Motor HONDA CIVIC 2002 7.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 2002, Model line: CIVIC, Model: HONDA CIVIC 2002 7.GPages: 1139, PDF Size: 28.19 MB

Page 191 of 1139

Engine Cooling

Cooling System

Component Location Index ......................................... 10-2

Radiator Cap Test ..................... .......... 10-3

RadiatorTest ............. 10-3

Fan Motor Test .......... l0-4

Thermostat Test ...................... ........... 10-4

Water Pump Inspection ..................... 10-5

Water Pump Replacement ................. 10-5

Coolant Check .............. ....................... 10-6

Coolant Replacement ......................... 10-6

Thermostat Replacement .................. 10-8

Water Passage Installation ................ 10-9

Water Outlet Installation .................... 10-9

Radiator and Fan Replacement ................................... 10-10

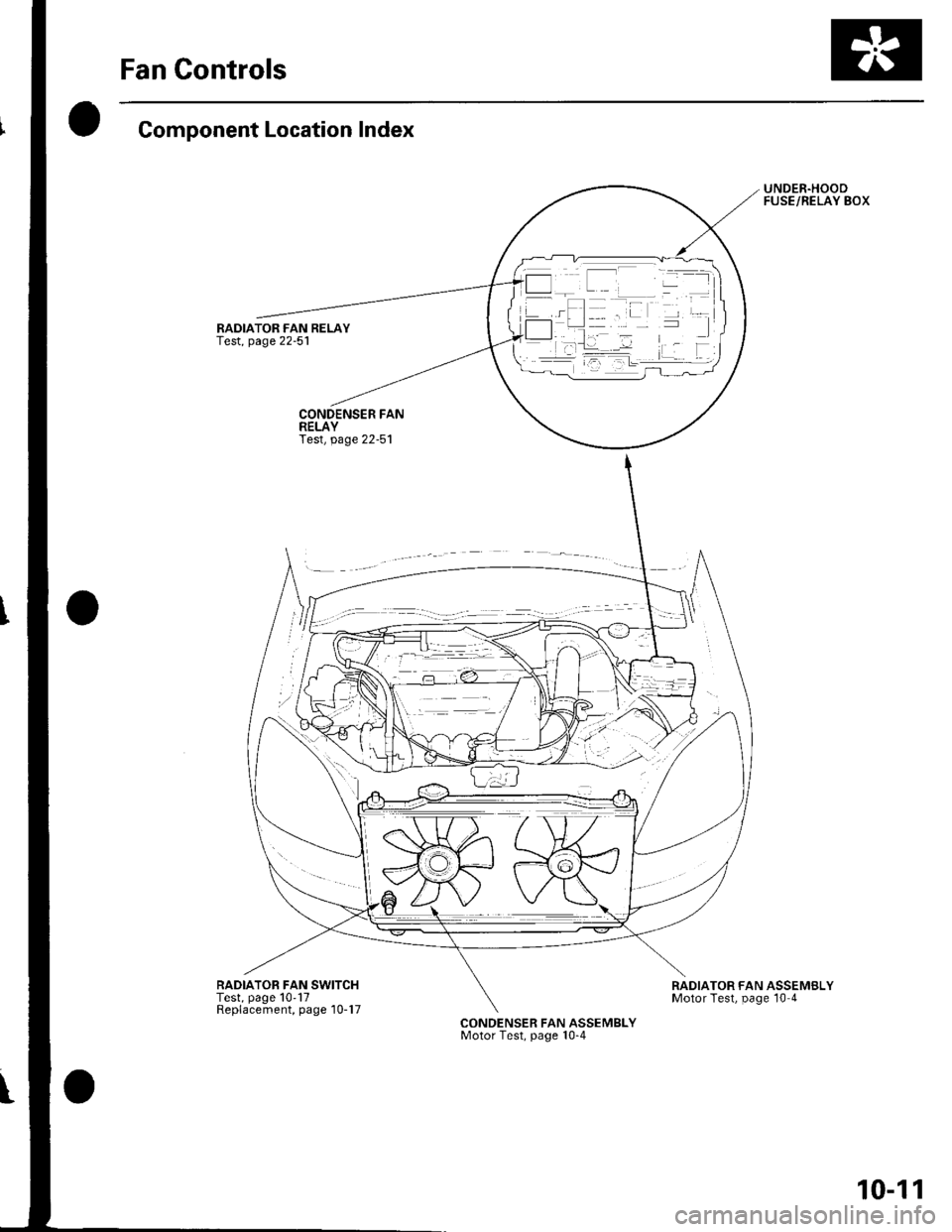

Fan Controls

Component Location Index ......................................... 10-11

Symptom Troubleshooting Index ............................... 10-12

Circuit Diagram ......... 10-13

Radiator Fan CircuitTroubleshooting ........................ 10-14

Radiator Fan Switch Circuit Troubleshooting

(Open) ............ ........ 10-16

Radiator Fan Switch Circuit Troubleshooting

(Short) ............ ........ 10-16

Radiator Fan Switch Test ................... 10-17

Radiator Fan Switch Reolacement .............................. 10-17

Page 192 of 1139

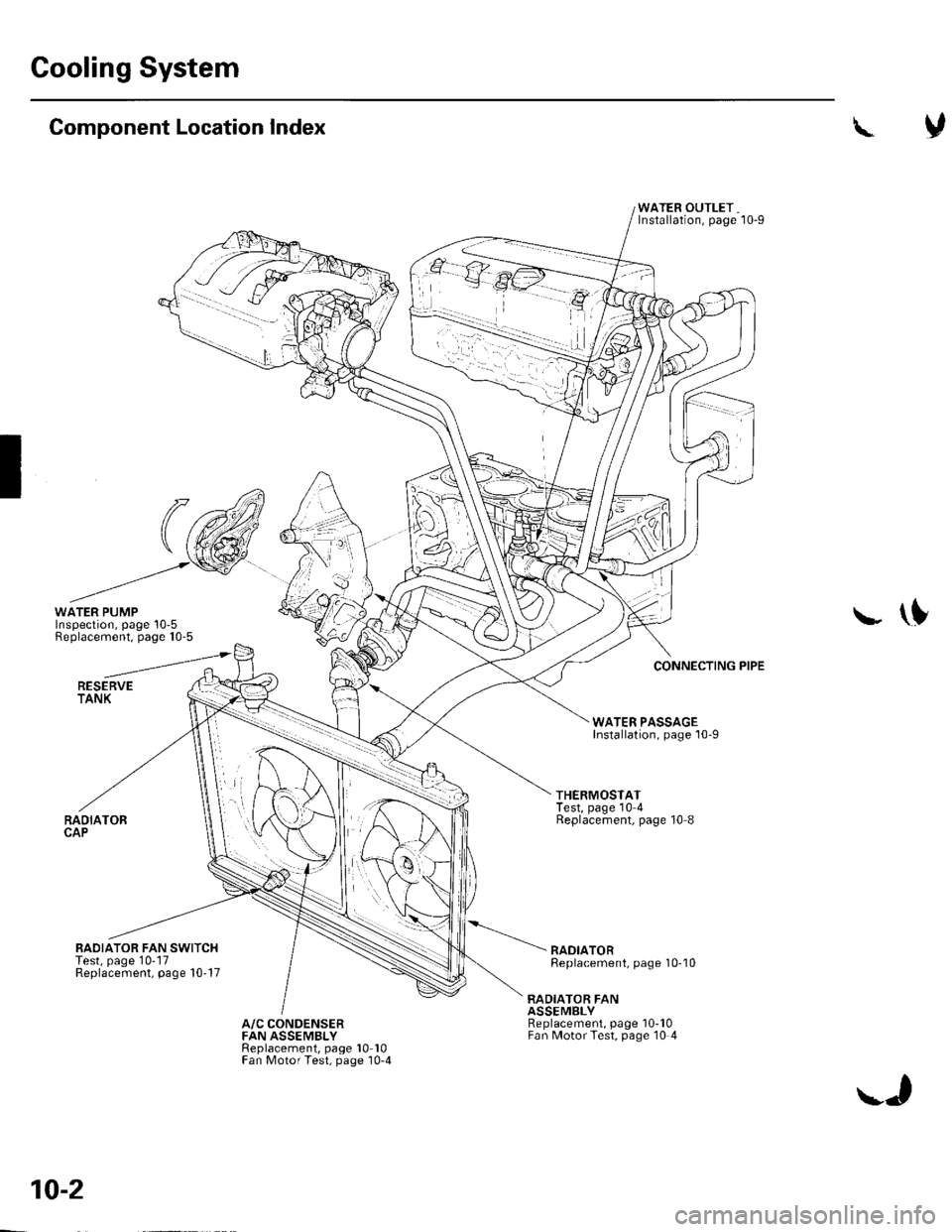

Cooling System

Component Location Index

WATER PUMPInspection, page 10-5Replacement. page 10-5

RESERVETANK

RADIATORCAP

RAOIATOR FAN SWITCHTest, page 10-17Replacement, page 10'17

\

WATER OUTLET,Installation, page'10-g

\f

CONNECTING PIPE

WATER PASSAGEInstallation, page 10-9

THERMOSTATTest, page 10 4Replacement, page 10 8

RADIATORReplacement, page 10-'l0

RADIATOR FANASSEMgLYReplacement, page 10-10Fan MotorTest, page 10 4A/C CONDENSERFAN ASSEMBLYReplacement, page 10 10Fan Motor Test, page '10-4

10-2

\J

Page 194 of 1139

Cooling System

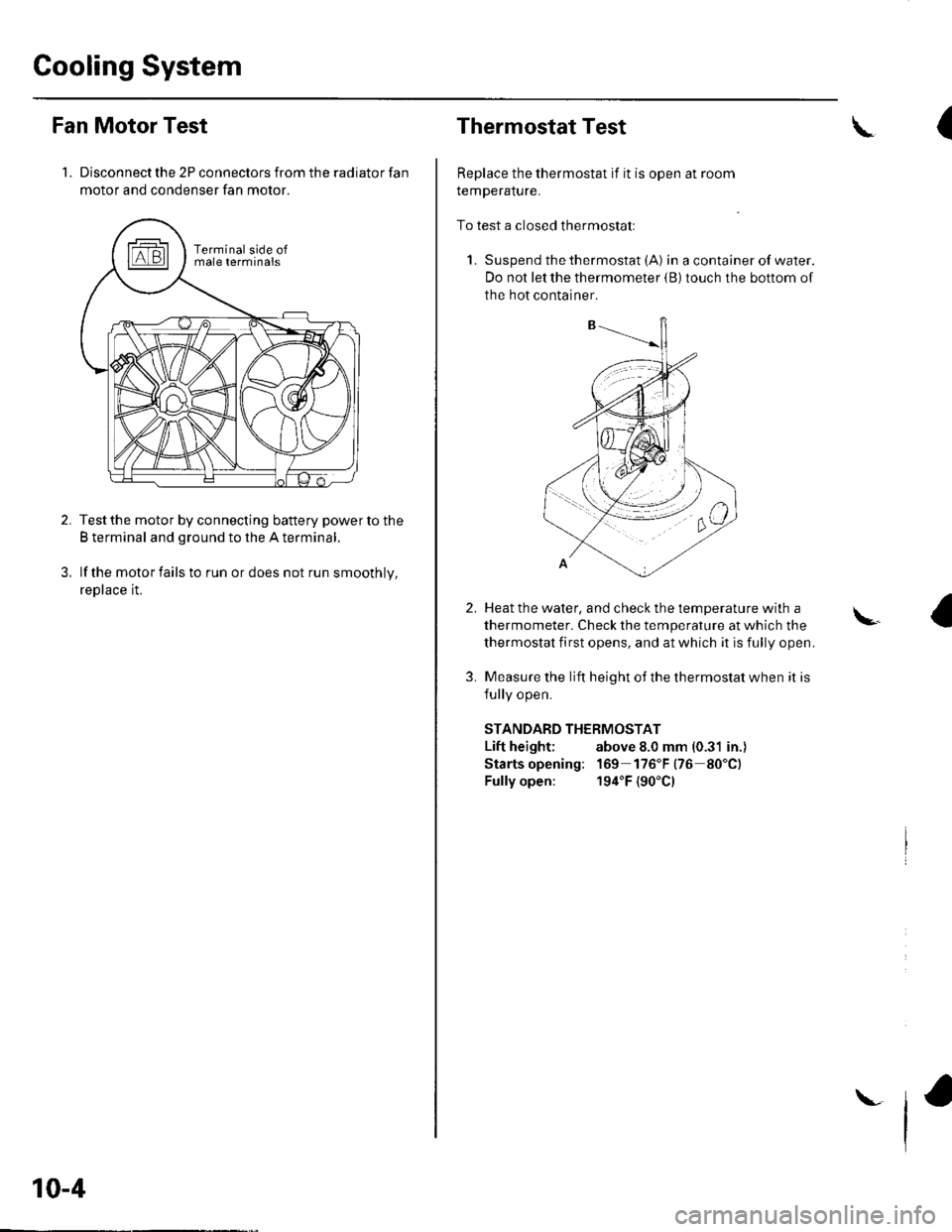

Fan Motor Test

1. Disconnect the 2P connectors from the radiator fan

motor and condenser fan motor.

Test the motor by connecting battery power to the

B terminal and ground to the A terminal.

lf the motor fails to run or does not run smoothly,

reptace rL

10-4

\

Thermostat Test

Replace the thermostat if it is open at room

remperalure.

To test a closed thermostatl

1. Suspend the thermostat (A) in a container of water.

Do not let the thermometer {B) touch the bottom of

the hot container.

(\

2.

3.

Heat the water, and check the temDerature with a

thermometer. Check the temperature at which the

thermostat first opens, and at which it is fully open.

Measure the lift height of the thermostat when it is

fullv ooen.

STANDARD THERMOSTAT

Lift height; above 8.0 mm (0.31 in.)

Starts opening: 169 176"F(76 80"C)

Fully open: 194"F {90'Cl

\.

Page 200 of 1139

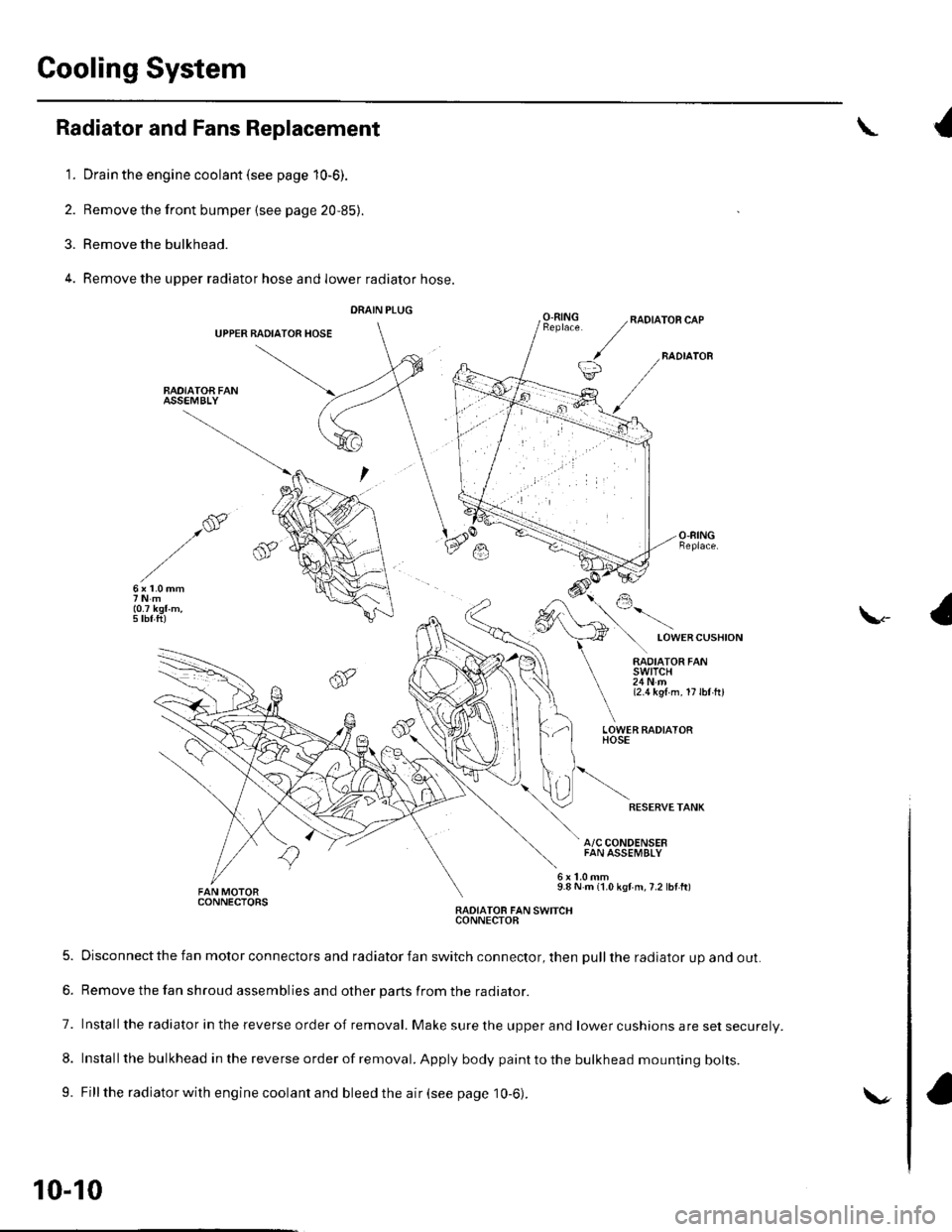

Cooling System

Radiator and Fans Replacement

1. Drain the engine coolant (see page 10-6).

2. Remove the front bumper {see page 20,85).

3. Remove the bulkhead.

4. Remove the upper radiator hose and lower radiator hose.

DRAIN PLUG

UPPER BADIATOR HOSE

BAOIATOA FANASSEMBLY

{

O.RINGRADIATOR CAP

BADIATOB

LOWERCUSHION

\-

RADIATOR FANswtTcH24Nm{2.1t kgl m. 17lbl hl

LOWER FADIATORHOSE

RESERVETANK

A/C CONDENSERFAN ASSEMBLY

9.8 N m {1.0 kgf m,7.2 lbf ft)CONNECTORSRADIATOB FAN SWITCHCONNECTOB

5. Disconnect the fan motor connectors and radiator fan switch connector, then pull the radiator up and out.

6. Remove the fan shroud assemblies and other parts from the radiator.

7. Installthe radiator in the reverse order of removal. Make sure the upper and lower cushions are set securelV.

8. Install the bulkhead in the reverse order of removal. Apply body paint to the bulkhead mounting bolts.

9. Fill the radiator with engine coolant and bleed the air (see page 10-6).

10-10

\.

Page 201 of 1139

Fan Controls

Component Location Index

RADIATOR FAN RELAY

RADIATOB FAN SWITCHTest, page 10'17Replacement, page'10-17

UNDER.HOODFUSE/RELAY BOX

RADIATOR FAN ASSEMBLYMotor Test, page 10 4

CONDENSER FAN ASSEMBLYMotor Test, page 10-4

10-11

Page 205 of 1139

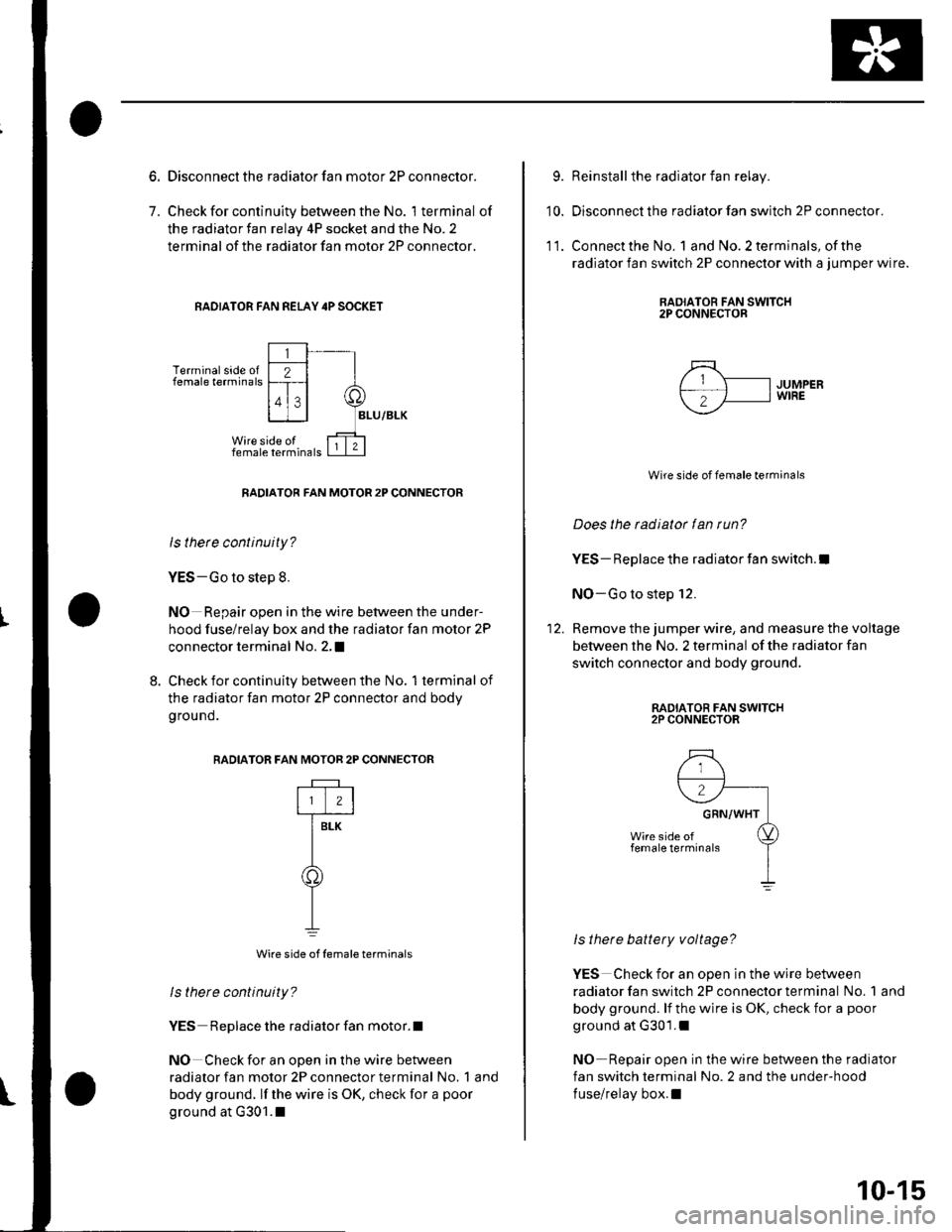

7.

Disconnect the radiator fan motor 2P connector.

Check for continuity between the No. 1 terminal of

the radiator fan relay 4P socket and the No. 2

terminal of the radiator fan motor 2P connector.

RAOIATOR FAN REI-AY 4P SOCKET

Terminal side offemale terminals

RADIATOR FAN MOTOR 2P CONNECTOR

ls thete continuity?

YES-Go to step 8.

NO Repair open in the wire between the under-

hood fuse/relay box and the radiator fan motor 2P

connector terminal No. 2,I

8. Check for continuity between the No, 1terminal of

the radiator fan motor 2P connector and bodv

g rou nd.

RADIATOR F

Wire side of female terminals

ls there continuity?

YES Replace the radiator fan motor.l

NO Check for an open in the wire between

radiator fan motor 2P connector terminal No. 1 and

body ground. lf the wire is OK, check for a poor

ground at G301.1

AN MOTOR 2P CONNECTOR

rftr

T-

Y

9.

10.

Reinstall the radiator fan relay.

Disconnect the radiator fan switch 2P connector.

Connect the No. 1 and No. 2 terminals, of the

radiator fan switch 2P connector with a jumper wire.

RAOIATOR FAN SWITCH2P CONNECTOR

11.

5\- IJUMPERf-; 'fl I wrRE

--

Wire side of female terminals

Does the radiator fan run?

YES- Replace the radiator fan switch.l

NO-Go to step 12.

Remove the jumper wire, and measure the voltage

between the No, 2 terminal of the radiator fan

switch connector and body ground,

RADIATOR FAN SWITCH2P CONNECTOR

ls there battery voltage?

YES Check for an open in the wire between

radiator fan switch 2P connector terminal No. 1 and

body ground. lf the wire is OK, check for a poor

ground at G301.1

NO Repair open in the wire between the radiator

fan switch terminal No. 2 and the under-hood

fuse/relay box.l

10-15

Page 413 of 1139

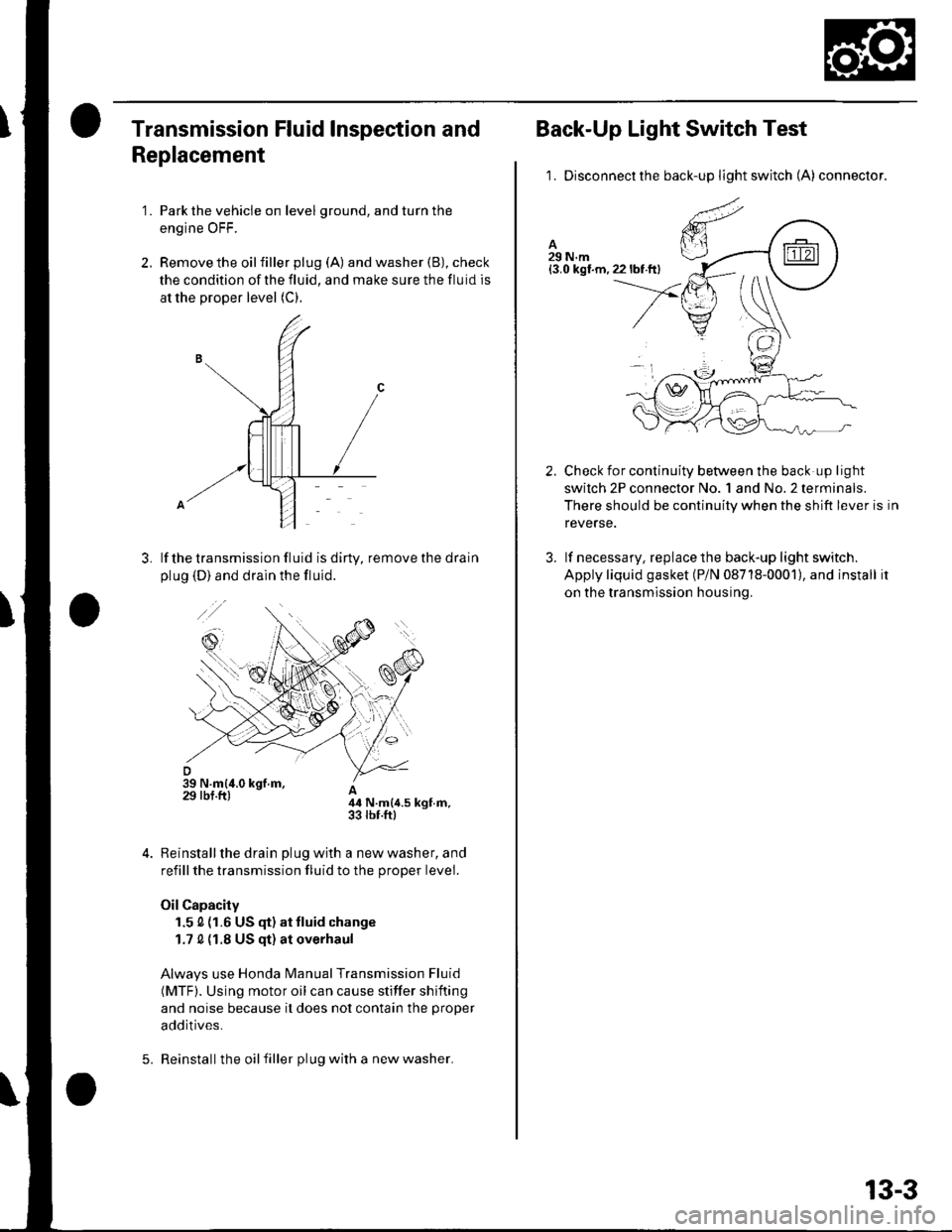

Transmission Fluid Inspection and

Replacement

'1. Park the vehicle on level ground, and turn the

engine OFF.

2. Remove the oilfiller plug (A) and washer (B), check

the condition of the fluid, and make sure the fluid is

at the proper level (C).

lf the transmission fluid is diny, remove the drain

plug (D) and drain the fluid.

A44 N.m{4.5 kgt.m,33 rbr.ftl

Reinstall the drain plug with a new washer, and

refill the transmission fluid to the proper level.

Oil Capacity

1.5 0 (1.6 US (F) at tluid change

1.7 0 {1.8 US qt) at overhaul

Always use Honda Manual Transmission Fluid

(MTF). Using motor oil can cause stiffer shifting

and noise because it does not contain the proper

additives.

Reinstall the oil filler plug with a new washer.5.

13-3

Back-Up Light Switch Test

1. Disconnectthe back-up light switch (A) connector.

Check for continuity between the back up light

swilch 2P connector No. 1 and No.2 terminals.

There should be continuity when the shift lever is in

reverse.

lf necessary, replace the back-up light switch.

Apply liquid gasket (P/N 08718-0001), and install it

on the transmission housing.

2.

3.

Page 506 of 1139

Electrical Power Steering (EPSI

SpecialTools ............. 17 -16

Component Location Index ......................................... 17-17

General Troubleshooting Information ....................... 17-18

DTC Troubleshooting Index .............. 17-22

Symptom Troubleshooting Index ............................... 17 -23

System Description ................. ........... 17-24

Circuit Diagram ......... 17-26

DTC Troubleshooting ............... .......... 17-28

EPS lndicator Circuit Troubleshooting ....................... 17-47

Motor Removal/lnstallation ............... 17-49

Steering Gearbox Removal ............... 17-51

Steering Gearbox Overhaul ............... 17-55

Steering Gearbox Installation ........... 17-63

EPS Control Unit Remova l/lnsta llation ....................... 17-67

Tie-rod Ball Joint Boot Replacement .......................... 17-67

Page 508 of 1139

![HONDA CIVIC 2002 7.G User Guide Component Location Index

UNDER.HOODFUSE/RELAY BOX

EPS CONTROL UNITEPS Control Unit Removal/lnstallation,page 17 -67

UNDER.DASH FUSE/RELAY BOX

-,/.,....

.,i,

X ]

DATA LINK CONNECTOR I16P)

TOROUE SENS HONDA CIVIC 2002 7.G User Guide Component Location Index

UNDER.HOODFUSE/RELAY BOX

EPS CONTROL UNITEPS Control Unit Removal/lnstallation,page 17 -67

UNDER.DASH FUSE/RELAY BOX

-,/.,....

.,i,

X ]

DATA LINK CONNECTOR I16P)

TOROUE SENS](/img/13/5744/w960_5744-507.png)

Component Location Index

UNDER.HOODFUSE/RELAY BOX

EPS CONTROL UNITEPS Control Unit Removal/lnstallation,page 17 -67

UNDER.DASH FUSE/RELAY BOX

-,'/.,....

'.,i,

X ]

DATA LINK CONNECTOR I16P)

TOROUE SENSOR

STEERING GEARBOXSteering Gearbox Removal, page 17-51Steering Gearbox Overhaul, page 17-55Steering Gearbox Installation, page 17-63

Removal/lnstallation,page l7-49

GAUGE ASSEMBLY

MOTOR

17-17

Page 509 of 1139

EPS Components

aGeneral Troubleshooting Information

EPS Indicator

Under normal conditions, the EPS indicator comes on when

the ignitlon switch is turned to the ON (ll) position, then goes

off after the engine is started. This indicates that the bulb and

its circuit are operating correctly.

lf there is any trouble in the system after the engine is started,

the EPS indicator will stay on, and the power assist is turned

off.

When EPS indicator light comes on, the control unit

memorizes the DTC. In this case, the control unit will not

activate the EPS system after the engine starts again, but it

keeps the EPS indicator on.

When DTC 12, 16, 17, 18 or 67 is stored in the control unit, the

EPS indicator will stay on until the DTC is erased. When a

problem is detected and the EPS indicator comes on, there are

cases when the indicator stays on untilthe ignition switch is

turned 0FF, and cases when the indicator goes off

automatically when the system returns to normal. Even though

the system is operating normally, the EPS indicator will come

on under the following conditions:

Condition '1:

. The vehicle was traveling at least 12.4 mph (20 km/h), then. A rapid change in vehicle speed was detected, then. The vehicle (or the vehicle speed sensor signal) stopped for

at least 5 seconds. The engine speed was still 'l,640rpmorhigherforatleastS

seconds

Condition 2:

After the vehicle (or the vehicle speed sensor signal) has

stopped for at least 10 seconds, yet the engine speed was still

1,640 rpm or higherfor at least 20 seconds.

Condition 3:

When the engine speed is 280 rpm or less, and the vehicle is traveling at

a speed of 6,2 mph (10 km/h) or more for 3 seconds.

To determine the actual cause ofthe problem, question the

customer about the conditions during which the problem

occured, taking the above conditions into consideration.

Diagnostic Trouble Code (DTCI

. lf the CPU cannot be activated, or itfails,the EPS indicator

comes on, but the DTC is not memorized.. The memory can hold any number of DTCS. However, when

the same DTC is detected more than once, the most recent

DTC is written over the prior DTC, therefore only one

occurrence is memorized.. The DTCS are indicated repeatedly untilthe ignition switch is

turned OFF.. lf the DTC is not memorized,the EPS indicator blinks.

. The DTCS are memorized in the EEPRO| (non-volatile

memory) therefore the memorized DTCS cannot be erased

by disconnecting the battery. Perform the specified

procedures to clear DTCS.

Self-diagnosis

Self-diagnosis can be classified into two categories:.Initial diagnosis: performed right after the engine

starts and until the EPS indicator goes off.. Regular diagnosis: performed right after the initial

diagnosis until the ignition switch is turned OFF.

The EPS control unit performs the following functions

when a problem is detected by self-diagnosis;

'1. Turns on the EPS indicator.

2. Memorizes the DTC.

3. Stops power assist and manual steering operation

begrns.

NOTE:. When DTC 23 (a problem with the circuit for

engine speed signal) is detected, the power

assist will return to normal when the vehicle

speed is 0.62 mph (1 km/h) or above.. Fot DfCs 22,23, 64, or 66 the EPS indicator goes

off automatically when the system relurns to

normal. For all other codes, the EPS indicator

goes off when the system is OK after the ignition

switch is turned from OFF to ON (ll).

Restriction on Power Assist Operation

Repeated extreme steering force. such as turning the

steering wheel continuously back-and-forth with the

vehicle stopped, causes an increase of power

consumption in the EPS motor. The increase of electric

current causes the motor to heat up. Because this heat

adversely affects the system, the control unit monitors

the electric current of the motor.

When the control unit detects heat build-up in the motor,

it reduces the electric current to the motor gradually to

protect the system, and it restricts the power assist

operation. The EPS indicator does not come on during

this function.

When steering torque is not applied to the steering

wheel, or when the ignition is turned off, and the motor

cools, the control unit will restore the power assist

gradually until it's fully restored (after approximately 15

minutes maximum).

17-18