ect HONDA CIVIC 1999 6.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CIVIC, Model: HONDA CIVIC 1999 6.GPages: 2189, PDF Size: 69.39 MB

Page 1123 of 2189

)

1?

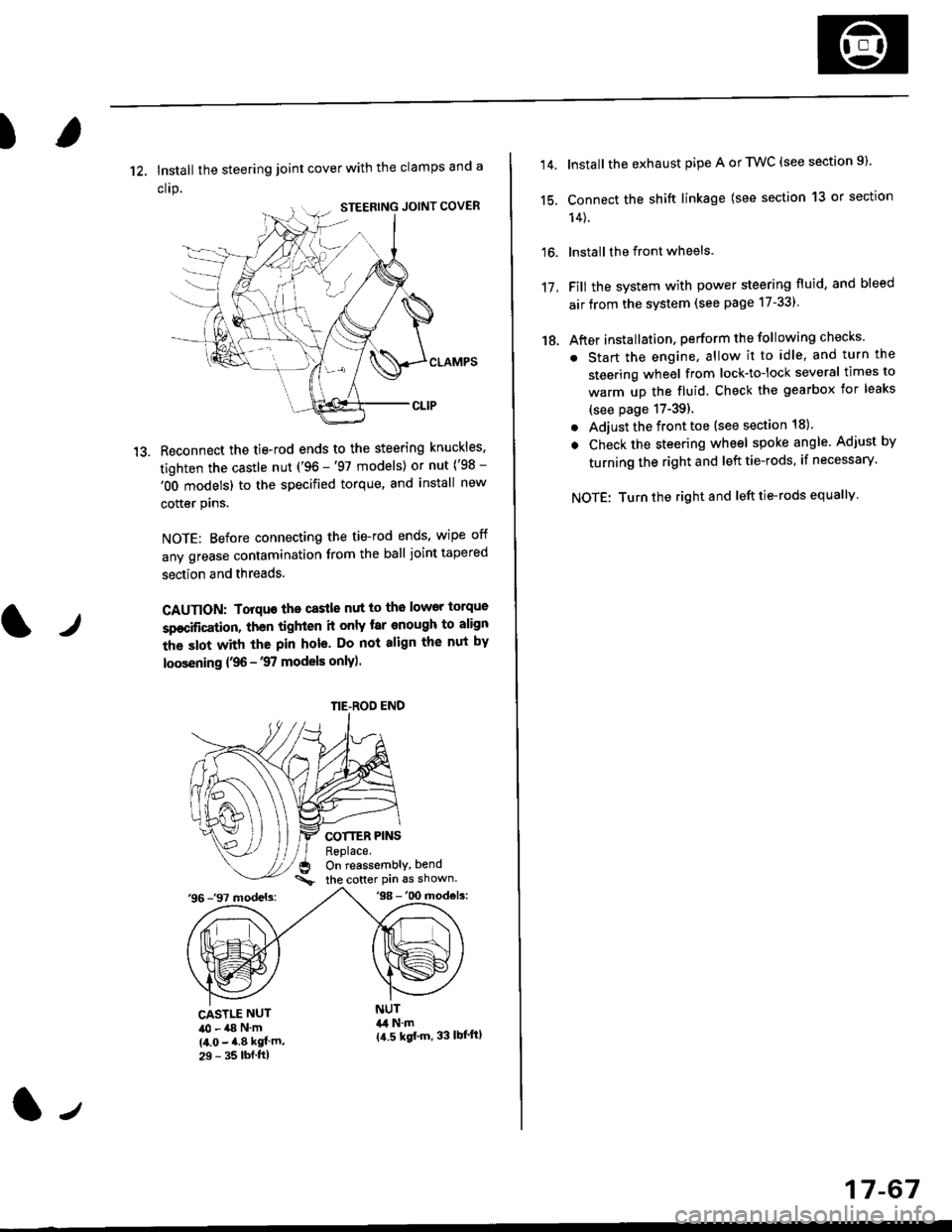

12, Install the steering joint cover with the clamps and a

clrp.

Reconnect the tie-rod ends to the steering knuckles,

tighten the castle nut ('96 -'97 models) or nut ('98 -

'OO models) to the specified torque, and install new

cotter plns.

NOTE: Before connecting the tie-rod ends, wipe off

any grease contamination from the ball joint tapered

section and threads.

CAUTION: Torquo the castle nut to the lower torque

sp€cification, then tighten it only tar enough to align

the slot with the pin hole. Do not align the nut by

loosening {,96 -'97 models only).

COTTER PINSReplace.On reassembly, bend

the cotter Pin 6s shown.'96 -'97 models:'98 -'00 mod€ls:

tr

CASTLE NUT40 - a8 N'm(4.0 - 4.8 kgf'm,29 - 35 lbf.ftl

NUT&l N.m{a.5 kgf'm, 33 lbl'ftl

NE-ROD END

(l-,

17-67

14.

15.

16.

17.

18.

Install the exhaust pipe A or TWC (see section 9).

Connect the shift linkage (see section 13 or section

14).

lnstall the front wheels

Fill the system with power steering fluid, and bleed

air from the system (see page 17-331

After installation, perform the following checks

. Start the engine, allow it to idle, and turn the

steering wheel from lock-tolock several times to

warm up the fluid. Check the gearbox for leaks

(see page 17-39).

. Adjust the front toe (see section 18).

. Check the steering wheel spoke angle. Adjust by

turning the right and left tie-rods, if necessary.

NOTE: Turn the right and left tie-rods equallv

Page 1124 of 2189

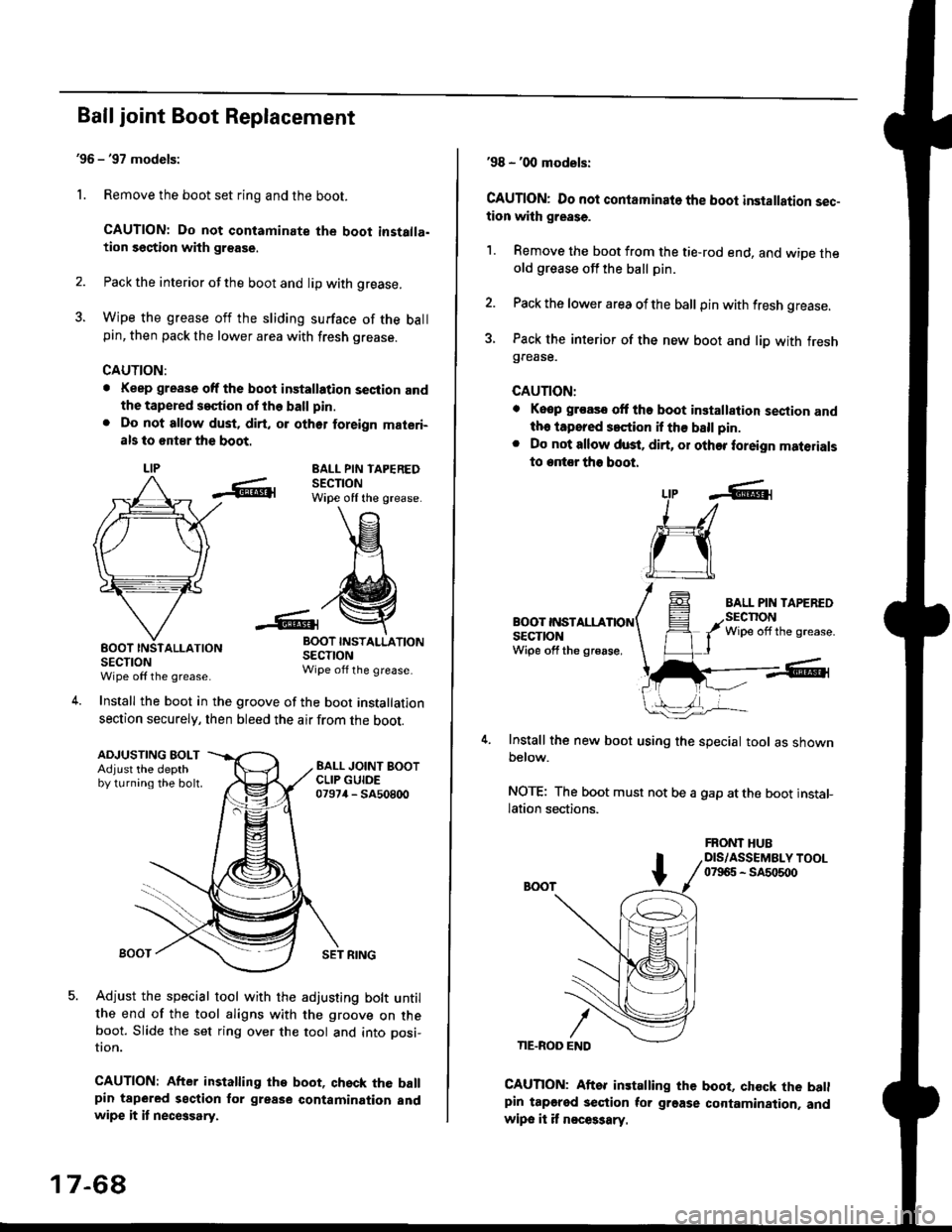

Ball joint Boot Replacement

'96 - '97 models:

1. Remove the boot set ring and the boot.

CAUTION: Do not contaminate the boot installa.tion section with grsase.

2. Pack the interior of the boot and lip with grease.

3. Wipe the grease off the sliding surface of the ballpin, then pack the lower area with fresh grease.

CAUTION:

. Keep grease off the boot installation seciion andthe tapered s€ction ot the ball pin.

. Do not allow dust, dirt, or oth6r foreign materi-

als to 6nt8r the boot.

LIPEALL PIN TAPEREDSECTIONWipe off the grease.

INSTALLATION

SECTIONWipe off the grease.

Install the boot in the groove of the boot installation

section securely, then bleed the air from the boot.

-6lrBOOTSECTIONWipe off the grease

4.

ADJUSTING BOLTAdjust the depthby turning the bolt.

SET RING

Adjust the special tool with the adjusting bolt untilthe end of the tool aligns with the groove on theboot. Slide the set ring over the tool and into posi-

UOn.

CAUTION: After installing the boot, qhsck the ballpin tapered section for grease contamination andwipe it it necGsary.

17-68

'98 - '00 models:

CAUTION: Do not contaminato the boot installation sec-tion with grease.

1. Remove the boot from the tie-rod end, and wiDe theold grease off the ball pin.

2. Pack the lower area ofthe ball pin with fresh grease.

3. Pack the interior of the new boot and liD with freshgrease.

CAUTION:

. Keop groasc ott tho boot installalion sestion andth. iapored s.ction if th€ ball pin.

. Do not allow dust. dirt, or other foreign materials

to entor tho boot.

BOOT INSTALLASECTIONWipe off the gr€ase,

Install the new boot using the special tool as shownbelow.

NOTE: The boot must not be a gap atthe boot installation sections.

LtP .6r

J_/

ru

CAUTION: Aftor installing the boot, chock the batlpin tapgred section tor grgase cortamination. andwipe it it n€ces3ary.

FRONT HUBDIS/ASSEMBLY TOOL07965 - SA5o500

Page 1125 of 2189

)

Suspension

Special Tools ............. 18-2

Component Locations

lndex ,,.............. ...... f8-3

Wheel Alignment

Caster .............. ....... 18-4

Camber .................. l8-4

Front Toe Inspection/

Adiustment ........ 18-5

Rear Toe lnspection/

Adiustment ........ 18-5

Turning Angle Inspection ................ 18-6

Wheel/Hub Inspection

Bearing End P|ay .............................. l8-7

Wheel Runout ....... 18-7

Front Suspension

Suspension Arms Replacement

('96 - 99 modelsl .......................... 18-8

Suspension Arms Replacement

('99 2D Si and Si-R models) ........ 18-9

Knuckle/Hub Replacement ............. 18-10

Lower Ball Joint Replacement ....... 18-16

Ball Joint Boot Replacement .......... 18-17

Front Damper

Removal ................. 18-17

Disassembly/1nspection .................. 18-18

Reassembly ........... 18-19

lnstallation ............. 18-19

Rear Suspension

Suspension Arms Replacement

('96 - 99 models) ....................,..... 18-21

Suspension Arms Replacement

('99 2D Si and Si-R models) ........ 1A-22

Hub Bearing Unit Replacement ...... 18-23

Upper Arm Eushing

Replacement .....18-25

Rear Damper

Removal ................. 18-26

Disassembly/|nspection ............. ..... 1A-27

Reassembly ........... 18-28

lnstallation ............. 18-29

lr

Page 1127 of 2189

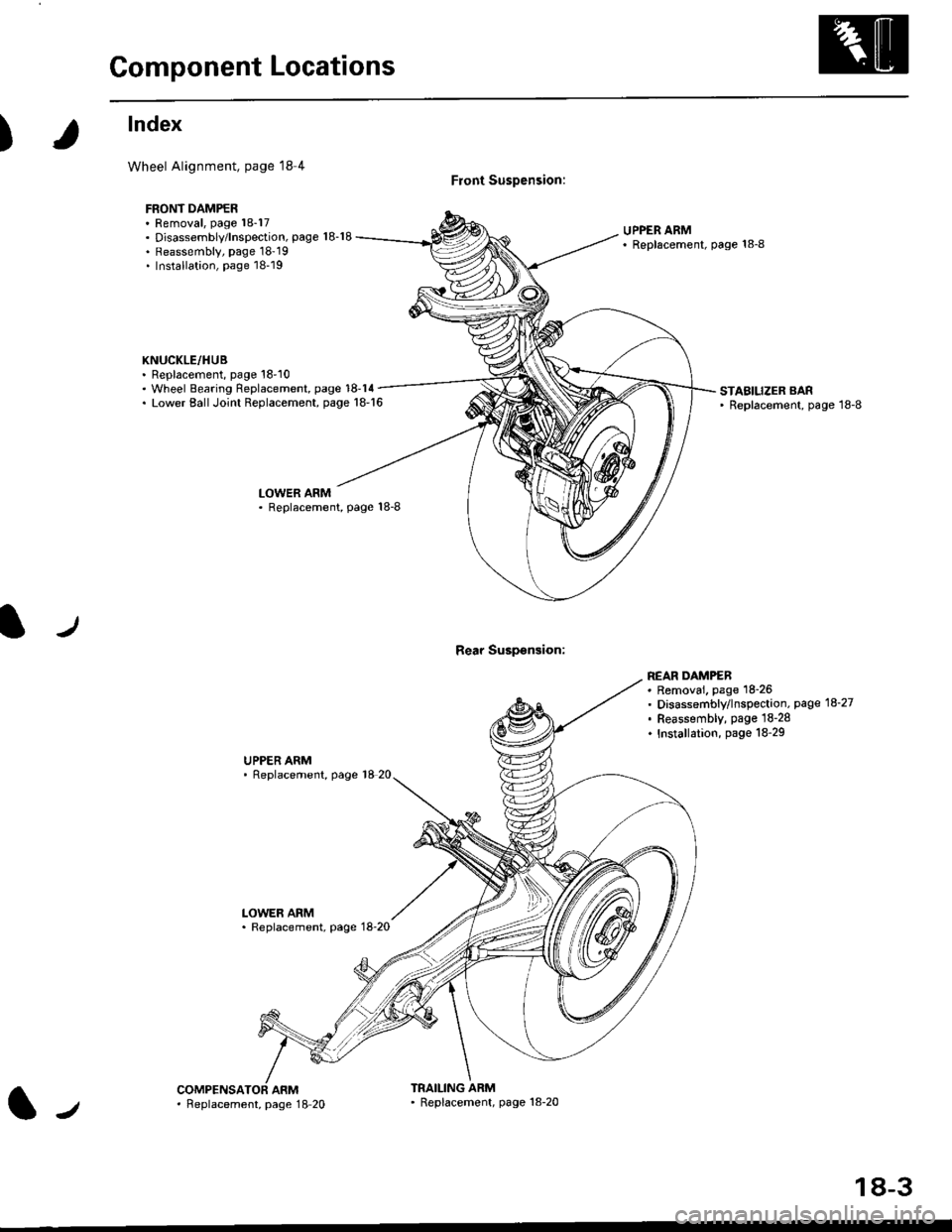

Component Locations

)

lndex

Wheel Alignment, page l8 4

FBONT DAMPER. Removal, page 18-17. Disassembly/lnspection, page 18-18. Reassembly, page 18'19. Installation, page 18-19

KNUCKLE/HUB. Replacement, page 18'10

Front Suspension:

Rear Suspsnsion:

UPPER ARM' Replscement, page 18-8

. Wheel Bearing Replacement, page 18-14. Lower EallJoint Replacement, page 18-16STABILIZER BAR' Replacement, page 18-8

LOWER ARM. Replacement, Page 18-8

UPPER ARM' Replacement, page 18 20

LOWER ARM. Replacement, page 18-20

REAR DAMPEB. Removai. page 18-26. Disassembly/lnspection, page 18-27. Feassembly, page lS-28. Installation, page 18-29

ARMTRAILING ARM' Replacement, page 18-20l-,. Feplacement, page 18 20

18-3

Page 1128 of 2189

Wheel Alignment

,f,

Caster

NOTE: For proper inspection/adjustment of the wheel

alignment check and adjust the following before check-

ing the alignment.

. Check that the suspension is not modified.

. Check the tire size and tire pressure.

. Check the runout of the wheels and tires.

. Check the suspension ball ioints. {Hold a wheel with

your hands and move it up and down and right and

left to check for wobbling.)

Inspection

NOTE: Use commercia lly-available computerized four

wheel alignment equipment to measure wheel align-

ment {caster. camber, toe, and turning angle). Follow

the equiDment manufacturer's instructions.

Check the caster angle.

Caster angle: 1',10' I 1'

lf out of specification, check for bent or damaged

suspensron components.

2.

1.

18-4

Camber

lnspection

NOTE: Use commercially-available computerized four

wheel alignment equipment to measure wheel align-

ment (caster, camber, toe, and turning angle). Follow

the equipment manufacturer's instructions.

1. Check the camber angle.

Camber angle:

Front: 0'00' j 1"

Rear:-1"11"

2. lf out ol specification, check for bent or damaged

suspensron components.

Page 1129 of 2189

?

Front Toe Inspection/Adiustment

NOTE: Use commercially-available computerized four

wheel alignment equipment to measure wheel align-

ment (caster, camber, toe, and turning angle). Follow

the equipment manufacturer's instructions.

1. Check the tire pressure.

Center steering wheel spokes.

Check the toe with the wheels pointed straight

a head.

Front toe: lN 1 1 2 mm llN l/16 r 1/16 inl

- lf adjustment is required, go on to step 4.

- lf no adjustment is required, remove alignment

equrpmenr.

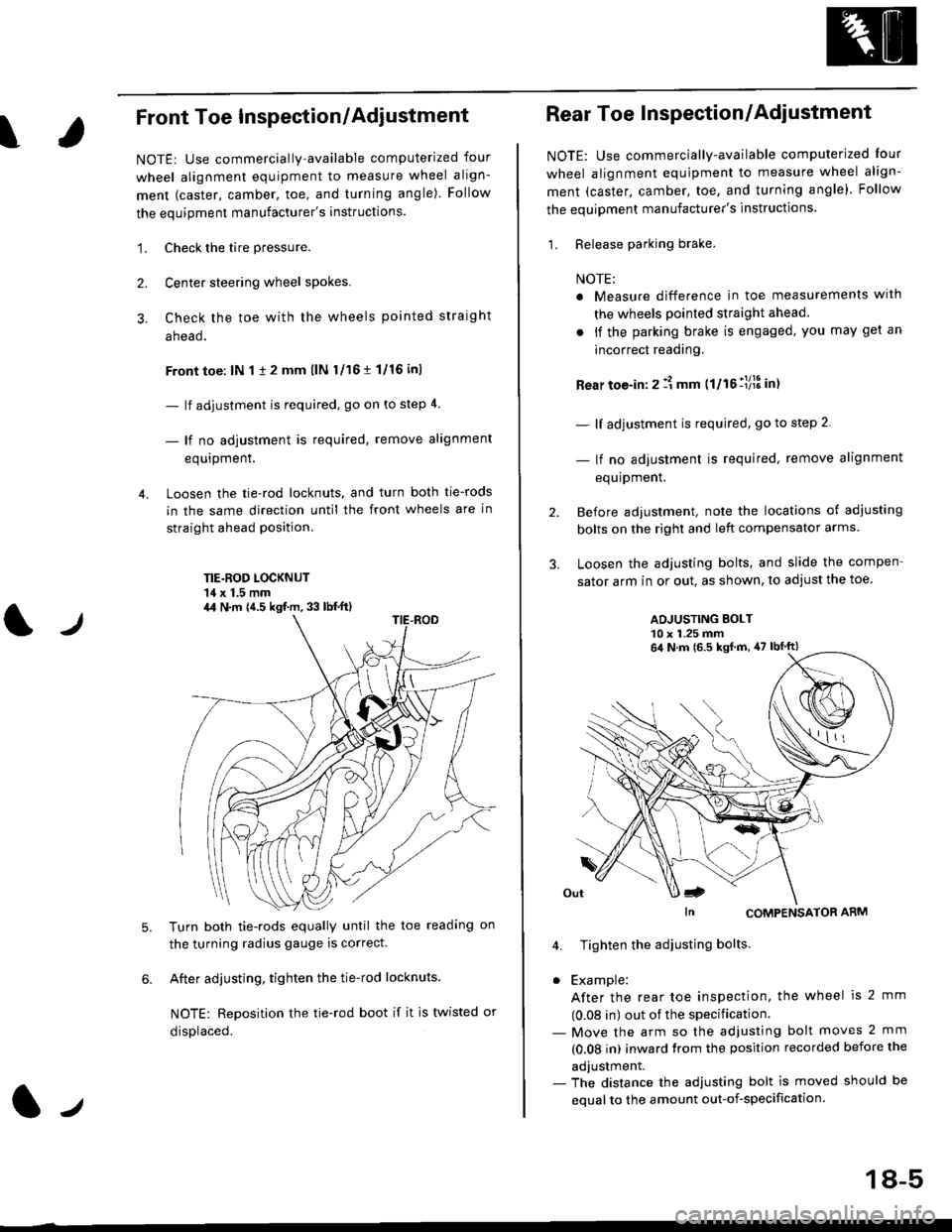

Loosen the tie-rod locknuts, and turn both tie-rods

in the same direction until the front wheels are in

straight ahead position.

TIE.ROD LOCKNUT'14 x 1.5 mm

4.

tJ

6.

Turn both tie-rods equally until the toe readang on

the turning radius gauge is correct.

After adjusting, tighten the tie-rod locknuts.

NOTE: Reposition the tie-rod boot if it is twisted or

displaced.

4,1 N.m {4.5 kgf.m, 33 lb{.ft)

2.

Rear Toe Inspection/Adiustment

NOTE: Use commercially-available computerjzed Iour

wheel alignment equjpment to measure wheel align-

ment (caster, camber, toe, and turning angle). Follow

the equipment manufacturer's instructions.

1. Release parking brake.

NOTE:

a Measure difference in toe measurements wlth

the wheels pointed straight ahead.

. if the parking brake is engaged, you may get an

incorrect readang,

Rear toe-in: 2 11 mm ttltollllS int

- lf adjustment is required, go to step 2.

- lf no adjustment is required, remove alignment

equipment.

Before adjustment, note the locations of adiusting

bolts on the right and left compensator arms

Loosen the adjusting bolts, and slide the compen

sator arm in or out. as shown, to adjust the toe

ADJUSTING BOLT10 x 1.25 mm

In CoMPENSAToR ARM

4. Tighten the adiusting bolts

. Example:

After the rear toe inspection, the wheel is 2 mm

(0.08 in) out of the specification.- Move the arm so the adjusfing bolt moves 2 mm

(0.08 in) inward trom the position recorded before the

adjustment.- The distance the adjusting bolt is moved should be

equal to the amount out-of-specification.

64 N.m 16.5 ksf m, 47 lbtft)

18-5

Page 1130 of 2189

Wheel Alignment

Turning Angle Inspection

NOTEr Use commercially-available computerized four

wheel alignment equipment to measure wheel align-

ment (caster, camber, toe, and turning angle). Follow

the equipment manufacturer's instructions.

'1. Turn the wheel right and left while applying the

brake, and measure the turning angle of both

wneets.

Turning angle:

lnward wheel: 39'50'

Outwald wheel (ref erencel: 33'10'

2.lf the turning angle

check for bent or

nents,

is not within the specifications,

da m aged suspension compo-

18-6

Page 1131 of 2189

Wheel/Hub Inspection

\

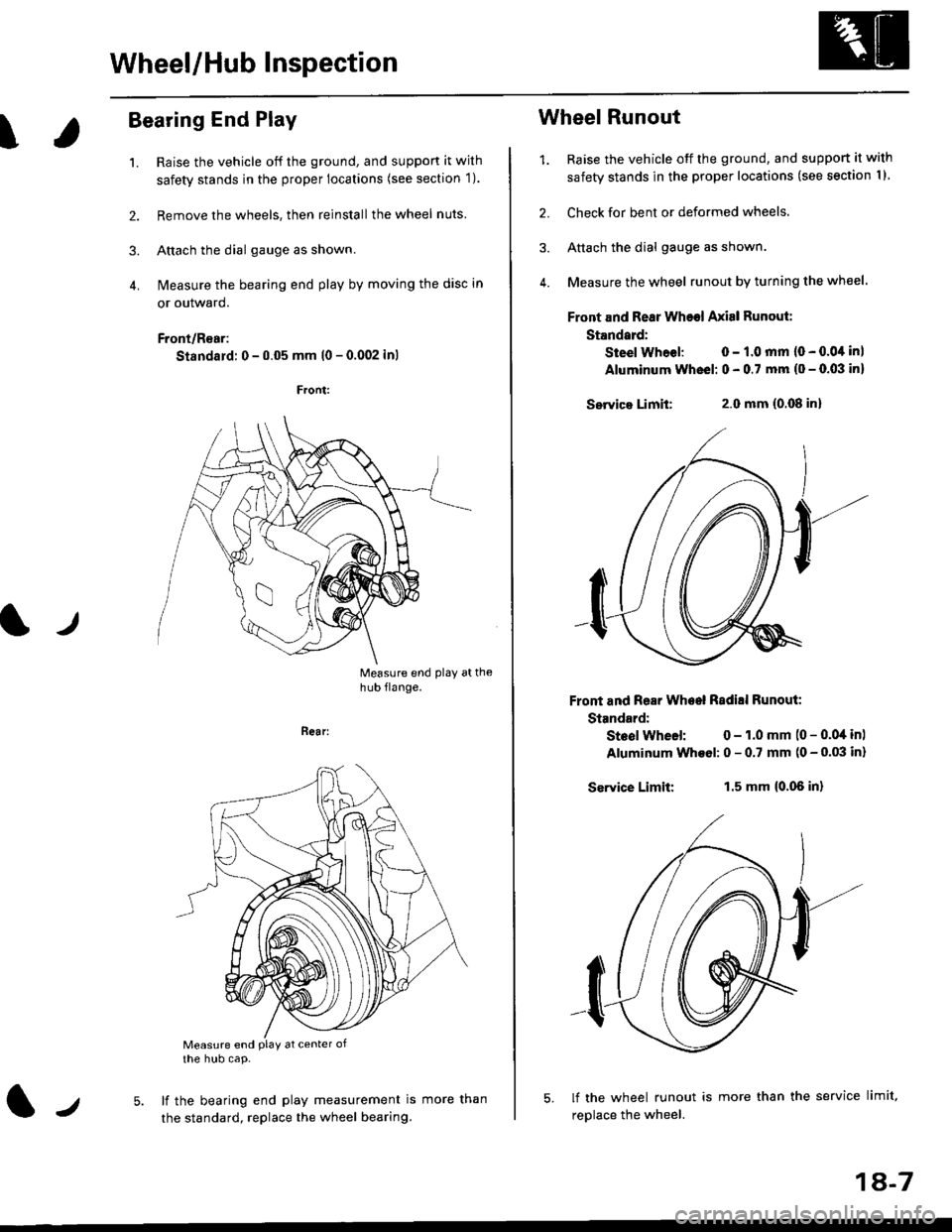

Bearing End Play

1. Raise the vehicle off the ground, and suppon it wjth

safety stands in the proper locations (see section 1).

2. Remove the wheels, then reinstallthe wheel nuts

3. Attach the dial gauge as shown.

4. N4easure the bearing end play by moving the disc in

or outward.

Front/R€ar:

Standard: 0 - 0.05 mm l0 - 0.002 inl

Measure end play athub flange.

t./

Bear:

Measure end PlaY at center ofthe hub cap.

lf the bearing end play measurement is

the standard, replace the wheel bearing.lJmore than

1A-7

Wheel Runout

1. Raise the vehicle off the ground, and support it with

safety stands in the proper locations (see section I I

2. Check for bent or deformed wheels.

3. Attach the dial gauge as shown.

4. Measure the wheel runout by turning the wheel.

Front and Rear Wheel Axisl Runout:

Standard:

Steel Whoel: 0 - 1.0 mm (0 - 0.0,1 inl

Aluminum Wheel: 0 - 0.7 mm (o - 0.03 in)

Servica Limit:2.0 mm (0.08 inl

Front and Rear Wheel Radill Runout:

Standard:

Steol Wheel: 0 - 1.0 mm (0 - 0.04 in)

Aluminum Wheol: 0 - 0.7 mm (0 - 0.03 in)

Service Limit:1.5 mm {0.06 in}

lf the wheel runout is more than the service limit,

replace the wheel.

Page 1132 of 2189

Front Suspension

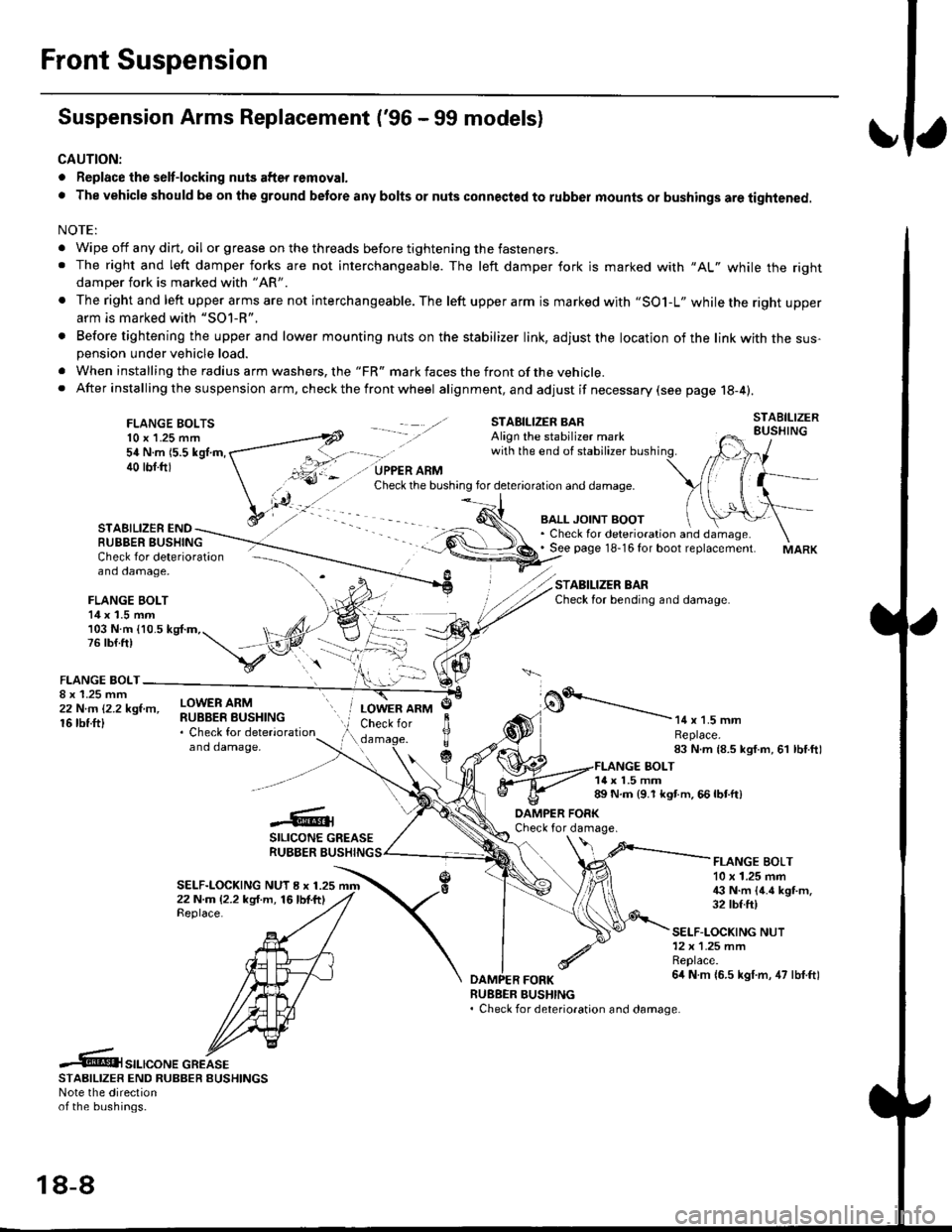

Suspension Arms Replacement ('96 - 99 models)

CAUTION:

. Replace the selt-locking nuts after removal.

. The vehicle should be on the ground betore any bolts or nuts connected to rubber mounts or bushings are tightened.

NOTE:

. Wipe off any dirt, oil or grease on the threads before tightening the fasteners.. The right and left damper forks are not interchangeable. The left damper fork is marked with "AL" while the rightdamper fork is marked with "AR'

. The right and left upper arms are not interchangeable. The left upper arm is marked with "SO1-L" while the right upperarm is marked with "SOl-R".

. Before tightening the upper and lower mounting nuts on the stabilizer link, adjust the location of the link with the sus-pension under vehicle load.

. When installing the radius arm washers, the "FR" mark faces the front ofthe vehicle.. After installing the suspension arm, ch eck the front wheel alignment, and adjust if necessary (see page 18-4).

FLANGE BOLTS10 x 1.25 mm54 N.m 15.5 kgl.m,40 tbf.ftl

STAEILIZER ENDRUBBER BUSHING

BALL JOINT BOOT. Check for deterioration and damage.. See page 18-16 for boot replacement.

STABILIZER BARCheck for bending and damage.

Check for deterioration - ---\--

and damage, -\

FLANGE BOLT14 x 1.5 mm/)l103 N.m {10.5 kg{.m,. t, ,/4,76lb{.ft) t,,"-iV

v:\FLANGE BOLT-

;iffillr-"- ilHitffi*::,"*"

and damaoe,

o.'-----------14 x 1.5 mmReplace.83 N.m {8.5 kgf.m, 61 lbf.ftl

LOWER ARMCheck for

c

JlTTda

1{ x 1.5 mm89 N.m {9.1 kgt m. 66 lbtft)

-6;SILICONE GREASERUBBER BUSHING

DAMPER FORKCheck for damage.

SELF-LOCKING NUT I x 1.2522 N.m (2.2 kg{.m, 16lbf.ftlReplace.

FLANGE BOLT10 x 1.25 mm€ N.m {4.6 kgt m.32 tbf.ft)

SELF-LOCKING NUT12x 1.25 mmReplace.6it N m {6.5 kgf.m, 47 lbf.ftl

RUEBER BUSHING. Check for deterioration and damage.

.6t",.,"o".c"KeSTAAIL|zER END RUBBER EUSHINGSNote the directionof the bushings.

18-8

Page 1133 of 2189

I

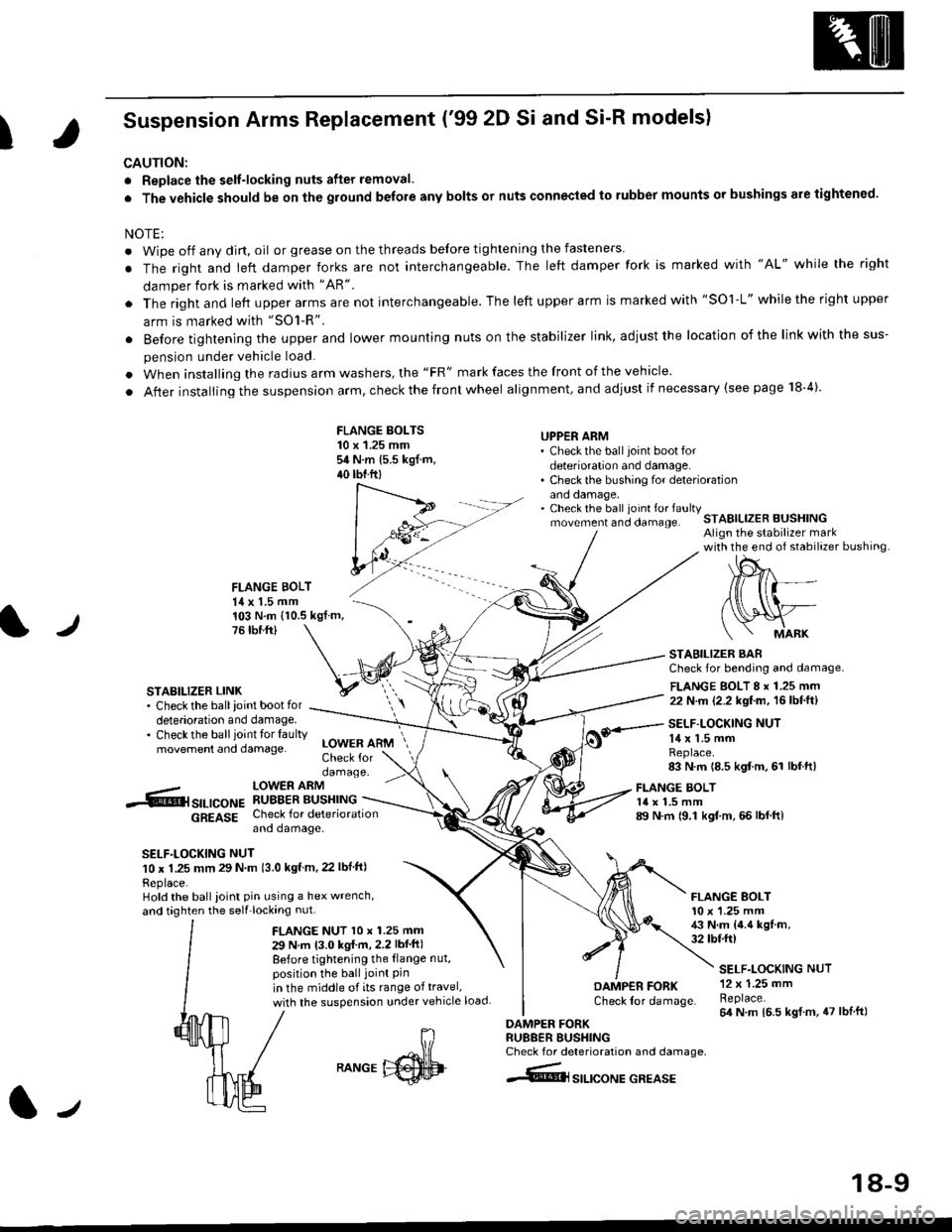

Suspension Arms Replacement ('99 2D Si and Si-R models)

CAUTION:

. Replace the selt-locking nuts after removal.

. The vehicle should be on the ground belore any bolts or nuts connected to rubber mounts or bushings are tightened.

NOTE:

. Wipe off any dirt, oil or grease on the threads before tightening the fasteners

. The right and ieft damper forks are not interchangeable. The left damper fork is marked with "AL" while the right

damper fork is marked with "AR"

. The right and left upper arms are not interchangeable. The left upper arm is marked with "SOl-L" while the right upper

arm is marked with "SO1-R".

. Before tightening the upper and lower mounting nuts on the stabilizer link, adiust the location of the link with the sus-

pension under vehicle load.

. When installing the radius arm washers, the "FR" mark faces the front of the vehicle.

. After installing the suspension arm, check the front wheel alignment, and adjust if necessary (see page 18-4).

FLANGE BOLTS10 x 1.25 mmsit N.m 15.5 kgf.m,40 tbtftl

UPPER ARM' Check the ball joint boot fordeterioration and damage.. Check the bushing for deteriorationano oamage,. Check the ball ioint fo. faultymovement and clamage.STABILIZER BUSHINGAlign the stabilizer markwith the end of stabilizer bushing

FLANGE BOLT14 x 1.5 mm

l./

103 N.m (10.5 kgf.m,76 tbr.ftl

STABILIZER LINK. Check the ballioint bootfordeterioration and damage.. Checkthe ballioint tor faultymovement and damage.

STABILIZER BARCheck for bending and damage.

FLANGE BOLT 8 x 1.25 mm22 N.m (2.2 kgf.m, 16lbf.ft)

SELF-LOCKING NUT14 x 1.5 mmReplace.83 N.m 18.5 kgf m, 61 lbf.ft)

-.6r srr-,co", hSHrtlrT.[*"u

6g619g Check for deteriorationano oamage.

SELF.LOCKING NUT10 x 1.25 mm 29 N m 13.0 kgf m, 22 lbf ftl

Replace.Hold the ball ioint pin using a hex wrench,

and taghten the self'locking nut.

LOWER ARMCheck fordamage.

FLANGE NUT l0 x 1.25 mm

29 N.m 13.0 kgI m,2.2 lbf ft)

Before tightening the {lange nut,position the ball joint Pinin the middle of its range of travel,

with the suspension under vehicle load

FLANGE BOLT14 x 1.5 mm89 N.m 19.1 kgf.m, 66 lbf.ft)

FLANGE BOLT10 x '1.25 mm43 N.m {4.4 kgf.m,32 tbtft)

DAMP€R FORKCheck lor damage.

DAMPER FORKRU88ER BUSHINGCheck for deterioration and damage.

4@lsrlrcoNE GREASE

SELF.LOCKING NUT12 x 1.25 mmReplace.64 N m 16.5 kgl.m, 47 lblft)

J

RANGE

18-9