Thrust HONDA CIVIC 1998 6.G Service Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CIVIC, Model: HONDA CIVIC 1998 6.GPages: 2189, PDF Size: 69.39 MB

Page 830 of 2189

Countershaft

Disassembly/Reassembly

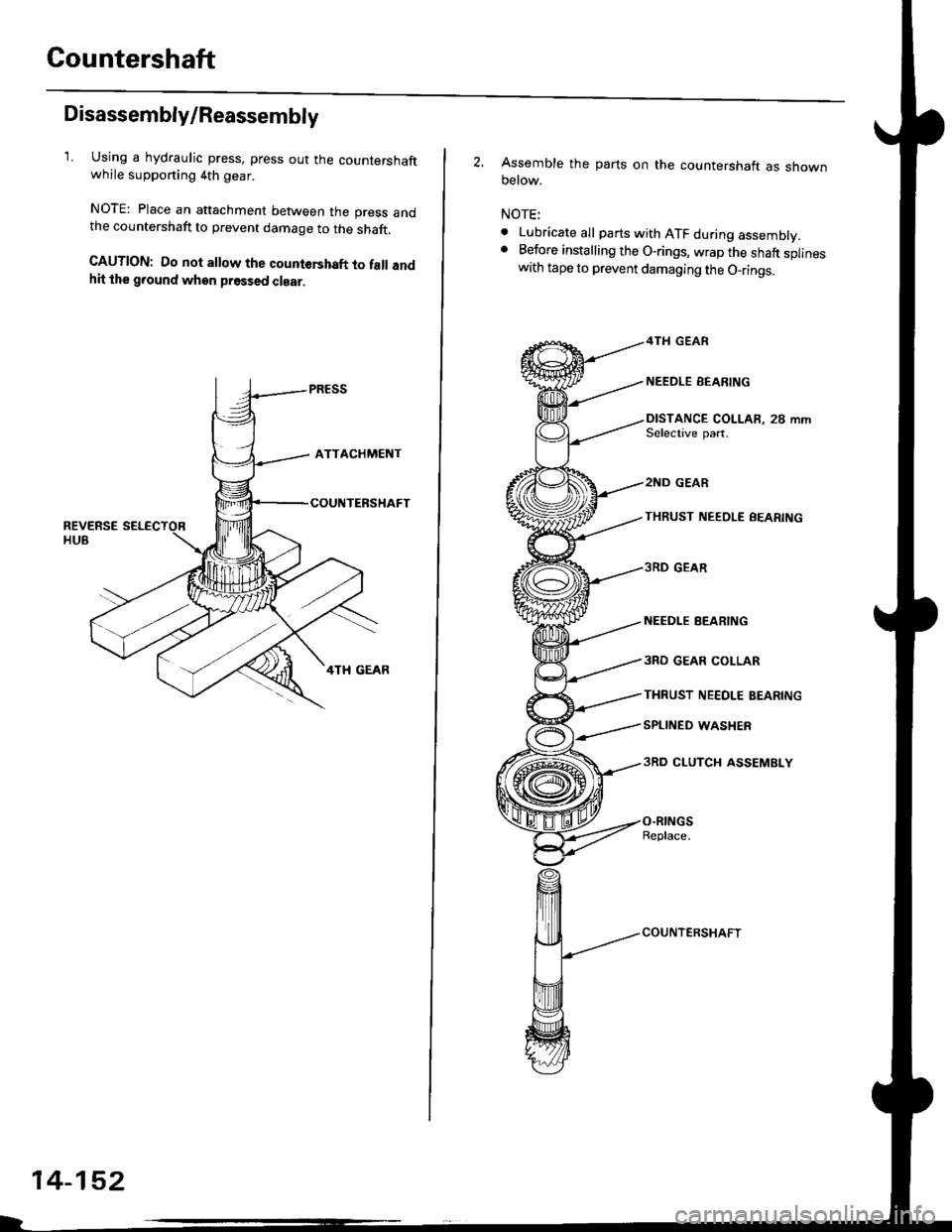

1. Using a hydraulic press, press out the countershaftwhile supporting 4th gear.

NOTE: Place an attachment between the press andthe countershaft to prevent damage to the shaft.

CAUTION: Do not allow the countershaft to fall andhit the g.ound when pressed clear.

14-152

2. Assemble the parts on the countershaft as shownoetow.

NOTE;

. Lubricate all parts with ATF during assembly.. Before installing the O-rings, wrap the shaft splineswith tape to prevent damaging the O_rings.

4TH GEAR

NEEDLE EEARING

DISTANCE COLLAR, 28 mmSelective part.

2ND GEAR

THRUST NEEOLE BEARING

3RD GEAR

NEEDI.E EEARING

3RO GEAR COLLAR

THRUST NE€OLE BEARING

SPLINED WASHER

3RD CLUTCH ASSEMBLY

O.RINGSReplace.

COUNTERSHAFT

Page 831 of 2189

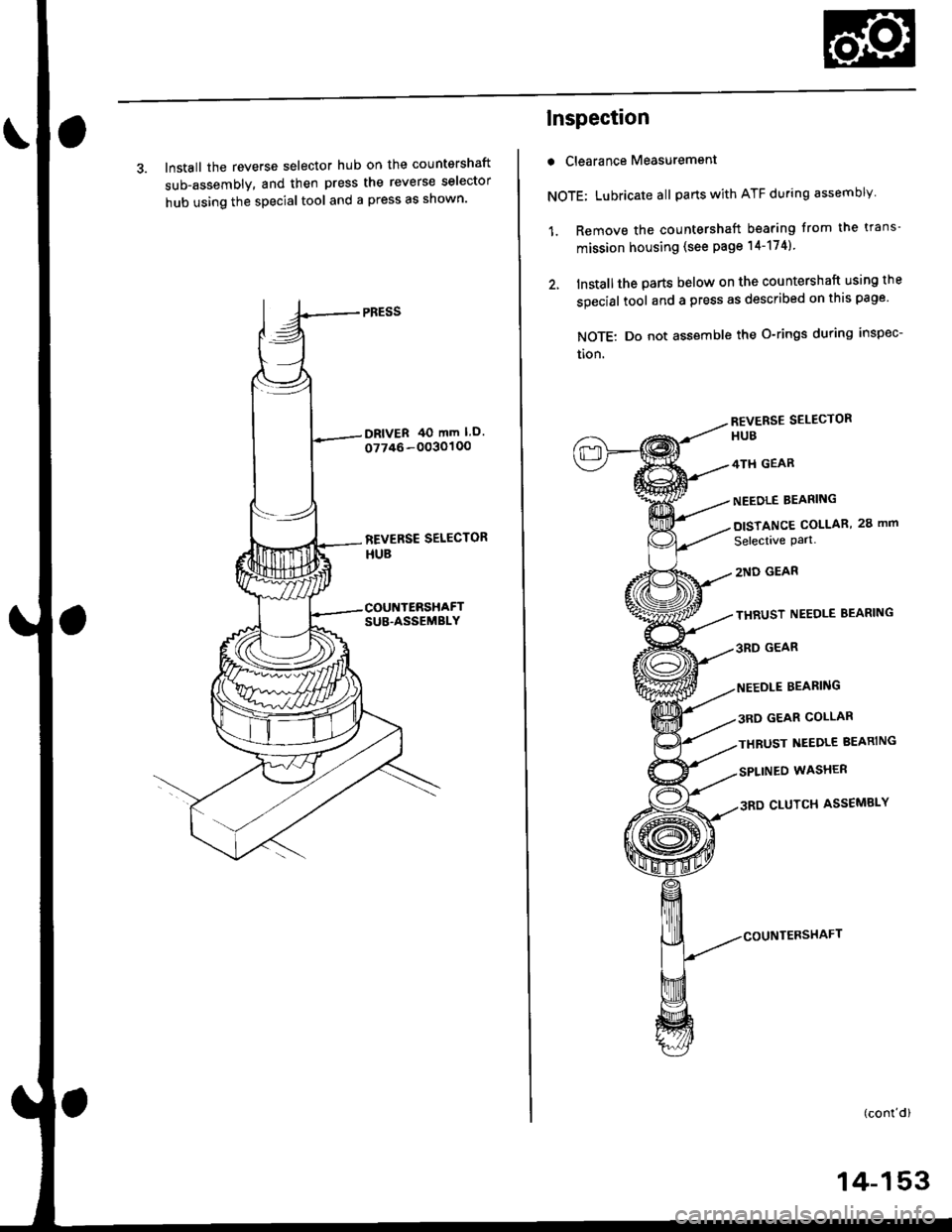

3. Install the reverse selector hub on the countershaft

sub-assembly, and then press the reverse selector

hub using the special tool and a press as shown'

Inspection

r Clearance Measurement

NOTE; Lubricate all parts with ATF during assembly

1. Remove the countershaft bearing from the trans-

mission housing (see page l4-174)

2. Installthe parts below on the countershaft using lhe

special tool and a press as described on this page

NOTE: Do not assemble the O-rings during inspec-

tion.

REVERSE SELECTOR

HUB

4TH GEAR

NEEDLE BEARING

DISTANCE COLLAR, 28 mm

Selectave Part.

2ND GEAR

THRUST NEEDLE BEARING

3RD GEAR

BEARING

3RD GEAR COLLAR

THBUST NEEDLE BEARING

SPLINEO WASHER

3RD CLUTCH ASSEMBLY

(conl'd)

14-153

Page 858 of 2189

Transmission

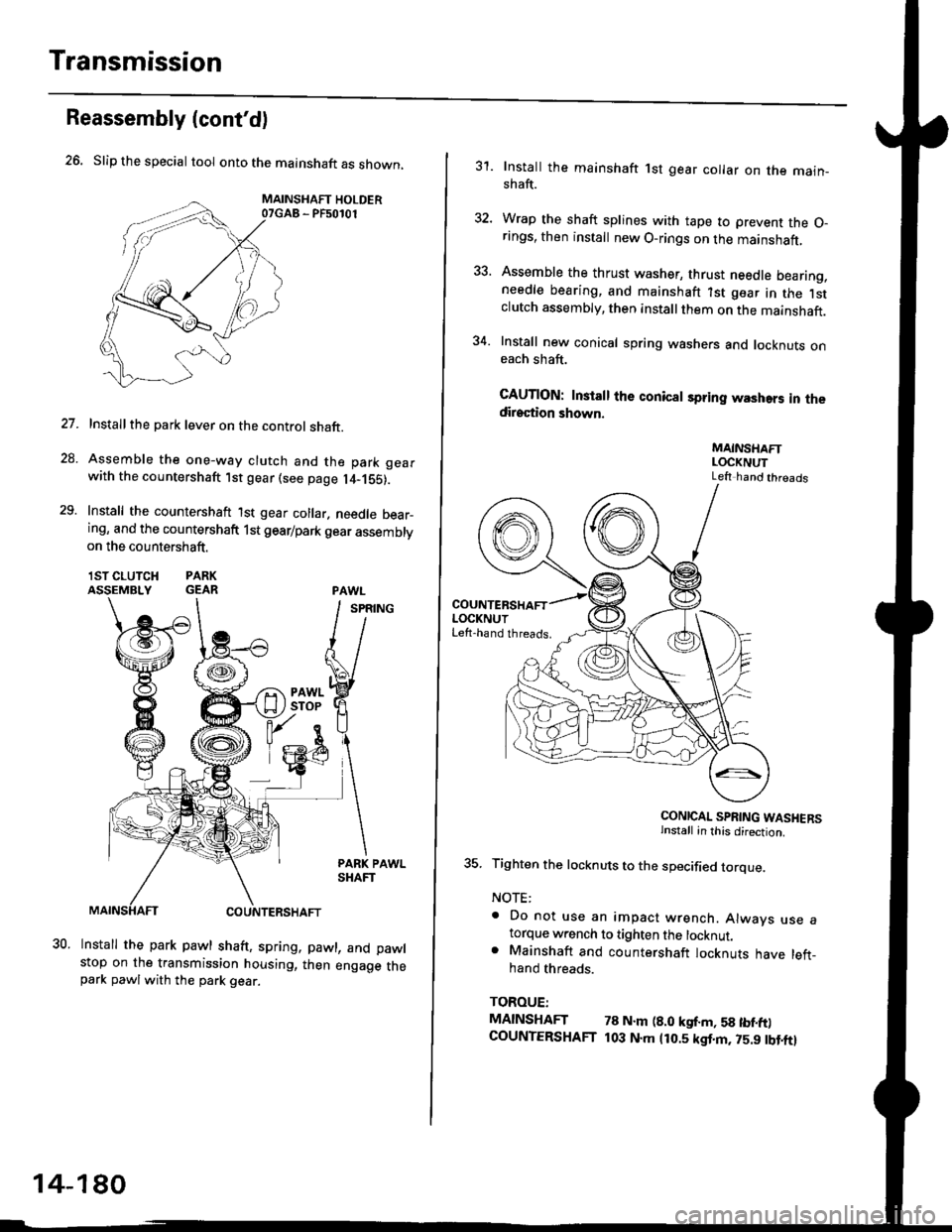

26. Slip the special tool onto the mainshaft as shown,

MAINSHAFT HOLDER07GAB - PF50101

Installthe park lever on the control shaft.

Assemble the one-way clutch and the park gearwith the countershaft lst gear (see page l4-1S5).

Install the countershaft lst gear collar. needle bear_ing, and the countershaft 1st gearlpark gear assembly

Reassembly (cont'dl

on the countershaft.

lSTCLUTCH PARKASSEMBLY GEAR

27.

28.

29.

30.Install the park pawl shaft, spring, pawl, and pawlstop on the transmission housing, then engage thepark pawlwith the park gear.

14-180

31. Install the mainshaft 1st gear collar on the main_shaft.

32. Wrap the shaft splines with tape to prevent the O-rings, then install new O-rings on the mainshaft,

33. Assemble the thrust washer, thrust needle bearing,needle bearing, and mainshaft ?st gear in the lstclutch assembly, then install them on the mainshaft.

34. Install new conical spring washers and locknuts oneach shaft.

CAUTION: Install the conical spring washers in thedirection shown.

MAINSHAFTLOCKNUTLeft hand threads

CONICAL SPRING WASHERSinstall in this direction.

35. Tighten the locknuts to the specified torque.

NOTE:

. Do not use an impact wrench. Alwavs use atorque w.ench to tighten the locknut.. Mainshaft and countershaft locknuts have left_hand threads.

TOROUE:

MAINSHAFT 78 N.m (8.0 kgf.m, 58 tbf.ft)COUNTERSHAFT t03 N.m 1r0.5 kgf.m, 75.9 tbt.ftl

Page 871 of 2189

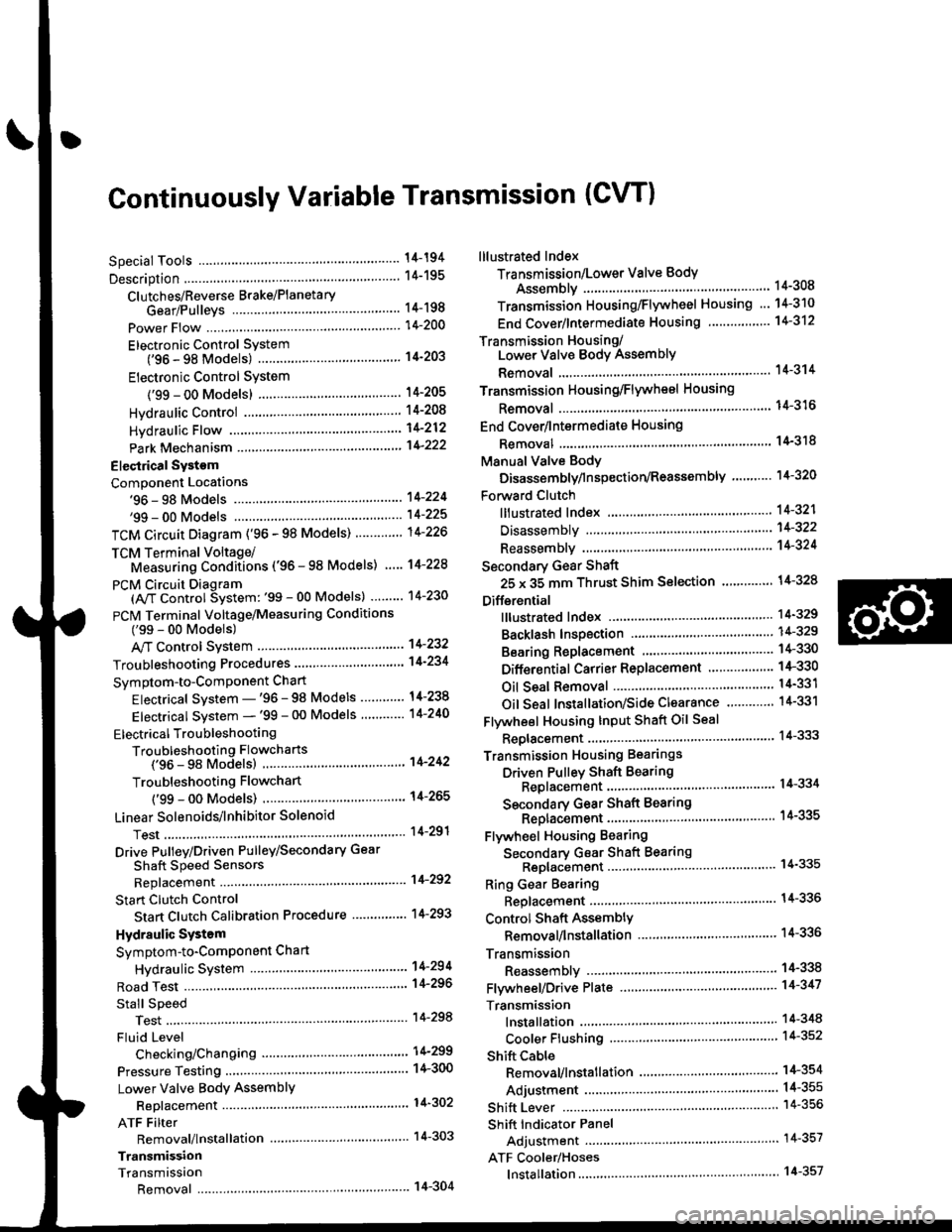

Continuously Variable Transmission (CVTI

Special Tools ................ 14-194

Description .................... 14-195

Clutches/Reverse Brake/Planetary

Gear/Pulleys .......... 14-198

power Flow ..............,..... 14-200

Electronic Control SYstem(,96 - 98 Modets) ......14-203

Electronic Control System

('99 - oo Models) " 14-205

Hydraulic Control '....... 14-208

Hydraulic Flow .'..-.....'... '14-212

Park Mechanism .....-...'.' 14-222

Eleqtrical Systom

Component Locations'96 - 98 Models """"""' 14-224,99 - 00 Modets ............. 14-225

TCM Circuit Diagram ('96 - 98 Models) ............. 14-226

TCM Terminal Voltage/Measuring Condiiions ('96 - 98 Models) '.... 14-228

PcM Circuit Oiaqram{A/T Control System: '99 - 00 Models} ...--.... 14-230

PCM Terminal Voltage/Measuring Conditions('99 - 00 Models)

A/4 Control System .'.'...14-232

Troubleshooting Procedures ... . .... .....',........."' '14-234

Symptom-to-ComPonent Chart

Electrical System - '96 - 98 Models ......'..... '14-234

Electrical System -'99 - 00 Models ..'....-..-. '11-210

Electrical Troubleshooting

Troubleshooting Flowcharts('96 - 98 Models) """'11-242

Troubleshooting Flowchart

('99 - 0O Modets) ...... 14-265

Linear Solenoids/lnhibitor Solenoid

Test ......................... . ...... 14-29f

Drive Pulley/Driven Pulley/Secondary Gear

Shaft Speed Sensors

Replacement .........'...... .14-292

Start Clutch Control

Start Clutch Calibration Procedure ....... ....,. 14-293

Hydraulic SYstem

Symptom-to-ComPonent Chart

Hydraulic System '.'.......14-294

Road Test ............................ 14-296

Stall Speed

Test......................... ...... 14-294

Fluid Level

Checking/Changing ....... 14-299

Pressure Testing ................. 14-300

Lower Valve BodY AssemblY

Replacement ..........,... 14-302

ATF Filter

Removal/lnstallation ..... 14-303

Transmission

Transmission

Removal ........... . 14-304

lllustrated Index

Transmission/Lower Valve BodY

Assembly ................. 14-308

Transmission Housing/Flywheel Housing ... 14-310

End Cover/f ntermediate Housing ..........'.'.... 14-312

Transmission Housing/Lower Valve Body Assembly

Removal ..........'.... .. " 14-314

Transmission Housing/Flywhesl Housing

Removal ................. ........ 1+316

End Cover/lntermediate Housing

14-318Removal .........,...............

Manual Valve Body

Disassembly/lnspection/Reassemblv .'.'.'..... 1 4-320

Forward Clutch

lltustrated Index ........................................ 14-321

Disassemblv .................. 14-322

Reassemblv , ,, . ',','......14-324

Secondary Gear Shaft

25 x 35 mm Thrust Shim Selection ..'.'....-... 14-324

Differential

lllustrated lndex ...,.....................,.,...-.-.-...'... 14-329

Backlash Inspection .-....14-329

Bearing Replacement ......'........'....'... ....'... 14-330

Differential Carrier Replacement ........'........ 14-330

Oil Seal Removal ........... 14-331

Oil Seal Installation/Side Clearance ....... . . 14-331

Flywheel Housing Input Shaft Oil Seal

Replacement .....,.... ...'.'.. 14-333

Transmission Housing Bearings

Driven Pulley Shaft Bearing

Replacenient ...................'. . ...................'.. 14-334

Secondary Gear Shaft Bearing

Reolacbment ...................... . .......... . ........ 14-335

Flywheel Housing Beating

Secondary Gear Shaft BearingReo1acement..................,........................... 14-335

Ring Gear Bearing

Replacement......... ........ 14-336

Control Shaft Assembly

Removal/lnstallation ....................'........... 14-336

Transmission

Reassembly .................. 14-338

Flywheel/Drive Plate .. . ...... . ...... ... . ....-.....'.'...14-341

Transmission

lnstalation ..................... 14-348

Cooler Flushing .'......... 14-352

shift cable

Removal/lnstallation....'........." """ 14-354

Adjustment .......'........ 14-355

Shift Lever ........................,. 14'356

Shift Indicator Panel

Adjustment ................ 14-357

ATF Cooler/Hoses

lnsta llation ......,,...... .... 14-357

Page 972 of 2189

t.

rl,

fl,

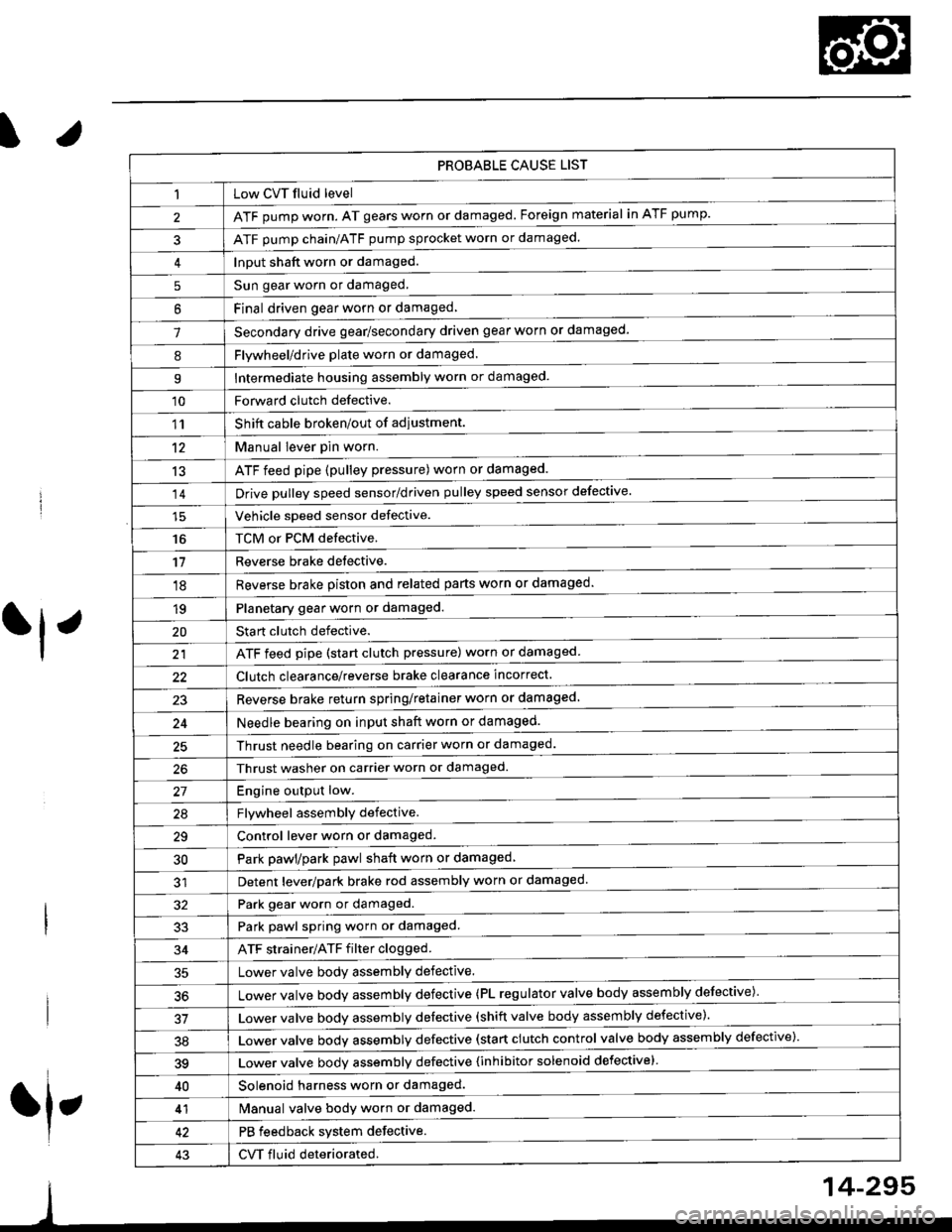

PROBABLE CAUSE LIST

Low CVT fluid level

ATF pump worn. AT gears worn or damaged. Foreign material in ATF pump.

ATF pump chain/ATF pump sprocket worn or damaged.

Input shaft worn or damaged.

Sun gear worn or damaged.

Final driven oear worn or damaqed,

Secondary drive gear/secondary driven gear worn or damaged-

5

6

1

8Flywheel/drive plate worn or damaged.

Intermediate housing assembly worn or damaged.9

'10Forward clutch defective.

Shift cable broken/out of adiustment.

M"nu"t t"uffi

ATF feed pipe (pulley pressure) worn or damaged.

Vchiclc speed sensor defective.

TCM or PCM defective.

Reverse brake detective.

1'�r

't2

13

14

16

'11

'18

1qPlanetary gear worn or damaged.

Sta rt clutch defective.

ATF feed pipe (start clutch pressure) worn or damaged

20

t't

Clutch clearance/reverse brake clearance incorrect.

23Reverse brake return spring/retainer worn or damaged

24Needle bearing on input shaft worn or damaged.

25Thrust needle bearing on carrier worn or damaged.

Thrust washer on carrier worn or damaged.

Enoine outout low.------------------------

Flvwhcel assemblv defective.

Control lever worn or damaged.

Park pawl/park pawl shaft worn or damaged

Detent lever/park brake rod assembly worn or damaged

27

29

30

32Park gear worn or damaged.

Park pawl spring worn or damaged.

ATF strainer/ATF filter clogged.

Lower valve body assembly defective.

Lower valve bodv assemblv defective (PL regulator valve body assembly defective)'

33

34

50

Lower valve bodv assembly defective (shift valve body assembly defective).

Lower valve bodv assemblv defective (start clutch control valve body assembly defective)'

39Lower valve bodv assemblv defective {inhibitor solenoid defective}

40Solenoid harness worn or damaged.

Manual valve body worn or damaged.

PB feedback system defective.

CVT fluid deteriorated.

41

43

14-295

Page 988 of 2189

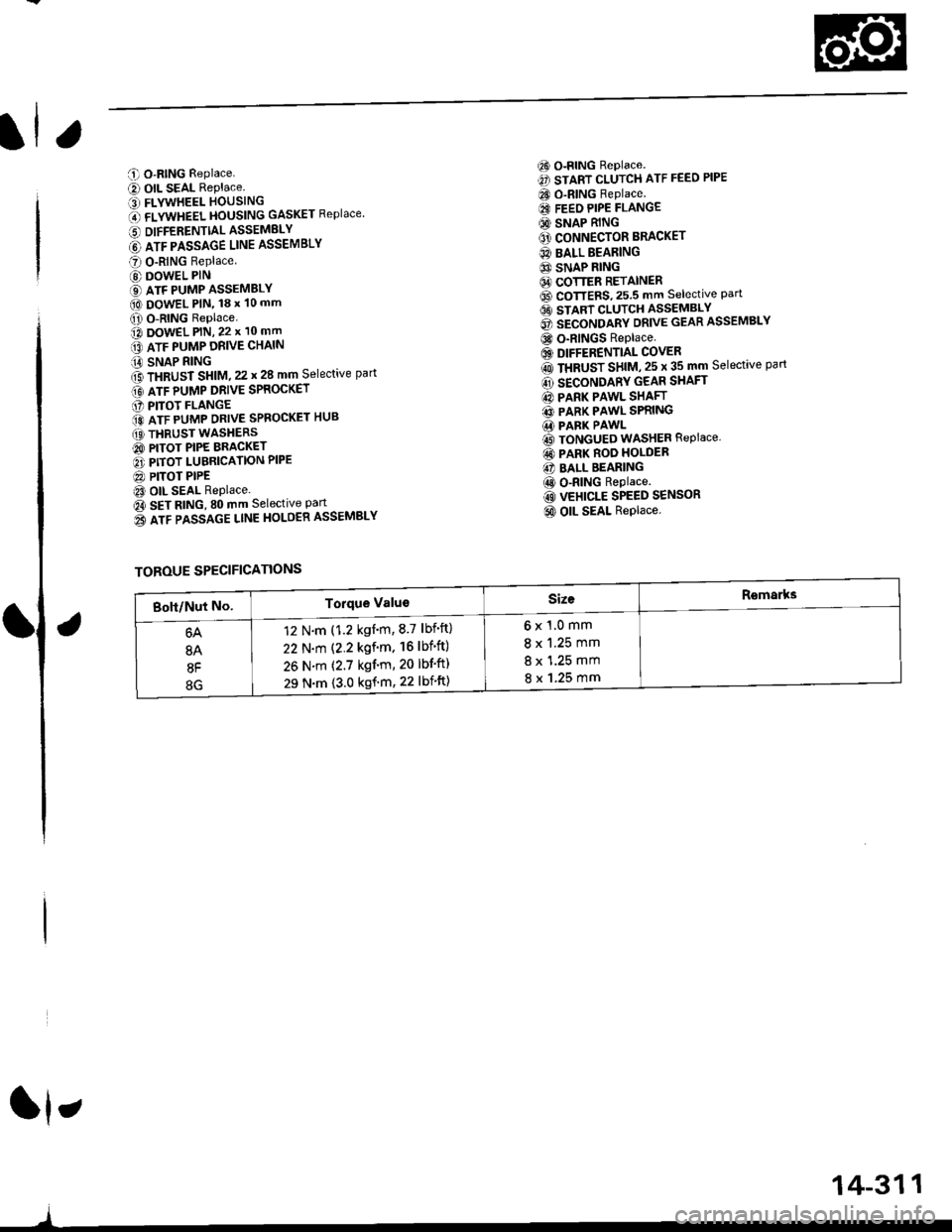

C O-RING Replace.

e) OIL SEAL RePlace.' FLYWHEEL HOUSING

O flVWneel }|OUSttttG GASKET Replace

6 DIFFERENTTALASSEMELY

@ lrr plsslce uruE ASSEMBLY

O O-RING Replace

@ DOWEL PIN

€) ATF PUMP ASSEMBLY(O DowEL PlN, 18 x 10 mm

O O-RING Replace.o DowEL PlN, 22 x 10 mm

lrr puup oRve cxltttt

iA SNAP RING

f3 fxaUst St|t|l, zz t 28 mm Selective part

Gt lrr punp ontve spaocxer

O PITOT FLANGE

ito nTF purrap ontve SPRoGKET HUB

(O THRUST WASHERS

@ PITOT PIPE BRACKET

O PITOT LUBRICATION PIPE

@ PITOT PIPEt3 OIL SEAL Replace.

Oa SEt AtitC, SO mm Selective Part

o3 lrr passlce ltnE HoLOER ASSEMBLY

6) o-RING Replace.

€) START CLUTCH ATF FEED PIPE

CO O-RING Replace.

€I FEEO PIPE FLANGE

@ SNAP RING

O' CONNECTOR BRACKET

@ BALL BEARING

6} SNAP RING64 COTTER RETAINER6D CoTTERS,25.5 mm selective Part6t stlnt cLutcH asseMsLv

@ secoruomv ontvE GEAR ASSEMBLY

@ o-RINGS Replace

6) DIFFERENTIAL COVER

rO ttaUSr SntU, zs t 35 mm Selective part

@ SECONDARY GEAR SHAFT

@ PARK PAWL SHAFT

@ PARK PAWL SPRING.1i PARK PAWL

@ TONGUED WASHER REPIACE,

@ PARK ROO HOLDER

@ BALL BEARING

@ o-RING Replace.

@ VEHICLE SPEED SENSOR

@ OIL SEAL Replace.

ft,

)

TOROUE SPECIFICATIONS

6x1.0mm

8 x 1.25 mm

8 x 1.25 mm

8 x 1.25 mm

12 N.m (1.2 kgnm,8.7 lbf'ft)

22 N.m (2.2 kgf'm. 16lbf'ft)

26 N.m (2.7 kgf'm, 20 lbf'ft)

29 N.m {3.0 kgf'm, 22 lbift)

14-311

Page 990 of 2189

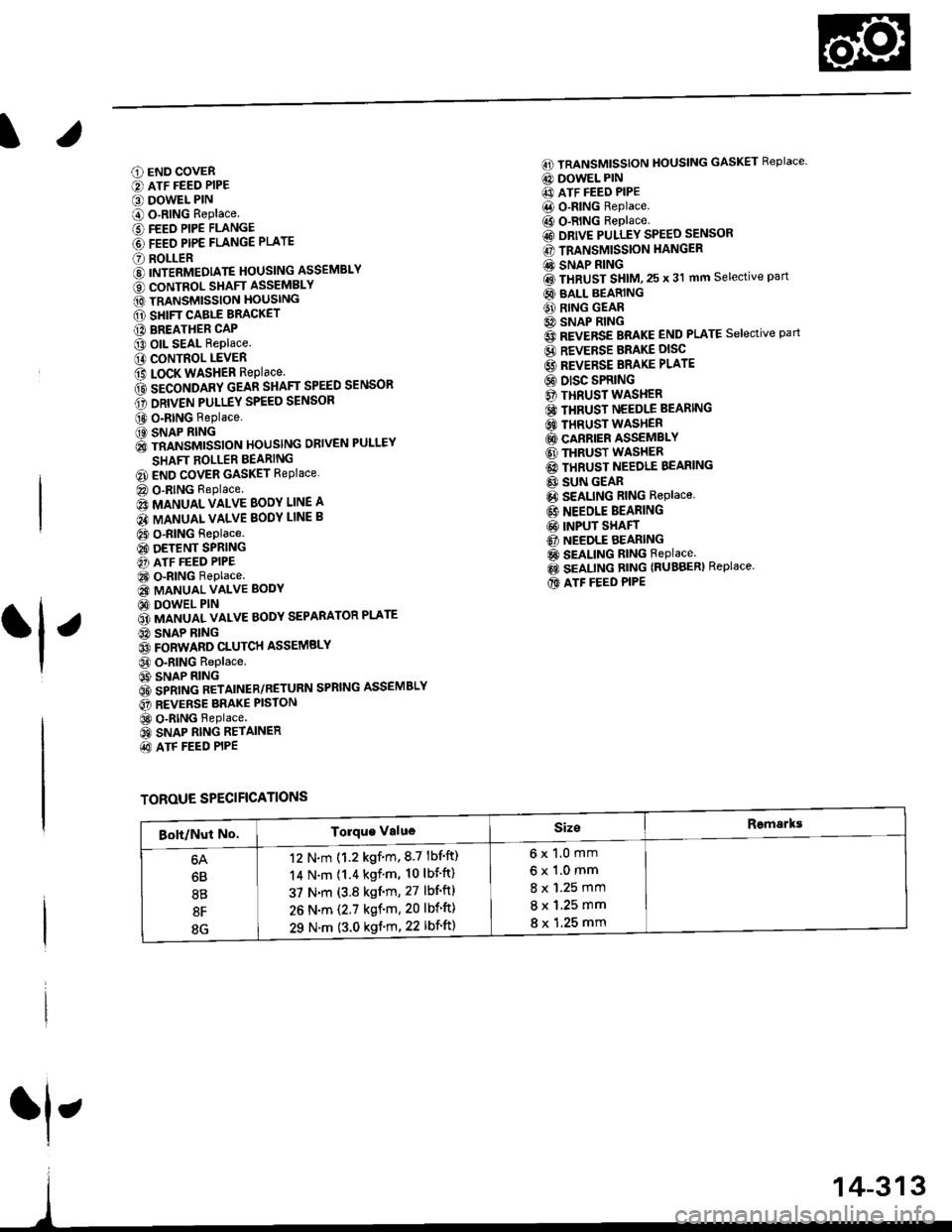

6) TRANSMISSION HOUSING GASKET Replace'

@ DOWEL PIN

@) ATF FEED PIPE

@ o-RING Replace.

60 o-RING Replace.

@) DRIVE PULLEY SPEED SENSOR

@ TRANSMISSION HANGER

@ SNAP RING

@ txaust Sxtfu, zs t 31 mm selective part

@ SALL BEARING

6J RING GEAR6D SNAP RING

@ aevense aRlxe rND PLATE Selective part

@ REVERSE BRAKE DISC

@ REVERSE BRAKE PLATE

@ DISC SPRING6} THNUST WASHER

@} finusr NeeoLr eelnNc

@ THRUST WASHER

@ GARRIER ASSEMBLY

@ THRUST WASHER

@ THRUST NEEDLE BEARING

@} SUN GEAR

@ SEALING RING REPIACE'

@ NEEDLE BEARING

@ INPUT SHAFT

@ NEEDLE BEARING

@ SEALING RING FEPIACE'

@ SEALING RING {RUBBERI Replace'

@ ATF FEED PIPE

O END COVER

O ATF FEED PIPE

O DOWEL PIN

@ O-RING Replace.G) FEED PIPE FLANGE

@ reeo ppe ruruce puru

O] ROLLERO IruTENMEDNTE XOUSING ASSEMBLY

ao corutnoL sxlrr lsseugLv

@ tnlrusmtsstottt ttoustt'tc

@ SHIFT CABLE BRACKET

c) BREATHER CAP

@ oll- SEAL Replace.

@ CONTROL LEVER

G LoCK WASHER Replace.(D secololaY ceaR SHAFT SPEED sENsoR

o) onvel put-uv sPEED SENSOR

@ O-RING Replace.(O SNAP RING6 rnmrsutsstoru xouslNc oRlvEN PULLEY

SHAFT ROLLER BEARING

@ END COVER GASKET REPIACE'

@ o-RING Replace

6o mnruulL vnLVe goDY LINE A

64 MANUAL VALVE BODY LINE B

@ O-RING Replace.

@ DETENT SPRING

O ATF FEED PIPE

@ O-RING Replace.

@ MANUAL VALVE EODY

@ DOWEL PIN

@ r'rllull valve goDY SEPARAToR PLATE

6D SNAP RING

@t roRwlno cturcx ASSEMBLY

@ o-RING Replace

@ SNAP RINGo3 spnlruc aetlrupn/RETURN SPRING ASSEMBLY

@ nevense ennr eBtottt

@ o-RING Feplace.

@ SNAP RING RE'AINER

@ ATF FEED PIPE

.1,

TOROUE SPECIFICATIONS

6x1.0mm

6x1.0mm

8 x 1.25 mm

8 x 1.25 mm

8 x 1.25 mm

12 N.m (1.2 kgf'm,8.7 lbf'ft)

14 N.m {1.4 kgf'm, 10 lbift)

37 N.m (3.8 kgf'm, 27 lbf'ft)

26 N.m (2.7 kgf'm,20 lbf'ft)

29 N.m (3.0 kgf'm, 22 lbf'ft)

6B

8B

8F

8G

14-313

rl,

Page 993 of 2189

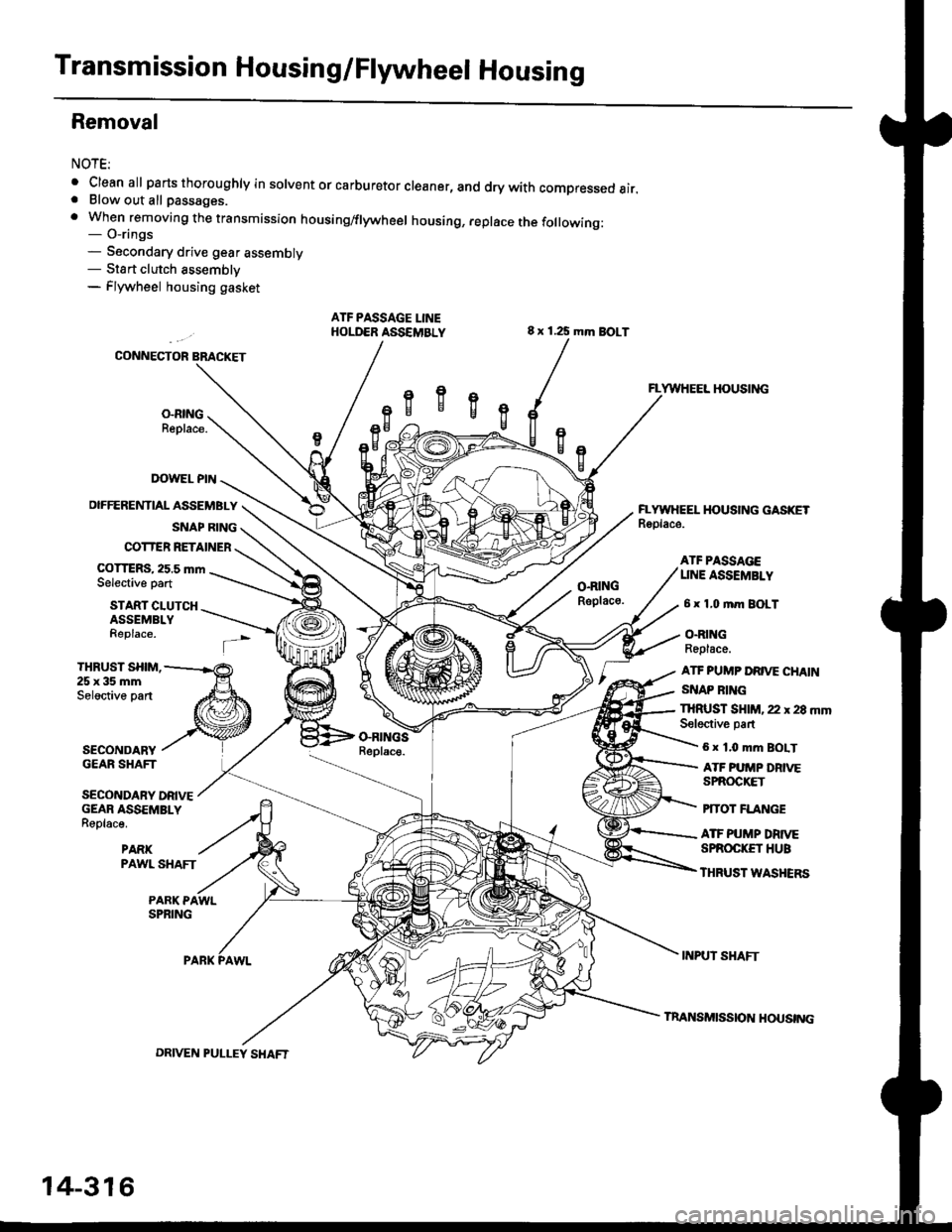

Transmission Housing/Flywheel Housing

Removal

NOTE:

. Cleanall parts thoroughly in solvent or carburetor cleaner, and dry with compressed air.. Blow out all passages.

. When removing the transmission housing/flywheel housing, replace the following:- O-rings- Secondary drive gear assembly- Sta rt clutch assemblv- Flywheel housing gasket

ATF PASSAGE LINEHOLD€R ASSEMBLY

IX)WEL PIN

OIFFERENTIAL ASSEMBLY

SNAP RING

COTTER RETAINER

COTTERS, 25.5 mmSelective part

8 x 125 mm BOLT

O.RINGRsplaco.

VWHEEL HOUSING

EYWIIEEL HOUSING GASKETRoolace.

START CLUTCHASSEMBLYReplace.

ATF PA$gAGEUNE ASSEMBLY

6 x 1,0 mm BOLT

O.RINGReplace.

ATF PUMP DRIVE CHAIN

SNAP RING

THRUST SHIM,25x35mmSeloctive part

SECONDARYGEAR SHAFT

SECONDARY DRIVEGEAR ASSEMBLYReplace.

PARKPAWL SHAFT

THRUST SHIM, 22 r 28 mmSeloctive partGRII{GSReplac€.6 x 1.0 mm BOIT

ATF PUMP DRIVESPROCKET

PfTOT FLANGE

ATF PUMP DRTVESPROC|(ET HUB

THRUST WASHERS

PARK PAWLSPRING

INPUT SHAFT

14-316

DRIVEN PULLEY SHAFT

InANSMISS|O]{ HOUSTNG

Page 994 of 2189

)

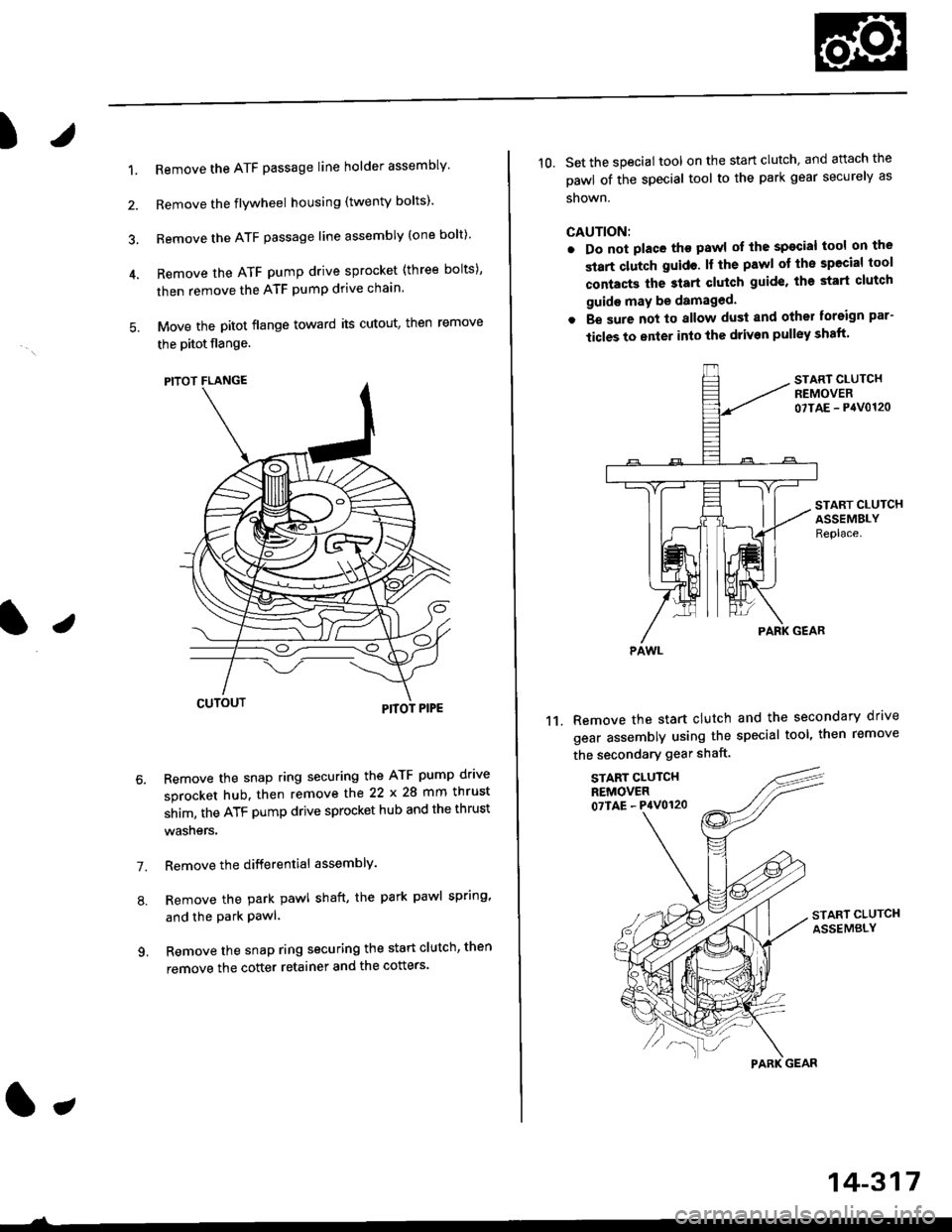

1.Remove the ATF passage line holder assembly'

Remove the flywheel housing (twenty bolts)'

Remove the ATF passage line assembly (one bolt)

Remove the ATF pump drive sprocket (three bolts),

then remove the ATF pump drive chaan.

Move the pitot flange toward its cutout, then remove

the pitot flange.

PITOT PIPE

Remove the snap ring securing the ATF pump drlve

sprocket hub. then remove the 22 x 28 mm thrust

shim, the ATF pump drive sprocket hub and the thrust

wasners,

Remove the differential assemblY.

Remove the park pawl shaft, the park pawl spring,

and the park Pawl'

Remove the snap ring securing the start clutch, then

remove the cotter retainer and the cotters.

7.

9.

J

14-317

10. Set the special tool on the start clutch' and attach the

oawl of the special tool to the park gear securely as

shown.

CAUTION:

. Do not place tho pawl of the spocial tool on the

start clutch guidc. ll the pawl ot the spocial tool

contacts the 3tart clutch guid€, the start clutch

guido may be damaged.

. Be sure not to allow dust and other foreign par-

ticles to enter into the drivon pull6y shaft'

START CLUTCHREMOVER07TAE - P4V0120

11.Remove the start clutch and the secondary drive

gear assembly using the special tool, then remove

the secondary gear shaft.

START CLUTCHREMOVER07TAE - P4V0120

START CLUTCHASSEMBLYReplace.

START CLUTCHASSEMBLY

PAWL

Page 995 of 2189

End Cover/lntermediate Housing

Removal

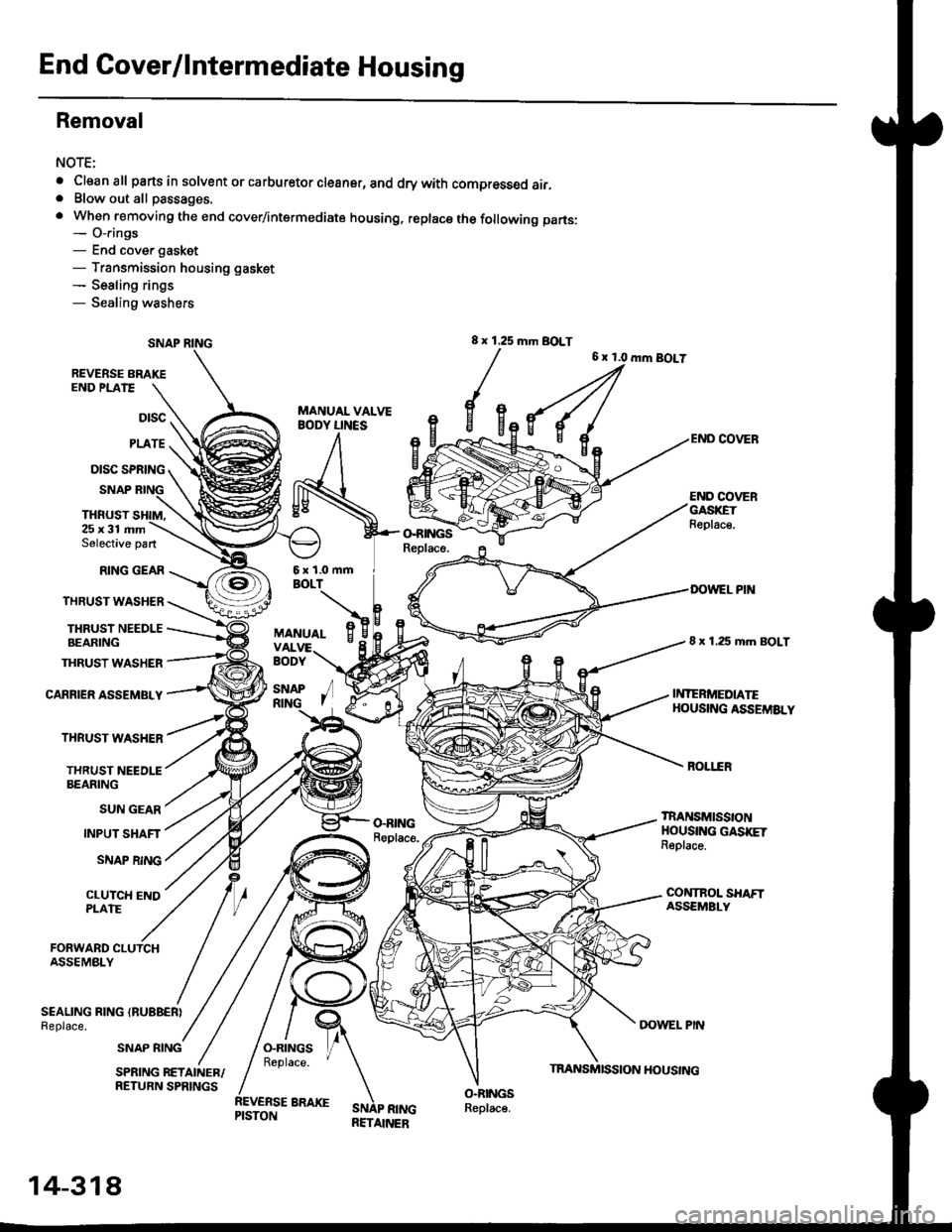

NOTE:

. Cleanall parts in solvent or carburetor cleansr, and drywith compressed air,. Blow out all passages.

. When removing the end cover/intermediate housing, replacs the following parts:- O-rings- End cover gasket- Transmission housing gasket- Sealing rings- Sealing washers

8 x 1 .25 mm BOLT

REVERSE BRAKE

{u

END PLATE

6 x 1.0 mm BOLT

Dtsc

PLATE

DISC SPRING

SNAP

THRUST

END COVERGASXETFeplac€.25x31 mmSelective part

RING GEAR

THRUST WASHER

THRUSI NEEDLEBEARING

THRUST WASHER

CARRIER ASSEMBLY

THRUST WASHER

THRUST NEEDLEBEARING

SUN GEAR

INPUT SHAFT

SNAP RING

CLUTCH ENDPLATE

sNAP /R|NG I

8 x 1.25 mm BOLT

TRANSMISSTONHOUSING GASKETReplace.

DOWEL PIN

INIERMEDIATEHOUSING ASSEMSLY

FORWARD CLUTCHASSEMBLY

SEALING RING (RUBBER}

Replace.

SNAP RING

o.BINGReplace.

SNAP RINGRETAINER

SPRING RETAINER/RETURN SPRINGS

14-318

HOUSING