cylinder HONDA CIVIC 1998 6.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CIVIC, Model: HONDA CIVIC 1998 6.GPages: 2189, PDF Size: 69.39 MB

Page 572 of 2189

Glutch Master Gylinder

IRemovaUlnstallation

CAU'NON:

. Do not sDill brake lluid onthevehicle;it may damage

the paint; if brake fluid does contact the paint, wash

it off immediatelY with water.

. Plug the end ofthe clutch line and reservoir hos€ with

a shop towelto prevent brake tluid from coming out

1. The brake tluid can be removed from the clutch

master cylinder reservoir with a syringe

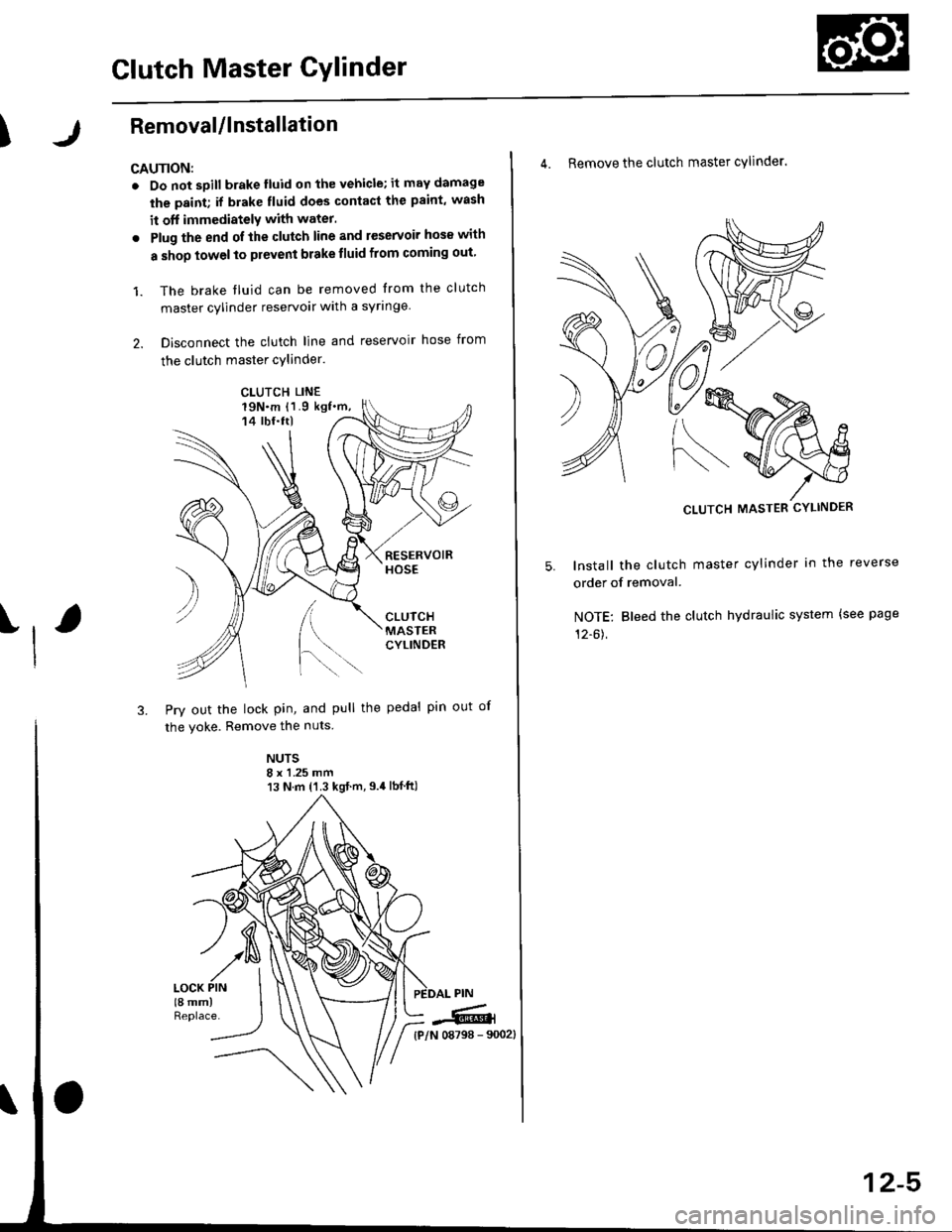

2. Disconnect the clutch line and reservoir hose from

the clutch master cylinder.

19N.m 11.9 kgf.m,14 tbf.ttl

[.

3. Pry out the lock pin, and pull the pedal pin out

the yoke. Remove the nuts

NUTS8 x 1 .25 mm13 N.m {'1.3 kgt.m,9.4lbf ft)

)

of

CLUTCH LINE

iffi,

4. Remove the clutch master cylinder.

CLUTCH MASTER CYLINDER

lnstall the clutch master cylinder in the reverse

order of removal.

NOTE: Bleed the clutch hydraulic system {see page

12-61,

12-5

Page 573 of 2189

Slave Gylinder

Removal/lnstallation

CAUTION:

. Do not spill brake tluid on the vehicle; it may damage

the paint; if brake fluid does contact th€ paint, wash

it off immodiatoly with water,

. Plug the end ot the clutch line with a shop towel to

prevsnt brake fluid from coming oul.

-61'srp", High Temp Urea crease (p/N

08798 - 90021.

: Brake Assembly Lube or equivalent rubber

grease.

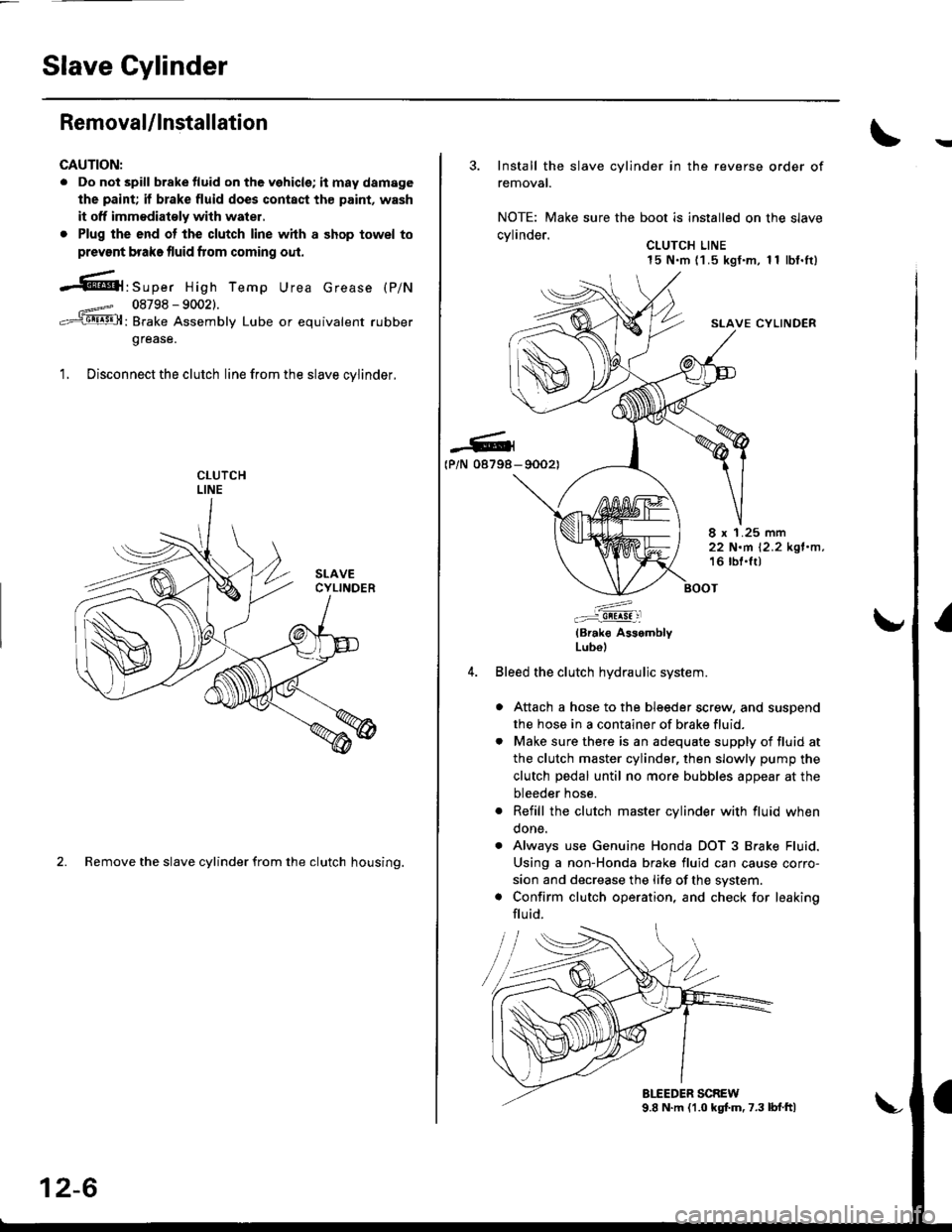

1. Disconnect the clutch line from the slave cvlinder.

2. Remove the slave cylinder from the clutch housing.

12-6

3. Install the slave cylinder in the reverse order of

removal.

NOTE: Make sure the boot is installed on the slave

cvlinder.. CLUTCH LINE15 N.m (1 .5 kgf.m, 1 1 lbf.It)

SLAVE CYLINDER

-G4(P/N 08798- 90021

8 x 1.25 mm22 N.m 12.2 kgl.n,16 lbl.lt)

:^..:i!!!!! :l

(Brak€ AssemblyLubol

Bleed the clutch hydraulic system.

a Attach a hose to the bleeder screw, and suspend

the hose in a container of brake fluid.

. Make sure there is an adequate supply of fluid at

the clutch master cylinder, then slowly pump the

clutch pedal until no more bubbles appear at the

bleeder hose.

. Refill the clutch master cylinder with fluid when

done.

. Always use Genuine Honda DOT 3 Brake Fluid.

Using a non-Honda brake fluid can cause corro-

sion and decrease the life of the system.

. Confirm clutch operation, and check for leaking

flu id.

Page 587 of 2189

12.

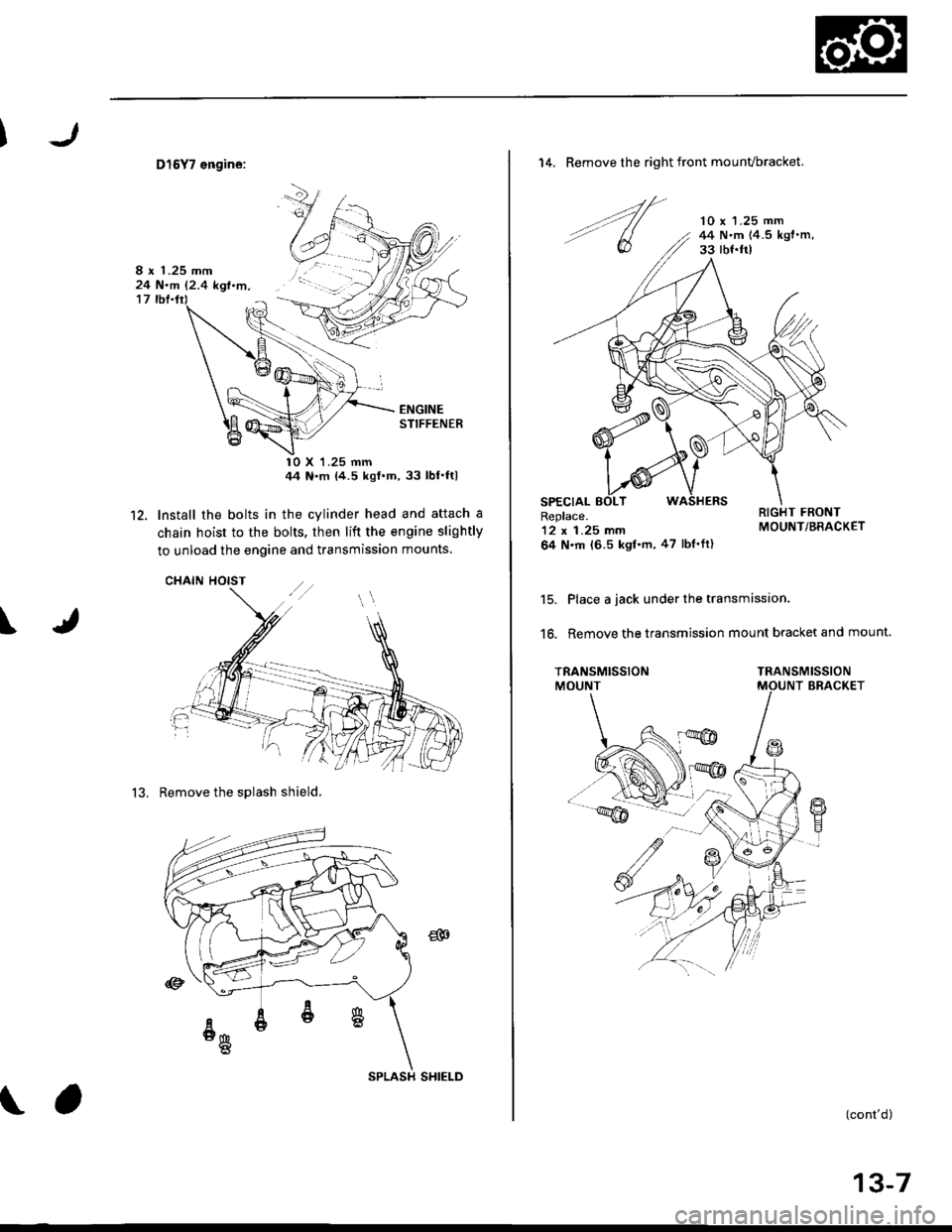

D16Y7 engine:

ENGINESTIFFENER

10 X 1.25 mmIt4 N'm (4.5 kqf'm,33 lbf'ltl

Install the bolts in the cylinder head and attach a

chain hoist to the bolts, then lift the engine slightly

to unload the engine and transmission mounts.

CHAIN HOIST

13. Remove the sDlash shield,

\

8 x 1.25 mm24 N.m {2.4 kgl.m,

SPLASH SHIELD

14. Remove the right front mounvbracket.

'lO x 'l.25 mm44 N'm (4.5 kgl.m,33 rbf.frl

Replace.12 x 1.25 mm

64 N.m t6.5 kgf.m,47 lbf'ft)

Place a jack under the transmission.

Remove the transmission mount bracket and mount.16.

TRANSMISSIONMOUNTTRANSMISSIONBRACKET

(cont'd)

13-7

Page 589 of 2189

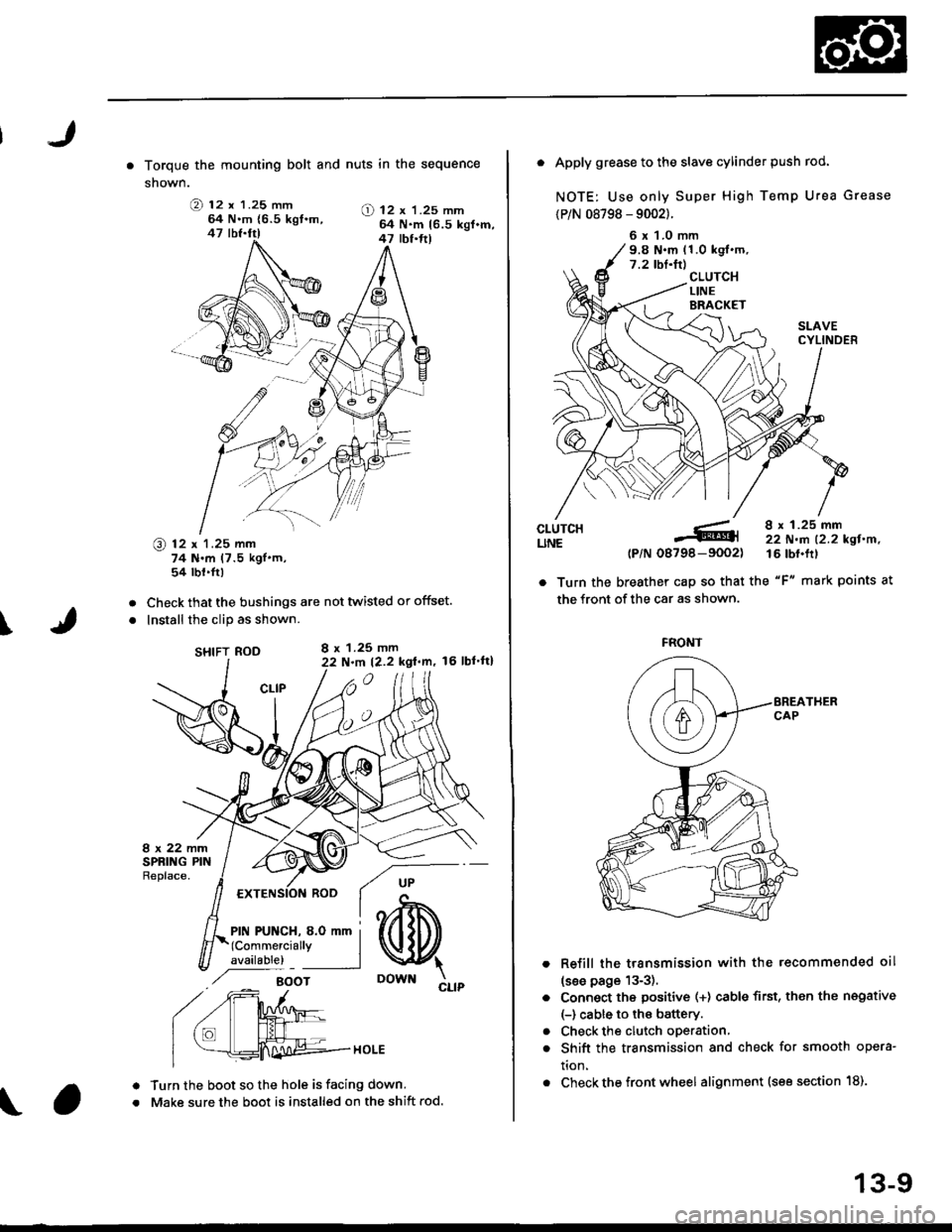

. Torque the mounting bolt and nuts in the sequence

shown.

O 12 x 1.25 mm64 N.m {6.5 kgt.m,47 lbf.fr)

@ 12 x 1.25 mm74 N.m (7.5 kgl'm,54 tbt.fr)

Check that the bushings are not twisted or offset.

Install the clip as shown.

SHIFT ROD

Turn the boot so the hole is facing down.

Make sure the boot is installed on the shift rod.

O) 12 x 'l.25 mm64 N.m 16.5 kgl.m,47 tbt.ft)

I

a

a

a

a

8 x 1.25 mmN.m t2.2 kgt.m, l6 lbl'tt)

6 x 1.0 mm9.8 N.m (1.0 kgl.m.7.2 tbf.tr)

. Apply grease to the slave cylinder push rod.

NOTE: Use only Super High Temp Urea Grease

{P/N 08798 - 9002}.

CLUTCHUNE

a

a

(P/N-6tl

08798-9002)

8 x 1.25 mm22 N.m 12.2 kgl.n.16 tbf.frl

. Turn the breather cap so that the "F" mark points at

the front of the car as shown.

Refill the transmission with the recommended oil

(see page 13-3).

Connect the positive (+) cable first, then the negative

(-) cable to the battery.

Check the clutch oDeration,

Shift the transmission and check for smooth opera-

tion.

Check the front wheel alignment (see section 18).

FRONT

13-9

Page 628 of 2189

Transmission Assembly

l

,

{

Removal

@Make sure iacks and safoty stands are placad plop-

erly (3ee section l).

Apply parking braks and block rear wheels so car

will not roll off stands and fall on you while working

under il.

CAUTION: Us6 fonder cove6 to avoid damaging painted

sudaces.

Disconnect the negative (-) cable from the battery,

then the positive (+l cable.

Drain the transmission oil. then reinstall the drain

plug with a new washer (see page 13-47).

Remove the intake air duct and the air cleaner hous-

ing assembly (see s€ction 5).

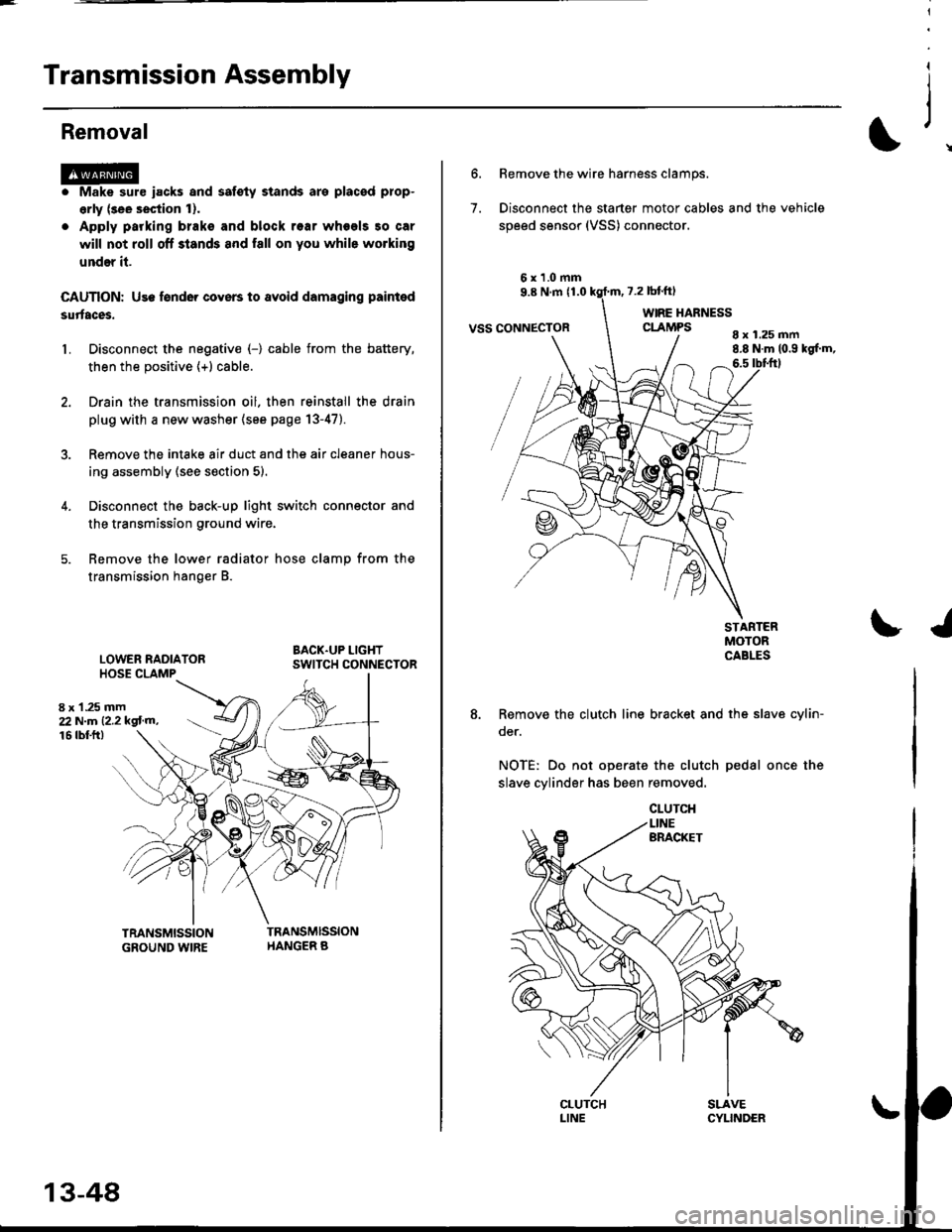

Disconnect the back-up light switch connector and

the transmission ground wire.

Remove the lower radiator hose clamp from the

transmission hanger B.

L

8 x 1 .25 mm22Nm12.2kgl'm�,

LOWER RADIATORHOSE CLAMP

16 rbtft)

13-48

7.

Bemove the wire harness clamps.

Disconnect the starter motor cables and the vehicle

speed sensor (VSS) connector.

8 x 1.25 mm8.8 N.m (0.9 kgf.m,6.5 tbtftl

STARTERMOTORCABLES

8. Remove the clutch line bracket and the slav6 cylin-

oer.

NOTE: Do not operate the clutch pedal once the

slave cylinder has been removed.

\J

Page 633 of 2189

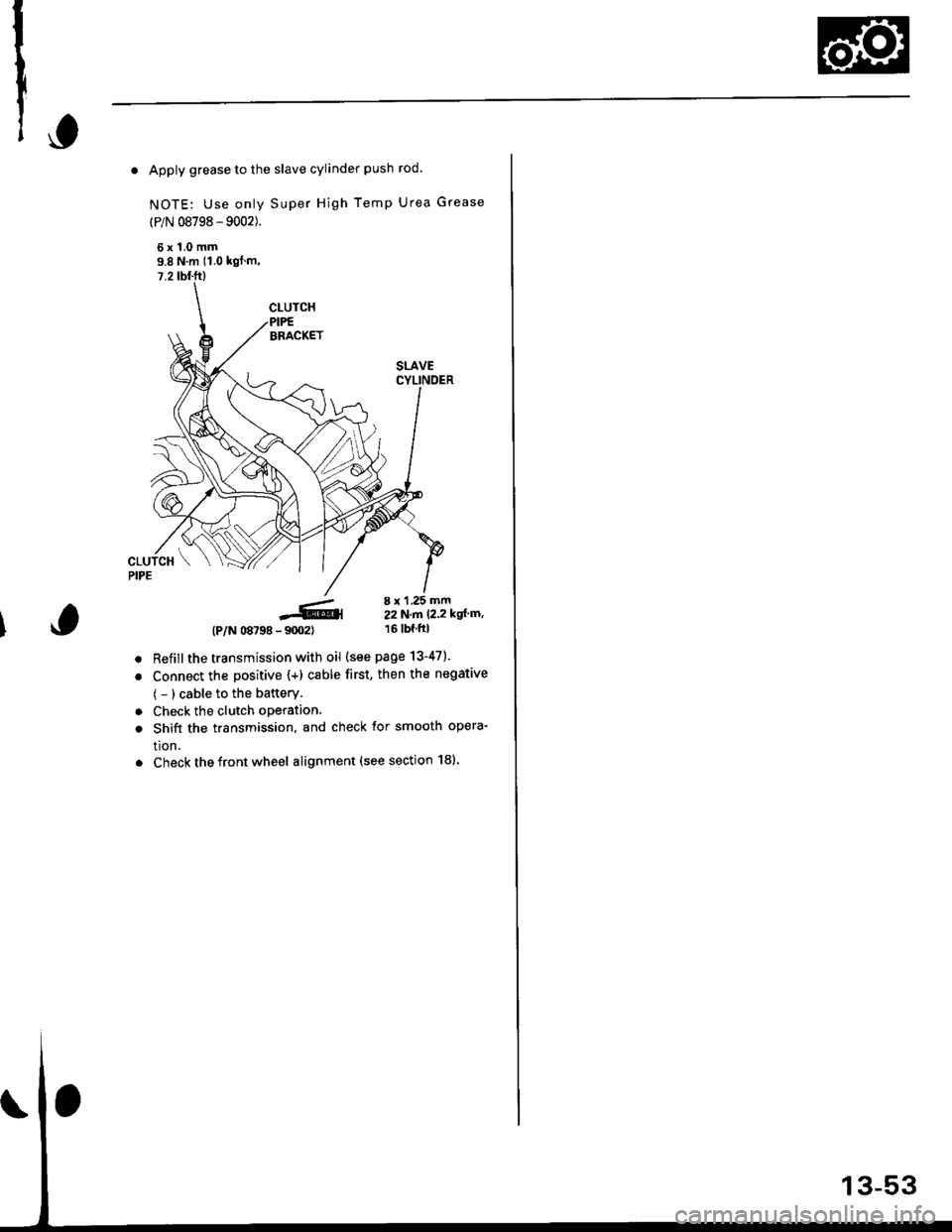

. Apply grease to the slave cylinder push rod.

NOTE: Use only Super High Temp Urea Grease

(P/N 08798 - 9002).

6x1.0mm9.8 N'm (1.0 kgl m,

7.2 tbl.ft)

-6,4- 9m2)

Refillthe transmission with oil (see page 13-47).

Connect the positive (+) cable first, then the negative

( - ) cable to the battery.

Check the clutch oPeration.

Shift the transmission, and check for smooth opera-

tion.

Check the front wheel alignment (see section 181.

(P/N 08798

8 x 1 .25 mm22N.n 12.2 kgl'm,16 tbf.ftl

a

a

a

a

Page 868 of 2189

Shift Cable

Adjustment

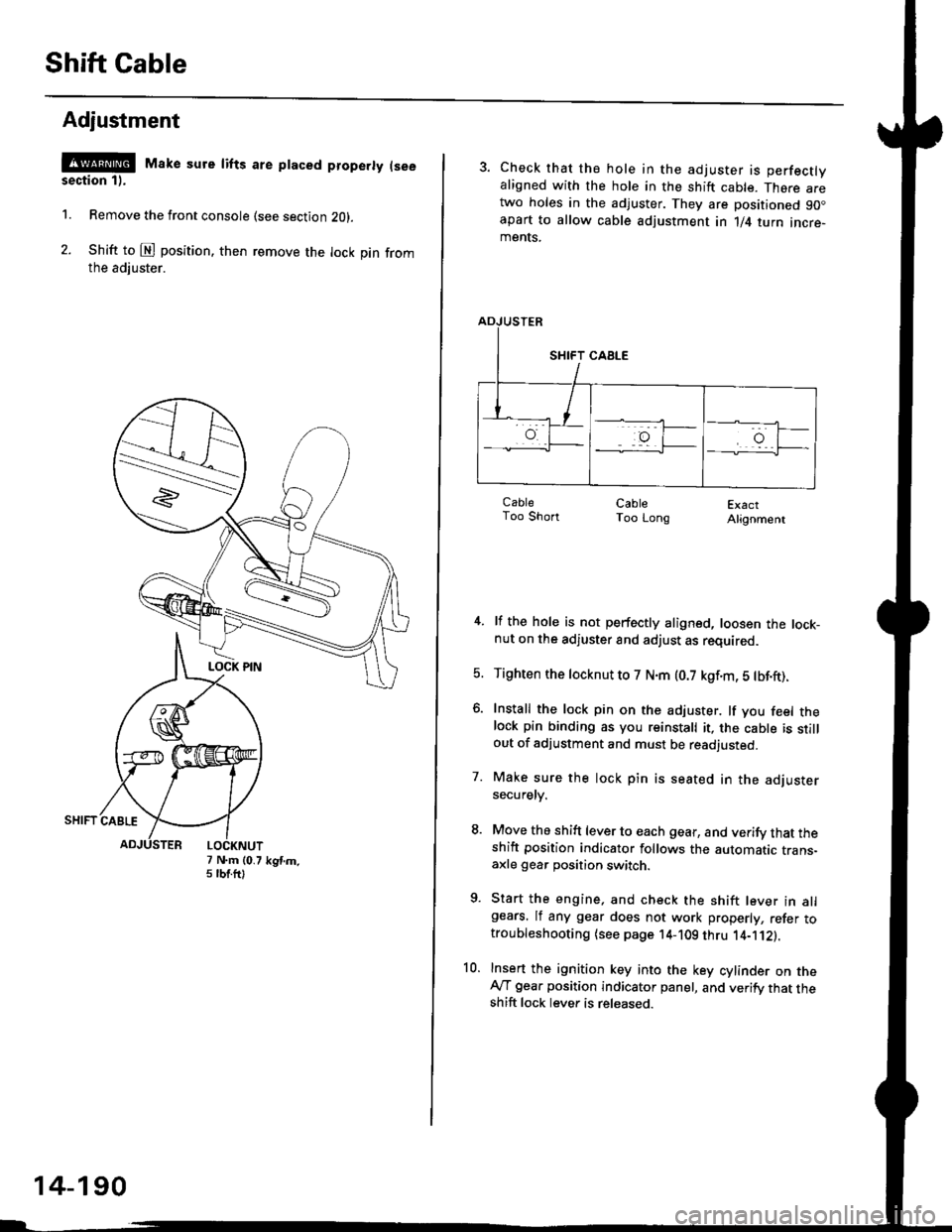

@ Make sure lifts are ptaced properly (see

section 1).

1. Remove the front console (see section Z0l.

2. Shift to @ position. then remove the lock pin fromthe adiuster.

7 N.m (0.75 tbtftlkgtm.

14-190

3. Check that the hole in the adjuster is perfectlyaligned with the hole in the shift cable. There aretwo holes in the adjuster. They are positioned 90.apart to allow cable adjustment in 1/4 turn incre-ments.

ExactAlignment

4. lf the hole is not perfectly aligned, loosen the lock-nut on the adjuster and adjust as required.

5. Tighten the tocknut to 7 N.m (0.7 kgf.m, 5 tbf.ft).

6. Install the lock pin on the adjuster. lf you feel thelock pin binding as you reinstall it, the cable is stillout of adjustment and must be readjusted.

7. Make sure the lock pin is seated in the adjustersecuretv.

8. Move the shift lever to each gear, and verify that theshift position indicator follows the automatic trans-axle gear position switch.

9. Start the engine, and check the shift lever in allgears. lf any gear does not work properly, refer totroubleshooting (see page 14-109 thru 1'4-'112).

10. Insert the ignition key into the key cylinder on theAy'T gear position indicator panel, and verify that theshift lock lever is released.

CableToo ShortCableToo Long

Page 1031 of 2189

t

Adjustment

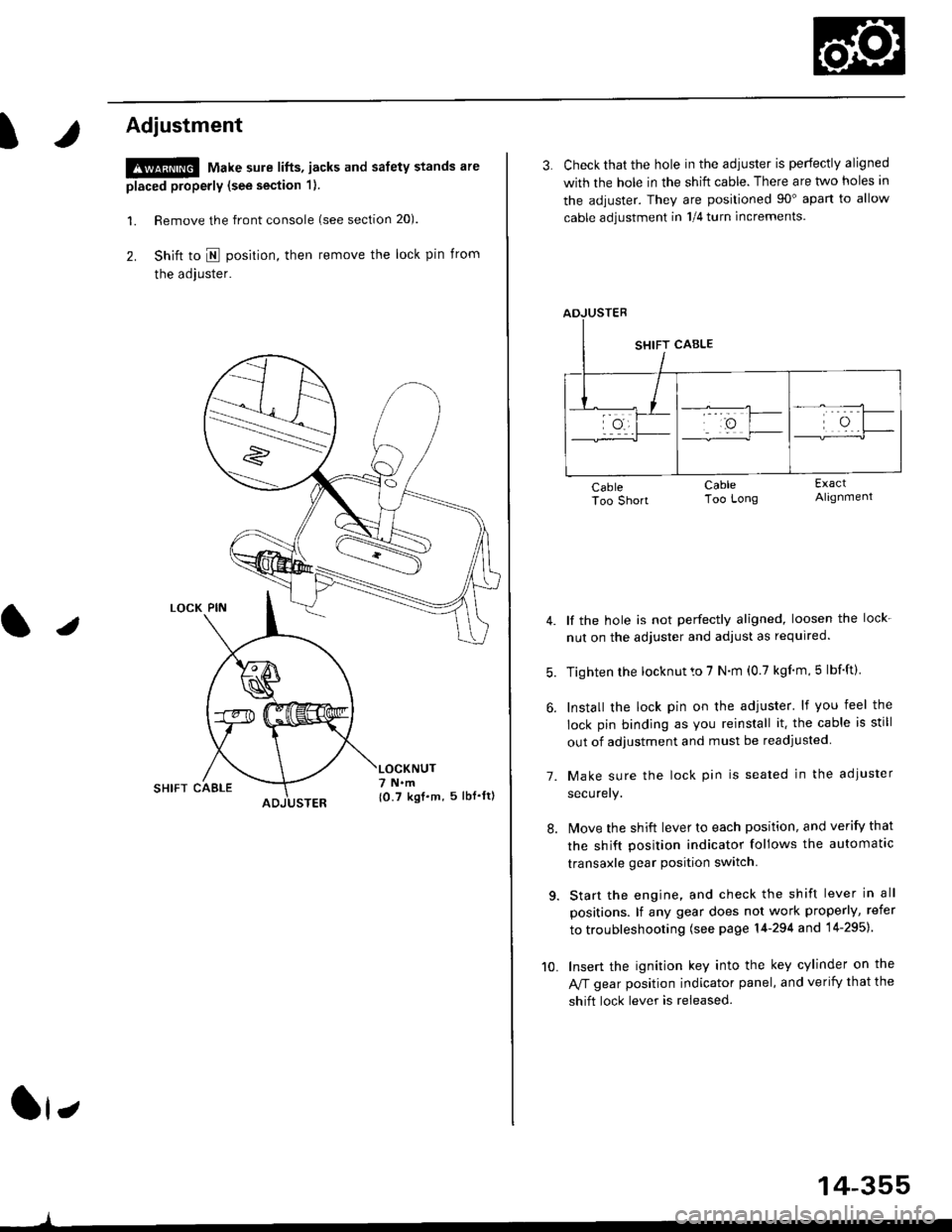

!@ Make sure lifts, jacks and safety stands are

placed properly (see section 1).

l. Remove the front console (see section 20).

2. Shift to I posirion, then remove the lock pin from

the adjuster.

SHIFT CAELE

l,

,l

{0.7 kgf.m, 5lbf'ltl

3. Check that the hole in the adiuster is perfectly aligned

with the hole in the shift cable. There are two holes in

the adjuster. They are positioned 90" apart to allow

cable adjustment in 1/4 turn increments.

lf the hole is not perfectly aligned, loosen the lock-

nut on the adjuster and adjust as required.

Tighten rhe locknut to 7 N.m (0.7 kgim,5 lbf'ft).

Install the lock pin on the adjuster' lf you feel the

lock pin binding as you reinstall it. the cable is still

out of adjustment and must be readjusted

Make sure the lock pin is seated in the adiuster

securery.

lMove the shift lever to each position, and verify that

the shift position indicator follows the automatlc

transaxle gear position switch.

Start the engine, and check the shift lever in all

positions. lf any gear does not work properly, refer

to troubleshooting (see page 14-294 and 14-295).

Insert the ignition key into the key cylinder on the

Aff gear position indicator panel, and verify that the

shift lock lever is released.

7.

10.

14-355

Page 1058 of 2189

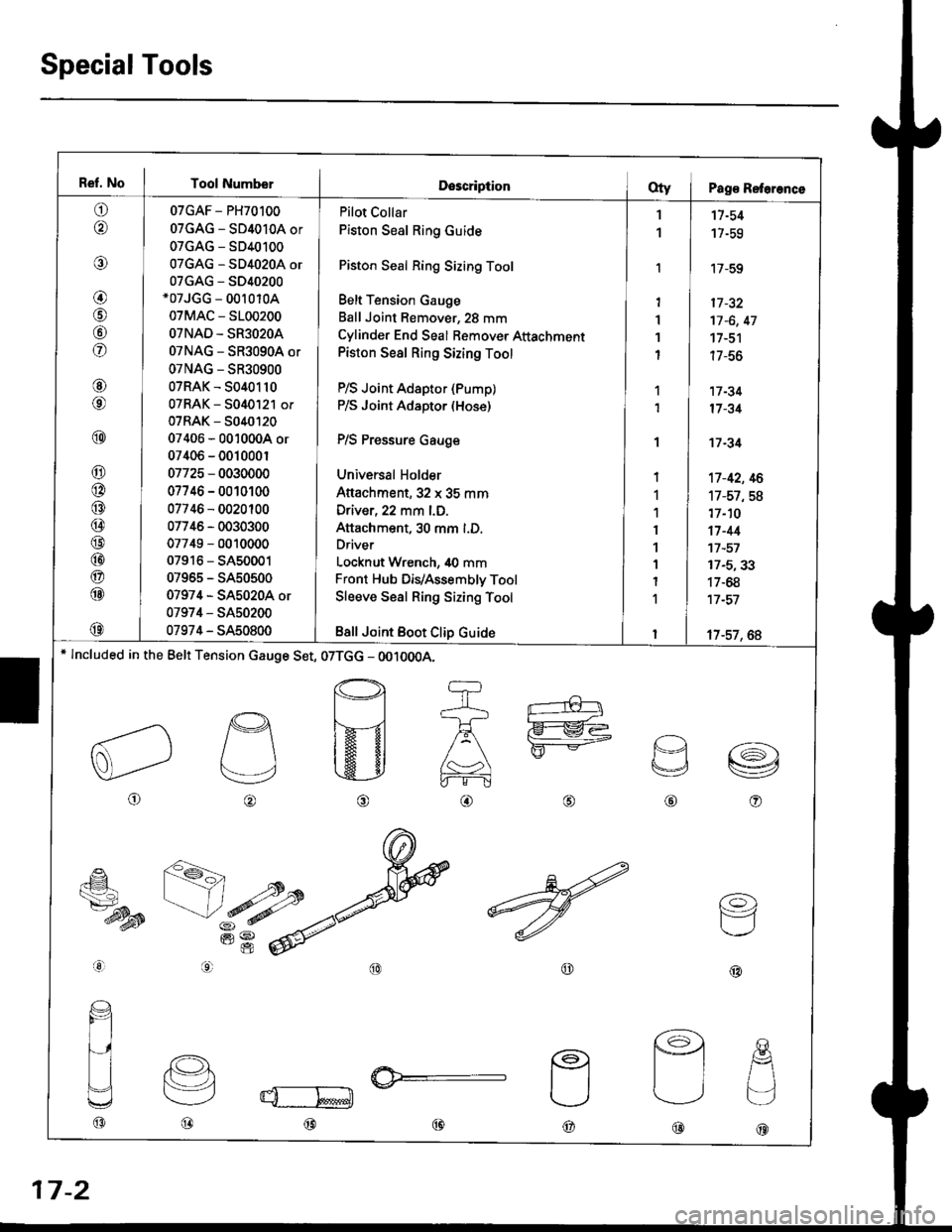

Ref. No I Tool NumberDescriptionOty I Pag€ Reterence

o

@

@

@

@

fof

@

@

@

@

@

@

@

@

@

@

@

@

@

07GAF - PH70100

07GAG - SD4010A or

07GAG - SD40100

07GAG - SD4020A or

07GAG - S040200*07JGG - 00r 010A

07MAC - 5100200

OTNAD - SR3O2OA

07NAG - SR3090A or

07NAG - SR30900

07RAK - 5040110

07RAK - 5040121 or

07RAK - 5040t20

07406 - 0010004 or

07406 - 001000r

07725 - 0030000

07746 - 0010100

07746 - 0020100

07746 - 0030300

07749 - 0010000

07916 - SA50001

07965 - SA50500

07974 - SA5020A or

07974 - SA50200

07974 - SA50800

Pilot Collar

Piston Seal Ring Guide

Piston Seal Ring Sizing Tool

Belt Tension Gauge

Ball Joint Remover, 28 mm

Cylinder End Seal Bemover Attachment

Piston Seal Ring Sizing Tool

P/S Joint Adaptor (Pump)

P/S Joint Adaptor (Hose)

P/S Pressure Gauge

Universal Holder

Attachment,32 x 35 mm

Driver, 22 mm l.D.

Attachment, 30 mm l.D.

Driver

Locknut Wrench, 40 mm

Front Hub DiVAssembly Tool

Sleeve Seal Ring Sizing Tool

Bsll Joint Boot Clip Guide

1

1

'I

1'I

1

I

1

1

I

1

1

I

1

1

I

1

I

11-54

17-59

'17-59

17 -32

17 -6, 47

17-51

| /-ao

17 -34

17 -31

't7 -34

't7-42, 16

17-57,58

17-10

17-44't7 -57

17-5,33

17-68

17 -57

17-57, 6A* lncluded in the Belt Tension cauge Set, 07TGG - OO10OOA.

o

p

v

@o

€_

ts7-dysB

aal

@@

(o)

F=1

@@@

@@@

17-2

Page 1063 of 2189

)

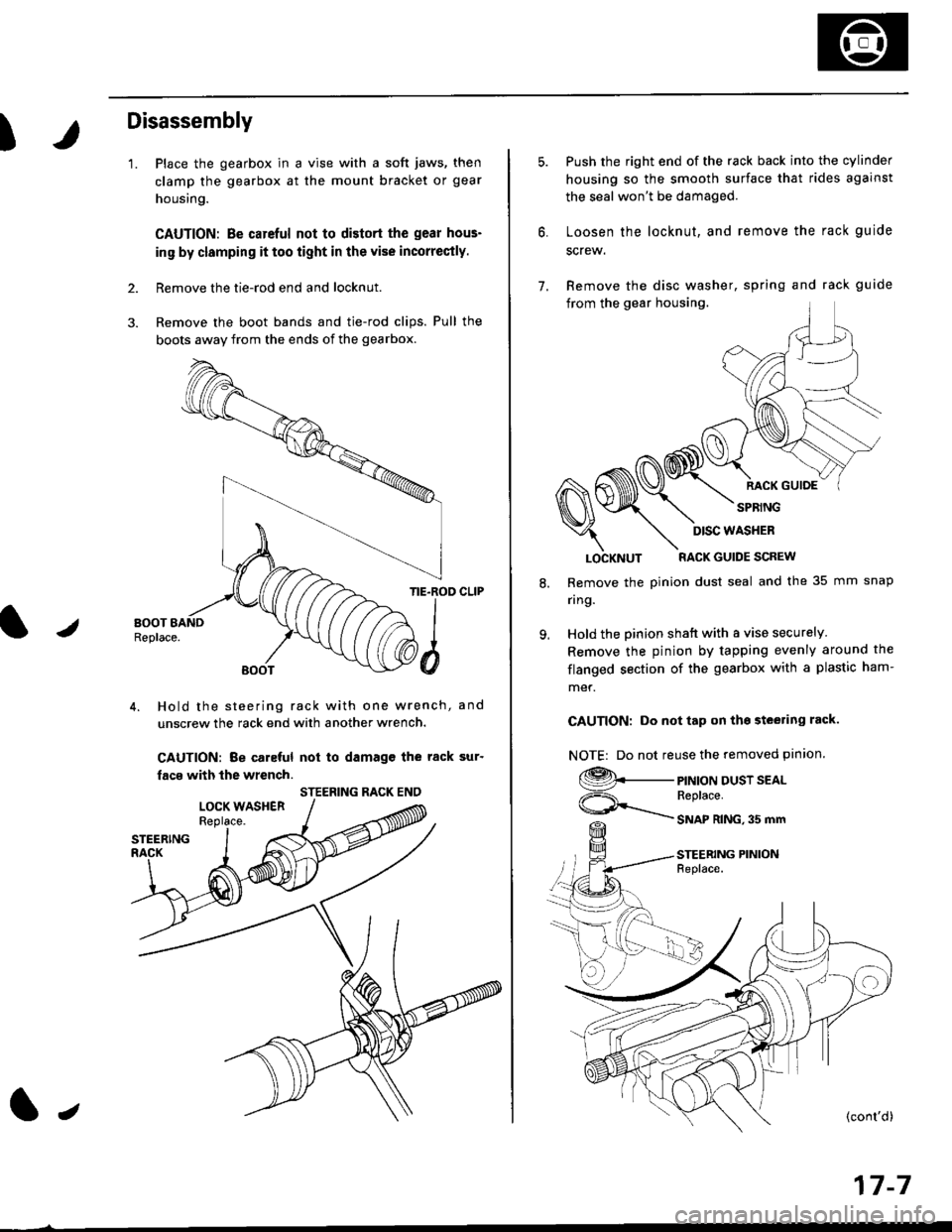

Disassembly

'1.

2.

Place the gearbox in a vise with a soft jaws, then

clamp the gearbox at the mount bracket or gear

housing.

CAUTION: Be carcful not to distort the gear hous-

in9 by clamping it too iight in the vise incorrectly.

Remove the tie-rod end and locknut.

Remove the boot bands and tie-rod clips. Pull the

bogts away from the ends of the gearbox.

/

TIE.ROD CLIP

4. Hold the steering rack with one wrench, and

unscrew the rack end with another wrench.

CAUTION: Be caleful not to damagc the rack sur'

facs with the wrench.

STEERING RACK ENO

l,

17-7

7.

Push the right end of the rack back into the cylinder

housing so the smooth surface that rides against

the seal won't be damaged.

Loosen the locknut, and remove the rack guide

screw.

Remove the disc washer, spring and rack guide

from the gear housing.

RACK GUIOE

SPRING

8.

9.

LOCKNUT RACK GUIDE SCREW

Remove the pinion dust seal and the 35 mm snap

nng.

Hold the pinion shatt with a vise securely

Remove the pinion by tapping evenly around the

flanged section of the gearbox with a plastic ham-

met.

CAUTION: Do not tap on tho steering rack.

NOTE| Do not reuse the removed pinion.

9._

ViF=\_

PINION DUST SEALReplace.

SNAP RING,35 mm

STEERING PINIONFeplace.

DISC WASHER