 mm (0.0{25 in)

23948 - PL3 800'1.1'1 mm (0.0437 4n)

23949-PL3-8001.14 mm (0.0449 inl

T23950-PL3-8001.17 mm (0.0461 in)

23951 - PL3 - 8001.20 mm (0.0472 in)

23952-PL3-8001.23 mm (0.0444 in)

239s3-PL3-8001.26 mm {0.0496 in)

X23954-PL3-8001.29 mm (0.0508 in)

2395s-PL3-8001.32 mm (0.0520 in)

z23956-PL3-8001.35 mm (0.0531 in)

23957-PL3-8001.38 mm (0.0543 in)

A823958-PL3-8001.41 mm (0.0555 in)

AC23959-PL3-8001.44 mm {0.0567 in)

AD23960-PL3-8001.47 mm (0.0579 in)

2396'�t-PL3-8001.50 mm (0.0591 in)

23962-PL3-8001.53 mm (0.0602 in)

AG23963-PL3-8001.56 mm (0.0614 in)

AH23964-PL3-8001.59 mm (0.0626 in)

23965-PL3-8001,62 mm (0.0638 in)

23966-PL3-8001.65 mm (0.0650 in)

AK23967-PL3-8001.68 mm (0.0661 in)

23968-PL3-8001.71 mm (0.0673 in)

23969-PL3-8001.74 mm (0.0685 in)

AN23970-PL3-8001.77 mm (0.0697 in)

AO23971- PL3 8001.80 mm (0.0709 inl

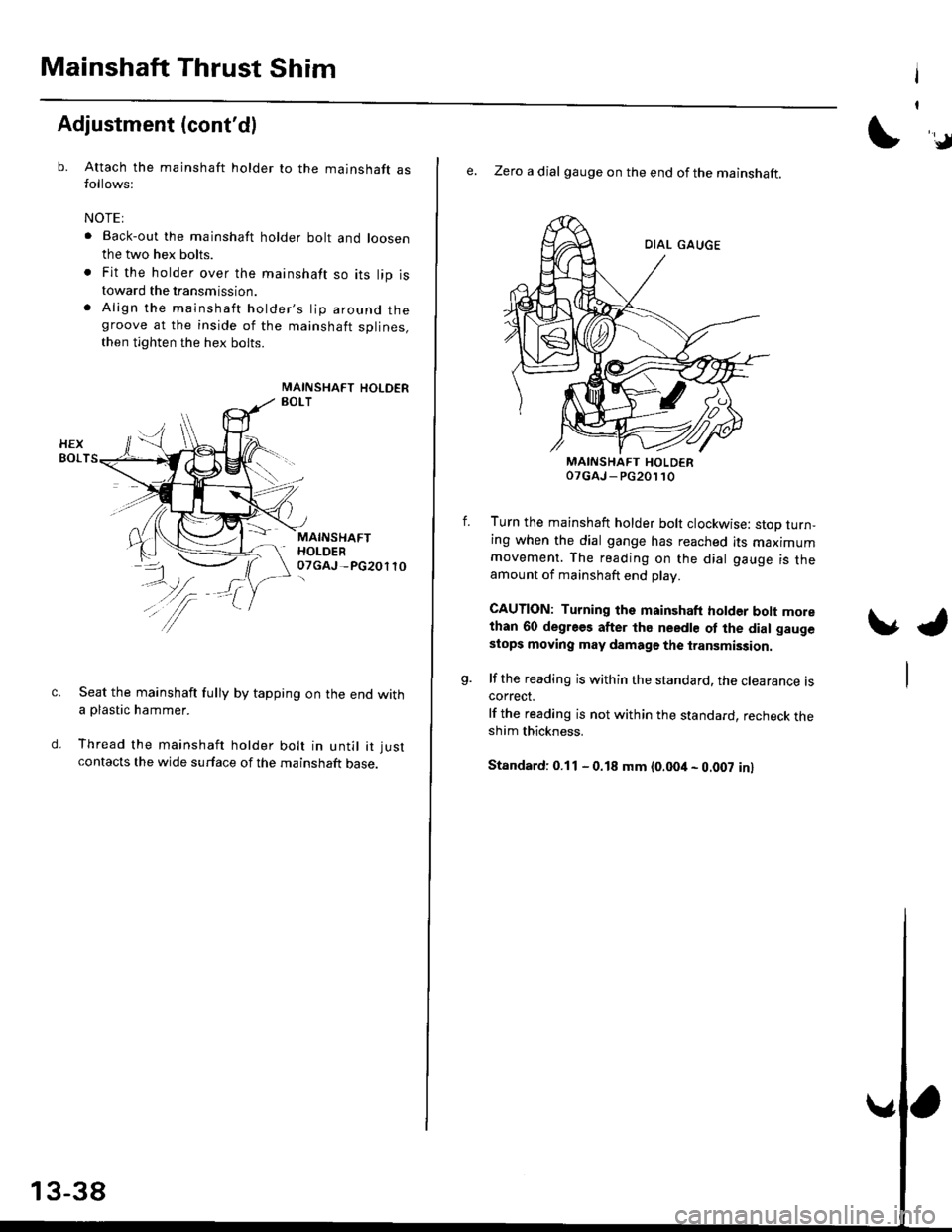

6. Installthe oil guide plate and selected thrust shim in

ths transmission housing

NOTE:

. Clean the thrust washer, spring washel and

thrust shim thoroughly belore installation.

. lnstall the thrust washer, spring washer and

thrust shim proPerlY.

THRUST SHIM

I

OIL GUIDEPLATE

TRANSMISSIONHOUSING

8.

o

10.

7, Install the thrust washer and spring washer in the

mainshaft.

lnstall the mainshaft in the clutch housing

Place the transmission housing over the mainshaft

and onto the clutch housing.

Tighten the clutch and transmission housings with

several 8 mm bolts.

NOTE: lt is not necessary to use sealing agent

between the housings'

8 x 1.25 mm

27 N'm t2.8 kgf.m. 20 lbf'ft)

Tap the mainshaft with a plastic hammer.

Check the thrust clearance in the manner doscribsd

below.

CAUnON: Mc.suromont 3hould bo mlde !t room

tomp9laturs.

a. Slide the mainshaft base and the collar over the

mainshaft.

CLUTCHHOUSING

11.

lz.

MAITISHAFT BASE07GAJ-PG20130COLLAF07GAJ -PG20120

{cont'd}

13-37

THRUST WASHER

SPRING WASI{ER

Page 618 of 2189

Mainshaft Thrust ShimI

I

Adjustment (cont'dl

b.Attach the mainshaft holder to the mainshaft asfollows:

NOTEI

. Back-out the mainshaft holder bolt and loosen

the two hex bolts.

. Fit the holder over the mainshaft so its lip istoward the transmission.

. Align the mainshaft holder's lip around thegroove at the inside of the mainshaft splines,then tighten the hex bolts.

MAINSHAFT HOLOERBOLT

MAINSIIAFTHOLDER07GAJ-PG20110

d.

Seat the mainshaft fully by tapping on the end witha plastic hammer.

Thread the mainshaft holder bolt in until it just

contacts the wide surface of the mainshaft base.

u

e. Zero a dial gauge on the end ofthe mainshaft.

MAINSHAFT HOLDER07cAJ_PG20110

Turn the mainshaft holder bolt clockwise: stop turn,ing when the dial gange has reached its maximummovement. The reading on the dial gauge is theamount of mainshaft end olav.

CAUTION: Turning the mainshaft holder bolt morethan 60 degre€s after the needle ot the dial gauge

stops moving may damage the iransmission.

lf the reading is within the standard. the clearance iscorrecl.

lf the reading is not within the standard, recheck theshim thickness.

Standard: 0.11 - 0.18 mm {0.00it - 0.007 in}

t.

\,J

Page 621 of 2189

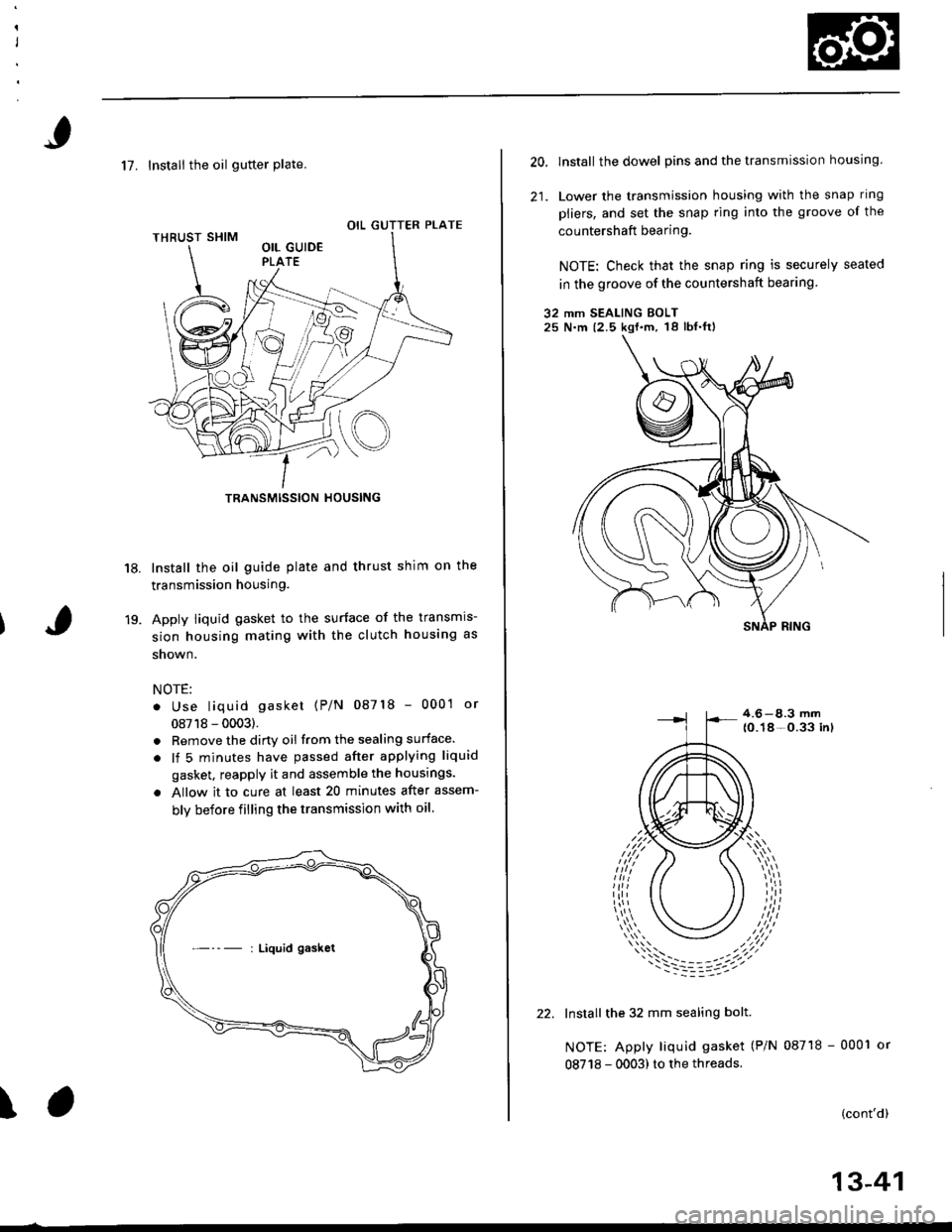

17. Instali the oil gutter Plate.

Install the oil guide plate and thrust shim on the

transmission housing.

Apply Iiquid gasket to the surface of the transmis-

sion housing mating with the clutch housing as

shown.

NOTE:

. Use liquid gasket {P/N 08718 - 0001 or

08718 - 0003).

. Remove the dirty oil fromthesealing surface.

. lf 5 minutes have passed after applying liquid

gasket, reapply it and assemble the housings.

. Allow it to cure at least 20 minutes after assem-

bly before filling the transmission with oil.

18.

19.

\

OIL GUTTER PTATE

TRANSMISSION HOUSING

Liquid gasket

20.lnstall the dowel pins and the transmission housing.

Lower the transmission housing with the snap ring

pliers, and set the snap ring into the groove of the

countershaft bearing.

NOTE: Check that the snap ring is securely seated

in the groove of the countershaft bearing

32 mm SEALING EOLT25 N.m (2.5 kgf.m, 18lbf.ftl

4.6 -8.3 mm10.14-0.33 inl

Install the 32 mm sealing bolt.

NOTE: Apply liquid gasket (P/N 08718 - 0001

08718 - 0003) to the threads.

(cont'd)

22.

13-41

Page 625 of 2189

S4C Model ('99 - 00 2-door Si, SiR)

Manual Transmission

Special Tools ............' 13-46

Maintenance

Transmission Oi1 ...................'.......... 13-47

Back-up Light Switch

Repfacement ...""" 13'47

Transmission Assembly

Removal ......'.......... 13-/tB

lnstallation ............. 13-52

lllustrated lndex ................................... 13-54

Transmission Housing

Removal ................. 13-55

Beverse Shift Holder, Reverse ldler Gear

Clearance lnspection ...................".. 13-57

Removal ................. 13-58

Change Holder Assembly

Clearance lnspection .................".... 13-59

Removal ....,,........... 13-61

Disassembly/Reassembly ............... 1 3-62

Mainshaft, Countershaft, Shift Fork

Removal ................. 13-63

Shift Rod

Removal .........."'.... 13-64

Shift Fork Assembly

lndex ................ ...... 13-65

Clearance lnspection .............'......... 13'66

Mainshaft Assembly

lndex ............"" ...... 13-67

Clearance lnspection ....................... 13-68

Disassembly .......... 13-71

fnspection '."'.......', 13'72

Reassembly .......'... 13-73

Countershaft Assembly

fndex ................ "....13-71

Glearance Inspection'......'...........'... 1 3'75

Disassembly .......... 13-76

fnspection .'............13'77

Reassembly "......... 13'78

Synchro Sleeve, Synchro Hub

Inspection .............. 13'8C

Installation ............. 13-80

Synchro Ring, Gear

Inspection .'............ 13-81

Differential

lndex ................ ...... 13-82

Backlash Inspection ..."..........."'...... 1 3-82

Final Driven Gear Replacement ...... 13-83

Bearing Replacement ....."'.......""'.. 13-83

Thrust Shim Adiustment ......""'..... 13-84

Clutch Housing Bearing

Replacement ..'...... 13-86

Mainshaft Thrust Glearance

Adiustment '.........'. 13-88

Transmission

Reassembly ."'....... 13-91

Oil Seals

Replacement ..'...... 13-96

Gearshift Mechanism

Overhaul ................ 13-97

\

Page 635 of 2189

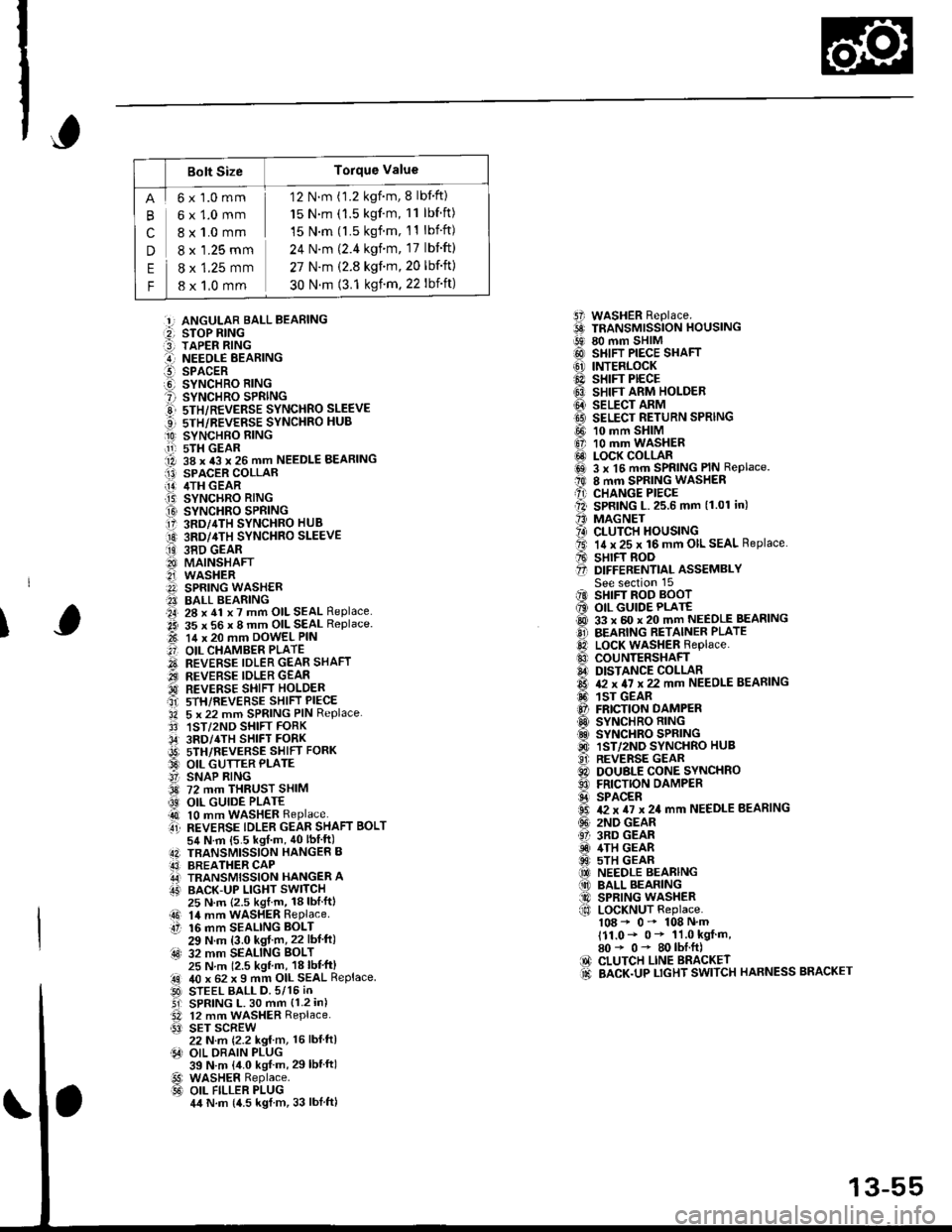

Bolt SizeTorque Value

cn

E

F

6x1.0mm

6x1.0mm

8 x 1.0 mm

8 x '1.25 mm

8 x 1.25 mm

8 x 1,0 mm

12 N.m (1.2 kgnm, 8 lbf'ft)

15 N.m (1.5 kgf'm, 11 lbf ft)

15 N.m (l.5 kgf.m, 11 lbift)

24 N'm (2.4 kgim, 17 lbift)

27 N.m (2.8 kgf.m,20 lbf'ft)

30 N.m (3.1 ksf m. 22 lbift)

5i WASHER Replace.6 TRANSMrssioN HouslNG!9 80 mm SHIM@ SHIFT PIECE SHAFT(6' INTERLOCK@ sHrFr PECE6} SHIFT ARM HOLDER@ seucr nnrvtI9 SELECT RETURN SPRING

@ 10 mm SHIM6, 10 mm WASHER@ LOCK COLLARi6sl 3 x l5 mm SPRING PIN Replace.t0 8 mm SPRING WASHERA) CHANGE PIECEll SPRING L.25.6 mm (1.01 in)'' MAGNET?4) CLUTCH HOUSINGta. 14 x 25 x 16 mm OIL SEAL Replace.A sHrFT BooO D|FFERENT|aL ASSEMBLYSee section 15iIO SHIFT ROD BOOT6 OIL GUIDE PLATE@ 33 x 60 x 20 mm NEEDLE BEASINGO BEARING RETAINER PLATElD LocK WASHER Replace..0 couNTERSHAFIA DISTANCE COLLAR6 & x 4I x 22 mm NEEDLE BEARING6. 1sr GEAR@ FRICTION DAMPERO SYNCHRO RING.d SYNCHRO SPRING@ 1ST/2ND SYNCHRO HUB..9i. REVERSE GEARC) DOUBLE CONE SYNCHROO FRICTION DAMPERS SPACER6 T2 x TI x 24 mm NEEDLE BEARING(!' 2ND GEAR61 3RD GEARiD 4TH GEAR@ 5TH GEAR(O NEEDLE BEARING(10 BALL BEARING@ SPRING WASHERf,o LoCKNUT Replace.108 - 0- 108 N'm111.0- 0* 11.0 kgf m,80* 0- 80lbI.ft)IO CLUTCH LINE BRACKET.d BACK.UP LTGHT SWITCH HARNESS BRACKET

:!, ANGULAR BALL BEABING:2, STOP RING:3] TAPER RING..-I NEEOLE BEARINGl!-- SPACERO SYNCHRO RING? SYNCHRO SPRINGE 5TH/REVERSE SYNCHRO SLEEVE...] sTH/REVERSE SYNCHRO HUB

O SYNCHBO EING.11-r sTH GEAR1A 38 x 43 x 26 mm NEEDLE BEARINGI13) SPACER COLLAR[!] /ITH GEAR.T5) SYNCHRO RING

O SYNCHRO SPRING17 3RD/4TH SYNCHRO HUB

O 3RD/4TH sYNcHRo SLEEVE

ii9 38D GEAR8I MAINSHAFT2i WASHERA SPRING WASH€R?I BALL BEARING.a4, 28 x 41 x 7 mm OIL SEAL Replace..2i 35 x 56 x 8 mm OIL SEAL Replace.t-t 14 x 20 mm DowEL PIN

.'] OIL CHAMBER PLATE

O REVERSE IDLER GEAR SHAFT.iI.., REVERSE IDLER GEAR'd REVERSE SHIFI HOLDERait srH/REVERSE sHIFT PIECE'34 5 x 22 mm SPRING PIN Replace.3' 1ST/2ND SHIFT FORK,34' 3RD/4TH SHIFT FORKi9t) srH/nevense sstrr ronx33 OIL GUTTER PLATE!' SNAP RING3d 72 mm THRUST SHIM

@ OIL GUIDE PLATE4t 10 mm WASHER Replaceti REVERSE TDLER GEAR SHAFT BoLT54 N.m {5.5 kgf m, 40lbIft)4N TBANSMISSION HANGER B43] BREATHER CAPA,J TRANSMISSION HANGER AIT' BACK-UP LIGHT SWITCH

I

25 N.m {2.5 kgl.m, 18lblftl14 mm WASHER RePlaceaO 14 mmtt 16 mm16 mm SEALING BOLT29 N.m (3.0 kgf m,22 lbf ft):4s) 32 mm SEALING BoLT25 N m 12.5 kgl m, 18 lbl'ft)40 x 62 x I mm OIL SEAL ReplaceSTEEL BALL D.5/15 iNSPRING L. 30 mm {1.2 in)12 mm WASHER Replace.SET SCREW22 N.m {2.2 kg{ m, 16 lbl ftlOIL DRAIN PLUG39 N.m {4.0 kgf m, 29lbtftlWASHER Replace.OIL FILLER PLUG4,t N.m {4.5 kgl m, 33 lblftl

.!rl00

@l

13-55

Page 637 of 2189

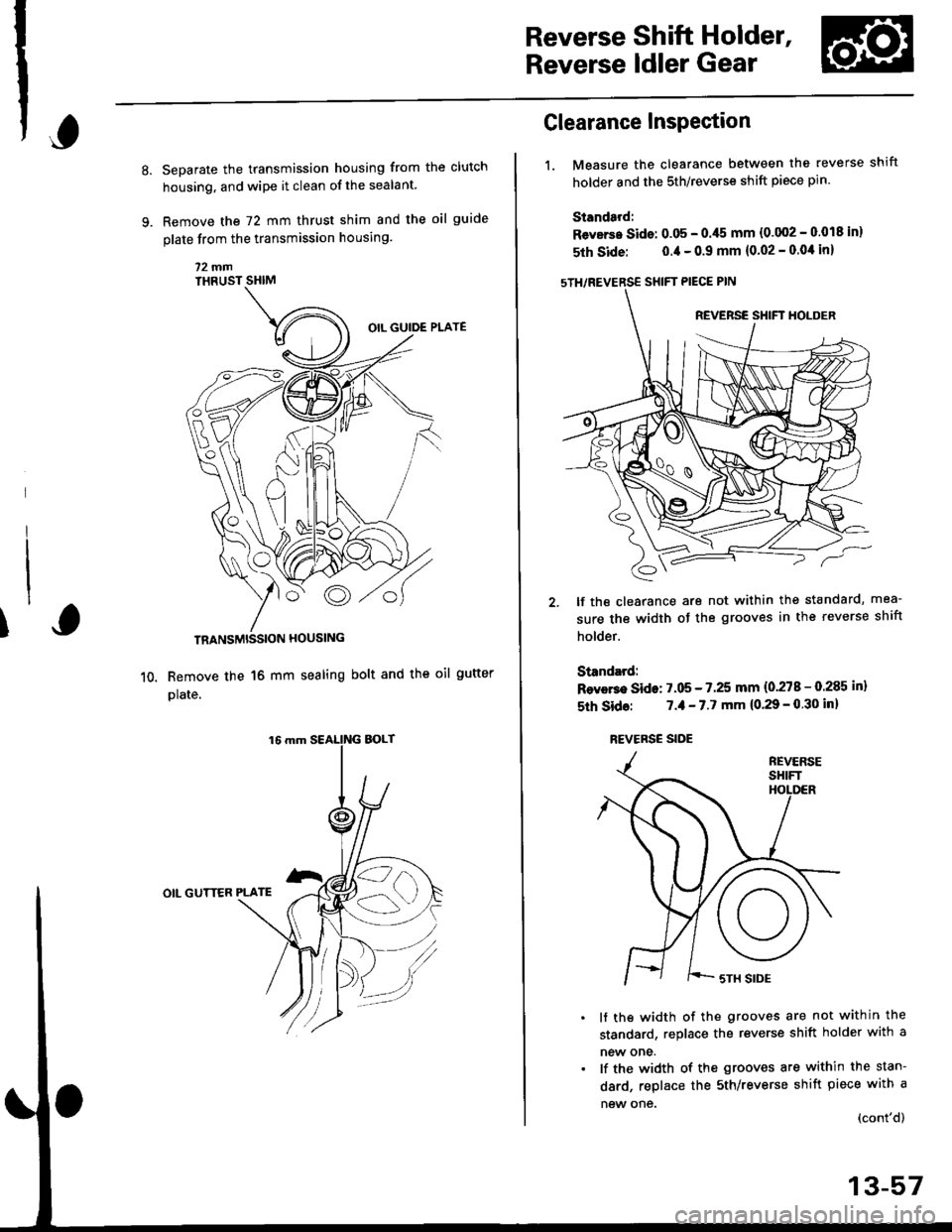

Reverse Shift Holder,

Reverse ldler Gear

Separate the transmission housing from the clutch

housing, and wipe it clean of the sealant.

Remove the 72 mm thrust shim and the oil guide

plate from the transmission housing

72fifiTHRUST SHIM

TRANSMISSION HOUSING

Remove the 16 mm sealing bolt and the oll gutter

plate.

OIL GUTTER PLATE

fi

1.

Clearance Inspection

Measure the clearance between the reverse shift

holder and the 5th/reverse shift piece pin

Standard:

Revsrs. Sids: 0.05 - 0./t5 mm {0'002 - 0.018 in}

5th Side: 0.4 - 0.9 mm (0.02 - 0.0'l in)

sTH/REVERSE SHIFT PIECE PIN

lf the clearance are not within the standard, mea-

sure the width of the grooves in the reverse shift

holder.

Standard:

Rsvers€ Side: 7.05 - 7.25 mm (0'278 - 0.285 in)

5th Sid6: 7.,1- 7.7 mm (0.29 - 0 30 inl

REVERSE SIDE

lf ths width of the grooves are not within the

standard, replace the reverse shift holder with a

new one.

lf the width of the grooves are within the stan-

dard, replace the sth/reverse shift piece with a

new one {cont'd)

13-57

Page 661 of 2189

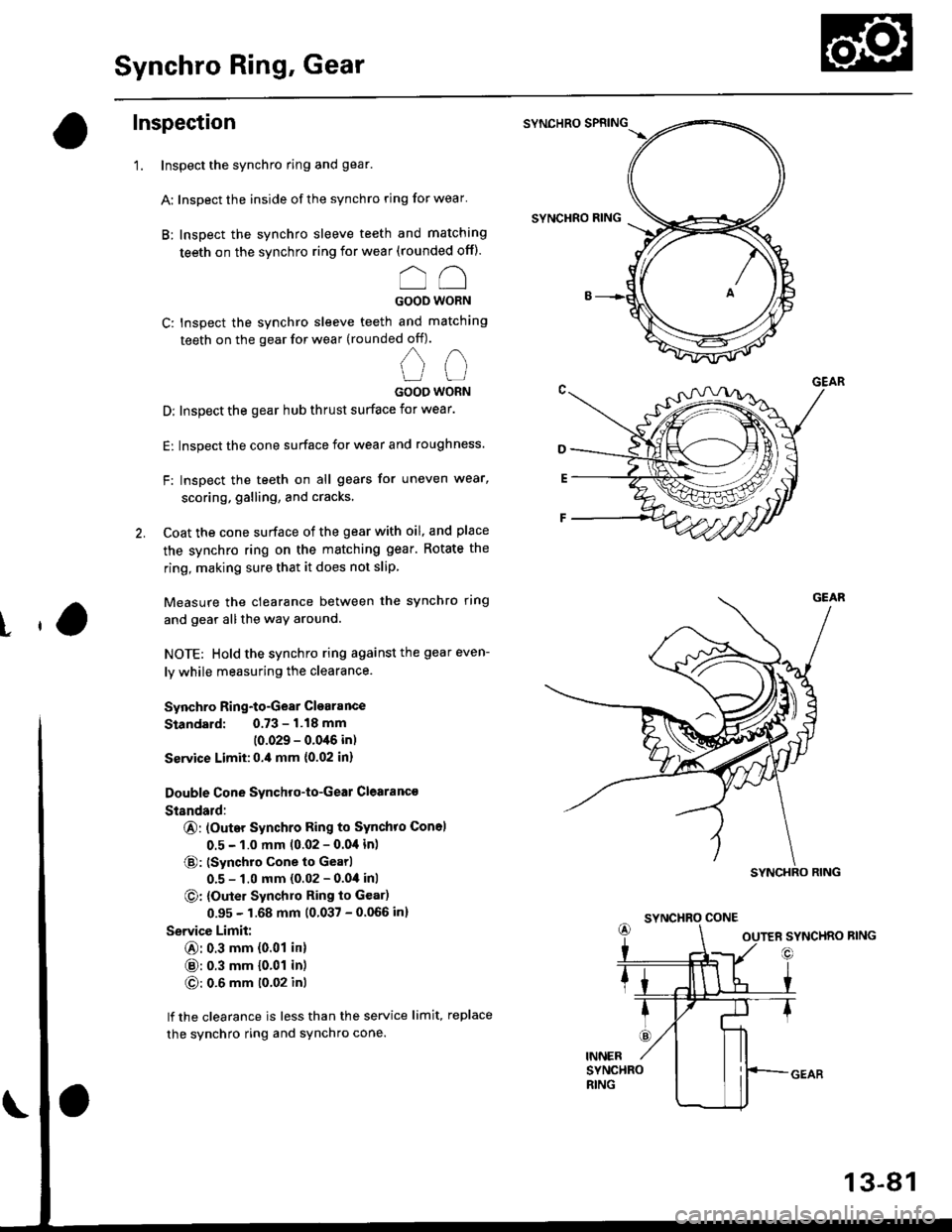

Synchro Ring, Gear

Inspection

'1. Inspect the synchro ring and gear.

A: Inspect the inside of the synchro ring for wear'

B: Inspect the synchro sleeve teeth and matching

teeth on the synchro ring for wear (rounded off).

oo

GOOD WORN

C: Inspect the synchro sleeve teeth and matching

teeth on the gear for wear (rounded off).

nn

UUGOOO WORN

D: Inspect the gear hub thrust surface for wear.

E: Inspect the cone surface for wear and roughness.

F: Inspect the teeth on all gears for uneven wear,

scoring, galling, and cracks'

2. Coat the cone surface of the gear with oil, and place

the synchro ring on the matching gear. Rotate the

ring, making sure that it does not slip

Measure the clearance between the synchro ring

and gear allthe way around.

NOTE: Hold the synchro ring against the gear even-

ly while measuring the clearance.

Synchro Ring-to-Gear Clearance

Standard: 0.73 - 1.18 mm

(0.029 - 0.0'16 in)

Ssrvice Limit:0.,0 mm {0.02 in}

Double Cone Synchro-to-Geal Clearanc€

Standald:

@: (Outer Synchro Ring to Synchro Con6l

0.5 - 1.0 mm 10.02 - 0.04 in)

@: (Synchro cone to Gearl

0.5 - 1.0 mm (0.02 - 0.04 inl

O: {Outer Synchlo Ring to Gear)

0.95 - 1.68 mm (0.037 - 0.066 in)

Service Limit:

@: 0.3 mm {0.01 in}

@: 0.3 mm {0.01 in)

O: 0.6 mm t0'02 inl

lf the clearance is less than the service limit, replace

the synchro ring and sYnchro cone.

SYNCHRO SPRING

SYNCHRO RING

t

SYNCHRO CONE

13-81

Page 664 of 2189

Differential

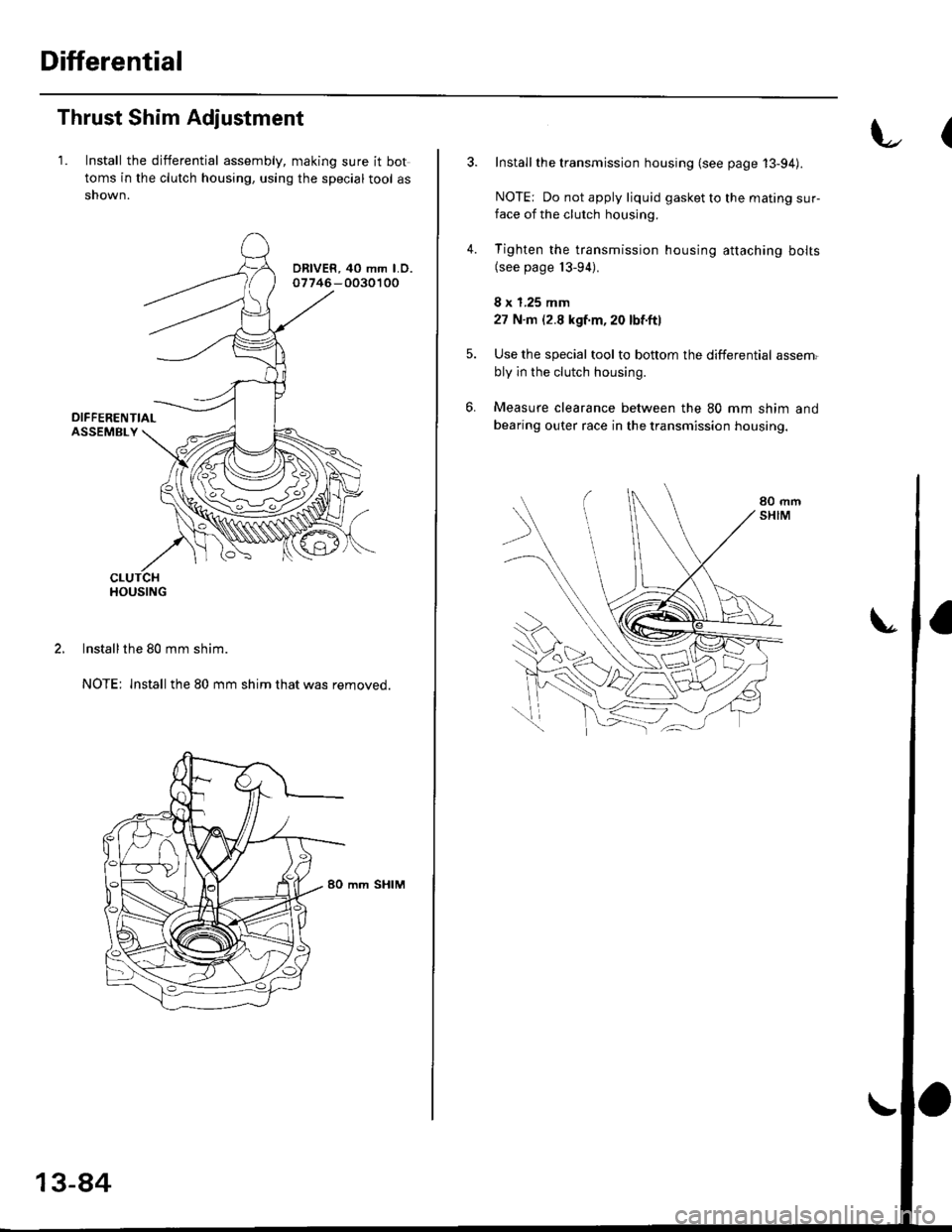

Thrust Shim Adjustment

1. Install the differential assembly, making sure it bot

toms in the clutch housing, using the special tool as

shown.

ORIVER, 40 mm LO.o7746-0030100

lnstall the 80 mm shim.

NOTE: lnstall the 80 mm shim that was removed.

mm SHIM

13-84

(

4.

Install the transmission housing (see page 13-94).

NOTE: Do not apply liquid gasket to the mating sur-

face of the clutch housing.

Tighten the transmission housing attaching bolts(see page 13-94).

I x 1.25 mm

27 N'm (2.8 kgf.m, 20 lbf.ftl

Use the special tool to bottom the differential assem.

bly in the clutch housing.

Measure clearance between the 80 mm shim and

bearing outer race in the transmission housing.

Page 668 of 2189

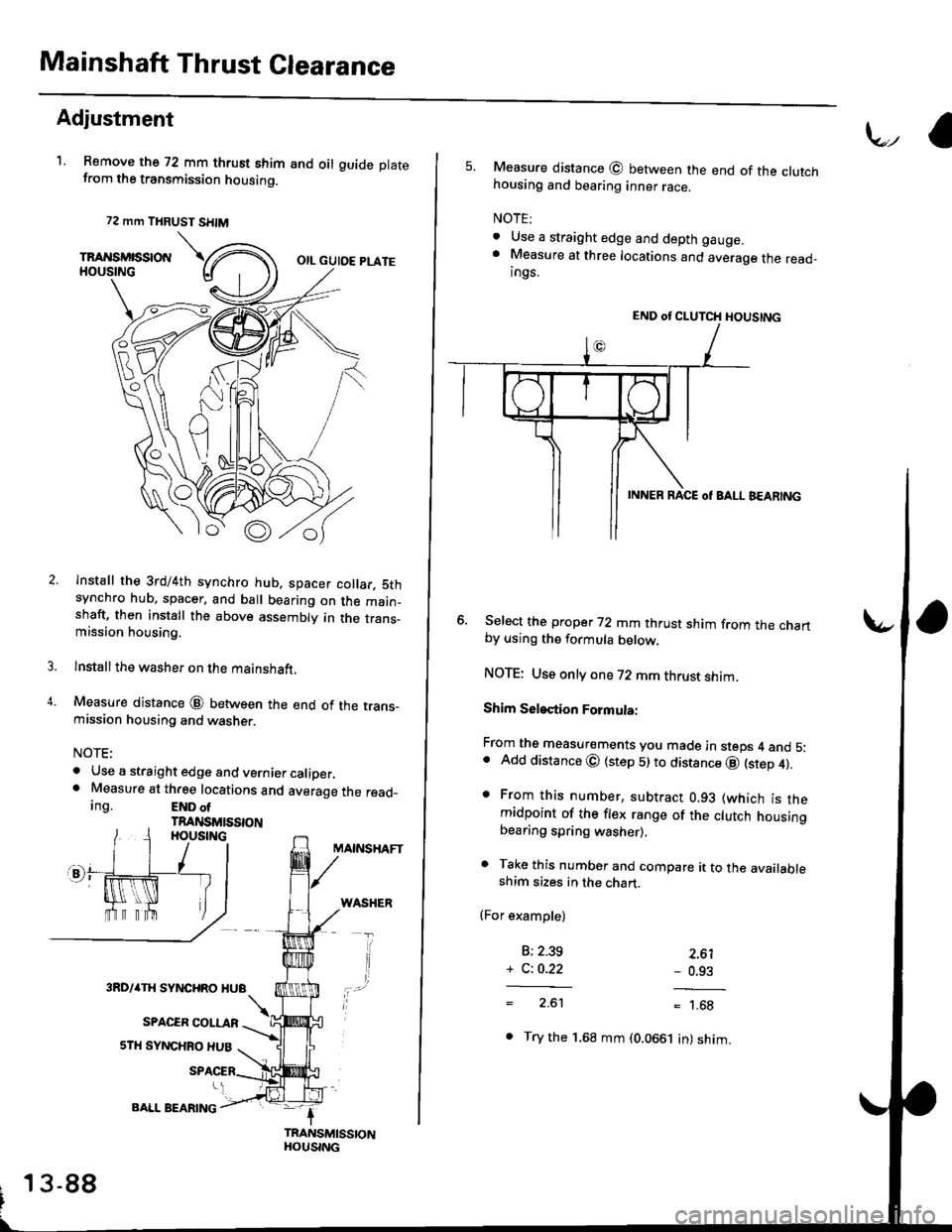

Mainshaft Thrust Clearance

Adjustment

1. Remove the 72 mm thrust shim and oil guide platefrom the transmission housing.

4.

TFANSMISSIONHOUSING

72 mm THRUST SH|M

TRAt{SMtSStONHOUSINGOIL GUIOE PLATE

lnstall the 3rd/4th synchro hub. spacer collar,5thsynchro hub. spacer, and ball bearing on the main_shaft, then install the above assembly in the trans_mission housing.

lnstall the washe[ on the mainshaft,

Measure distance @ between the end of the trans-mission housing and washer.

NOTE;

. Use a straight edge and vernier caliper.. Measure at three locations and average the read_ing.ENO otlnA sMtsstoNHOUSINGMAINSHAFT

3RD/irTH SYNCHRO HUB

SPACCR COLLAR

5TH SYNCHRO HUB

o

B

13-88

AALL BEARING

V.

5. Measure distance @ between the end of the clutchhousing and bearing inner race.

NOTE;

. Use a straight edge and depth gauge.. Measure at three locations and average the read-ings.

Select the prcpet 72 mm thrust shim from the chartby using the formula below.

NOTE: Us€ only one 72 mm thrust sntm.

Shim Selection Formula:

From the measurements you made in steps 4 and 5:. Add distance O lstep 5) to distance @ (step 4).

. From this number, subtract 0.93 (which is themidpoint of the flex range of the clutch housingbearing spring washer).

. Take this number and compare it to the availableshim sizes in the chart.

{For example)

B;2.39

+ C: 0.22- 0.93

2.61 = 1.68

Try the 1.68 mm (0.0661 in) shim.

INNER RACE ot EALL BEARING