engine HONDA CIVIC 2002 7.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2002, Model line: CIVIC, Model: HONDA CIVIC 2002 7.GPages: 1139, PDF Size: 28.19 MB

Page 237 of 1139

Fuel and Emissions Systems

(System Descriptions (cont'dl

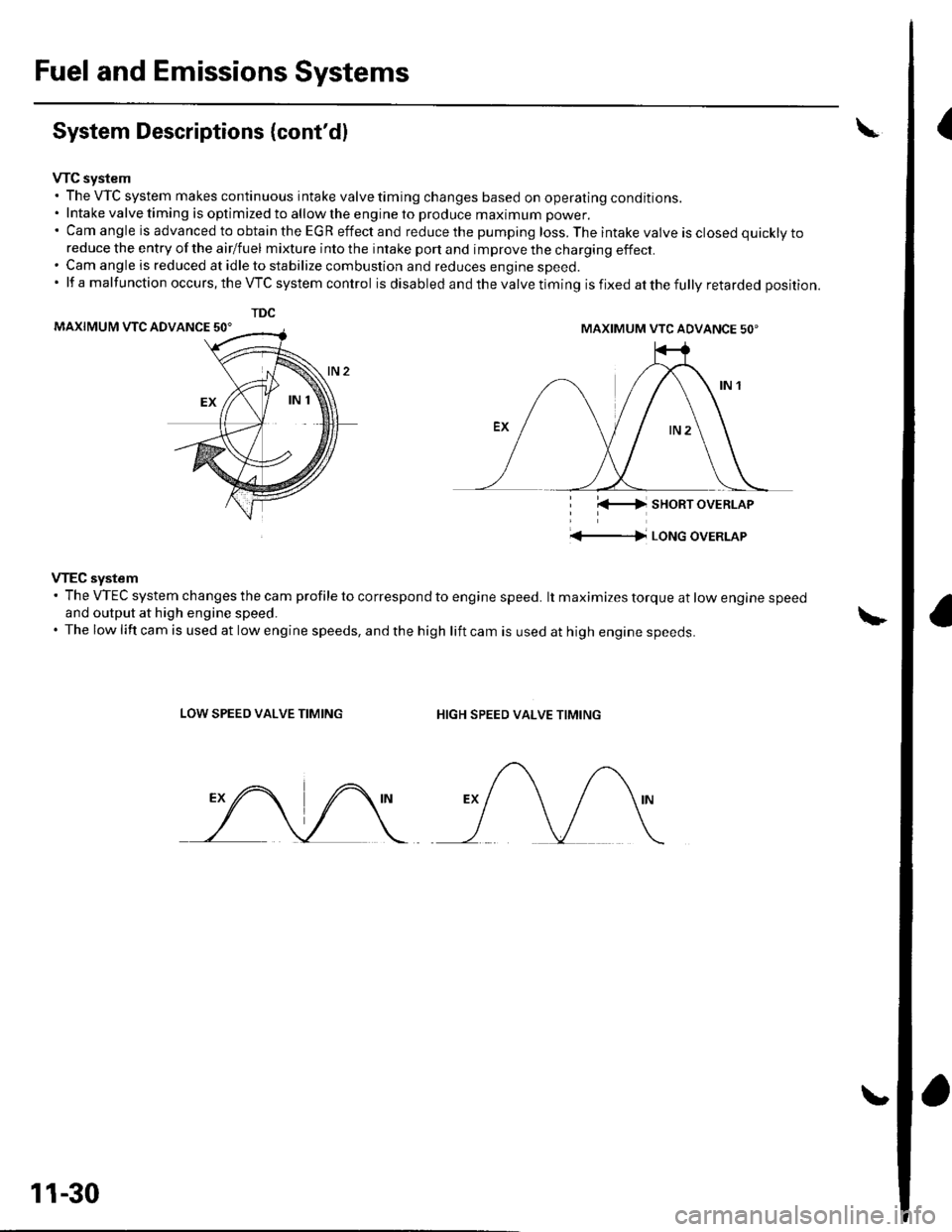

VTC system. The VTC system makes continuous intake valve timing changes based on operating conditions.. Intake valve timing is optimized to allow the engine to produce maximum power.'CamangleisadvancedtoobtaintheEGReffectandreducethepumpingloss.Theintakevalveisclosedquicklyto

reduce the entry of the airlfuel mixture into the intake port and improve the charging effect.. Cam angle is reduced at idle to stabilize combustion and reduces engine speed.'lfamalfunctionoccurs,theVTCsystemcontrol is disabled and the valve timing is fixed at the fully retarded position.

MAXIMUM VTC ADVANCE 50'

i l(-4 sHoRT oVERLAP

'+-|l LoNG oVERLAP

VTEC system' The VTEC system changes the cam profile to correspond to engine speed. lt maximizes torque at low engine speedand output at high engine speed.. The low lift cam is used at low engine speeds, and the high lift cam is used at high engine speeds.

LOW SPEED VALVE TIMINGHIGH SPEED VALVE TIMING

TDC

MAXIMUM VTC ADVANCE 50'

11-30

Page 239 of 1139

Fuel and Emissions Systems

(

{

System Descriptions (cont'd)

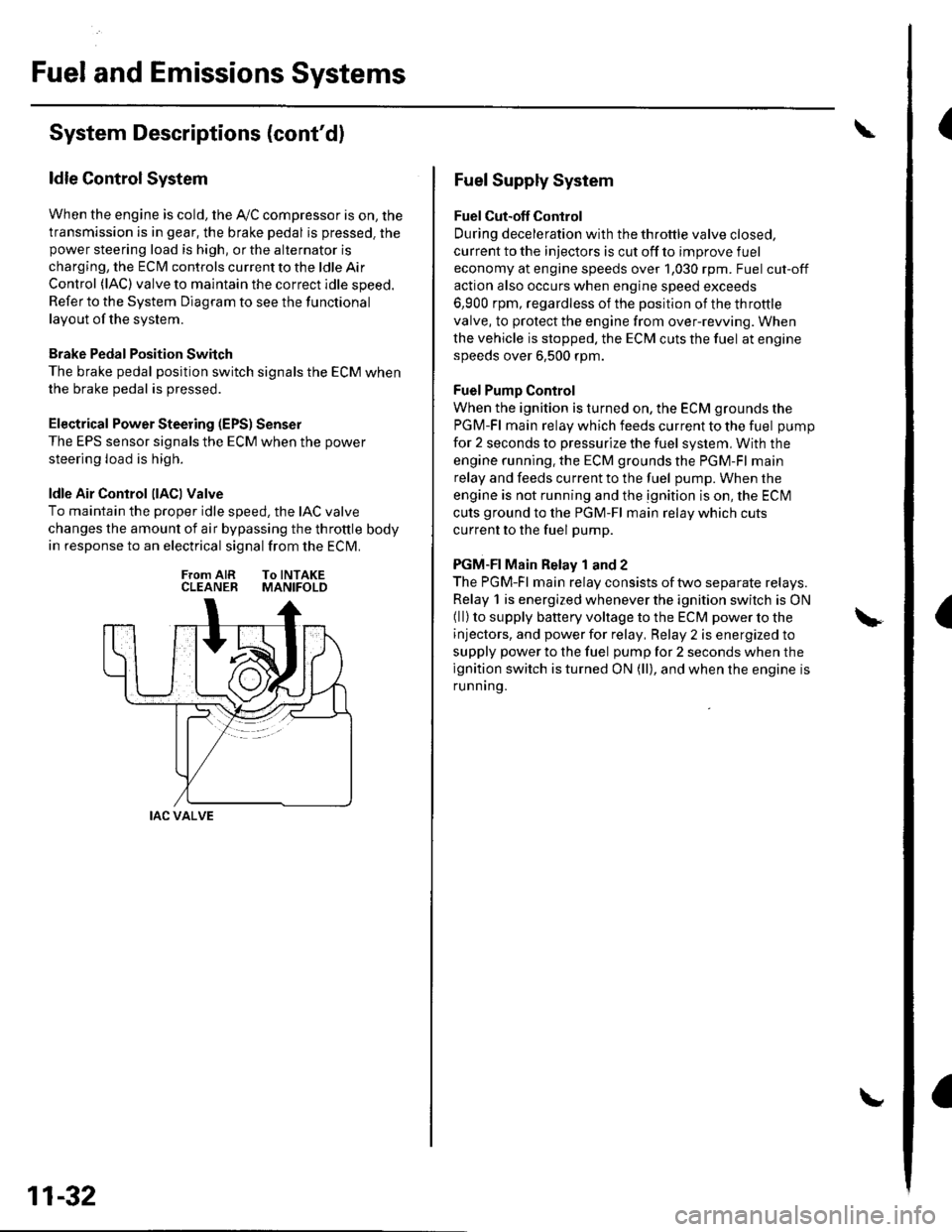

ldle Control System

When the engine is cold, the Ay'C compressor is on, the

transmission is in gear, the brake pedal is pressed. thepower steering load is high, or the alternator is

charging, the ECIM controls current to the ldle Air

Control (lAC) valve to maintain the correct idle speed.

Refer to the System Diagram to see the functional

layout of the system.

Brake Pedal Position Switch

The brake pedal position switch signals the ECM when

the brake pedal is oressed.

Electrical Power Steering (EPS) Senser

The EPS sensor signals the ECM when the power

steering load is high.

ldle Air Control llACl Valve

To maintain the proper idle speed, the IAC valve

changes the amount of air bypassing the throttle body

in response to an electrical signal from the ECM.

From AIR To INTAKECLEANER MANIFOLD

IAC VALVE

11-32

Fuel Supply System

Fuel Cut-off Control

During deceleration with the throttle valve closed,

current to the injectors is cut off to improve fuel

economy at engine speeds over 1,030 rpm. Fuel cut-off

action also occurs when engine speed exceeds

6,900 rpm, regardless of the position of the throttle

valve, to protect the engine from over-rewing. When

the vehicle is stopped. the ECM cuts the fuel at engine

speeds over 6,500 rpm.

Fuel Pump Control

When the ignition is turned on, the ECM grounds the

PGM-Fl main relay which feeds current to the fuel pump

for 2 seconds to pressurize the fuel system, With the

engine running. the ECM grounds the PGM-Fl main

relay and feeds current to the fuel pump. When the

engine is not running and the ignition is on, the ECI\4

cuts ground to the PGM-Fl main relay which cuts

current to the fuel pump.

PGM-FI Main Relay 1 and 2

The PGM-Fl main relay consists of two separate relays.

Relay 1 is energized whenever the ignition switch is ON(ll) to supply battery voltage to the ECM power to the

injectors, and power for relay, Relay 2 is energized to

supply power to the fuel pump for 2 seconds when the

ignition switch is turned ON (ll), and when the engine is

runnrng.

Page 240 of 1139

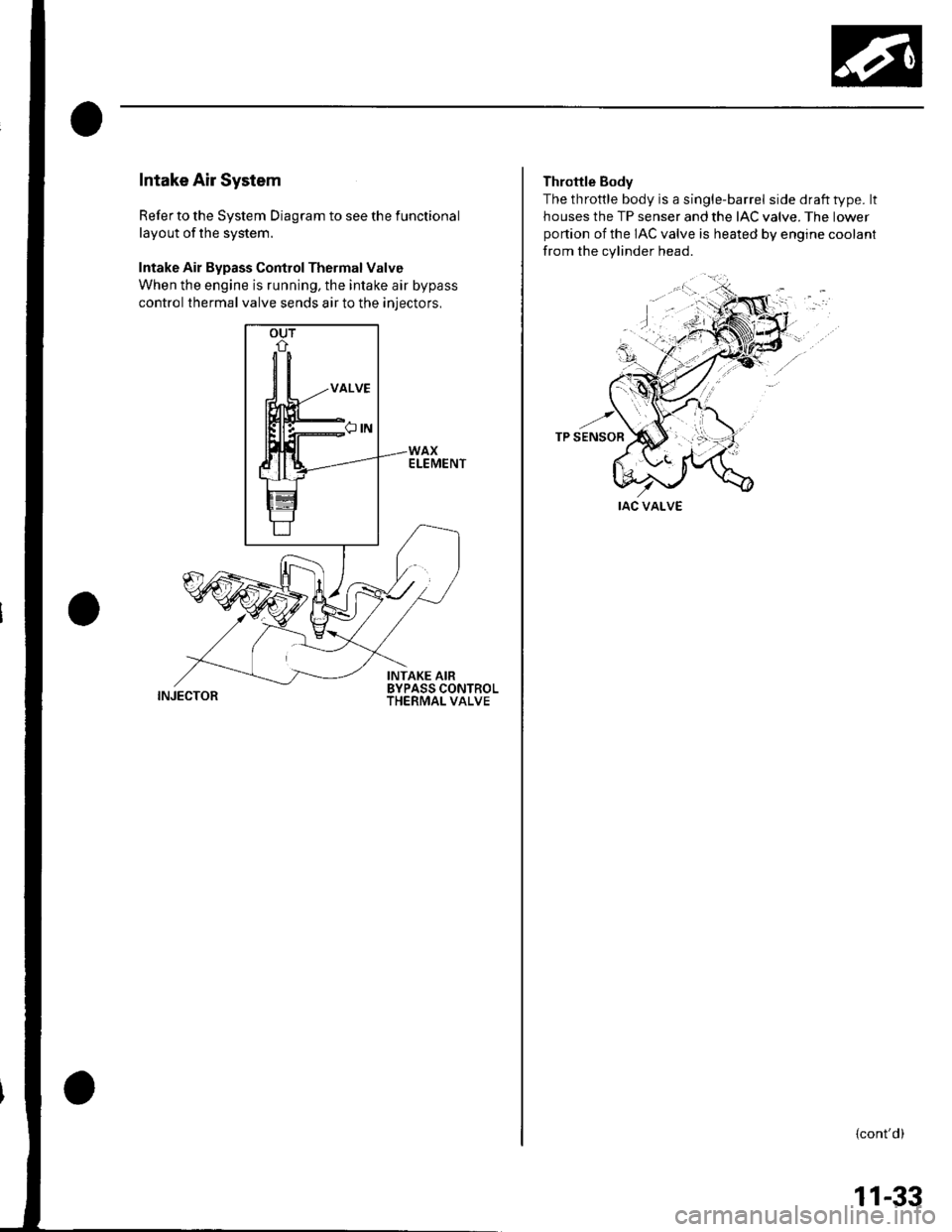

Intake Air System

Refer to the System Diagram to see the functional

layout of the system.

Intake Air Bypass Control Thermal Valve

When the engine is running, the intake air bypass

control thermal valve sends air to the iniectors,

INJECTOR

Throttle Body

The throttle body is a single-barrel side draft type. lt

houses the TP senser and the IAC valve. The lower

portion of the IAC valve is heated by engine coolant

from the cylinder head.

IAC VALVE

{cont'd)

11-33

Page 242 of 1139

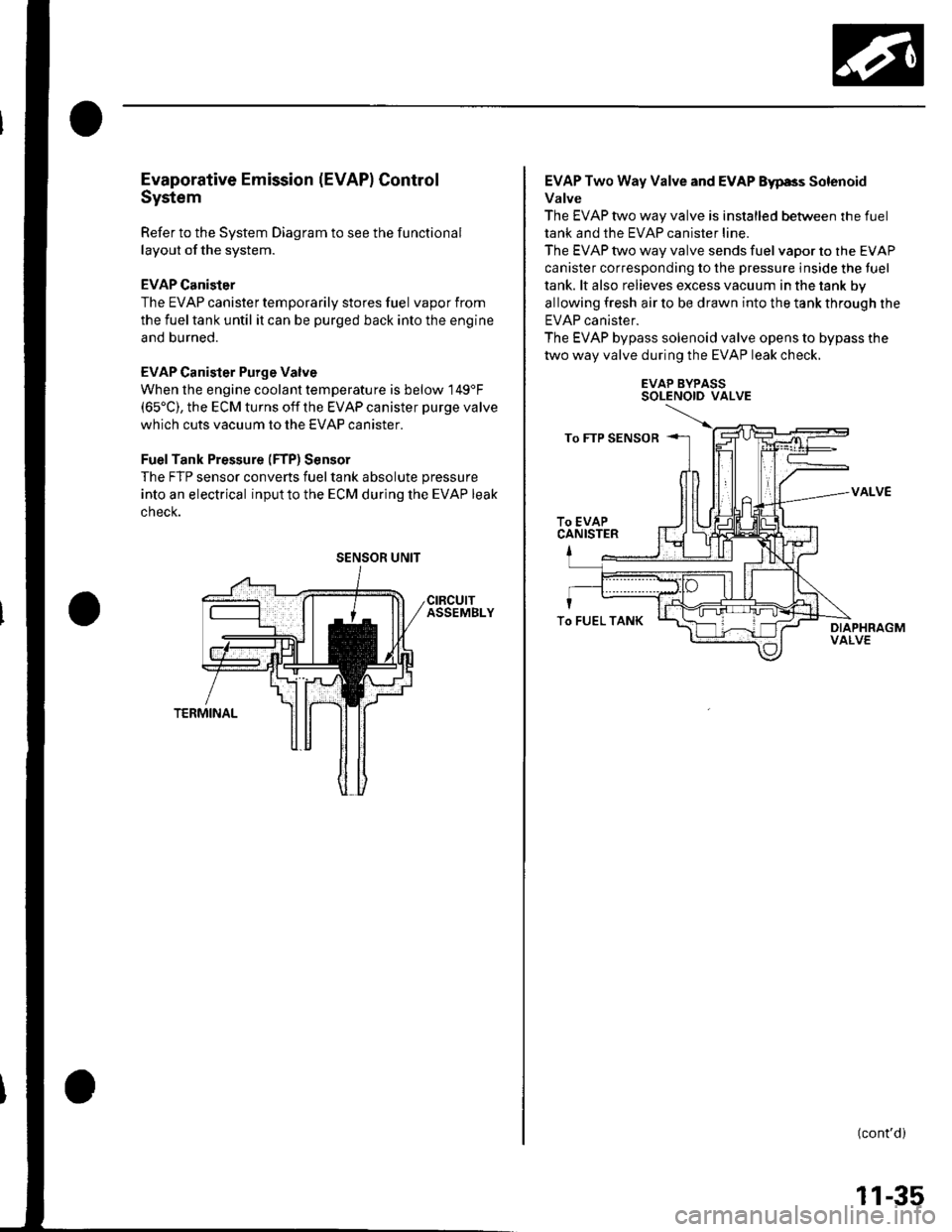

Evaporative Emission (EVAPI Control

System

Refer to the System Diagram to see the functional

layout of the system.

EVAP Canister

The EVAP canister temporarily stores fuel vapor from

the fuel tank until it can be purged back into the engine

and burned.

EVAP Canister Purge Valve

When the engine coolant temperatu re is below 149'F(65'C), the ECM turns off the EVAP canister purge valve

which cuts vacuum to the EVAP canister.

FuelTank Pressure (FTP) Sensor

The FTP sensor converts fueltank absolute pressure

into an electrical inputto the ECM during the EVAP leak

cnecK.

SENSOR UNIT

EVAP Two Way Valve and EVAP Eyp8s Solenoid

Valve

The EVAP two way valve is installed between the fuel

tank and the EVAP canister line.

The EVAP two way valve sends fuel vapor to the EVAP

canister corresponding to the pressure inside the tuel

tank. lt also relieves excess vacuum in the tank by

allowing fresh air to be drawn into the tank through the

EVAP canister.

The EVAP bypass solenoid valve opens to bypass the

two way valve during the EVAP leak check.

EVAP BYPASSSOLENOID VALVE

VALVE

(cont'd)

To FUEL TANK

11-35

Page 243 of 1139

Fuel and Emissions Systems

System Descriptions (cont'dl

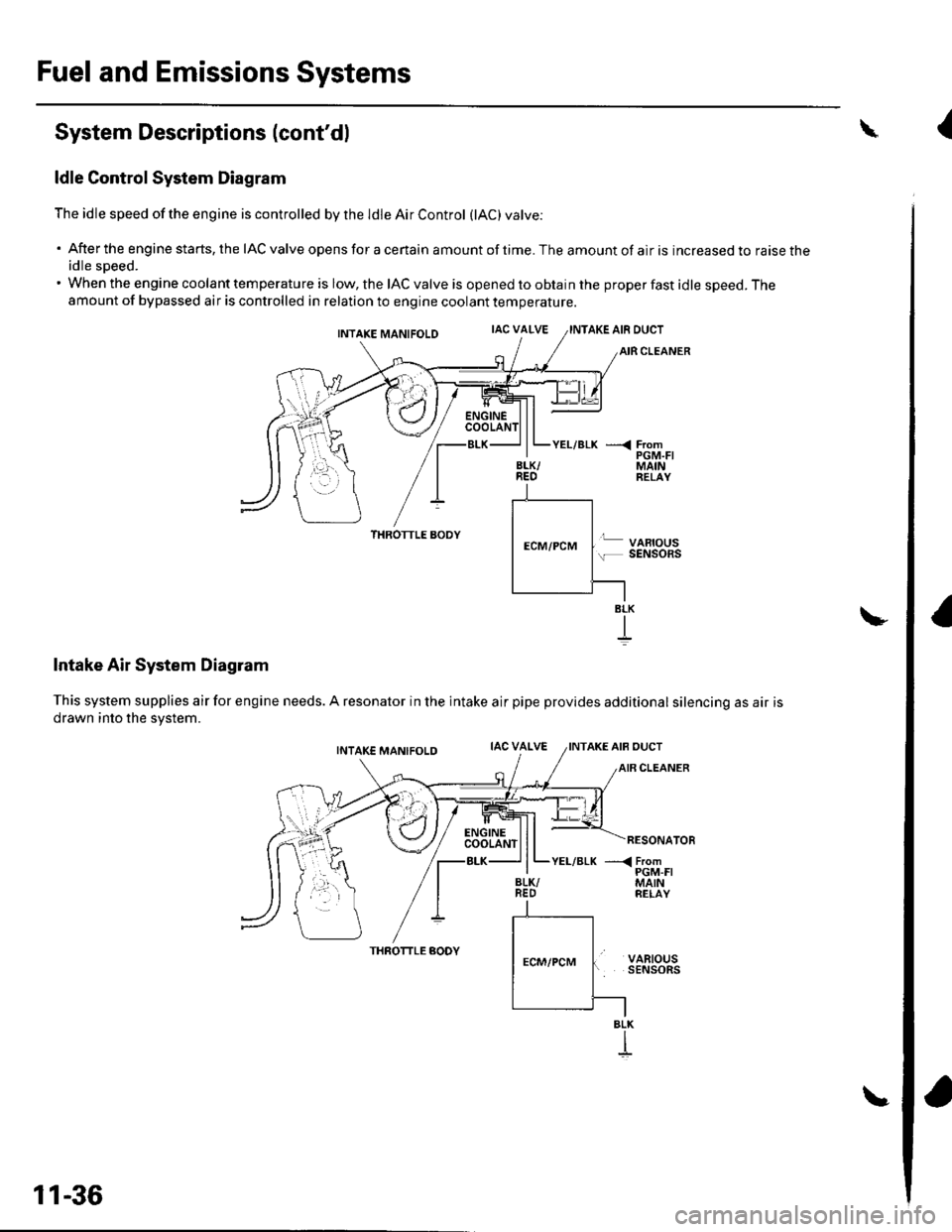

ldle Control System Diagram

The idle speed of the engine is controlled by the ldle Air Control (lAC) varve:

'Aftertheenginestarts,theIACvalveopensforacertainamountoftime.Theamountofairisincreasedtoraisethe

idle sDeed.. When the engine coolant temperature is low, the IAC valve is opened to obtain the proper fast idle speed. Theamount of bypassed air is controlled in relation to engine coolant temperature.

INTAKE MANIFOLDIAC VALVEAKE AIR DUCT

CLEANER

\

BLK/REO

YEL/BLK ---< FromPGM.FIMAINRELAY

THROTTLE AODY

Intake Air System Diagram

This system supplies air for engine needs. A resonator in the intake air

drawn into the svstem.

VARIOUSSENSOnS

pipe provides additional silencing as air is

THROTTLE AODYVARIOUSSENSORS

BLK

BLK

I

11-36

{

Page 244 of 1139

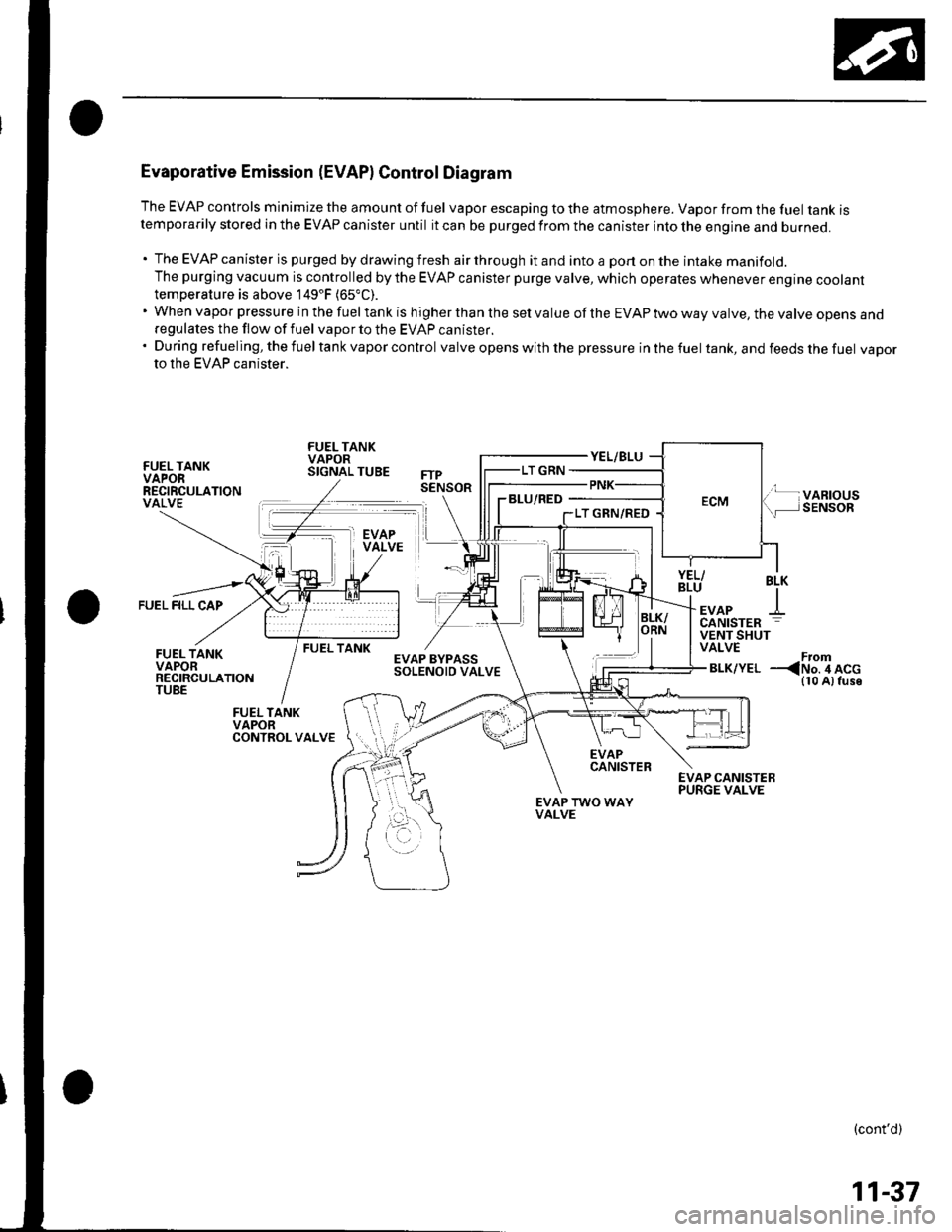

Evaporative Emission (EVAPI Control Diagram

The EVAP controls minimize the amount of fuel vapor escaping to the atmosphere. Vapor from the fuel tanK rstemporarily stored in the EVAP canister until it can be purged from the canister into the engine and burneo.

. The EVAP canister is purged by drawing fresh air through it and into a port on the intake manifold.The purging vacuum is controlled by the EVAP canister purge valve, which operates whenever engine cootanttemperature is above 149'F (65"C).

'WhenvaporpressureinthefueltankishigherthanthesetvalueoftheEVAPtwowayvalve,thevalveopensano

regulates the flow of fuel vapor to the EVAP canister.'Duringrefueling,thefueltankvaporcontrol valve opens with the pressure in the fuel tank, and feeds the fuel vaDorto the EVAP canister.

FUEL TANKVAPORRECIRCULATIONVALVE

FUEL TANKVAPORSIGNAL TUBE

BLU/RED

FUEL FILL CAP

BLK

+EVAPCANISTER

FUEL TANKVENT SHUTVALVE

BLK/YELFrom--

EVAPCANISTER

EVAP TWO WAYVALVE

(cont'd)

11-37

Page 253 of 1139

Fuel and Emissions Systems

How to Set Readiness Codes

Malfunction lndicator Lamp (MlL) Indication

(ln relation to Readiness Codesl

The vehicle has certain "readiness codes" that are part

of the on-board diagnostics for the emissions systems.

lf the vehicle's battery has been disconnected or gone

dead, if the DTCS have been cleared, or if the ECM has

been reset, these codes are set to incomplete. In some

states, part of the emission testing is to make su re these

codes are set to complete. lf all of them are not set to

complete, the vehicle may fail the emission test, or the

test cannot be finished.

To check ifthe readiness codes are complete, turn the

ignition switch ON (ll), but do not start the engine. The

MIL will come on for 15 20 seconds. lf it then goes off,

the readiness codes are complete. lf it blinks several

times, one or more readiness codes are not complete.

To set readlness codes from incomplete to complete.

do the procedure for the appropriate code.

11-46

L

Catalytic Converter Monitor and Readiness

Code

NOTE:. Do not turn the ignition switch off during the

procedure.

. All readiness codes are cleared when the battery is

disconnected or when the ECM is cleared with the

OBD ll scan tool or Honda PG lvl Tester.. Low ambient temperatures or excessive slop-and-go

traffic may increase the drive time needed to switch

the readiness code from incomplete to complete.' The readiness code will not switch to com Dlete until

all the enable criteria are met.. lf a fault in the secondary HO2S system caused the

MIL to come on. the readiness code cannot be set to

comDlete until vou correct the fault.

Enable Criteria. ECT at 158"F (70'C) or higher.. Intake air temperature (lAT) at 20"F (-7'C) or higher.. Vehicle speed is steady, and vehicle speed sensor

(VSS) reads more then 25 mph (13km/h).

Procedure

1. Connect the scan tool to the vehicle's data link \

connector (DLCi, and bring up the tool's generic \"

OBD ll mode.

Start the engine.

Test-drive the vehicle under stop-and-go conditions

with short periods of steady cruise. After about

5 miles (3 km), the readiness code should switch

from incomplete to complete.

lf the readiness code is still set to incomplete, check

for a temporary DTC. lf there is no DTC, one or

more of the enable crlteria were probably not met;

2.

3.

Page 254 of 1139

Evaporative Emissions (EVAP) Control

System Monitor and Readiness code

NOTE:

All readiness code are cleared when the batterV is

disconnected or when the ECM is cleared with the

OBD ll scan tool or Honda PGM Tester.

The enable criteria must be repeated if the intake air

temperature (lAT) drops lower than 36'F (20"C) from

its value at engine $an up.

Enable Criteria

At engine start up, ECT and IAT are higher than 32'F(0"C) , but lower than 95'F (35"C).

At engine start up, the ECT and IAT are within 12'F(7'C) of each other.

Procedure

1. Connect the scan tool to the vehicle's data link

connector (DLC), and bring up the tool's generic

OBD ll mode.

2. Start the engine.

3. Test-drive the vehicle under stop-and-go conditions

with short periods of steady cruise. After about

2.5 miles (1.6 km), the readiness code should

switch f rom incomplete to complete.

4. lf the readinesscode isstill setto incomplete, check

for a temporary DTC. lf there is no DTC, one or

more of the enable criteria were probably not met;

repeat the procedure.

Air Fuel Ratio (A/Fl Sensor Monitor and

Readiness Code

NOTE:. Do not turn the ignition switch off during the

orocedure.. All readiness codes are cleared when the baftery is

disconnected or when the ECM is cleared with the

OBD ll scan tool or Honda PGM Tester.

Enable Criteria

ECT at 140'F (60"C) or higher.

Procedure

1. Connect the scan toolto the vehicle's data link

connector (DLC), and bring up the tool's generic

OBD ll mode.

2. Start the engine.

3. Test-drive the vehicle under stop-and-go conditions

with short periods of steady cruise. During the

drive, decelerate (wirh the throttle fully closed) for

5 seconds. After about 3.5 miles (2.2 km). the

readiness code should switch from incomDlete to

complete.

4. lfthereadinesscodeisstill set to incomplete, check

for a temporary DTC. lfthere is no DTC, the enable

criteria was probably not meU repeat the procedure.

Air/Fuel Ratio (A/Fl Sensor Heater Monitor

Readiness Code

NOTE; All readiness codes are cleared when the battery

is disconnected or when the ECM is cleared with the

OBD ll scan tool or Honda PGM Tester,

Procedure'1. Connect the scan tool to the vehicle's data link

connector {DLC), and bring up the tool's generic

OBD ll mode.

2. Start the engine, and let it idle for 1 minute. The

readiness code should switch from incomplete to

comDlete.

3. lf the readiness code is still set to incomplete, check

for a temporary DTC. lf there is no DTC, repeat theproceoure.

(cont'd)

11-47

Page 255 of 1139

Fuel and Emissions Systems

a

a

How to Set Readiness Codes (cont'd)

Misfire Monitor and Readiness Code

. This readiness code is always set to available

because misfiring is continuously monitored.. l\4onitoring pauses, and the misfire counter resets, if

the vehicle is driven over a rough road.. Monitoring also pauses, and the misfire counter

holds at its current value. if the throttle position

changes more than a predetermined value, or if

driving conditions fall outside the range of any

related enable criteria,

Fuel System Monitor and Readiness Code

. This readiness code is always setto available

because the fuel system is continuously monitored

during closed loop operation.. Monitoring pauses when the catalytic converter,

EVAP control system, and Ay'F sensor monitors are

active.. Monitoring also pauses when any related enable

criteria are not being met. Monitoring resumes when

lhe enable criteria is again being met.

Comprehensive Component Monitor and

Readiness Code

This readiness code is always set to available because

the comprehensive component monitor is continuously

running whenever the engine is cranking or running.

11-48

\-

L

Page 256 of 1139

![HONDA CIVIC 2002 7.G Workshop Manual PGM-FI System

Component Location Index

CAMSHAFT POS]TION {CMP) SENSOR B(TOP DEAD CENTER (TDC}SENSORITroubleshootina. oaoe 1 1-95Replacement, p;ge 1-1.1 14

ELECTRICAL LOADDETECTOR {ELDITroubleshooting, HONDA CIVIC 2002 7.G Workshop Manual PGM-FI System

Component Location Index

CAMSHAFT POS]TION {CMP) SENSOR B(TOP DEAD CENTER (TDC}SENSORITroubleshootina. oaoe 1 1-95Replacement, p;ge 1-1.1 14

ELECTRICAL LOADDETECTOR {ELDITroubleshooting,](/img/13/5744/w960_5744-255.png)

PGM-FI System

Component Location Index

CAMSHAFT POS]TION {CMP) SENSOR B(TOP DEAD CENTER (TDC}SENSORITroubleshootina. oaoe 1 1-95Replacement, p;ge 1-1.1 14

ELECTRICAL LOADDETECTOR {ELDITroubleshooting,page 1'l -92

INTAKE AIR TEMPERATURE{IATI SENSORTroubleshooting,page 'l'l-55

Replacement, page 11-'l 15

f- \

rl

KNOCK SENSORTroubleshooting, page 1 1-77Beplacement, page 11 115

ENGINE COOLANT TEMPERATURE(ECTI SENSORTroubleshooting, page 1 1-57Replacement, page 11 114

MANIFOLD ABSOLUTE PRESSURE(MAP) SENSORTroubleshooting, page 1 1-52

THROTTLE POSITIONITP} SENSORTroubleshooting, page 11-60CRANKSHAFT POSITIONICKPISENSORTroubleshooting, page'l 1-78Beplacement, page 1 1-'l 16

AIR FUEL RATIO {A/F)SENSOR ISENSOR 1}Trorrbleshooting, page 1 1-84Replacement, page 11- 1 13

{cont'd)

ii'- r'1

.I11 ---:,I''.!,i(..,.?:fir-J-

.....,..:--.

11-49