Body HONDA CIVIC 1999 6.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CIVIC, Model: HONDA CIVIC 1999 6.GPages: 2189, PDF Size: 69.39 MB

Page 871 of 2189

Continuously Variable Transmission (CVTI

Special Tools ................ 14-194

Description .................... 14-195

Clutches/Reverse Brake/Planetary

Gear/Pulleys .......... 14-198

power Flow ..............,..... 14-200

Electronic Control SYstem(,96 - 98 Modets) ......14-203

Electronic Control System

('99 - oo Models) " 14-205

Hydraulic Control '....... 14-208

Hydraulic Flow .'..-.....'... '14-212

Park Mechanism .....-...'.' 14-222

Eleqtrical Systom

Component Locations'96 - 98 Models """"""' 14-224,99 - 00 Modets ............. 14-225

TCM Circuit Diagram ('96 - 98 Models) ............. 14-226

TCM Terminal Voltage/Measuring Condiiions ('96 - 98 Models) '.... 14-228

PcM Circuit Oiaqram{A/T Control System: '99 - 00 Models} ...--.... 14-230

PCM Terminal Voltage/Measuring Conditions('99 - 00 Models)

A/4 Control System .'.'...14-232

Troubleshooting Procedures ... . .... .....',........."' '14-234

Symptom-to-ComPonent Chart

Electrical System - '96 - 98 Models ......'..... '14-234

Electrical System -'99 - 00 Models ..'....-..-. '11-210

Electrical Troubleshooting

Troubleshooting Flowcharts('96 - 98 Models) """'11-242

Troubleshooting Flowchart

('99 - 0O Modets) ...... 14-265

Linear Solenoids/lnhibitor Solenoid

Test ......................... . ...... 14-29f

Drive Pulley/Driven Pulley/Secondary Gear

Shaft Speed Sensors

Replacement .........'...... .14-292

Start Clutch Control

Start Clutch Calibration Procedure ....... ....,. 14-293

Hydraulic SYstem

Symptom-to-ComPonent Chart

Hydraulic System '.'.......14-294

Road Test ............................ 14-296

Stall Speed

Test......................... ...... 14-294

Fluid Level

Checking/Changing ....... 14-299

Pressure Testing ................. 14-300

Lower Valve BodY AssemblY

Replacement ..........,... 14-302

ATF Filter

Removal/lnstallation ..... 14-303

Transmission

Transmission

Removal ........... . 14-304

lllustrated Index

Transmission/Lower Valve BodY

Assembly ................. 14-308

Transmission Housing/Flywheel Housing ... 14-310

End Cover/f ntermediate Housing ..........'.'.... 14-312

Transmission Housing/Lower Valve Body Assembly

Removal ..........'.... .. " 14-314

Transmission Housing/Flywhesl Housing

Removal ................. ........ 1+316

End Cover/lntermediate Housing

14-318Removal .........,...............

Manual Valve Body

Disassembly/lnspection/Reassemblv .'.'.'..... 1 4-320

Forward Clutch

lltustrated Index ........................................ 14-321

Disassemblv .................. 14-322

Reassemblv , ,, . ',','......14-324

Secondary Gear Shaft

25 x 35 mm Thrust Shim Selection ..'.'....-... 14-324

Differential

lllustrated lndex ...,.....................,.,...-.-.-...'... 14-329

Backlash Inspection .-....14-329

Bearing Replacement ......'........'....'... ....'... 14-330

Differential Carrier Replacement ........'........ 14-330

Oil Seal Removal ........... 14-331

Oil Seal Installation/Side Clearance ....... . . 14-331

Flywheel Housing Input Shaft Oil Seal

Replacement .....,.... ...'.'.. 14-333

Transmission Housing Bearings

Driven Pulley Shaft Bearing

Replacenient ...................'. . ...................'.. 14-334

Secondary Gear Shaft Bearing

Reolacbment ...................... . .......... . ........ 14-335

Flywheel Housing Beating

Secondary Gear Shaft BearingReo1acement..................,........................... 14-335

Ring Gear Bearing

Replacement......... ........ 14-336

Control Shaft Assembly

Removal/lnstallation ....................'........... 14-336

Transmission

Reassembly .................. 14-338

Flywheel/Drive Plate .. . ...... . ...... ... . ....-.....'.'...14-341

Transmission

lnstalation ..................... 14-348

Cooler Flushing .'......... 14-352

shift cable

Removal/lnstallation....'........." """ 14-354

Adjustment .......'........ 14-355

Shift Lever ........................,. 14'356

Shift Indicator Panel

Adjustment ................ 14-357

ATF Cooler/Hoses

lnsta llation ......,,...... .... 14-357

Page 873 of 2189

Description

The Continuously Variable Transmission (CVT) is an electronically controlled automatic transmission with drive and driv

en Oullevs, and a steel belt. The CVT provides non stage speeds forward and one reverse. The entire unit is positioned in

line with the engine.

Transmission

Around the outside of the flywheel is a ring gear which meshes with the starter pinion when the engine is being staned.

The transmission has four parallel shafts: the input shaft, the drive pulley shaft. the driven pulley shaft, and the secondary

gear shaft. The input shaft is in line with the engine crankshaft. The drive pulley shaft and the driven pulley shaft consist of

movable and fixed face pulleys. Both pulleys are linked by the steel belt.

The input shaft includes the sun gear. The drive pulley shaft includes the forward clutch which mounts the carrier assem-

bly on the forward clutch drum. The carrier assembly includes the pinion gears which mesh with the sun gear and the ring

gear. The ring gear has a hub-mounted reverse brake disc.

The driven pulley shaft includes the start clutch and the secondary drive gear which is integral with the park gear' The sec-

ondary gear shaft is positioned between the secondary drive gear and the final driven gear. The secondary gear shaft

includes the secondary driven gear which serves to change the rotation direction. because the drive pulley shaft and the

driven oullev shaft rotate the same direction. When certain combinations of planetary gears in the transmission are

engaged by the clutches and the reverse brake, power is transmitted from the drive pulley shaft to the driven pulley shaft

to provide E, E, E, and El.

Electronic Control'96 - 98 Models:

The electronic control system consists of the Transmission Control Module (TCM), sensors, three linear solenoids, and a

inhibitor solenoid. Shifting is electronically controlled under all conditions'

The TCM is located below the dashboard, behind the kick panel on the driver's side.'99 - 00 Models:

The electronic control svstem consists of a Powertrain Control Module (PCM), sensors, three linear solenoids and an

inhibitor solenoid. Shifting is electronically controlled under all conditions. A Grade Logic Control System to control shift-

ing in E position while the vehicle is ascending or descending a slope.

The PCM is located below the dashboard, under the kick panel on the passenger's side.

Hydraulic Control

The lower valve body assembly includes the main valve body, the Pressure Low (PL) reguiator valve body, the shift valve

body, the start clutch control valve body, and the secondary valve body. They are positioned on the lower part of the

transmission housing.

The main valve body contains the Pressure High (PH) control valve, the lubrication valve, and the pitot regulator valve.

The secondary valve body contains the PH regulator valve, the clutch reducing valve, the start clutch valve accumulator,

and the shift inhibitor valve. The PL regulator valve body contains the PL regulator valve and the PH-PL control valve

which is ioined to the PH,PL control linear solenoid. The inhibitor solenoid valve is bolted on the PL regulator valve body.

The shift valve body contains the shift valve and the shift control valve. which is joined to the shift control linear solenoid.

The start clutch control valve body contains the start clutch control valve, which is joined to the start clutch control linear

solenoid. The linear solenoids and the inhibitor solenoid are controlled by the TCM or PCM. The manual valve body which

contains the manual valve and the reverse inhibitor valve, is bolted on the intermediate housing.

The ATF pump assembly is located on the transmission housing, and is linked with the input shaft by the sprockets and

the sprocket chain. The pulleys and the clutch receive fluid from their respective feed pipes, and the reverse brake receives

fluid from internal hydraulic circuit.

Shift Control Mechanism

Input from various sensors located throughout the vehicle determines which linear solenoid the TCM or PCM will activate.

Activating the shift control linear solenoid changes the shift control valve pressure, causing the shift valve to move. This

pressurizes the drive pulley pressure to the drive pulley and the driven pulley pressure to the driven pulley and changes

their effective pulley ratio. Activating the start clutch control linear solenoid moves the start clutch control valve. The start

clutch control valve uncovers the port, providing pressure to the start clutch to engage it(cont'd)

14-195

,!

Page 886 of 2189

Description

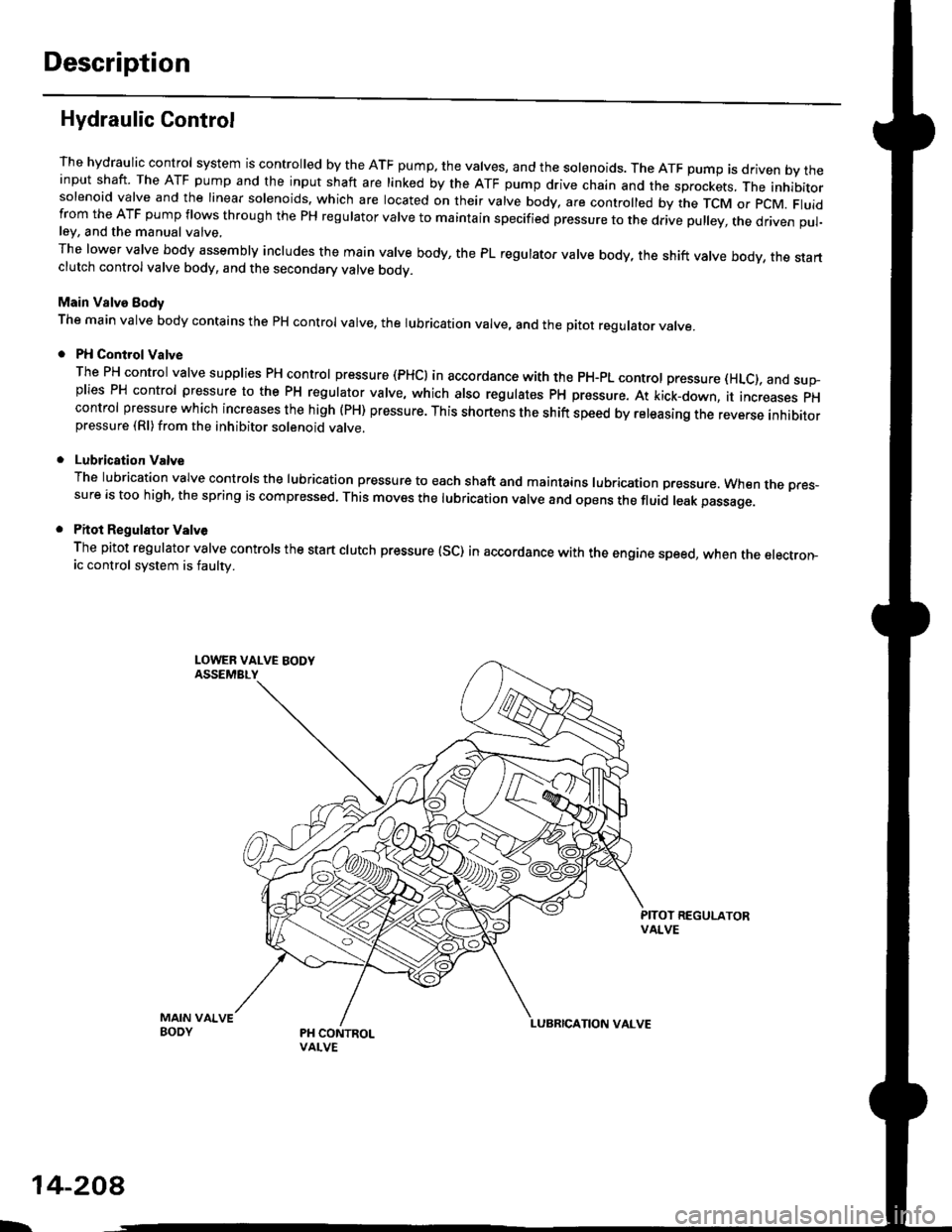

Hydraulic Control

The hydraulic control system is controlled by the ATF pump. the valves, and the solenoids. The ATF pump is driven by theinput shaft. The ATF pump and the input shaft are linked by the ATF pump drive chain and the sprockets, The inhibitorsolenoid valve and the linear solenoids. which are located on their valve body, are controlled by the TCM or pcM. Fluidfrom the ATF pump flows through the PH regulator valve to maintain specified pressure to the drive pulley, the driven pul-ley, and the manual valve,

The lower valve body assembly includes the main valve body, the PL regulator valve body, the shift valve body, the startclutch control valve body, and the secondary valve bodv.

Main Valve Eody

The main valve body contains the pH control valve, the rubrication valve, and the pitot regulator valve.

PH Control Valve

The PH control valve supplies PH control pressure (PHCI in accordance with the pH-pL control pressure (HLc), and sup-plies PH control pressure to the PH regulator valve, which also regulatss PH pressure. At kick-down, it increases pHcontrol pressure which increases the high (PH) pressure. This shortens the shift speed by releasing the reverse inhibitorpressure (Rl)from the inhibitor solenoid valve.

Lubrication Valve

The lubrication valve controls the lubrication pressure to each shaft and maintains lubrication pressure. When rne pres-sure is too high, the spring is compressed. This moves the lubrication valve and opens the fluid leak passage.

Pitot Regulalor Valv6

The pitot regulator valve controls the start clutch pressure (SC) in accordance with the engine speed, when the electron-ic control system is faulw.

MAIN VAIVEBODY

L.

14-208

Page 887 of 2189

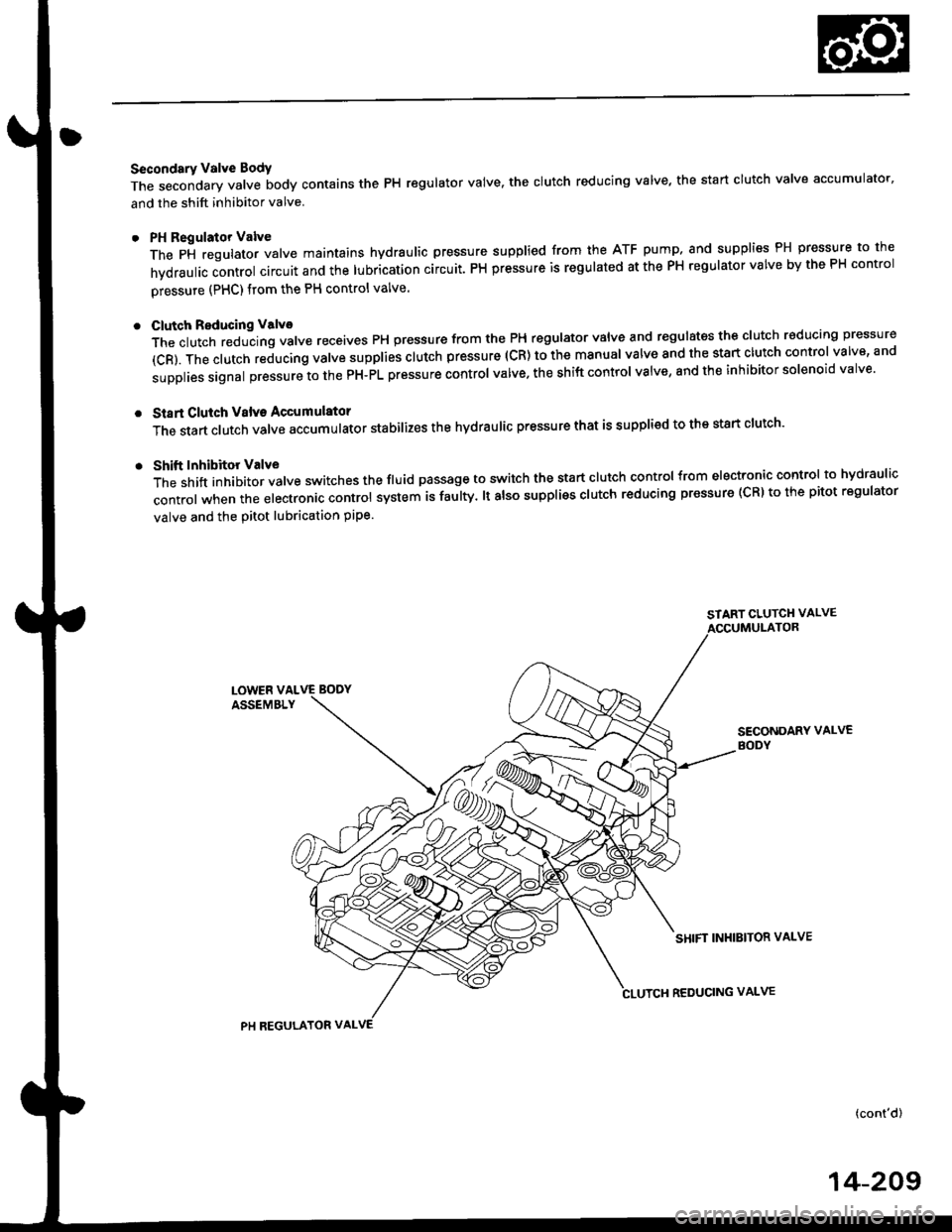

Secondary Valve Body

The secondary valve body contains the PH regulator valve. the clutch reducing valve' the start clutch valve accumulator'

and the shift inhibitor valve

PH Regulator Valve

The pi regulator valve maintains hydraulic pressure supplied from the ATF pump. and supplies PH pressure to the

hvdraulic control circuit and the lubrication circuit. PH pressure is regulated at the PH regulator valve by the PH control

pressure (PHC) from the PH control valve.

Cluteh Reducing Valvo

The clutch reducing valve receives PH pressure from the PH regulator valve and regulates the clutch reducing pressure

(cR). The clutch reducing valve supplies clutch pressure (cR) to the manual valve and the start clutch control valve' and

supplies signal pressure to the PH-PL pressure control valve. the shift control valve, and the inhibitor solenoid valve'

Start Clutch Valv€ Accumulator

The start clutch vatve accumutator stabilizes the hydraulic pressure that is supplied to the start clutch'

Shift Inhibitor Valve

The shift inhibitor valve switches the fluid passage to switch the start clutch control from electronic control to hydraulic

control when the electronic control system is faulty. lt also suppliss clutch reducing pressure (cR) to the pitot regulator

valve and the pitot lubrication pipe.

START CLUTCH VALVE

SECONDARY VALVEBODY

SHIFT INHIBITOE VALVE

(cont'd)

PH REGULATOR VAL

REDUCING VALVE

14-209

Page 888 of 2189

Description

Hydraulic Control {cont'dl

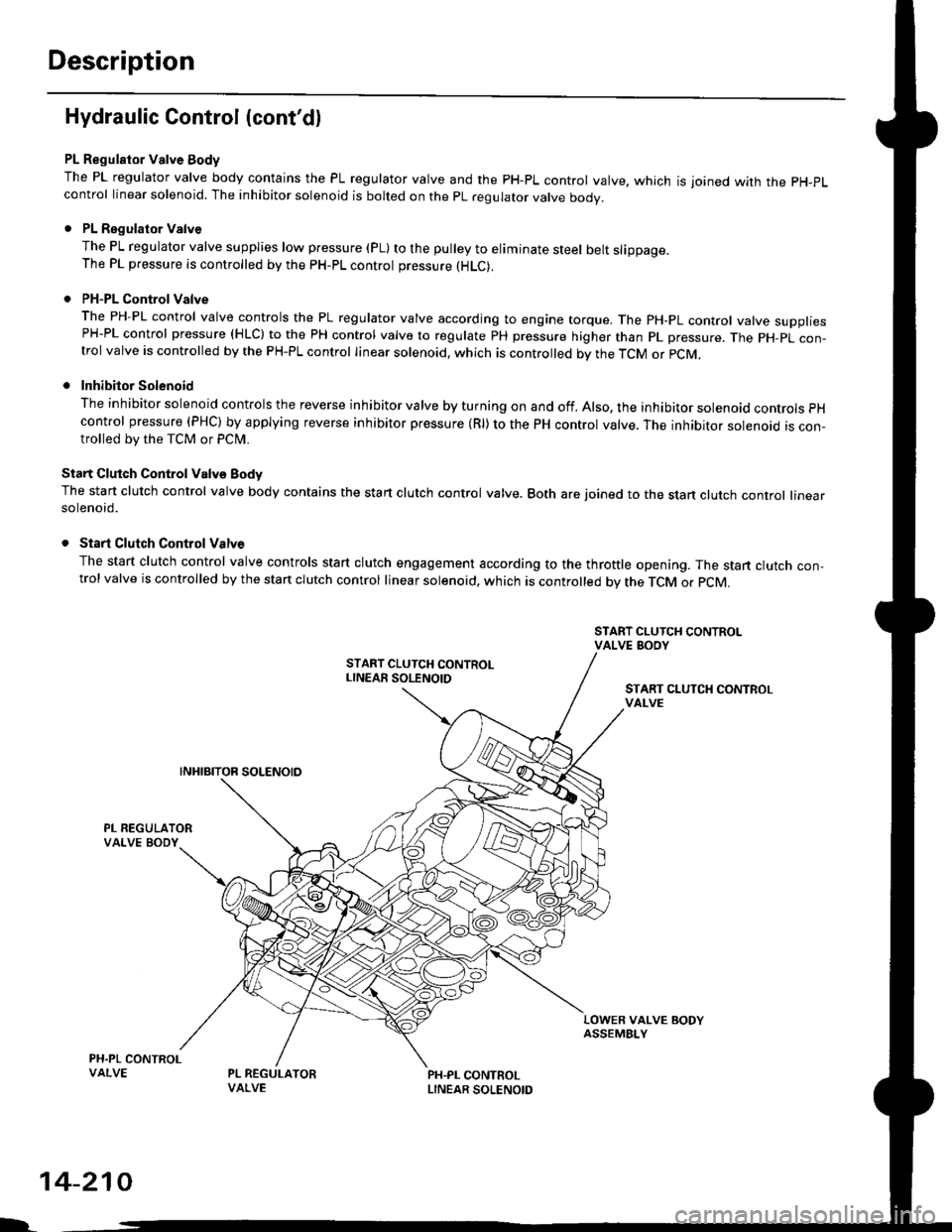

PL Regulator Valve Body

The PL regulator valve body contains the PL regulator valve and the PH-PL control valve. which is joined wirh the pH-pL

control linear solenoid. The inhibitor solenoid is bolted on the pL regulator valve body.

. PL Regulator Valve

The PL regulator valve supplies low p.essure (pL) to the pulley to eliminate steel belt slippage.The PL pressure is controlled by the pH-pL control pressure (HLC).

. PH-PL Control Valve

The PH-PL control valve controls the PL regulator valve according to engine torque. The PH-PL control valve suooliesPH-PL control pressure (HLC) to the PH control valve to regulate PH pressure higher than pL pressure. The pH-pL con-trol valve is controlled by the PH-PL control linear solenoid. which is controlled by the TcM or pcM,

. Inhibitor Solenoid

The inhibitor solenoid controls the reverse inhibitor valve by turning on and off. Also, the inhibitor solenoad controls pH

control pressure (PHC) by applying reverse inhibitor pressure (Rl) to the PH control valve. The inhibitor solenoid is con-trolled by the TCM or Pclvl.

Start Clutch Control Valv€ Body

The start clutch control valve body contains the start clutch control valve. Both are joined to the stan clutch control linearsolenoid.

. Start Clutch Control Valve

The start clutch control valve controls start clutch engagement according to the throttle opening. The start clutch con,trol valve is controlled by the stan clutch control linear solenoid, which is controlled bv the TCM o. pCM.

START CLUTCH CONTROLvAt-vE

LOWER VALVE BODYASSEMBI-Y

PH.PL CONTROLLINEAR SOLENOID

I.

14-210

Page 889 of 2189

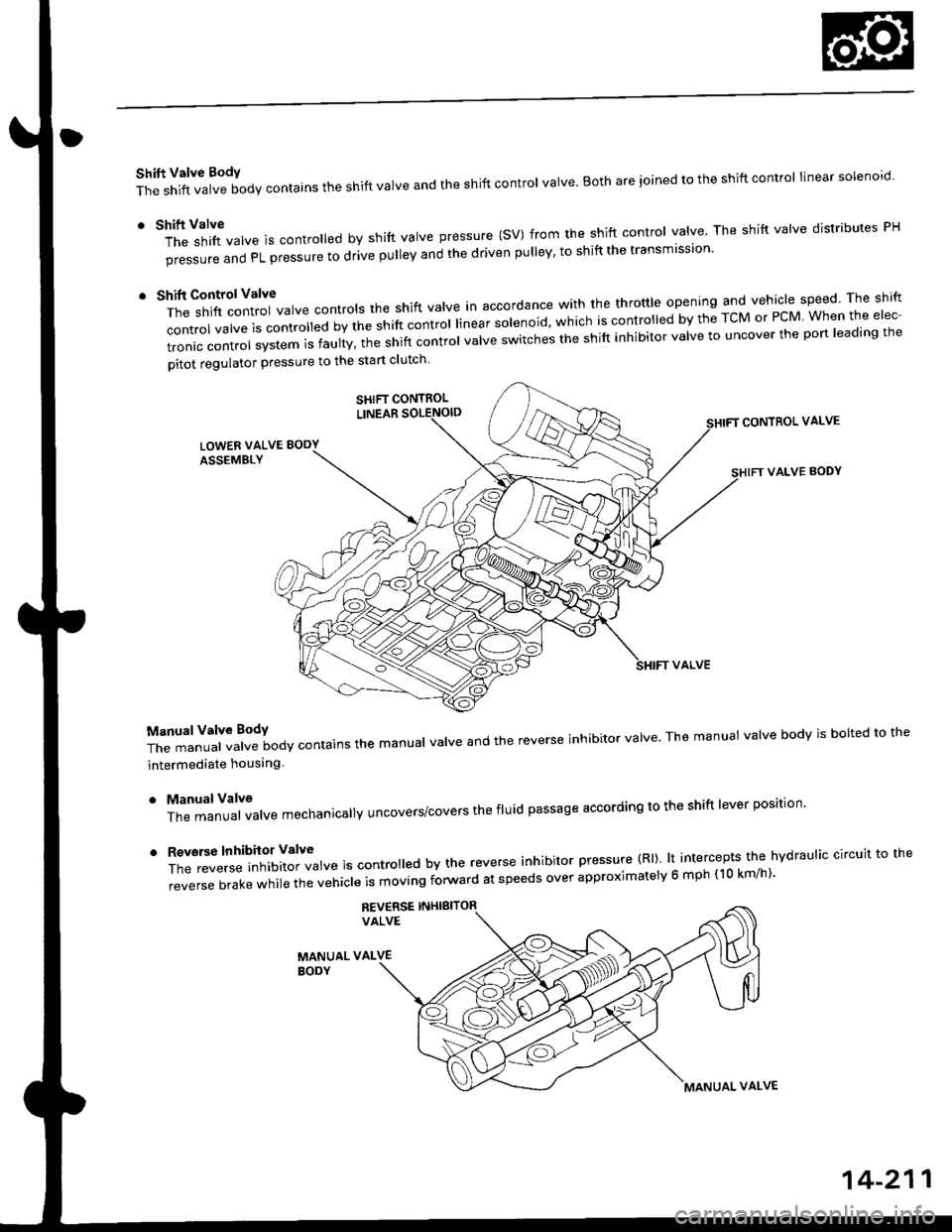

Shift Valve BodY

The shift valve body contains the shift valve and the shift control valve. Both are ioined to the shift control linear solenoro.

r tl'ft1il1rf"","" is controred by shift varve pressure (sV) from the shift contror varve. The shift varve distributes pH

pi""aur" "nO PL pressure to drive pulley and the driven pulley' to shift the transmission'

t t*"rilf:::lr';ivarve contrors the shift varve in accordance with the throttre opening and vehicle speed rhe shift

control valve is convorr"o uv ti" "iirt "ontrol linear solenoid, which is controlled by the TcM or PcM When the elec-

tronic control system is faulty, t;; snift controt uutue "witches the shift inhibitor valve to uncover the port leading the

pitot regulator pressure to the start clutch

CONTROL VALVE

VALVE BODY

T;J:"i"""1ff"t""ilody contains the manuar varve and the reverse inhibitor varve. The manuat varve bodv is borted to the

intermediate houslng

. ManualValve

The manual valve mechanicallY uncovers/covers the fluid passage according to the shift lever position'

'

ff:e;;;.'::'?Xftl::T",* is contro ed by the reverse inhibitor pressure (Rl). lt intercepts the hvdraulic circuit to the

reverse brake while the vehicle is moving forward at speeds over approximatelv 6 mph (10 km/h)'

REV€RSE INHIBITORVALVE

MANUAL VALVEBODY

SHIFT CONTROL

MANUAL VALVE

14-211

Page 927 of 2189

Electrical Troubleshooting (,96 - 9g Modelsl

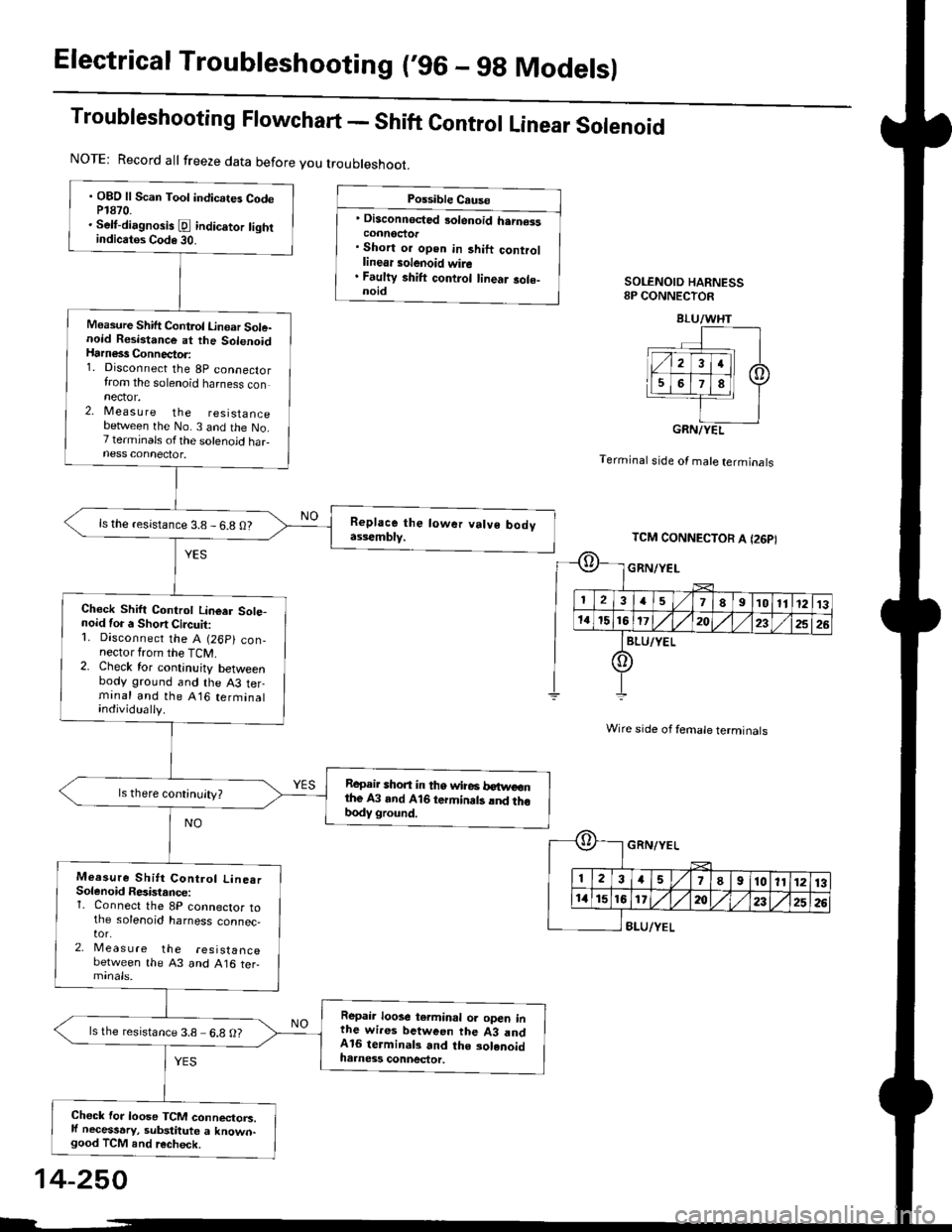

Troubleshooting Flowchart - Shift Control Linear Solenoid

Possible Cause

' Disconnected 3olenoid h.rn€isconnoctor. Short or open in 3hift controllinear solenoid wire. Faulty shift control linear sole-noidSOLENOID HARNESS8P CONNECTOR

Terminal stde of male terminals

Wire side of female terminals

8LU/YEL

NOTE: Record all freeze data before you troubleshoot.

. OBD ll Scan Toot indicates CodeP1870.. Selt-dirgnosis [d indic.tor tightindicatos Code 30.

Measure Shift Control Linoar Sole-noid Resistance at the SolenoidHarness Connector:1. Disconnect the 8p connectorfrom the solenoid harness connector.2, Measu re the resistancebetlveen the No. 3 and the No.7 terminals ofthe solenoid haFness connector.

ls the resistance 3.8 - 6.8 O?

Check Shift Controt Linear Sote-noid for a Short Circuit:1. Disconnect the A (26p) con,nector from the TCM.2. Check for continuity betweenbody ground and the A3 terminal and the A16 terminalindividually.

Repair shon in tho wire6 betweonthe A3 and A16 termin.ts lnd thobody ground.

Measure Shitt Control Line.rSolenoid Resistance:1. Connect the 8P connector tothe solenoid harness connec,tor.2, Meas u re the resistancebetween the 43 and A16 ter-

Repair loose terminal oa open inthe wires between the 43 andA16 terminal3 and the solenoidharness connector.

ls the resistance 3.8 6.8 O?

Chock for loose TCM connectorc.ll necessary, substitute a known-good TCM and recheck.

BLU/WHT

GRN/YEL

TCM CONNECTOR A I26PI

GRN/YEL

ll 12l:

IriGlx

1578910111213

172t)232526

14-250

Page 928 of 2189

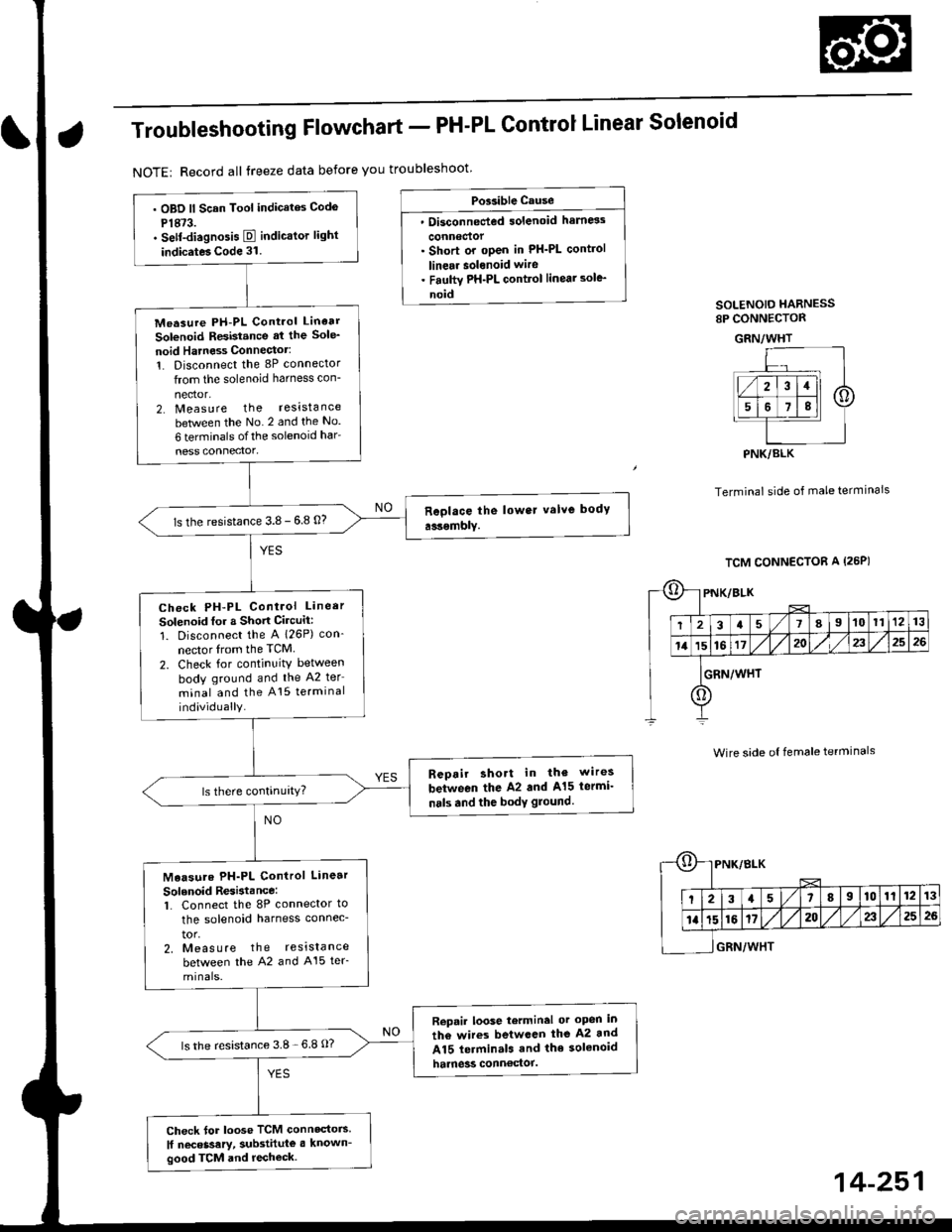

Troub|eshootingF|owchart_PH-PLControJLinearSo|enoid

NOTE| Record all treeze data before you troubleshoot

Possible cause

' Disconnected solenoid harness

connectof. Short or oPen in PH_PL control

linear solenoid wire. Faulty PH-PL control linear sole_

noidSOLENOIO HARNESS8P CONNECTOR

GRN/WHT

Terminal side of male termlnals

Wire side ol female terminals

. OBD ll Scan Tool indicates Codo

P1873.. sef-diagnosis E indicalor light

indicat6 Code 31.

Measure PH-PL Control Linear

Solenoid Resistance at the Sole_

noid Hatness Connectot:1. Disconnect the 8P connector

from the solenoid harness con-

nector,2. Measure the resistance

between the No 2 and the No.

6 terminals ofthe solenoid har

ness connector'

ls the resistance 3.8 - 6.8 0?

Check PH-PL Control Lineer

Solenoid for a Short Circuit:

1. Disconnect the A 126P) con-

nector lrom the TCM

2. Check for continuity between

body ground and the A2 ter

minal and the A15 terminal

individually.

Repair short in th€ wires

between the A2 and A15 lermi_

nals and the body glound.

Measute PH-PL Control Linear

Solenoid Resi3tance:1. Connect the 8P connector to

the solenoid harness connec-

tor,2, Meas u re the reslslance

between the ,q2 and A15 ter_

Rep.il loose tetminal or oPen in

th6 wires betwccn the A2 and

A15 lerminals and the solenoid

harness conn€ctol.

lsthe resistance 3.8-6 8 O?

Check for loose TCM connactors

lf neceasery, Substitute a known-good TCM and rechock.

PNK/BLK

TCM CONNECTOR A (26P)

oPNK/BLK

I234578I10l11213

11't5161720/,,/232526

IGRN/wHr

o

*r}l

t'T,

E[

PNK/8LK

3a5I910111213

1620232526

GRN/WHT

14-251

Page 929 of 2189

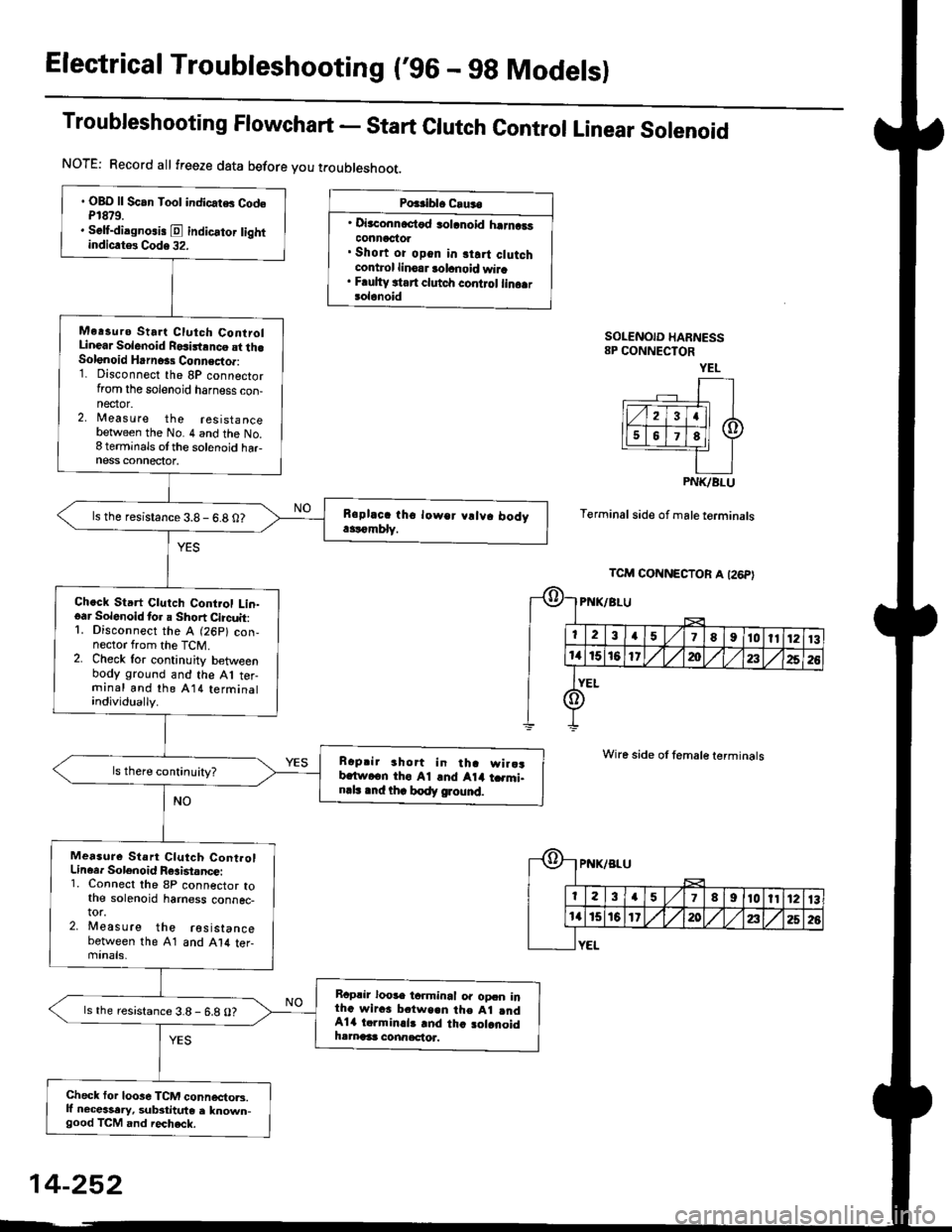

Electrical Troubleshooting ('96 - gg Modelsl

Troubleshooting Flowchart - start clutch control Linear solenoid

NOTE: Record all freeze data before you t.oubleshoot.

Po$iblo C.u.o

' Di3aonnoctod solanoid harncatconnactol. Short or opon in start clutchcontrol linoar tolanoid wira. Faulty ttart clutch control lino.rsolanoid

SOLENOID HARNESS8P CONNECTOR

Terminal side of male terminals

Wire side of female terminals

. OBO ll Scan Tool indicatG CodeP1879.. Self-dilgno.is E indicator lightindiclt$ Code 32.

Me.suro Sta.t Clutch ControlLinear Solenoid Rosirtrnco st th.Solenoid Hrrn6rs Connecto.:1. Disconnect the 8P connectorfrom the solenoid harness con-nector.2, Measure the resistancebetween the No. 4 and the No.8 terminals otthe solenoid har-ness connectot.

ls the resistance 3.8 - 6.8 0?

Chock Start Clutch Control Lin-oar Solenoid tor a Short Circuit:1. Disconnect the A (26p) con,nector from the TcM.2. Check lor continuity betweenbody ground and the A1 ter-rninal and lhe Al il terminalindividually.

Raprir 3hort in tha wira3b.ftvcen tho A1 .nd Atil t .mi.n.l. .nd thr body ground.

Measure Stan Clutch Cont.olLineer Solenoid F6aist.ncei1. Connect the 8P connector tothe solenoid harness connec-tor.2. Meas u re the resistancebetween the 41 and Al4 ter-minals,

Rcplir loose tcrminal or oDcn inthG wiras b.tween the Al rndAla torminal3 rnd tha 3olanoidhamaas connactor.

ls the resistance 3.8- 6.8 O?

Check for loose TCM connecto.s.lf necessary, substitute a known-good TCM and iecheck.

YEL

PNK/BLU

TCM CONNECTOR A I26P}

-{r-

E

PNK/BLU

23a51I910ll1213

a15t61'20a252G

YEL

14-252

Page 930 of 2189

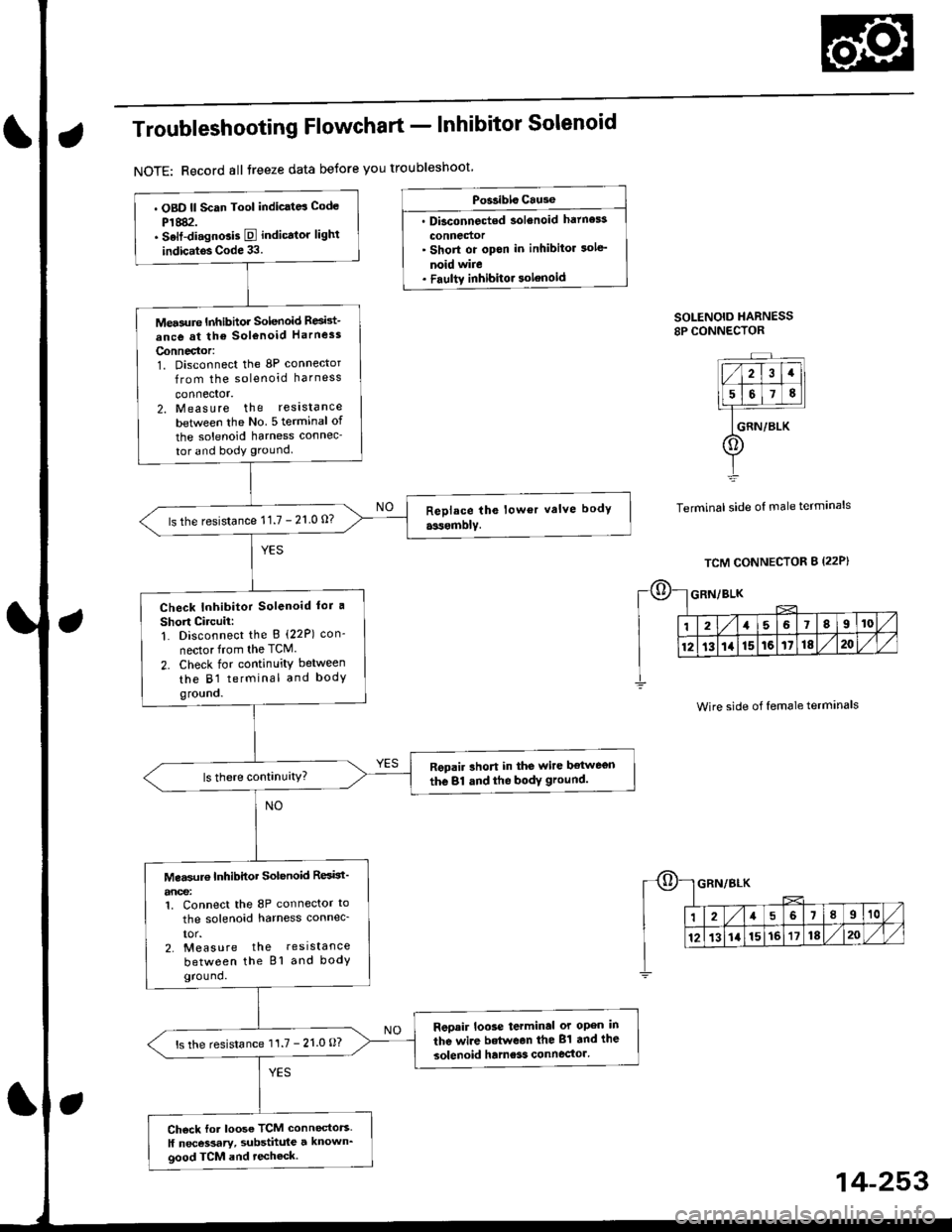

Troubleshooting Flowchart - Inhibitor Solenoid

NOTE: Record all treeze data betore you troubleshoot

Po$ibls Cause

. Dbconnected solenoid hatness

connedor' Short or opon in inhibitor sole'

noid wire. Faultv inhibitor solenoid

SOLENOID HARNESS8P CONNECTOR

Terminal side of male terminals

. OBD ll Scan Tool indic.td Code

P1882.. Selt-di.gnGis E indicator lighl

indic.tos Code 33.

Mea3ure Inhibhor Solenoid Resid-

ance at the sol€noid Harness

Connector:1. Disconnect the 8P connector

from the solenoid harness

connector.2. Measure the reslstance

betlveen the No 5 terminal of

the solenoid harness connec-

tor and body ground.

ls the resistance 11.7 - 21 0 0?

Check Inhibitor Solenoid lor a

Short Circuii:1. Disconnect the B (22P) con-

nector from the TCM.

2. Check for continuity between

the B1 terminal and bodygro!no.

Repair rhort in the wire ltetwegn

the 81 dnd the bodY ground.

Mea$rr€ Inhibitor Solenoid ResBt'

anoe:1. Connect the 8P connector to

the solenoid harness connec_

IOr.2. Measure the resistance

between the Bl and bodyground.

Reoair loose terminal or open in

the wire betwean the 81 and the

solenoid hame3s connector'ls the resistance 11.7 - 21.0 O?

Ch6ck for loose TCM connectors.

ll necessary, substhule a known_good TCM and techeck.

Wire side of female terminals

14-253