b16 HONDA CIVIC 1998 6.G Owner's Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CIVIC, Model: HONDA CIVIC 1998 6.GPages: 2189, PDF Size: 69.39 MB

Page 518 of 2189

\

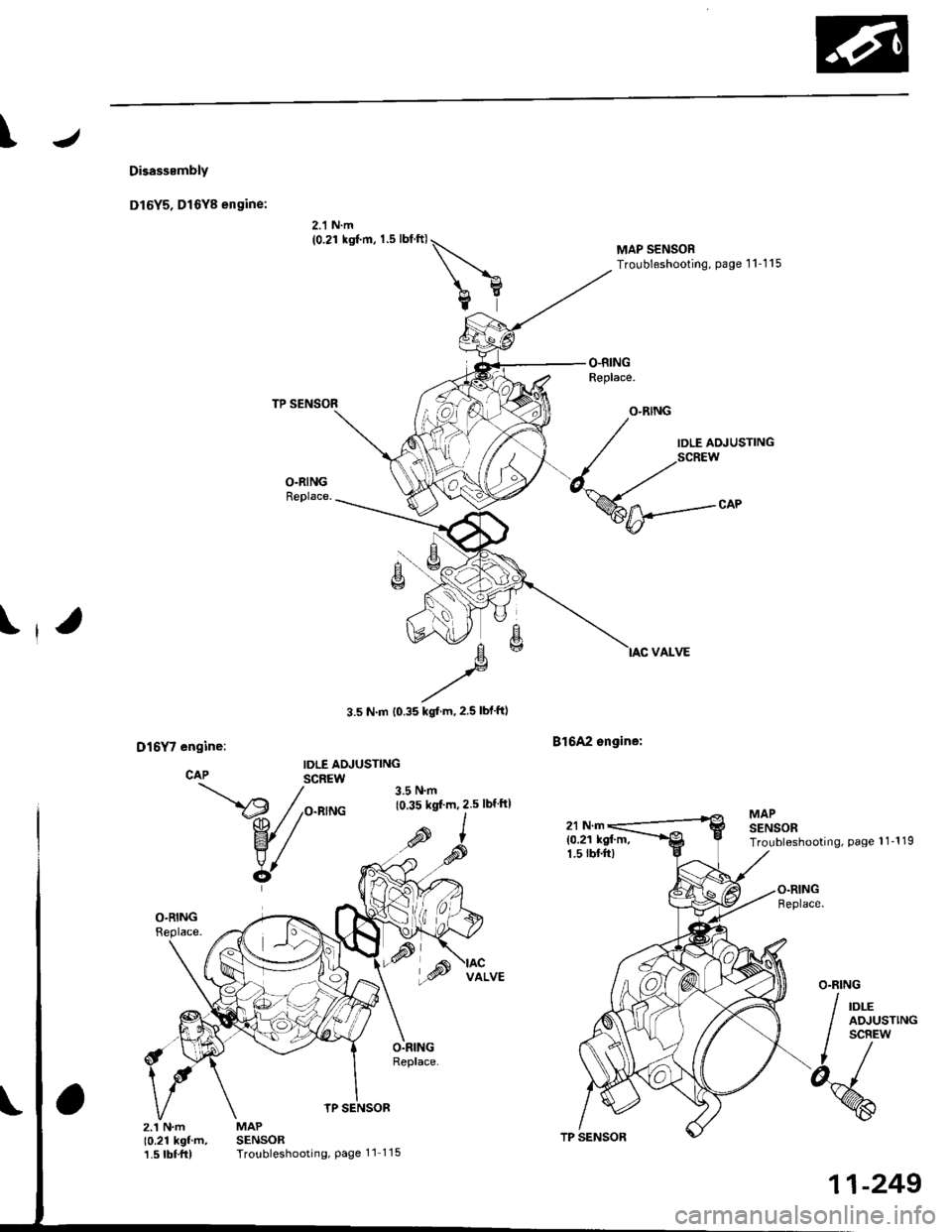

Disasssmbly

Dl6Y5, Dl6Y8 engine:

2.1 N.m(0.21 ksf.m, 1.5 lblftl\

bY

TP SENSOR

MAPSENSORTroubleshooting, Page 11 115

3.5 N.m t0.35 kgl m,2.5 lblftl

B16A2 sngine:

MAP SENSORTroubleshooting, page 1 1'1 15

IDLE AOJUSTING

MAPSENSORTroubleshooting, Page 1 1-1 19

z.'�t N.m10.21 kgf'm,1.5 tbf.frl

TP SENSOR

11-249

Page 663 of 2189

rla

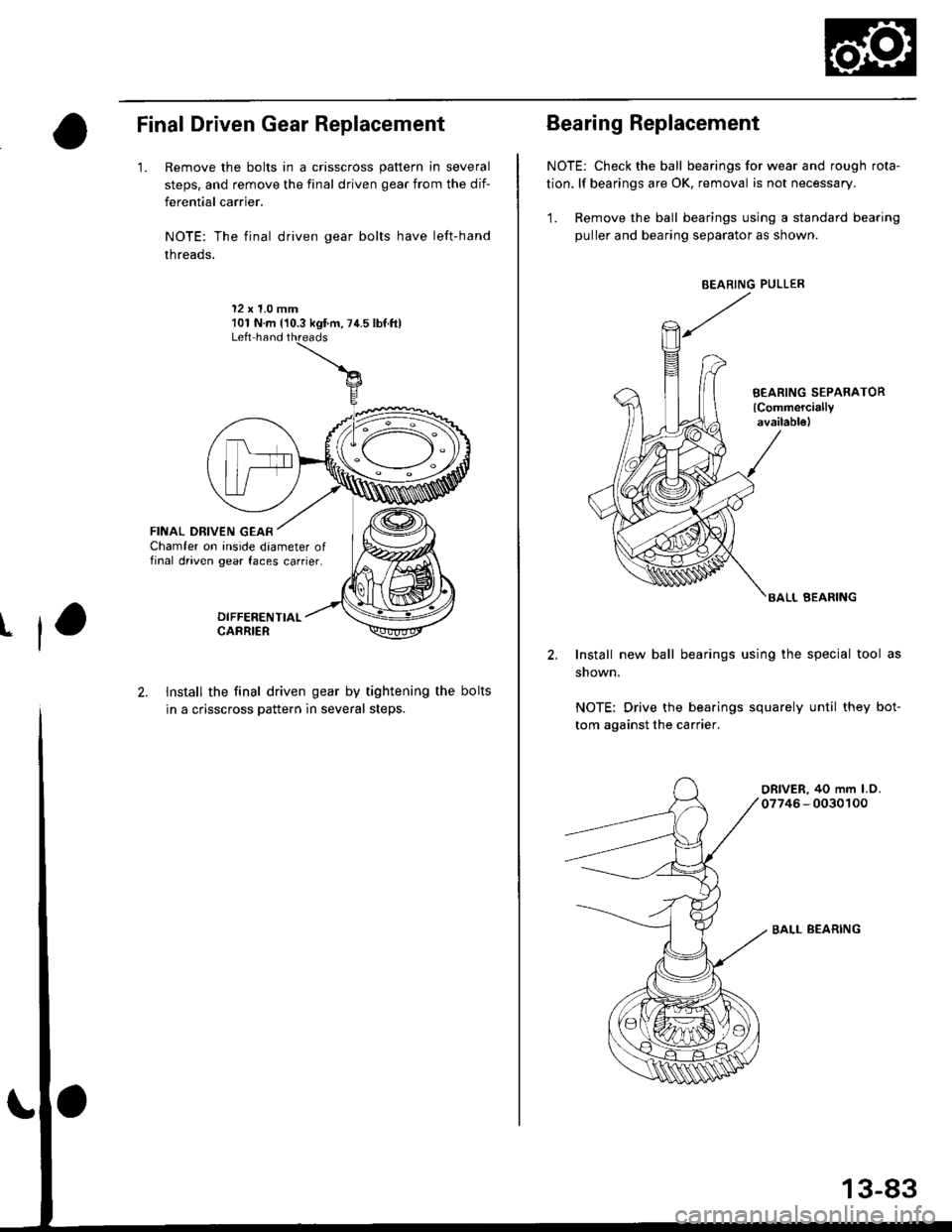

Final Driven Gear Replacement

'1. Remove the bolts in a crisscross pattern in several

steps, and remove the final driven gear from the dif-

ferential carrier.

NOTE: The final driven gear bolts have left-hand

threads,

12 x 1.0 mm101 N.m {'10.3 kgf.m,74.5 lbf.ftlLeft hand

FINAL DRIVEN GEARChamfer on inside daameter offinal driven gear faces carrier.

2. Install the final driven gear by tightening the bolts

in a crisscross pattern in several steps.NOTE: Drive the bearings squarely until they bot-

tom against the carrier.

BALL BEARING

13-83

Bearing Replacement

NOTE: Check the ball bearings for wear and rough rota-

tion. lf bearings are OK, removal is not necessary.

1. Remove the ball bearings using a standard bearing

puller and bearing separator as shown.

BEARING PULLER

BEARING SEPARATOR

lCommerciallyavailab16)

BALL BEARING

2. Install new ball bearings using the special tool as

shown.

Page 1088 of 2189

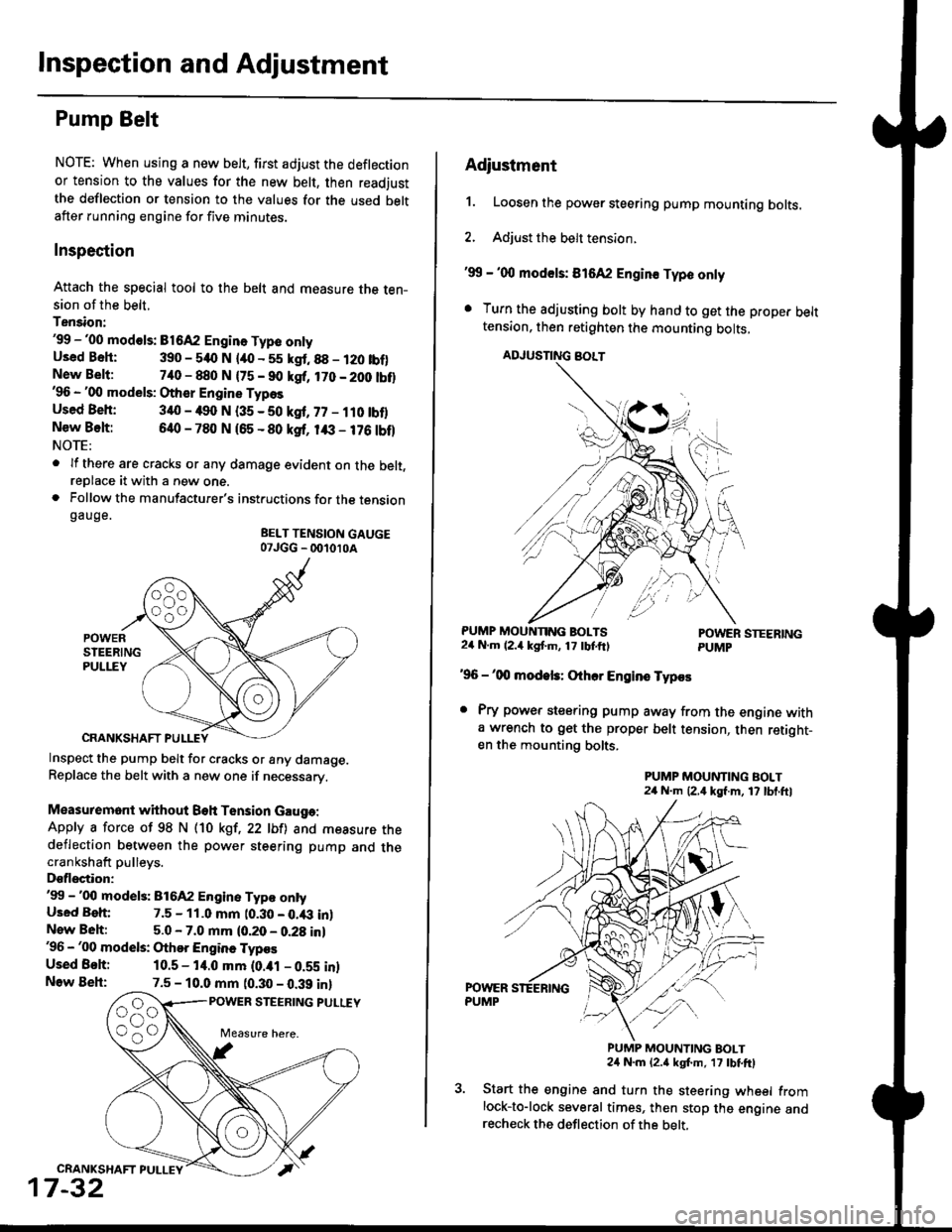

Inspection and Adjustment

Pump Belt

NOTE: When using a new belt, first adjust the deflection

or tension to the values for the new belt, then readjust

the deflection or tension to the values for the used beltafter running engine for five minutes.

Inspection

Attach the special tool to the belt and measure the ten-sion of the belt.

Tension:'99 -'00 mod€ls: B1642 Engin. Type onlyUsed Bsh: 390 - 540 N lao - 55 kgt.88 - 120 tbf)New Belt:740 - 880 N {75 - 90 kgf, 170 - 200 tbt}'96 - '00 models: Other Engine Types

Used Beh: 340 - 490 N (35 - 50 kgf, 77 - ilO tbflNew Belt:640 - 780 N 165 - 80 ksf, 1& - 176 tbf)NOTE:

. lf there are cracks or any damage evident on the belt,reDlace it with a new one.. Follow the manufacturer's instructions for the tensiongauge.

BELT TENSION GAUGE07JGG _ 001010A

Inspect the pump belt for cracks or any damage.Replace the belt with a new one if necessary.

Measuremont without Beh Tension Gauga:

Apply a force of 98 N (10 kgt,22 lbfl and measure thedeflection between the power steering pump and thecrankshaft pulleys.

Dsflectior:'99 -'00 model3: 816A2 Engine Typ€ ontyUsed Beh: 7.5 - 11.0 mm t0.30 - 0.43 inlNew Beh:5.0 - 7.0 mm (0.20 - 0.28 in)'96 - '00 models: Othor Engine Typos

Used Behi 10.5 - 14.0 mm (0.ial - 0.59 inlNow Beh:7.5 - 10.0 mm (0.30 - 0.39 inl

POWER STEERING PULUY

CRANKSHAFT PULLEY

17-32

Adiustment

1. Loosen the power steering pump mounting bolts.

2. Adjust the belt tension.

'99 - '00 mod€ls: 816A2 Engin€ Typo only

. Turn the adjusting bolt by hand to get the proper belttension, then retighten the mounting bolts,

ADJUSNNG BOLT

PUMP MOUNNNG BOLTS24 N.m (2.4 kgf'm, 17 tbtftlPOWER STEERINGPUMP

'96 -'00 modek: Othcr Engins Typos

. Pry power steering pump away from the engine witha wrench to get the proper belt tension, then retight-en the mounting bolts.

PUMP MOUNTING BOLT24 N.m (2,4 kgf.m, 17 lbl.ftl

PUMP MOUNTING BOLT24 N.m {2.a kgt m, 17 tbtftl

Start the engine and turn the steering wheel fromlock-to-lock several times, then stop the engine andrecheck the deflection of the belt,

Page 1467 of 2189

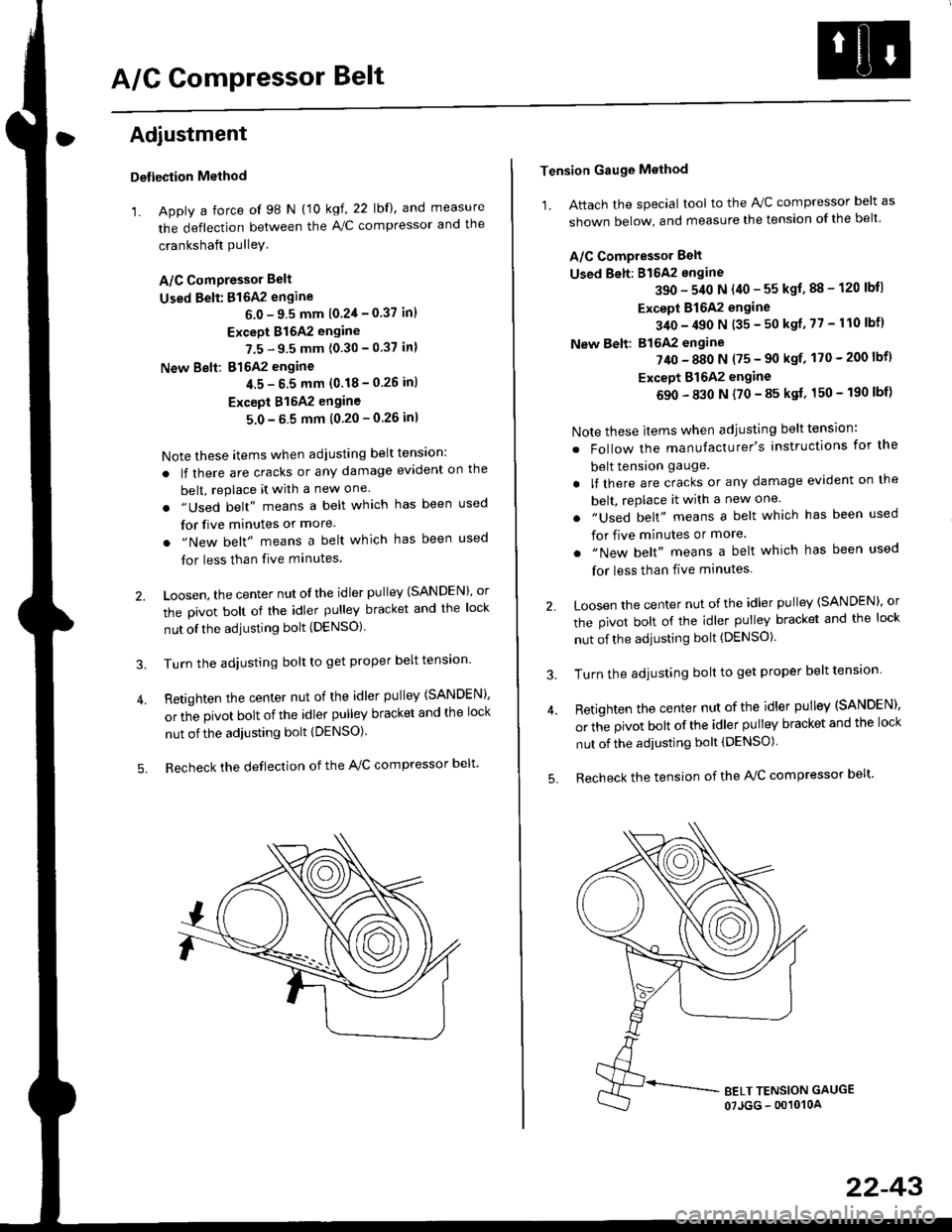

A/G GomPressor Belt

Adjustment

Detlection Method

'1. Apply a force of 98 N (10 kgf, 22 lbf), and measure

the deflection between the A,/C compressor and the

crankshaft PulleY

A/C ComPressor Belt

Used Belt: 816A2 engine

6.0 - 9.5 mm 10 2'l - 0.37 inl

Except 816A2 engine

7.5 - 9.5 mm (0.30 - 0.37 in)

New Belt: 816A2 engine

4.5- 6 5 mm (0.18-0.26 in)

Except 815A2 engine

5.0-5 5 mm (0.20-0.26 inl

Note these items when adjusting belt tens'on:

. lf there are cracks or any damage evident on the

belt, replace it with a new one.

. "Used belt" means a belt which has been used

for five minutes or more.

. "New belt" means a belt which has been used

tor less than five minutes.

2. Loosen, the center nut ofthe idler pulley (SANDEN), or

the pivot bolt of the idler pulley bracket and the lock

nut ofthe adjusting bolt (DENSO).

3. Turn the adjusting bolt to get proper belt tension'

4. Retighten the center nut of the idler pulley (SANDEN),

or the pivot bolt of the idler pulley bracket and the lock

nut of the adjusting bolt (DENSO).

5. Recheck the deflection of the A,/C compressor belt'

Tension Gauge Method

1. Attach the special tool to the IVC compressor belt as

shown below, and measure the tension of the belt

A/C Compressor Belt

Used Belt: 816A2 engine

390 - 540 N (40 - 55 kgf, 88 - 120 lbll

Except 816A2 engine

340 - 490 N (35 - 50 ksf, 77 - 110 lbfl

New Belt: B16A2 engine

?40 - 880 N {75 - 90 ksf' 170 - 200 lbf)

Except Bl642 engine

690 - 830 N (70 - 85 ksf, 150 - 190 lbf)

Note these items when adjusting belt tension:

. Follow the manufacturer's instructions for the

belt tension gauge.

. lf there are cracks or any damage evident on the

belt, rePlace it with a new one.

. "Used belt" means a belt which has been used

for five minutes or more.

. "New belt" means a belt which has been used

for less than five minutes

2 Loosen the center nut of the idler pulley (SANDEN)' or

the pivot bolt of the idler pulley bracket and the lock

nut of the adjusting bolt (DENSO).

3. Turn the adjusting bolt to get proper belt tension

4. Retighten the center nut of the idler pulley (SANDEN),

or the pivot bolt of the idler pulley bracket and the lock

nut of the adjusting bolt (DENSO)

5. Recheck the tension of the A/C compressor belt'

22-43

Page 1547 of 2189

![HONDA CIVIC 1998 6.G Owners Manual rt

99-00 models:

(5i%ease)E>4 BRNiBLK

i.,.,].,,-

ERNi BtK

BRIVBLK

BFN/BLK

BRN/BLK

BRN]BLK

BRIl/8LK

BFN/BLK

r * s r;l ao^r,qt r

CKF s€nsor 1t -1ll ELU/FEU

Knoq( sonsor (r15J -l !l r{EUl6LU

P maryH HONDA CIVIC 1998 6.G Owners Manual rt

99-00 models:

(5i%ease)E>4 BRNiBLK

i.,.,].,,-

ERNi BtK

BRIVBLK

BFN/BLK

BRN/BLK

BRN]BLK

BRIl/8LK

BFN/BLK

r * s r;l ao^r,qt r

CKF s€nsor 1t -1ll ELU/FEU

Knoq( sonsor (r15J -l !l r{EUl6LU

P maryH](/img/13/6068/w960_6068-1546.png)

rt

'99-00 models:

(5i%ease)E>4 BRNiBLK

i.,.,].',,-

ERNi BtK

BRIVBLK

BFN/BLK

BRN/BLK

BRN]BLK

BRIl/8LK

BFN/BLK

r * s r;l ao^r,qt r

CKF s€nsor 1t -1ll ELU/FEU

Knoq( sonsor (r15J '-l !l r{EUl6LU

P maryHo2s*?H wHT

Mainshafl speeo ssnsor -1ll fiEU

Coutershall sp€ed sensor -+F ] BLU) ..",r.u,.0n

016Y7, Dl6Y5 (CW) ongines

;;=-"r,i,-l

Ly"::::::::

I Secondary Ho2s :{ WHT/RED-;'4:v-..1

RED/BLU - I

wHT - f rau,rru (an )

pgTpse- J

*1i016Y5, Dl6Y8engines *4:016Y7, Bl6AzerEines lcont'd)*2: Excepl DI6YSengino ([VT) *5: D16Y5, D16Y7, D16Y8Bngines* 3:Dl6Y5 sngine ([VT) *6:B16M, D16Y8,016Y5 (CW)engines

015Y5 (LVT) sngine

41-.1

Dfiv6 prirEy speeo sonsot -1l l hEL,bLU

Driven gr ley sp€ed sensor -- F I WHT

Secondary gea sian sp€ed sensor .-ll WHT/RED

E : Engine w re harness E : Rear h€al6d orygen sensor sLlb harness

IIJ : Main wire harnsss ------ shielding

816A2, Dl6Ygengiftes

23-77

Page 1600 of 2189

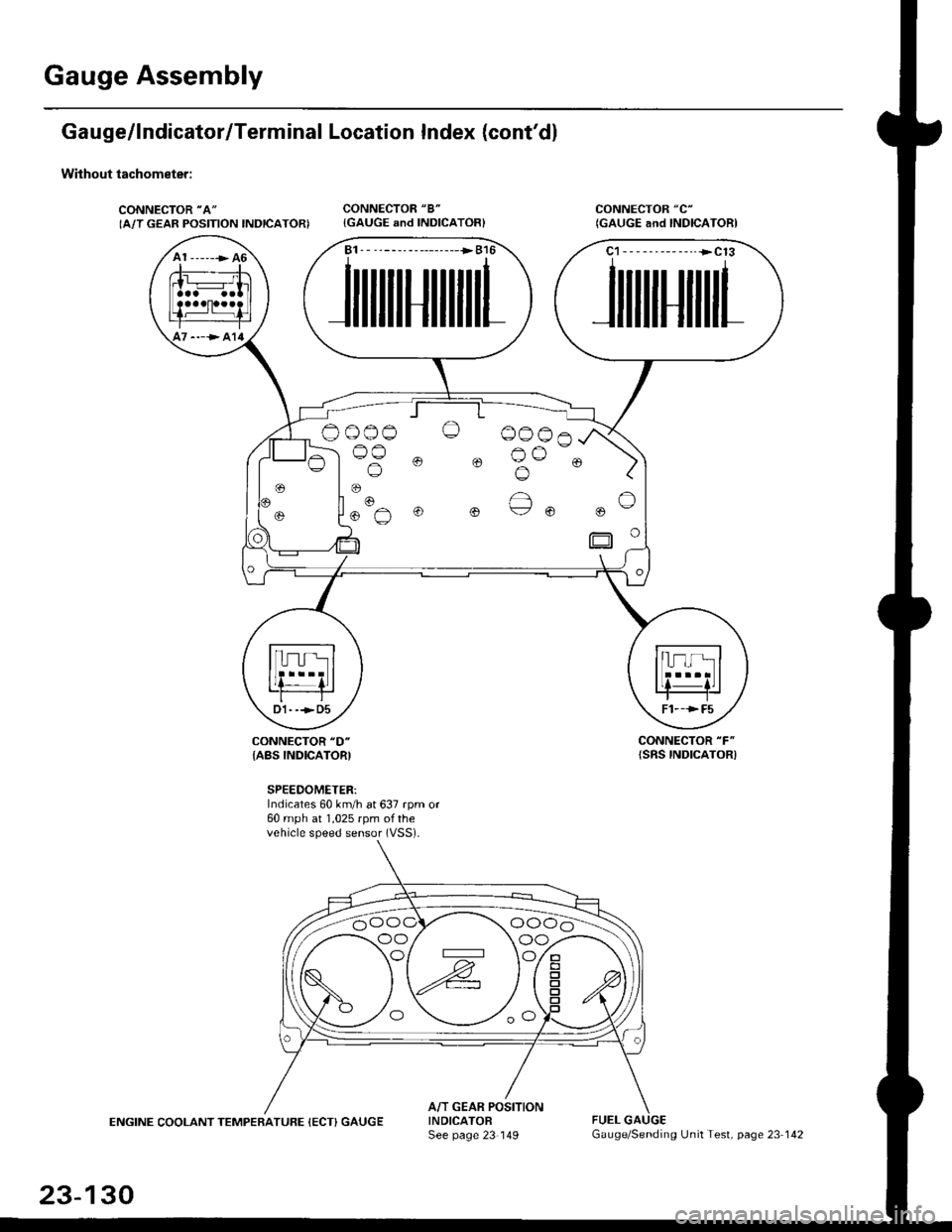

Gauge Assembly

Gauge/lndicator/Terminal Location Index (cont'd)

Without tachometer:

CONNECTOR "A"

IA/T GEAR POSITION INDICATORICONNECTOR "8"

{GAUGE and INDICATOR}CONNECTOR "C"

(GAUGE and INDICAIORI

CONNECTOR "F"

{SRS INDICATOR)CONNECTOR "D"

{ABS INDICATORI

SPEEDOMETER:Indicates 60 km/h at 637 rpm or60 mph at 1,025 rpm ofthevehicle speed sensor (VSS).

ENGINE COOLANT TEMPERATUFE (ECT) GAUGEA/T GEAR POSITIONINDICATOFSee page 23 149FUEL

A1 ------> 46

----> al4

B1. - --------------->B16

JilililHililil1

C1-- - --------..+C13

JililHililL

Oo_o-o O 0006

lus 0 0 Bu-. )

oo/ \oo

23-130

Gauge/Sending Unit Test, page 23 142

Page 2102 of 2189

127.Letl Rear of Trunk ('98)130. Behind Left Side of Dash\

128. Rear of Dl6Y8 Engine with n/VT (B16AZD16Y5 Similar)131. Underside of Vehicle, Rear of Engine

129. Behind Left Side of Dash ('98)132. Underside of Hatch Lid ('98-'00)

b

201-21