engine HONDA CIVIC 2002 7.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2002, Model line: CIVIC, Model: HONDA CIVIC 2002 7.GPages: 1139, PDF Size: 28.19 MB

Page 319 of 1139

PGM-FI System

Injector Replacement (cont'd)

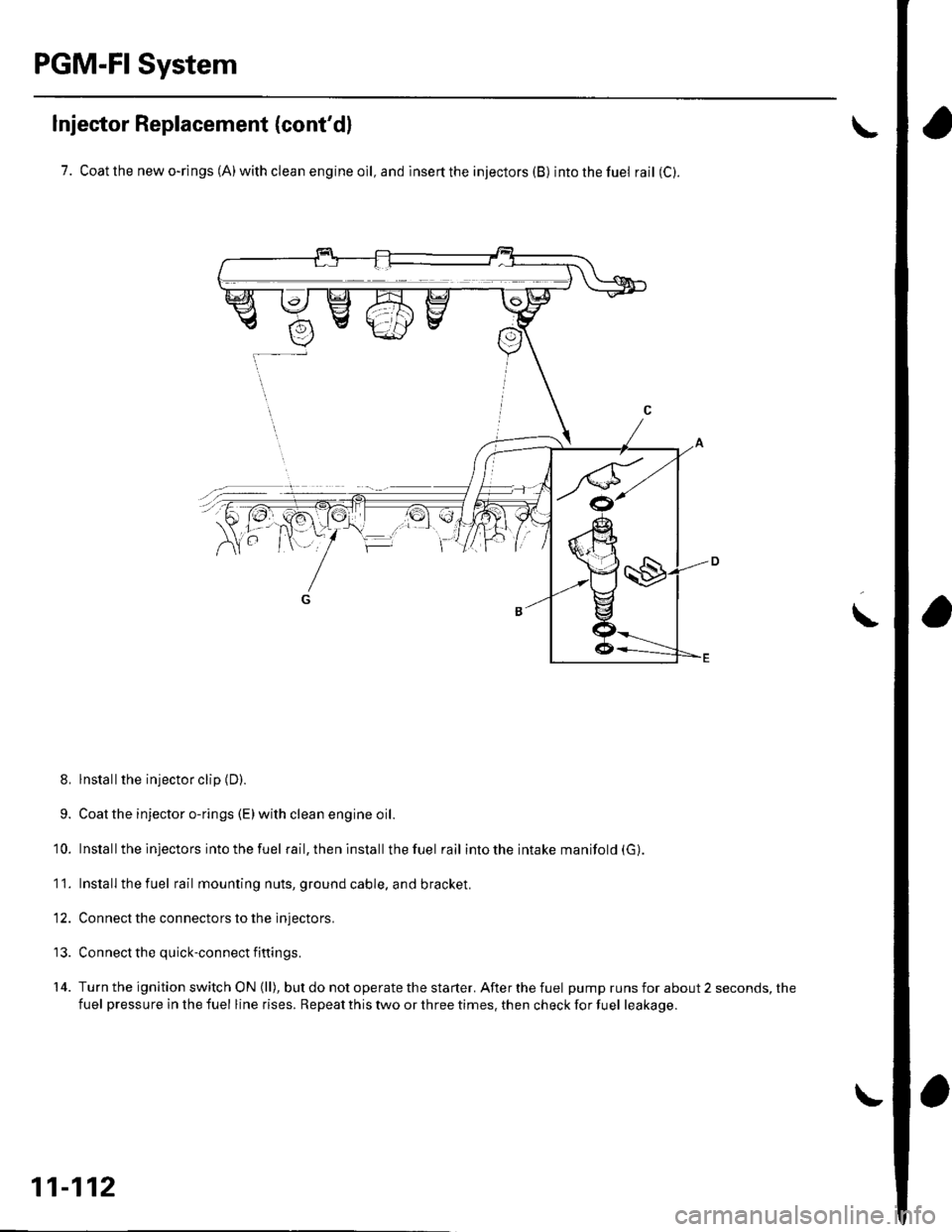

7. Coatthenewo-rings(A)withcleanengineoll,andinserttheinjectors(B) intothefuel rail (C).

8, lnstall the injector clip {D).

9. Coat the injector o-rings (E)with clean engine oil.

10. Installthe injectors intothefuel rail, then install the fuel rail intotheintakemanifold(G).

1 '1. Install the fuel rail mounting nuts, ground cable. and bracket.

12. Connect the connectors to the injectors.

13. Connect the quick-connect fittings.

14. Turnthe ignition switch ON (ll), butdo notoperatethe starter. Afterthefuel pump runs for about 2 seconds, the

fuel pressure in the fuel line rises. Repeat this two or three times. then check for fuel leakage.

\

11-112

Page 325 of 1139

VTEC/VTC

DTG Troubleshooting

DTC P0010: WC Oil Control Solenoid ValveMalfunction

1. Resetthe ECM (see page 11-4).

2. Start the engine. Hold the engine at 3,000 rpm withno load (in neutral) until the radiator fan comes on,

then let it idle.

3. Test-drive at a steady speed between 20-40 mph(30-60 km/h) for 10 minutes.

ls DTC P0010 indicated ?

YES Go to step 4.

NO- Intermittent failure, system is OK at this time.

Check for poor connections or loose terminals at

the VTC oil control solenoid valve and at theECM.I

4. Turn the ignition switch OFF.

5. Disconnect the ECM connector B {24P).

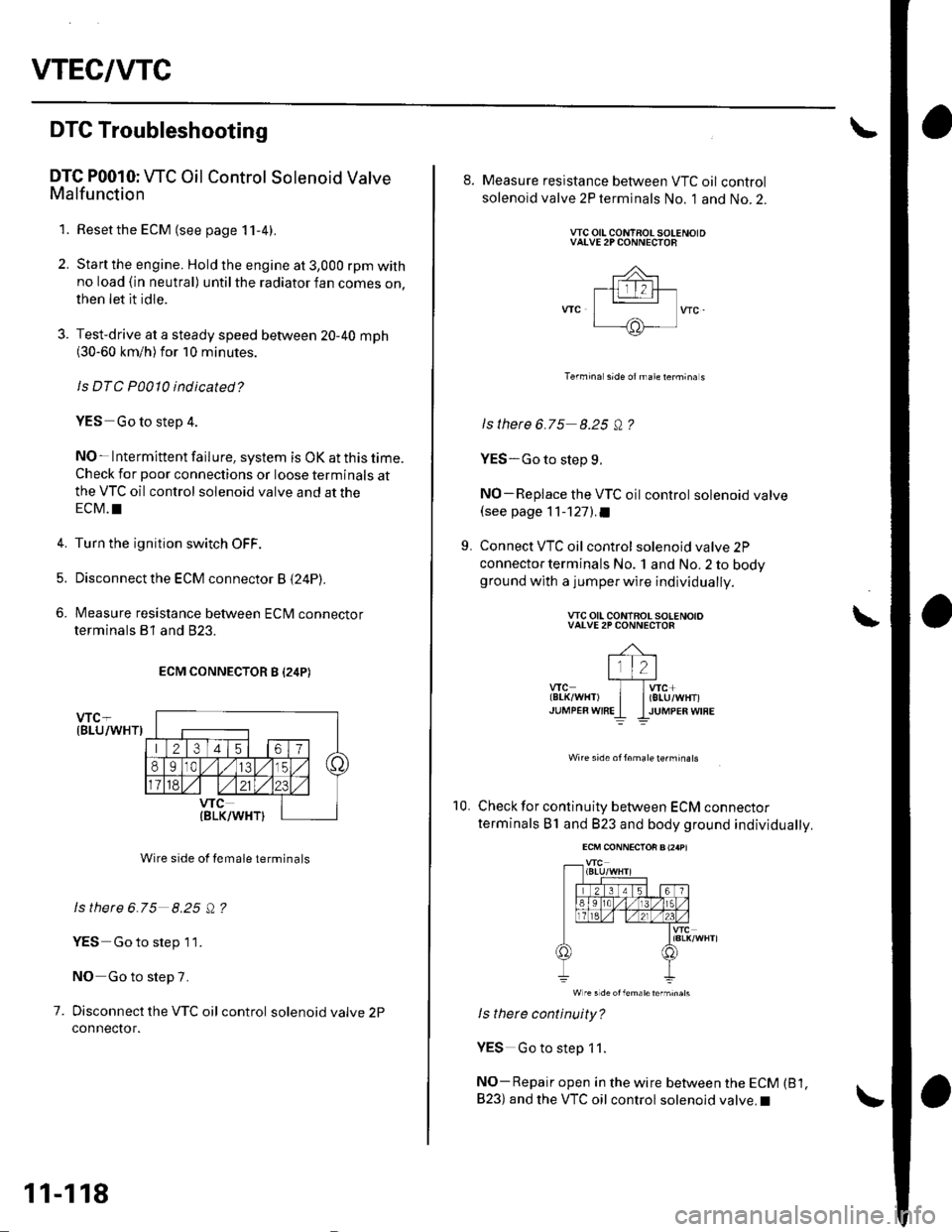

6. Measure resistance between ECrU connector

terminals B1 and 823.

ECM CONNECTOR B I24P)

Wire side of female terminals

ls there 6.75 8.25 Q ?

YES Go to step 1 1.

NO Go to step 7.

7. Disconnect the VTC oil control solenoidvalve2P

connector.

11-118

8. Measure resistance between VTC oil control

solenoid valve 2P terminals No. 1 and No. 2.

VTC OIL CONTAOL SOLENOIDVAI"VE 2P CONNECTOB

Termina sid6 otmate termina s

ls there 6.75 8.25 Q ?

YES-Go to step L

NO-Replace the VTC oil control solenoid valve(see page 11-1271.a

9. Connect VTC oil control solenoidvalve2P

connector terminals No. 1 and No. 2 to bodyground with a jumperwire individually.

wc otl coNTBoL sotENotoVALVE 2P CONNECTOR

-4-t1t2l

wc I lwc*tBr-K/wHT) | liELU/WHT)JUMPER WTREI IJUMPEn W|RE

Wire side of16male te.minats

10. Check for continuity between ECM connector

terminals B1 and 823 and body ground individually.

ls there continuity?

YES Go to step 11.

NO- Repair open in the wire between the ECM (B 1,

B23) and the VTC oil control solenoid valve.I

\

Page 326 of 1139

11. Check for continuity between ECM connector

terminals B1 and B23 and body ground individually.

VTC(BtK/WHT)

ls there continuity?

YES Go to step 12.

NO Update the ECM if it does not have the latest

software, or substitute a known-good ECM, then

recheck (see page 11-6). lf the symptom/indication

goes away with a known-good ECM, replace the

original EClvl. !

Disconnect the VTC oil control solenoid valve 2P

connector.

Check for continuity between ECM connector

terminals B1 and 823 and body ground individually.

12.

13.

vfc(8LK/WHT)

Wire side of female rermina s

ls there continuity?

YES-Repair short in the wire between the ECM (B1,

B23) and the VTC oil control solenoid valve.l

NO Replace the VTC oil control solenoid valve

(see page 11-1211.a

4.

DTC P0011: VTC System Malfunction

1. Reset the EClvl (see page 1 1-4).

2. Start the engine. Hold the engine at 3,000 rpm with

no load (in neutral) until the radiator fan comes on.

3. Test-drive at a steady speed between 20 40 mph

(30 60 km/h) for 10 minutes.

Check for Temporary DTC P0011 with the scan tool

ls Tempotaty DTC P0011 indicated?

YES-Go to step 5.

NO- Intermittent failu re, system is OK at this time.

Check for poor connections or loose wires at the

VTC oil control solenoid valve and at the ECM.I

Watch the low oil pressure light with the engine

ru n n ing.

ls the low oil pressute light on?

YES- Check the oil pressure (see page 8-4).I

NO-Go to step 6.

Turn the ignition switch OFF.

Remove the auto-tensioner (see page 4-28).

6.

7.

(cont'd)

11-119

Page 327 of 1139

VTEC/VTC

DTC Troubleshooting (cont'dl

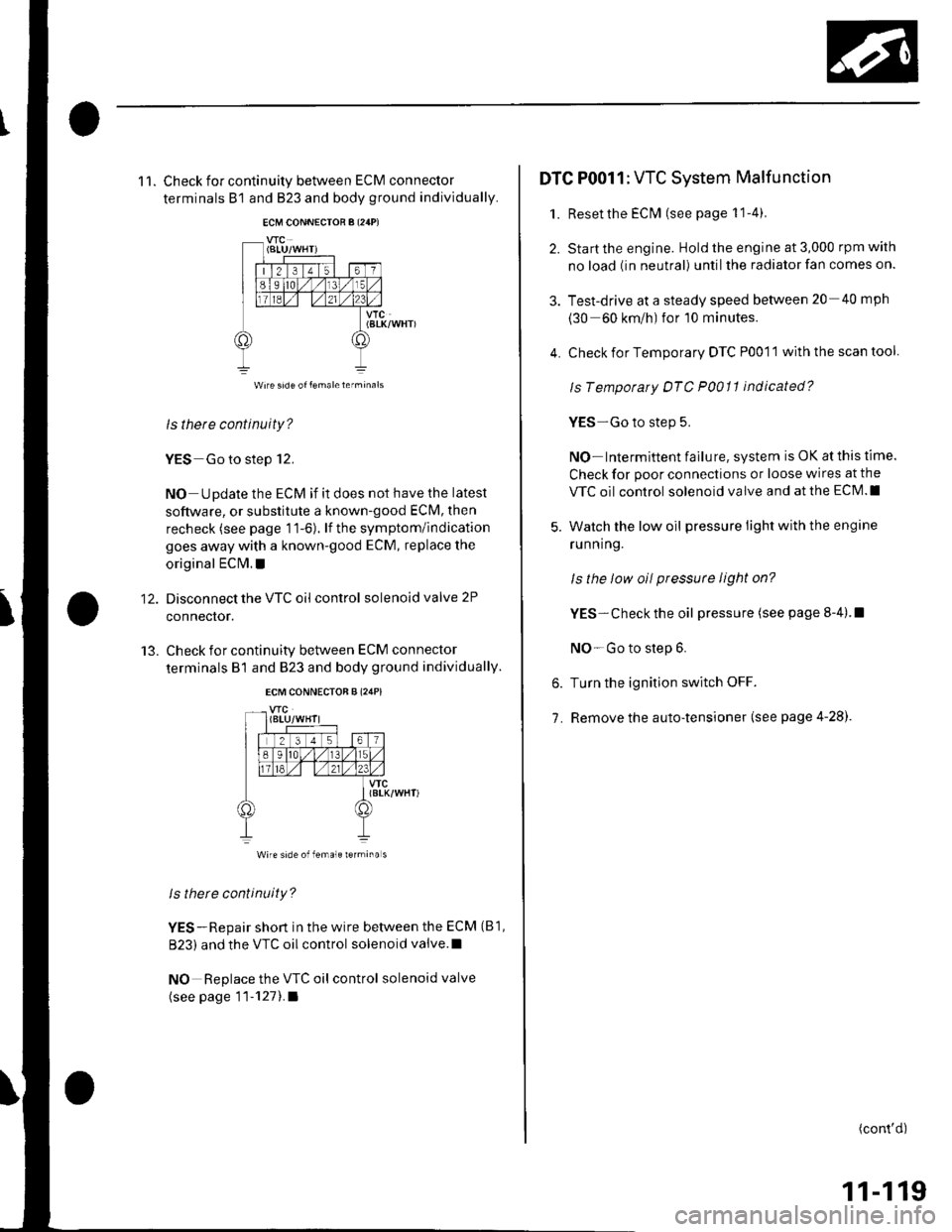

Remove the VTC strainer (A). Check the WC

strainer for clogging.

ls the strainet OK?

YES Go to step g.

NO-Clean the VTC strainer, then replace the

engine oil filter and the engine oil.l

9. Check the VTC oil control solenoidvalve {see page

11-127 ).

ls the VTC oilcontrol solenoid valve OK?

YES Go to step 10.

NO Clean the ports of the WC oil control solenoidvalve, or replace the VTC oil control solenoid valve

{see page 11-127).a

Installthe VTC oil control solenoid valve.

Start the engine. Hold the engine at 700 1,000 rpm.

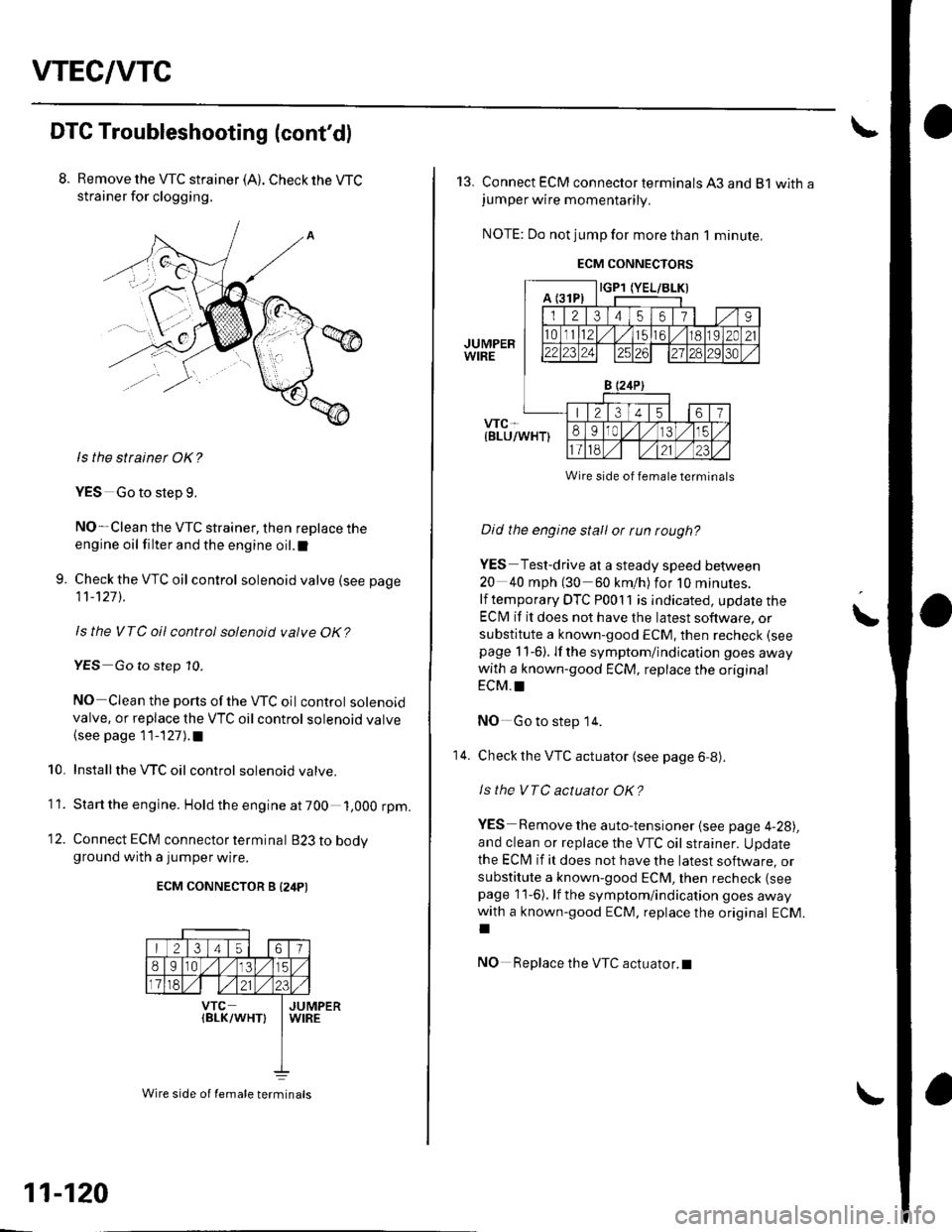

12. Connect ECM connector terminal B23tobodvground with a jumper wire.

ECM CONNECTOR B {24PI

10.

11.

213 41567

8e l1a ,/1,/15

1181./l l./2123

vTc(BLK/WHT}JUMPERWIRE

11-120

Wire side of temale terminals

13. Connect ECM connector terminals A3 and 81 withajumper wire momentarily.

NOTE: Do not jump for more than 1 minute,

ECM CONNECTORS

Did the engine stall or run rough?

YES Test-drive at a steady speed between

20 40 mph (30 60 km/h) for 10 minutes.

lf temporary DTC P00'l 1 is indicated, update the

ECIVI if it does not have the latest software, or

substitute a known-good ECM, then recheck (see

page 11-6). lf the symptom/indication goes awaywith a known-good ECM, replace the original

ECM. !

NO Go to step 14.

Check the VTC actuator (see page 6,8).

ls the VTC actuatot OK?

YES Remove the auto-tensioner (see page 4-281,

and clean or replace the VTC oil strainer. Update

the ECI\4 if it does not have the latest software, orsubstitute a known-good ECM, then recheck (see

page 11-6). lf the symptom/indication goes awaywith a known-good ECM, replace the original ECM.

T

NO Replace the VTC actuator.t

\

14.

Wire side of female terminals

Page 328 of 1139

DTC P0340: CMP Sensor A No Signal

DTG P0344: CMP Sensor A Intermittent

Interruption

1. Reset the ECM (see page '11-4).

2. Start the engine.

ls DTC P0340 and/or P0344 indicated?

YES-Go to step 3.

NO Intermittent failure, system is OK at this time.

Check for poor connections or loose terminals at

the CMP sensor A and at the ECM.I

3. Turn the ignition switch OFF.

4. Disconnect the CMP sensor A 3P connector.

5. Turn the ignition switch ON (ll).

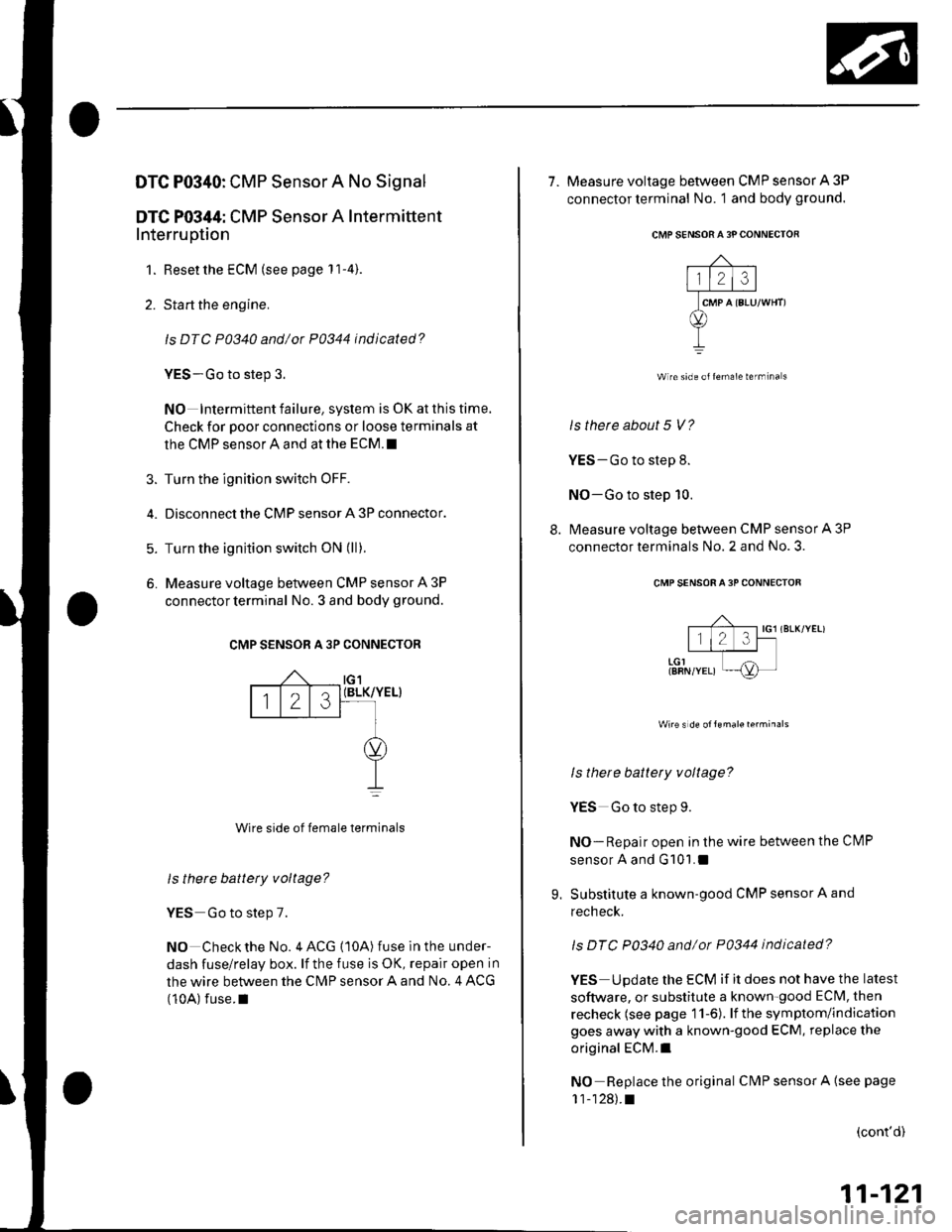

6. Measure voltage between CMP sensor A 3P

connector terminal No. 3 and body ground.

CMP SENSOR A 3P CONNECTOR

(BLK/YEL}

Wire side of female terminals

ls there battety voltage?

YES Go to step 7.

NO Check the No. 4 ACG {10A) fuse in the under-

dash fuse/relay box. lf the fuse is OK, repair open in

the wire between the CN4P sensor A and No. 4 ACG

(10A) fuse.I

tG1

123

7. Measure voltage between CMP sensor A 3P

connector terminal No. 1 and body ground.

CMP SENSORA 3P CONNECTOR

Wire side olfemale termina s

ls therc about 5 V?

YES-Go to step 8.

NO-Go to step 10.

8. Measure voltage between CMP sensor A 3P

connector terminals No. 2 and No. 3.

CMP SENSOR A 3P CONNECTOF

;f-;-1 ,o, ,r.*,"r.,

I l1 J l-t

,-or---T--I{8RN/YEL) ni-

ls there battety voltage?

YES Go to step 9.

NO-Repair open in the wire between the Cl\4P

sensor A and G101.1

9. Substitute a known-good CMP sensor A and

recheck.

ls DTC P0340 and/ot P0344 indicated?

YES Update the ECM if it does not have the latest

software, or substitute a known-good ECM, then

recheck (see page 11-6). lf the symptom/indication

goes away with a known-good ECM, replace the

original ECM.I

NO Replace the original CMP sensor A {see page

11-128).t

(cont'd)

11-121

Page 329 of 1139

VTEC/VTC

10.

DTC Troubleshooting (cont'd)

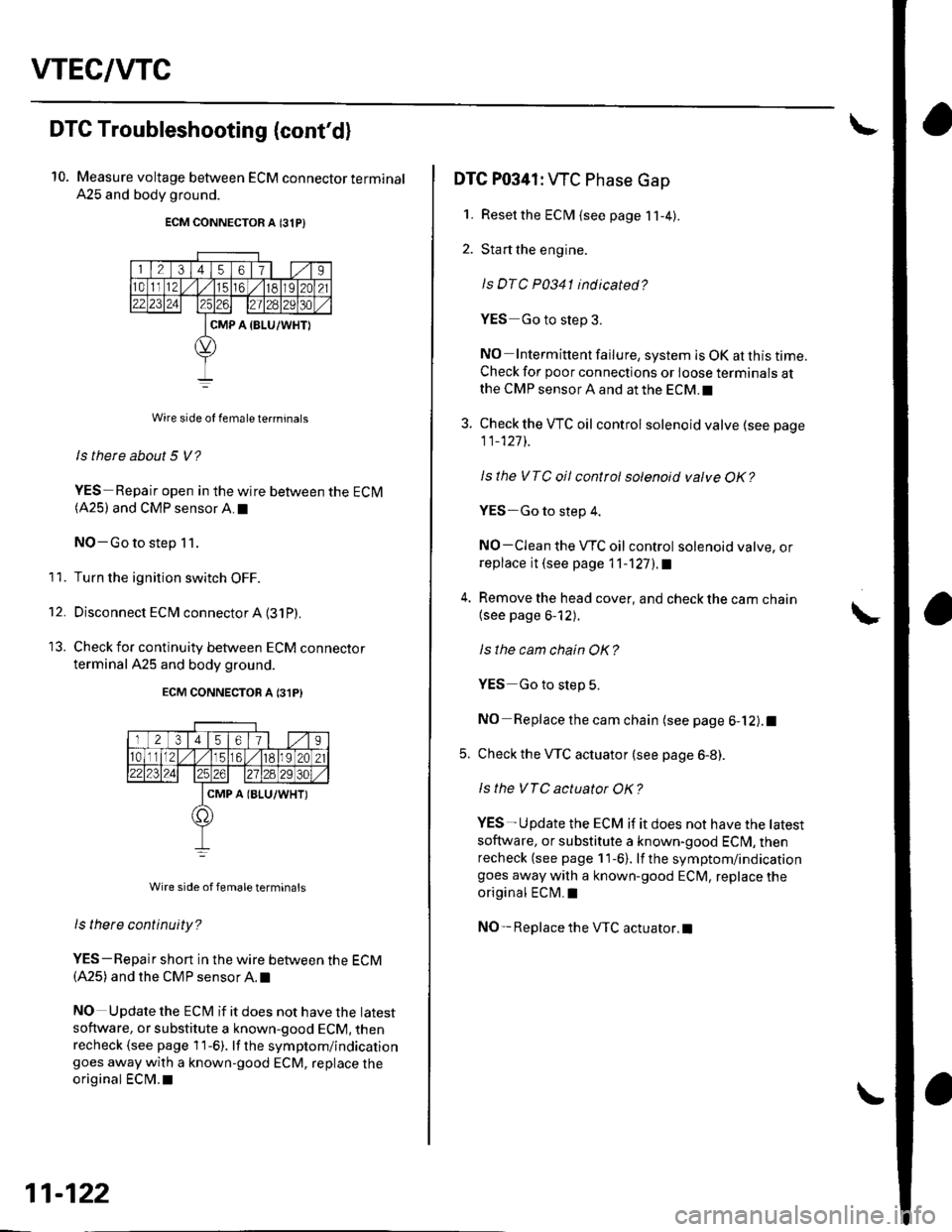

Measure voltage between ECM connector terminal

A25 and body ground.

ECM CONNECTOR A 131P)

Wire side of female te.minals

ls there about 5 V?

YES-Repair open in the wire between the ECM(A25) and CMP sensor A.I

NO-Go to step 11.

Turn the ignition switch OFF.

Disconnect ECM connector A (31P)

Check for continuity between ECM connecror

terminal A25 and body ground.

ECM CONNECTON A 131P}

Wire side of femaleterminals

ls tnere continuity?

YES-Repair short in the wire between the ECM(A25) and the CMP sensor A. t

NO Update the ECt\4 if it does not have the latest

software, or substitute a known-good ECM, thenrecheck (see page 1 1-6). lf the symptom/indicationgoes away with a known-good ECM, replace the

original ECM.I

11.

't2.

11-122

DTC P0341: WC Phase Gap

1. Resetthe ECM {see page 11-4).

2. Start the engine.

ls DTC P0341 indicated?

YES Go to step 3.

NO Intermittent failure, system is OK at this time.Check for poor connections or loose terminals atthe CMP sensor A and at the ECM.I

3. Check the VTC oil control solenoid valve (see page

11_127]-.

Isthe VTC oil control solenoid valve OK?

YES-Go to step 4.

NO-CIean the VTC oil control solenoid valve, orreplace it (see page 11-'l27l.a

4. Remove the head cover, and check the cam chain

{see page 6-12).

ls the cam chain OK?

YES Go to slep 5.

NO Replace the cam chain (see page 6-12).1

5. Check the VTC actuator (see page 6-8).

ls the VTC actuator OK?

YES- U pdate the ECM if it does not have the tatest

soflware, or substitute a known-good ECI\4, thenrecheck (see page 11-6). lf the symptom/indicationgoes away with a known-good ECM, replace the

original ECM.I

NO- Replace the VTC actuator.l

Page 330 of 1139

DTC Pl259: WEC System Malf unction

SpecialTools Required. Pressure gauge adapter 07NAJ P07010A

. A/T low pressure gauge w/panel 07406-0070300. A/T pressure hose 07406-0020201. Av/T pressure hose,2,210 mm 07IMAJ-PY4o11A

. l"/T pressure adapter 07MAJ-PY40120

. Oil pressure hose 07ZAJ-S54,4200

1. Reset the ECM (see page 11-4).

2. Check the engine oil level, and refill ifnecessary.

3. Start the engine. Hold the engine at 3,000 rpm with

no load {in neutral) until the radiator fan comes on.

4. Road testthe vehicle:

Accelerate in the 1st gear to an engine speed over

4.000 rpm. Hold the speed for at least 2 seconds. lf

DTC P1259 is not repeated during the first road test,

repeat the test two more times.

ls DTC P1259 indicated?

YES Go to step 5.

NO-lntermittent failure, system is OK at this time

Check the oil consumption if oil was added in step

2. Check for poor connections or loose terminals at

the VTEC solenoid valve, the VTEC oil pressure

switch, and at the ECI\4. I

5, Turn the ignitjon switch OFF.

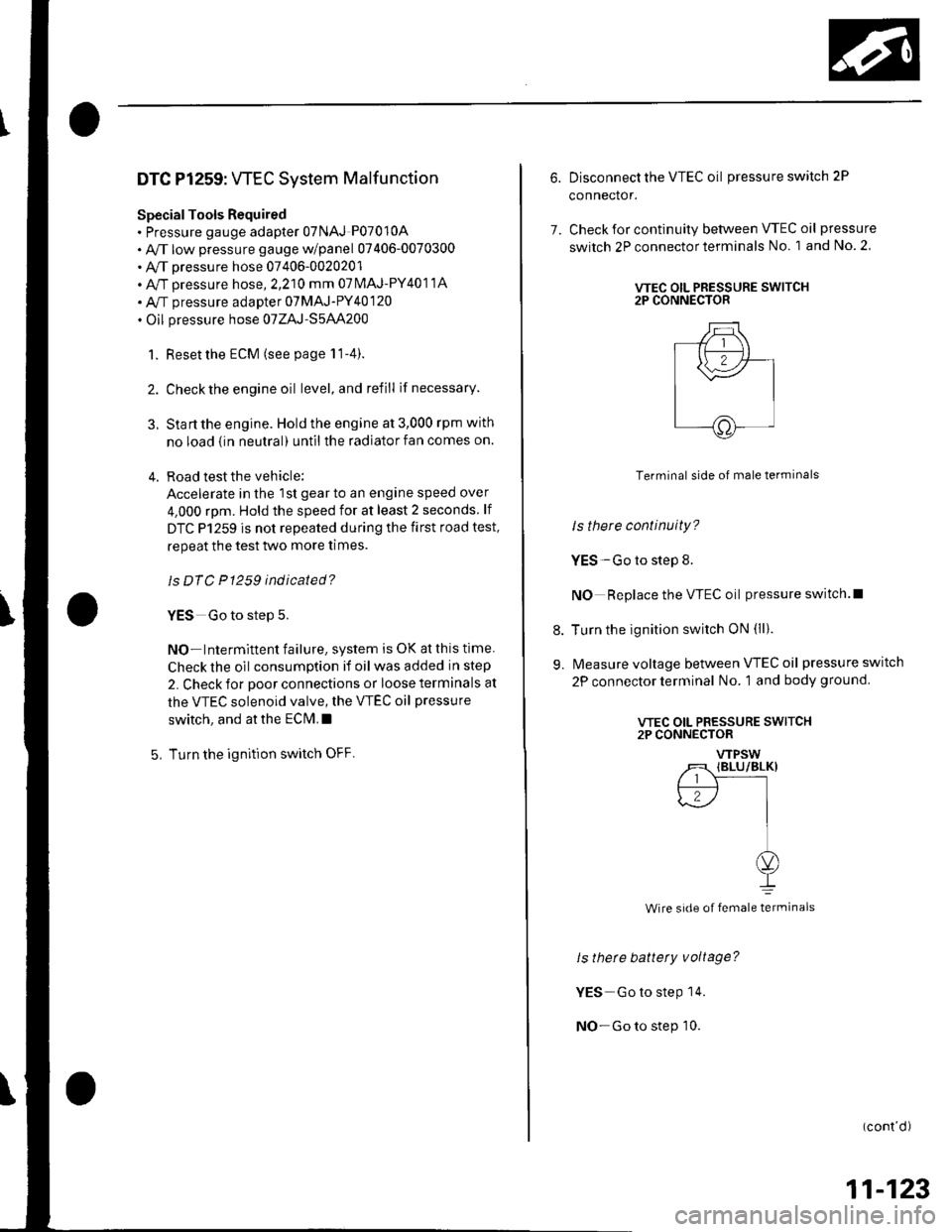

6. Disconnect the VTEC oil pressureswitch 2P

connector.

7. Check for continuity between VTEC oil pressure

switch 2P connector terminals No. 1 and No. 2

VTEC OIL PRESSURE SWITCH2P CONNECTOR

Terminal side of male terminals

Is there continuity?

YES-Go to step 8.

NO Replace the VTEC oil pressure switch.l

8. Turn the ignition switch ON (ll).

9. Measure voltage between VTEC oil pressure switch

2P connector terminal No. 1 and body ground

ls there battety voltage?

YES Go to steP 14.

NO-Go to step 10.

(cont'd)

VTEC OIL PRESSURE SWITCH2P CONNECTOR

VTPSW

/T {BLU/BLK}

{.--r r-l'--.l

J II

oI

Wire side of female terminals

11-123

Page 332 of 1139

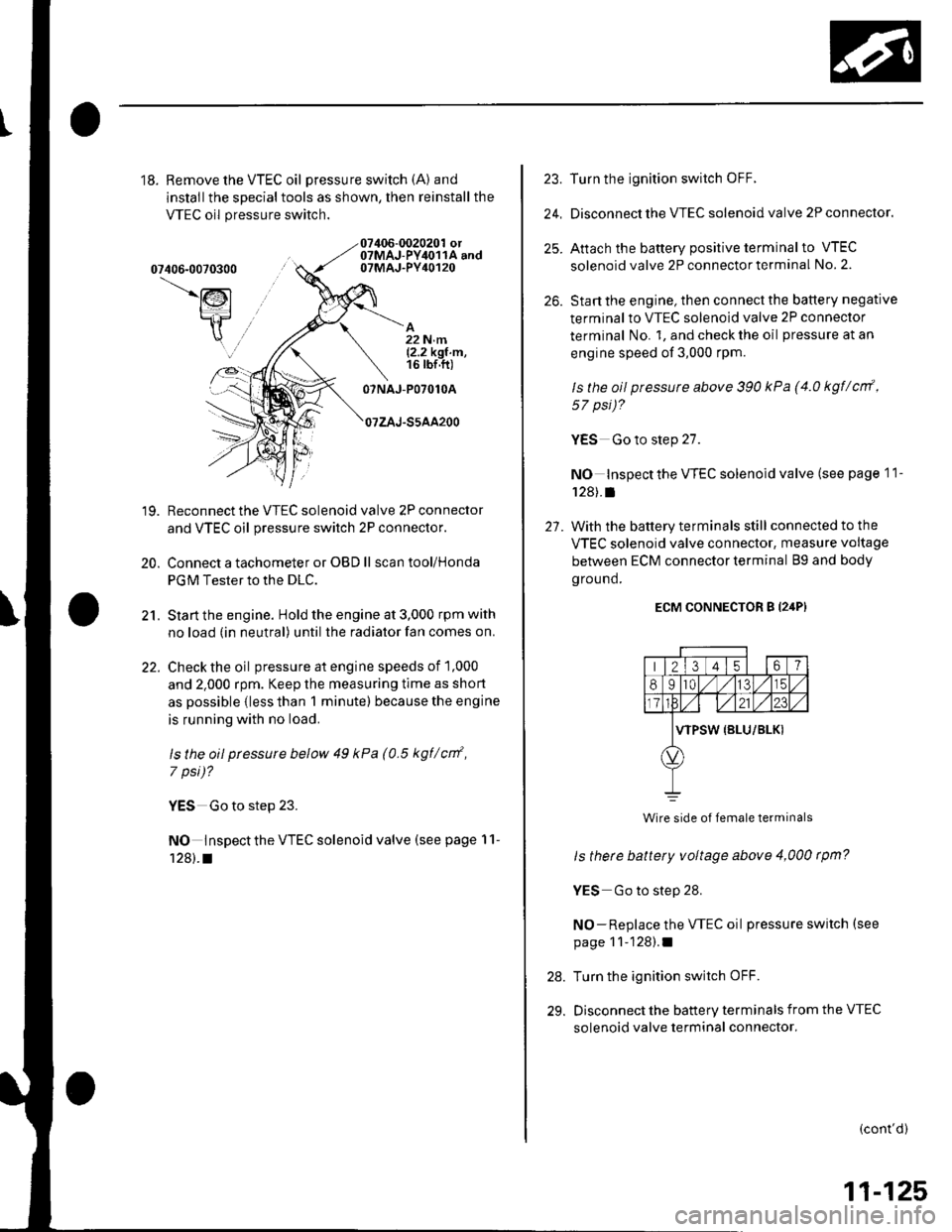

18.Remove the VTEC oil pressure switch (A) and

installthe specialtools as shown, then reinstall the

VTEC oil pressure switch.

07406-0070300

\lsl

t:={

R

07406-0020201 ot07MAJ-PY,lo11A and07MAJ-PY40120

A22 N.ml2.2kgt.m,16 rbf.ft)

19.

20.

21.

22.

07NAJ-P07010A

Reconnect the VTEC solenoid valve 2P connector

and VTEC oil pressure switch 2P connector.

Connect a tachometer or OBD ll scan tool/Honda

PGM Tester to the DLC.

Start the engine. Hold the engine at 3,000 rpm with

no load (in neutral) until the radiator fan comes on.

Checkthe oil pressure at engine speeds of 1,000

and 2.000 rpm. Keep the measuring time as shon

as possible {less than 1 minute) because the engine

is running with no load.

ls the oil ptessure below 49 kPa (0.5 kgf/cnf,

7 psi)?

YES Go to step 23.

NO Inspect the VTEC solenoid valve (see page 11-'t28l.a

23.

24.

25.

26.

Turn the ignition switch OFF.

Disconnect the VTEC solenoid valve 2P connector.

Aftach the battery positive terminalto VTEC

solenoid valve 2P connector terminal No. 2.

Start the engine, then connect the battery negative

terminalto VTEC solenoid valve 2P connector

terminal No. 1, and check the oil pressure at an

engine speed of 3,000 rpm.

ls the oil pressure above 390 kPa (4.0 kgt/crtf ,

57 psi)?

YES Go to step 27.

NO Inspectthe VTEC solenoid valve (see page I1-

12Al.a

27. With the battery terminals still connectedtothe

VTEC solenoid valve connector, measure voltage

between ECM connector terminal 89 and bodv

oround.

ECM CONNECTOR B {24P)

ls there battery voltage above 4,000 tpm?

YES Go to step 28.

NO-Replace the VTEC oil pressure switch (see

page 11'128).1

Turn the ignition switch OFF.

Disconnect the battery terminals from the VTEC

solenoid valve terminal connector.

(cont'd)

28.

29.

Wire side of female terminals

11-125

Page 334 of 1139

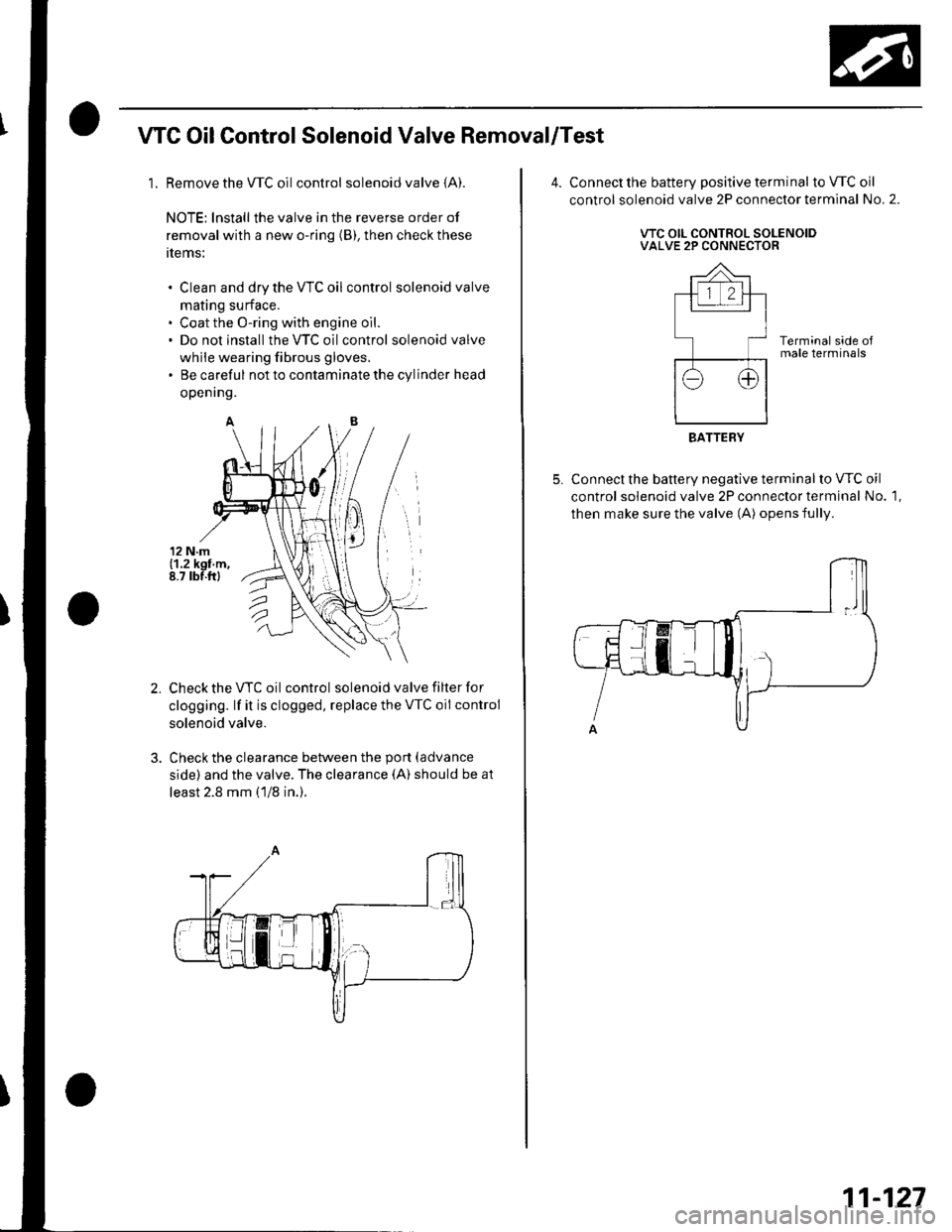

WC OilControl Solenoid Valve Removal/Test

1. Remove the WC oilcontrol solenoid valve (A).

NOTE: lnstall the valve in the reverse order of

removal with a new o-ring (B), then check these

tlems:

Clean and dry the VTC oil control solenoid valve

mating surface.

Coat the O-ring with engine oil.

Do not install the VTC oilcontrol solenoid valve

while wearing fibrous gloves,

Be careful not to contaminate the cylinder head

openrng.

Check the VTC oil control solenoid valve filter for

clogging. lf it is clogged, replace the VTC oil control

solenoid valve.

Check the clearance between the port (advance

side) and the valve. The clearance (A) should be at

least 2.8 mm (1/8 in.).

Connect the battery positive terminal to VTC oil

control solenoid valve 2P connector terminal No. 2.

VTC OIL CONTROL SOLENOIDVALVE 2P CONNECTOR

Terminal side oJmale terminals

Connect the battery negative terminal to VTC oil

control solenoid valve 2P connector terminal No. 1,

then make sure the valve (A) opens fully.

BATTERY

11-127

Page 335 of 1139

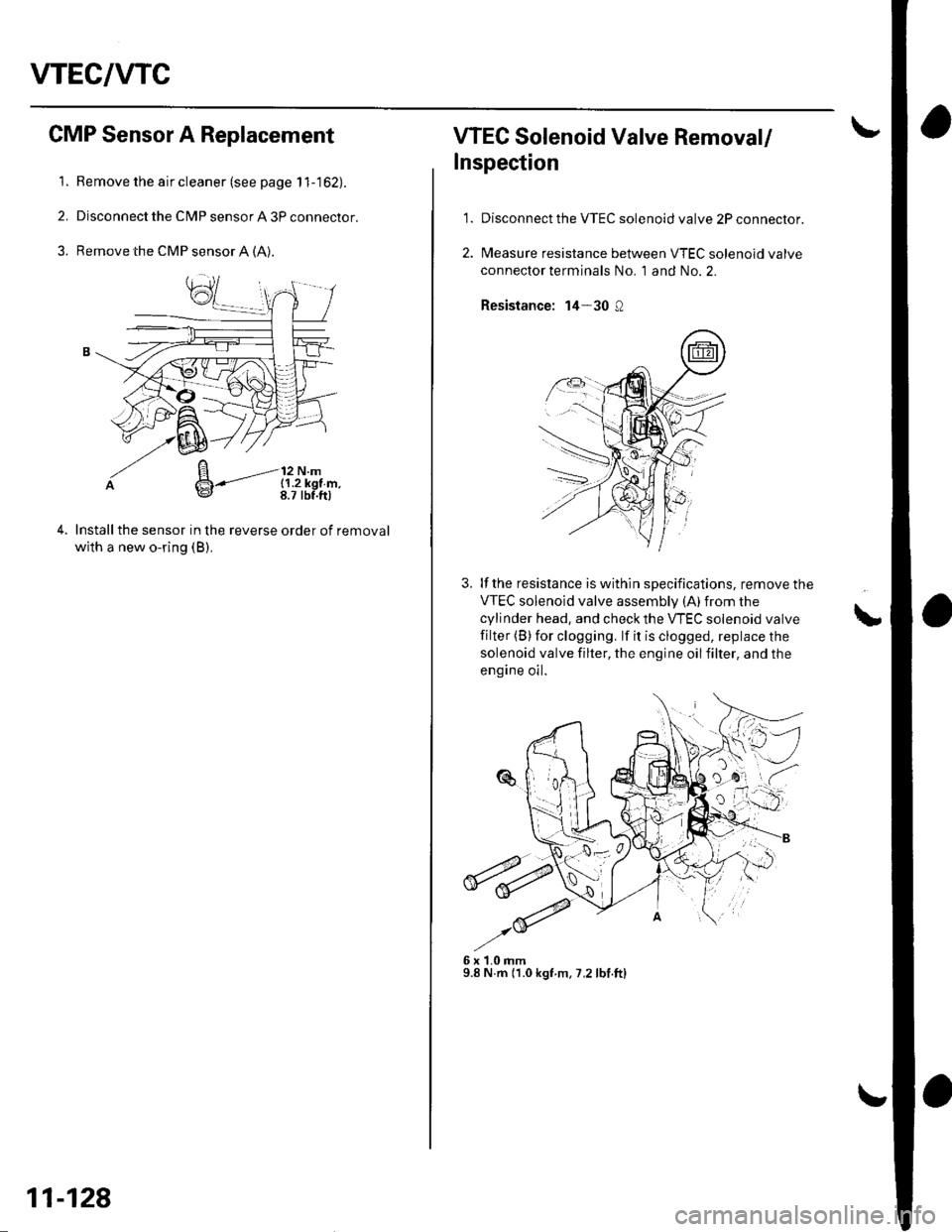

VTEC/WC

1.

CMP Sensor A Replacement

Remove the air cleaner (see page 1 1-162).

Disconnect the CMP sensor A 3P connector.

Remove the CMP sensor A (A).

Installthe sensor in the reverse order of removal

with a new o-ring (B).

B-'-----'-l:,",14*

11-128

WEC Solenoid Valve Removal/

Inspection

1.Disconnect the VTEC solenoid valve 2P connector.

Measure resistance between VTEC solenoid valve

connector terminals No. 1 and No. 2.

Resistance: 14-30 Q

3. lf the resistance is within specifications, remove the

VTEC solenoid valve assemblv (A)from the

cylinder head, and check the VTEC solenoid valve

filter (B)for clogging. lf it is clogged, replace the

solenoid valve filter, the engine oilfilter, and the

engine oil.

6x1.0mm9.8 N.m (1.0 kgf.m, 7,2 lbf.ftl

L