Seat HONDA CIVIC 1999 6.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CIVIC, Model: HONDA CIVIC 1999 6.GPages: 2189, PDF Size: 69.39 MB

Page 1514 of 2189

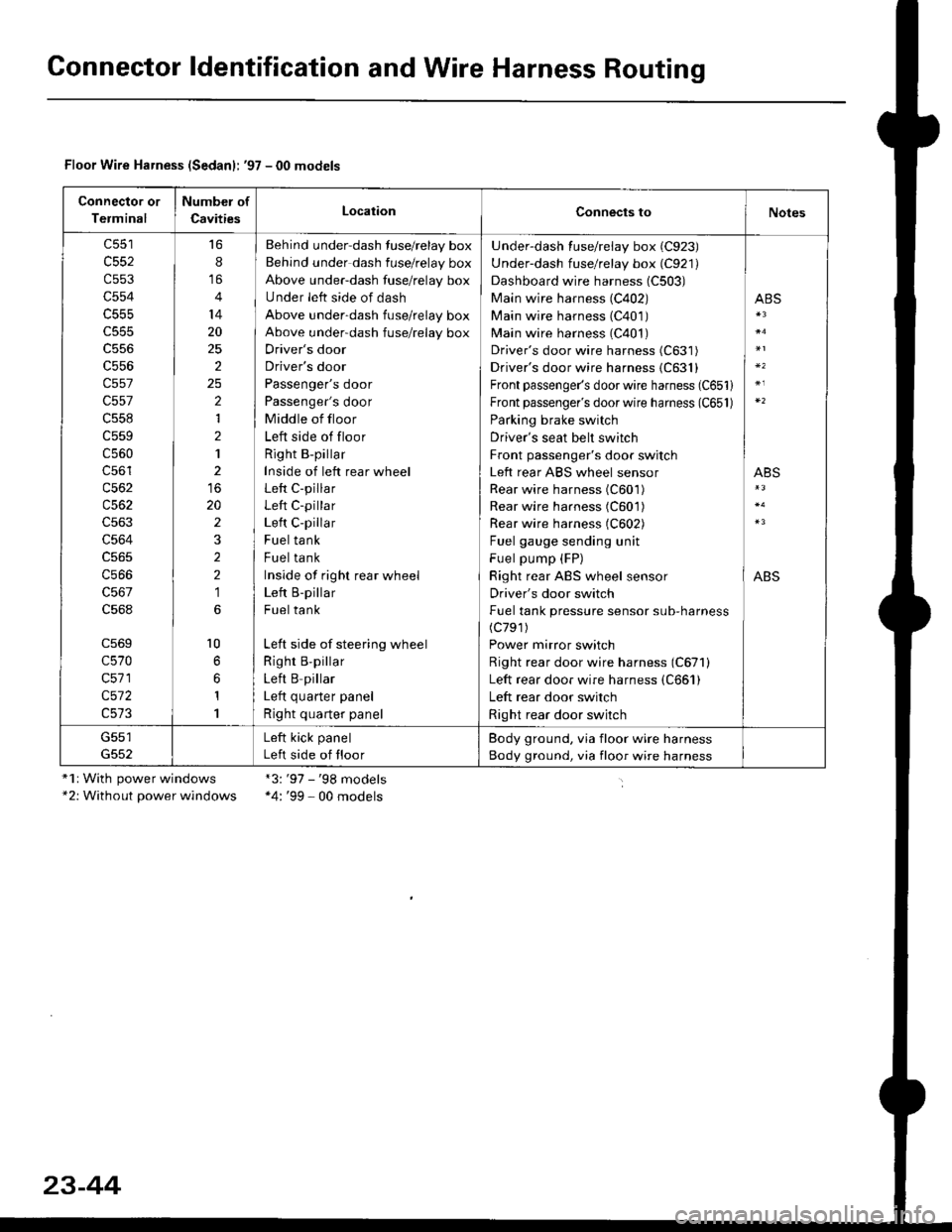

Gonnector ldentification and Wire Harness Routing

Floor Wire Harness (Sedanl: '97 - 00 models

Connector or

Terminal

Number of

CavitiesLocationConnects toNotes

c552

c553

c554

c555

c556

c557

c557

c558

c559

c560

c56'l

c562

c563

c564

c566

c568

c569

c570

c571

c572

16

8

14

20

25

2

2

1

2

1

20

2

2

2

1

l0

1

1

Behind under-dash fuse/relay box

Behind under dash fuse/relay box

Above under-dash fuse/relay box

Under left side of dash

Above under-dash fuse/relay box

Above under-dash fuse/relay box

Driver's door

Driver's door

Passenger's door

Passenger's door

Middle of floor

Left side of floor

Right B-pillar

Inside of left rear wheel

Left C-pillar

Left C-pillar

Left C-pillar

Fuel tank

Fuel tank

Inside of righr rear wheel

Left B-pillar

Fuel tank

Left side of steering wheel

Righr B,pillar

Left B pillar

I ofr ^,,.riar ^.^al

Right quarter panel

Under-dash fuse/relay box (C923)

Under-dash fuse/relay box (C921)

Dashboard wire harness (C503)

Main wire harness (C402)

Main wire harness (C401)

Main wire harness (C401)

Driver's door wire harness (C631)

Driver's door wire harness {C631}

Front passenger's door wire harness (C651)

Front passenger's door wire harness (C651)

Parking brake switch

Driver's seat belt switch

Front passenger's door switch

Left rear ABS wheel sensor

Rear wire harness (C601)

Rear wire harness (C601)

Rear wire harness (C602)

Fuel gauge sending unit

Fuel pump (FP)

Right rear ABS wheel sensor

Driver's door switch

Fuel tank pressure sensor sub-harness(c791)

Power mirror switch

Right rear door wire harness (C671)

Left rear door wire harness (C661)

Left rear door switch

Right rear door switch

ABS

ABS

ABS

G551Left kick panel

Left side of floor

Body ground, via floor wire harness

Body ground, via floor wire harness

"1r With power windows*2: Without power windows

*3:'97 - '98 models*4: '99 - 00 models

23-44

Page 1569 of 2189

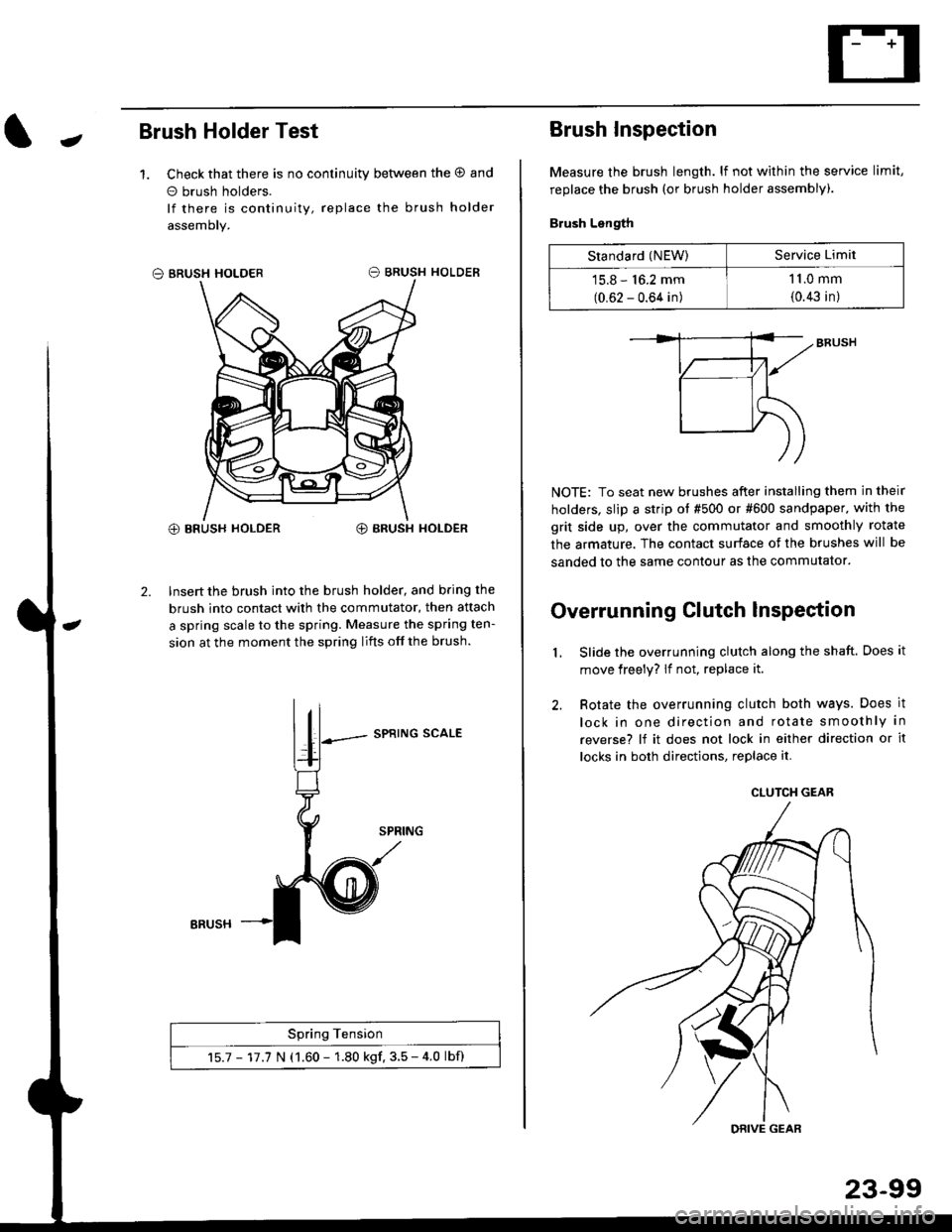

JBrush Holder Test

1. Check that there is no continuity between the O and

o brush holders.

lf there is continuity, replace the brush holder

assemoly.

O BRUSH HOLDER

@ BRUSH HOLDER€) BRUSH HOLDER

2. Insert the brush into the brush holder, and b.ing the

brush into contact with the commutator, then attach

a spring scale to the spring. Measure the spring ten-

sion at the moment the spring lifts off the brush.

SPRING SCALE

Spring Tension

15.7 - 17.7 N (1.60 - 1.80 kgf. 3.5 - 4.0 lbf)

ERUSH

Brush Inspection

Measure the brush length. lf not within the service limit,

replace the brush (or brush holder assembly).

Brush Length

NOTE: To seat new brushes after installing them in their

holders, slip a strip ot #500 or #600 sandpaper. with the

grit side up, over the commutator and smoothly rotate

the armature. The contact surface of the brushes will be

sanded to the same contour as the commutator.

Overrunning Clutch lnspection

Slide the overrunning clutch along the shaft. Does it

move freely? lf not, replace it.

Rotate the overrunning clutch both ways. Does it

lock in one direction and rotate smoothly in

reverse? lf it does not lock in either direction or it

locks in both directions, replace it.

2.

L

Standard (NEW)Service Limit

15.8 - 16.2 mm

(0.62 - 0.64 in)

1 1.0 mm

{0.43 in)

CLUTCH GEAR

DRIVE GEAR

Page 1570 of 2189

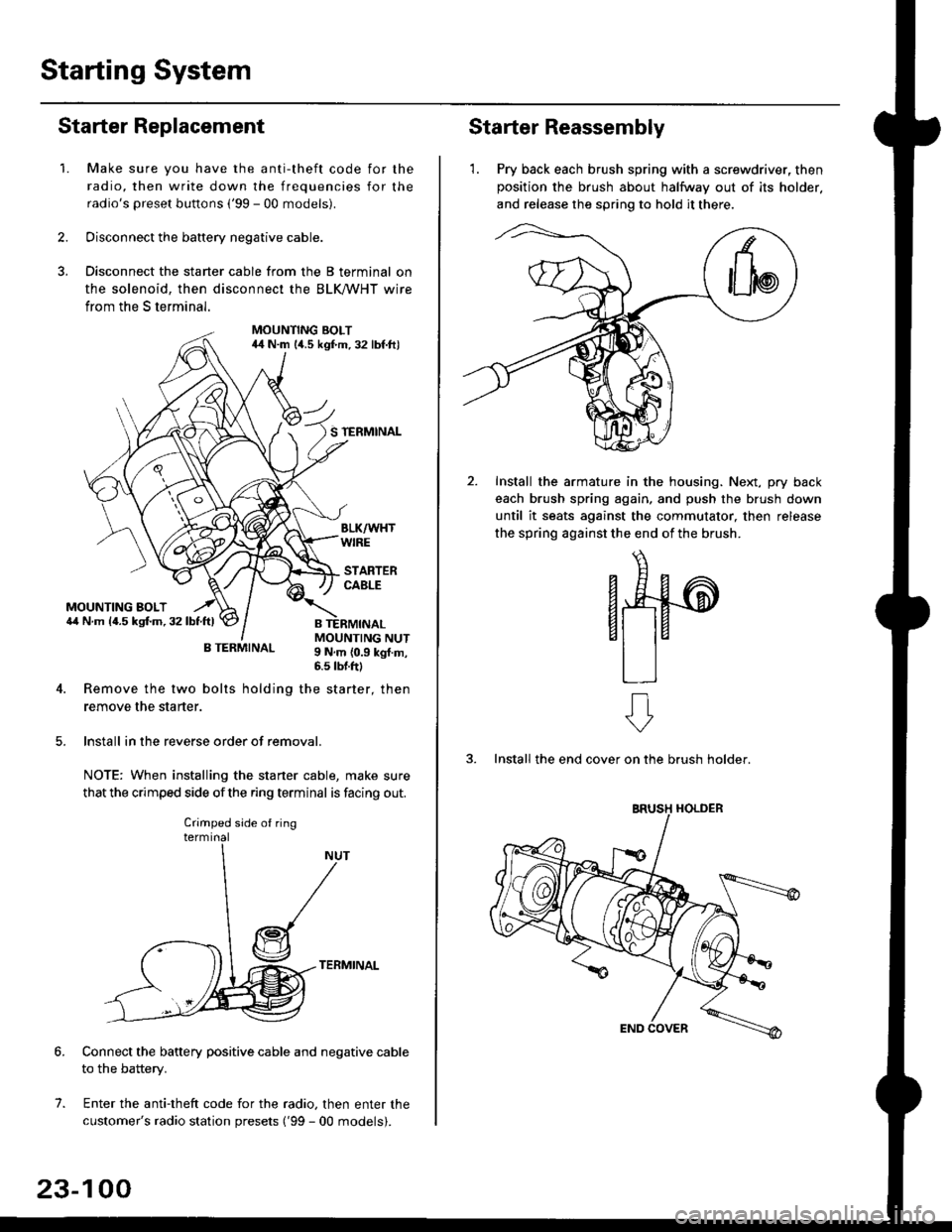

Starting System

Starter Replacement

1.Make sure you have the anti-theft code for the

radio, then write down the frequencies for the

radio's preset buttons ('99 - 00 models).

Disconnect the battery negative cable.

Disconnect the starter cable from the B terminal on

the solenoid, then disconnect the BLK trHT wire

from the S terminal.

MOUNTING BOLT44 N.m l/t.s kgf.m. 32 lbf.ft)

S TERMINAL

MOUNTING BOLT6,1 N.m {4.5 kstm.32lbtftl

MOUNTING NUT9 N,m {0.9 kgl.m,6.s lbtftl

B TERMINAL

4. Remove the two bolts holding the starter, then

remove the starter.

lnstall in the reverse order of removal.

NOTE: When installing the staner cable, make sure

that the crimped side ofthe ring terminal is facing out.

TERMINAL

Connect the battery positive cable and negative cable

to the battery.

Enter the anti-theft code for the radio, then enter the

customer's radio station presets ('99 - 00 models).

7.

Crimped side of ring

23-100

Starter Reassembly

'1. Pry back each brush spring with a screwdriver, then

position the brush about halfway out of its holder.

and release the spring to hold it there.

Install the armature in the housing. Next, pry back

each brush spring again, and push the brush down

until it seats against the commutator, then release

the spring against the end of the brush.

aw

3. Install the end cover on the brush holder.

ERUSH HOLDER

Page 1591 of 2189

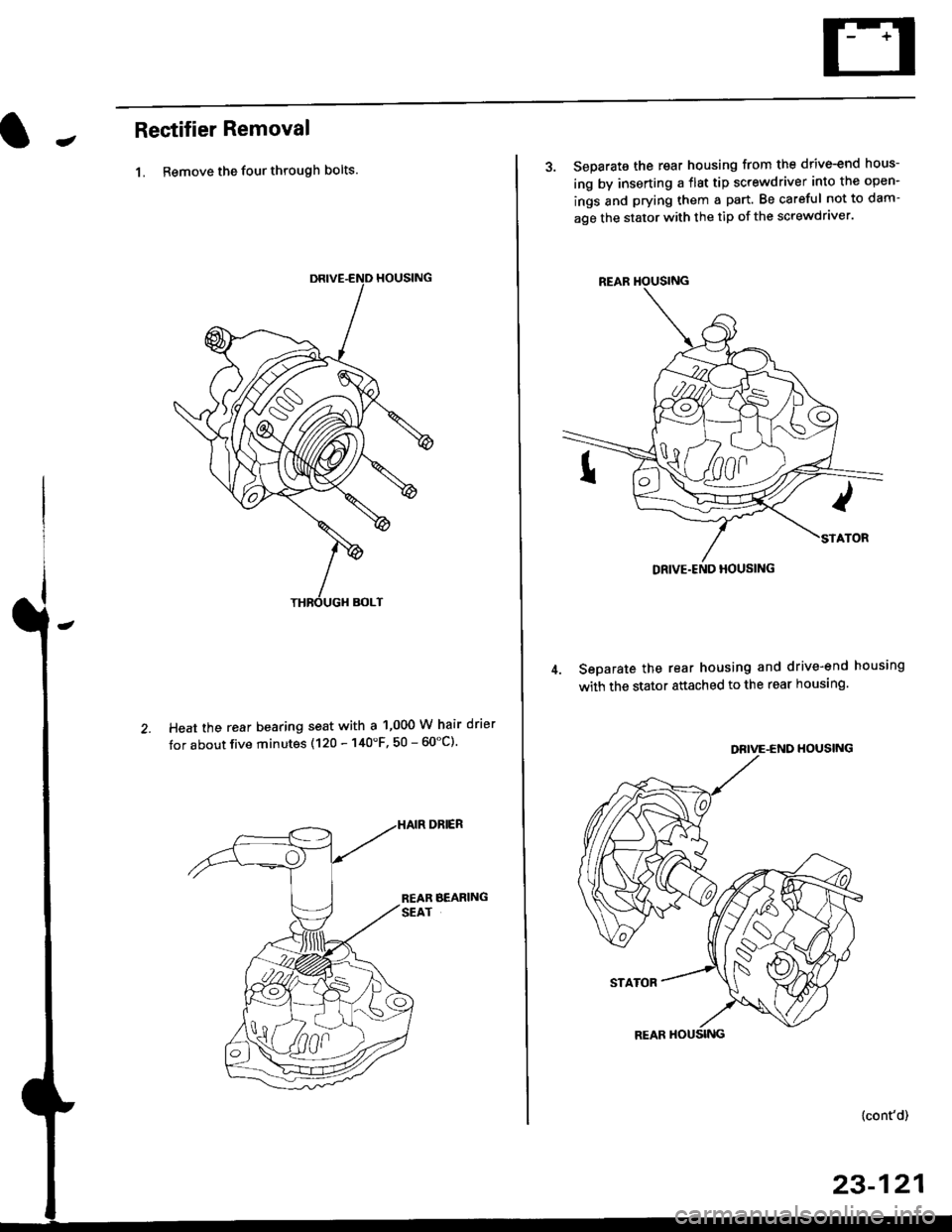

JRectifier Removal

1. Remove the four through bolts.

Heat the rear bearing seat with a 1,000 W hair drier

tor about five minutes (120 - 140'F, 50 - 60"C).

3. Separate the rear housing from the drive-end hous-

ing by inserting a flst tip screwdriver into the open-

ings and prying them a part. Be careful not to dam-

age the stator with the tip of the screwdraver.

Seoarate the rear housing and drive-end housing

with the stator attached to the rear housing.

DEIVE-END HOUSING

STATOR

{cont'd)

23-121

REAR HOUSING

Page 1594 of 2189

Gharging System

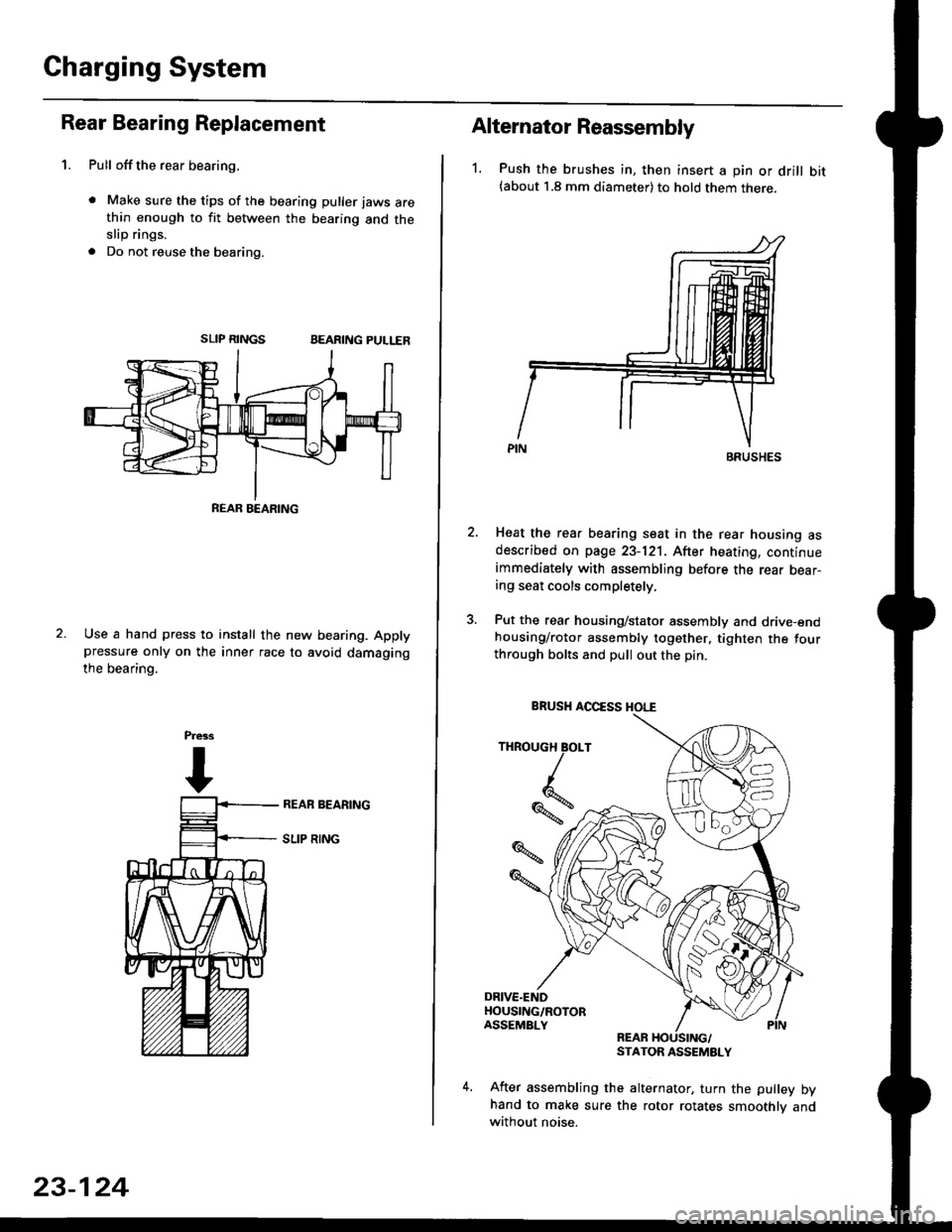

Rear Bearing Replacement

1. Pull offthe rear bearing,

. Make sure the tips of the bearing puller jaws arethin enough to fit between the bearing and theslip rings.

. Do not reuse the bearing.

SLIP RINGSBEARING PULLER

Use a hand press to install the new bearing. Applypressure only on the inner race to avoid damaging

the bearino.

REAB BEARING

23-124

Alternator Reassembly

1. Push the brushes in, then insert a pin or drill bit(about 1.8 mm diameter) to hold them there.

Heat the rear bearing seat in the rear housing asdescribed on page 23-121. After heating, continueimmediately with assembling before the rear bear-ing seat cools completely,

Put the rear housing/stator assembly and drive-endhousing/rotor assembly together. tighten the fourthrough bolts and pull out the pin.

REARSTATOR ASSEMBLY

After assembling the alternator, turn the pulley byhand to make sure the rotor rotates smoothlv andwithout noise.

BRUSHES

THROUGH BOLT

Iq

%*z

BRUSH AOCESS HOI."E

Page 1606 of 2189

Gauge Assembly

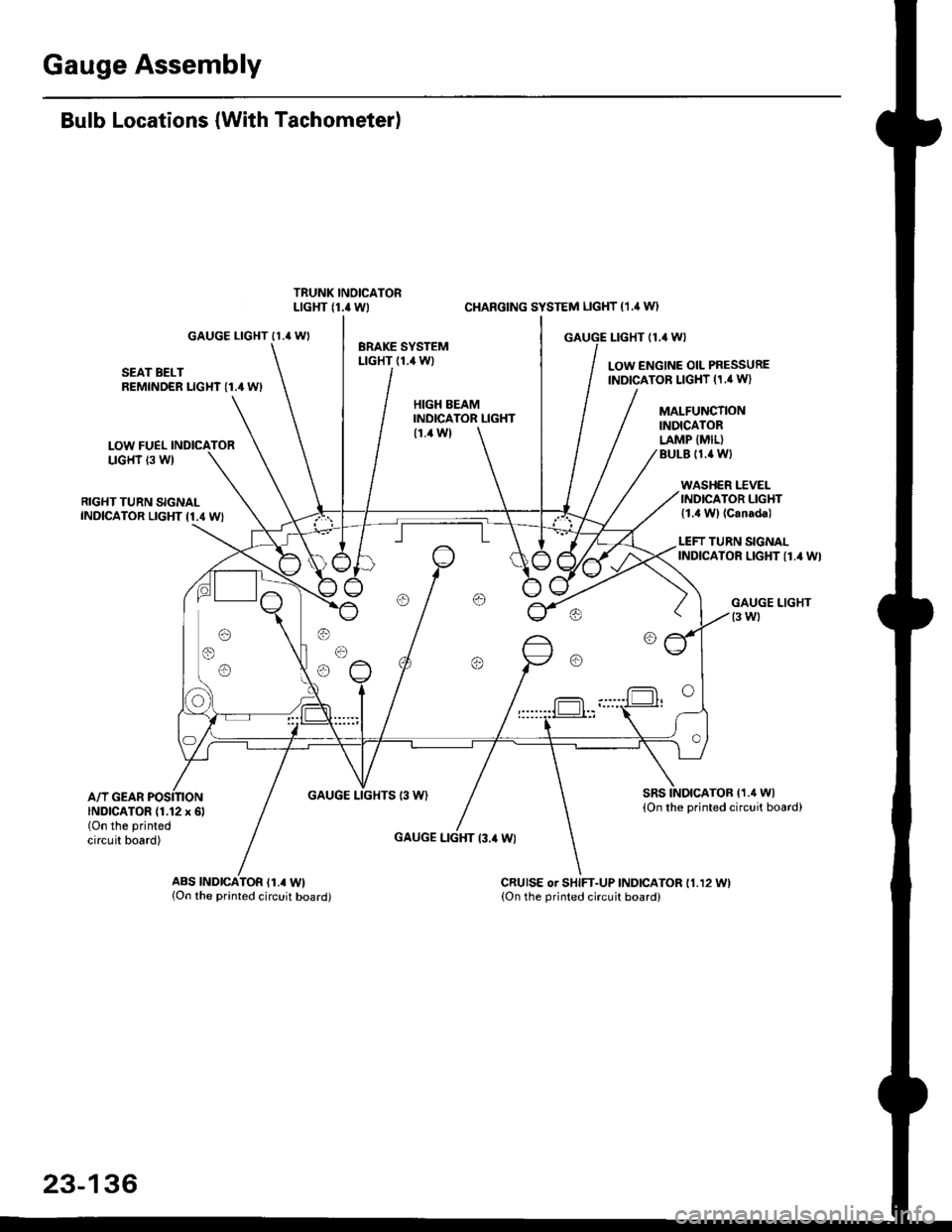

Bulb Locations (With Tachometer)

GAUGE LIGHT II.' WI

SEAT BELTREMINDER LIGHT I1.4 WI

LOW FUELLIGHT 13 W)

RIGHT TURN SIGNALINDICATOR LIGHT I1.4 WI

A/T GEARGAUGE LIGHTS 13 W)

CI{ARGING SYSTEM LIGHT (1.,1W)

GAUGE I-IGHT {1,4 WI

LOW ENGINE OIL PRESSUREINDICATOR LIGHT (1,' W}

HIGH EEAMINDICATOR LIGHT(1.4 W)

GAUGE LIGHT l3.il Wl

MALFUNCTIONINDICATORLAMP {MIL}BULE (1.{ Wl

WASHER I.'C VELINDICATOR LIGHT{1.4 Wl (Canada)

LEFT TURN SIGNALINDICATOR LIGHT {1.4 WI

sRsTOB (1.4 Wl

{On the printed circuit board)INDICATOR (1.12 x 6l(On the printed

circuit board)

ABS |ND|CATOR (1.. Wl{On the printed circuit board)CRUISE or SHIFT-UP INDICATOR 11.12 11.{On the orinted circuit board)

23-136

Page 1607 of 2189

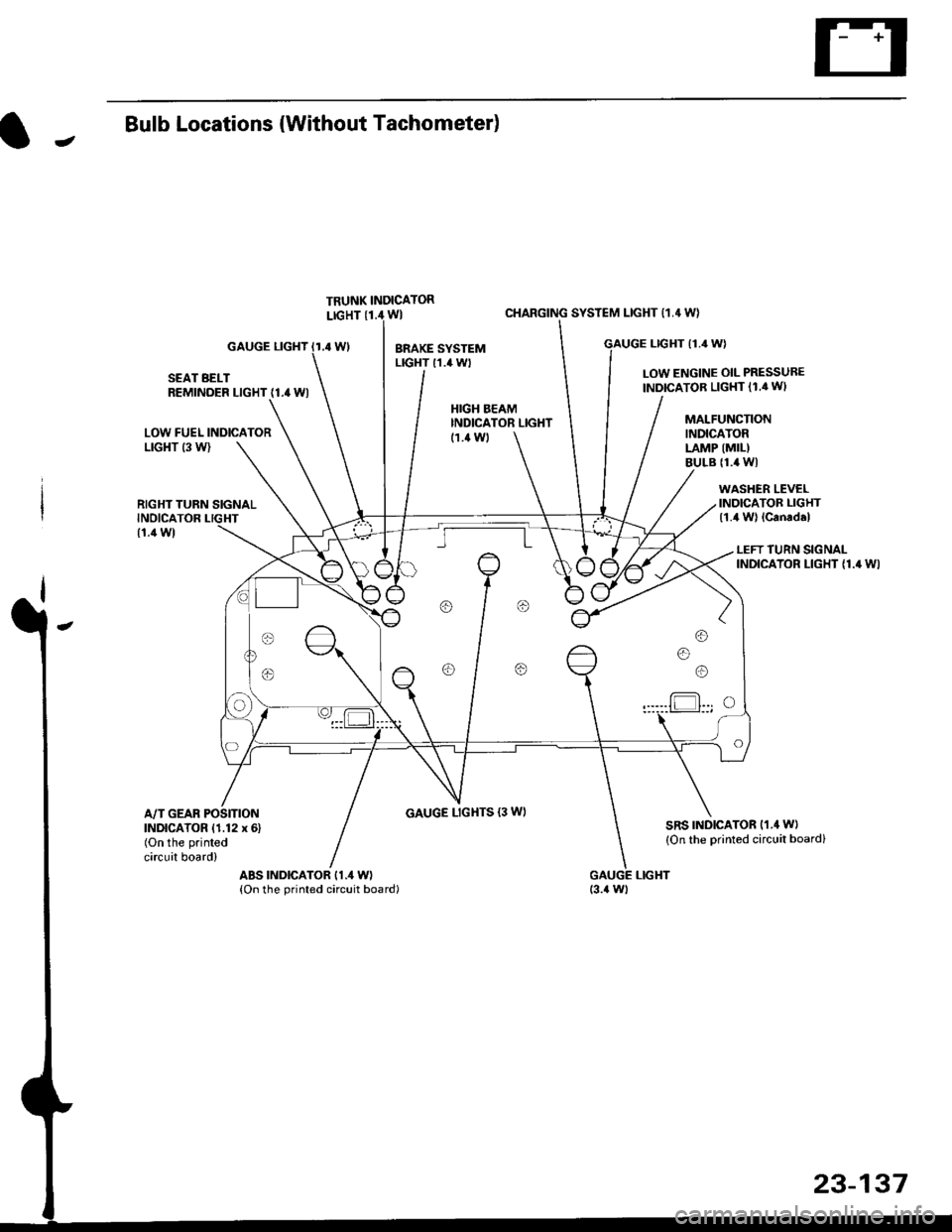

JBulb Locations {Without Tachometer)

TRUNK INDICATORLIGHT {1.i1W}

.4 Wl

CHARGING SYSTEM LIGHT 11,4 W}

LTGHT (1.4 W)GAUGE LIGHT

SEAT BELTREMINDER LIGHT (1.4 WI

LOW ENGINE OIL PRESSUBE

INDICATOB LIGHT (1.4 WI

LOW FUEL INDICATORLrGl{T (3 W)

RIGHT TURN SIGNALINOICATOR LIGHT

(1.1Wt

GAUGE LIGHTS {3 WI

WASHER LEVELINDICATOR LIGHT{1.4 W} lcanad.l

HIGH BEAMINDICATOR LIGHTMALFUNCTIONINDICATORLAMP (MIL)

BULB {1.4 WI

{1.ilW)

LEFT TURN SIGNALINDICATOR LIGHT {1.4 WI

A/T GEAR POSITIONINDICATOR (1.12 x 6)(On the printed

circuit board)

sRs TND|CATOR 11.4 W)

{On the Drinted circuit board}

aBs tNDtcAToR t1.4 W)(On the printed circuit board)(3.{ Wt

o/ o \7 o

23-137

Page 1630 of 2189

Integrated Gontrol Unit

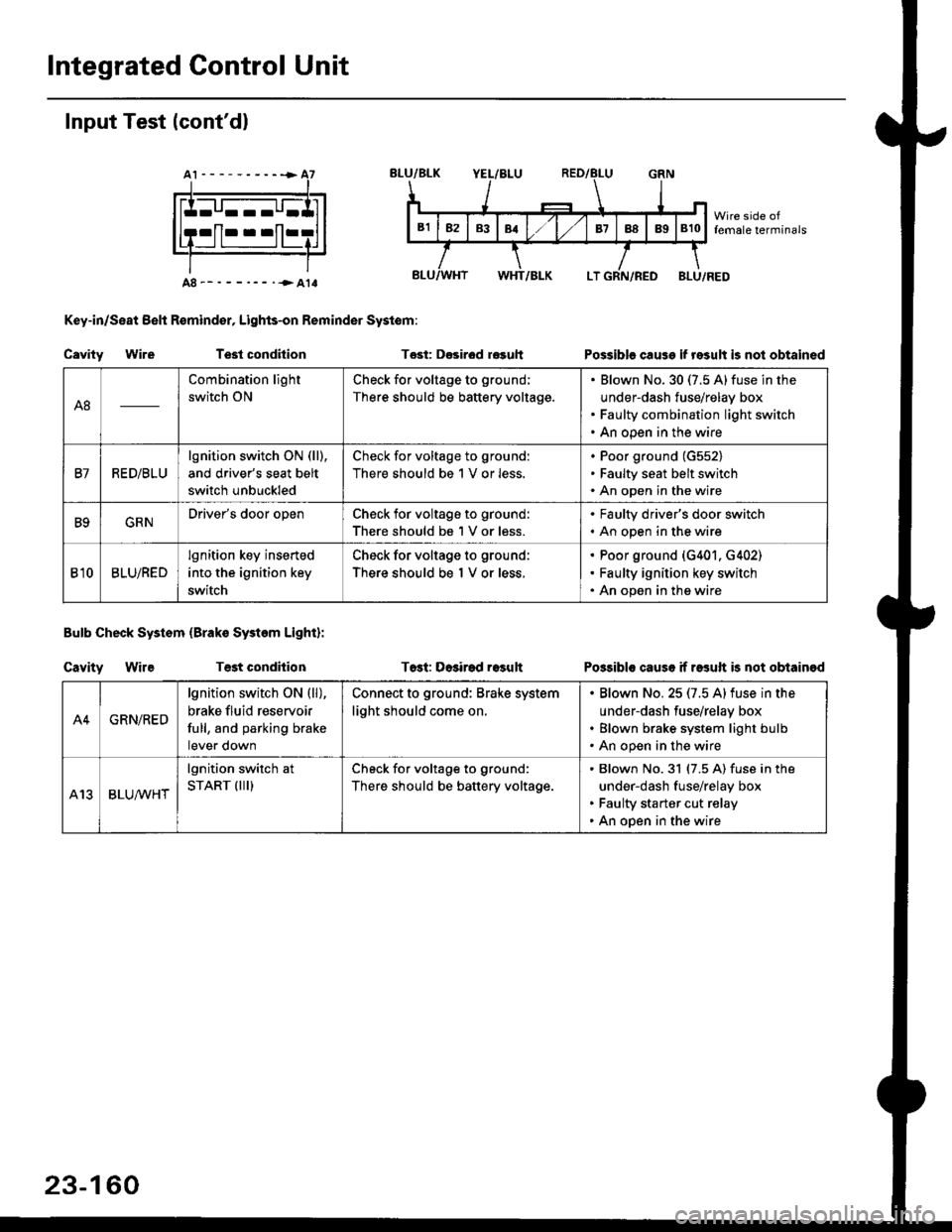

Input Test (cont'dl

A8--------.--all

Key-in/Seat Belt R€mind€r, Lights-on Reminder Systom:

Cavity WireTest condhion

Bulb Check System (Brako System Light):

Cavity WireTest condilion

Tost: D€sirod r€guh

T6st: Dosirad result

Possible cause if result is not obtained

Possibls cause if rasuft b not obtainod

A8

Combination light

switch ON

Check for voltage to ground;

There should be battery voltage.

Blown No.30 (7.5 A)fuse in the

under-dash fuse/relay box

Faulty combination light switch

An open in the wire

B7RED/BLU

lgnition switch ON (ll),

and driver's seat belt

switch unbuckled

Check for voltage to ground:

There should be 1 V or less.

Poor ground (G552)

Faulty seat belt switch

An open in the wire

B9GRNDriver's door openCheck for voltage to ground:

There should be 1 V or less.

. Faulty driver's door switch. An open in the wire

Bl0BLU/RED

lgnition key inserted

into the ignition key

switch

Check for voltage to ground:

There should be 1 V or less.

Poor ground (G401. G402)

Faulty ignition key switch

An open in the wire

A4GRN/RED

lgnition switch ON {ll),

brake fluid reservoir

full, and parking brake

tever oown

Connect to ground: Brake system

light should come on.

Blown No.25 (7.5 Alfuse in the

under-dash fuse/relay box

Blown brake system light bulb

An open in the wire

A13BLUA/1r'HT

lgnition switch at

START (III)Check for voltage to ground:

There should be battery voltage.

Blown No.31 (7.5 A) fuse in the

under-dash fuse/relay box

Faulty starter cut relay

An open in the wire

23-160

Page 1638 of 2189

Headlights

Adjustment

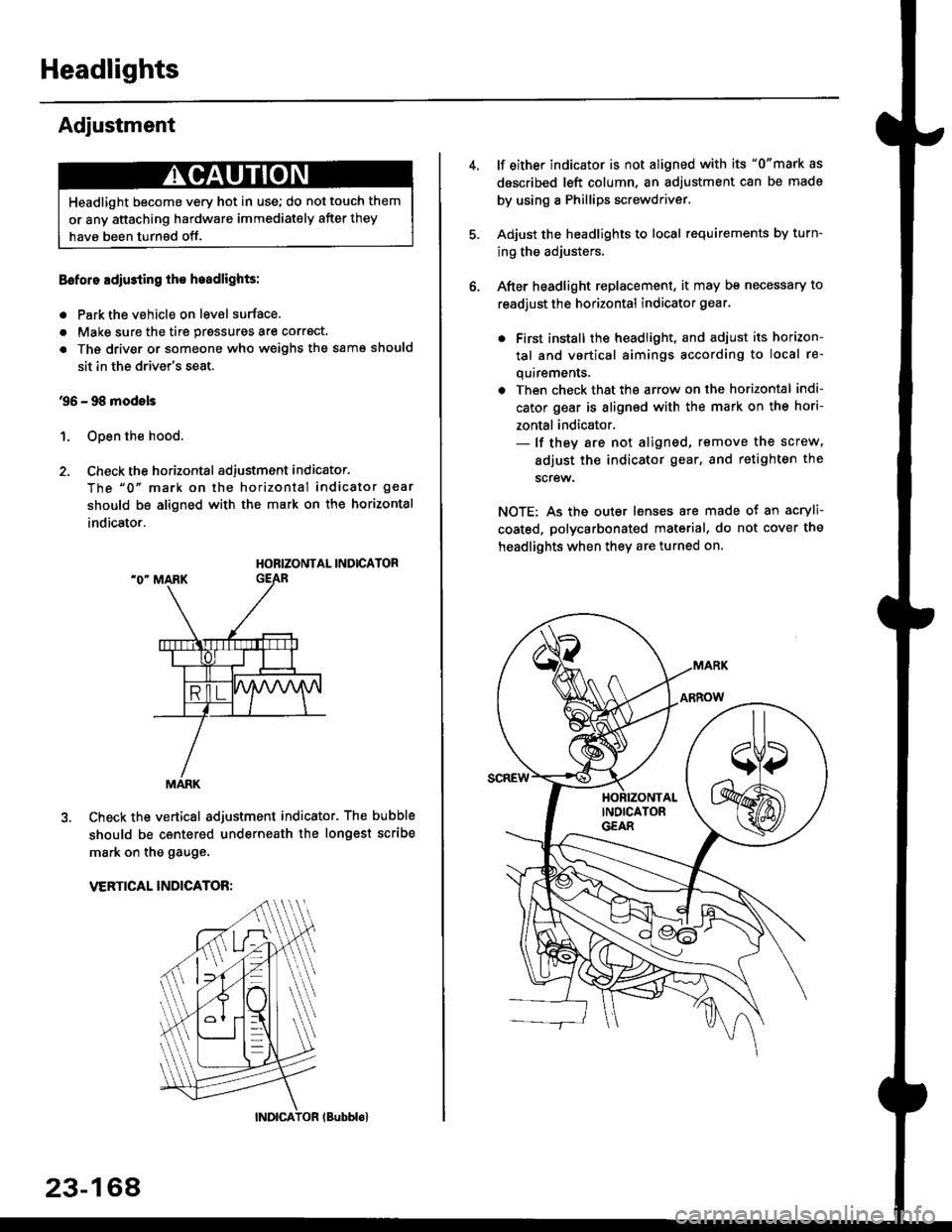

Eoforo adiu3ting th€ h.adlights:

. Park the vehicle on level surface.

. Make sure the tire prgssures are correct.

a The driver or someone who weighs the same should

sit in the driver's seat.

96 - 98 modols

1. Open the hood.

2. Check the horizontal adjustment indicator.

The "0" mark on the horizontal indicator gear

should be aligned with the mark on the horizontal

indicator.

HORIZONTAL INDICATOR

Check the vertical adjustment indicator. The bubble

should be centered underneath the longest scribe

mark on the gauge.

VERTICAL INDICATOR:

Headlight become very hot in use; do not touch them

or any attaching hardware immediately after they

have been turnsd off.

MARK

23-164

(Bubblol

lf either indicator is not aligned with its "0"mark as

described left column, an adjustment can be made

by using a Phillips screwdriver.

Adjust the headlights to local requirements by turn-

ing the adjusters.

After headlight replacement, it may bs necessary to

readjust the horizontal indicator gear.

. First install the headlioht, and adjust its horizon-

tal and vertical aimings according to local re-

quirements.

. Then check that the arrow on the horizontal indi-

cator gear is aligned with the mark on the hori-

zontal indicator.- lf they are not aligned, remove the screw,

adiust the indicator gear, and retighten the

screw.

NOTE: As the outer lenses are made ot an acryli-

coated, polycarbonated material, do not cover the

headlights when they are turned on.

Page 1743 of 2189

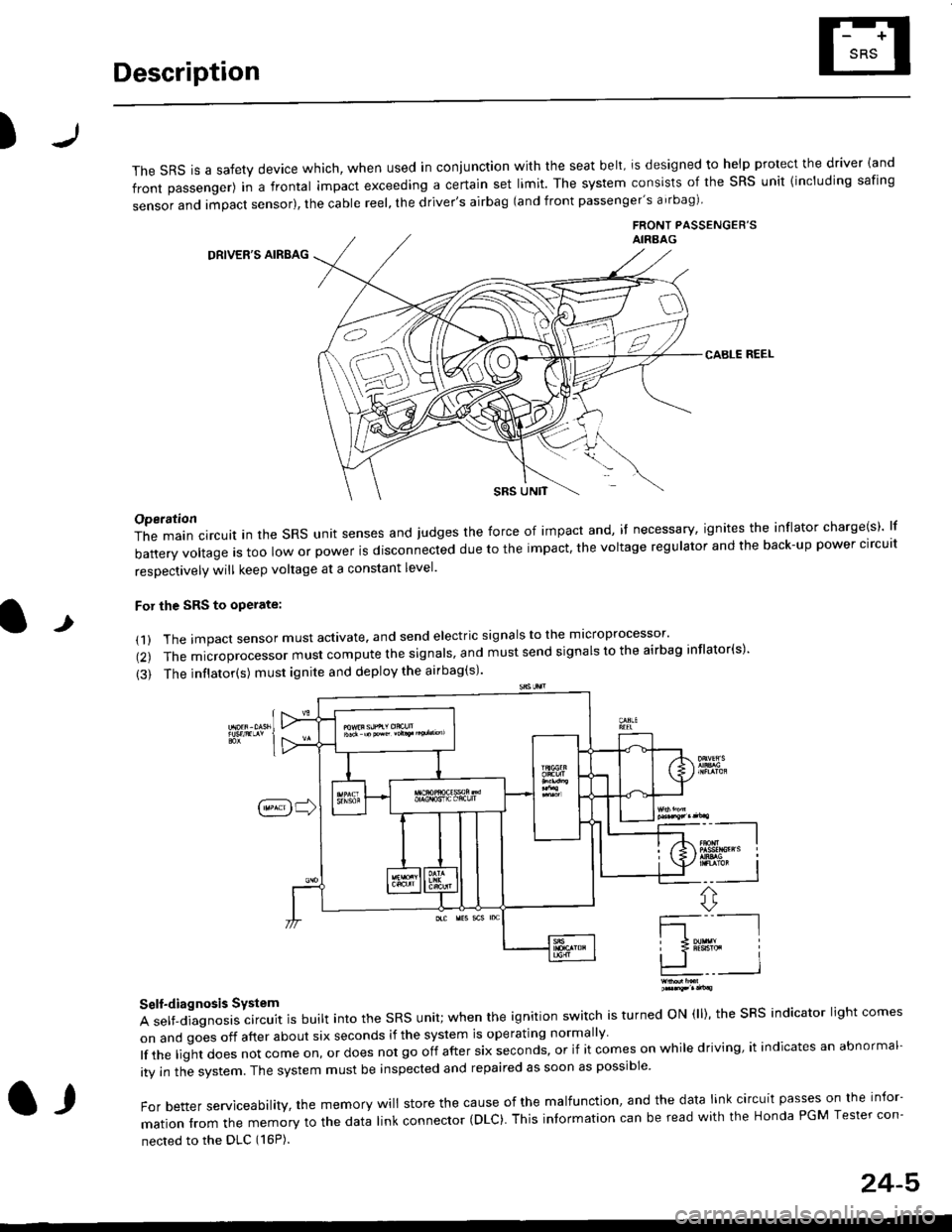

Description

)

The sRS is a safety device which, when used in coniunction with the seat belt, is designed to help protect the driver land

front passenger) in a frontal impact exceeding a certain set limit. The system consists of the sRS unit {including safing

sensor and impact sensor), the cable reel, the driver's airbag (and front passenger's airbag)

FRONT PASSENGEB'SAIRAAG

DRIVER'S AIRBAG

CABLE REEL

SRS UNtT

t

Operation

The main circuit in the SRS unit senses and judges the force of impact and, if necessary, ignites the inflator charge(s) lf

battery voltage is too low or power is disconnected due to the impact, the voltage regulator and the back-up power clrcult

resoectivelv will keep voltage at a constant level.

For the SRS to operate:

(1) The impact sensor must activate. and send electric signals to the mlcroprocessor'

(2) The microprocessor must compute the signals' and must send signals to the airbag inflator(s)'

{3) The inflator(s) must ignite and deploy the airbag(s)'

_"-_-l

Ir3B!#h i

!.. I

ffi,*

Self-diagnosis System

A self-diagnosis circuit is built into the SRS unit; when the ignition switch is turned ON (ll), the SRS indicator light comes

on and goes off after about six seconds if the system is operating normally

lf the liglt does not come on, or does not go off after six seconds, or if it comes on while driving, it indicates an abnormal-

ity in the system. The system must be inspected and repaired as soon as possible

For better serviceability, the memory will store the cause of the malfunctlon, and the data link circuit passes on the infor-

mation from the memory to the data link connector (DLC). This intormation can be read with the Honda PGM Tesler con-

nected to the DLC (16P).

l,

24-5