HONDA CIVIC 1999 6.G Workshop Manual

Manufacturer: HONDA, Model Year: 1999, Model line: CIVIC, Model: HONDA CIVIC 1999 6.GPages: 2189, PDF Size: 69.39 MB

Page 811 of 2189

1.Remove the 13 bolts securing the end cover, then

remove the cover.

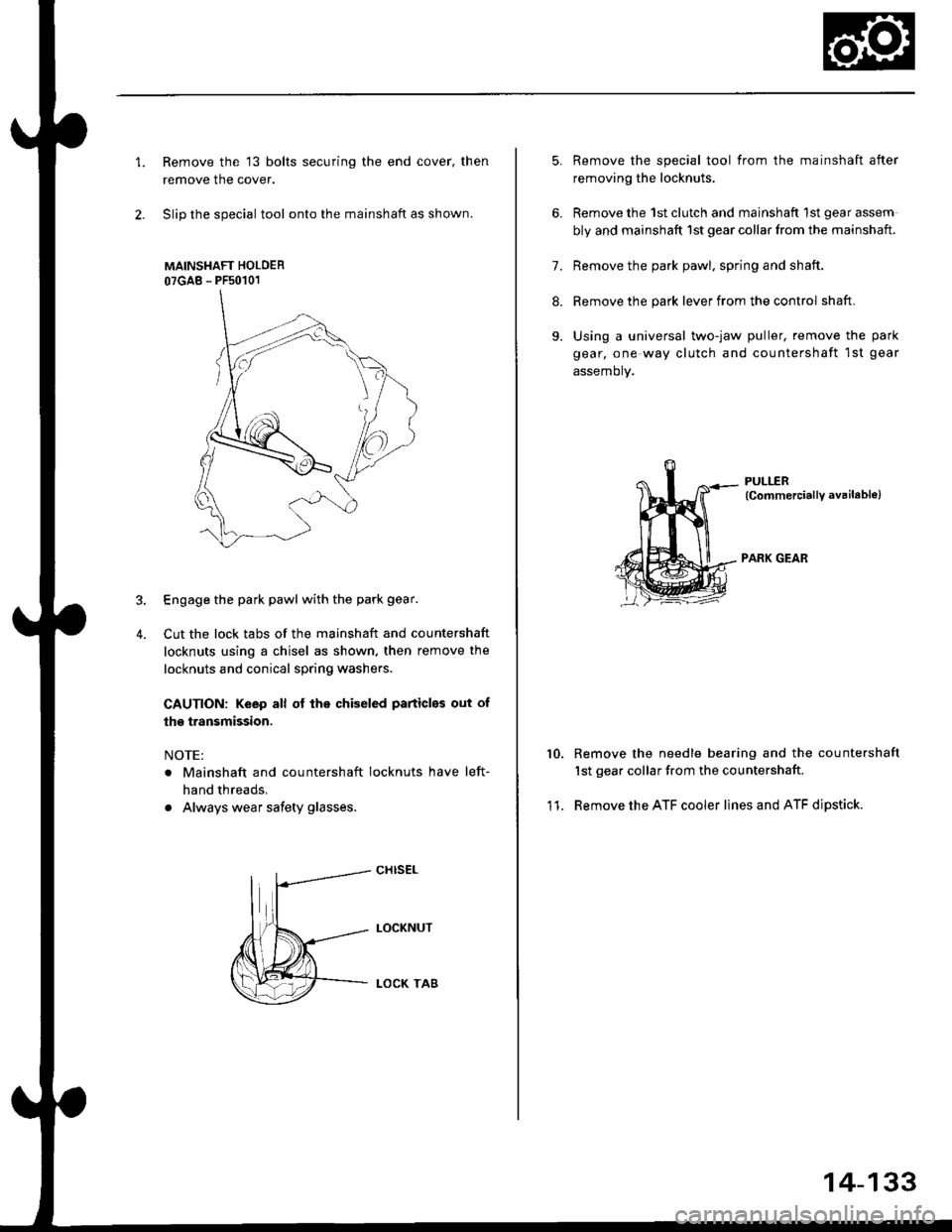

Slip the special tool onto the mainshaft as shown.

MAINSHAFT HOLOER

07GAB - PFs0101

Engage the park pawl with the park gear.

Cut the lock tabs of the mainshaft and countershaft

locknuts using a chisel as shown. then remove the

locknuts and conical spring washers

CAUTION: Keep all of lhe chiseled particles out of

the transmission.

NOTE:

. Mainshaft and countershaft locknuts have left-

hand threads.

. Always wear safety glasses.

4.

cHrs€L

LOCKNUT

LOCK TA8

5.

6.

11.

Remove the special tool from the mainshaft after

removing the locknuts.

Remove the 1st clutch and mainshaft 1st gear assem

bly and mainshaft 1st gear collar from the mainshaft.

7. Remove the park pawl. spring and shaft.

8. Remove the park lever from the control shaft.

9. Using a universal two-jaw puller, remove the park

gear, one way clutch and countershaft 1st gear

assemory.

PULLER(CommerciallY available)

PARK GEAR

10.Remove the needle bearing and the countershaft

1st gear collar from the countershaft

Remove the ATF cooler lines and ATF dipstick.

14-133

Page 812 of 2189

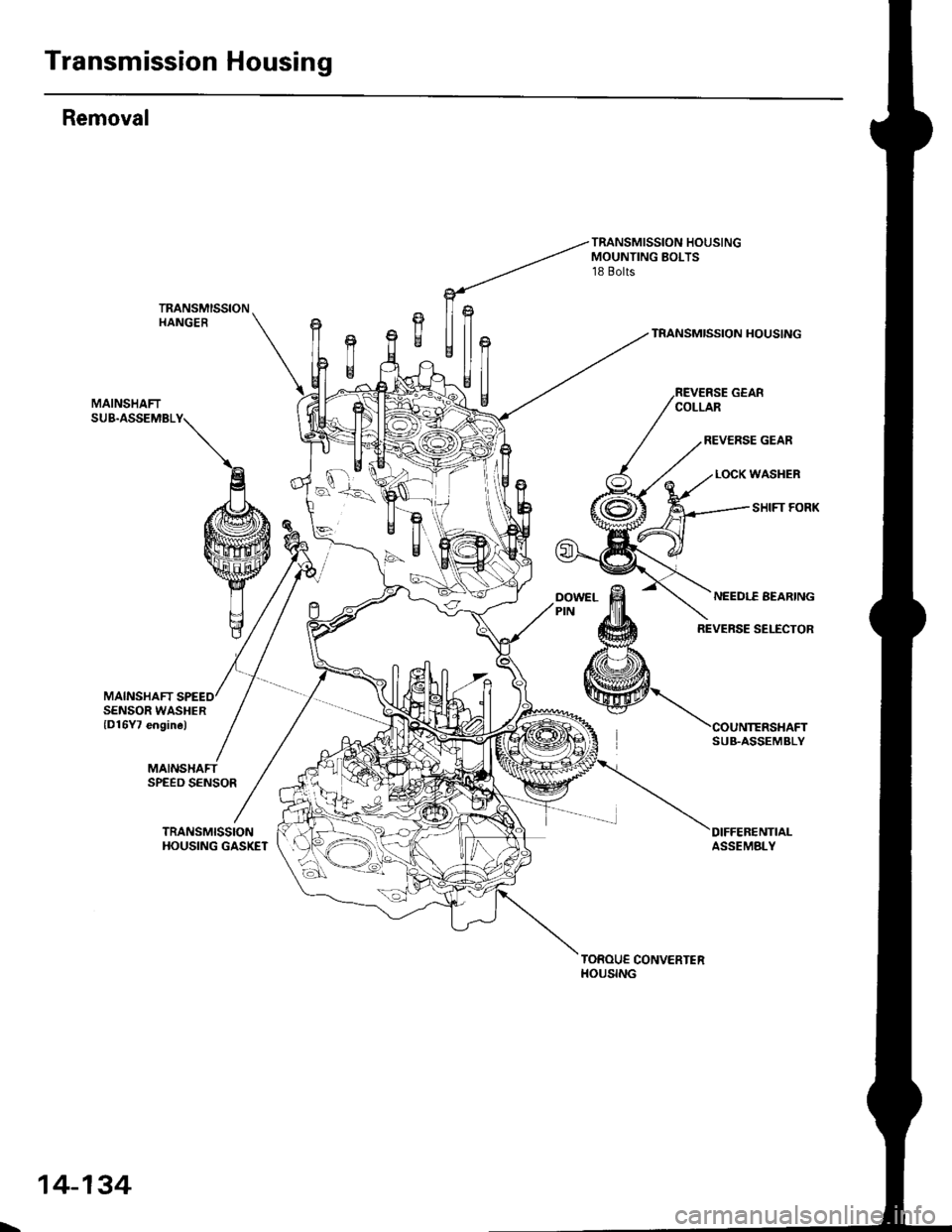

Transmission Housing

Removal

MAINSHAFT

TRANSMISSION HOUSINGMOUNTING BOLTS18 Bolts

TRANSMISSIONHANGERTRANSMISSION HOUSING

MAINSHAFTSUB.ASSEMBLY

SENSOR WASHERlD16Y7 engine)

MAINSHAFTSPEED SENSOR

TRANSMISSIONHOUSING GASKETDIFFEBENTIALASSEMBLY

TOROUE CONVERTERHOUSING

SUB.ASSEMBLY

L,

14-134

Page 813 of 2189

Page 814 of 2189

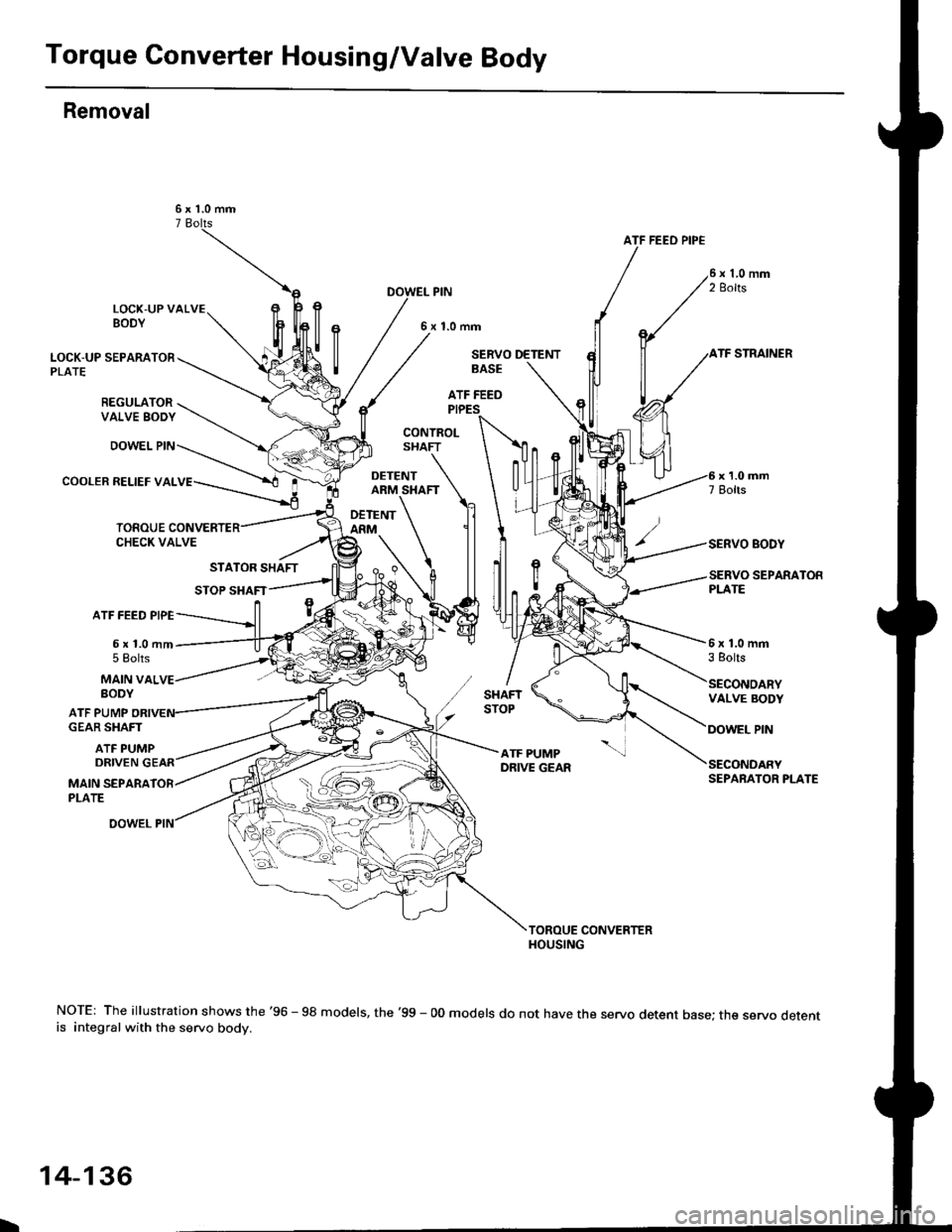

Torque Converter Housing/Valve Body

Removal

ATF FEEO PIP€

LOCK-UP VALVEBODY

PIN

6x1.0mm

LOCK-UP SEPARATORPLATE

REGULATORVALVE SODY

DOWEL PIN

COOLER RELIEF VAL

SERVO DETENTSTRAINER

SERVO EODY

SEPARATON

BASE

ATF FEEDPIPES

CONTROLSHAFT

DETENTARM SHAFT

DETENTARM

ATF FEED PIPE

6x1.0mm5 Eolts6x1.0mm3 Eolts

MAIN VALBODY

ATF PUMP

DRIVEN

VALVE BODY

PINGEAR SHAFT

ATF PUMP

MAIN SEPARAPLATE

SECONDARYSEPARATOR PLATE

NOTE: The illustration shows the '96 - 98 models, the '99 - 00 models do not have the servo detent base; the servo detentis integral with the servo body.

L

14-136

Page 815 of 2189

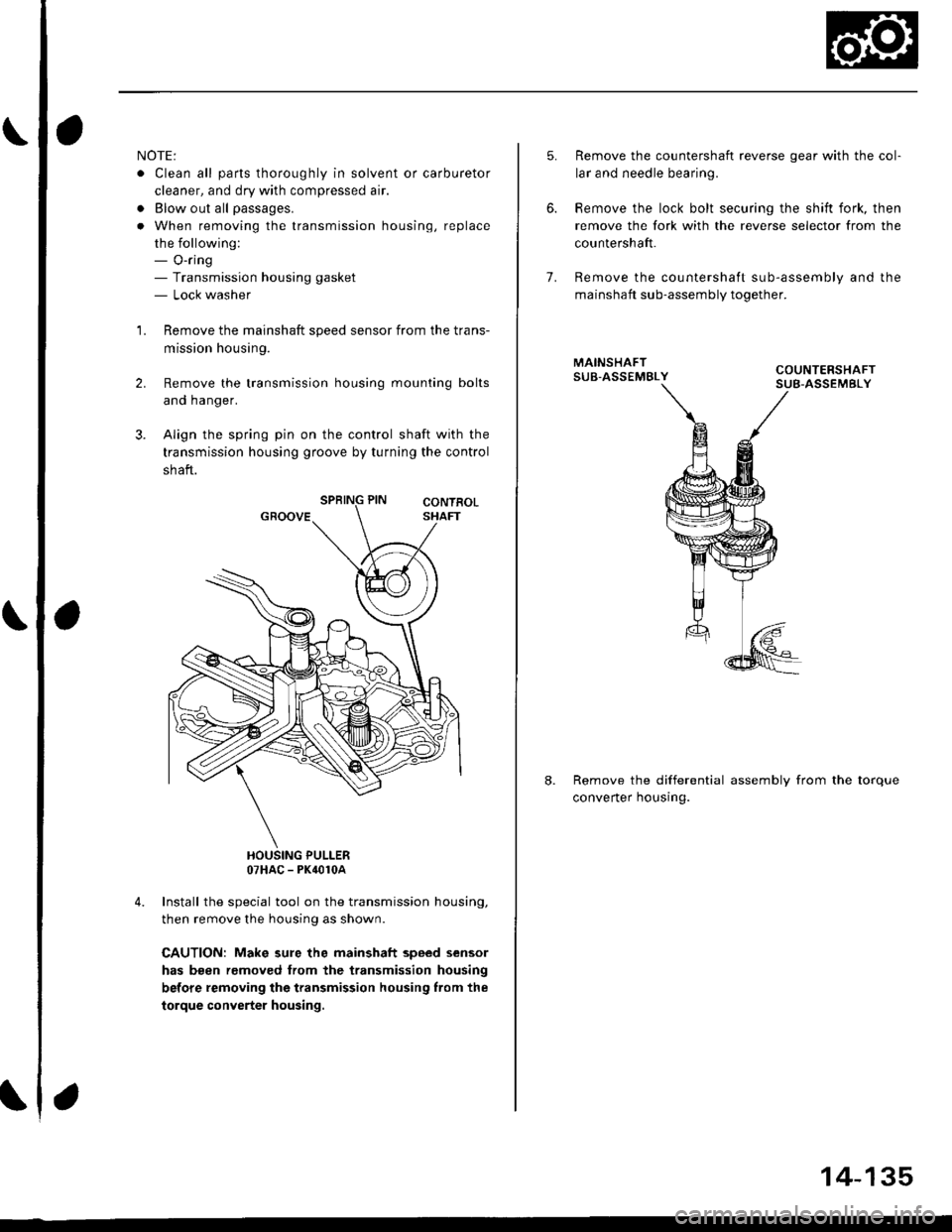

NOTE;

. Clean all parts thoroughly in solvent or carburetor

cleaner, and dry with compressed air.

. Blow out all passages.

. When removing the valve body, replace the O-ring.

l, Remove the ATF feed pipes from the servo body,

secondary valve body and main valve body.

For'96 - 98 models: Remove the ATF strainer and

servo detent base (two bolts).

For'99 - 00 models: Remove the ATF strainer (one

bolt).

Remove the servo body and servo separator plate

{'96 - 98 models: seven bolts,'99 - 00 models: eight

bolts).

Remove the secondary valve body, shaft stop and

secondary separator plate (three bolts).

Remove the lock-up valve body and separator plate

{seven bolts).

Remove the regulator valve body (one boltl.

Remove the stator shaft and stop shaft.

Remove the detent spring from the detent arm. then

remove the control shaft from the to.que converter

housing.

Remove the detent arm and detent arm shaft from

the main valve body.

Remove the main valve body (five bolts).

NOTE: Do not let the eight check balls fall outofthe

main valve body when removing the main valve

body.

Remove the ATF pump driven gear shaft, then remove

the ATF pump gears.

Remove the main separator plate and two dowel

pins.

7.

't'1.

10.

12.

14.

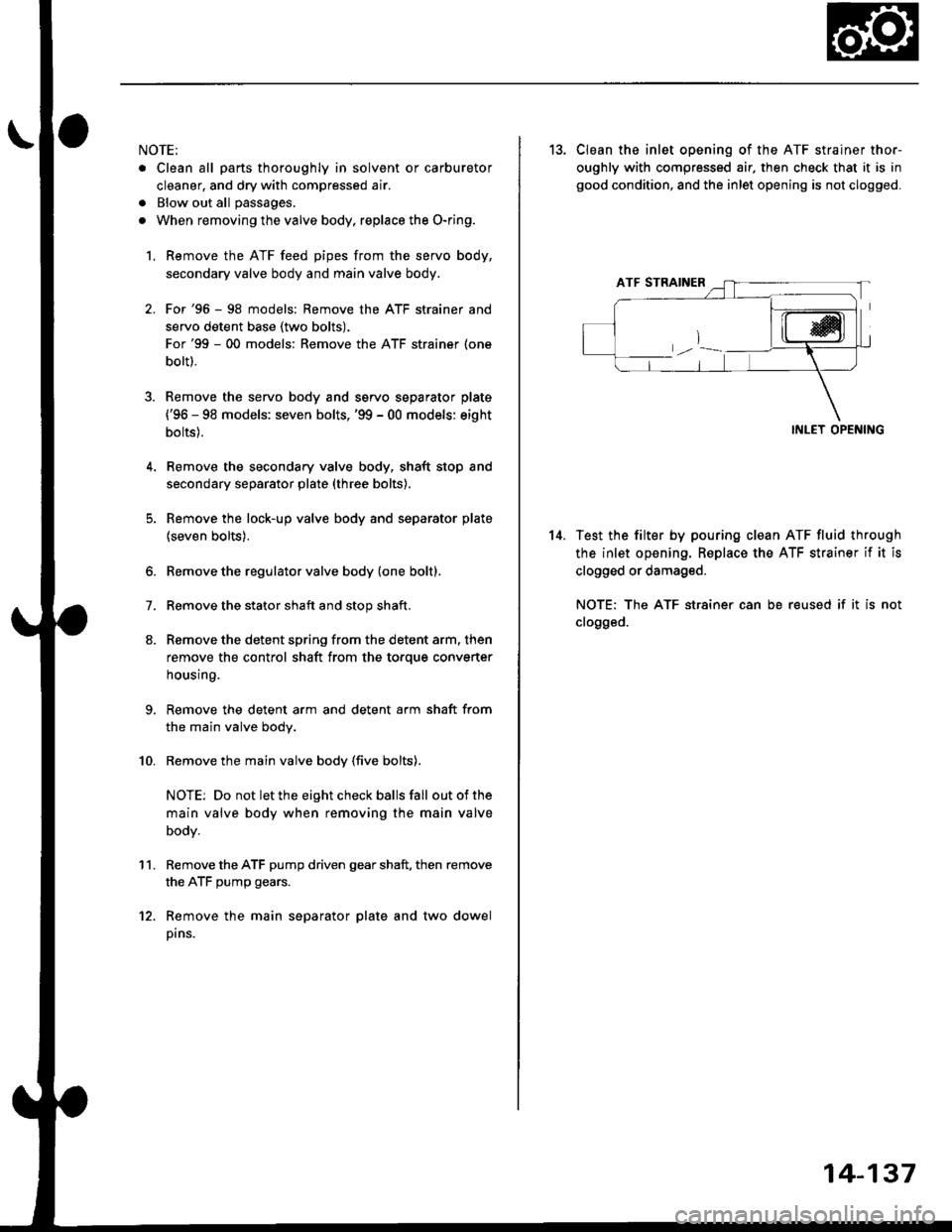

13. CIean the inlet opening of the ATF strainer thor-

oughly with compressed air. then check that it is in

good condition, and the inlet opening is not clogged.

INLET OPENING

Test the filter by pouring clean ATF fluid through

the inlet opening. Beplace the ATF strainer if it is

clogged or damaged.

NOTE: The ATF str8iner can be reused if it is not

clogged.

14-137

Page 816 of 2189

Valve Caps

Description

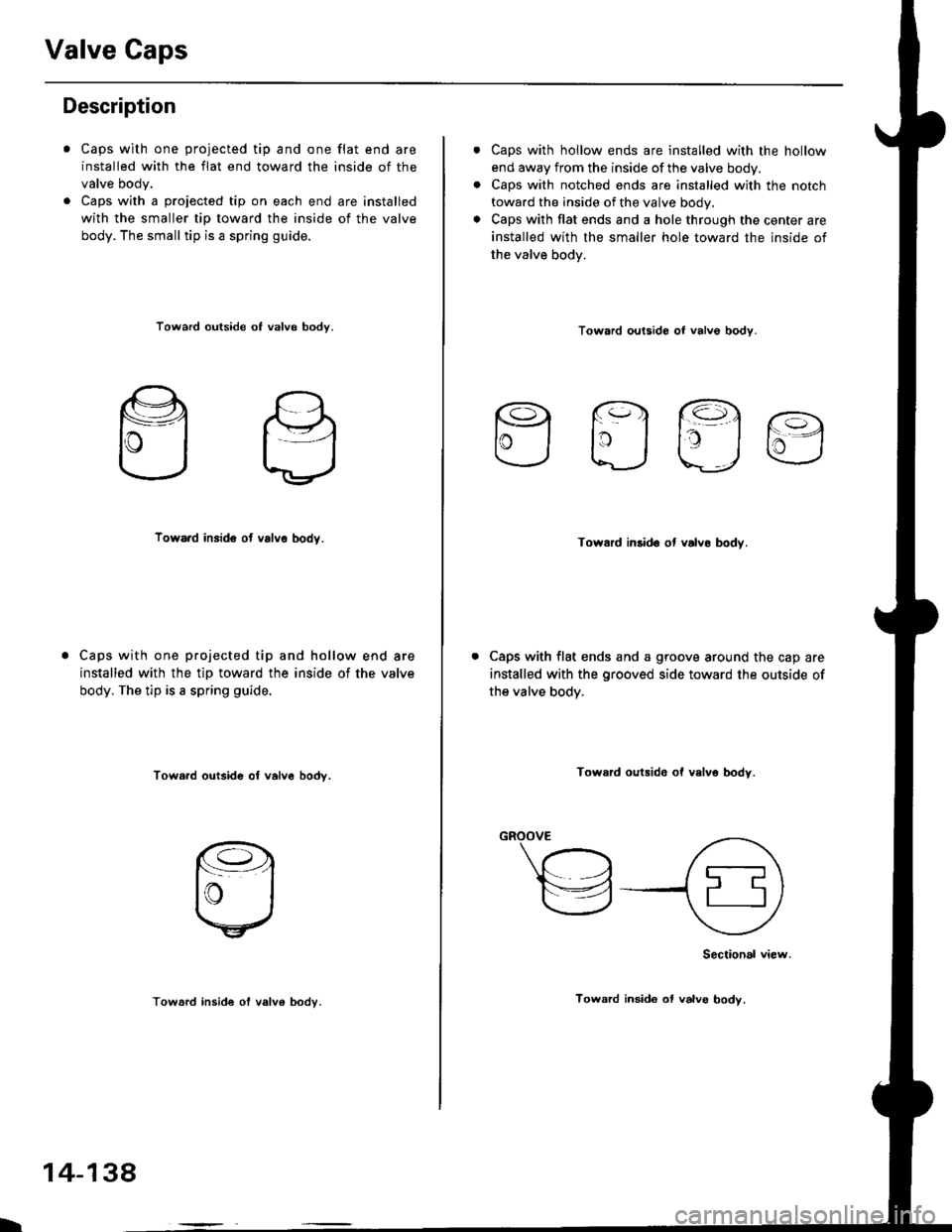

Caps with one projected tip and one flat end are

installed with the flat end toward the inside of the

valve body.

Caps with a projected tip on each end are installed

with the smaller tip toward the inside of the valve

body. The small tip is a spring guide.

Toward outside of valvo body.

Toward insido ot valvo body.

Caps with one projected tip and hollow end are

installed with the tip toward the inside of the valve

body. The tip is a spring guide.

Towa.d outside o, valv6 bodv.

I

14-138

Toward insid€ of valv6 bodv.

Caps with hollow ends are installed with the hollow

end away from the inside ofthe valve body.

Caps with notched ends are installed with the notch

toward the inside of the valve body.

Caps with flat ends and a hole through the center are

installed with the smaller hole toward the inside of

the valve bodv.

Toward outsido of valve bodv.

Efla

Toward inlido ot valve bodv,

Caps with flat ends and a groove around the cap are

installed with the grooved side toward the outside of

the valve body.

Toward oulsido of valv6 body.

"-\"h

,A

\za9

Sectional view.

Toward insido ol valvo body.

Page 817 of 2189

Valve Body

2.

Repair

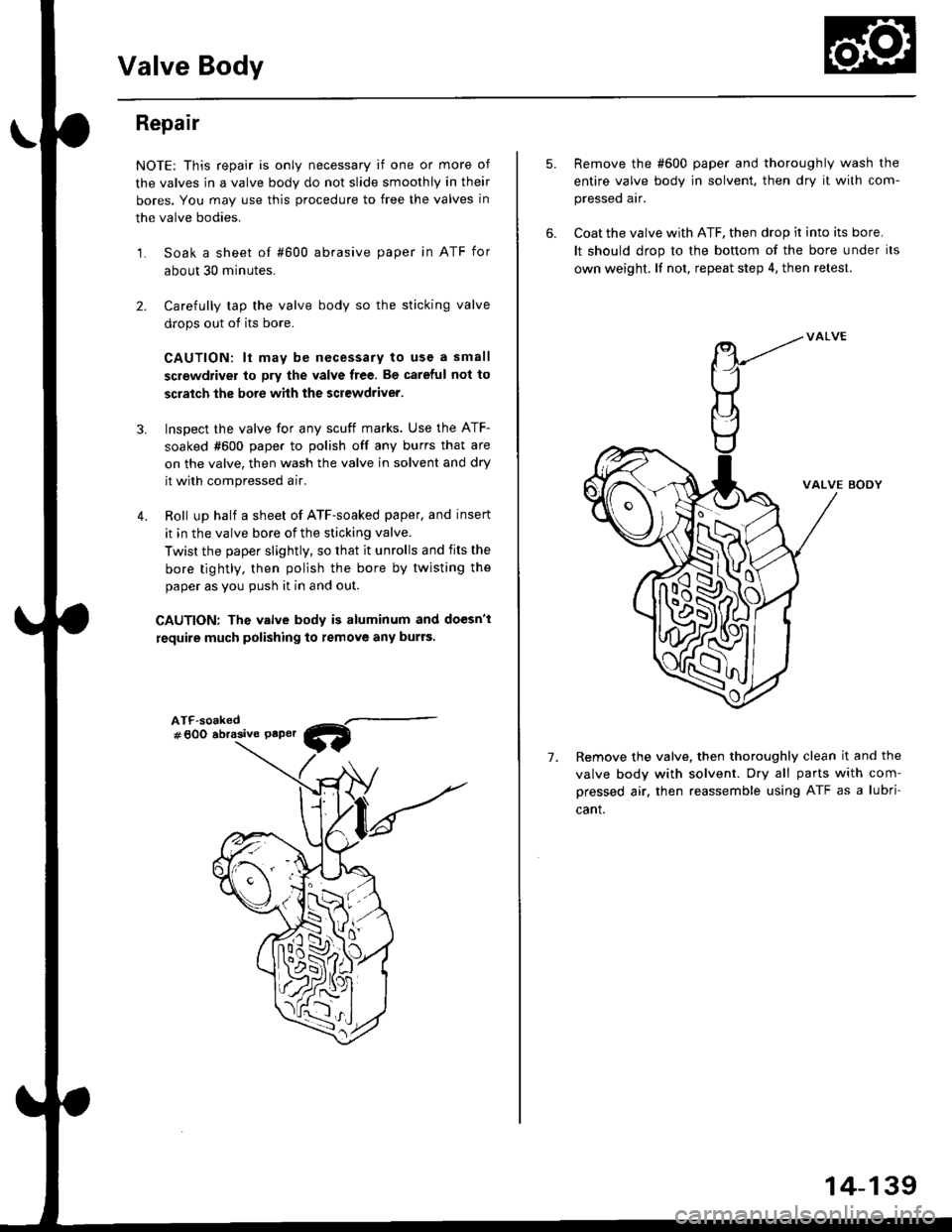

NOTE: This repair is only necessary if one or more of

the valves in a valve body do not slide smoothly in their

bores. You may use this procedure to free the valves in

the valve bodies.

1. Soak a sheet of #600 abrasive paper in ATF for

about 30 minutes.

Carefully tap the valve body so the sticking valve

drops out of its bore.

CAUTION: lt may b€ necessary to use a small

screwdriver to pry the valve free. Be careful not to

scratch the bore whh the screwdriver.

Inspect the valve for any scuff marks. Use the ATF-

soaked #600 paper to polish off any burrs that are

on the valve, then wash the valve in solvent and dry

it with compressed a ir.

Roll up half a sheet of ATF-soaked paper, and insert

it in the valve bore of the sticking valve.

Twist the paper slightly, so that it unrolls and fits the

bore tightly, then polish the bore by twisting the

paper as you push it in and out.

CAUTION: The valve body is aluminum and doesn't

require much polishing to remove any burrs,

3.

4.

ATF-soaked#600 abrasive Paper

5.

7.

Remove the #600 paper and thoroughly wash the

entire valve body in solvent. then dry it with com-

pressed air.

Coat the valve with ATF, then drop ir into its bore.

It should drop to the bonom of the bore under its

own weight. lf not, repeat step 4, then retest.

VALVE BODY

Remove the valve. then thoroughly clean it and the

valve body with solvent. Dry all parts with com-

pressed air. then reassemble using ATF as a lubri

cant.

W

-M

14-139

Page 818 of 2189

Valve

Assembly

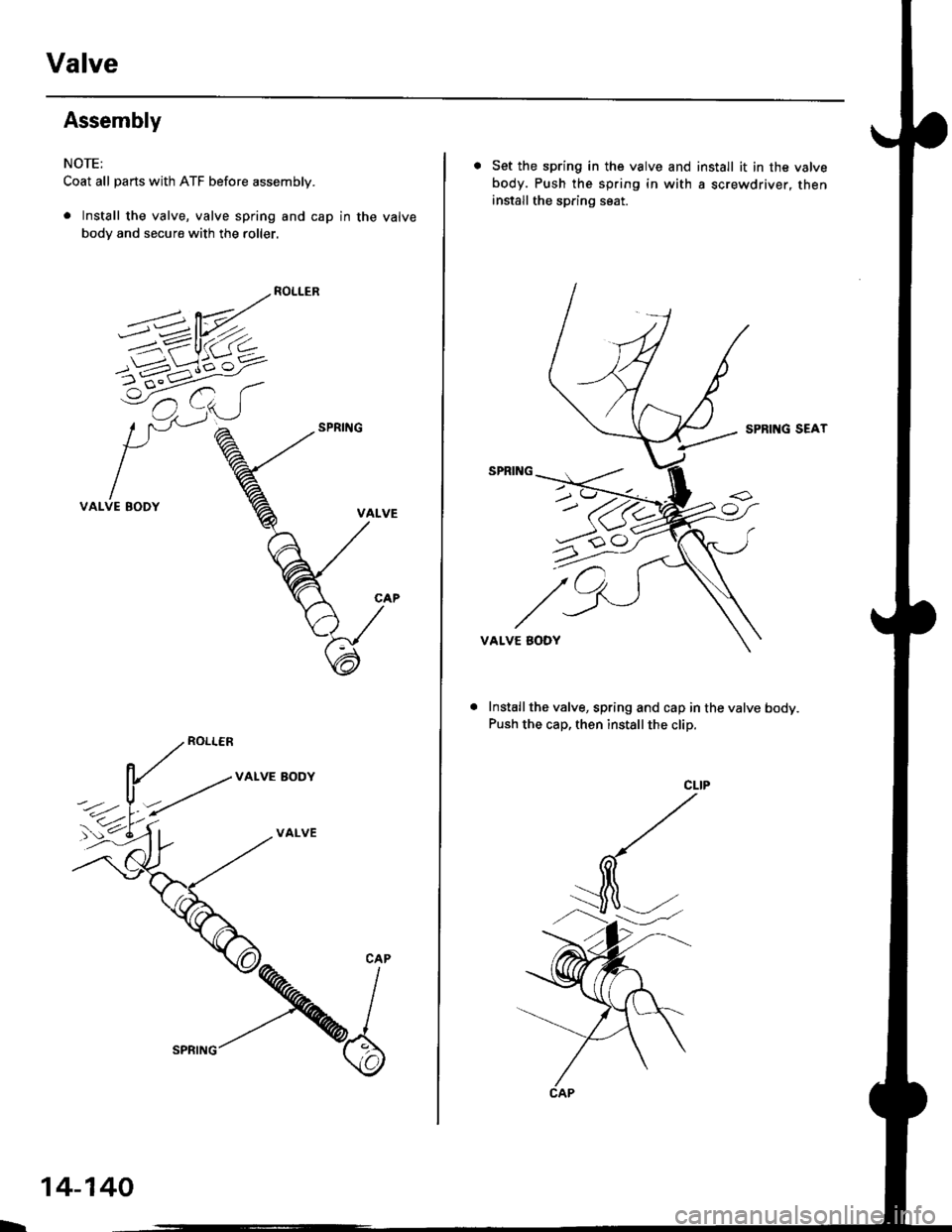

NOTE:

Coat all parts with ATF before assembly.

. Install the valve, valve spring and cap in the valve

body and secure with the roller.

5-'--------P/-_^?=w_

=/ /- ( ,. )l_/1 -,.1)

VALVE BODY

VALVE AODY

VALVE

h

14-140

SPRING

. Set the spring in the valve and install it in the valve

body. Push the spring in with a screwdriver, theninstall the spring seat.

SPRIITG SEAT

VALVE BODY

Install the valve, spring and cap in the valve body.

Push the cap, then installthe clip.

Page 819 of 2189

ATF Pump

Inspection

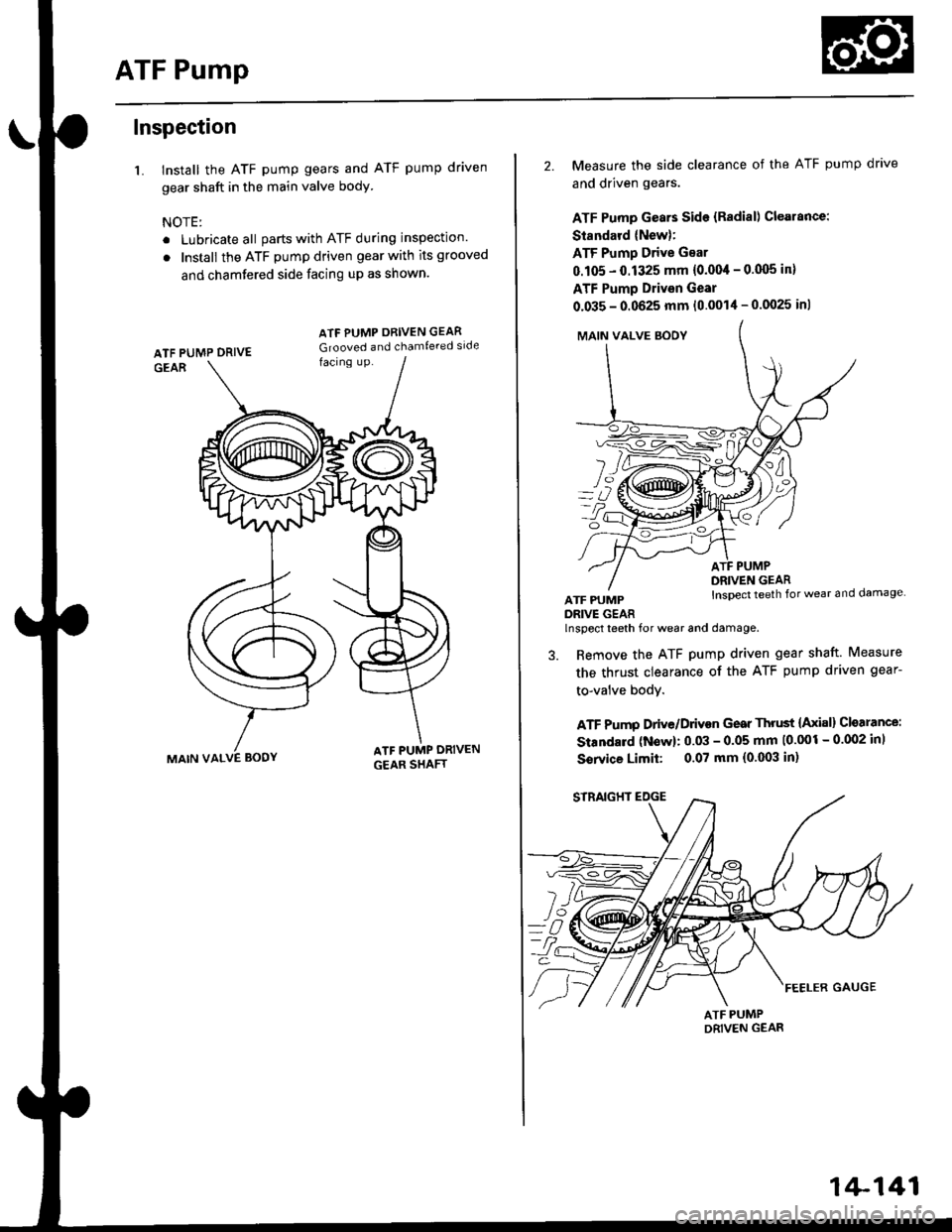

1. Install the ATF pump gears and ATF pump driven

gear shaft in the main valve body

NOTE:

. Lubricate all parts with ATF during inspection.

. Install the ATF pump driven gear with its grooved

and chamfered side facing up as shown.

MAIN VALVE BODY

ATF PUMP ORIVEN GEAR

Grooved and chamfe.ed side

2. Measure the side clearance of the ATF pump drave

and driven gears.

ATF Pump Gears Side {Radial) Clearance:

Standard (New):

ATF Pump Drive Gear

0.105 - 0.1325 mm {0.004 - 0.q)5 in}

ATF Pump Drivsn Gear

0.035 - 0.0625 mm (0.0014 - 0.0025 inl

MAIN VALVE SOOY

YZ]

o?

ATF PUMPDRIVE GEAR

ATF PUMPDRIVEN GEARInspect teeth for wear and damage

lnspect teeth for wear and damage.

3. Remove the ATF pump driven gear shaft. Measure

the thrust clearance of the ATF pump driven gear-

to-valve bodY.

ATF Pump Drive/Drivon Gear Thrust {Axial} Cloarance:

Standard (Now): 0.03 - 0.05 mm 10'001 - 0.002 inl

Sorvice Limit: 0.07 mm (0.003 in)

1+141

Page 820 of 2189

Main Valve Body

Disassembly/lnspection/Reassembly

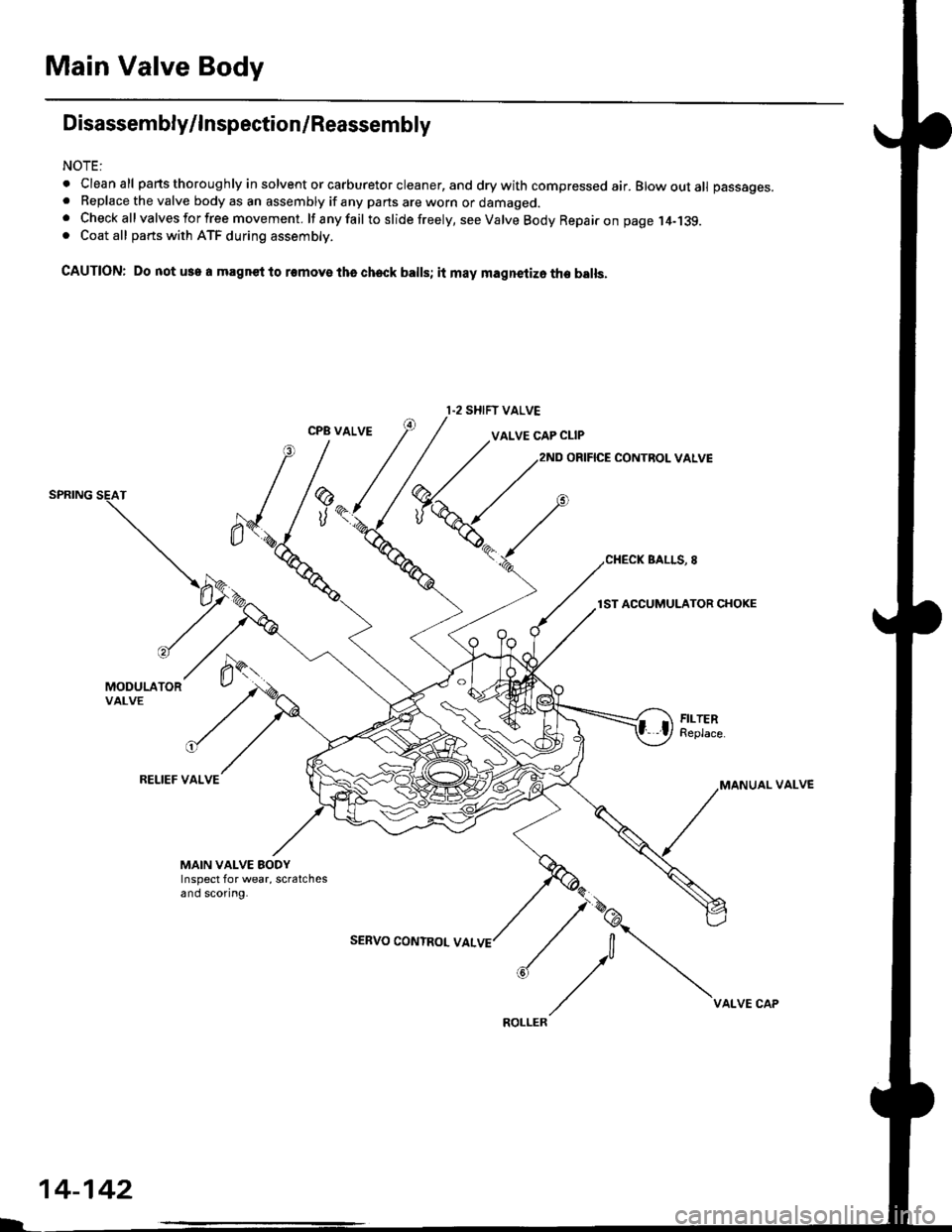

NOTE:

. Cleanall parts thoroughly in solvent or carburetor cleaner, and drywith compressed air. Blowoutall passages.. Replace the valve body as an assembly if any pans are worn or damaged.. Check all valves for free movement. lf anyfail toslidefreely, see Valve Body Repairon page,l4-139.. Coat all parts with ATF during assembly.

CAUTION: Do not use a magnet to removs tha check balls; it may magnetizo the balls.

CPB VALVEVALVE CAP CLIP

ORIFICE CONTROL VALVE

BALLS, 8

lST ACCUMULATOR CHOKE

MODULATORVALVE

RELIEF VALVEVALVE

MAIN VALVE EODYInspect for wear, scratchesand scoring.

SEBVO CONTROL VAL

I.2 SHIFT VALVE

14-142

VALVE CAP