check engine HONDA CIVIC 1998 6.G Manual PDF

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CIVIC, Model: HONDA CIVIC 1998 6.GPages: 2189, PDF Size: 69.39 MB

Page 243 of 2189

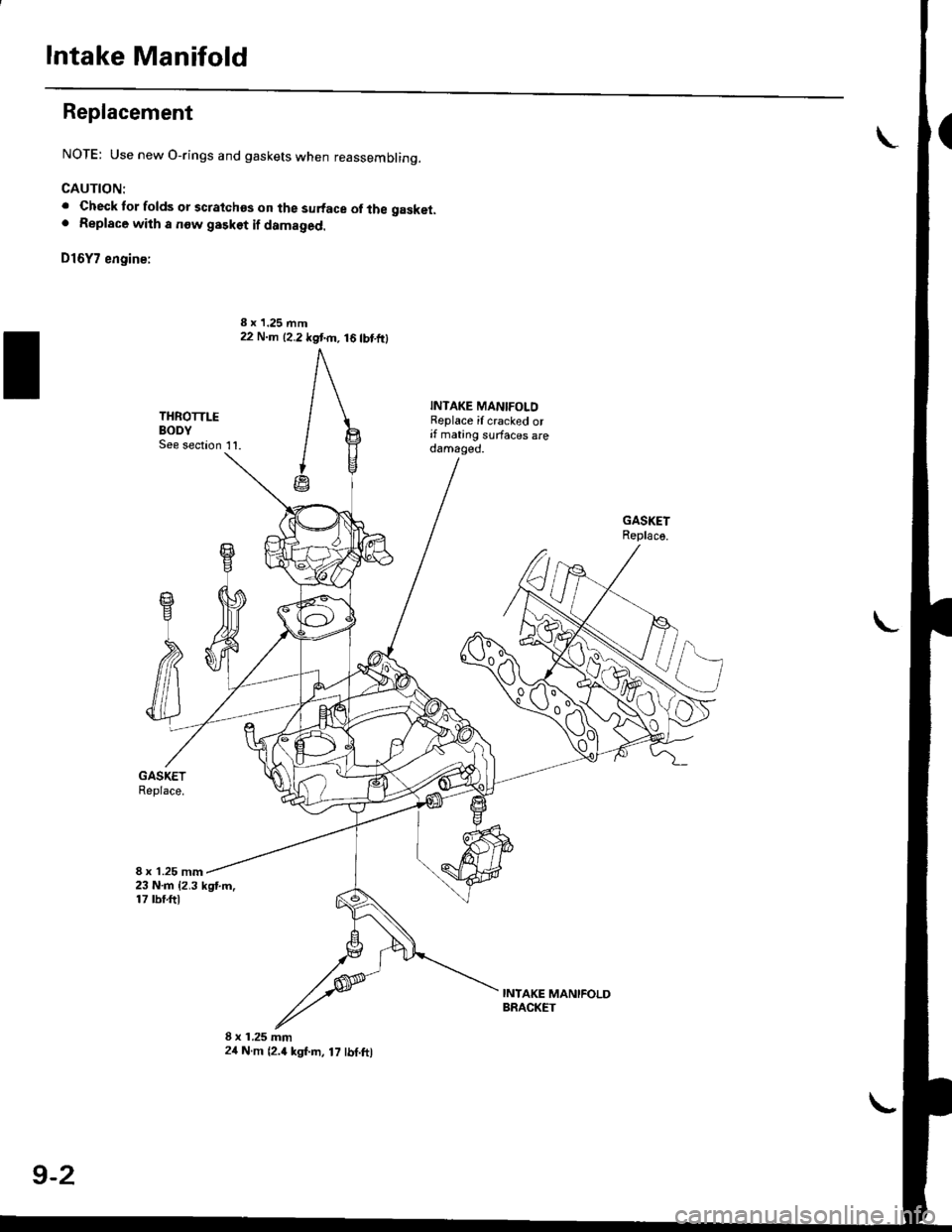

Intake Manifold

Replacement

NOTE: Use new O-rings and gaskets when reassemblinq.

CAUTION:

. Check tor folds or scratchos on the surface of tbe gasket.. Replace with a now gasket if damaged.

D16Y7 engine:

8 x 1.25 mm22 N.m 12.2 kgtm, 16 tbtftl

INTAKE MANIFOLDReplace if cracked orif mating surfaces aredamaged.

8 x 1.25 mm23 N.m {2,3 kgt m.17 rbf.ftl

INTAKE MANIFOLDBRACKET

8 x 1.25 mm24 N.m {2.4 kgf.m, 17 tbf.ftl

9-2

Page 245 of 2189

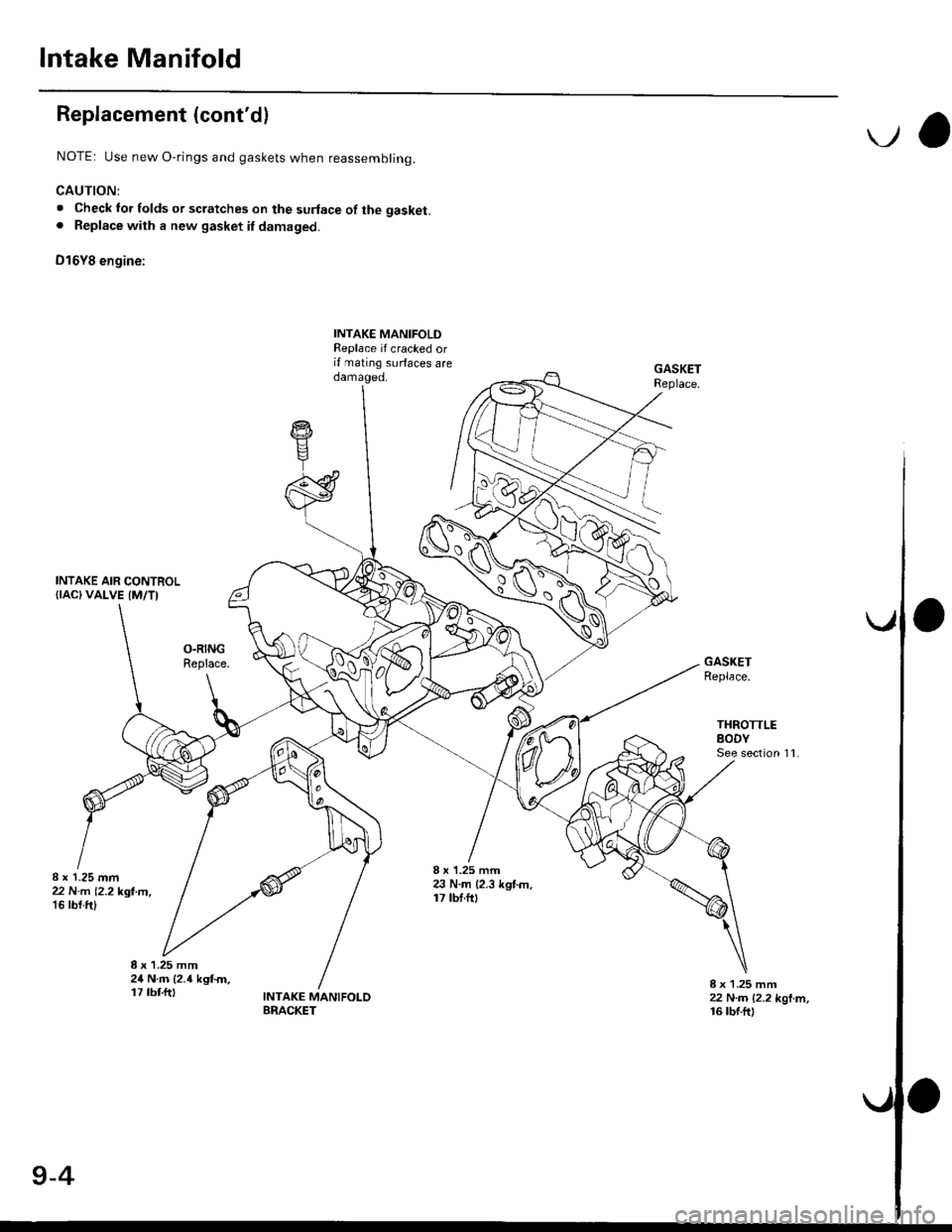

lntake Manifold

Replacement (cont'dl

NOTE: Use new O,rings and gaskets when reassembling.

CAUTION:

. Check lor folds or scratches on the surface of the gasket.. Replace with a new gasket il damaged.

D16Y8 engine:

INTAKE MANIFOLDReplace if cracked orif mating surfaces areoamageo,

INTAKE AIR CONTROL{ract vAt_vE {M/Tl

GASKETReplace.

8 x 1.25 mm24 N.m {2.{ kgtm.17 tbtftt

THROTTLEBODY

8 x 1.25 mm22 N.rn |.2.2 kgl.rn,16 tbtft)INTAKE MANIFOLDBRACKET

9-4

Page 247 of 2189

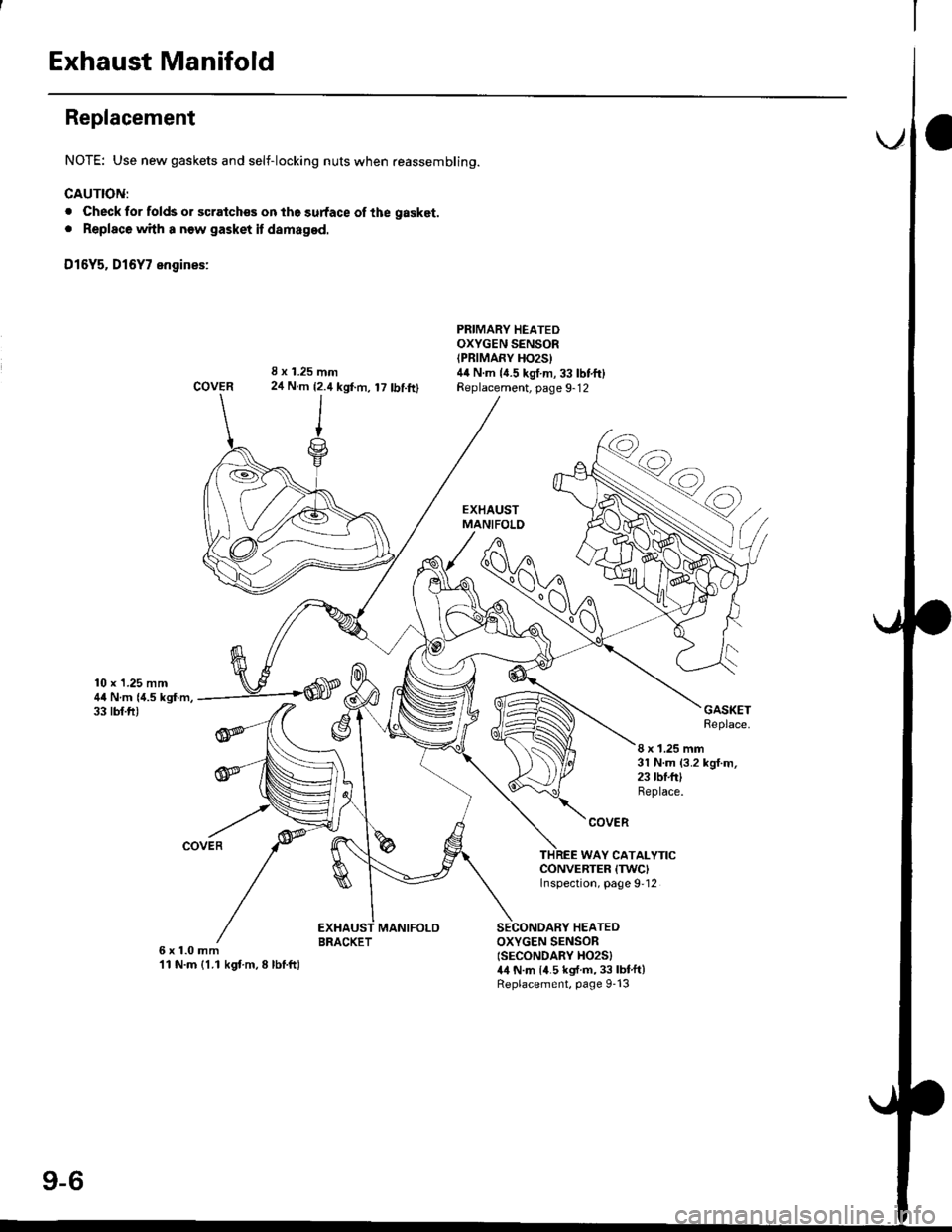

Exhaust Manifold

Replacement

NOTE: Use new gaskets and self-locking nuts when reassembling.

CAUTION:

. Check for folds or scratch€s on the surface of the gasket.

. Replace with a new gasket it damaged.

D16Y5. D16Y7 engines:

I x 1.25 mm24 N.m {2.4 kgt.m, 17 tbtft}

MANIFOLDBRACKET

PRIMARY HEATEDOXYGEN SENSORIPRIMAFY HO2SI44 N.m {4.5 kgf m, 33 lbtft)Replacement, page 9-12

GASKETReplace.

I x 1.25 mm31 N.m (3.2 kgf.m,23 tbf.ft)Beplace.

WAY CATALYTICCONVERTER {TWCIlnspection, page 9'12

6x1.0mm11 N.m {1.1 kgt m,8 lbf.ft)

SECONDARY HEATEDOXYGEN SENSOR(SECONDARY HO2S}44 N.m 14.5 kgf.m,33 lbf.ft)Replacement, page 9-13

9-6

Page 249 of 2189

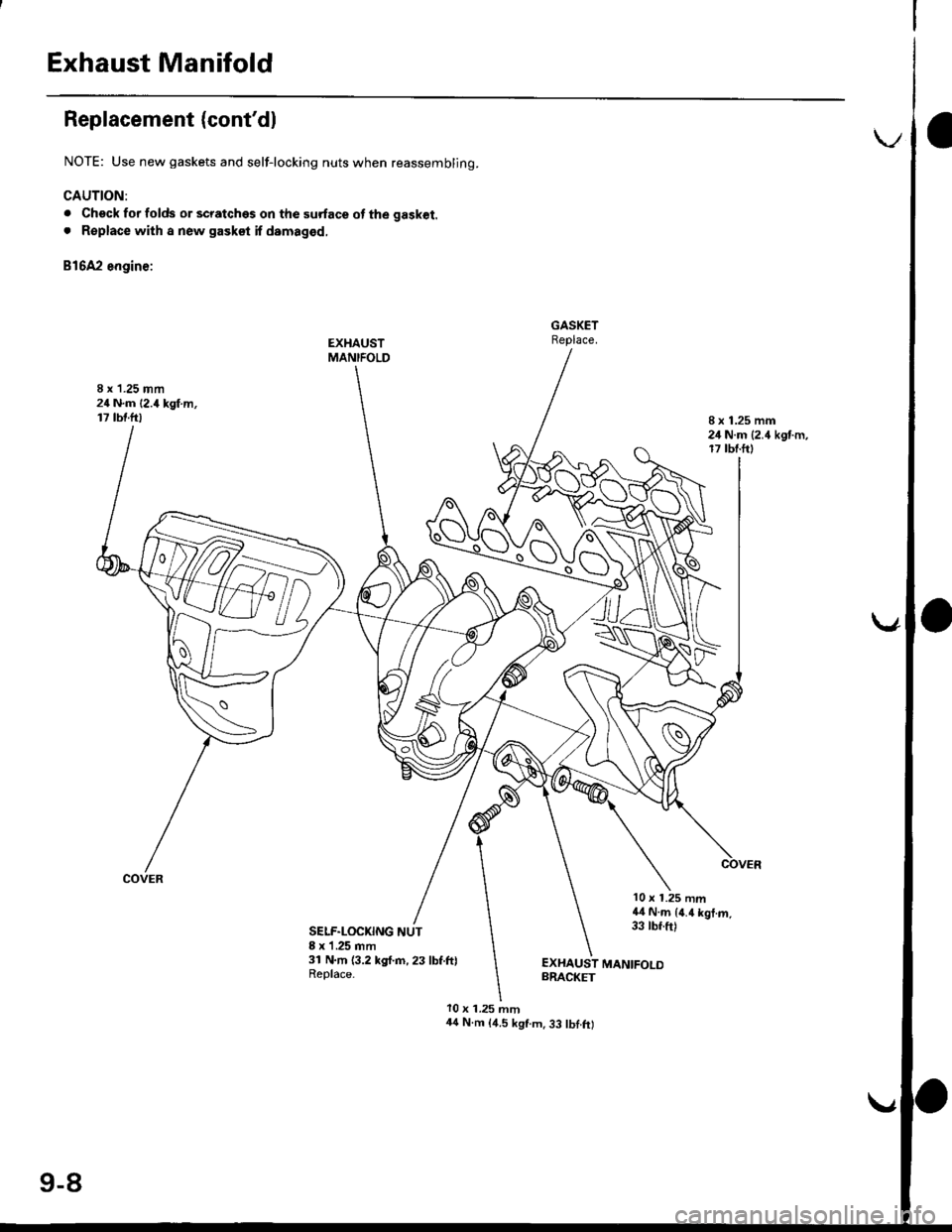

Exhaust Manifold

Replacement (cont'dl

NOTE: Use new gaskets and self-locking nuts when reassembljng.

CAUTION:

. Check for folds or scratches on the surface ot the gask€t.

. R€place with a new gaskot if damagod,

B16A2 engine:

GASKETReplace.

10 x 1.25 mm44 N.m {4.4 kgt.m,33 tbl.ft)SELF.LOCKING NUT8 x 1 .25 mm31 N.m (3.2 kg{.m, 23 lbf.ft)Replace-EXHAUST MANIFOLDBRACKET

10 x 1.25 mm4{ N.m (4.5 kgf.m. 33 tbt.fil

9-8

Page 253 of 2189

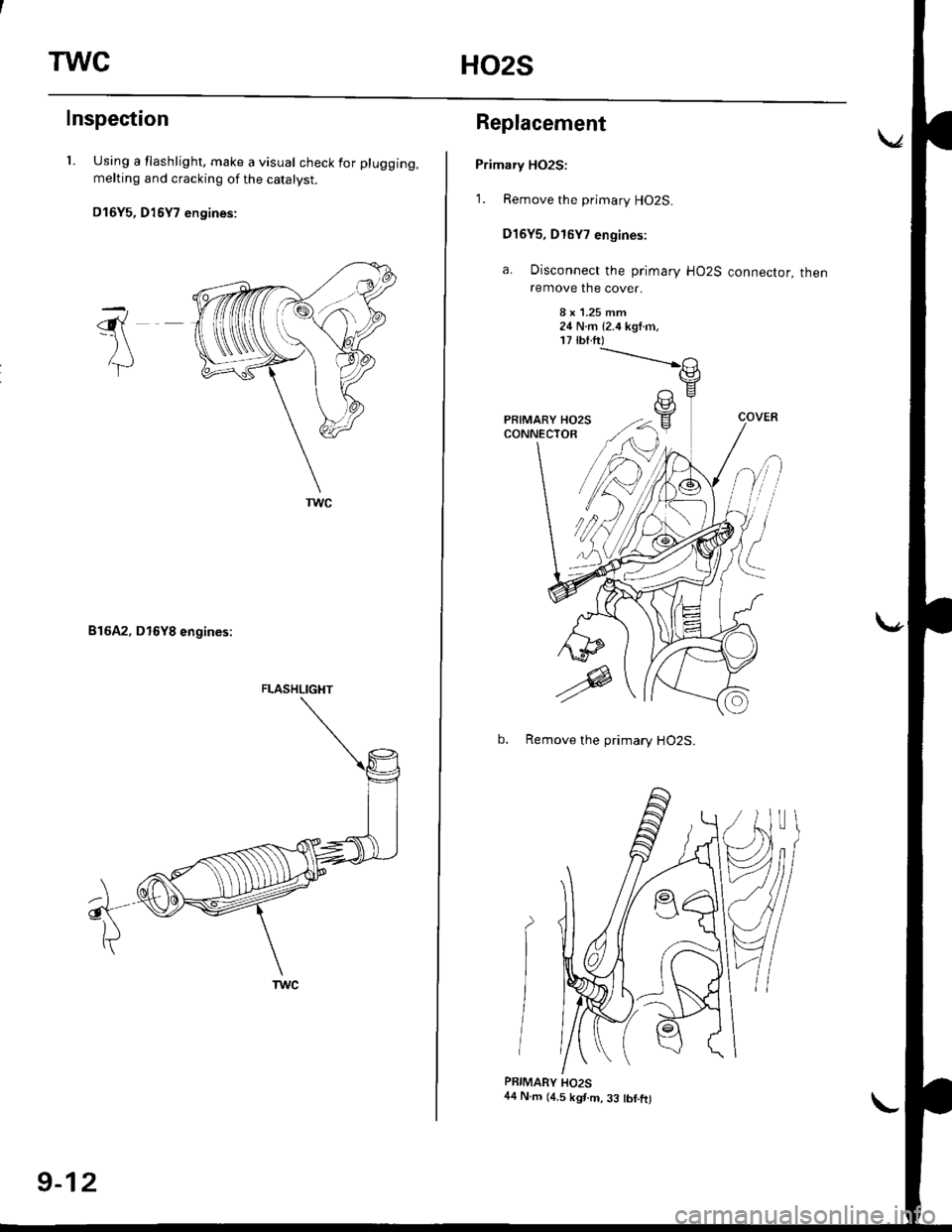

TWCHO2S

Inspection

l. Using a flashlight, make a visual check for plugging,

melting and cracking of the catalyst.

D16Y5, D16Y7 engines:

816A2, D16Y8 engines:

-\6{-)\

lT

a

A

FLASHLIGI{T

9-12

Replacement

Primary HO2S:

1. Remove the primary HO2S.

D16Y5, D15Y7 engines:

a. Disconnect the primary HO2S connector, thenremove the cover.

8 x'1.25 mm24 N.m {2.4 kgl.m,

PRIMARY H02SCONNECTOR

b. Remove the primary HO2S.

| \l ,l(

I bK/l

l llw.

/

(

PBIMARY HO2S44 N m (4.5 kgf.m, 33 tbI.ft)

Page 257 of 2189

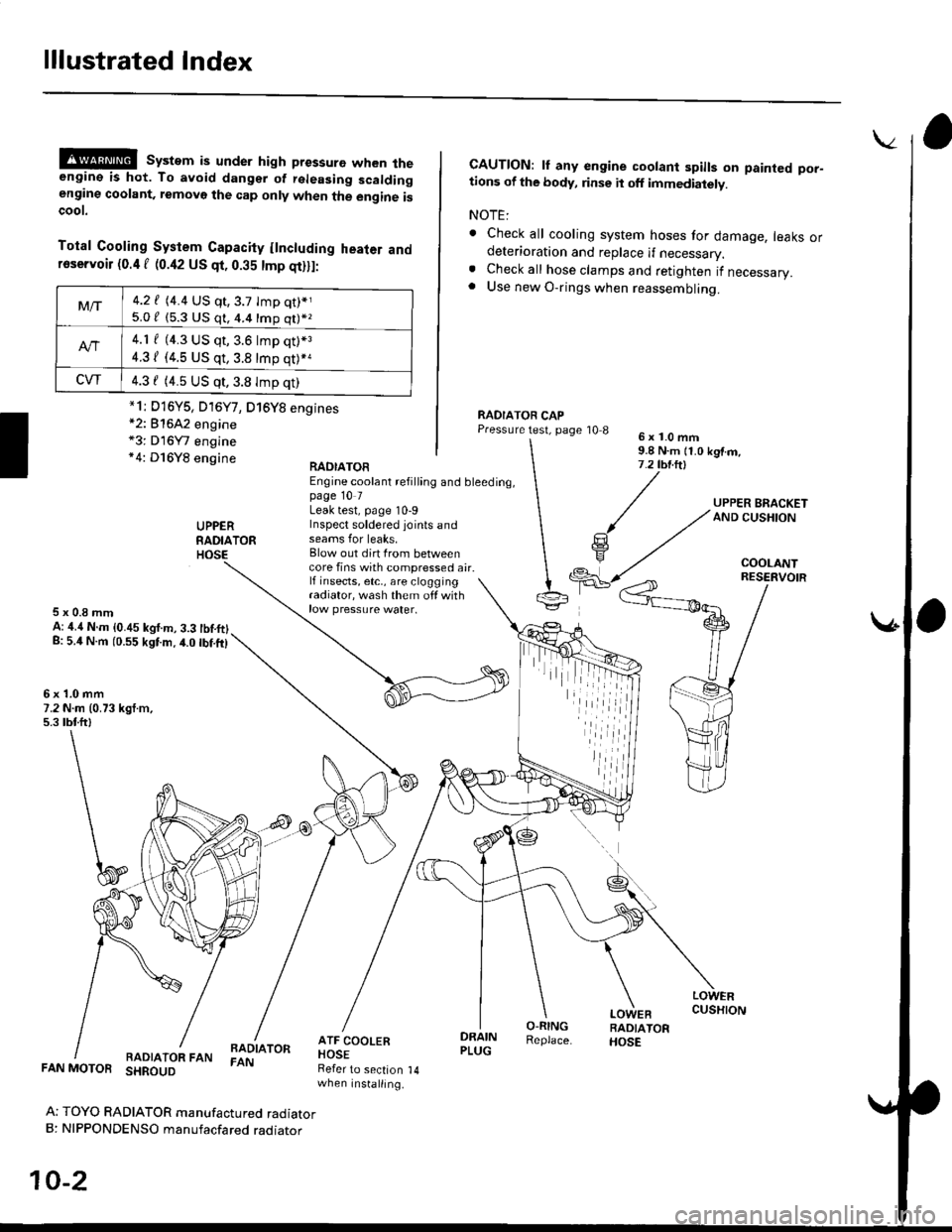

lllustrated Index

@@ system is under high pressure when theengine is hot. To avoid dangsr of rsleasing scaldingengine coolant, removo the cap only when the engine iscoot.

Total Cooling System Capacity flncluding heater andfoservoir (0.4 f (0.42 US qt, 0.35 tmp qt)ll:

*2: 81642 engine*3: D16Y7 engine*4: D16Y8 engine

CAUTION: lf any engine coolant spills on painted por-tions of the body, rinse it off immediately.

NOTE:

. Check all cooling system hoses for damage, leaks ordeterioration and replace if necessary.. Check all hose clamps and retighten if necessary.. Use new O-rings when reassembling.

RADIATOR CAPPressure test, page '10 86x1.0mm9.8 N.m {1.0 kgtm,7.2 tbt.ltl

UPPERRADIATORHOSE

UPPER BRACKETAND CUSHION

COOLANT

RAOIATOREngine coolant refilling and bleeding,page 10 7Leak test, page 10-9Inspect soldered joints andseams for leaks,Blow out dirt Irom betweencore fins with compressed air.lf insects, etc,, are cloggingradiator, wash them off withrow pressure water.

RESERVOIR

5x0.8mmA: ,1.4 N.m {0.45 kgf.m, 3.3 tbtftlg: 5.4 N.m (0.55 kgtm.4.0 tbf.ft)

6x1.0mm7.2 N.m (0.73 kgt.m,5.3 tbtftl

LOWERCUSHION

RADIATOR FANBADIATORFAN

DRAINPLUG

O-RINGReplace.

LOWEBRADIATORHOSE

FAN MOTOR SHROUD

Ar TOYO RADIATOR manufactured radiatorB: NIPPONDENSO manufacfared raoraror

10-2

Refer to section 14when installing.

Mt-|-4.2 f (4.4 US qt,3.7 tmp qt)*j

5.0 / (5.3 U$ q1, 4.4 16p q11*z

4.1 f (4.3 US qt, 3.6 lmp q0*3

4.31 (4.5 US qt, 3.8 tmp qt)*a

CVT4.3 f (4.5 US qt,3.8 Imp qt)

*1i D16Y5, D16Y7, D16Y8 engines

iil

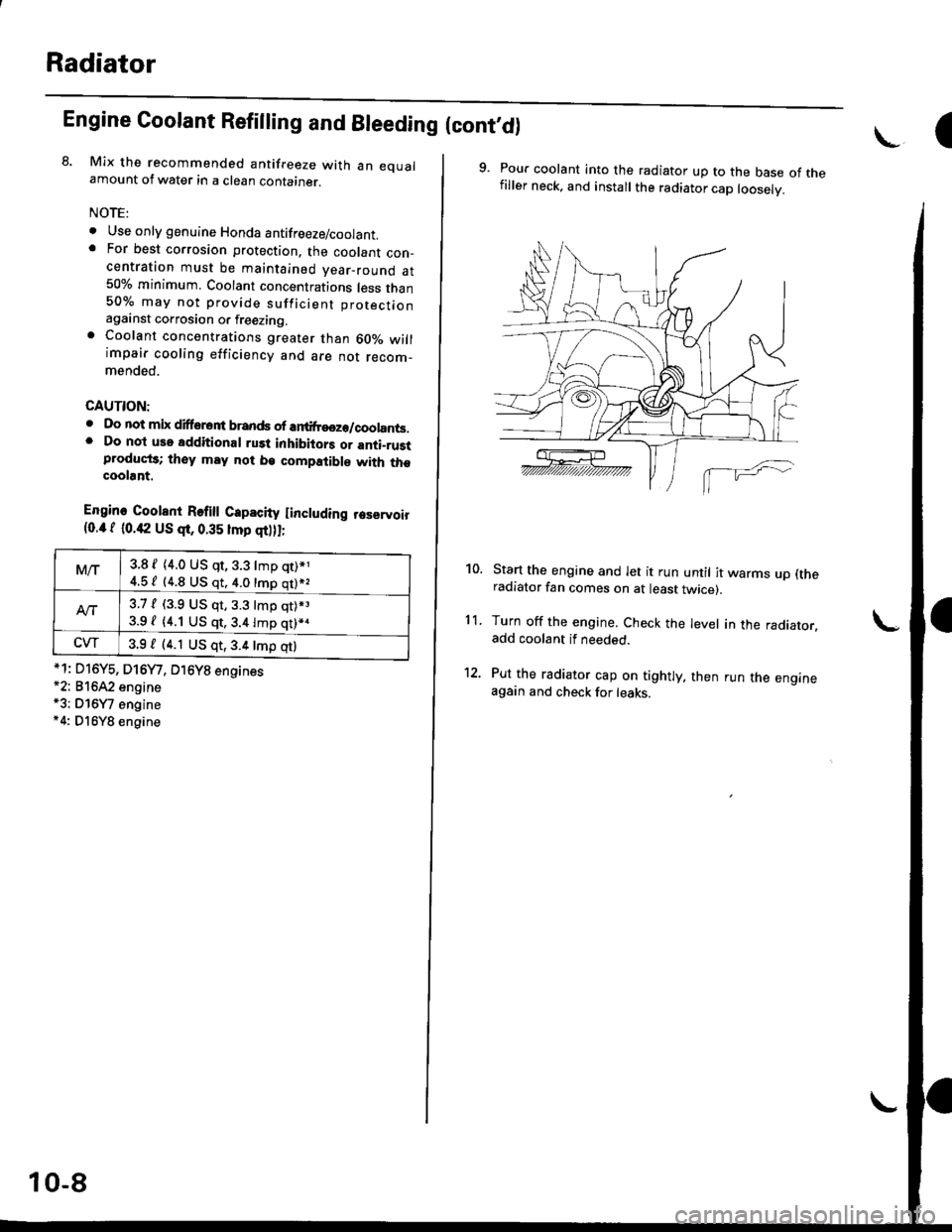

Page 263 of 2189

Radiator

Engine Coolant Refilting and Bleeding (cont,dl

8. Mix the recommended antifreeze with an eoualamount of water in a clean container.

NOTE:

o Use only genuine Honda antifreeze/coolant.. For best corrosion protection. the coolant con_centration must be maintained year_round at50% minimum. Coolant concentrations less than50% may not provide sufficient protectionagainst corrosion or freezing.. Coolant concentrations greater than 60010 willimpair cooling efficiency and are not recom_mended.

CAUTION:

. Do not mix difforont brands ofar ilreeze/coolants.. Do not use additional rust inhibiiors or anti_rustproduqt3; they may not be compatible with thecoolant.

Engine Coolent Refi

Capacity Iincluding reservoir{0.4 f 10.42 US qr, 0.35 lmp qt),I;

*1: D16Y5, D16Y/, O16Y8 engines*2: 81642 engine*3; Dl6Y7 engine*4: Dl6Y8 engine

M/r3.8 f {4.0 US qt, 3.3 lmp qt)*1

4.5 / (4.8 US qt. 4.0 tmp qt)*,

Att3.7, (3.9 US qr,3.3 tmp qt).3

3.9 / (4.1 US qt,3.4lmp qt)*.

CW3.9 / (4.1 US qt,3.4 tmp qtl

10-8

\.-I

9. Pour coolant into the radiator up to the base of thefiller neck. and install the radiator cap looselv.

Start the engine and let it run until it warms up (theradiator fan comes on at least twicer.

Turn off the engine. Check the level in the radiator.add coolant if needed.

Put the radiator cap on tightly, then run the engineagain and check for leaks.

10.

11.

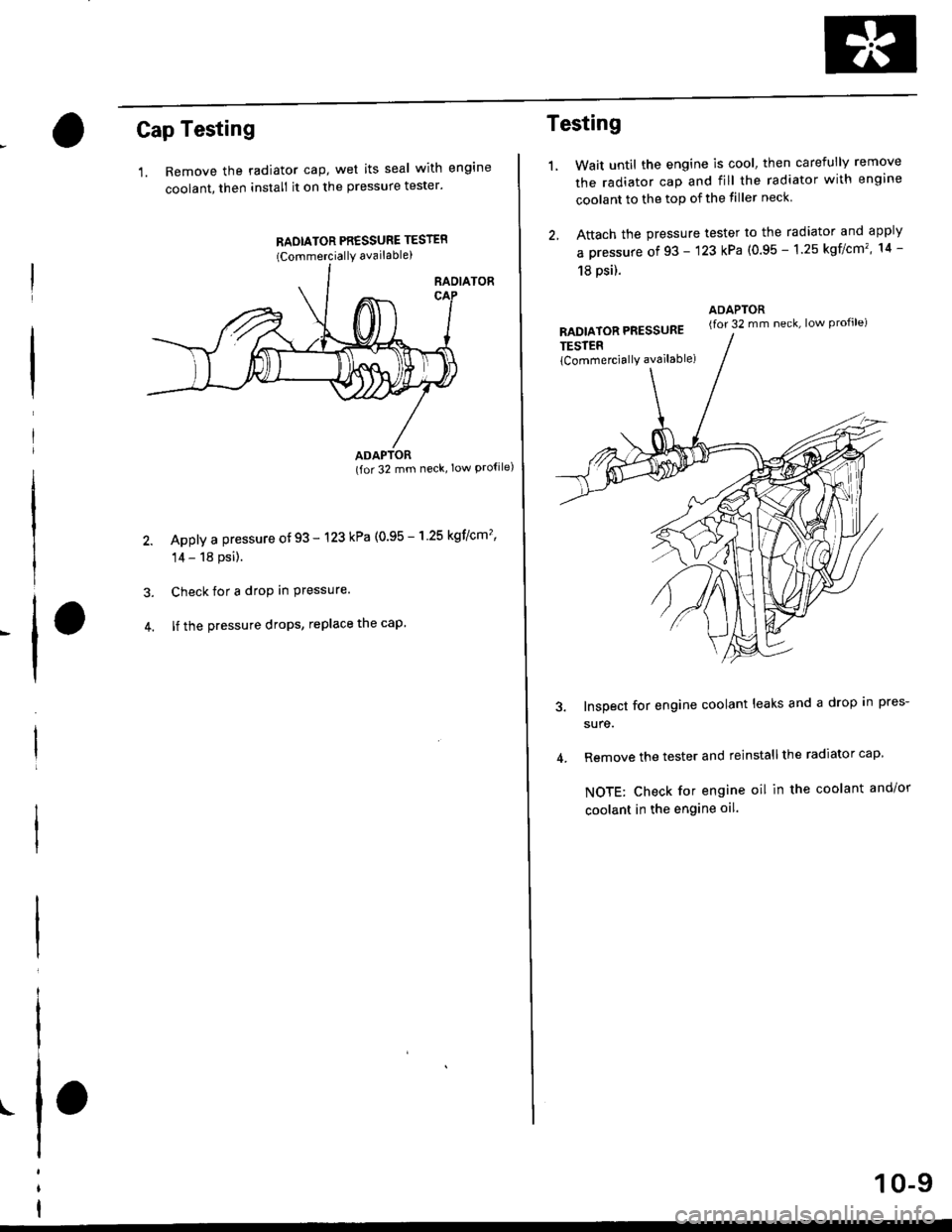

Page 264 of 2189

Cap Testing

1. Remove the radiator cap, wet its seal with engine

coolant, then install it on the pressure tester'

RADIATOR PR€SSURE TESTER(CommerciallY available)

RAOIATOR

(for 32 mm neck' low Pro{ile)

Apply a pressure of 93 - 123 kPa (0.95 - 'l 25 kgflcm'�'

14 - 18 psi).

Check for a drop in Pressure.

lf the pressure drops, replace the cap

I

t

ADAPTOR

Testing

LWait until the engine is cool, then carefully remove

the radiator cap and fill the radiator with engine

coolant to the top of the tiller neck

Attach the pressure tester to the radiator and apply

a pressure of 93 - '123 kPa (0.95 - 1.25 kgflcm'�, 14 -

18 psil.

RADIATOR PRESSURE

TESTER

lCommerciallY available)

ADAPTOR(for 32 mm neck, low Profile)

Inspect for engine coolant leaks and a drop In pres-

sure.

Remove the tester and reinstall the radiator cap

NOTE: Check for engine oil in the coolant and/or

coolant in the engine oil.

10-9

Page 266 of 2189

EGT Switch

-f

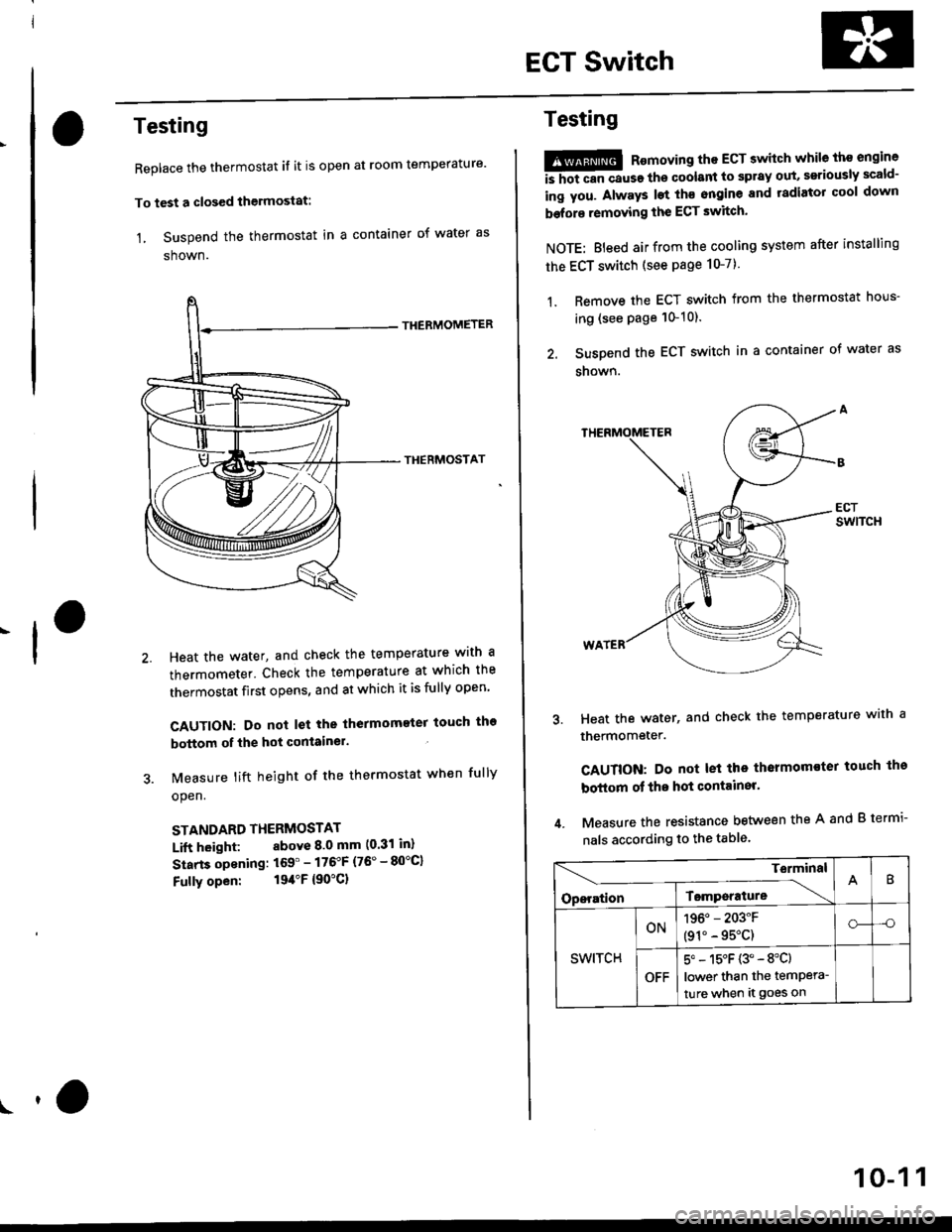

Testing

Replace the thermostat if it is open at room temperature'

To test a closed thermostat:

1, Suspend the thermostat in a container of water as

shown.

THEBMOMETER

THERMOSTAT

Heat the water, and check the temperature with a

thermometer. Check the temperature at which the

thermostat first opens, and at which it is fully open

CAUTION: Do not let the thermometer touch the

bottom of the hot Gonlainel.

Measure lift height of the thermostat when fully

open.

STANDARD THERMOSTAT

Lift height above 8.0 mm (0.31 inl

Starts opsning: 169' - 176'F (76' - 80'Cl

Fully open: 194'F {90"C1

!'o

10-1 1

Testing

!!@ Romoving the EcT swhch while lhs engine

i!-ot can cause the coolant to sPray out, seriously scald-

ing you. Always lst th€ ongine and rediator cool down

before removing ihe ECT switch.

NOTE: Bleed air from the cooling system after installing

the ECT switch (see Page 10-7)

1. Remove the ECT switch from the thermostat hous-

ing (see Page'10-10).

2. Suspend the ECT switch in a container of water as

shown.

Heat the water, and check the temperature with a

thermometer.

CAUTION: Do not let the thermomoter touch tho

bottom of the hot container'

Measure the resistance between the A and B termi-

nals according to the table.4.

Terminal

Oo"rffi

swlTcH

ON196' - 203"F

(91" - 95'C)o--o

OFF

5" - 15'F {3" - 8'C)

lower than the temPera-

ture when t goes on

Page 269 of 2189

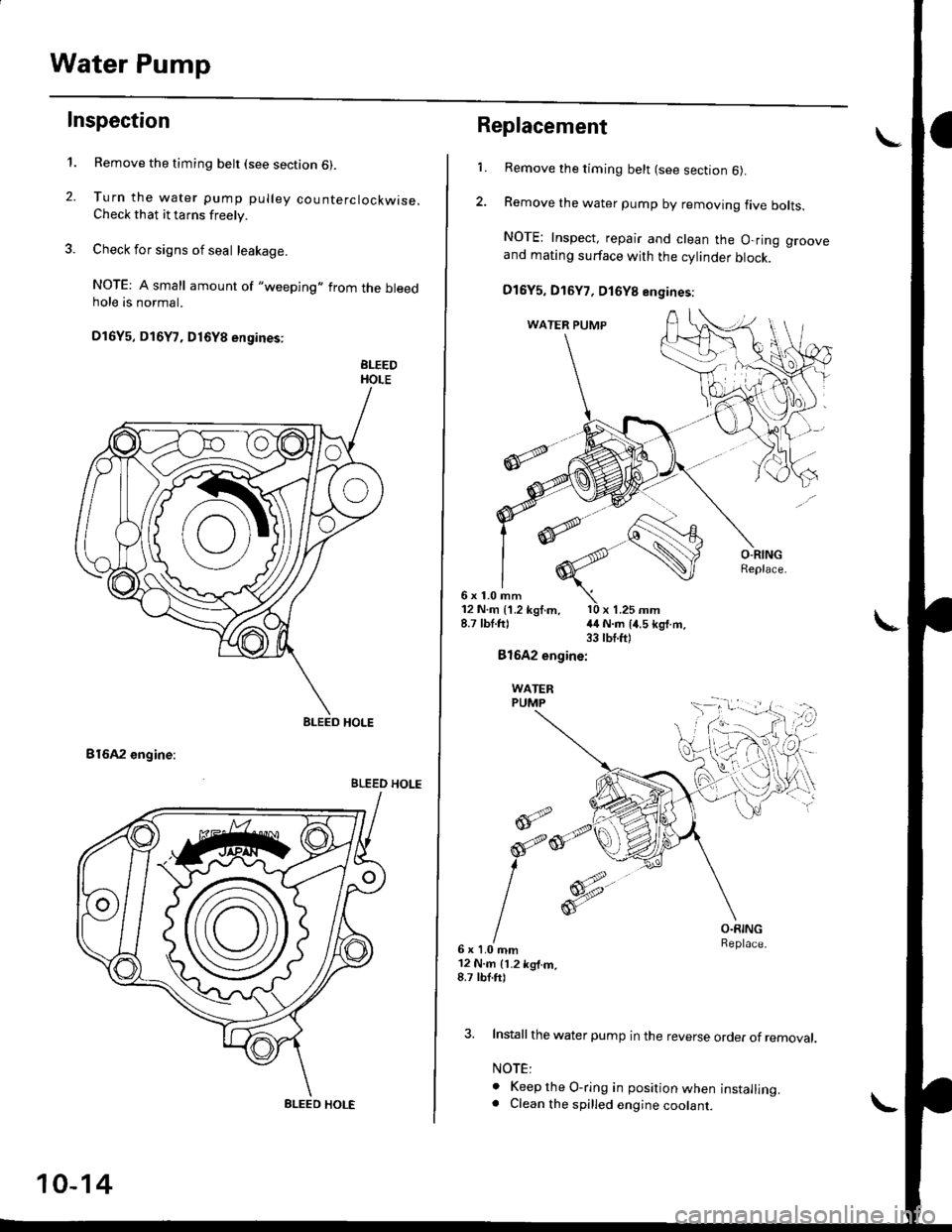

Water Pump

Inspection

't.

2.

Remove the timing belt (see section 6).

Turn the water pump pulley counterclockwise.Check that it tarns freely.

Check for signs of seal leakage.

NOTE: A small amount of "weeping,,from the bleedhole is normal.

Dl6Y5, Dl6Y7, D16Y8 engines:

BLEEDHOLE

B16A2 engine:

BLEED HOLE

BLEED HOLE

BLEED HOLE

10-14

Replacement

6x1.0mm

1.Remove the timing belt (see section 6).

Remove the water pump by removing five bolts.

NOTE: Inspect, repair and clean the O-ring grooveand mating surface with the cylinder block.

D16Y5, D16Y7, D16Y8 engines:

12 N.m {1.2 kgf.m, l0 x 1.25 mm8.7 lbt.ft) {4 N.m 14.5 kg{.m.33 tbt.ft)

Bl642 engine:

WATERPUMP

@;2

6x1.0mm12 N.m 11.2 kg{.m,8.7 tbf.ft)

O.RINGReplace.

3. Install the water pump in the reverse order of removal.

NOTE:

o Keep the O-ring in position when installing.. Clean the spilled engine coolant.

d

orp,

I