ac line HONDA CIVIC 1999 6.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CIVIC, Model: HONDA CIVIC 1999 6.GPages: 2189, PDF Size: 69.39 MB

Page 1360 of 2189

Body ('98 model)

Opener and Latch

Hood Latch Cover Replacement ""'.' 20-132

Hatch Handle Replacement ..'.'....'...' 20-132

Hatch Latch/Lock CYlinder

Replacement "...'.."..'.'... 20-133

Outline of '98 Model Changes

. The hood latch cover was added

. The hatch handle was added (3D)

Page 1364 of 2189

Body ('99 model)

Dashboard

Center Panel Removal and

lnstallation

Bumpers

Front Grille Removal and

lnstallation

Front Air Spoiler Replacement ."'.....

Seats

Front Seat DisassemblY and

ReassemblY 20-138

Front Seat Torsion Bar

Replacement '.'...".'....'... 20-139

Emblems

tnstallation 20-140

20-136

20-136

20-137

Outline of '99 Model Changes

The center Danel removal and installation procedures are different'

The front grille removal and installation procedures are different'

The front air spoiler has been added for some models of 2D'

A height-adjustable driver's seat was added to some models'

Emblems were added for some models ot 2D'

Page 1367 of 2189

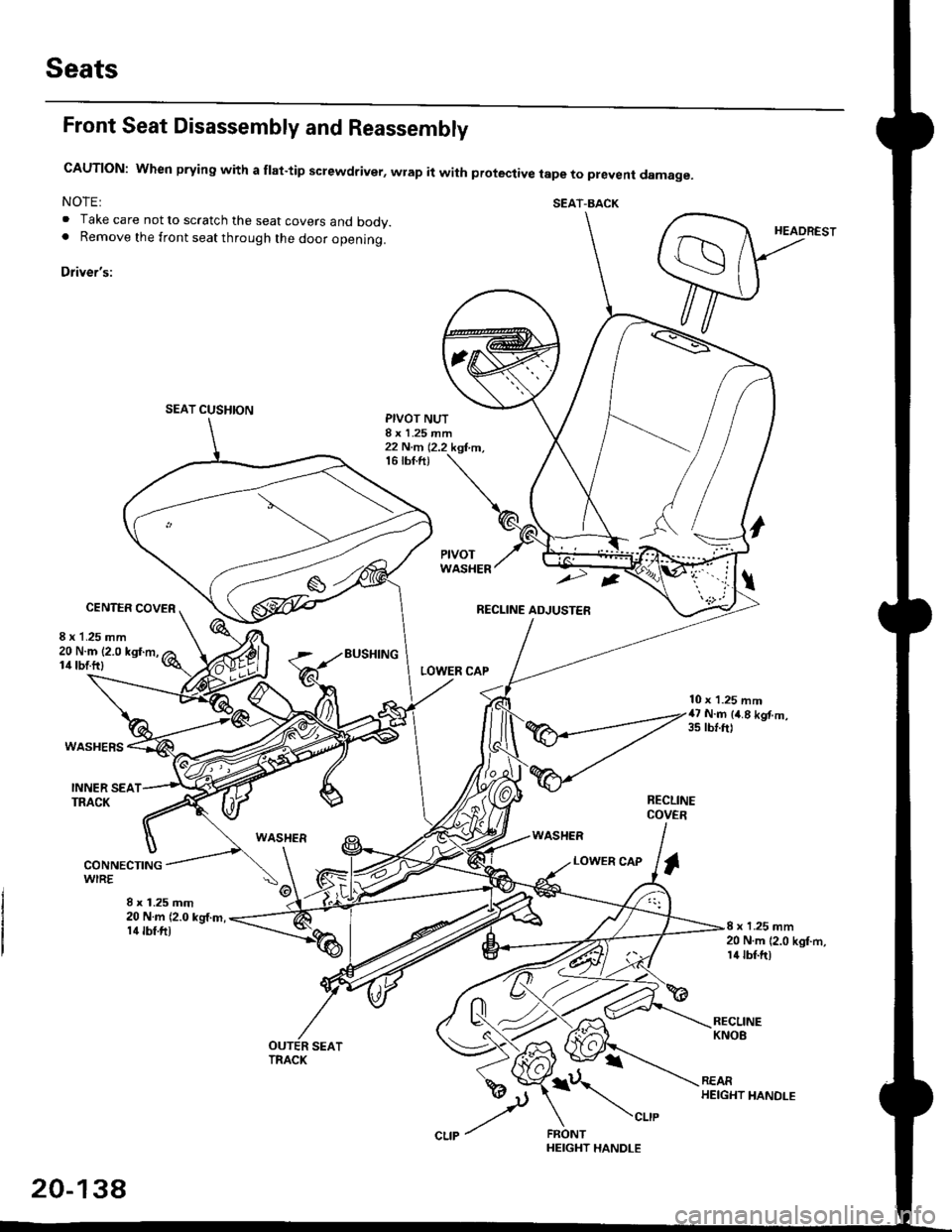

Seats

Front Seat Disassembly and Reassembly

CAUTION: When prying with a flat-tip screwdriver, wrap it with protective tape to prevent damage.

NOTE: SEAT-BACK. Take care not to scratch the seat covers and body.. Remove the front seat through the door openlng.

Driver's:

SEAT CUSHION

HEADREST

PIVOT NUTI x 1.25 mm22 N.m 12.2 kgf,m,16 tbf.ft)

CENTER COVER

8 x 1.25 mm

LOWER CAP

RECLINE ADJUSTER

WASHER

20 N.m 12.0 kgf.m,lil lbtftl

WASHERS

EUSHING

10 x 1.25 mm47 N.m (4.8 kgf.m,3s rbl.ft)

INNER SEATTRACKRECLINECOVER

WASHER

8 x 1.25 mm20 N.m (2.0 kg,f.m,14 tbf.fit

LOWER CAPI

8 x 1.25 mm20 N.m {2.0 kgI.rn,l4 tbf.ft)

i\",-,"

20-13A

HEIGHT HANDLE

Page 1370 of 2189

Body {'00 model}

Seat Belts

Child Seat Anchor Plate Removal/

f nstallation 20-142

Emblem

f nstallation 20-144

Outline of '00 Model Changes

The child seat anchor plate removal and installation procedures are different'

An emblem was added for some model of 3D.

Page 1380 of 2189

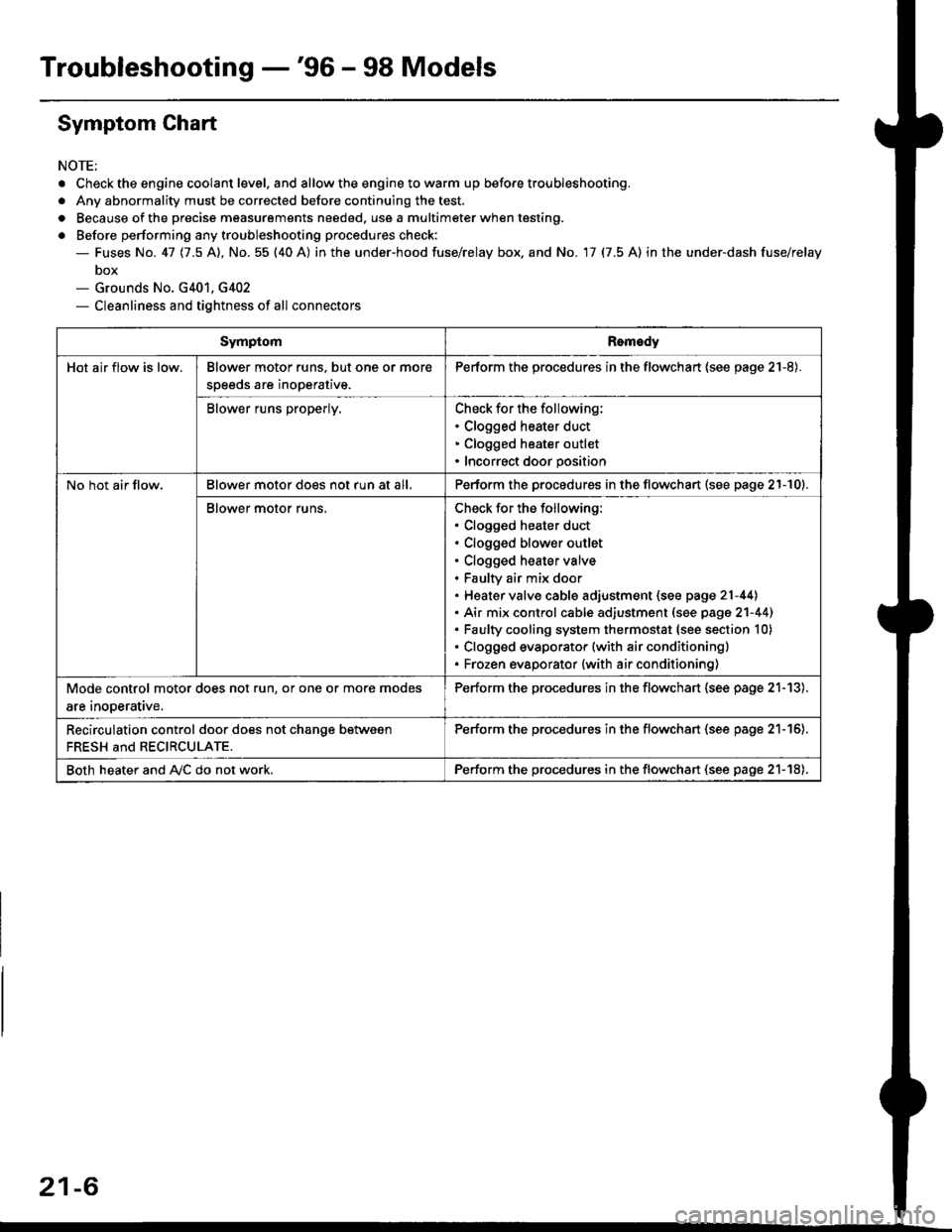

Troubleshooting -'96 - 98 Models

Symptom Chart

NOTE;

. Check the engine coolant level. and allow the engine to warm up before troubleshooting.

. Any abnormality must be corrected before continuing the test.

. Because of the precise measurements needed. use a multimeter when testing.

o Before performing any troubleshooting procedures check:- Fuses No. 41 11.5 Al, No. 55 (40 A) in the under-hood fuse/relay box. and No. 17 (7.5 A) in the under-dash fuse/relay

box- Grounds No. G401, G402- Cleanliness and tightness of all connectors

SymptomRomedy

Hot air flow is low.Blower motor runs. but one or more

speeds are inoperative.

Perform the procedures in the flowchart (see page 21-8).

Blower runs properly.Check for the following:. Clogged heater duct. Clogged heater outlet. Incorrect door position

No hot air flow.Blower motor does not run at all,Perform the procedures in the flowchart (see page 21-10).

Blower motor runs.Check for the following:. Clogged heater duct. Clogged blower outlet. Clogged heater valve. Faultv air mix door. Heater valve cable adjustment (see page 21-44). Air mix control cable adiustment (see page 2'l-441. Faulty cooling system thermostat (see section 10). Clogged evaporator (with air conditioning). Frozen evaporator {with air conditioning)

Mode control motor does not run, or one or more modes

are inooerative.

Perform the procedures in the flowchart (see page 21-13).

Recirculation control door does not chanqe between

FRESH and RECIRCULATE.

Perform the procedu.es in the flowchan (see page 21-16).

Both heater and A,/C do not work.Perform the procedures in the flowchart (see page 21-18),

21-6

Page 1393 of 2189

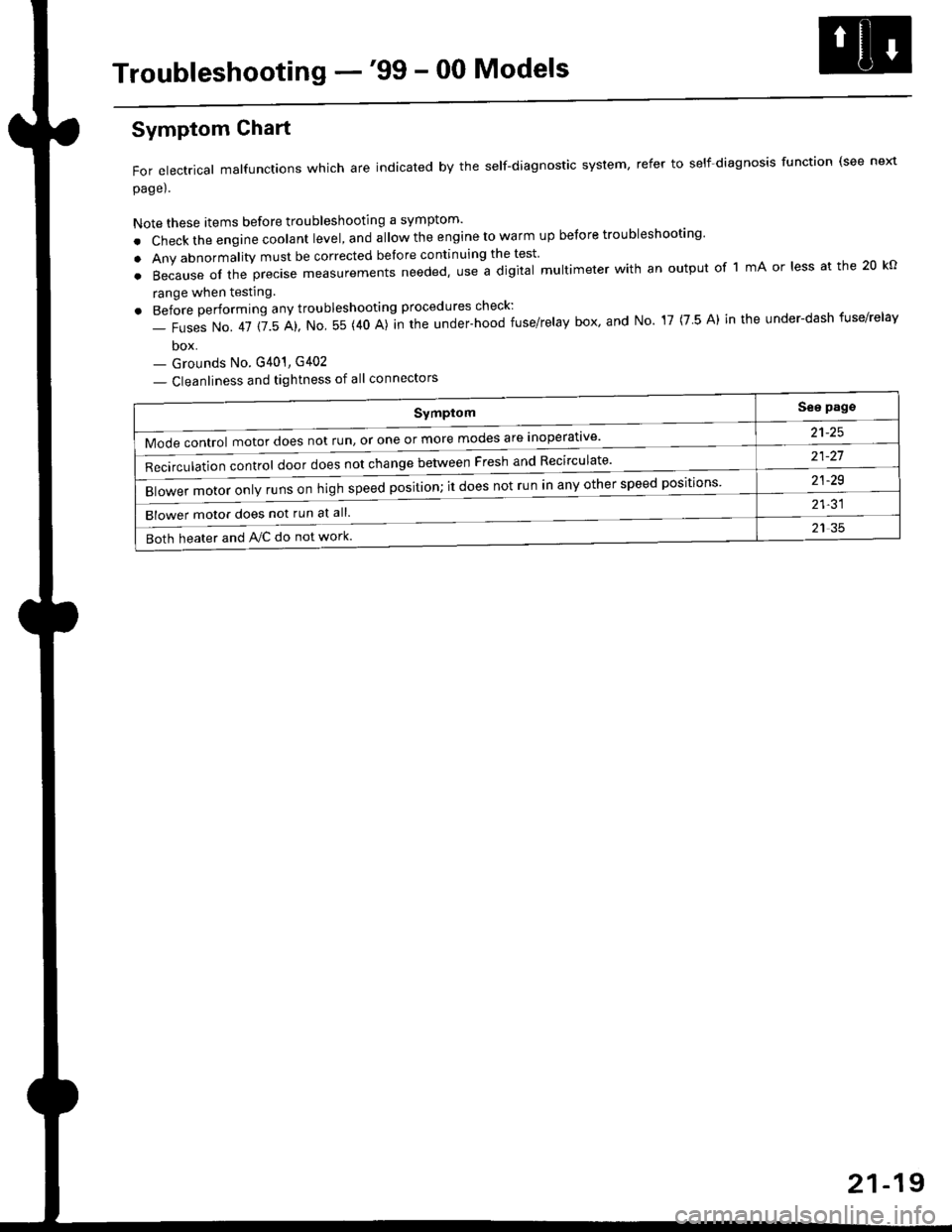

Troubleshooting -'99 - 00 Models

Symptom

Mode control motor does not run, or one or more modes are inoperat've'

Recirculation control door does not change between Fresh and Recirculate'

Blower motor only runs on high speed position; it does not run in any other speed positions

Blower motor does not run at all.

Both heater and Ay'C do not work

See pags

a1_tq

21-21

21-29

21-31

21 35

Symptom Chart

For electrical malfunctions which are indicated by the self-diagnostic system, refer to self-diagnosis function (see next

page).

Note these items before troubleshooting a symptom'

. Check the engine coolant level, and allow the engine to warm up before troubleshooting'

. Any abnormality must be corrected before continuing the test

.Becauseoftheprec|semeasurementsneeded,UseadigitaImu|timeterwithanoutputoflmAor|essatthe20ko

range when testing

. Before performing any troubleshooting procedures check:

- Fuses No. 41 115 Al, No 55 (40 A)]n the under-hood fuse/relay box' and No 17 (7 5 A) in the under-dash fuse/relav

box- Grounds No. G401, G402

- Cleanliness and tightness of all connectors

21-19

Page 1413 of 2189

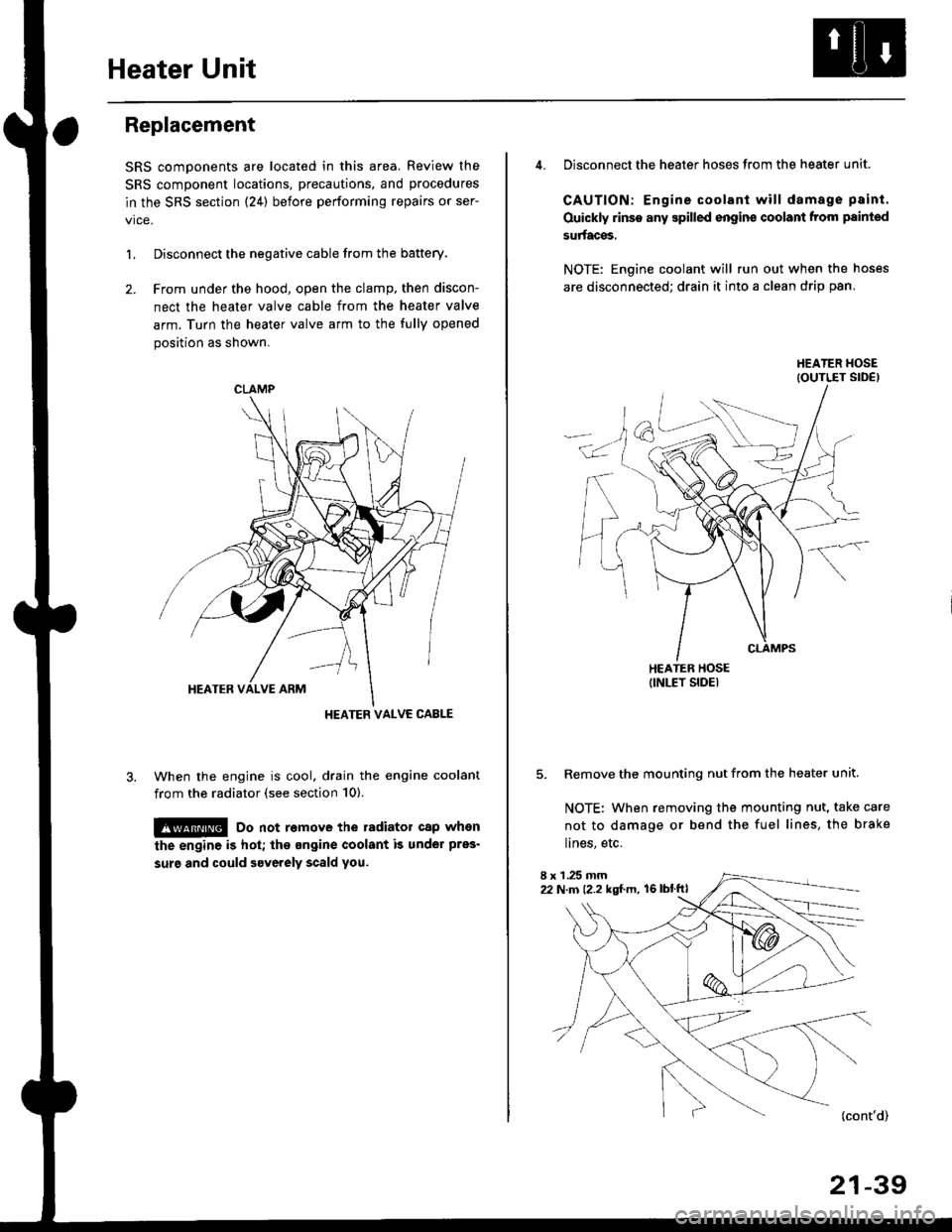

Heater Unit

Replacement

SRS components are located in this area. Review the

SRS component locations, precautions, and procedures

in the SRS section {24} before performing repairs or ser-

L Disconnect the negative cable from the battery.

2. Frcm under the hood, open the clamp, then discon-

nect the heater valve cable from the heater valve

arm. Turn the heater valve arm to the fully opened

position as shown.

When the engine is cool. drain the engine coolant

from the radiator (see section 10).

!@ Do not remove the radiator cap when

the engine is hot; the ongine coolant is under pres'

surg and could severely scald you.

CLAMP

HEATER VALVC CABLE

4. Disconnect the heater hoses from the heater unit.

CAUTION: Engine coolant will damage p8int.

Ouickly rinse any spilled engins coolant from painted

su aces,

NOTE: Engine coolant will run out when the hoses

are disconnected; drain it into a clean drip pan.

5. Remove the mounting nut from the heater unit.

NOTE: When removing the mounting nut, take care

not to damage or bend the fuel lines, the brake

lines, etc.

I x 1 .25 mm22 N.m {2.2 kgl.m, 16lblftl

21-39

Page 1429 of 2189

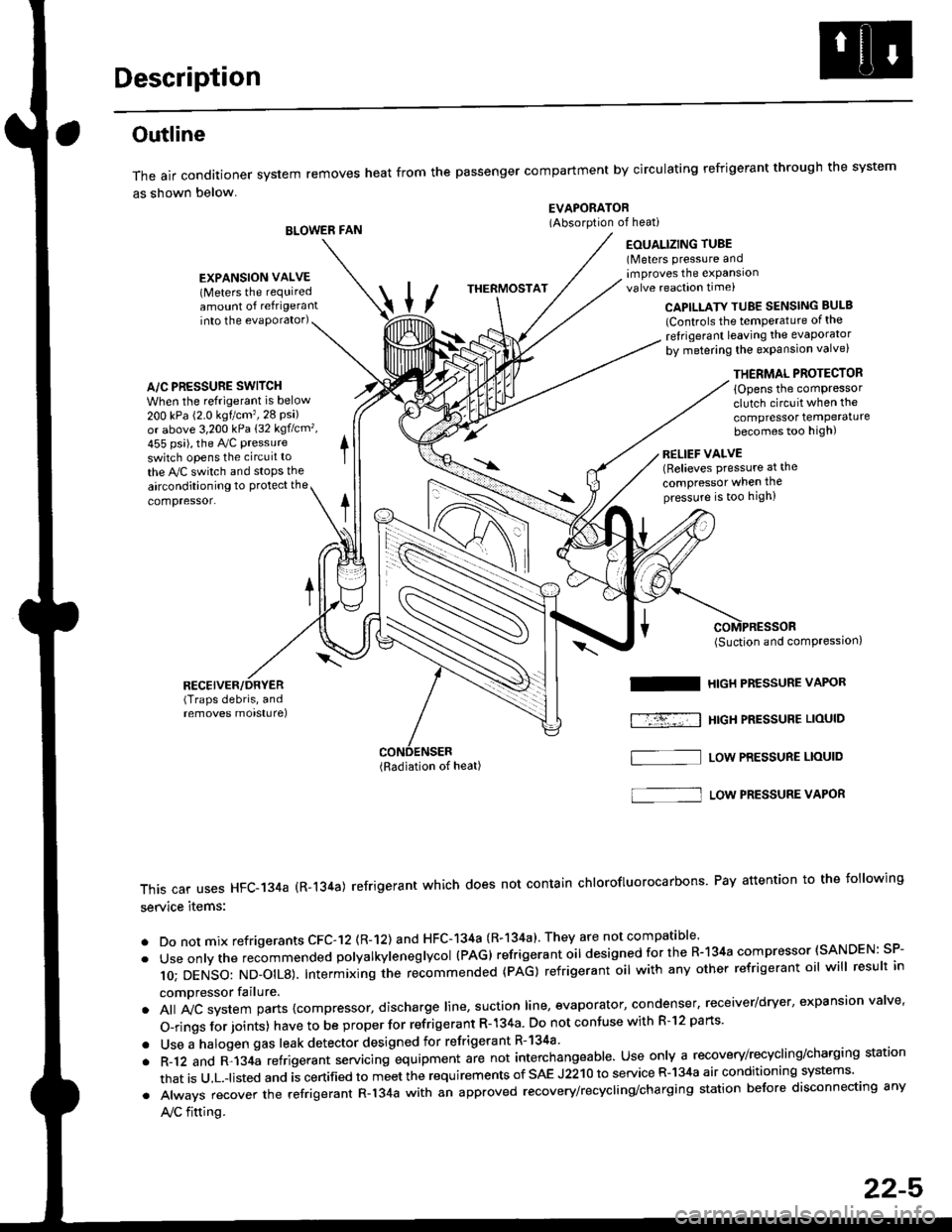

Description

Outline

The air conditioner system removes heat from the passenger compartment by circulating refrigerant through the system

as shown below.

BLOWER FAN

EVAPORATOR(Absorption of heati

EOUALIZING TUBE(Meters pressure andimproves the expansionvalve reaction time)

into the evaporator)CAPILLATY TUBE SENSING BULB

lControls the temPerature of the

ref rigerant leaving the evaporator

by metering the expansion valve)

/\

THERMOSTAT

A/C PRESSURE SWITCH

When the refrigerant is below

200 kPa (2.0 kgtcm'�,28 Psi)or above 3,200 kPa 132 kgflcm',

455 psi), the Ay'C pressure

switch opens the circuit to

the A,/C switch and stops the

EXPANSION VALVE(Meters the requiredamount of refrigerant

airconditioning to Protect the

compressor.

RECEIVER/DRYER(Traps debris, andremoves morsturel

THERMAL PROTECTOR

{Opens the comPressorclutch circuit when the

compressor temPeraturebecomes too high)

RELIEF VALVE(Relieves pressure at the

compressor when thepressure is too high)

(Radiation of heat)

I

f-r-�-; I

(Suction and comPression,

HIGH PRESSURE VAPOR

HtGH PRESSUBE LIOUID

LOW PRESSURE LIOUID

This car uses HFC-134a (R-134a) refrigerant which does not contain chlorofluorocarbons Pay attention to the following

service items:

. Do not mix refrigerants CFC-12 (R-12) and HFC-134a (R-134a)' They are not compatible'

. Useonlythe recommended polyalkyieneglycol (PAG) refrigerant oil designedforthe R-134a compressor (SANDEN: SP-

10; DENSO: ND_OIL8). Intermixing ihe re-commended (pAG) refrigerant oil with any other refrigerant oil will result in

compressor failure.

. All A,,ic system parts {compressor, discharge line, suction line, evaporator, condenser, receiver/dryer, expansion valve'

O-rings for joints) have to be proper for refrigerant R- 134a Do not confuse with R-l2 parts'

. Use a halogen gas leak detector designed for refrigerant R-134a

. R-12 and R-134a refrigerant servacing equipment are not interchangeable. Use only a recovery/recycling/charging station

that is u,L.-listed and is certified to meet the requirements of sAE J2210 to service R-134a air conditioning systems'

. Always recover the refrigerant R-134a with an approved recovery/recycling/charging station before disconnecting any

A,/C fitting.

S]

22-5

Page 1432 of 2189

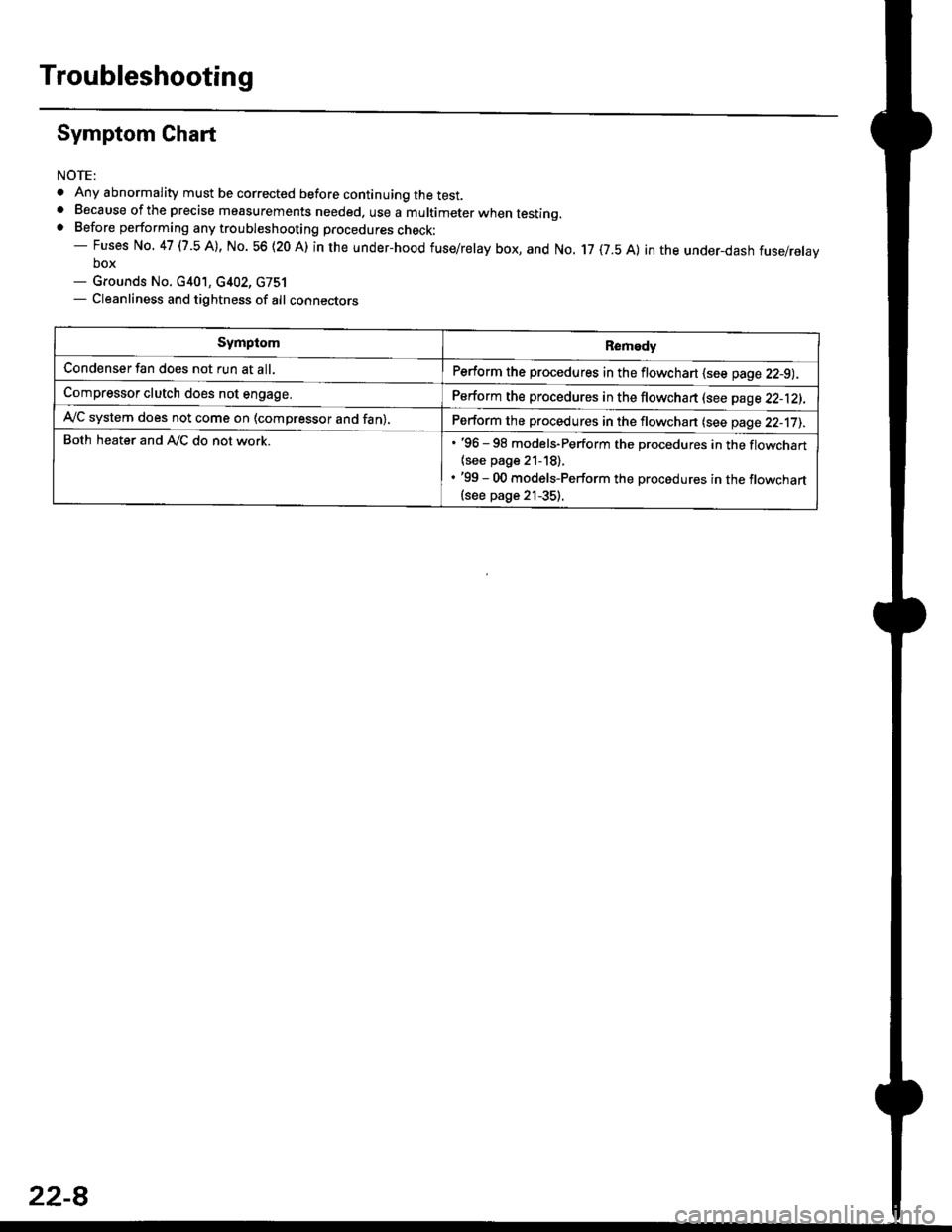

Troubleshooting

Symptom Chart

NOTE:

. Any abnormality must be corrected before continuing the test.. Because of the precise measurements needed. use a multimeter when testinq.. Before performing any troubleshooting procedures check:- Fuses No. 47 l7 -5 Al, No. 56 (20 A) in the under-hood fuse/relay box, and No. 17 (7.5 A) in the under_dash fuse/relavbox- Grounds No. c401, c402, G751- Cleanliness and tightness of alt connectors

SymptomRemedy

Condenser fan does not run at all.Perform the procedures in the flowchart {see page 22-9).

Compressor clutch does not engage.Perform the procedures in the flowchart lsee page 22-12).

Ay'C system does not come on (compressor and fan),Perform the procedures in the flowchan (see page 22-17).

Both heater and A,/C do not work.. '96 - 98 models-Perform the procedures in the flowchart

{see page 21-18).. '99 - 00 models-Perform the procedures in the flowchart(see page 21-35).

22-8

Page 1446 of 2189

A/C Service Tips and Precautions

The air conditioner system uses HFC-134a (R-134a) refrigerant and polyalkyleneglycol (PAG) refrigerant oil*, which are not

compatible with CFC-12 (R-12) refrigerant and mineral oil. Do not use R-12 refrigerant or mineral oil in this system, and do

not attempt to use R-12 servicing equipmenU damage to the air conditioner system or your servicing equipment will result.*Sanden SP-10:

. P/N 38897 - P13 - A0lAH: 120 ml 14ll.oz, 4.2lmp.oz)

. P/N 38899 - P13 - A0l | 40 mf 11 1/3ll.oz,1.4 lmp'oz)

Use only service equipment that is U.L. listed and is certified to meet the requirements of SAE J2210 to remove R 134a

from the air conditioner system.

CAUTION: Exposure to air conditioner ref;ige;ant and lubricant vapol or mist can irritate syes, nose and throat, Avoid

breathing the air conditioner refrigerant and lubricant vapor or misl.

lf accidental system discharge occurs, ventilate work area before resuming service.

R-'134a service equipment or vehicle air conditioner systems should not be pressure tested or leak tested with compressed

ai.

!@@ some mixtures of air and R-t3ila have been shown to be combustible at elevated pressures and can result

in tire or explosion causing iniury or property damage. Never use compressed air lo pressure tesl R-134a service equip-

ment or vehicle 8ir conditioner systoms.

Additional health and safety information may be obtained from the refrigerant and Iubricant manufacturers.

L Always disconnect the negative cable from the battery whenever replacing air conditioning pans.

2. Keep moisture and dust out of the system. When disconnecting any lines, plug or cap the fittings immediately; don't

remove the caps or plugs until just before you reconnect each line.

3. Before connecting any hose or line, apply a few drops of refrigerant oilto the O-ring.

4, When tightening o. loosening a fitting, use a second wrench to support the matching fitting.

5. When discharging the system, use a R-134a refrigerant recovery/recycling/charging station; don't release refrigerant

into the atmosphere,

6. Add refrigerant oil after replacing the following parts:

NOTE:

. To avoid contamination, do not return the oil to the container once dispensed, and never mix it with other refriger-

ant oils.

. lmmediately after using the oil, replace the cap on the container, and seal it to avoid moisture absorption.

. Do not spill the refrigerant oil on the vehicle; it may damage the paint; if the refrigerant oil contacts the paint, wash

it off immediately.

Condenser .......2o ml (2/3 fl.oz, 0.7 lmp.ozl

Evaporator .,.,.,. i[5 m{ 11 213 tl.oz,1,6lmp.ozl

Line or hose ..... 10 mf (1/3 fl.oz, 0.4 lmp.ozl

Receiver/Dryer 10 m{ (1/3 fl.oz,0.'l lmp.ozl

Leakage repair 25 m{ (5/6 fl.oz, 0.9 lmp.ozl

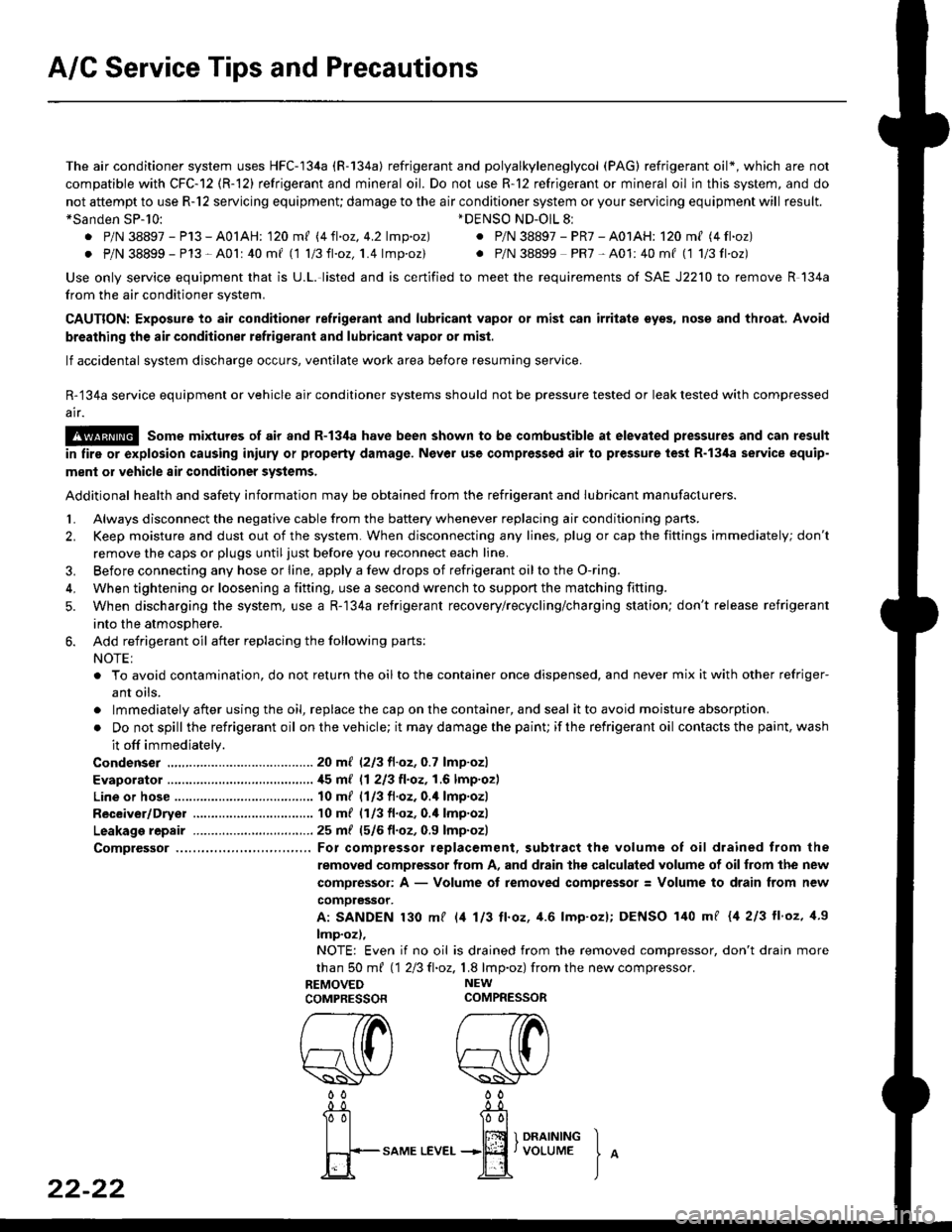

Comptessor ... For compressor replacement. subtract the volume of oil drained trom the

removed compressor from A, and drain the calculated volume of oilfrom the new

compressor: A - Volume of removed compressor: Volume to drain from new

comoressor.

A: SANDEN 130 mf l/t 113 ll.oz, 4.6 lmp'ozl; DENSO 140 mf {4 213 ll'oz, 1.9

lmp.oz),

NOTE: Even if no oil is drained from the removed compressor, don't drain more

than S0 m{ 112Ell.oz,1.8 lmp.oz) fromthe new compressor.

REMOVED NEW

COMPRESSORCOMPRESSOR

*DENSO ND-OlL 8l

. P/N 38897 - PR7 - A01AH: 120 ml (4 fl.oz)

. P/N 38899 PR7-A01:40mf (1 1/3fl'oz)

rereW W0000

22-22

-0_!- -0_a

Tol l00l

| | lffi 1 onrrrutrc I

fi+-sAME

LEvEr...+jEf,voLUME

J

^