7-1 HONDA CIVIC 1999 6.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CIVIC, Model: HONDA CIVIC 1999 6.GPages: 2189, PDF Size: 69.39 MB

Page 210 of 2189

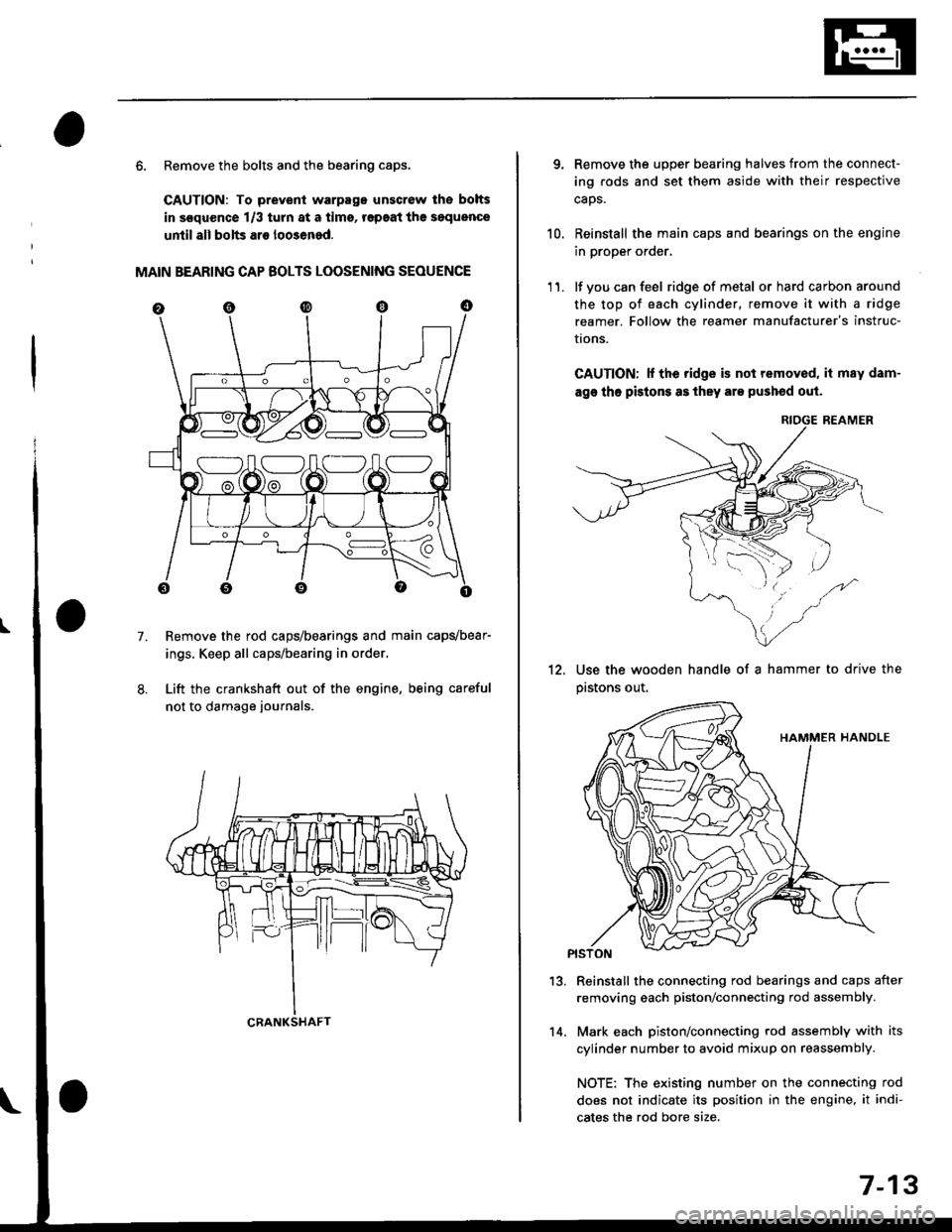

6. Remove the bolts and the bearing caps.

CAUTION: To prevenl warpago unscrow lhe bolts

in s€quence 1/3 turn at a tims, r€paat the soquence

until all bolts ar€ loo3ened.

MAIN BEARING CAP BOLTS LOOSENING SEOUENCE

Remove the rod caps/bearings and main capvbear-

ings. Keep all caps/bearing in order.

Lift the crankshaft out of the engine, being careful

not to damage journals.

7.

S:_]ILOJLOAO

CRANKSHAFT14.

7-13

qRemove the upper bearing halves from the connect-

ing rods and set them aside with their respective

caos.

Reinstall the main caps and bearings on the engine

in proper order,

lf you can feel ridge of metal or hard carbon around

the top of each cylinder, remove it with a ridge

reamer. Follow the reamer manufacturer's instruc-

I|ons.

CAUTION; lf the ridge is not removed, it may dam-

age tho pistons as they are pushod out.

RIOGE REAMER

10.

11.

12.Use the wooden handle of a hammer to drive the

pastons out.

13.Reinstall the connecting rod bearings and caps after

removing each piston/connecting rod assembly.

Mark each piston/connecting rod assembly with its

cylinder number to avoid mixup on reassembly.

NOTE: The existing number on the connecting rod

does not indicate its position in the engine, it indi-

cates the rod bore size.

Page 211 of 2189

Crankshaft

Inspection

. Clean the crankshaft oil passages with pipe cleaners

or a suitable brush.

. Check the keyway and threads.

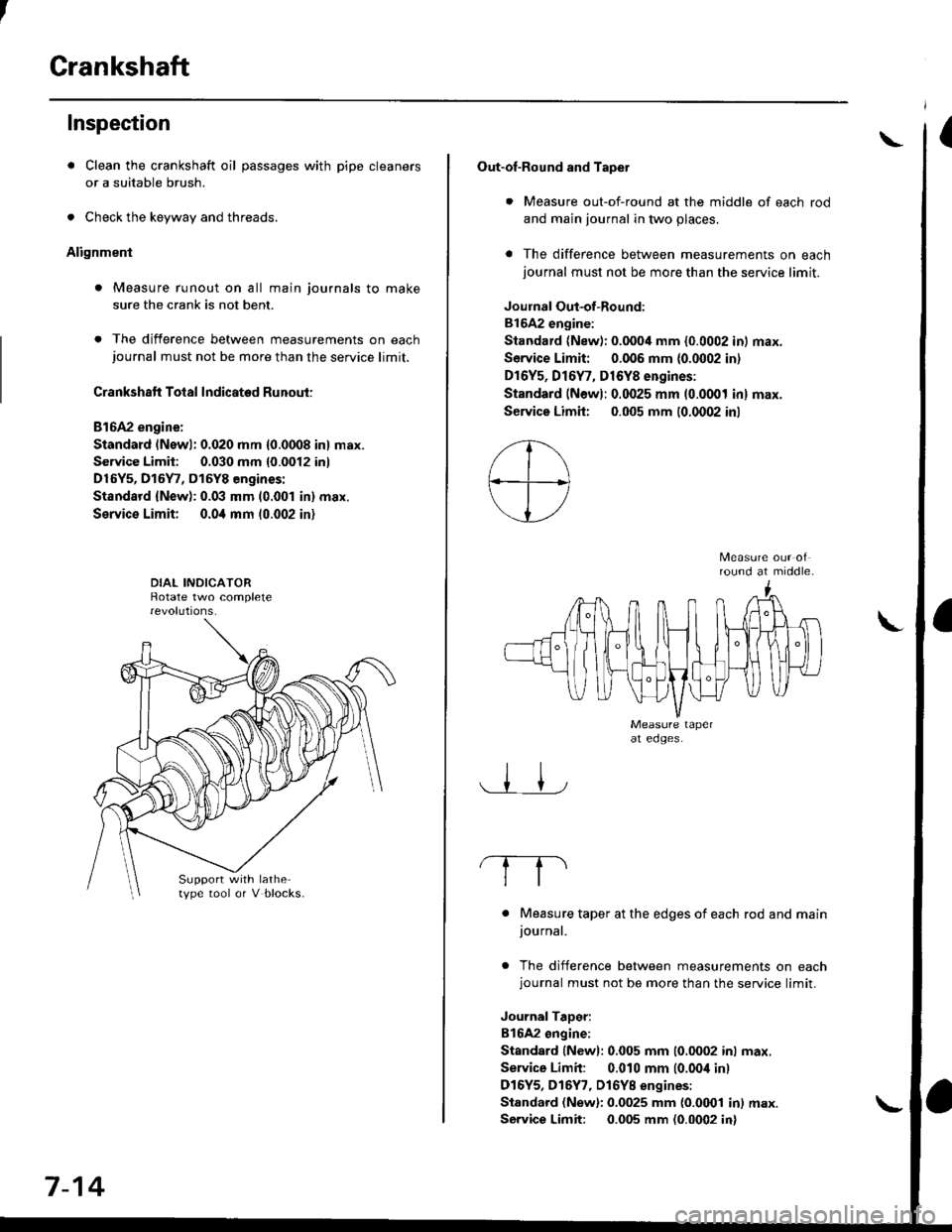

Alignment

. Measure runout on all main journals to make

sure the crank is not bent.

. The difference between measurements on eachjournal must not be more than the service limit.

Crankshaft Total Indicated Runout:

Bl6A2 engine:

Standard (Newl: 0.020 mm {0.0008 in} max.

Service Limit: 0.030 mm {0.0012 inl

D16Y5, D15Y7, D15Y8 engines:

Standsrd {New): 0.03 mm (0.001 in} max.

Service Limit; 0.0i1 mm 10.002 in)

Support with lathetype tool or V blocks.

7-14

Out-of-Round and Tapet

. Measure out-of-round at the middle of each rod

and main journal in two places.

a The difference between measurements on eachjournal must not be more than the service limit.

Joulnal Out-of-Round:

81642 engine:

Standard (New): 0.0004 mm {0.0002 in) max.

Service Limit: 0.006 mm {0.0002 in)

Dr6Y5, Dl6Y7, D16Y8 engines:

Standard (Newl: 0.0025 mm (0.0001 inl max.

Service Limh: 0.005 mm (0.0002 inl

round at middle.

. Measure taper at the edges of each rod and mainjournal.

. The difference between measurements on eachjournal must not be more than the service limit.

JournalTaDer:

B16A2 ongine:

Standard lNewl: 0.005 mm (0.0002 inl max.

Service Limit: 0.010 mm (0.00i1 inl

D16Y5, D16Y7, Dl6YB engines:

Standard (New): 0.0025 mm {0.0001 in) max.

Service Limit: 0.005 mm (0.0002 in)

\

Page 212 of 2189

Pistons

Inspection

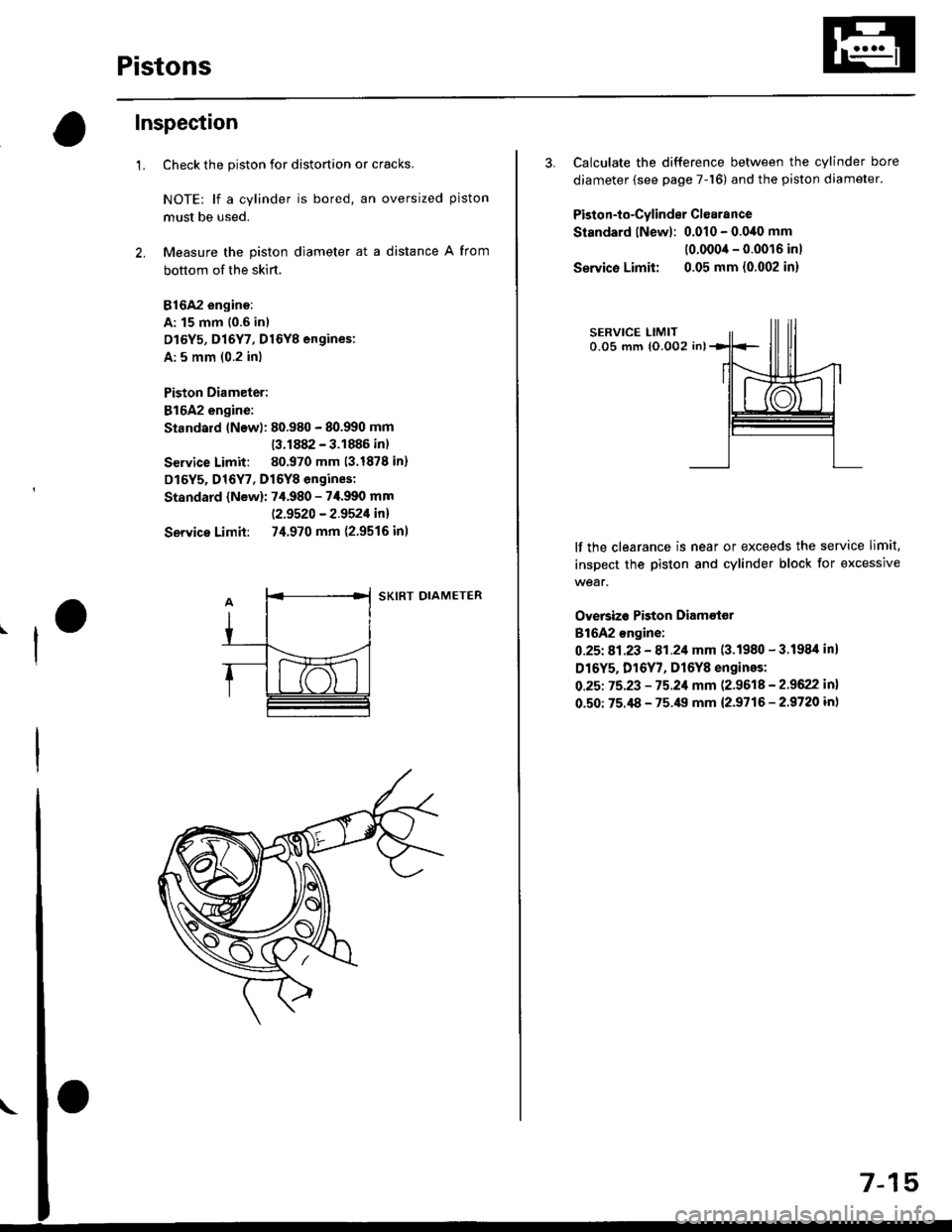

1.Check the piston for distortion or cracks,

NOTE: lf a cylinder is bored. an oversized piston

must be used.

Measure the piston diameter at a distance A from

bottom of the skirt.

816A2 engino:

A: 15 mm 10.6 in)

D16Y5, D16Y7, D16Y8 engines:

A: 5 mm (0.2 inl

Piston Diameter:

816A2 engine:

Standard lNewl: 80.980 - 80.990 mm

13.1882 - 3.1886 in)

Service Limit: 80.970 mm (3.1878 in)

D16Y5, D16Y7, D16Y8 engines:

Standard {New): 7,f.980 - 7i1.990 mm

|.2.9520 - 2.9521in!

Service Limit: 74.970 mm {2.9516 inl

SKIRT DIAMETER

57-1

3. Calculate the difference between the cylinder bore

diameter (see page 7-16) and the piston diameter.

Piston-to-Cylinder Clsarance

Standard lNewl: 0.010 - 0.0,10 mm

(0.0004 - 0.0016 inl

Servico Limit: 0.05 mm {0.002 in}

lf the clearance is near or exceeds the service limit,

inspect the piston and cylinder block for excessive

wear.

Oversizo Piston Diametor

816A2 ongine:

0.25t 81.23 - 81.21 mm (3.1980 - 3.1984 inl

D16Y5. D16Y7, D16Y8 engines:

O.25t 75.23 - 75.21 mm (2.9618 - 2.9622 in)

0.50: 75.i18 - 75.49 mm {2.9716 - 2.9720 in}

Page 213 of 2189

Cylinder Block

Inspection

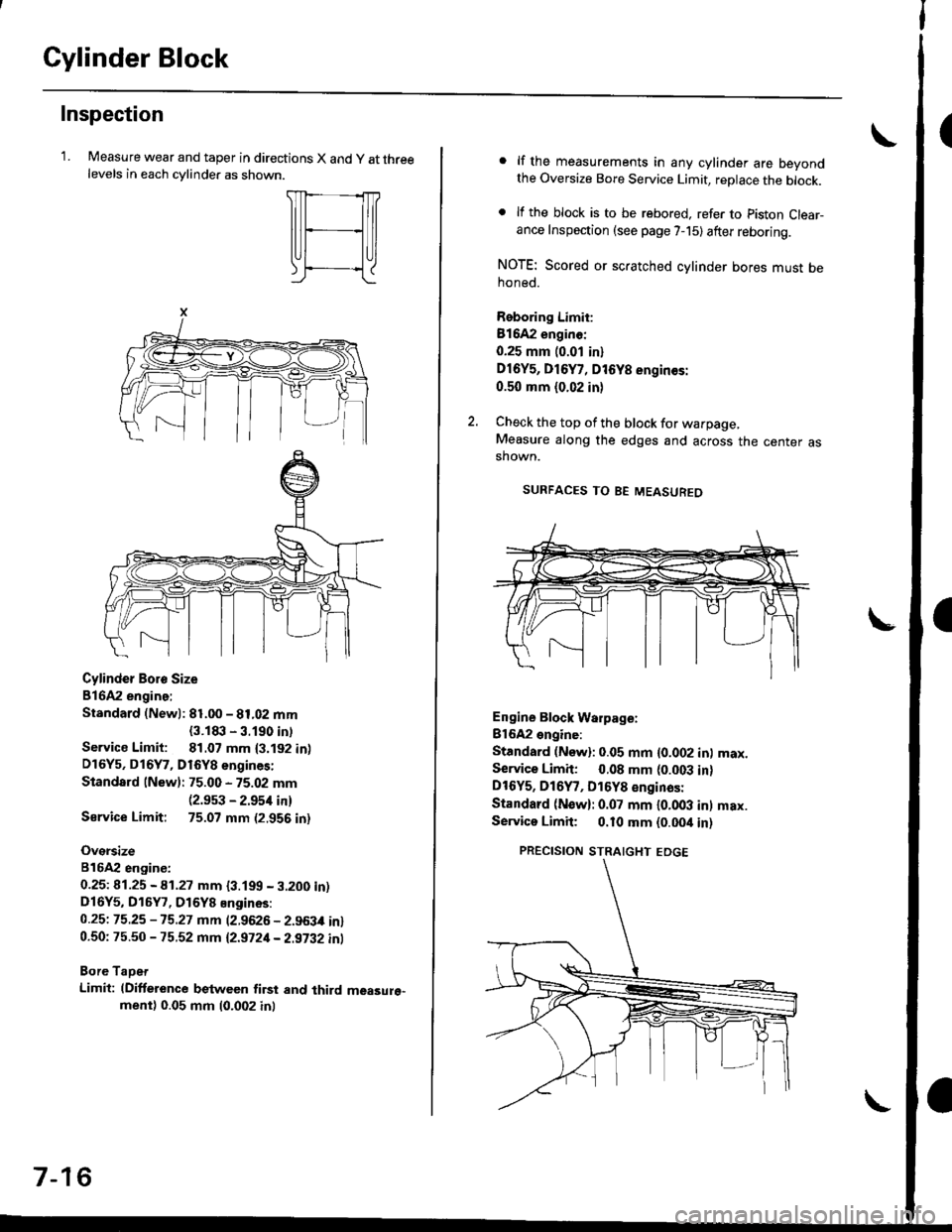

'LMeasure wear and taper in directions X and y at threelevels in each cvlinder as shown.

Cylinder Boro Size

816A2 engine:

Standard (Newl: 81.00 - 81.02 mm

{3.1t|:l - 3.190 intService Limit: 81.07 mm {3.192 in)D16Y5, D16Y7, D16Y8 engines:

Standard lNew): 75.00 - 75.02 mm(2.9s3 - 2.954 in)

Sarvice Limit: 75.07 mm (2.956 in)

Oversize

816A2 engiDe:

0.25t 41.25 - A1.27 mm {3.199 - 3.200 in)D16Y5, D16Y7, D16Y8 Engines:

0.25t 75.25 -15.27 mm (2.9626 - 2.963,0 in)0.50: 75.50 - 75.52 mm 12.9721- 2.9i32 inl

Bore TaDet

Limit: (Difference between first and third measure"ment) 0.05 mm (0.002 inl

7-16

lf the measurements in any cylinder are beyondthe Oversize Bore Service Limit, replace the block.

lf the block is to be rebored. refer to piston Clear-ance Inspection (see page 7-15) after reboring.

NOTE: Scored or scratched cylinder bores must behoned.

Reboring Limit:

Bl642 enginc:

0.25 mm (0.01 in)

Dl6Y5, D16Y7, D16Y8 engin€s:

0.50 mm (0.02 in)

Check the top of the block for warpage,Measure along the edges and across the center asshown.

SURFACES TO BE MEASUREO

Engine Block Warpage:

Bl6A2 engine:

Standard (Now): 0.05 mm {0.002 inl max.Service Limh: 0.08 mm (0.003 in)DtOYs, D16Y7, D16Y8 €nginas:

Standard (N€w): 0.07 mm l0.OO3 inl max.Servica Limit; 0.10 mm {0.00it in)

PRECISION STRAIGHT EDGE

Page 214 of 2189

Cylinder BlockPiston Pins

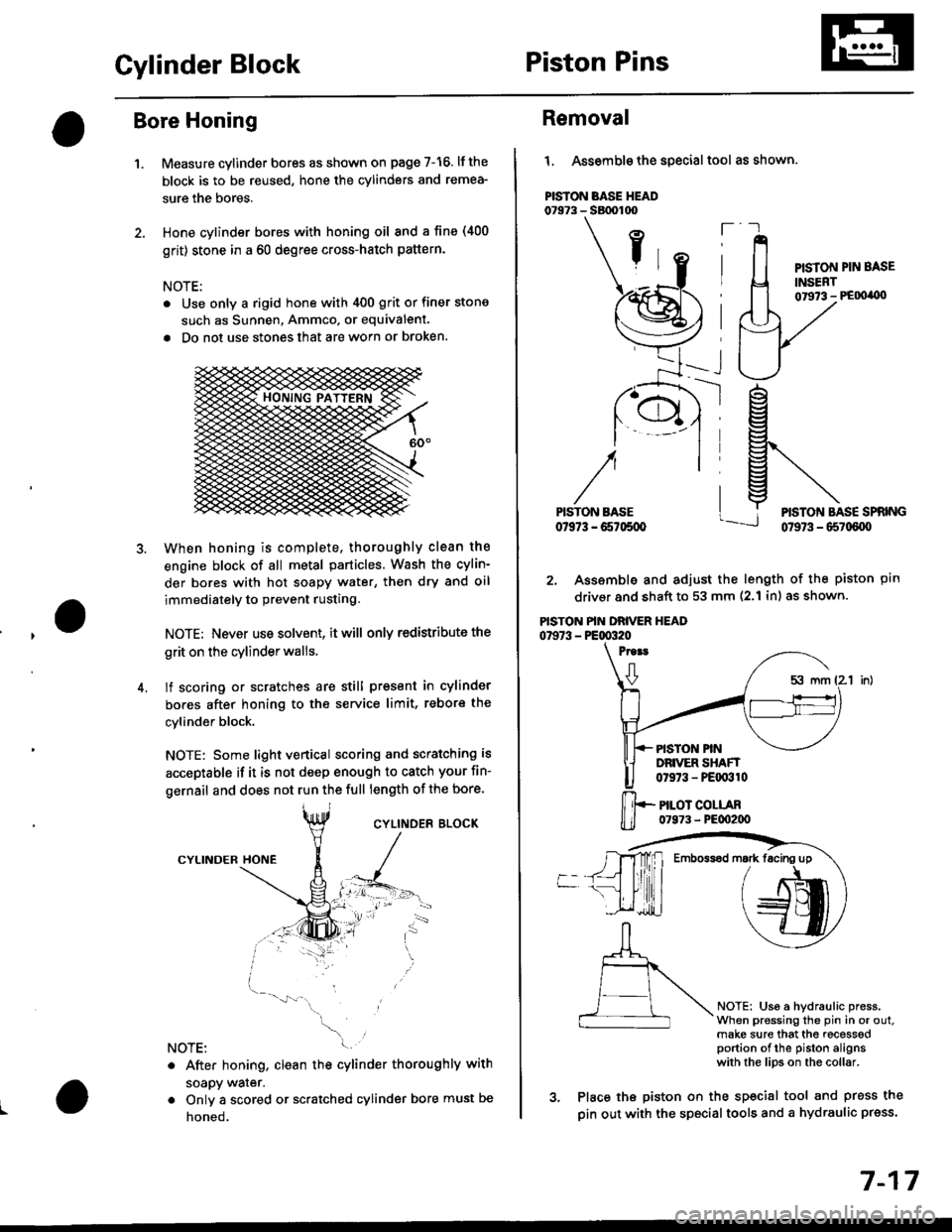

Bore Honing

1.Measure cylinder bores as shown on page 7-16. lf the

block is to be reused, hone the cylinders and remea-

sure the bores.

Hone cylinder bores with honing oil 8nd a fine (400

grit) stone in a 60 degree cross-hatch pattern.

NOTE:

. Use only a rigid hone with 400 grit or finer stone

such as Sunnen, Ammco, or equivalent.

. Do not use stones lhat are worn or broken.

When honing is complete, thoroughly clean the

engine block of all metal particles. Wash the cylin-

der bores with hot soapY water, then dry and oil

immediately to prevent rusting.

NOTE: Never use solvent. it will only redistribute the

grit on the cylinder walls.

lf scoring or scratches are still present in cylinder

bores after honing to the service limit, rebore the

cylinder block.

NOTE: Some light vertical scoring and scratching is

acceptable if it is not deep enough to catch your fin-

gernail and does not run the full length of the bore.

CYLINOES BLOCK

CYLINDER

NOTE:

. After honing, clean the cylinder thoroughly with

soapy warer.

. Onlv a scored or scratched cylinder bore must be

noneo.

Removal

l. Assemble the special tool as shown.

PISTON BASE HEAD07973 - SBtx)too

ft

PISTON PIN BASE

INSERT01973 - PE00'0)

ptn

NOTEi Us6 a hydraulic press.When pressing the pin in or out.make sure that the recesssdportion of the piston alignswith the lips on the collar.

rg

g\

lj*N*,""

2. Assemble and adjust the length of the piston

driver and shaft to 53 mm (2.1 inl as shown.

PISTON PIN DRIVER HEAD07973 - PE00320

Proat

0

PISTON PINDRIVER SHAFT0t973 - PEqr310

PILOT COLLAR07973 - PE00200

3. Place the piston on the sp€cial tool and press the

pin out with the special tools and a hydraulic press.

Emboss6d mark facing up

7-17

Page 215 of 2189

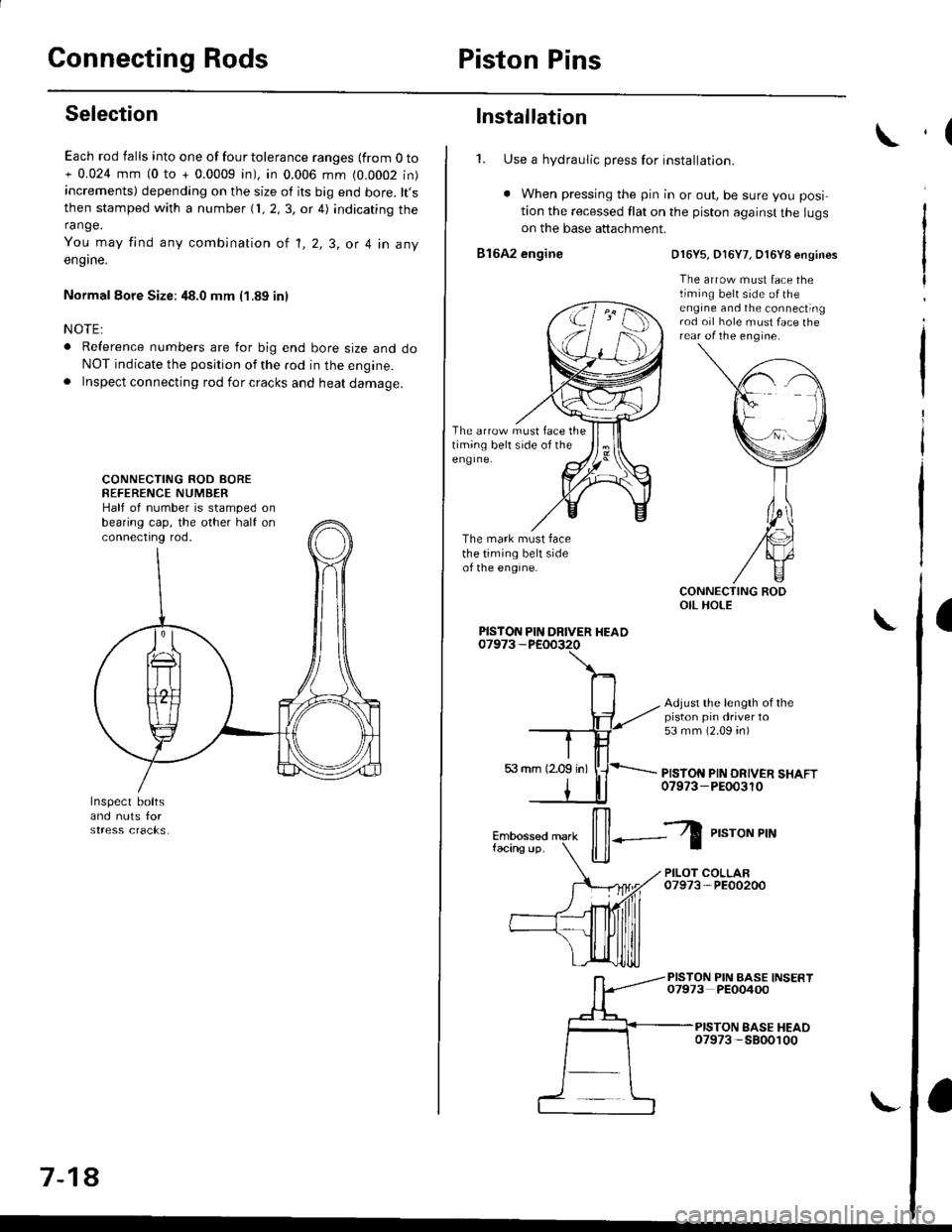

Connecting RodsPiston Pins

Selection

Each rod falls into one of four tolerance ranges {from O to+ 0.024 mm (0 to + 0.0009 in), in 0.006 mm (0.0002 in)increments) depending on the size of its big end bore. lt,sthen stamped with a number {1, 2,3, or 4) indicating therange.

You may find any combination ot l, 2, 3, or 4 in any

engrne.

Normal Eore Size: 48.0 mm (1.89 in)

NOTE:

o Reference numbers are for big end bore size and doNOT indicate the position of the rod in the engine.. Inspect connecting rod for cracks and heat damage.

CONNECTING ROD AOREREFERENCE NUMBERHalf of number is stamped onbearing cap, the other half onconnectrng rod.

7-18

Installation

1. Use a hydraulic press for installation.

. When pressing the pin in or out, be sure you posi

tion the recessed flat on the piston against the lugson the base attachment.

816A2 engine

The arrow must face thetiming belt side of theeng Ine.

The mark must facethe timing belt sideof the engine.

D16Y5, D16Y7, O16Y8 engines

The arrow must face thetiming belt side o{ theengine and the connectingrod oil hole must face therear of the engine.

Adjust the length of thepiston pin driver to53 mm (2.09 4n)

PISTON PIN DRIVER SHAFT07973-PEOo3r0

PISTON PIN DRIVER HEAD

il--Z

P,"roNPrN

PILOT COLLAR07973-PE00200

PISTON PIN BASE INSERT07973 PEO0400

PISTON EASE HEAO07973 -5800100

,(

a

Page 216 of 2189

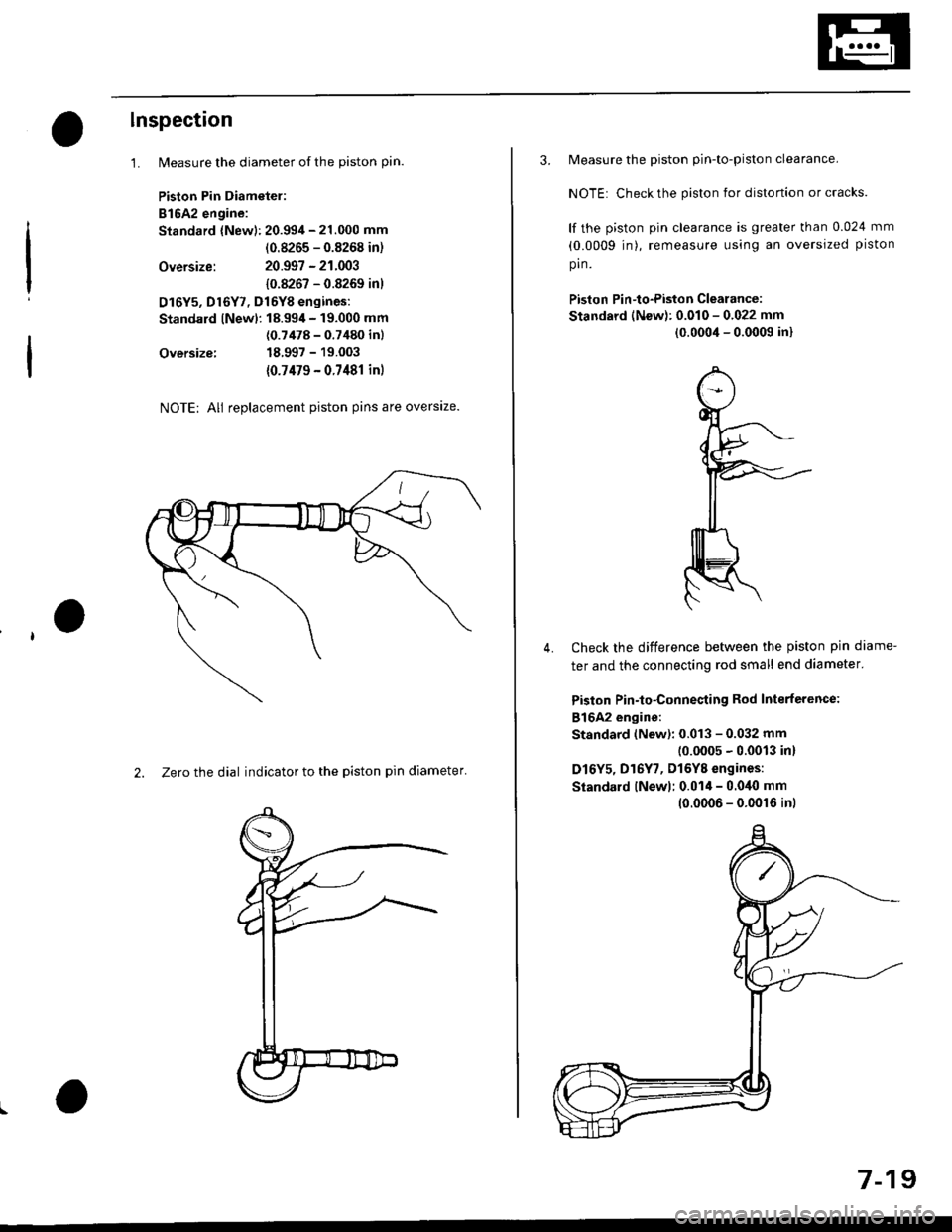

lnspection

1.

Oversize:

Oversize:

NOTE; All replacement piston pins are overslze.

2. Zero the dial indicator to the piston pin diameter'

Measure the diameter of the piston pin.

Piston Pin Diametel:

B16A2 engine:

Standard {New): 20.994 - 21.000 mm

(0.8265 - 0.8268 in)

20.997 - 21.003

10.8267 - 0.8269 inl

D16Y5, Dl6Y7, Dl6YB engines:

Standard lNewl: 18.99,1- 19.000 mm

(0.7478 - 0.7480 inl

18.997 - 19.003

{0.7479 - 0.7481 in)

3. Measure the piston pin-to-piston clearance.

NOTE: Check the piston for distortion or cracks.

lf the piston pin clearance is greater than 0.024 mm

(0.0009 jn), remeasure using an oversized piston

pin.

Piston Pin-to-Piston Clearance:

Standard (New): 0.010 - 0.022 mm

(0.0004 - 0.0009 in)

Check the difference between the piston pin diame-

ter and the connecting rod small end diameter'

Piston Pin-to-Connesting Rod Interterence:

816A2 engine:

Standard (New): 0.013 - 0.032 mm(0.0005 - 0.0013 in)

D16Y5, D16Y7, Dl6YB engines:

Siandard lNewl; 0.014 - 0.040 mm

4.

10.0006 - 0.0016 inl

7-19

Page 217 of 2189

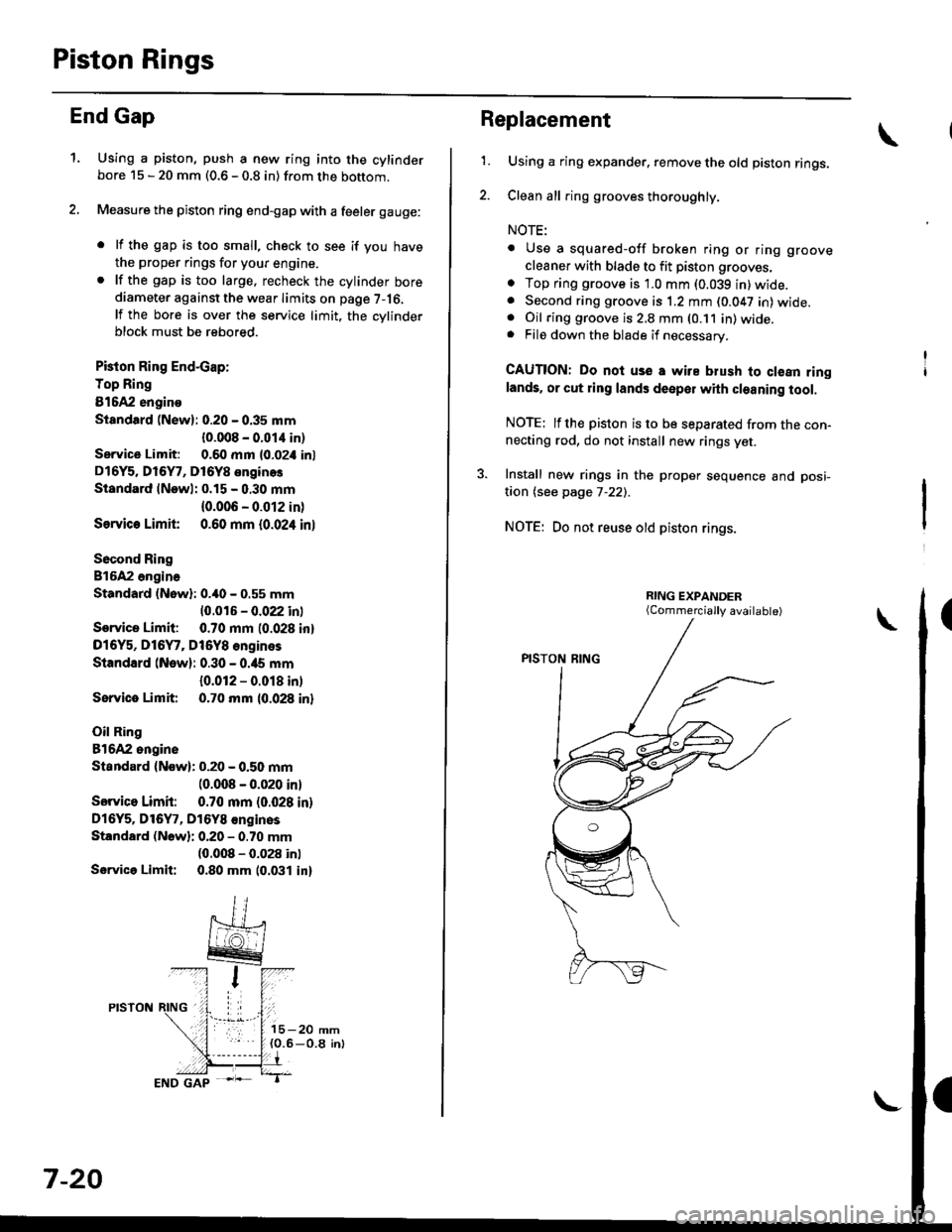

Piston Rings

End Gap

1.Using a piston, push a new ring into the cylinderbore 15 - 20 mm (0.6 - 0.8 in) from the bottom.

Measure the piston ring end-gap with a feeler gauge:

. lf the gap is too small, check to see if you have

the proper rings for your engine.. lf the gap is too large. recheck the cylinder borediameter against the wear limits on page 7-16,

lf the bore is over the service limit, the cvlinderblock must be rebored.

Pkton Ring End-cap:

Top Ring

81642 engino

Siandtrd (New): 0.20 - 0.35 mm

{0.008 - 0.01,1 in)

Service Limit: 0.60 mm l0-02i1 inl

D16Y5. Dl6Y7, D16Y8 enginos

Standard lNewl: 0.15 - 0.30 mm

{0.006 - 0.012 in)

Ssrvic€ Limit 0.60 mm {0.024 inl

Socond Ring

816A2 ongina

Standard (Nowl: 0.40 - 0.55 mm

10.016 - 0.022 inl

Service Limit: 0.70 mm (0.028 inl

D16Y5, D16Y7, Dt6Y8 engines

Standard (New): 0.30 - 0.ia5 mm

{0.012 - 0.018 in)

Sorvice Limit 0.70 mm 10.028 inl

Oil Ring

81642 ongine

Standard {Now): 0.20 - 0.50 mm(0.008 - 0.020 inl

Sorvico Limit: 0.70 mm (0.028 in)

Dl6Y5. Dl6Y7, D16Y8 €nginos

Standard (Nowli 0.20 - 0.70 mm(0.008 - 0.028 inl

Servica Limit: 0.80 mm 10.031 in)

7-20

Replacement

1.Using a ring expander. remove the old piston rings.

Clean all ring grooves thoroughly.

NOTE:

. Use a squared-off broken ring or ring groove

cleaner with blade to fit piston grooves.

o Top ring groove is 1.0 mm (0.039 in)wide.. Second ring groove is 1.2 mm (0.047 in) wide.. Oil ring groove is 2,8 mm (0.11 in) wide.. File down the blade if necessary.

CAUTION: Do noi use a wire blush to clean ringlands. or cut ring lands deepol with cleaning tool.

NOTE: lfthe piston is to be separated from the con-necting rod, do not install new rings yet.

3. Install new rings in the proper sequence and posi-

taon (see page 7-22).

NOTE: Do not reuse old piston rings.

(Commercially available)

Page 220 of 2189

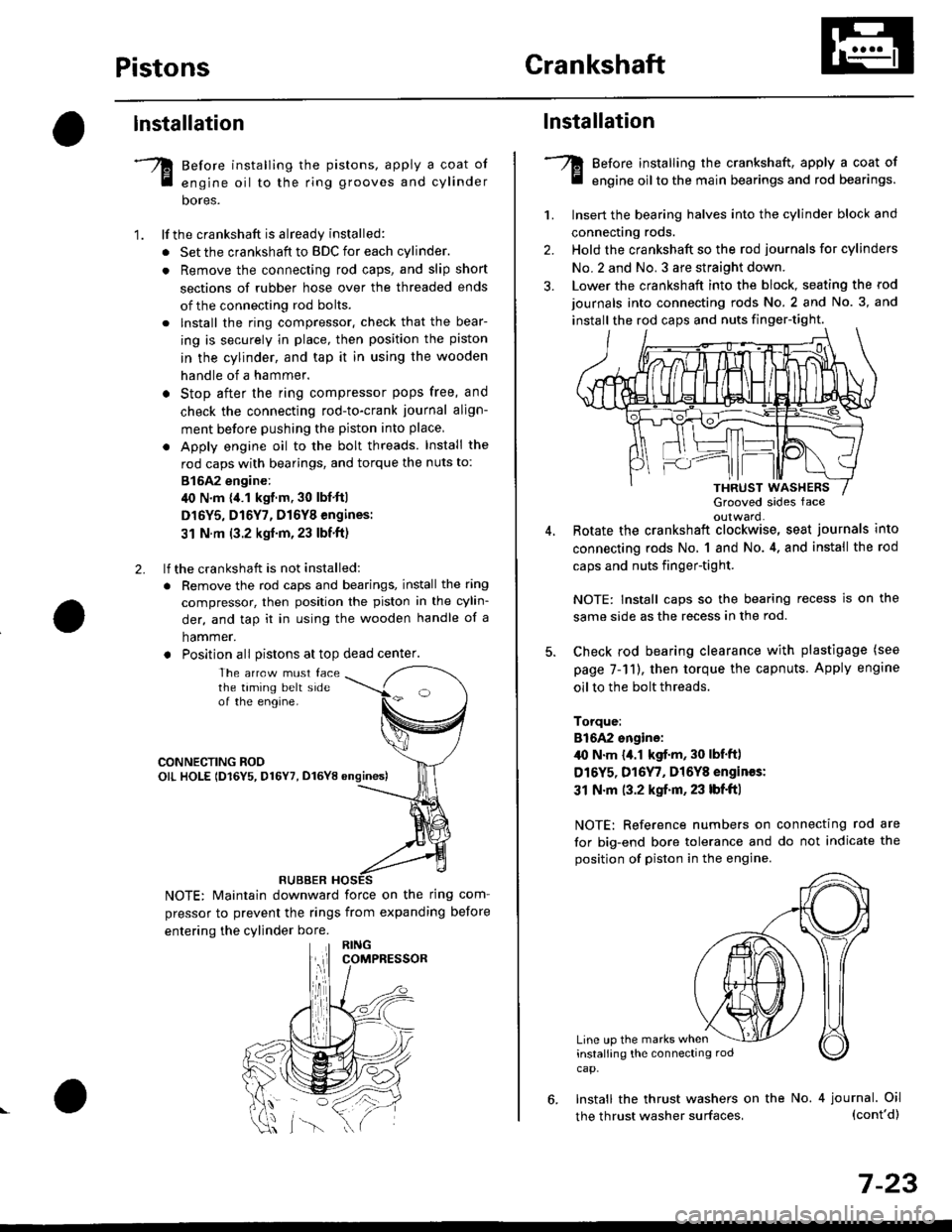

PistonsGrankshaft

lnstallation

Before installing the pistons, apply a coat of

engine oil to the ring grooves and cylinder

bores.

lf the crankshaft is already installed:

. Set the crankshaft to BDC for each cylinder.

. Remove the connecting rod caps, and slip short

sections of rubber hose over the threaded ends

of the connecting rod bolts.

. lnstall the ring compressor. check that the bear-

ing is securely in place, then position the piston

in the cylinder, and tap it in using the wooden

handle of a hammer.

o Stop after the ring compressor pops free, and

check the connecting rod-to-crank journal align-

ment before pushing the piston into place

. Apply engine oil to the bolt threads. Install the

rod caps with bearings, and torque the nuts to:

815A2 engine:

40 N.m {,1.1 kgf.m, 30 lbf'ft|

D16Y5, D16Y7, D16Y8 engines:

31 N.m (3.2 kgf'm,23 lbf'ft)

lf the crankshaft is not installed:

. Remove the rod caps and bearings, install the ring

compressor, then position the piston in the cylin-

der, and tap it in using the wooden handle of a

hammer.

. Position all Distons at top dead center.

1.

2.

The arrcw must facethe taming belt sideof the engine.

CONNECTING ROOOIL HOLE lD16Y5, D16Y7, D16YB ongines)

NOTE: Maintain downward force on the ring com-

pressor to prevent the rings from expanding before

entering the cylinder bore.

RUBBER

,lll

lnstallation

Before installing the crankshaft, apply a coat of

engine oil to the main bearings and rod bearings.

Insert the bearing halves into the cylinder block and

connecting rods.

Hold the crankshaft so the rod journals for cylinders

No.2 and No. 3 are straight down.

Lower the crankshaft into the block, seating the rod

journals into connecting rods No. 2 and No. 3, and

install the rod caps and nuts finger-tight.

1.

2.

3.

5.

Grooved sides faceoulward.Botate the crankshaft clockwise, seat journals into

connecting rods No, 1 and No.4, and install the rod

caps and nuts finger-tight.

NOTE: Install caps so the bearing recess is on the

same side as the recess in the rod.

Check rod bearing clearance with plastigage (see

page 7-11), then torque the capnuts. Apply engine

oil to the bolt threads.

Torque:

816A2 sngine:/l{, N.m {a.l kgf.m, 30 lbf'ftl

D16Y5, D16Y7, Dl6Y8 engines:

31 N.m (3.2 kgf.m, 23 lbf'ft|

NOTE: Reference numbers on connecting rod are

for big-end bore tolerance and do not indicate the

position of piston in the engine.

Line up the marks wheninstalling the connectrng rod

cap.

6. Install the thrust washers on the No. 4 journal. Oil(cont'd)

7-23

the thrust washer surfaces,

Page 1057 of 2189

l.

t

Steering

Speciaf Tools ....."'.....17-2

Manual Steering

Component Locations

lndex ................ ....... 17-3

Inspection and Adiustment

Steering Operation "'......"............... 17-4

Rack Guide Adiustment ................... 17-5

*Steering Wheel

(See power steering section)

*Steering Column

(See power steering sectionl

Steering Gearbox

Removal ................. 17-5

Disassembly ......."" 17-7

ReassemblY ..'......... 17-9

lnstallation ............. 17-13

Power Steering

Component Locations

lndex "......."..... """' 17-15

System DescriPtion

Fluid Flow Diagram .........""............. 17'16

Steering Pump ............'... "........"'...-- 17 -17

Steering Gearbox .".................'...'.'.' 17-20

Troubleshooting

Generaf Troubleshooting ..........--.... 17'22

Noise and Vibration ......................... 17 -26

Ffuid Leaks .............17-28

Inspection and Adiustment

Steering Operation'......."'........'...... 1 7-30

Power Assist Check

With Vehicle Parked .."................ 17-30

Steering Linkage and Gearbox ....." 17-31

Pump Beft ...--.""".. 17-32

Rack Guide Adiustment .'.......'.......'. 17'33

Fluid Replacement .....'.."................. 17-33

Pump Pressure Check .............'....-. " 17 -34

'Steering Wheel

Removal .."'........'... 17-35

lnstallation ............. 17-35

Disassembly/Reassembly ......'.....'.' 17-36

*Steering Column

Removal/lnstallation ....'........... ---.... 17'37

lnspection .............. 17'38

Power Steering Hoses, Lines

Fluid Leakage Inspeetion ............'.... 17-39

Replacement ......".. 17-39

Power Steering PumP

Removal/lnstallation .'.'..'..'............. 17-40

Disassembly ".........17-41

fnspection .......---'." 17'42

Reassembly ..'.........17-44

Steering Gearbox

Removal ....'........."' 17'47

DisassemblY ..........' 17-49

Reassembly '........... 17-55

lnstallation ............. 17-65

Ball Joint Boot Replacement .......'.. 17-68

Ir/

lp