Seat HONDA CIVIC 1999 6.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CIVIC, Model: HONDA CIVIC 1999 6.GPages: 2189, PDF Size: 69.39 MB

Page 1367 of 2189

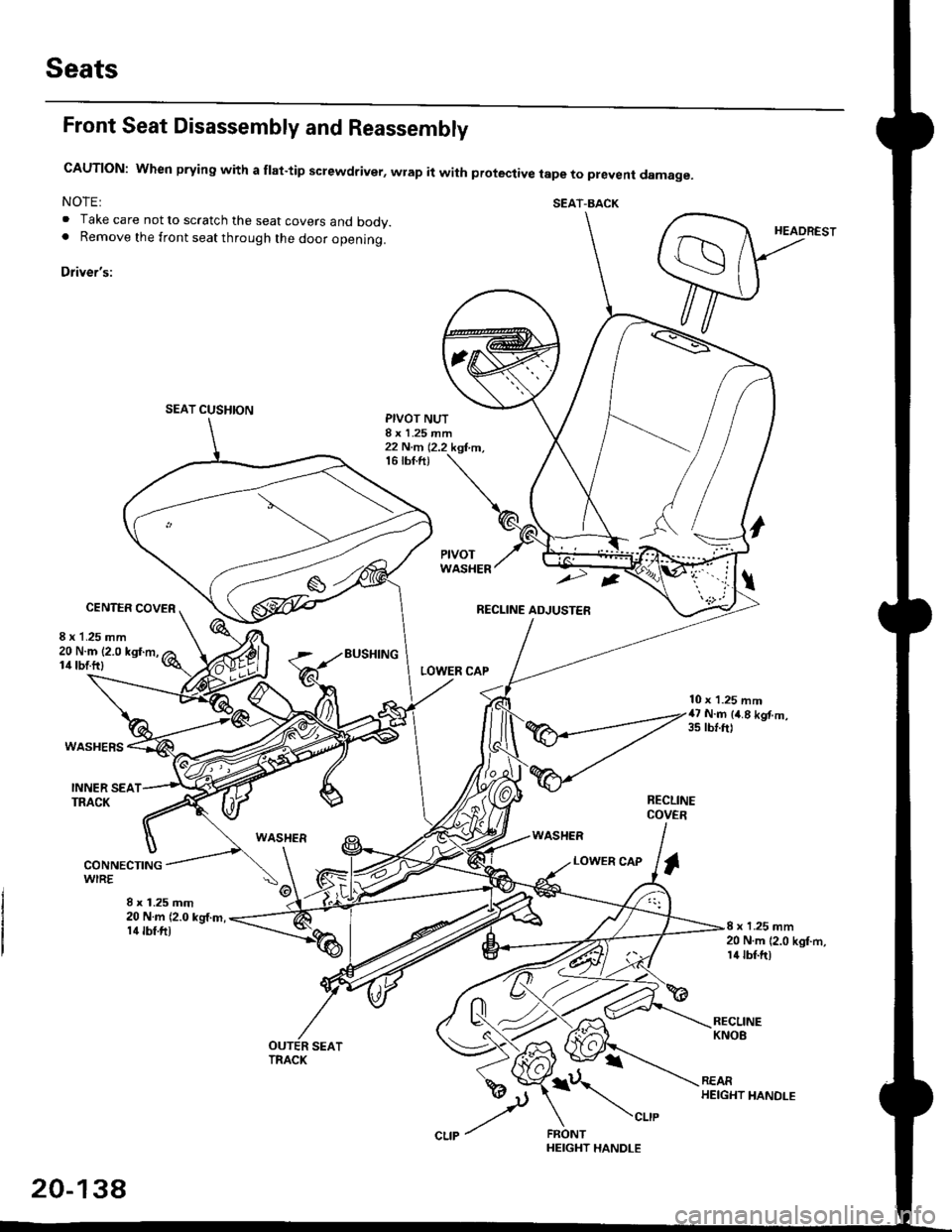

Seats

Front Seat Disassembly and Reassembly

CAUTION: When prying with a flat-tip screwdriver, wrap it with protective tape to prevent damage.

NOTE: SEAT-BACK. Take care not to scratch the seat covers and body.. Remove the front seat through the door openlng.

Driver's:

SEAT CUSHION

HEADREST

PIVOT NUTI x 1.25 mm22 N.m 12.2 kgf,m,16 tbf.ft)

CENTER COVER

8 x 1.25 mm

LOWER CAP

RECLINE ADJUSTER

WASHER

20 N.m 12.0 kgf.m,lil lbtftl

WASHERS

EUSHING

10 x 1.25 mm47 N.m (4.8 kgf.m,3s rbl.ft)

INNER SEATTRACKRECLINECOVER

WASHER

8 x 1.25 mm20 N.m (2.0 kg,f.m,14 tbf.fit

LOWER CAPI

8 x 1.25 mm20 N.m {2.0 kgI.rn,l4 tbf.ft)

i\",-,"

20-13A

HEIGHT HANDLE

Page 1368 of 2189

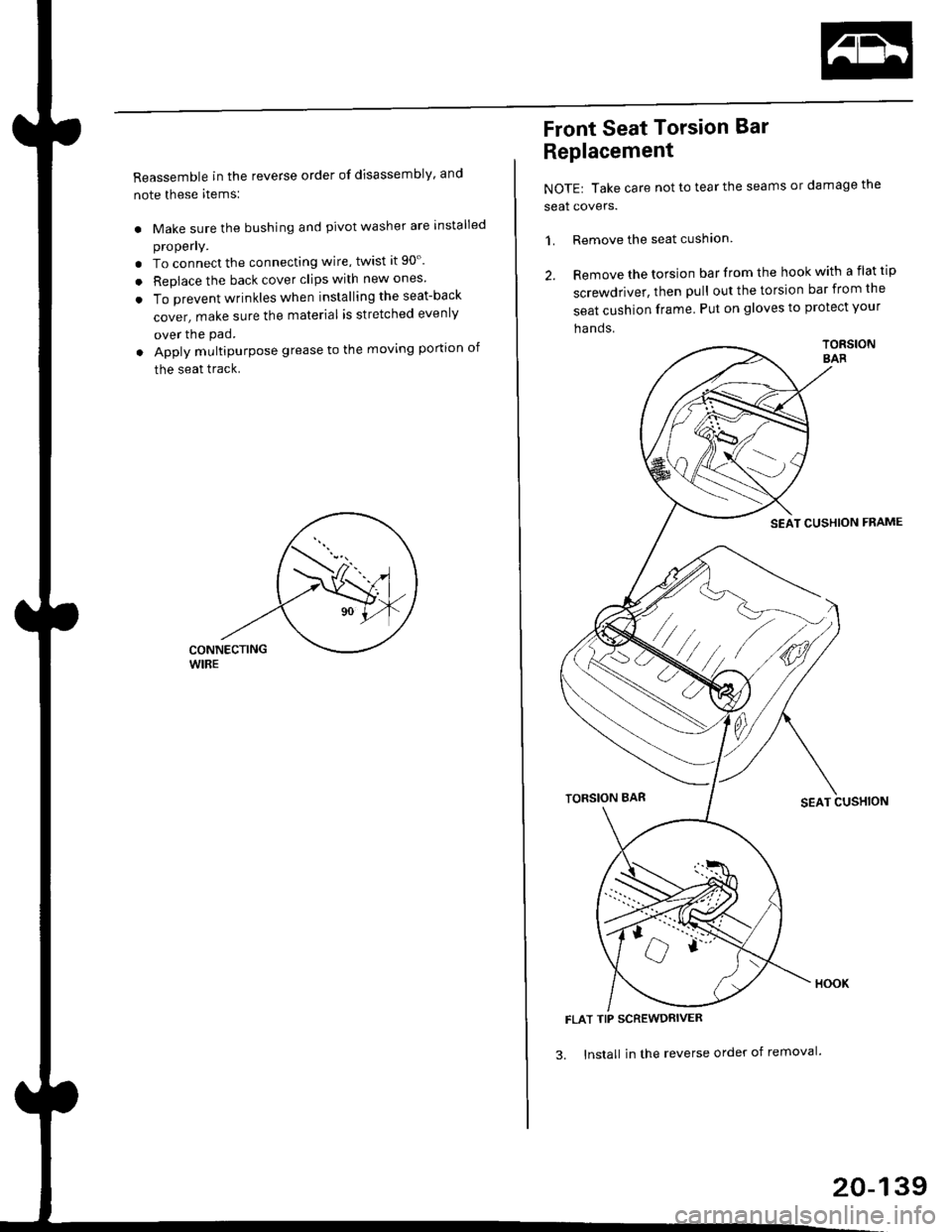

Reassemble in the reverse order of disassembly' and

note these items:

. Make sure the bushing and pivot washer are installed

properly.

. To connect the connecting wire, twist it 90'.

. Replace the back cover clips with new ones

. To prevent wrinkles when installing the seat-back

cover, make sure the material is stretched evenly

over the pad.

. Apply multipurpose grease to the moving portion of

the seat track.

Front Seat Torsion Bar

Replacement

NOTE| Take care not to tear the seams or damage the

seat covers.

1. Remove the seat cushlon

2. Remove the torsion bar from the hook with a flat tip

screwdriver, then pull out the torsion bar from the

seat cushion frame Put on gloves to protect your

ha nds.

TORSIONSAR

SEAT CUSHION FNAME

TORSION BARSEAT CUSHION

FLAT TIP SCREWDRIVER

3. lnstall in the reverse order of removal'

20-139

Page 1370 of 2189

Body {'00 model}

Seat Belts

Child Seat Anchor Plate Removal/

f nstallation 20-142

Emblem

f nstallation 20-144

Outline of '00 Model Changes

The child seat anchor plate removal and installation procedures are different'

An emblem was added for some model of 3D.

Page 1371 of 2189

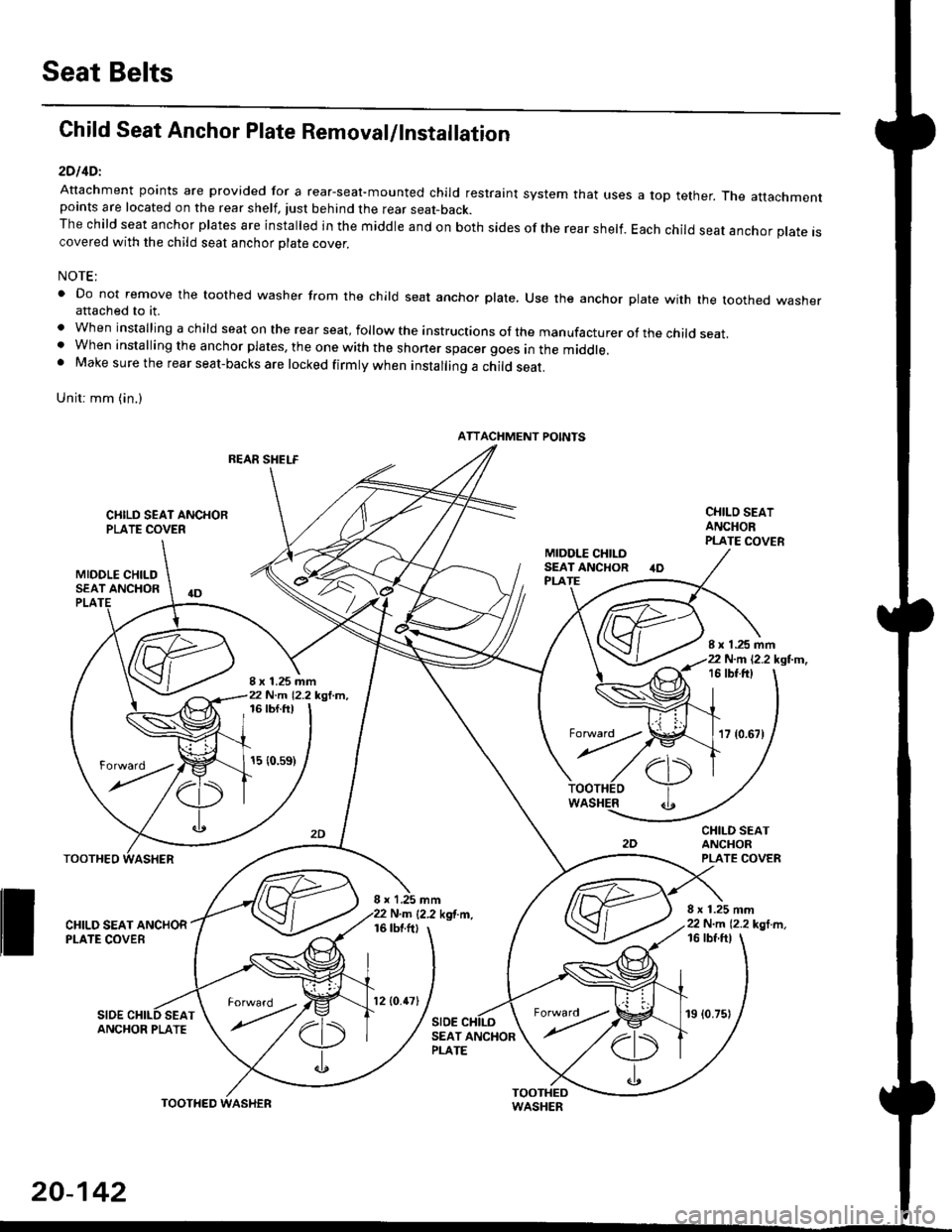

Seat Belts

Child Seat Anchor Plate Removal/lnstallation

2DllDl

Attachment points are provided for a rear-seal-mounted child restraint system that usespoints are located on the rear shelf, tust behind the rear seat-back.The child seat anchor plates are installed in the middle and on both sides of the rear shelf.covered with the child seat anchor olate cover.

a top tether. The attachment

Each child seat anchor plate is

NOTE:

' Do not remove the toothed washer from the child seat anchor plate, Use the anchor plate with the toothed washerattached to it.

. When installing a child seat on the rear seat, follow the instructions of the manufacturer of the child seat.. When installing the anchor plates, the one with the shoner spacer goes in the middle.. Make sure the rear seat-backs are locked firmly when installing a child seat.

Unit: mm (in.)

REAR SHELF

CIIILD SEAT ANCHORPLATE COVER

MIDOLE CHILDSEAT ANCHOR

CHILO SEATANCHORPLATE COVER

CHILD SEATANCHORPLATE COVER

8 x 1.25 mm22 N.m 12.2 kgl m,

PLA

8 x 1.25 mm22 N.m 12.2 kgl.m,

I x 1.25 mm22 N.m 12.2 kgl.m,16 tbt.ftt

17 {0.67)

16 tbf.ft)

15 {0.s9)

WASHER

rl)

.t

TOOTHEO

ll ff*,".rd,',i"'"o*

SIDESEAT

I x 1,25 mmN.m {2.2 kgf.m.16 tbtftl

SIDE

16 tbf ftl

ANCHOR PLATESEAT ANCHORPLATE

ATTACHMENT POINTS

torward .

20-142

TOOTHED

12lO.47l19 (0.75)

Page 1372 of 2189

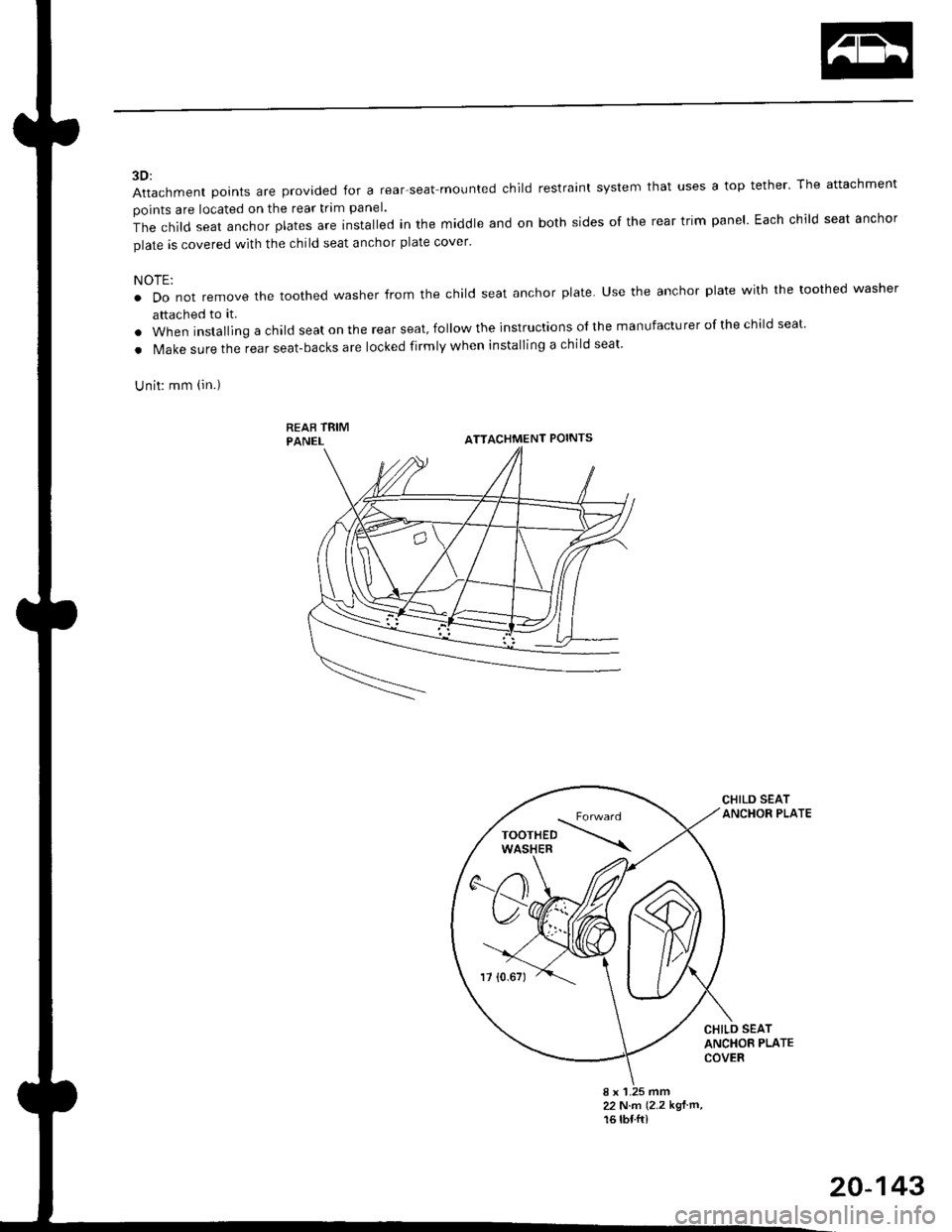

3D:

Attachment points are provided for a rear-seat mounted child restraint system that uses a top tether' The attachment

points are located on the rear trim panel.

The child seat anchor plates are rnstalled in the middle and on both sides of the rear trim panel Each child seat anchor

plale is covered with the child seat anchor plate cover'

NOTE:

. Do not remove the toothed washer from the child seat anchor plate. use the anchor plate with the toothed washer

attached to it.

. when installing a child seat on the rear seat, follow the instructions ol the manufacturer of the child seat'

. Make sure the rear seat-backs are locked firmly when installing a child seat'

gn;1 6rn (in.)

ATTACHMENT POINTS

CHILO SEATANCHOR PLATE

CHILD SEATANCHOB PLATECOVER

8 x 1.25 mm22 N..n (2.2 kgl'm.16 tbfft)

;x?',rff{-*.

20-143

Page 1459 of 2189

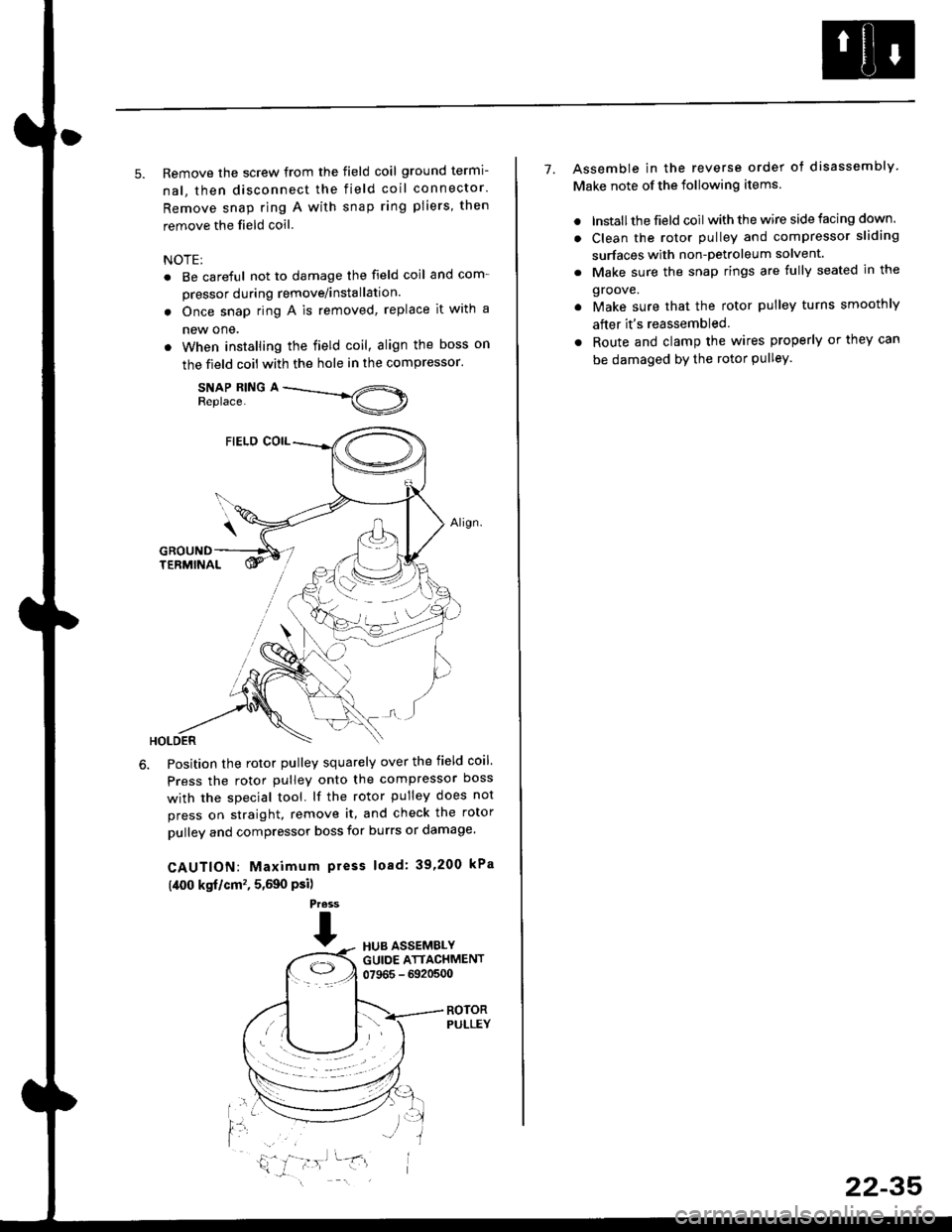

5. Remove the screw from the field coil ground termi-

nal, then disconnect the field coil connector.

Remove snap ring A with snap ring pliers, then

remove the field coil

NOTE:

. Be careful not to damage the field coil and com-

pressor during remove/installation.

. Once snap ring A is removed, replace it with a

new one.

. When installing the field coil, align the boss on

the field coil with the hole in the compressor.

SNAP RING AReplace.

Position the rotor pulley squarely over the field coil.

Press the rotor pulley onto the compressor boss

with the special tool. lf the rotor pulley does not

press on straight, remove it, and check the rotor

pulley and compressor boss for burrs or damage.

CAUTION: Maximum press load: 39,200 kPa

(,[00 kgf/cm'�, 5,590 Psi)

Press

THUB ASSEMBLYGUIDE ATTACHMENT07965 - 6920500

ROTORPULLEY

t'l

i,'

7. Assemble in the reverse order of disassembly

Make note of the following items.

. lnstall the field coil with the wire side facing down.

. Clean the rotor pulley and compressor sliding

surfaces with non-petroleum solvent.

. Make sure the snap rings are fully seated in the

groove.

. Make sure that the rotor pulley turns smoothly

after it's reassembled

. Route and clamp the wires properly or they can

be damaged bY the rotor Pulley.

22-35

Page 1466 of 2189

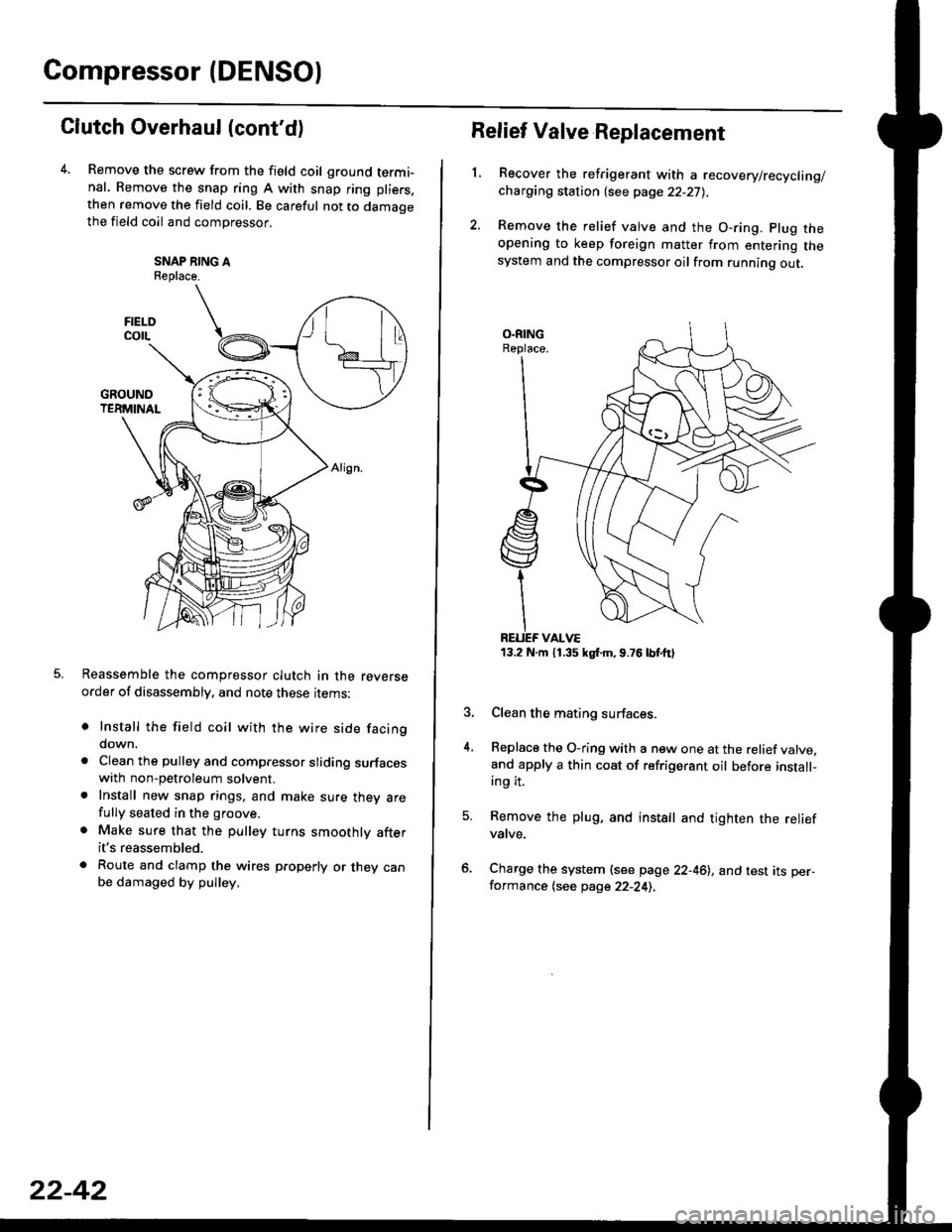

Compressor (DENSO)

Clutch Overhaul (cont'd)

Remove the screw from the field coil ground termi-nal. Remove the snap ring A with snap ring pliers.

then remove the field coil. Be careful not to damaoethe field coil and compressor.

SNAP NING AReplace.

Reassemble the compressor clutch in the reverseorder of disassembly, and note these rrems:

o Install the field coil with the wire side facingdown.

a Clean the pulley and compressor sliding surfaceswith non-petroleum solvent.. Install new snap rings, and make sure thev arefully seated in the groove.

. Make sure that the pulley turns smoothly afterit's reassembled.

. Route and clamp the wires p.operly or they canbe damaged by pulley.

FIELOcorL

22-42

13.2 N.m 11.35 kgt m,9.76lbtttl

Relief Valve Replacement

L

4.

Recover the refrigerant with a recovery/recycling/charging station {see page 22-27),

Remove the relief valve and the O-ring. plug theopening to keep foreign matter from entering thesystem and the compressor oilfrom running out.

Clean the mating surfaces.

Replace the O-ring with a new one at the relief valve.and apply a thin coat of refrigerant oil before install-ing it.

Remove the plug, and install and tighten the reliefvatve.

Charge the system (see page 22-46), and test its per-formance (see page 22-24),

Page 1474 of 2189

Troubleshooting

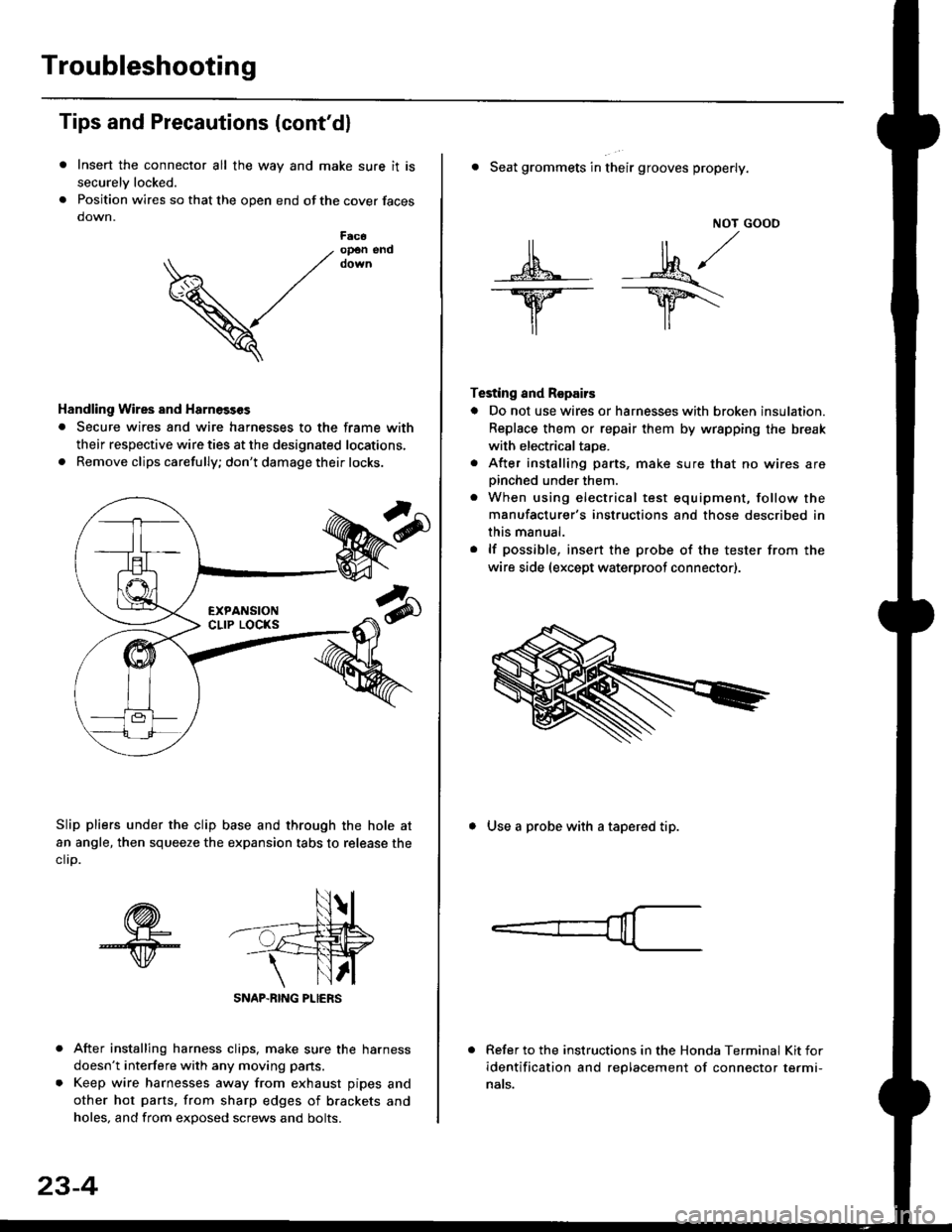

Tips and Precautions (cont'dl

Insert the connector all the way and make sure it is

securelv locked.

Position wires so that the open end of the cover faces

down.

After installing harness clips, make sure the harness

doesn't interfere with any moving pans.

Keep wire harnesses away from exhaust pipes and

other hot parts. from sharp edges of brackets and

holes, and from exDosed screws and bolts.

V

F6c6op€n end

Handling Wires and Harnosscs

. Secure wires and wire harnesses to the frame with

their respective wire ties at the designated locations,

. Remove clips carefully; don't damage their locks.

Slip pliers under the clip base and through the hole at

an angle, then squeeze the expansion tabs to release the

clrp.

SNAP-BING PLIERS

23-4

NOT GOOO

ll il,/

s*' -.1}8."/_Y--_Y5\

il ,,

Testing and Repairs

o Do not use wires or harnesses with broken insulation.

Replace them or repair them by wrspping the break

with electricaltaoe.

. After installing parts, make sure that no wires arepinched under them.. When using electrical test equipment, follow the

manufacturer's instructions and those described in

this manual.

. lf possible, insert the probe of the tester from the

wire side (except waterproof connector).

. Seat grommets in their grooves properly.

. Use a probe with a tapered tip.

Refer to the instructions in the Honda Terminal Kit for

identification and replacement of connector termi-

nats.

Page 1510 of 2189

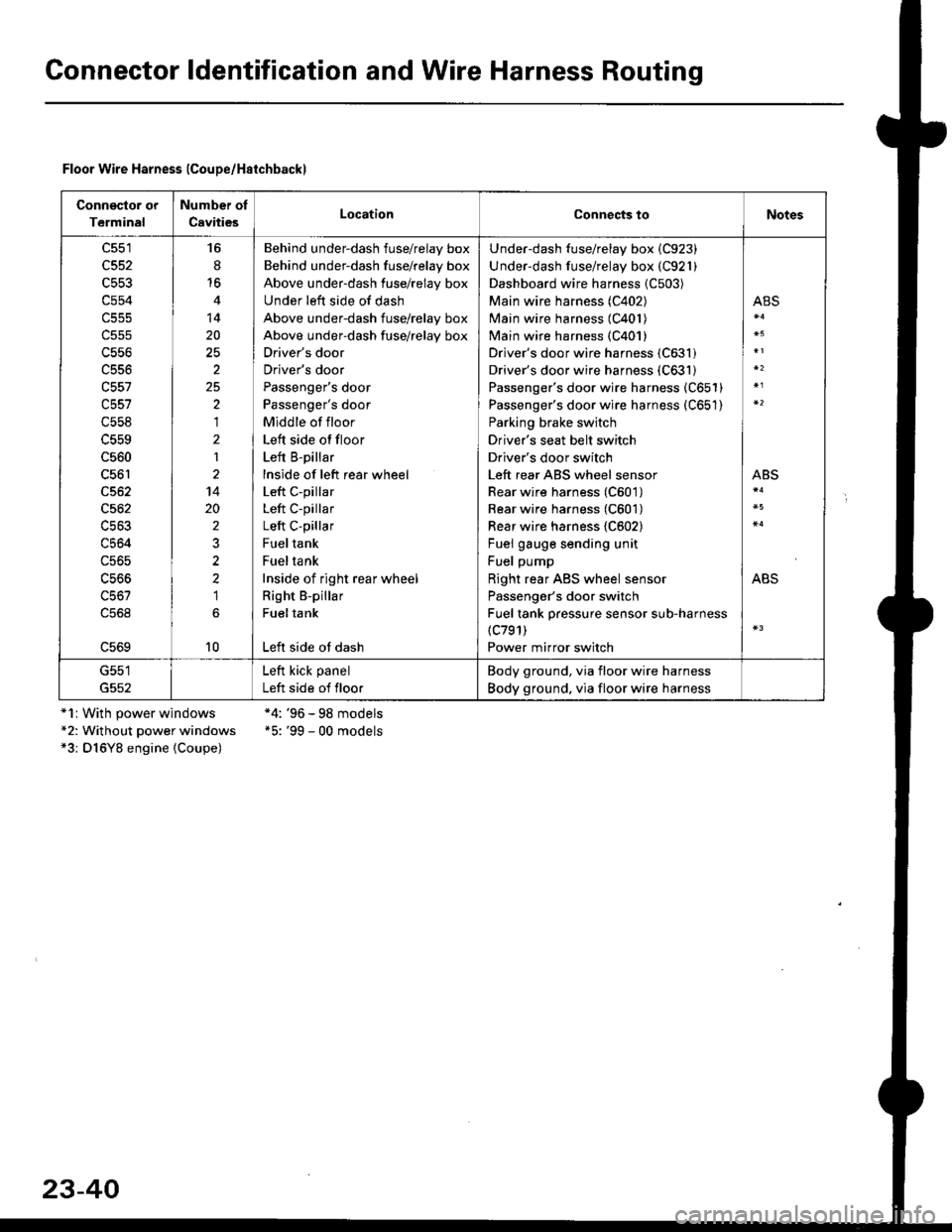

Gonnector ldentification and Wire Harness Routing

Floor Wire Harness lCoupe/Haichbackl

Connsclor or

Terminal

Number of

CavitiesLocationConnects toNotes

c551

c552

c553

c554

c556

c556

c557

c558

c560

c561

c562

c564

c56s

16

8'16

14

20

2

25,)

,I

2

1

14

20

2

2?

1

10

Behind underdash fuse/relay box

Behind under-dash fuse/relay box

Above under-dash fuse/relay box

Under left side of dash

Above under-dash fuse/relay box

Above under-dash fuse/relay box

Driver's door

Driver's door

Passenger's door

Passenger's door

Middle of floor

Left side offloor

Left B-pillar

lnside of left rear wheel

Left c-pillar

Left C-pillar

Left C-pillar

Fueltank

Fueltank

Inside of right rear wheel

Right B-pillar

Fueltank

Left side ot dash

Under-dash fuse/relay box {C923)

Under-dash fuse/relay box (C921)

Dashboard wire harness {C503)

Main wire harness (C402)

Main wire harness (C401)

Main wire harness {C401)

Driver's door wire harness (C631)

Driver's door wire harness (C631)

Passenger's door wire harness (C651)

Passenger's door wire harness (C651)

Parking brake switch

Driver's seat belt switch

Driver's door switch

Left rear ABS wheel sensor

Rear wire harness (C601)

Rear wire harness (C601)

Rear wire harness {C602}

Fuel gauge sending unit

Fuel pump

Right rear ABS wheel sensor

Passenger's door switch

Fuel tank pressure sensor sub-harness(c791)

Power mirror switch

ABS

ABS

ABS

G551

G552

Left kick panel

Left side of floor

Body ground, via floor wire harness

Body ground. via floor wire harness

*1r With power windows*2: Without power windows*3: D16Y8 engine {Coupe)

*4: '96 - 98 models*5: '99 - 00 models

23-40

Page 1512 of 2189

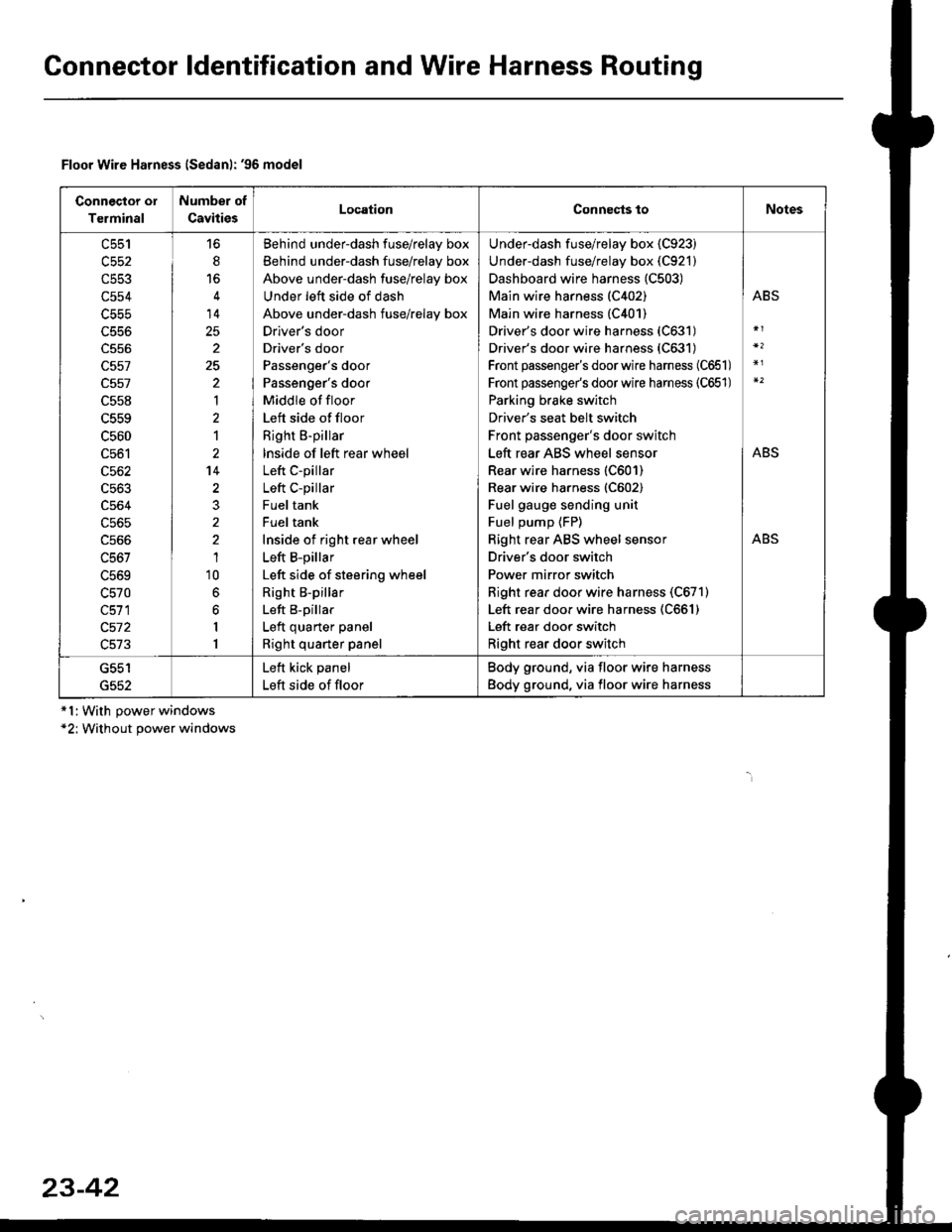

Gonnector ldentification and Wire Harness Routing

Connector ol

Terminal

Number of

CavitiesLocationConnects toNotes

c553

c554

c556

c557

c557

c558

c559

c560

c561

c562

c563

c564

c565

c566

c567

L5bY

c570

c511

c572

c513

6

14

25

2

25

'|

1

2't4

1'10

6

6

I

1

Behind underdash fuse/relay box

Behind under-dash fuse/relay box

Above under-dash fuse/relay box

Under left side of dash

Above under-dash fuse/relay box

Drlver's door

Driver's door

Passenger's door

Passenger's door

Middle of floor

Left side of floor

Right B-pillar

lnside of left rear wheel

Left C-pillar

Left C-pillar

Fuel tank

Fuel tank

Inside of right rear wheel

Left B-pillar

Left side of steering wheel

Right B-pillar

Left B-pillar

Left quarter panel

Right quarter panel

Under-dash fuse/relay box {C923)

Under-dash fuse/relay box (C921)

Dashboard wire harness (C503)

Main wire harness (C402)

Main wire harness (C401)

Driver's door wire harness (C631)

Driver's door wire harness (C631)

Front passenger's doorwire harness (C651)

Front passenge/s doorwire harness (C651)

Parking brake switch

Driver's seat belt switch

Front passenger's door switch

Left rear ABS wheel sensor

Rear wire harness (C601)

Rear wire harness (C602)

Fuel gauge sending unit

Fuel pump {FP)

Right rear ABS wheel sensor

Driver's door switch

Power mirror switch

Right rear door wire harness (C671)

Left rear door wire harness (C661)

Left rear door switch

Right rear door switch

ABS

ABS

ABS

G552

Left kick panel

Left side of floor

Body ground, via floor wire harness

Body ground, via floor wire harness

Floor Wire Harness lSedanl: '96 model

*l:With power windows*2; Without power windows

23-42