ect HONDA CIVIC 1999 6.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CIVIC, Model: HONDA CIVIC 1999 6.GPages: 2189, PDF Size: 69.39 MB

Page 1029 of 2189

![HONDA CIVIC 1999 6.G Workshop Manual l.

17.Make sure the transmission is in the E] position.

Fill the transmission with cvT Fluid, and run the

engine for 30 seconds or until approximately 0 95 {

(1.0 US qt.,0.8 lmp qt.) is discharged.

Re HONDA CIVIC 1999 6.G Workshop Manual l.

17.Make sure the transmission is in the E] position.

Fill the transmission with cvT Fluid, and run the

engine for 30 seconds or until approximately 0 95 {

(1.0 US qt.,0.8 lmp qt.) is discharged.

Re](/img/13/6068/w960_6068-1028.png)

l.

17.Make sure the transmission is in the E] position.

Fill the transmission with cvT Fluid, and run the

engine for 30 seconds or until approximately 0 95 {

(1.0 US qt.,0.8 lmp qt.) is discharged.

Remove the drain hose, and reconnect the cooler

return hose to the transmission (see page 14-355)

Refill the transmission with CVT Fluid to the proper

level (see page 14-299).

18.

'19.

.l ,

TOOL MAINTENANCE

1. Empty and rinse after each use. Fill the can with water

and pressurize the can. Flush the discharge line to

ensure that the unit is clean.

2, lf discharge liquid does not foam, the orifice may be

blocked.

3. To clean, disconnect the plumbing from the tank at

the large couPling nut.

FILTER

\

\- 0--D

i

I

O.RING

Remove the in-line tilter from the discharge side and

clean if necessary'

The fluid orifice is located behind the filter. Clean it

with the pick stored in the bottom of the tank han-

dle. or blow it clean with air. Securely reassemble

all parts.

COUPLINGNUT

II

-@q

\ORIFICE

FILLER CAP

14-353

Page 1030 of 2189

Shift Cable

RemovaUlnstallation

@ Make sure lifts, iacks and safety stands are

placed properly (see seqtion 11,

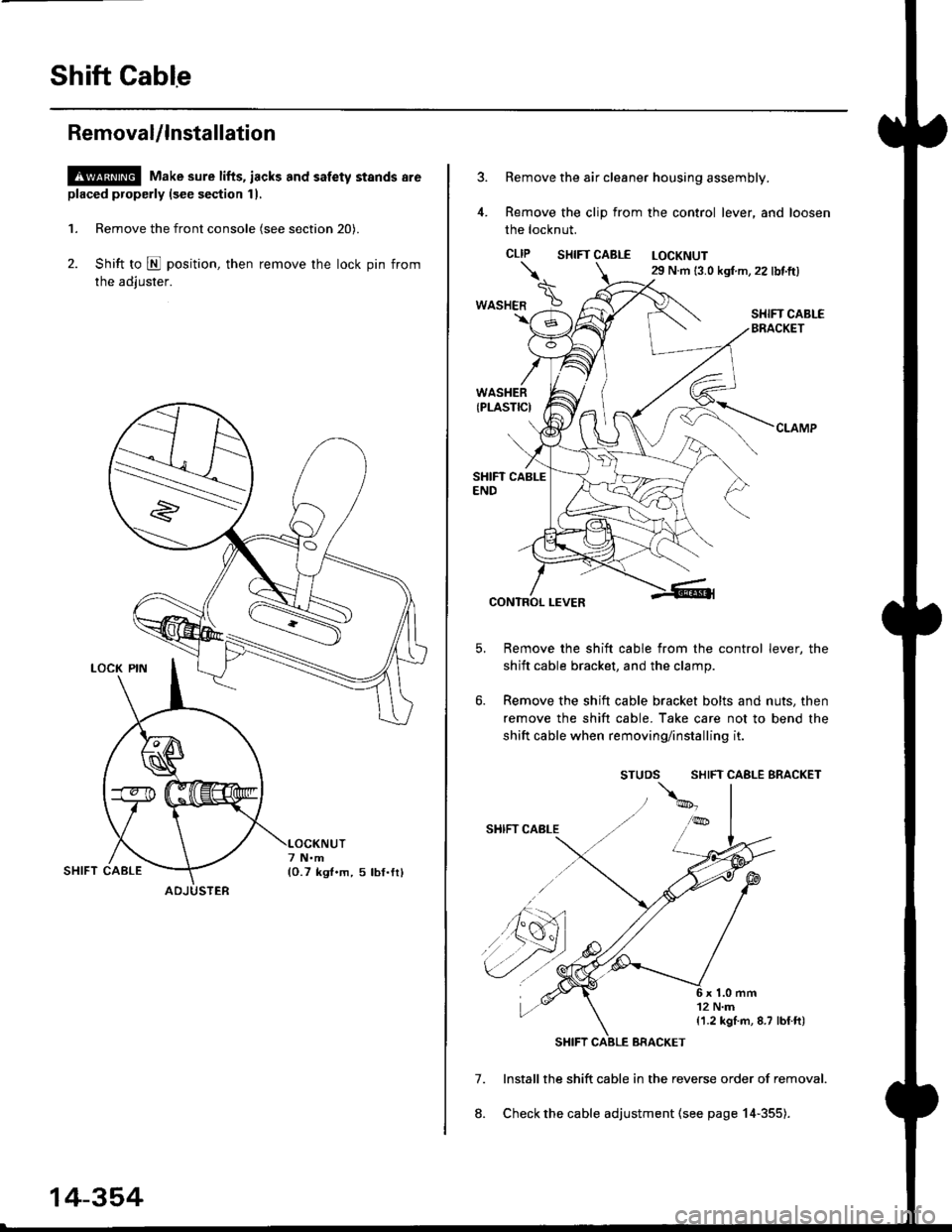

1. Remove the front console (see section 20).

2. Shift to E position, then remove the lock pin from

the adiuster.

ADJUSTER

14-354

Remove the air cleaner housing assembly.

Remove the clip from the control lever, and loosen

the locknut.

CLIP SHTFT CABLE LOCKNUT29 N.m 13.0 kgf m,22 lbf.ft)

SHIFT CABI-EBRACKET

7.

8.

CONTROL LEVER

Remove the shift cable from the control lever, the

shift cable bracket, and the clamp.

Remove the shift cable bracket bolts and nuts, then

remove the shift cable. Take care not to bend the

shift cable when removing/installing it.

SHIFT CABLE BRACKET

lnstall the shift cable in the reverse order of removal.

Check the cable adjustment (see page 14-355).

\.

*o"ra" \

{1.2 kgI m, 8.7 lblft)

Page 1031 of 2189

t

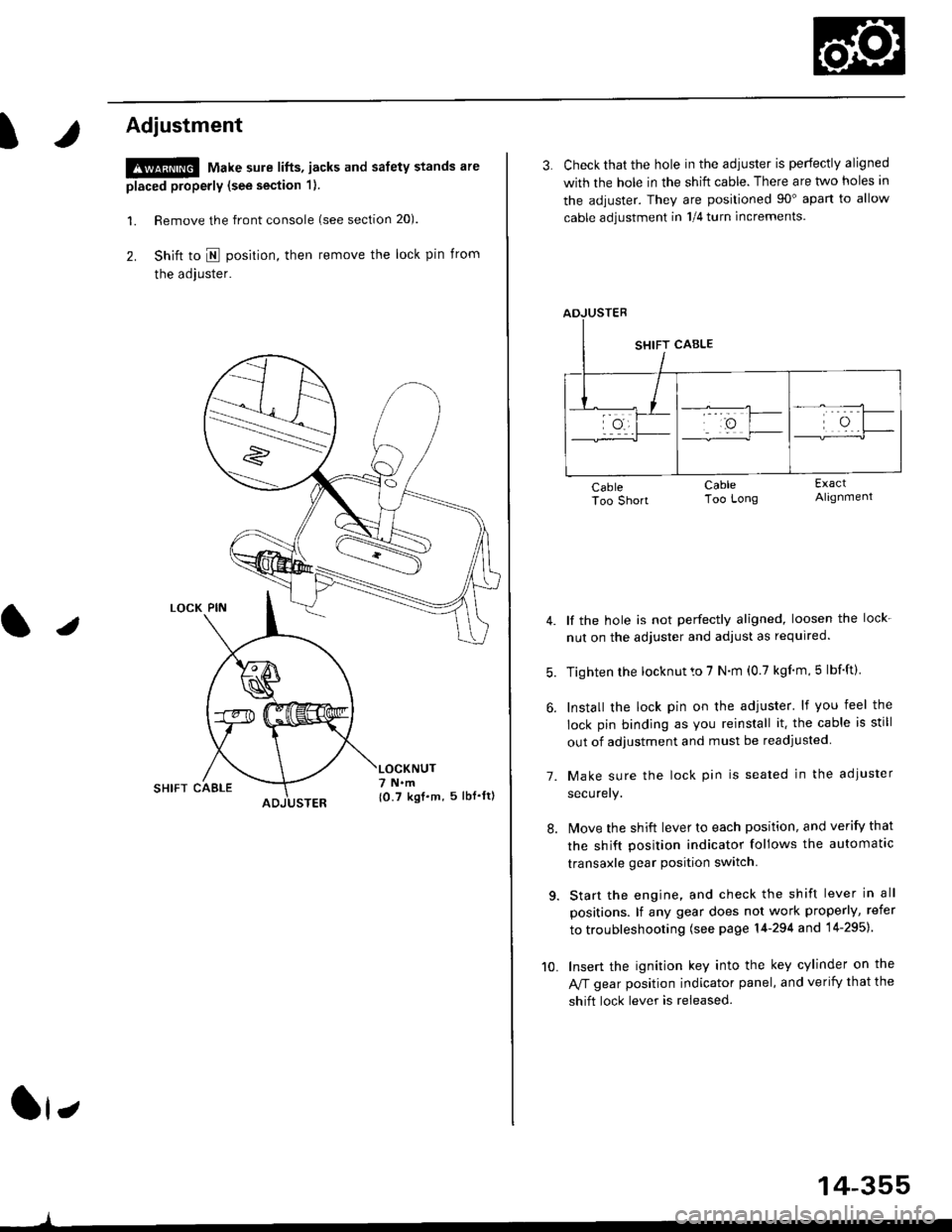

Adjustment

!@ Make sure lifts, jacks and safety stands are

placed properly (see section 1).

l. Remove the front console (see section 20).

2. Shift to I posirion, then remove the lock pin from

the adjuster.

SHIFT CAELE

l,

,l

{0.7 kgf.m, 5lbf'ltl

3. Check that the hole in the adiuster is perfectly aligned

with the hole in the shift cable. There are two holes in

the adjuster. They are positioned 90" apart to allow

cable adjustment in 1/4 turn increments.

lf the hole is not perfectly aligned, loosen the lock-

nut on the adjuster and adjust as required.

Tighten rhe locknut to 7 N.m (0.7 kgim,5 lbf'ft).

Install the lock pin on the adjuster' lf you feel the

lock pin binding as you reinstall it. the cable is still

out of adjustment and must be readjusted

Make sure the lock pin is seated in the adiuster

securery.

lMove the shift lever to each position, and verify that

the shift position indicator follows the automatlc

transaxle gear position switch.

Start the engine, and check the shift lever in all

positions. lf any gear does not work properly, refer

to troubleshooting (see page 14-294 and 14-295).

Insert the ignition key into the key cylinder on the

Aff gear position indicator panel, and verify that the

shift lock lever is released.

7.

10.

14-355

Page 1033 of 2189

Shift Indicator PanelATF Gooler/Hoses

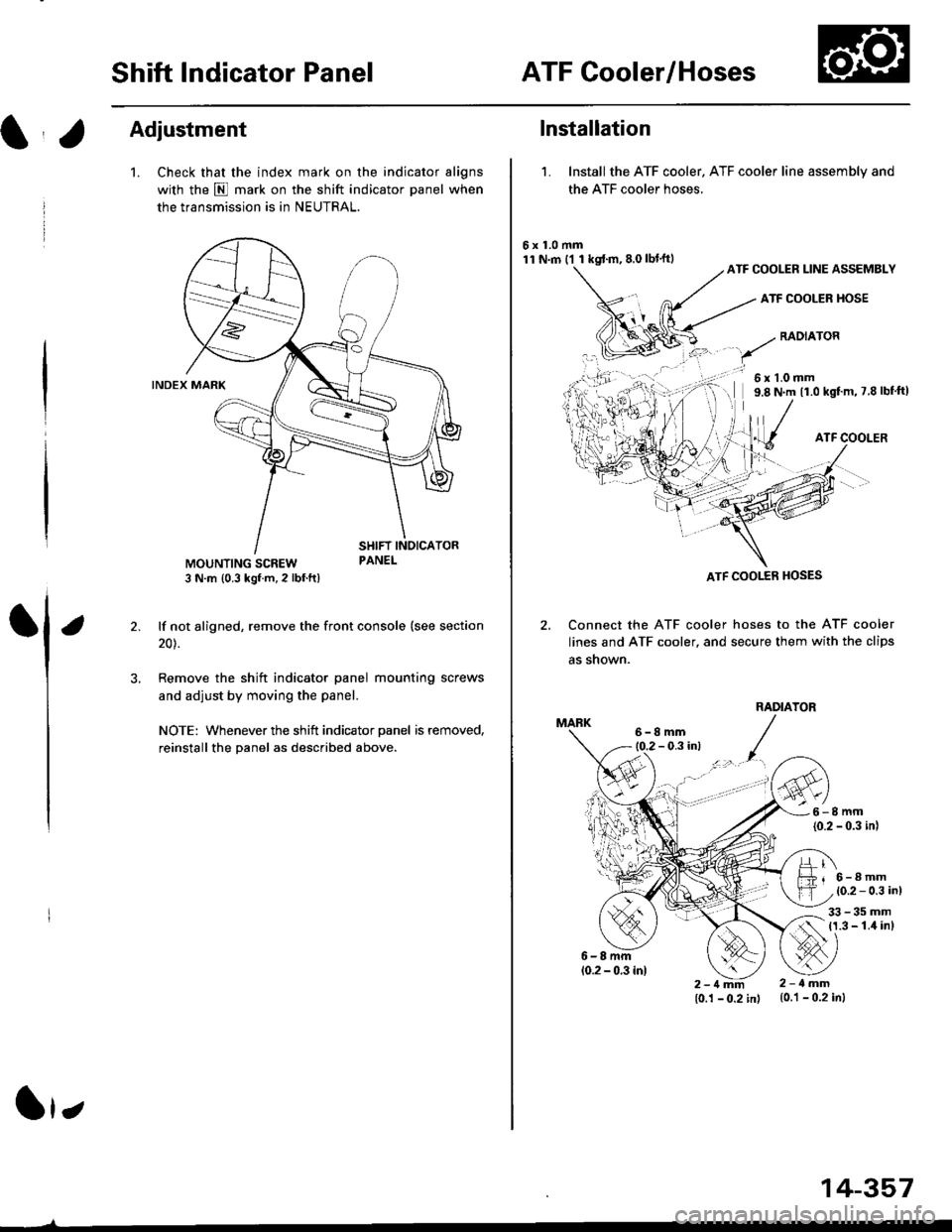

Adjustment

1.Check that the index mark on the indicator aligns

with the E mark on the shift indicator panel when

the transmission is in NEUTRAL.

lf not aligned, remove the front console {see section

20).

Remove the shift indicator panel mounting

and adjust by moving the panel.

NOTE: Whenever the shift indicator panel is removed,

reinstallthe Danel as described above.

It,

14-357

lnstallation

1. Installthe ATF cooler, ATF cooler line assembly and

the ATF cooler hoses.

6x1.0mm11 N.m ('l 1 kgf.m,8.0lbl'ftlATF COOLER LINE ASSEMBLY

ATF COOLER HOSE

RADIATOR

6x1.0mm9.8 N.m 11.0 kgf'm, 7 8 lbf'ft)

ATF COOLER

Connect the ATF cooler

lines and ATF cooler. and

as shown.

hoses to the ATF cooler

secure them with the clips

1l lTf{il.T

6-8mm10.2 - 0.3 in)

33-35mm11.3 - 1.4 inl

2-1mm10.1 - 0.2 in)

2-ilmm{0.1 - 0.2 in)

ATF COOI..ER HOSES

Page 1036 of 2189

Driveshafts

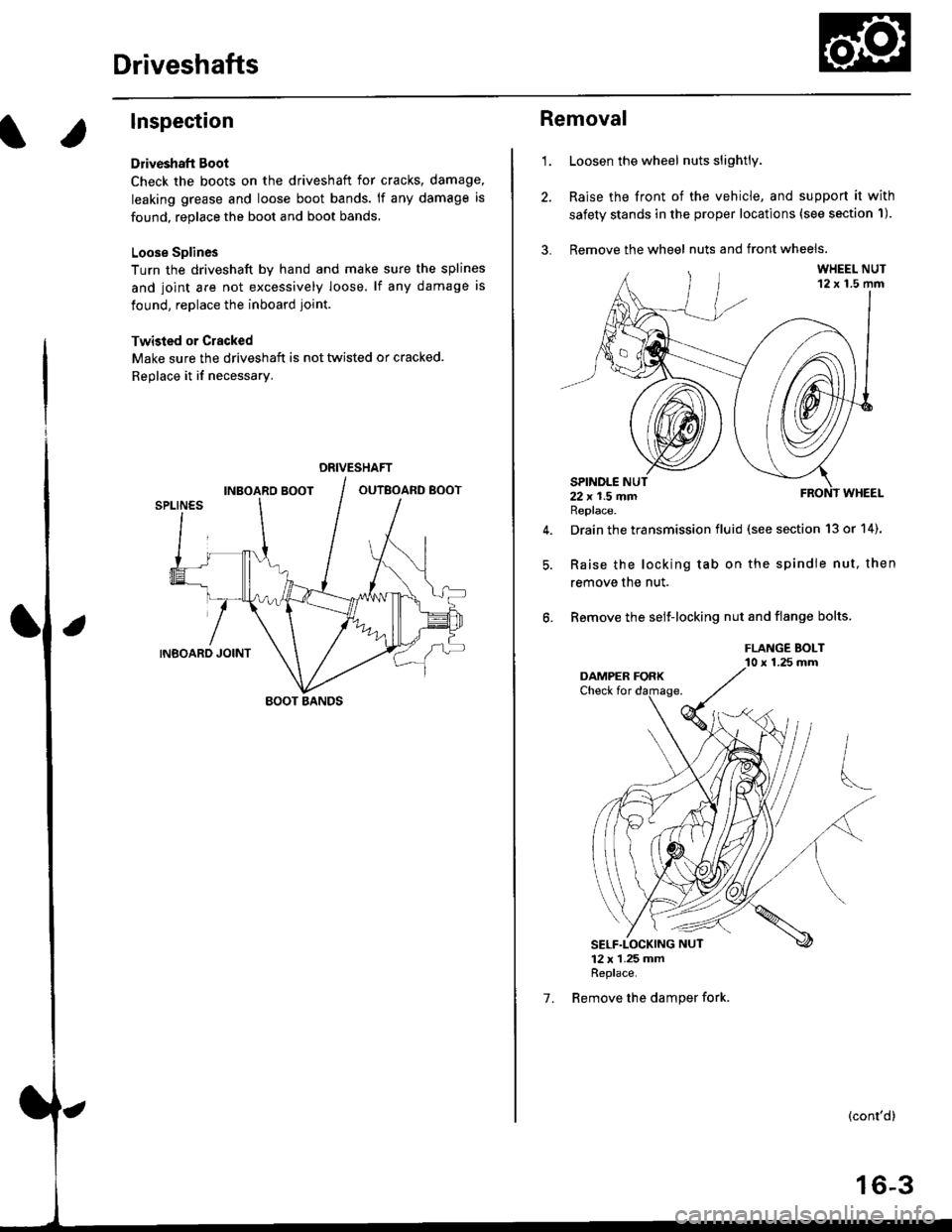

Inspection

Driveshaft Boot

Check the boots on the driveshaft for cracks, damage,

leaking grease and loose boot bands. lf any damage is

found, replace the boot and boot bands,

Loose Splines

Turn the driveshaft by hand and make sure the splines

and joint are not excessively loose. lf any damage is

found, replace the inboard joint.

Twisied or Cracked

Make sure the driveshaft is not twisted or cracked.

Reolace it if necessarv.

DRIVESHAFT

BOOT BANDS

1.

Removal

Loosen the wheel nuts slightly.

Raise the front of the vehicle, and support it with

safety stands in the proper locations (see section 'l).

Remove the wheel nuts and front wheels.

Drain the transmission fluid (see section 13 or 14).

Raise the locking tab on the spindle nut, then

remove the nut.

Remove the selJ-locking nut and flange bolts.

FLANGE BOLT10 x 1.25 mm

(cont'd)

16-3

1.

Page 1037 of 2189

Driveshafts

Removal (cont'd)

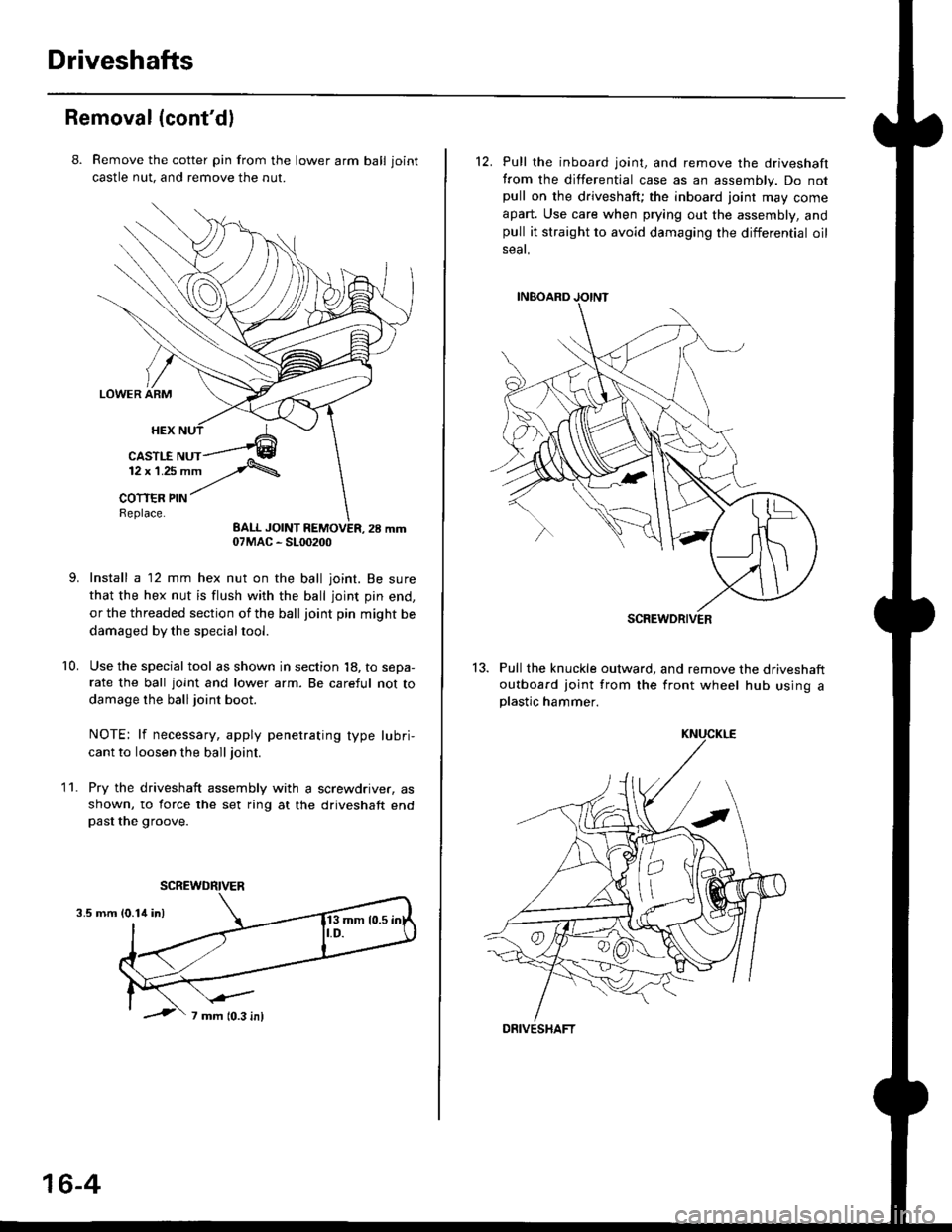

8. Remove the cotter pin from the lawer arm ball joint

castle nut. and remove the nut.

Install a 12 mm hex nut on the ball joint. Be sure

that the hex nut is flush with the ball joint pin end,

or the threaded section of the ball joint pin might be

damaged by the special tool.

Use the special tool as shown in section 18, to sepa-

rate the ball joint and lower arm. Be careful not to

damage the ball joint boot.

NOTE: lf necessary, apply penetrating type lubri,

cant to loosen the ball joint.

Pry the driveshaft assembly with a screwdriver, as

shown, to force the set ring at the driveshaft endpast the groove.

10.

11.

3.5 mm

07MAC - SL00200

SCREWDRIVER

16-4

12. Pull the inboard joint, and remove the driveshaft

from the differential case as an assembly. Do notpull on the driveshaft; the inboard joint may come

apart. Use care when prying out the assembly, andpull it straight to avoid damaging the differential oil

seat.

13. Pull the knuckle outward, and remove the driveshaft

outboard joint from the front wheel hub using aplastic hammer.

SCREWDRIVER

DRIVESHAFT

Page 1038 of 2189

t

Disassembly

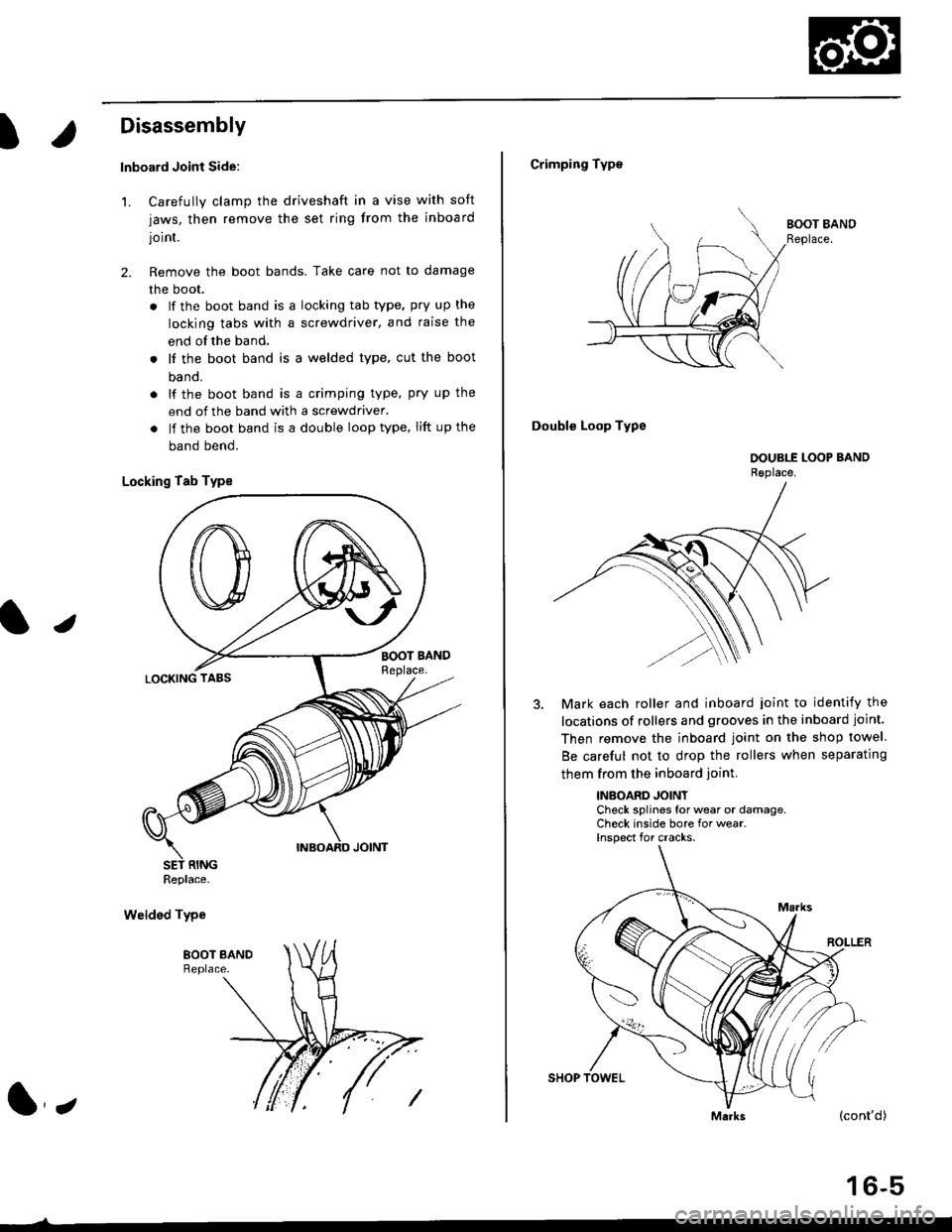

lnboard Joint Side:

1. Carefully clamp the driveshaft in a vise with soft

jaws, then remove the set ring from the inboard

joint.

2. Remove the boot bands. Take care not to damage

the boot.

. lf the boot band is a locking tab type, pry up the

locking tabs with a screwdriver, and raise the

end of the band.

. It the boot band is a welded type, cut the boot

ba nd.

. lf the boot band is a crimping type, pry up the

end of the band with a screwdraver.

. lf the boot band is a double loop type, lift up the

band bend.

Locking Tab Typs

Welded Type

J

Replace.

l,

Crimping Type

Double Loop Type

Mark each roller and inboard joint to identify the

locations of rollers and grooves in the inboard joint.

Then remove the inboard joint on the shop towel.

Be careful not to drop the rollers when separating

them from the inboard ioint.

INBOARD JOINTCheck splines for wear or damage,Check inside bore for wear.Inspect for cracks.

(cont'd)

16-5

Page 1039 of 2189

Driveshafts

Disassembly (cont'dl

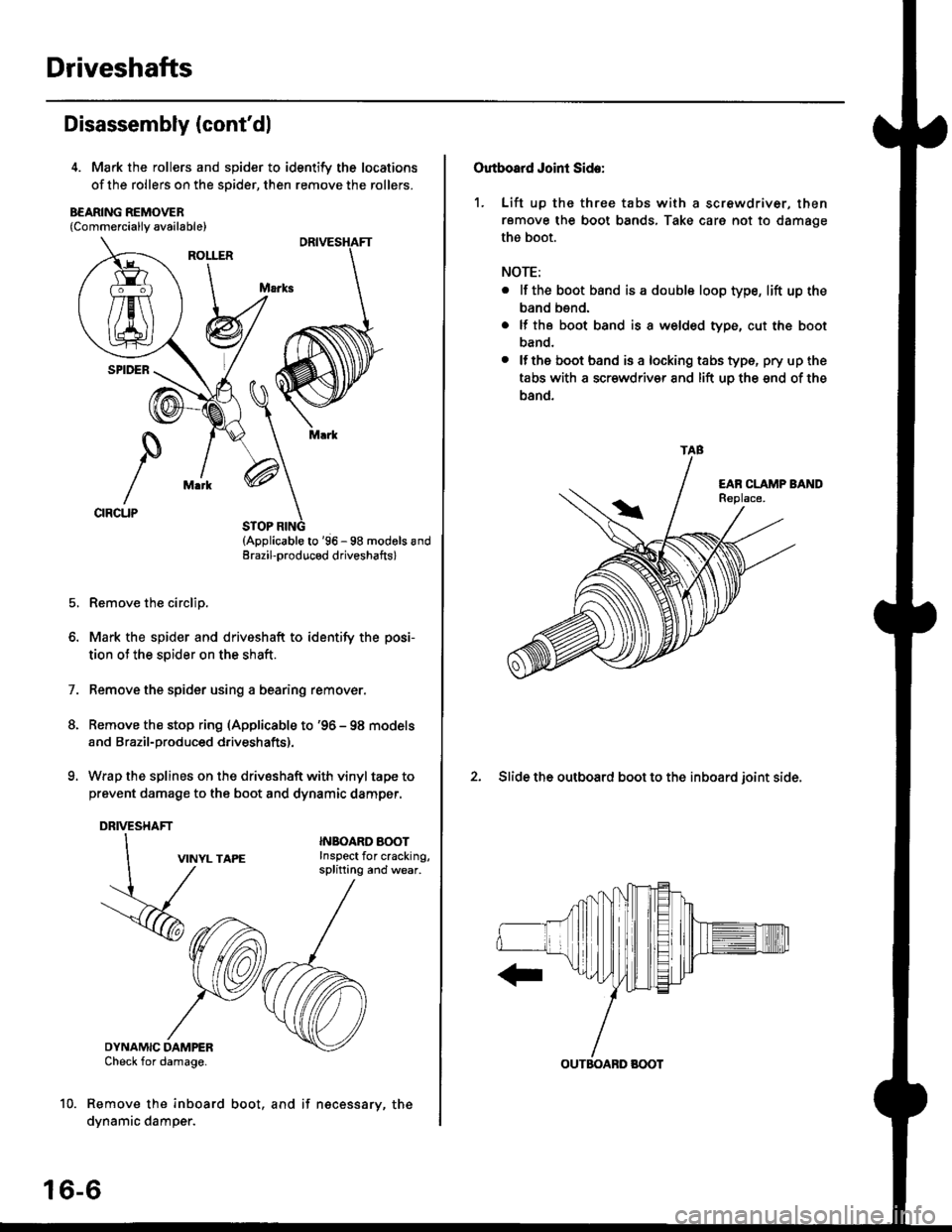

4. Mark the rollers and spider to identify the locations

of the rollers on the sDider, then remove the rollers.

B€ARING REMOVER{Commerciallv available}

STOP RING(Applicable to '96 - 98 modols andErazil-produced driveshafts)

Remove the circlip.

Mark the spider and driveshaft to identify the posi-

tion ot the spider on the shaft.

Remove the spider using a bearing remover.

Remove the stop ring (Applicable to '96 - 98 models

and Brazil-produced driveshafts).

Wrap the splines on the drivsshaft with vinyl tape to

prevent damage to the boot and dynamic damper.

DRIVESHAFT

1.

VINYL TAPE

DYNAMIC DAMPERCheck for damage.

Remove the inboard

dynamic damper.

INBOARO AOOTInspect for cracking,splitting and wear.

16-6

boot, and if necessary, the

Outboard Joint Side:

1. Lift up thc three tabs with a screwdriver, then

remove the boot bands, Take care not to damage

the boot.

NOTE:

. lf the boot band is a double loop type, lift up the

band bend.

. lf the boot band is a welded type, cut the boot

band.

. lfthe boot band is a locking tabs type, pry up the

tabs with a scr€wdriv€r and lift uo the snd of the

band.

2. Slide the outboard boot to the inboard ioint side.

TAB

OUTBOABD BOOT

Page 1046 of 2189

l.

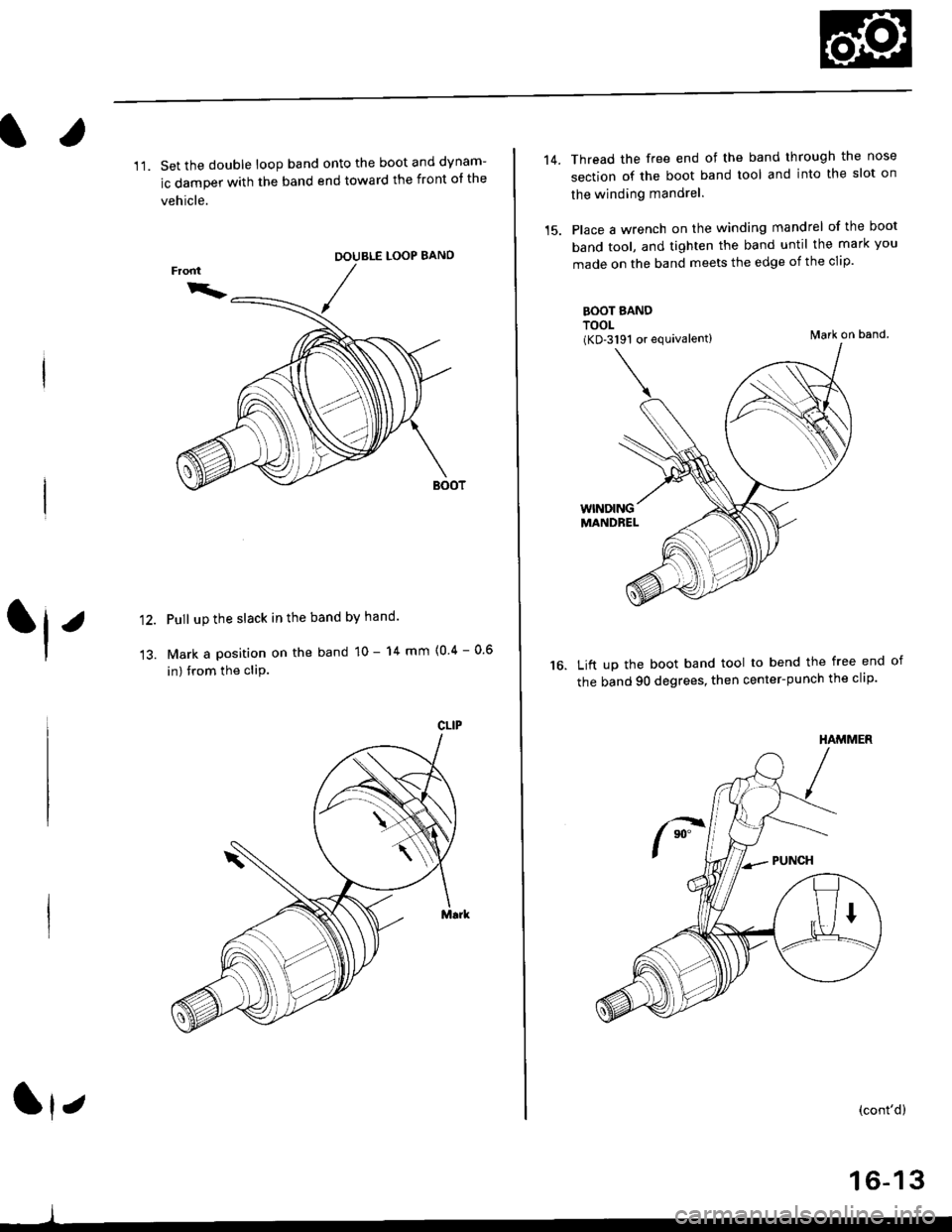

11. Set the double loop band onto the boot and dynam-

ic damper with the band end toward the front ot the

vehicle.

LOOP BANO

Pull up the slack in the band bY hand

Mark a position on the band 10 - 14 mm {0 4 - 0 6

in) from the cliP.

DOUBLE

,

1')

13.

CLIP

Ip

14.

15.

Thread the free end of the band through the nose

section of the boot band tool and into the slot on

the winding mandrel.

Place a wrench on the winding mandrel of the boot

band tool, and tighten the band until the mark you

made on the band meets the edge of the clip.

Mark on band.

Lift up the boot band tool to bend the free end

the band 90 degrees, then center-punch the clip'16.

(cont'd)

16-13

(KD-3191 or equivalent)

HAMMER

Page 1050 of 2189

I

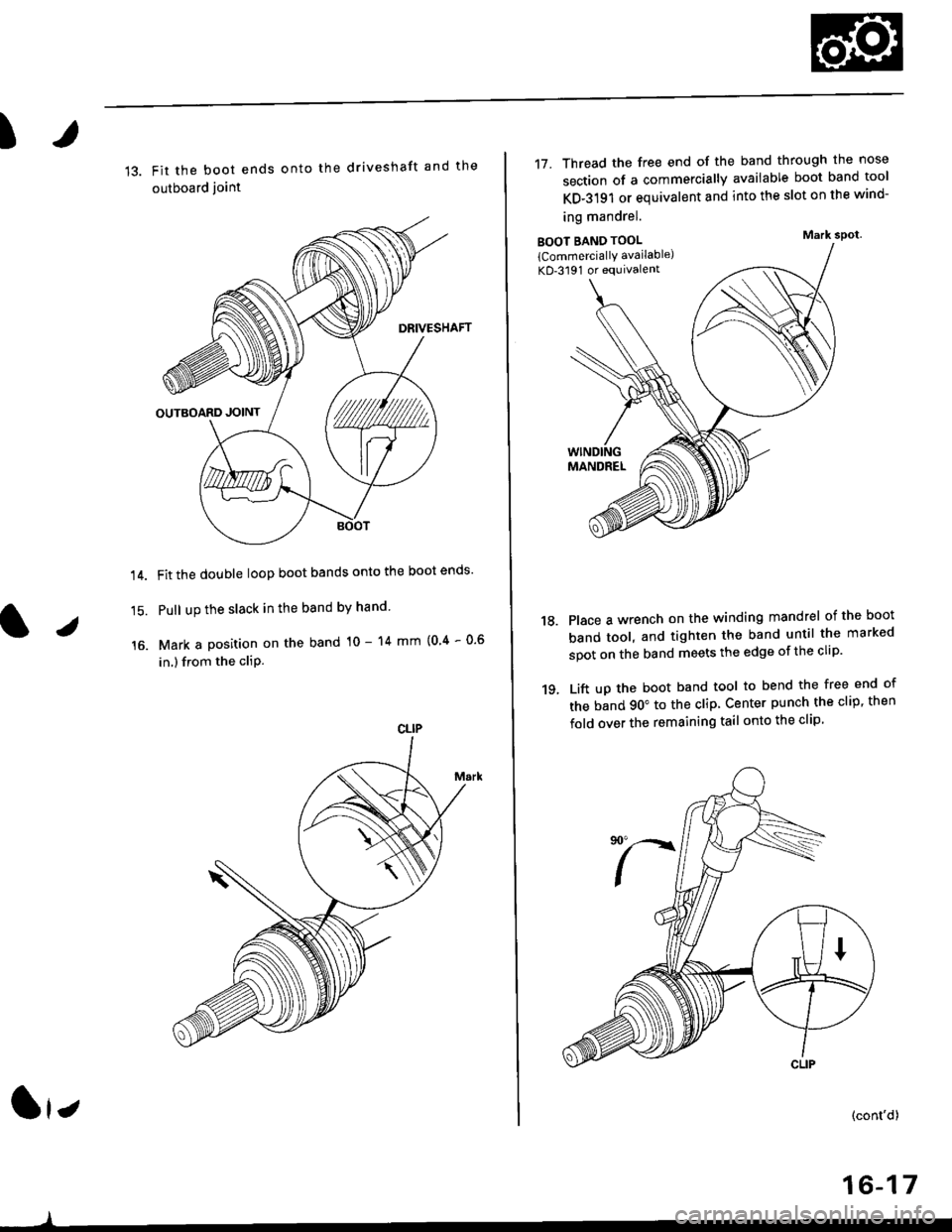

13. Fit the boot ends onto the driveshaft and the

outboard joint

Fit the double loop boot bands onto the boot ends'

Pull up the slack in the band by hand'

Mark a position on the band 10 - 14 mm {0 4 - 0 6

in,) from the cliP.

14.

16.

CLIP

lrz

17. Thread the free end of the band through the nose

section of a commercially avaiiable boot band tool

KD-3191 or equivalent and into the slot on the wind-

ing mandrel.

BOOT BAND TOOL

lCommerciallY available)

KD-3191 or equivalent

MANDREL

Place a wrench on the winding mandrel of the boot

band tool, and tighten the band until the marked

spot on the band meets the edge of the clip'

Lift uo the boot band tool to bend the free end of

the band 90" to the clip Center punch the clip, then

fold over the remaining tail onto the clip

Mark spot.

18.

1q

(cont'd)

16-17