ac line HONDA CIVIC 1999 6.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CIVIC, Model: HONDA CIVIC 1999 6.GPages: 2189, PDF Size: 69.39 MB

Page 1492 of 2189

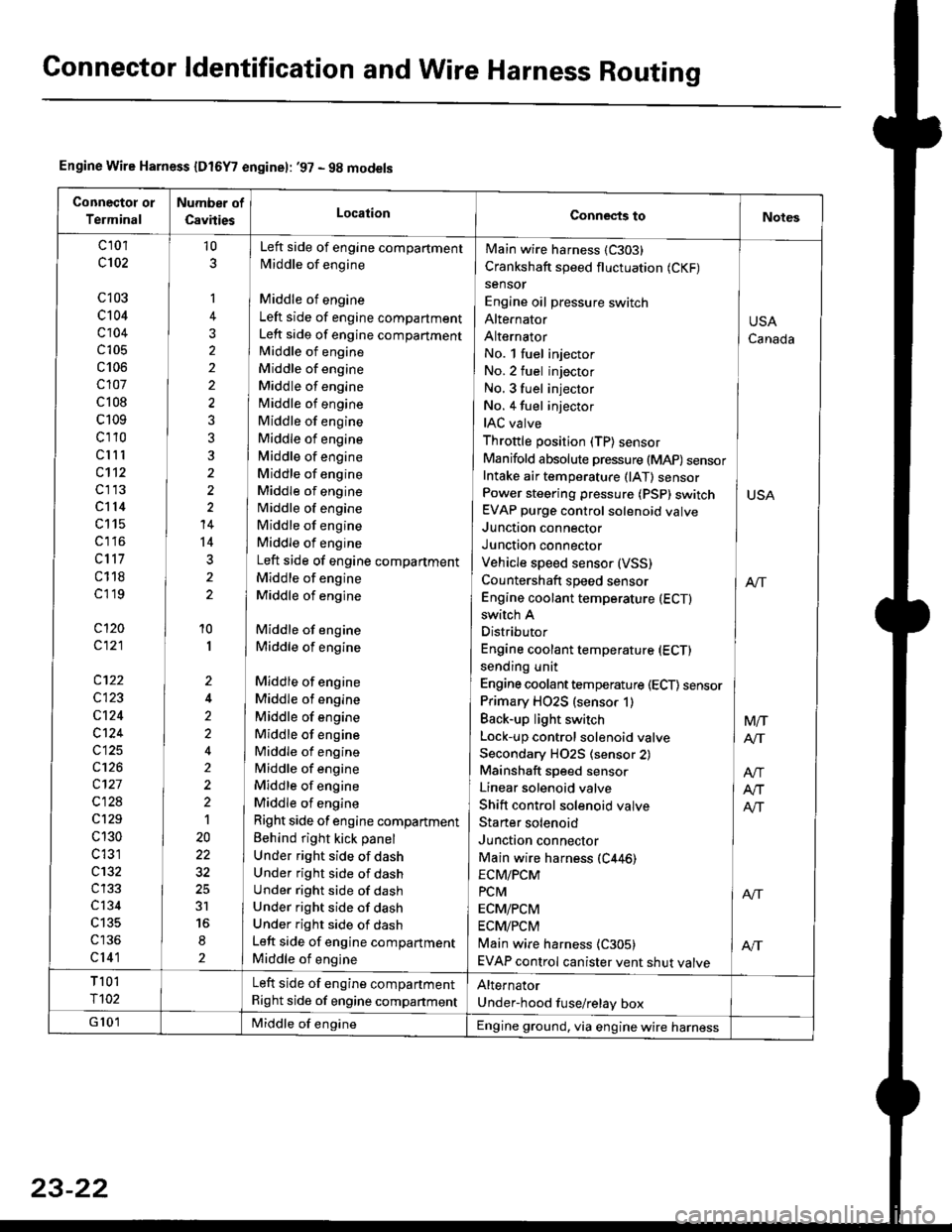

Connector ldentification and Wire Harness Routing

Engine Wire Harness {Dt6Y7 enginel: '97 - 9g models

Connectot or

Terminal

Number of

CsvitiesLocationConnects toNotes

c 101

c102

c103

c104

c104

c105

c106

c107

c 108

c109

cl10

clll

c112

cl13

cl14

c115

c1 l6

c117

c118

cl 19

cl20

c121

c122

c123

cl24

c124

c125

c126

c127

c128

c129

c 130

c 131

c132

c134

c135

cl41

10

1

2

10

I

2

2'>

4

t

20

3r

2

No. l fuel injector

No.2 fuel injector

No. 3 fuel injector INo. 4 fuel injector

IAC valve ]Throttle position (TP) sensor IManifold absolute pressure (MAP) sensorIntake air temperature (lAT) sensor ]Power steering pressure (PSp) switch I USAEVAP purge control solenoid valve

Junction connector IJunction connector IVehicle speed sensor (VSS)

Countershaft speed sensor I enEngine coolant temperature (ECTI

Main wire harness (C303)

Crankshaft speed fluctuation (CKF)

sensor

Engine oil pressure switch

Alte|'nator

Alternator

switch A

Distributor

Engine coolant temperature (ECT)

sending unit

Engine coolant temperature (ECT) sensor

Primary HO2S (sensor 1)

Back-up light switch

Lock-up control solenoid valve

Secondary H02S (sensor 2)

Mainshaft speed sensor

Linear solenoid valve

Shift control solenoid valve

Staner solenoid

Junction connector

Main wire harness (C446)

Left side of engine compartment

Middle of engine

Middle of engine

Left side of engine compartment

Left side of engine compartment

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Left side of engine compartment

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Right side of engine compartment

Behind right kick panel

Under right side of dash

Under right side of dash

Under right side of dash

Under right side of dash

Under right side of dash

Left side of engine compartment

Middle of engine

USA

Canada

Mtr

AIT

ECM/PCM

PcM I ArrECM/PCM

ECM/PCM

Main wire harness {C305) | AftEVAP control canister vent shut valve

T 101

r102

Left side of engine compartment

Right side of engine companment

Alternator

Under-hood fuse/relay box

G 101Middle of engineEngine ground, via engine wire harness

23-22

Page 1494 of 2189

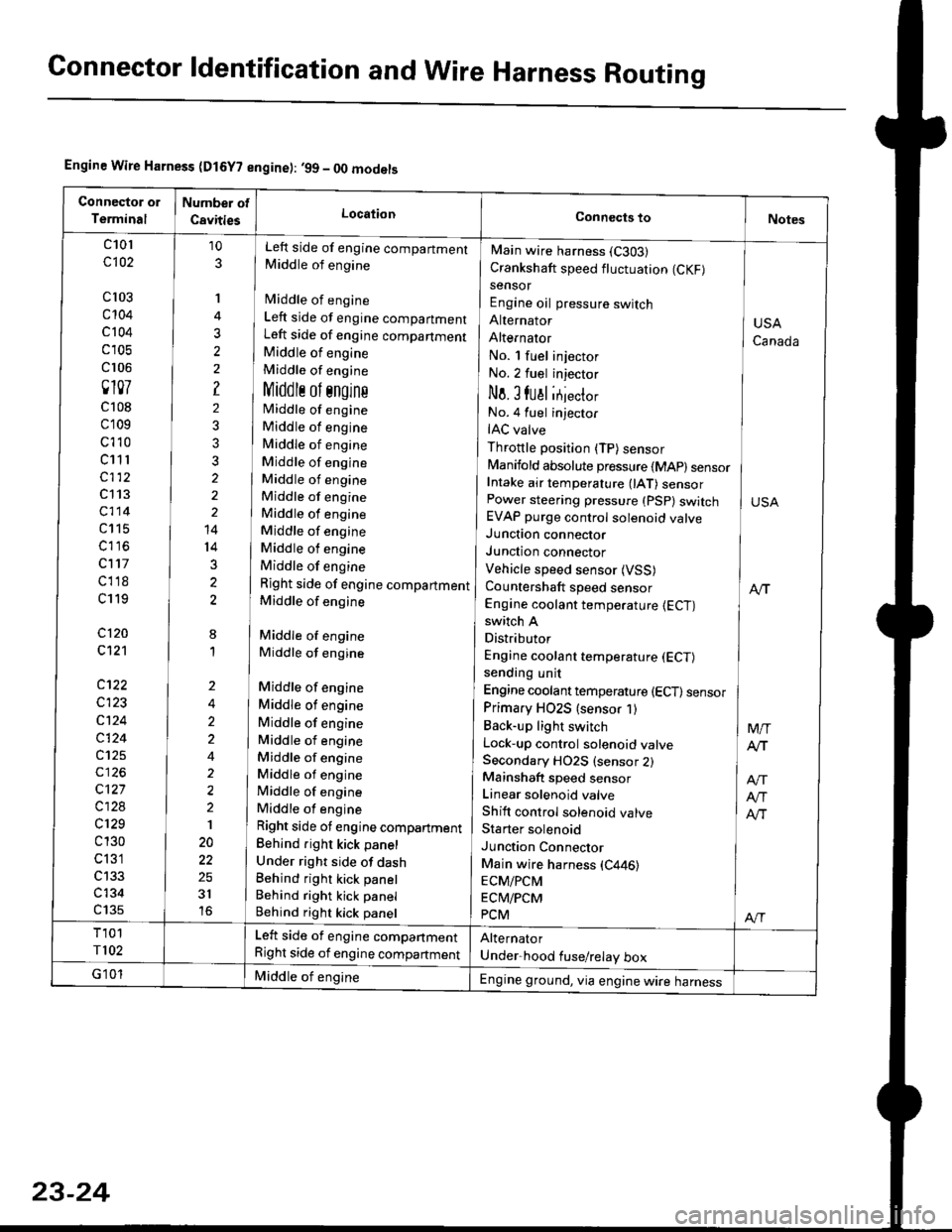

Connector ldentification and WireHarness Routing

Engine Wire Harness (D15Y? engine): ,99 - OO models

c101

c102

cl03

c't04

c 104

c 105

cr 06

0107

c108

c109

c't 10

c11 r

c112

c113

c114

c115

c116

c117

cl18

c119

c120

c121

c122

c123

c124

c124

c125

c127

c128

c129

c 130

c 131

c134

c135

10

3

'I

3

?

2

3?

2

14

14

3

2

8

1

Left side of engine compartment

Middle of engine

fvliddle of engine

Left side of engine compartment

Left side of engine companment

Middle of engine

Middle of engine

Middlr ol sngins

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Right side of engine compartment

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Right side ot engine compartment

Behind right kick panel

Under right side of dashBehind right kick panel

Behind right kick panel

Behind right kick panel

Main wire harness (C303)

Crankshaft speed fluctuation (CKF)

sensor

Engine oil pressure switch

Alternator

AlternatOr

No. l fuel injector

No.2 fuel injector

No. I fual itjecto,

No.4 fuel injector

IAC valve

Throttle position (TP) sensor

Manifold absolute pressure {MAp) sensorIntake air temperature 0AT) sensorPower steering pressure (PSp) switchEVAP purge control solenoid valveJunction connector

Junction connector

Vehicle speed sensor (VSS)

Countershaft speed sensor

Engine coolant temperature {ECT)switch A

Distributor

Engine coolant temperature (ECT)

sending unit

Engine coolant temperature (ECT) sensor

Primary HO2S (sensor 1)

Back-up light switch

Lock-up control solenoid valveSecondary HO2S (sensor 2)Mainshaft speed sensor

Linear solenoid valve

Shift control solenoid valve

Starter solenoid

Junction Connector

Main wire harness (C446)

ECM/PCM

ECM/PCM

PCM

USA

Canada

M/T

Atr

Atr

Alr

Al-|.

Left side of engine compartment

Right side of engine compartment

Middle of engineEngine ground, via engine wire harness

23-24

Page 1566 of 2189

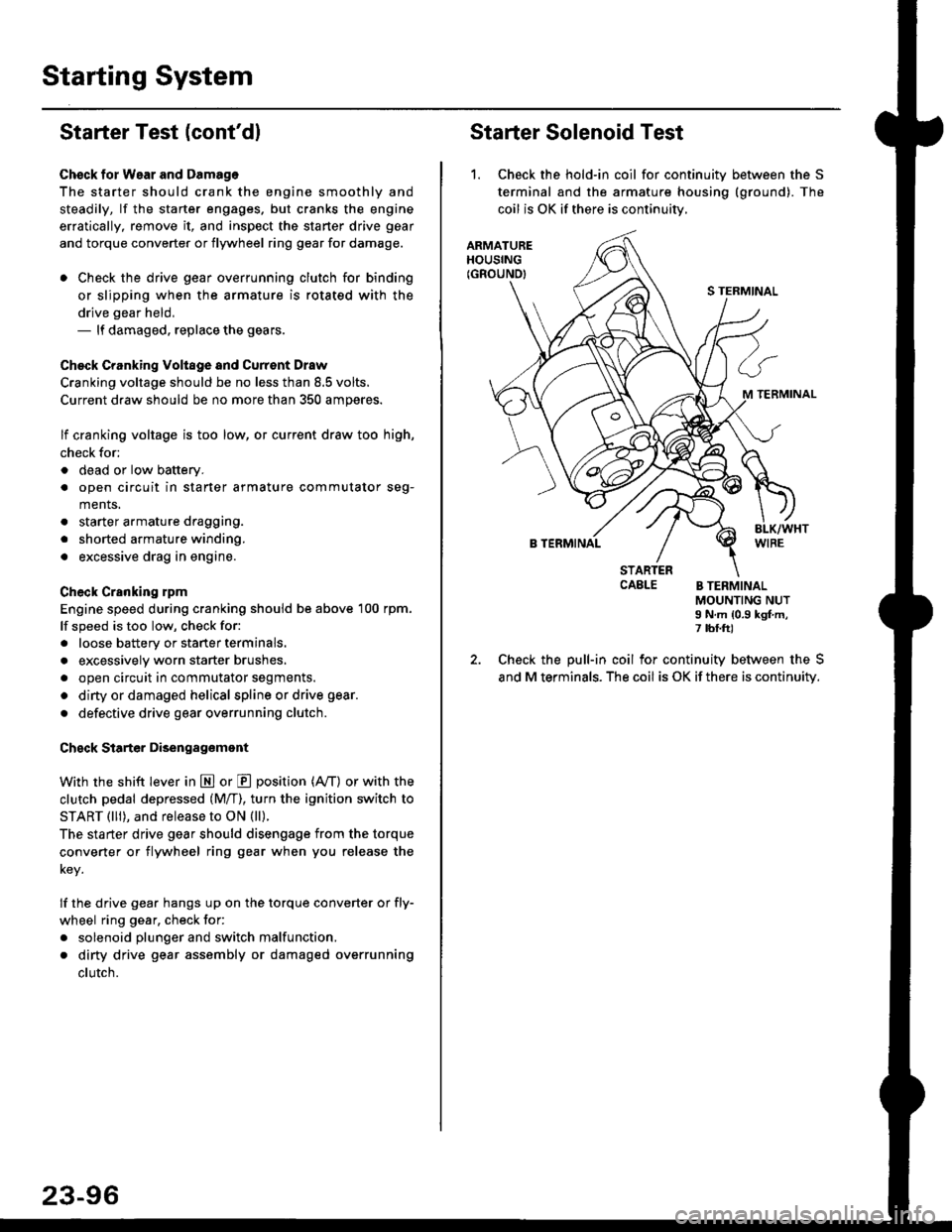

Starting System

Starter Test lcont'dl

Ch€ck tor Wear and Damage

The starter should crank the engine smoothly and

steadily, lf the starter engages. but cranks the engine

erratically, remove it, and inspect the starter drive gear

and torque converter or flywheel ring gear for damage.

. Check the drive gear overrunning clutch for binding

or slipping when the armature is rotated with the

drive gear held,- lf damaged. replace the gears.

Check Cranking Voltsge and Curr€nt Draw

Cranking voltage should be no less than 8.5 volts.

Current draw should be no more than 350 amperes.

lf cranking voltage is too low, or current draw too high,

check for;

. dead or low batterv.

. open circuit in starter armature commutator seg-

ments,

. starter armature dragging.

. shorted armature winding.

o excessive drag in engine.

Check Cranking rpm

Engine speed during cranking should be above 100 rpm,

lf speed is too low, check for:

. loose battery or stanerterminals.

. excessively worn starter brushes,

. open circuit in commutator segments.

o dirty or damaged helical spline or drive gear.

. defective drive gear overrunning clutch.

Check Siarter Disengag€ment

With the shift lever in El or @ position (A/T) or with the

clutch pedal depressed (M/T), turn the ignition switch to

START (lll), and release to ON (ll).

The starter drive gear should disengage from the torque

converter or flywheel ring gear when you release the

Key.

lf the drive gear hangs up on the torque converter or fly-

wheel ring gear, check for:

. solenoid plunger and switch malfunction,

. dirty drive gear assembly or damaged overrunning

clutch.

Starter Solenoid Test

1. Check the hold-in coil for continuitv between the S

terminal and the armature housing (ground). The

coil is OK if there is continuitv,

ARMATUREHOUSING(GROUND)

S TERMINAL

M TERMINAL

B TERMINAL

STARTERCAELE B TERMINALMOUNTING NUTI N.m {0.9 kgf.m,7 tbf.ft)

Check the pull-in coil for continuity between the S

and M terminals. The coil is OK if there is continuity.

Page 1586 of 2189

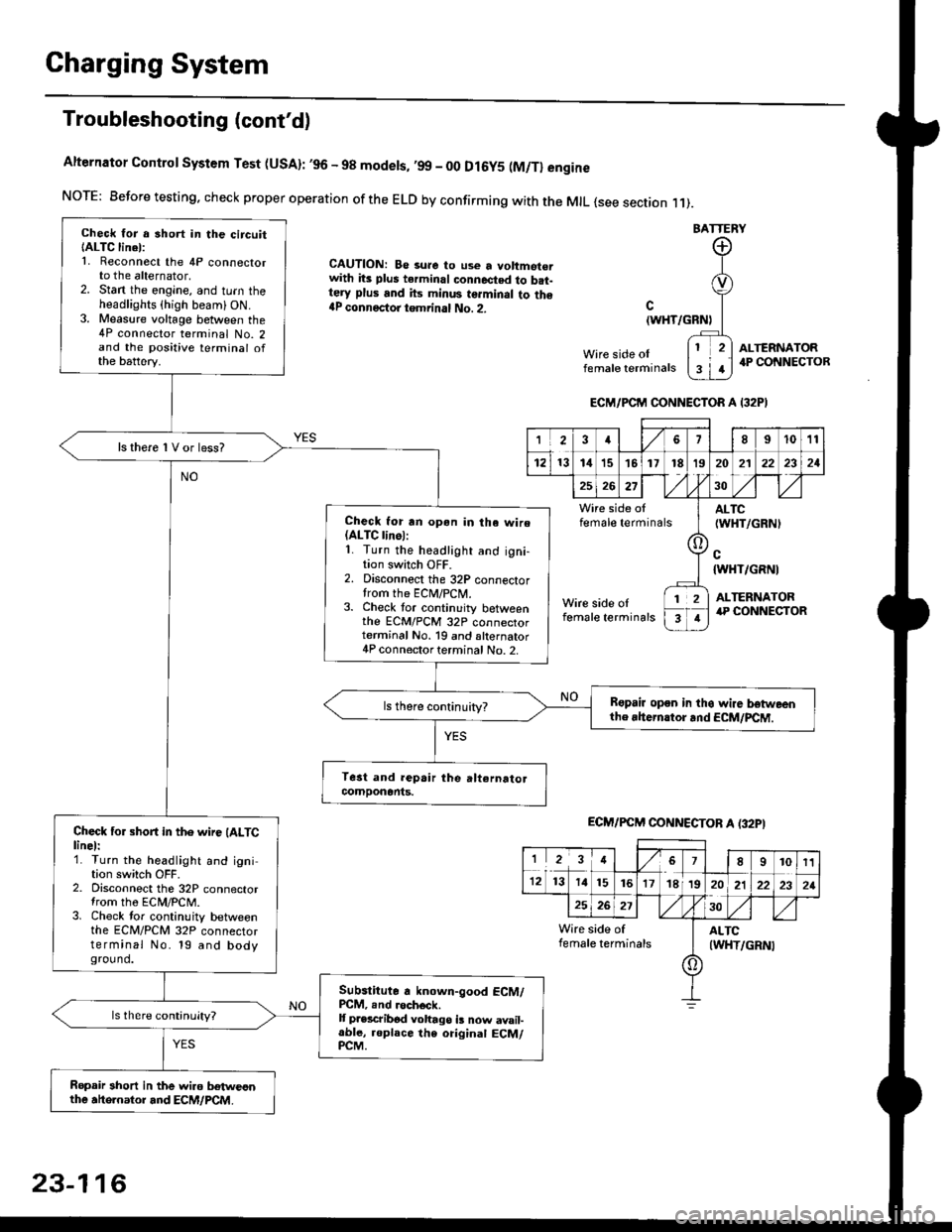

Charging System

Troubleshooting (cont'd)

Alternator Control System Test (USA): ,96 - 98 modets, ,99 _ 00 Dl6y5 (M/Tl engine

NorE: Before testing. check proper operation of the ELD by confirming with the MrL {see section r 1).

BATTERY

CAUTION: Be 3ure to use a voltmot€.with its plus terminal connected to b.t-tery plus and its minus terminal to the{P connectoi tgmrinal No. 2.c

{WHT/GRNt

Wire side oIfemale terminals

ALTERNATOR.P CONNECTOB

Check for a 3hort in the circuitIALTC linel:1. Reconnect the 4P connectorto the alternator,2. Stan the engine, and turn theheadlights {high beam) ON.3. Measure voltage between the4P connector terminal No. 2and the positive terminal ofthe battery.

ls there 1V or less?

Check for rn opon in tha wire(ALTC linol:1. Turn the headlight and igni-tion switch OFF.2. Disconnect the 32P connectortrom the ECM/PCN4.3. Check tor continuity betweenthe ECM/PCM 32P connectorterminal No. 19 and alternator4P connector terminal No. 2.

Bspair open in thg wire lrstweenthe rhern.tor .nd ECM/PCM.

Check for short in the wire (ALTClinel:1. Turn the headlight and ignition switch OFF.2. Disconnect the 32P connectortrom the ECM/PCM.3. Check tor continuity betweenthe ECM/PCM 32P connectorterminal No. 19 and bodyground.

Subslitute a known-good ECM/PCM, .nd .och6ck.It p.escribod vohago i! now avail-able, replace the original ECM/PCM.

Ropair 3hort in the wiro betweonthe ahe.nator and ECM/PCM.

ECM/PCM CONNECTOR A I32PI

'Ia18I1011

121314151718t9

7

202'l2221

262730

Wire side offemale terminalsALTC(WHT/GRNI

c{WHT/GRNI

ALTERNATORWire side oIfemale terminals

([l

T

12

1

ECM/PCM CONNECTOB A (32PI

I23478910t1

1213 14151617182021222321

262730

Wire side of I AITCfemate terminats

A

(WHT/GRN|

23-116

Page 1587 of 2189

-

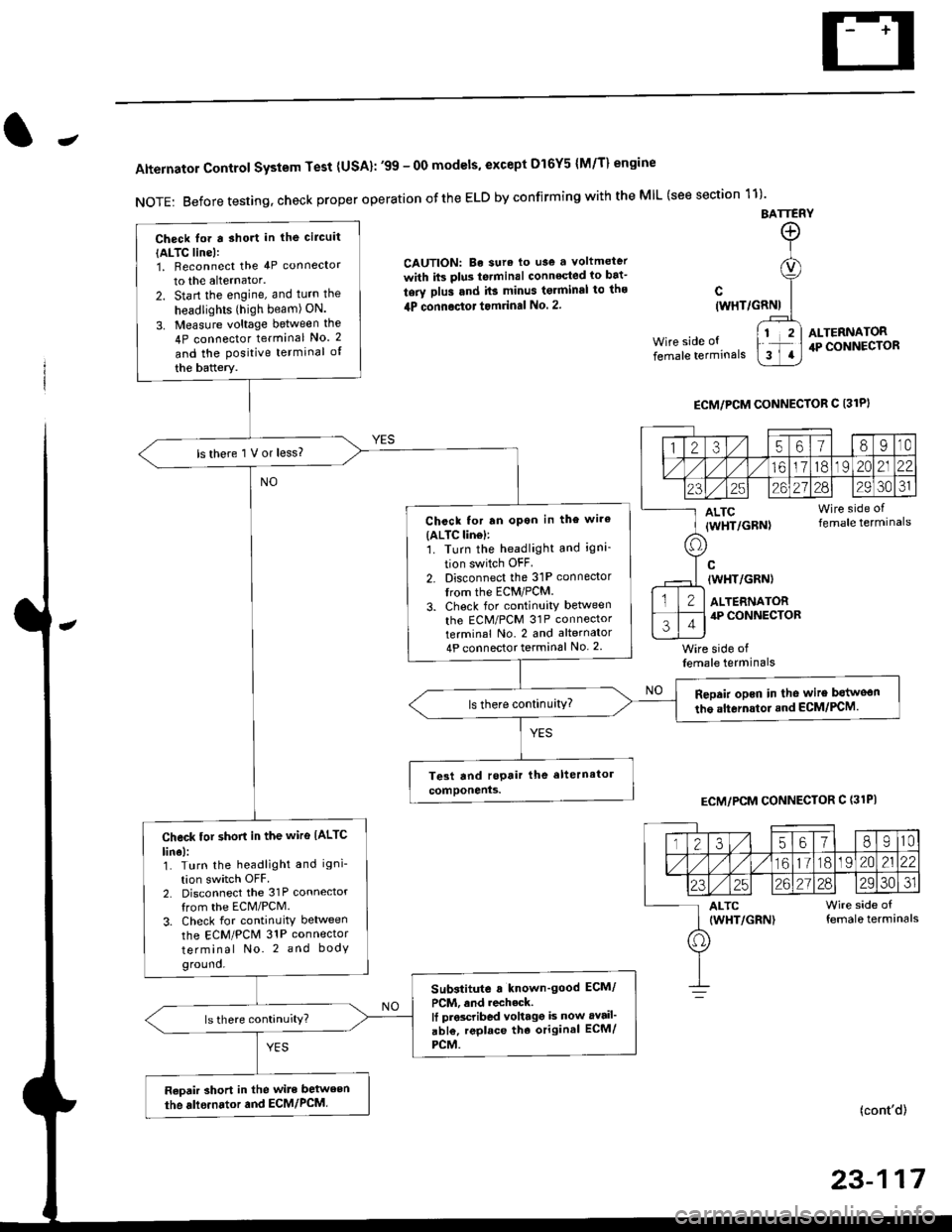

Alternator Control System Test {USA}: '99 - 0O models, except Dl6Y5 {M/T} engine

NOTE: Before testing, check proper operation ofthe ELD by confirming with the MIL (see section 11)'

BATTERY

CAUTION: Be sura lo use a voltmeter

with its plus te.minal conneqted io bat-

tery plus and it3 minus tgrminal to ths

4P connoctot tomrinal No. 2.

Wire side of

female terminals

c(WHT/GRNI

wire side offemale terminals

ALTERNATOR.P CONNECTOR

ECM/PCM CONNECTOR C 13lPI

ECM/PCM CONNECTOR C (31PI

(cont'd)

23-117

Check lor a sho.t in the circuit

{ALTC line):1, Beconnect the 4P connector

to the alternator.

2. Start the engine, and turn the

headlights (high beam) ON.

3. Measure voltage between the

4P connector terminal No. 2

and the Positive terminal of

the battery.

ls there 1 V or less?

Chcck for rn opon in the wire(ALTC lin6l:1. Turn the headlight and igni-

tion switch OFF

2. Disconnect the 31P connector

trom the ECM/PCM.

3. Check for continuity betlveen

the ECM/PCM 31P connectorterminal No. 2 and alternator

4P connector terminal No. 2

Repair opcn in the wire botweon

the alternstoi.nd ECM/PCM.ls there continuity?

Check tor short in the wire IALTC

line):1. Turn the headlight and igni-

tion switch OFF2. Disconnect the 31P connector

from the ECM/PCM.

3. Check for continuity between

the ECM/PCM 31P connector

terminal No. 2 and body

ground.

Substitute a known'good ECM/

PCM, and recheck.It prscribed voltagg is now avail'

abl€, replace tho original ECM/

PCM.

Raoair short in the wite between

the alle.nator and ECM/PCM,

1235618I10

/11611lo191 zo2122

23252621?82930JI

ALTC Wire side of(WHT/GRN) female terminals

o

Page 1708 of 2189

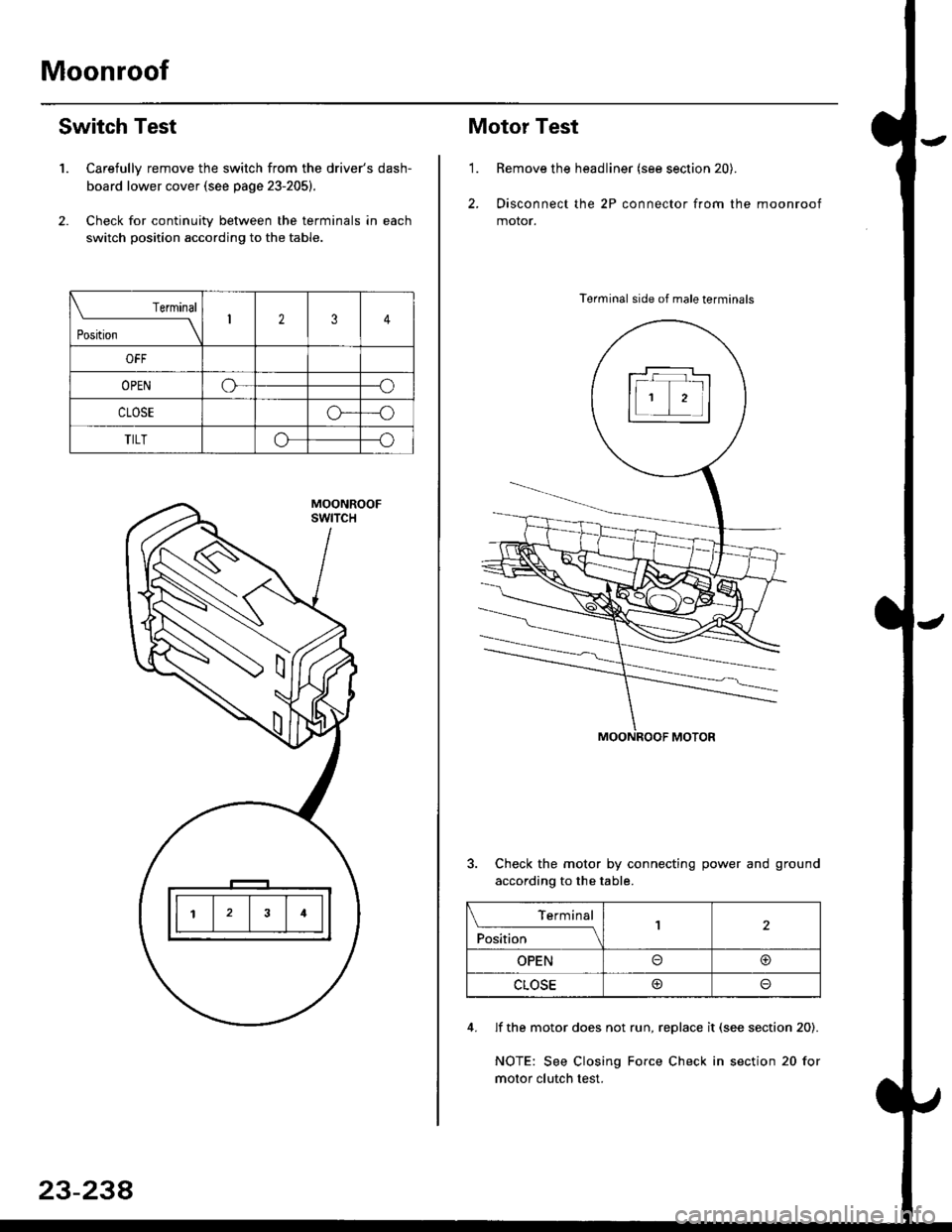

Moonroof

1.

Switch Test

Carefully remove the switch from the driver's dash-

board lower cover {see page 23-205}.

Check for continuitv between the terminals in each

switch position according to the table.

Terminal

t*',*-----__\I234

ut-t-

OPENo--o

CLOSEo---o

TILTo--o

23-234

Motor Test

'1.Remove the headliner (see section 20).

Disconnect the 2P connector from the moonroof

motor.

Terminal side of male terminals

Check the motor by connecting power and ground

according to the table.

4. lf the motor does not run, replace it (see section 20).

NOTE: See Closing Force Check in section 20 for

motor clutch test.

\_____lTr1

Position

,l

OPENo@

CLOSE@

Page 1709 of 2189

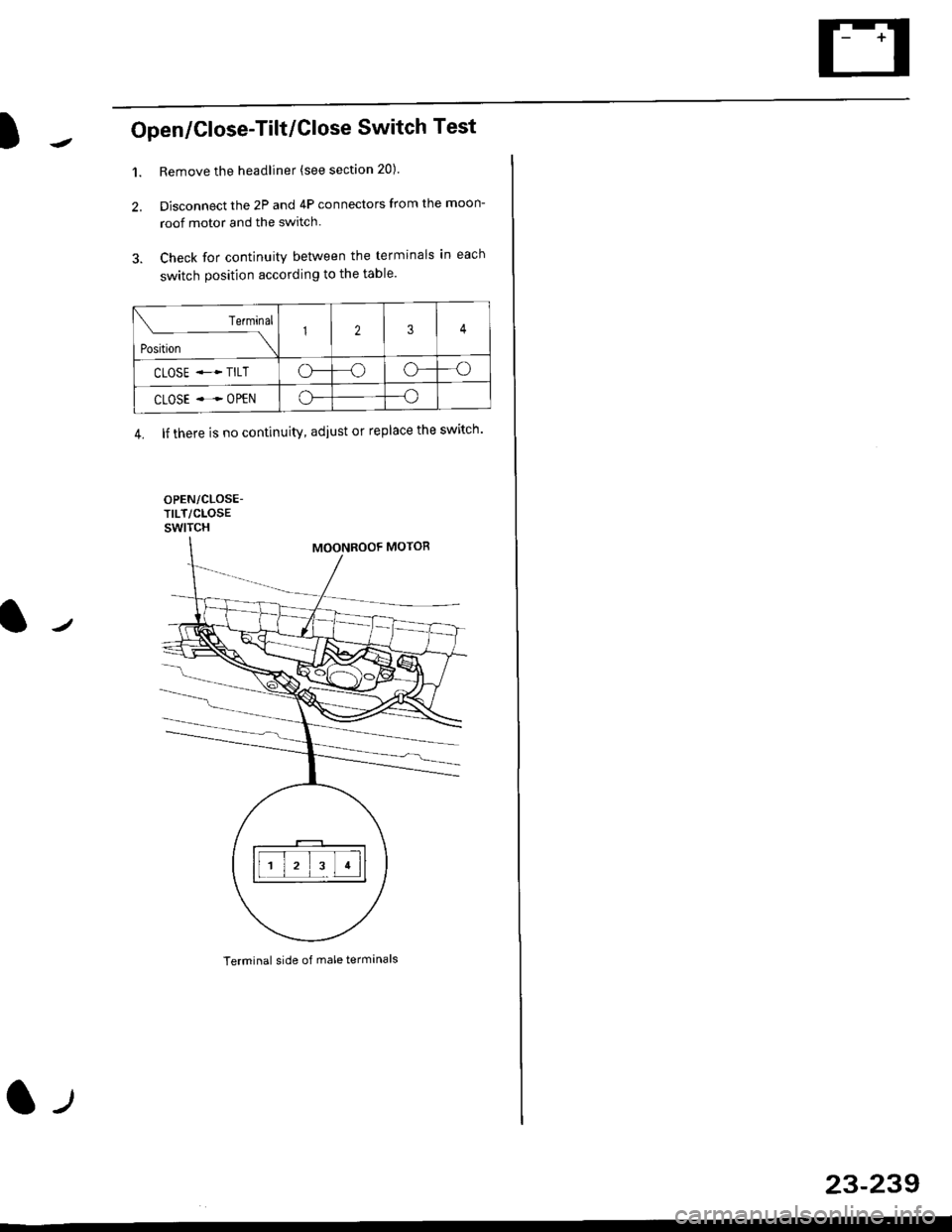

Open/Close-Tilt/Close Switch Test

1. Remove the headliner (see section 20).

2. Disconnect the 2P and 4P connectors from the moon-

roof motor and the switch.

3. Check for continuity between the terminals in each

switch position according to the table.

Terminal side of male terminals

Terminal

*r*"-

-\123

CLOSE .* TILTo--oo---o

CLOSE ..--. OPENo--o

4. lf there is no continuity, adiust or replace the switch'

l-t

23-239

Page 1717 of 2189

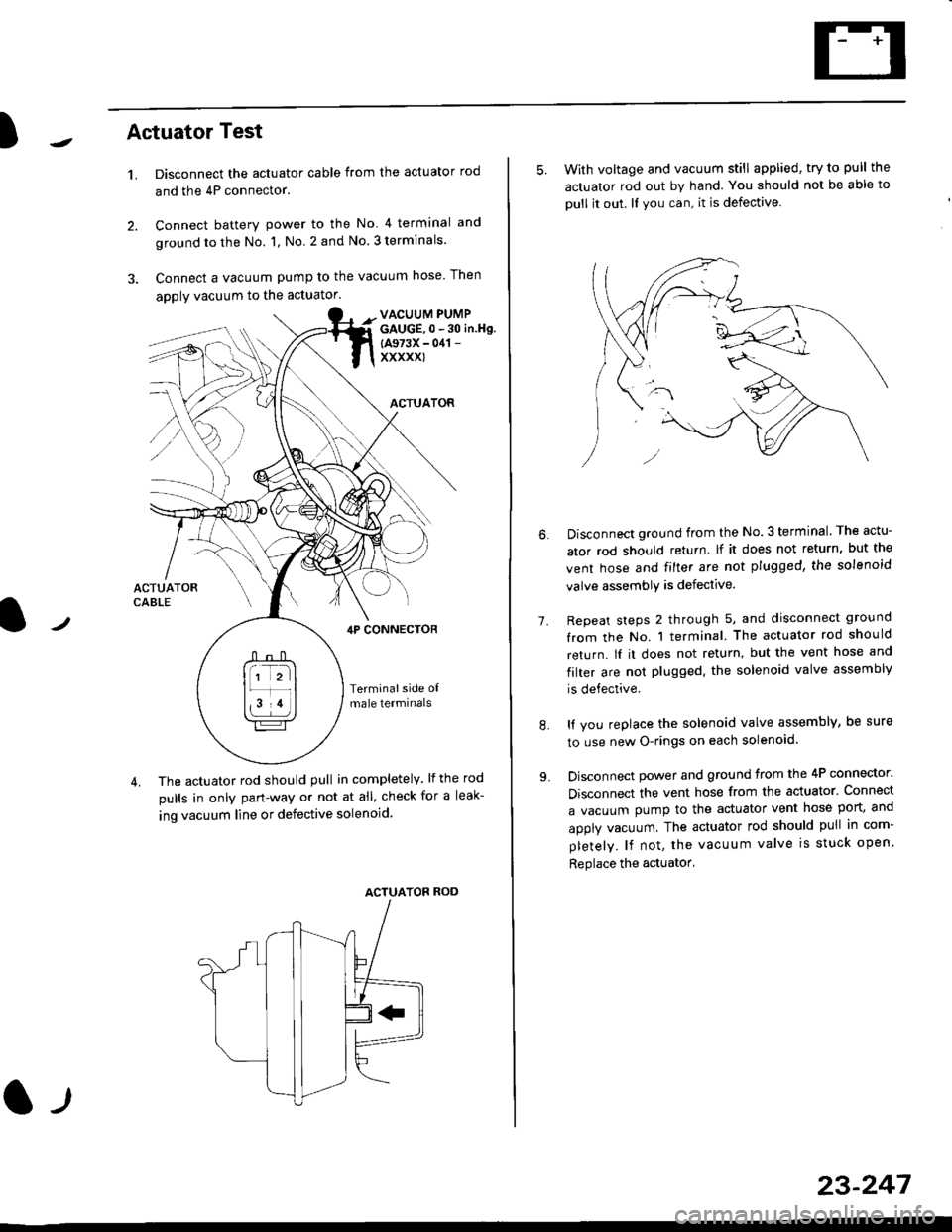

)Actuator Test

't.Disconnect the actuator cable from the actuator rod

and the 4P connector.

Connect battery power to the No 4 terminal and

ground to the No. 1, No. 2 and No. 3 terminals.

Connect a vacuum pump to the vacuum hose Then

apply vacuum to the actuator.

2.

VACUUM PUMPGAUGE,0 - 30 in.Hg.

{A973X - 041 -

xxxxxl

ACTUATOR

,lP CONNEcToR

Terminalside o{male termrnals

4. The actuator rod should pull in completely. lf the rod

pulls in only pan-way or not at all' check for a leak-

ing vacuum line or defective solenoid.

ACTUATOF ROD

l-t

23-247

5. With voltage and vacuum still applied, try to pull the

actuator rod out by hand. You should not be able to

oull it out. ll you can, it is defective

1.

Disconnect ground from the No.3 terminal. The actu-

ator rod should return lf it does not return, but the

vent hose and filter are not plugged, the solenoid

valve assembly is defective.

Repeat steps 2 through 5, and disconnect ground

from the No. 1 terminal. The actuator rod should

return. lI it does not return, but the vent hose and

filter are not plugged. the solenoid valve assembly

is defective.

It you replace the solenoid valve assembly, be sure

to use new O-rings on each solenoid.

Disconnect power and ground from the 4P connector.

Disconnect the vent hose from the actuator. Connect

a vacuum pump to the actuator vent hose port, and

apply vacuum. The actuator rod should pull in com-

pletely. lf not, the vacuum valve is stuck open.

Replace the actuator'

8.

Page 1756 of 2189

Troubleshooting

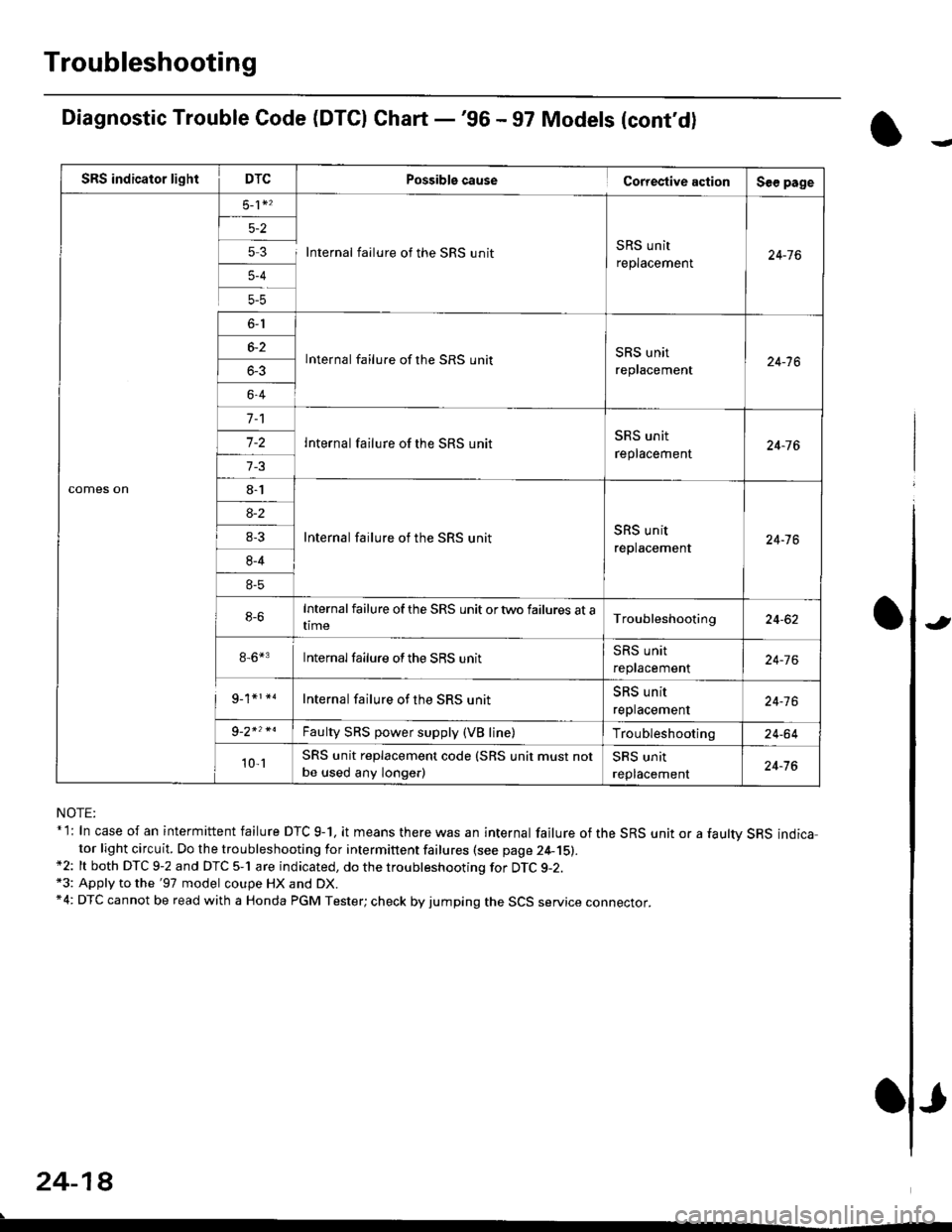

Diagnostic Trouble Code (DTCI Ghart -'96 - 97 Models (cont'd)

NOTE:* l: In case of an intermittent failure DTC g-1, it means there was an internal failure of the SRS unit or a faultv SRS indicator light circuit. Do the troubleshooting for intermittent failures (see page 24-15).*2: lt both DTC 9-2 and DTC 5-1 are indicated, do the troubleshooting for DTC g-2.*3: Apply to the '97 model coupe HX and DX.*4: DTC cannot be read with a Honda PGM Tester; check by jumping the SCS service connector.

24-18

.

Possiblg cause Cortestive action

5 3 I Internal failure of the SRS unitSRS unit

replacement

lnternal failure of the SRS unitSRS unit

replacement

Internal failure of the SRS unit

Internal failure of the SRS unitSRS unit

replacement

Internalfailure of the SRS unit ortwo failures at atime

8-6*3 Internalfailure ofthe SRS unit

Internal failure of the SRS unit

Faulty SRS power supply (VB line)

SRS unit replacement code (SRS unit must not

be used any longe.)

J

Page 1757 of 2189

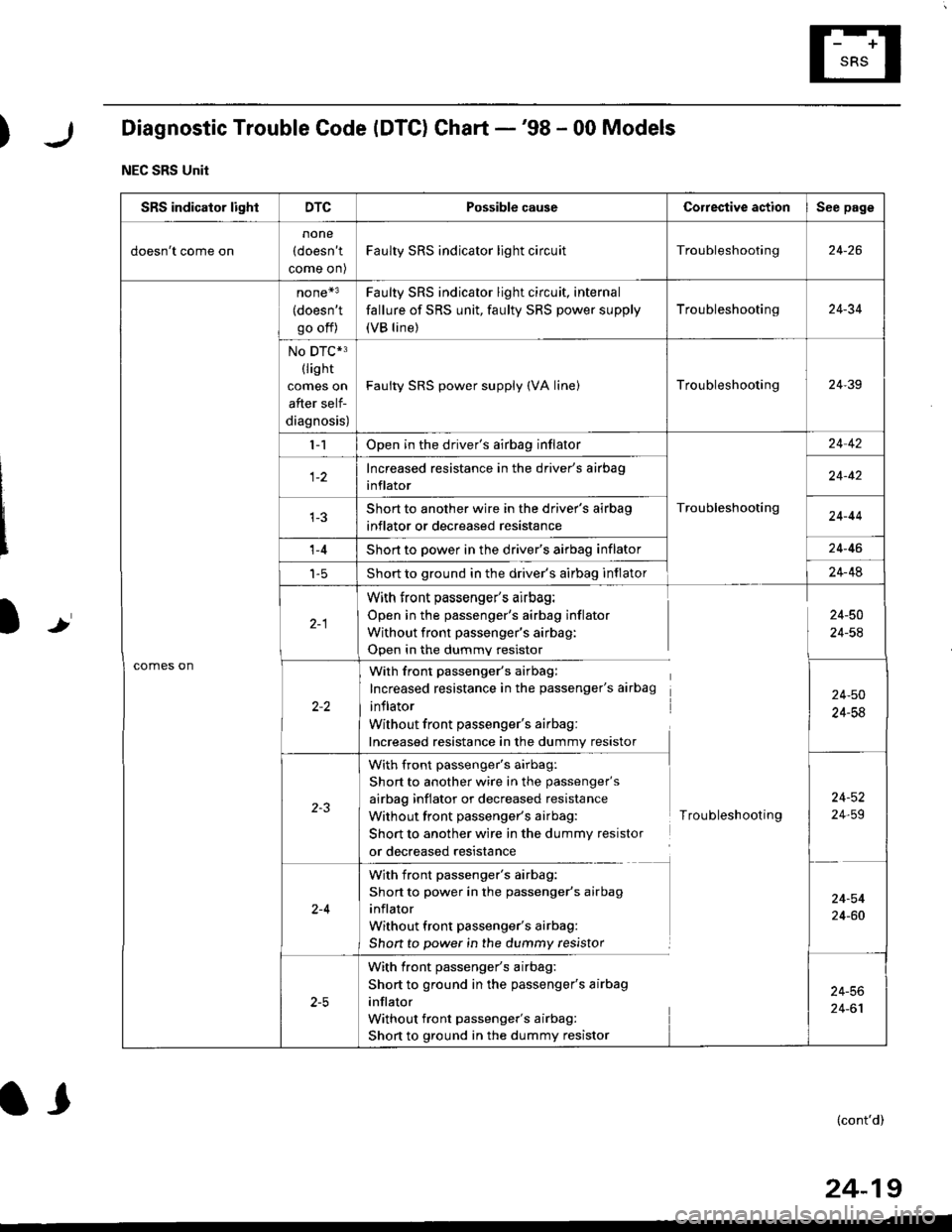

)Diagnostic Trouble Code (DTC) Chart -'98 - 00 Models

NEC SRS Unit

Ir

SRS indicator lightDTCPossible causeCorrestive actionSee page

doesn't come on

none

(doesn't

come on)

Faulty SRS indicator light circuitTroubleshooting24-26

comes on

none*3

(doesn't

go off)

Faulty SRS indicator light circuit, internal

fallure of SRS unit, faulty SRS power supply

(VB line)

Troubleshooting24-34

No DTC*3(lis ht

comes on

after self-

diagnosis)

Faulty SRS power supply (VA linelTroubleshooting24-39

l-1Open in the driver's airbag inflator

Troubleshooting

24 42

Increased resistance in the driver's airbag

inflator24-42

Short to another wire in the driver's airbag

inflator or decreased resistance24-44

't -4Short to power in the driver's airbag inflator24-46

t-5Short to ground in the driver's airbag inflator24-48

With front passenger's airbag:

Open in the passenger's airbag inflator

Without front passenger's airbag:

Open in the dummv resistor

24-50

24-54

With front passenger's airbag:

Increased resistance in the passenger's airbag

inflator

Without front passenger's airbag:

Increased resistance in the dummy resistor

24-50

24-58

with front passenger's airbag:

Short to another wire in the passenger's

airbag inflator or decreased resistance

Without front passenger's airbag:

Short to another wire in the dummy resistor

or decreased resistance

Troubleshooting

24-52

24,59

2-4

With front passenger's airbag:

Short to power in the passenger's airbag

inflator

Without front passenger's airbag:

Shon to power in the dummy resistor

24-54

24-60

With front passenger's airbag:

Short to ground in the passenger's airbag

inflator

Without front passenger's airbag:

Short to ground in the dummy resistor

24-56

24-61

(cont'd)

24-19

l,