cylinder HONDA CIVIC 1998 6.G Repair Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CIVIC, Model: HONDA CIVIC 1998 6.GPages: 2189, PDF Size: 69.39 MB

Page 192 of 2189

Valves

1.

Installation

Coat the valve stems with oil. lnsert the valves into

the valve guides.

NOTE: Check that the valves move up and downsmoothly.

Installthe spring seats on the cylinder head.

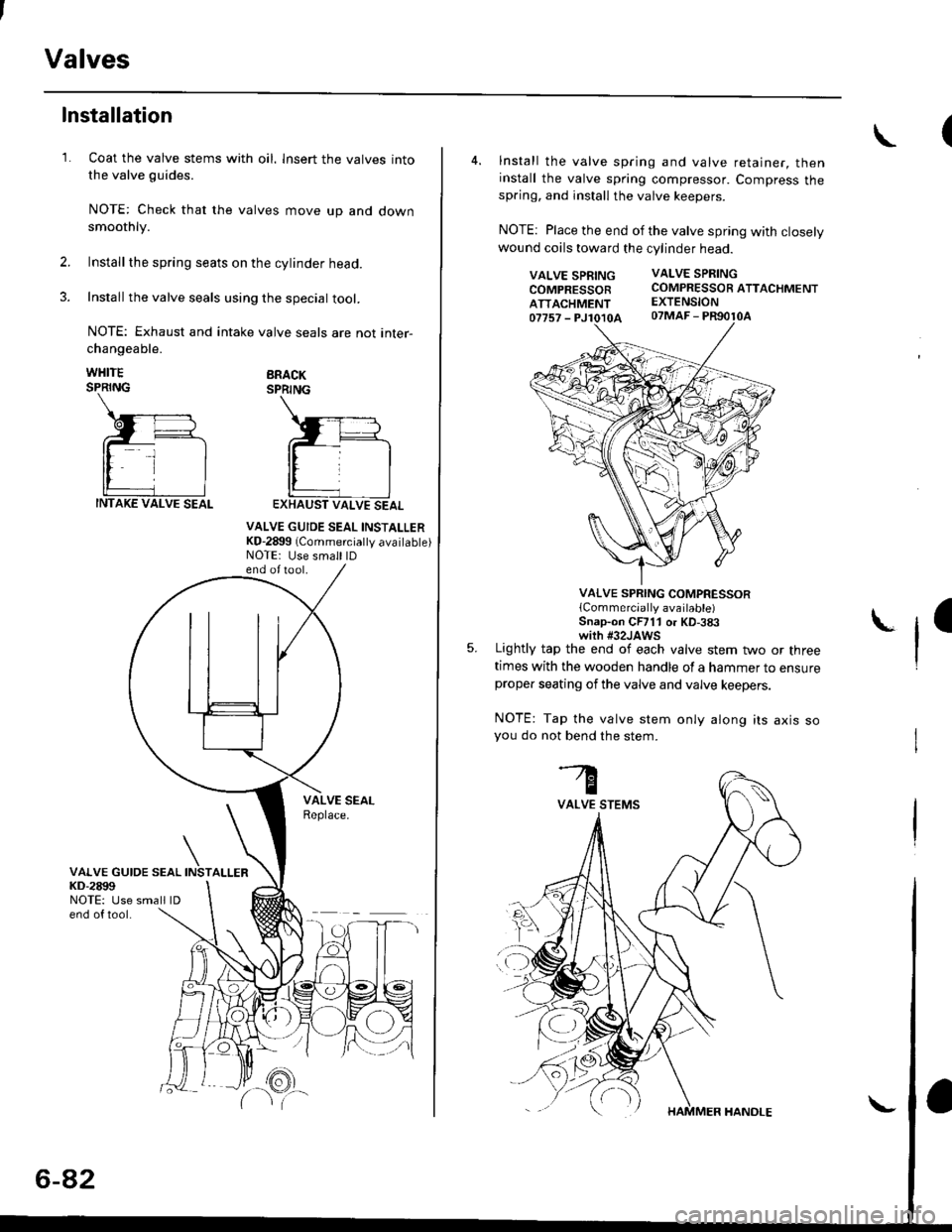

Install the valve seals using the special tool.

NOTE: Exhaust and intake valve seals are not inter-

changeable.

WHITESPRING

VALVE GUIDE SEAL INSTALLERKD-28)g (Commercially available)NOTE: Use small lDend of tool,

2.

BRACKSPRING

VALVE SEALReplace.

tNsTALLERVALVE GUIDE SEALKD-2899NOTE: Use small lDend of tool

(

4. lnstall the valve spring and valve retainer, theninstall the valve spring compressor. Compress thespring, and install the valve keepers.

NOTE: Place the end of the valve spring with closely

wound coils toward the cylinder head.

VALVE SpRtNG VALVE SPRTNG

COMpRESSOR COMPRESSORATTACHMENT

ATTACHMENT EXTENSTON

0775? _ pJlOl0A o?MAF - PR9010A

VALVE SPRING COMPRESSORlCommercially available)Snap-on CF711 or KD-3tXlwith #32JAWSLightly tap the end of each valve stem two or threetimes with the wooden handle of a hammer to ensureproper seating of the valve and valve keepers.

NOTE: Tap the valve stem only along its axis soyou do not bend the stem.

I

5.

Page 193 of 2189

Rocker Arms

lnstallation

1.

2.

3.

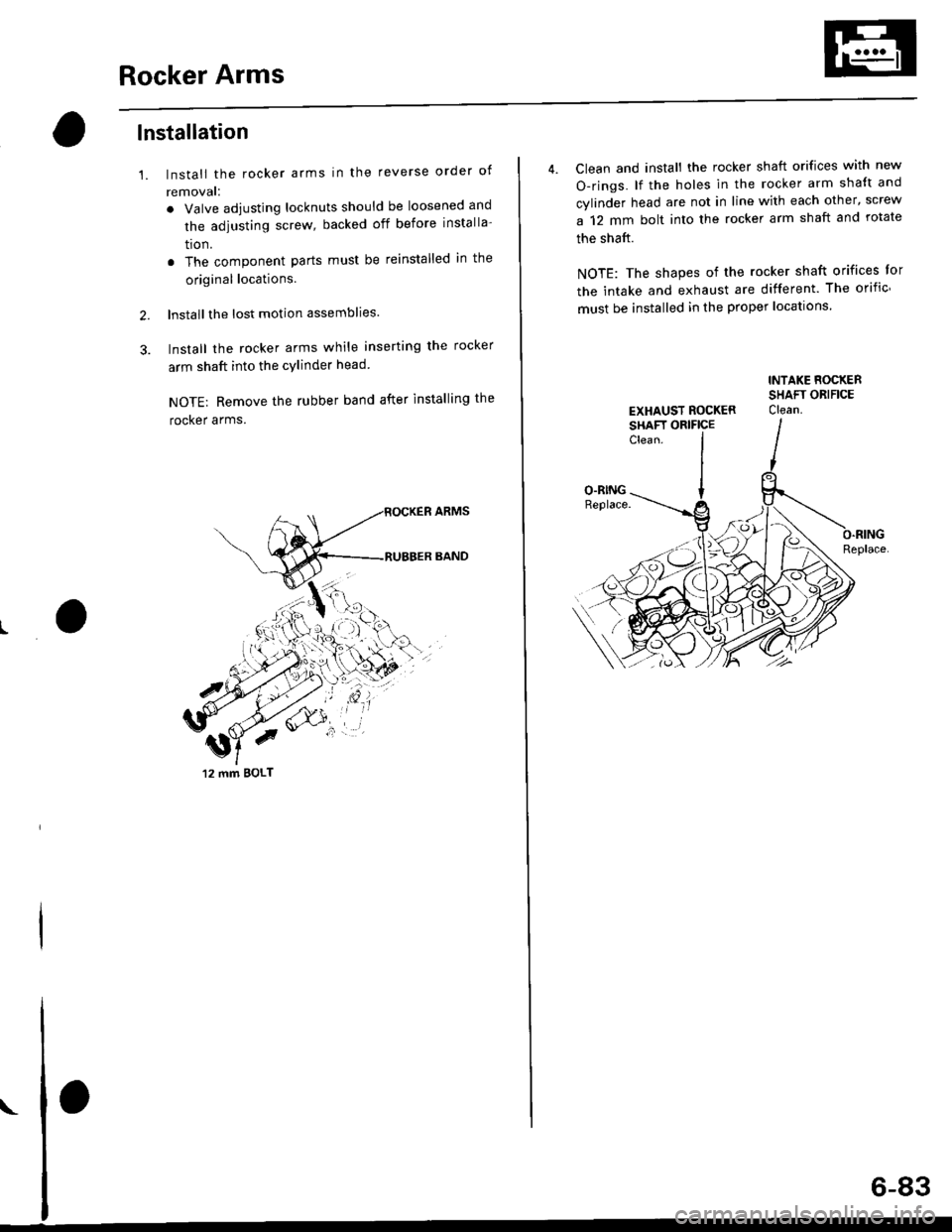

lnstall the rocker arms in the reverse order of

removal:

. Valve adjusting locknuts should be loosened and

the adiusting screw, backed off before installa-

tron.

. The component parts must be reinstalled in the

original locations.

lnstall the lost motion assemblies.

lnstall the rocker arms while inserting the rocker

arm shaft into the cylinder head

NOTE: Remove the rubber band after installing the

rocker arms.

12 mm BOLT

\

6-83

4. Clean and install the rocker shaft orifices with new

O-rings. lf the holes in the rocker arm shaft and

cylinder head are not in line with each other, screw

a 12 mm bolt into the rocker arm shaft and rotate

the shaft.

NOTE: The shapes of the rocker shaft orifices tor

the intake and exhaust are different. The orific'

must be installed in the proper locations.

INTAKE ROCKER

SHAFT ORIFICE

EXHAUST ROCKER Clean

SHAFT ORIFICE

O.RING

O

Page 194 of 2189

I

Cylinder Head

Installation

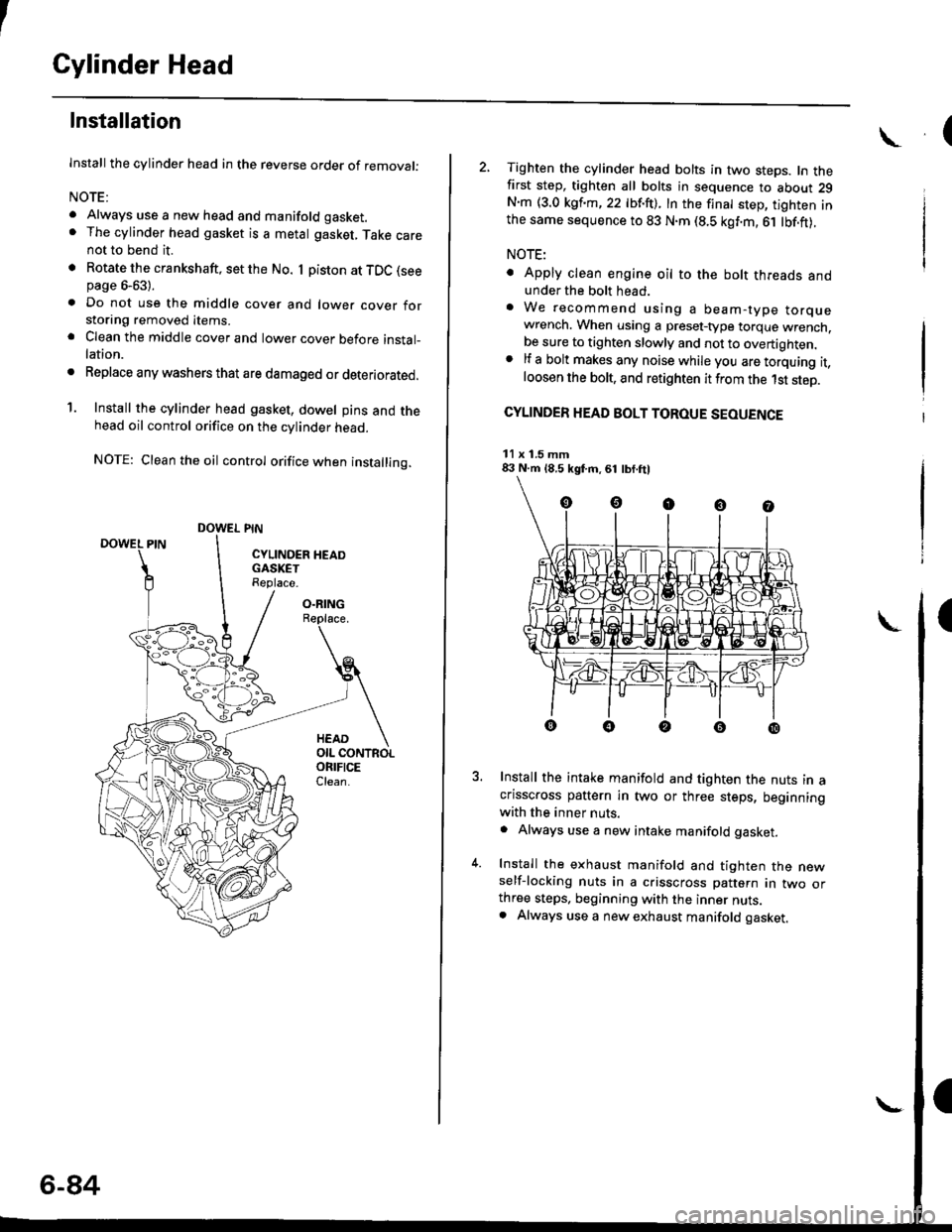

lnstall the cylinder head in the reverse order of removal:

NOTE:

. Always use a new head and manifold gasket.. The cylinder head gasket is a metal gasket, Take carenot to bend it.

. Rotate the crankshaft, set the No. 1 piston at TDC (seepage 6-63).

. Do not use the middle cover and lower cover forstorang removed items.. Clean the middle cover and lower cover before instal_lation.

o Replace any washers that are damaged or deteriorated.

1. Install the cylinder head gasket, dowel pins and thehead oil control orifice on the cylinder head.

NOTE: Clean the oil control orifice when installing.

DOWEL PIN

6-84

2, Tighten the cylinder head bolts in two steps. In thefirst step, tighten all bolts in sequence to about 29N.m (3.0 kgf.m, 22 tbf.ftl. ln the final step, tighten inthe same sequence to 83 N.m (8.S kgf.m,6t lbf.ft).

NOTE:

. Apply clean engine oil to the bolt threads andunder the bolt head.. We recommend using a beam-type torquewrench. When using a preset-type torque wrench,be sure to tighten slowly and not to overtighten.. lf a bolt makes any noise while you are torquing it,loosen the bolt, and retighten it from the 1st step.

CYLINDER HEAD BOLT TOROUE SEOUENCE

11x 1.5 mm83 N.m 18.5 kgf.m, 61 tbf.ftl

Install the intake manifold and tighten the nuts in acflsscross pattern in two or three steps, beginningwith the inner nuts.. Always use a new intake manifold gasket.

Install the exhaust manifold and tighten the newself-locking nuts in a crisscross pattern in two orthree steps. beginning with the inner nuts.. Always use a new exhaust manifold gasket.

4.

Page 195 of 2189

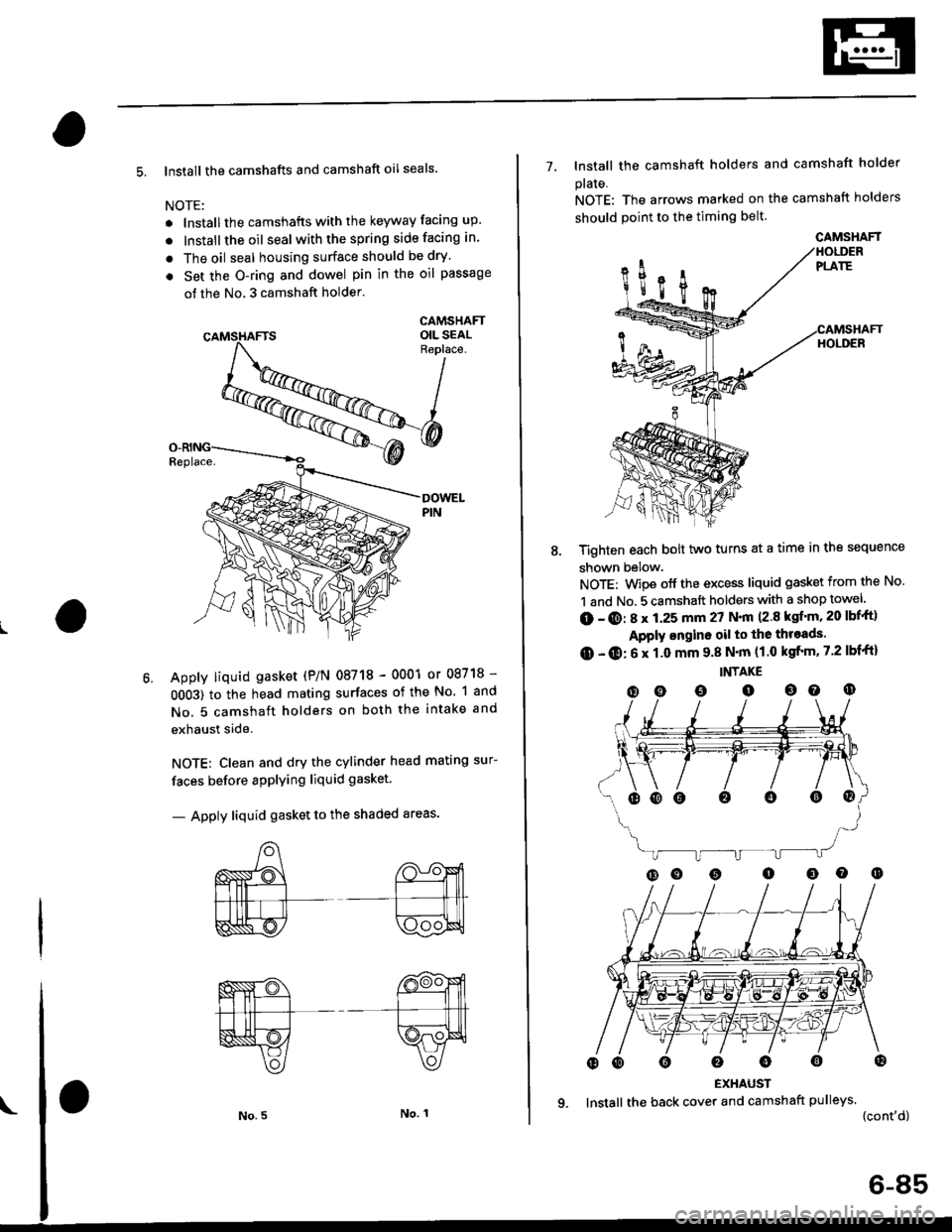

5. lnstall the camshafts and camshaft oil seals.

NOTE:

. lnstallthe camshafts with the keyway facing up.

. lnstall the oil seal withthespring side facing in.

. The oil seal housing surface should be dry'

. Set the O-ring and dowel pin in the oil passage

of the No, 3 camshaft holder'

CAMSHAFTOIL SEALReplace.

Apply liquid gasket (P/N 08718 - 0001 or 08718 -

0OO3) to the head mating surfaces of the No. 1 and

No. 5 camshaft holders on both the intake and

exhaust side.

NOTE: Clean and dry the cylinder head mating sur-

faces before applying liquid gasket.

- Apply liquid gasket to the shaded areas'

7- lnstall the camshaft holders and camshaft holder

plaIe.

NOTE: The arrows marked on the camshaft holders

should point to the timing belt.

Tighten each bolt two turns at a time in the sequence

shown below.

NOTE: Wipe off the excess liquid gasket from the No.

1 and No. 5 camshaft holders with a shop towel

(D - @: 8 x 1.25 mm 27 N.|n (2.8 ksf'm, 20 lbf'ft)

Apply ongine oil to the throads.

O - O: 6 x 1.0 mm 9.8 N'm (1.0 kgfrm, 7.2 lbf'ft)

INTAKE

(D o o o oo o

EXHAUST

lnstall the back cover and camshaft pulleys.

{cont'd)

oooo0o@

CAMSHAFT

6-85

Page 196 of 2189

Cylinder Head

Installation (cont'dl

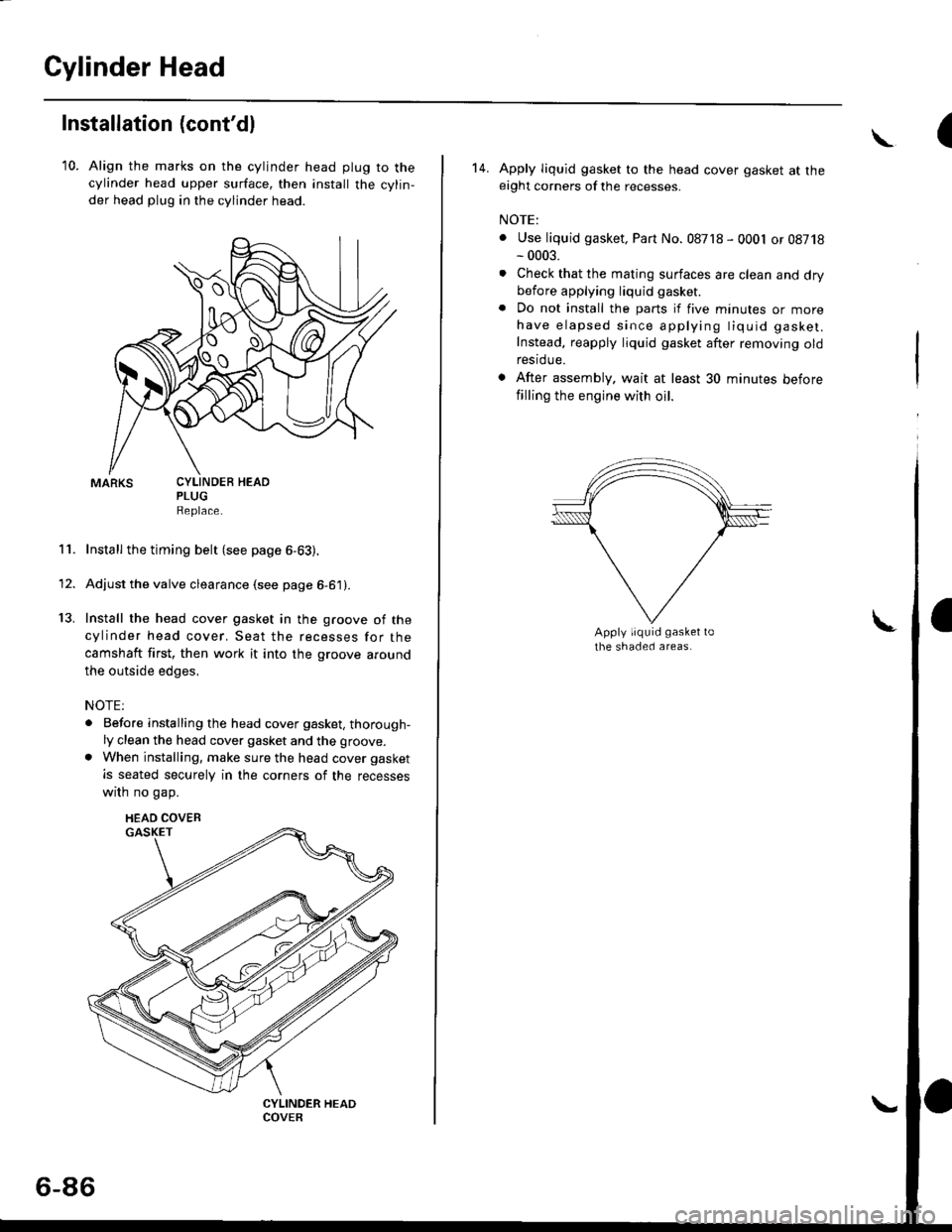

10. Align the marks on the cylinder head plug to thecylinder head upper surface, then install the cylin,

der head plug in the cylinder head.

PLUGReplace.

Install the timing belt (see page 6-63).

Adjust the valve clearance (see page 6-61).

Install the head cover gasket in the groove of the

cylinder head cover. Seat the recesses for the

camshaft first, then work it into the groove around

the outside edges,

NOTE:

. Before installing the head cover gasket, thorough-ly clean the head cover gasket and the groove.

. When installing, make sure the head cover gasket

is seated securely in the corners of the recesses

wrrn no gap.

11.

13.

1'

CYLINDEB HEAD

HEAD COVEB

6-86

(\

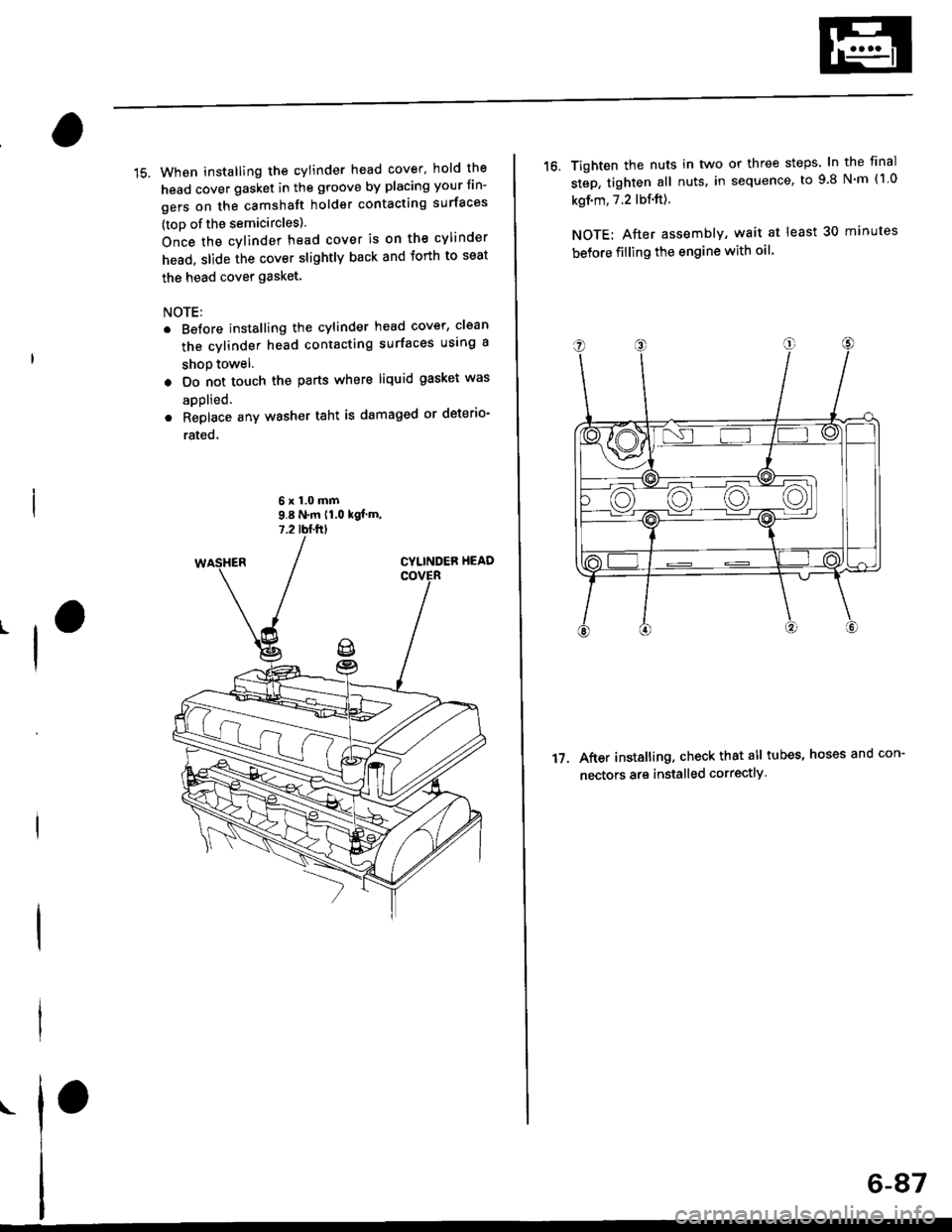

14. Apply liquid gasket to the head cover gasket at theeight corners of the recesses.

NOTE:

. Use liquid gasket, Part No. 08718 - 0001 or 08718- 0003.

. Check that the mating surfaces are clean and drybefore applying liquid gasket

. Do not install the parts if five minutes or morehave elapsed since applying tiquid gasket.

Instead, reapply liquid gasket after removing oldrestdue.

. After assembly. wait at least 30 minutes before

filling the engine with oil.

Page 197 of 2189

15. When installing the cylinder head cover, hold the

head cover gasket in the groove by placing your fin-

gers on the camshaft holder contacting surfaces

(toD of the semicircles).

Once the cylinder head cover is on the cylinder

head, slide the cover slightly back and forth to seat

the head cover gasket.

NOTE:

. Be{ore installing the cylinder head cover, clean

the cvlinder head contacting surfaces using a

shoP towel.

. Oo not touch the parts where liquid gasket was

applied.

. Replace any washer taht is damaged or deter'o-

rated.

t

\

6-A7

16. Tighten the nuts in two or three steps. In the final

step, tighten all nuts, in sequence, to 9 8 N'm {1 0

kgf.m, 7.2 lbf.ft).

NOTE: After assembly, wait at least 30 minutes

before filling the engine with oil.

After installing, check that all tubes' hoses and con-

nectors are installed correctly.17.

Page 198 of 2189

Engine Block

Speciaf Tools ..........." 7-2

lllustlated Index ...................."..'.......... 7-3

Flywheel and Drive Plate

Repf acement """'.' 7-7

Connecting Rod and Crankshaft

End Play ..........."....7-8

Main Bearings

Clearance ............... 7-9

Selection ................7-10

Connecting Rod Bearings

clearance ....'.......... 7-11

Selection ................ 7-11

Pistons and Crankshaft

Removaf ................. 7 -12

Crankshaft

Inspection ."".........7-14

Pistons

Inspection ......"'.....7-15

fnstaffation .............7-23

Cylinder Block

lnspec'tion ..............7-16

Bore Honing ..........7-17

Piston Pins

Removal ...,...........'.7-17

lnstallation .............7-18

Inspection .'............7-19

Connecting Rods

Selection ................7-18

Piston Rings

End Gap ..........".."' 7'2O

Repfacement .........7-2O

Ring-to-Groove Clearance ...........'.'. 7 -21

Afignment .......""'.. 7'21

Crankshaft Oil Seal

fnstaffation .............7-22

Crankshaft

fnstaffation ..-.-..'.".' 7'23

Oil Pan

lnstallation .............7-26

Oil Seals

fnstaffation ....""""' 7-29

r-f

Page 203 of 2189

lllustrated Index

(cont'd)

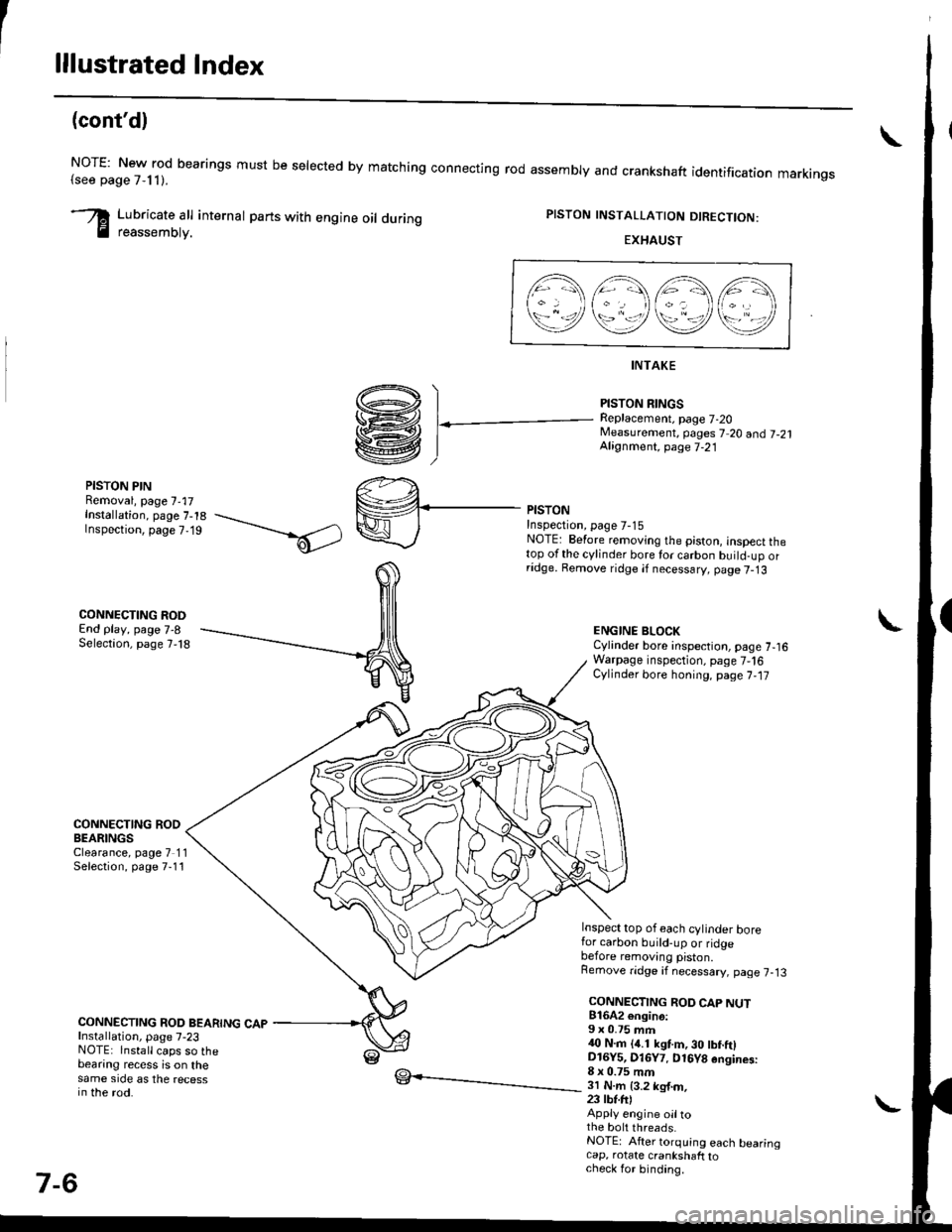

NOTE: New rod bearings must be selected by matching connecting rod assembly and crankshaft(see page 7,11).identification markings

Lubricate all internal parts with engine oil duringreassembtv.

PISTON INSTALLATION DIRECTION:

EXHAUST

4\/=\6\z\

\e/!rqrf/

INTAKE

PISTON RINGSReplacement. page 7-20Measurement, pages 7 20 andj-21Alignment, page 7-21

PISTON PINRemoval, page 7,17Installation, page 7-18Inspection, page 7,19

CONNECTING RODEnd play, page 7-8Selection, page 7,18

CONNECTING RODBEARINGSClearance, page 7 11Selection, page 7-11

CONNECTING ROD BEARING CAPInstallation, page 7-23NOTE: lnstall caps so thebearing recess is on thesame side as the recessin the rod.

PISTONInspectron, page 7-15NOTE: Betore removing the piston, inspect thetop of the cylinder bore for carbon build-up orridge. Bemove ridge if necessary, page 7-13

ENGINE BLOCKCylinder bore inspection, page 7-16Warpage inspection, page 7,'16Cylinder bore honing, page 7,17

Inspect top of each cylinder borefor carbon build-up or ridgebefore removing piston.Remove ridge if necessary, page 7-13

CONNECTING ROD CAP NUT816A2 €ngin6:9 x 0.75 mm{0 N.m (4.1 kgt m, 30 tbf.ftlD16Y5, Dl6Y7. D16Y8 engines:8 x 0.75 mm3l N.m {3.2 kg{.m,23 tbt.fr)Apply engine oiltothe bolt threads.NOTE: After torquing each bearingcap, rotate crankshaft tocheck for binding.

7-6

Page 210 of 2189

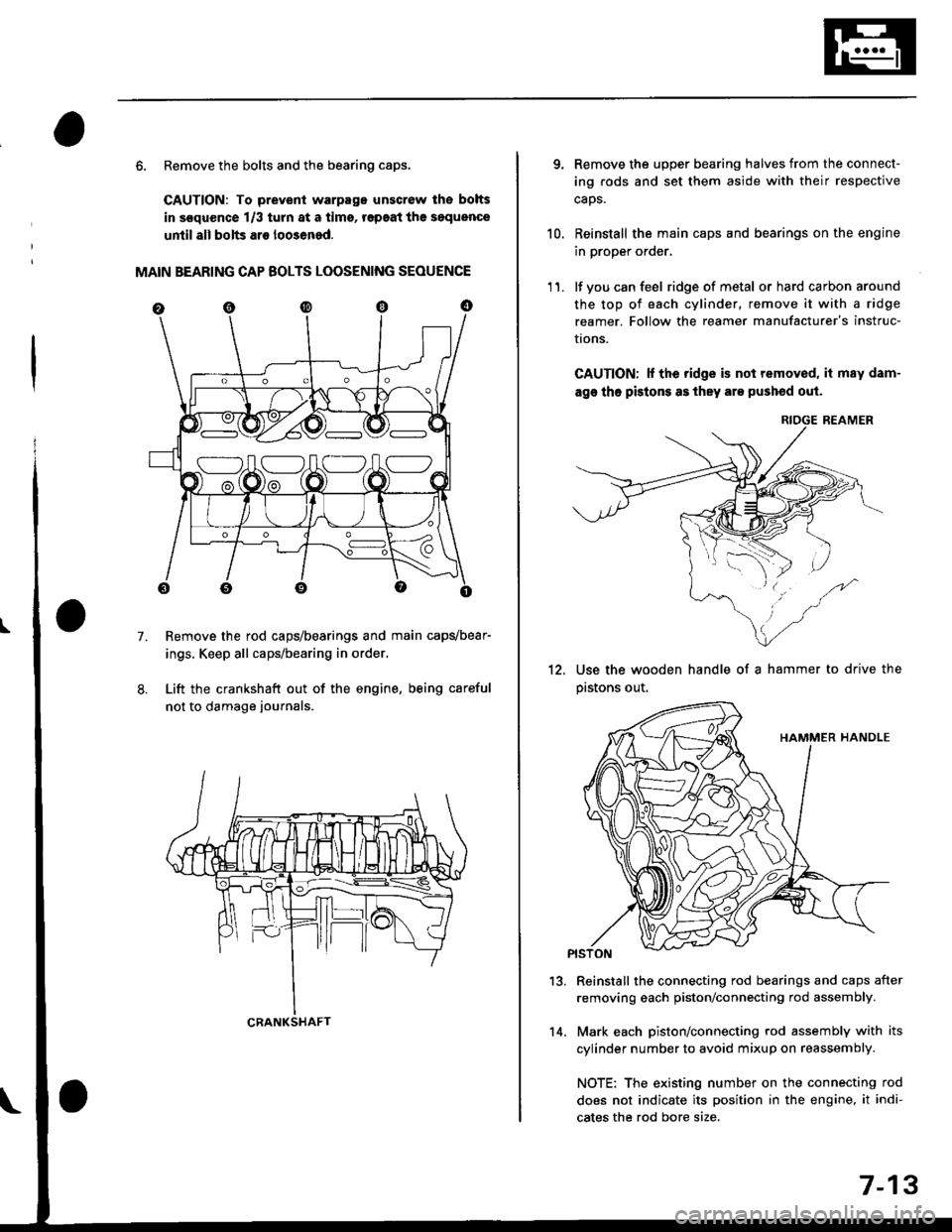

6. Remove the bolts and the bearing caps.

CAUTION: To prevenl warpago unscrow lhe bolts

in s€quence 1/3 turn at a tims, r€paat the soquence

until all bolts ar€ loo3ened.

MAIN BEARING CAP BOLTS LOOSENING SEOUENCE

Remove the rod caps/bearings and main capvbear-

ings. Keep all caps/bearing in order.

Lift the crankshaft out of the engine, being careful

not to damage journals.

7.

S:_]ILOJLOAO

CRANKSHAFT14.

7-13

qRemove the upper bearing halves from the connect-

ing rods and set them aside with their respective

caos.

Reinstall the main caps and bearings on the engine

in proper order,

lf you can feel ridge of metal or hard carbon around

the top of each cylinder, remove it with a ridge

reamer. Follow the reamer manufacturer's instruc-

I|ons.

CAUTION; lf the ridge is not removed, it may dam-

age tho pistons as they are pushod out.

RIOGE REAMER

10.

11.

12.Use the wooden handle of a hammer to drive the

pastons out.

13.Reinstall the connecting rod bearings and caps after

removing each piston/connecting rod assembly.

Mark each piston/connecting rod assembly with its

cylinder number to avoid mixup on reassembly.

NOTE: The existing number on the connecting rod

does not indicate its position in the engine, it indi-

cates the rod bore size.

Page 212 of 2189

Pistons

Inspection

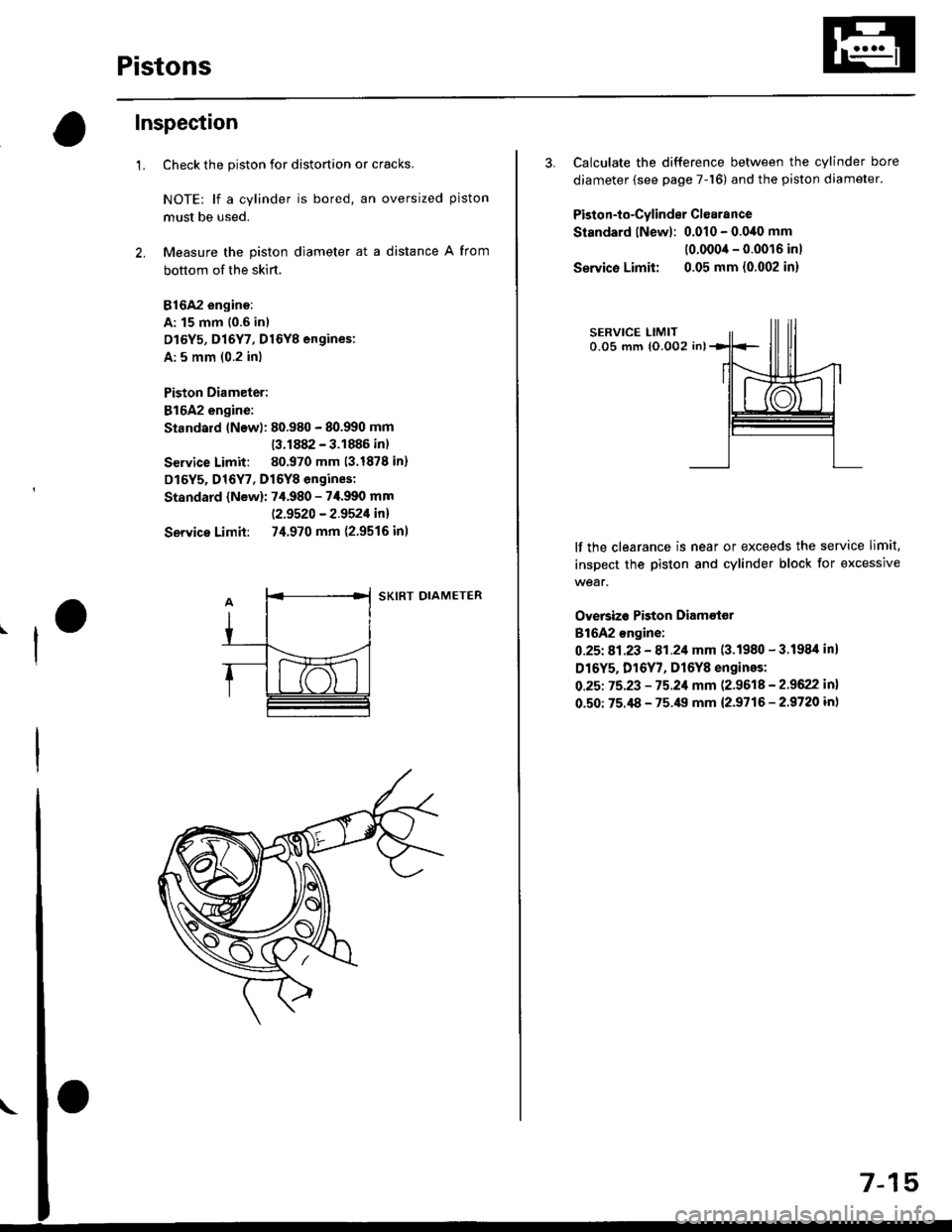

1.Check the piston for distortion or cracks,

NOTE: lf a cylinder is bored. an oversized piston

must be used.

Measure the piston diameter at a distance A from

bottom of the skirt.

816A2 engino:

A: 15 mm 10.6 in)

D16Y5, D16Y7, D16Y8 engines:

A: 5 mm (0.2 inl

Piston Diameter:

816A2 engine:

Standard lNewl: 80.980 - 80.990 mm

13.1882 - 3.1886 in)

Service Limit: 80.970 mm (3.1878 in)

D16Y5, D16Y7, D16Y8 engines:

Standard {New): 7,f.980 - 7i1.990 mm

|.2.9520 - 2.9521in!

Service Limit: 74.970 mm {2.9516 inl

SKIRT DIAMETER

57-1

3. Calculate the difference between the cylinder bore

diameter (see page 7-16) and the piston diameter.

Piston-to-Cylinder Clsarance

Standard lNewl: 0.010 - 0.0,10 mm

(0.0004 - 0.0016 inl

Servico Limit: 0.05 mm {0.002 in}

lf the clearance is near or exceeds the service limit,

inspect the piston and cylinder block for excessive

wear.

Oversizo Piston Diametor

816A2 ongine:

0.25t 81.23 - 81.21 mm (3.1980 - 3.1984 inl

D16Y5. D16Y7, D16Y8 engines:

O.25t 75.23 - 75.21 mm (2.9618 - 2.9622 in)

0.50: 75.i18 - 75.49 mm {2.9716 - 2.9720 in}