Motor HONDA CIVIC 2002 7.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2002, Model line: CIVIC, Model: HONDA CIVIC 2002 7.GPages: 1139, PDF Size: 28.19 MB

Page 2 of 1139

INTRODUCTION

Safety

Your safety, and the satety of others, is very important. To helpyou make informed decisions, we have provided safetymessages, and other safety information throughout this manual.Of course, it is not practical or possible to warn you about all thehazards associated with servicing this vehicle. You must useyour own good judgment.

You will find impoftant safety information in a variety of formsincluding:. Satety Labels - on the vehicle.. Satetv Messages preceded by a salety alert symbol A andone of three signal words, DANGEF, WARNING, or CAUTION.These signal words mean:

tmEnEEril y;,: H,ll i": 5* i5"?;r s E R I o u s LY H u Br ir

E$EEEE ys,: f#,ff ,:hl:3,:JjERrousLY HURT ir

tlGtltT]llilll You cAN b€ HUBT if vou don't follow

. lnstructions - how to service this vehicle correctlv and safelv.

All information contained in this manual is based on the latestproduct information available at the time of printing. We reservethe right to make changes at any time without notice. No part ofthis Oublication maV be reDrodLrced, or stored in a retrievalsystem, or transmitted, in any form by any means, electronic,mechanical, photocopying, recording, or otherwise, without theprior written permission o{ the publisher. This includes text,figures, and tables-

As vou read this manual, vou will tind information that ispreceded by a @ symbol. The purpose of this message isto help prevent damage to your vehicle, other property, or theenvironment,

*Bodyz-tl!^t l

First Edition 8/2002 1,168 pages HONDA MOTOR CO.. LTD.All Rights Reserved Service Publication OfficeSpecifications apply to U.S.A. and Canada

As seclion3 with *inclode SRS comoonentsispecial precautionsare required when servicing.

How to Use This Manual -

This manual is divided into 23 sections. The first page of eachseclion is marked with a black tab that lines up with itscorresponding thumb index tab on this page and the back cover.You can quickly find the first page of each section withoutlooking through a full table of contents. The symbols printed atthe top corner of each page can also be used as a quickre{erence system.

Each section includes:1. A table of contents, or an exploded view index showingl. Parts disassembly sequence.. Bolt torques and thread sizes.. Page references to descriptions in text.Disassembly/assembly procedures and tools.Inspefiron.Testing/troubleshootin g.Repair.Adjustments.

2.3.4.5.6.

Specifications1)ll:{l+'

Maintenance

Emissions

*Restraints

Page 4 of 1139

General Information

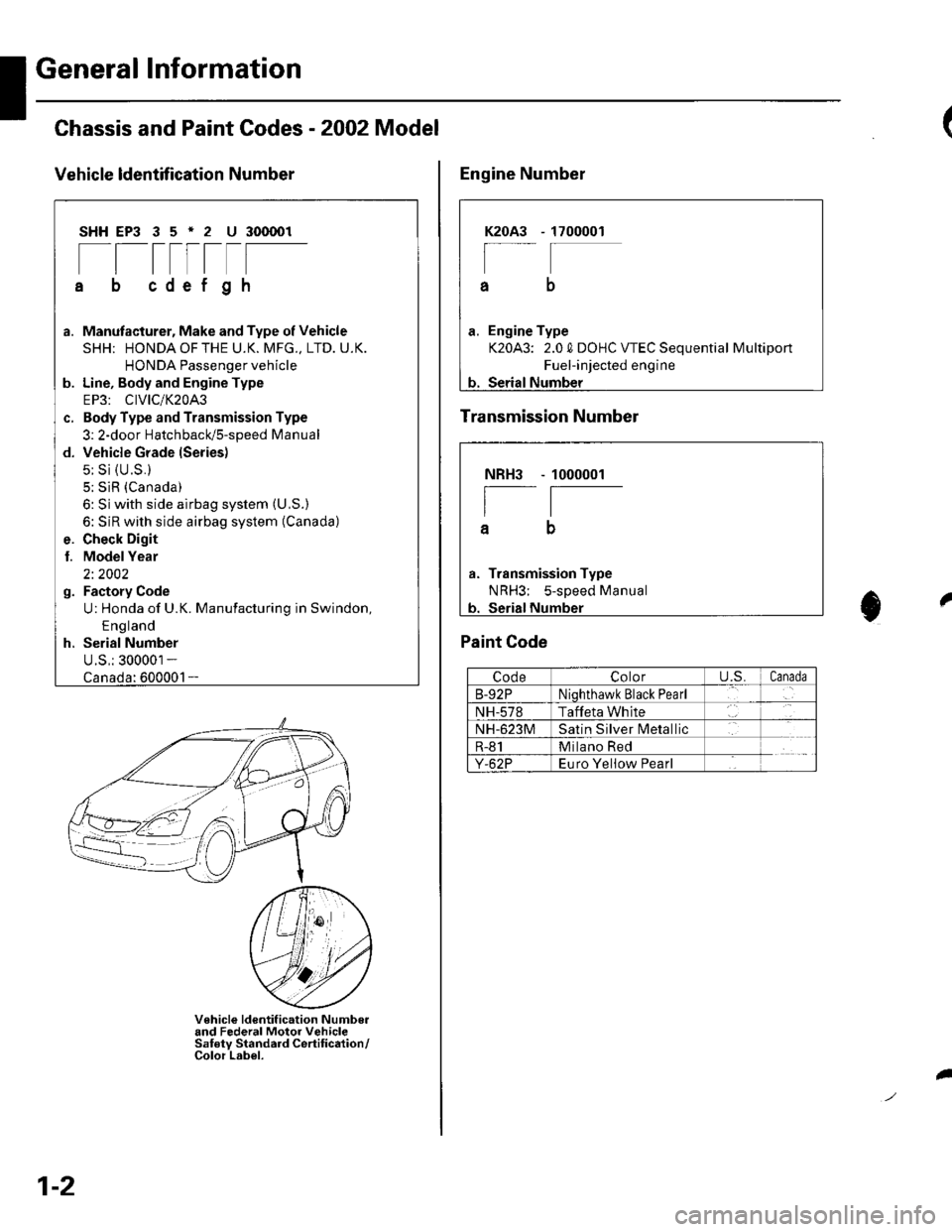

Chassis and Paint Codes - 2OO2 Model

Vehicle ldentffi cation Number

SHHEP3 35'2 U 300001

[[tttrtF

cdef gh

a. Manufacturer, Make and Type of Vehicle

SHH; HONDAOFTHE U.K. MFG., LTD. U.K.

HONDA Passenger vehicle

b. Line, Body and Engine Type

EP3: CIVIC/K20A3

c. Body Type and Transmission Type

3: 2-door HatchbacUs-speed Manual

d. Vehicle Grade lSeries)

5: Si {U.S.}

5; SiR (Canada)

6: Si with side airbag system (U,S.)

6: SiR with side airbag system (Canada)

e. Check Digit

l. ModelYear

2i 2002

g. Factory Code

U: Honda of U.K. Manufacturing in Swindon,

E ng land

h. Serial Number

U.S,: 300001 -

1-

V€hicle ldentif ication Numbo.and Federal Motor VehicleSaf ety Standard Certif ication/Color Label.

1-2

I

1700001K2OA3

a

a. Engine Type

K20A3: 2.0 0 DOHC VTEC Sequential Multiport

Fuel-injected engine

b. Serial Number

Engine Number

Transmission Number

Paint Code

CodeColoru.s.Canada

B-92PNiqhthawk Black Pearl

NH-578Taffeta White

NH-623MSatin Silver lvletallic

R-81Milano Red

Y-62PEuro Yeliow Pearl

NBH3

I

a

Transmission Type

NRH3; s-sDeed Manual

1000001

t0

Page 5 of 1139

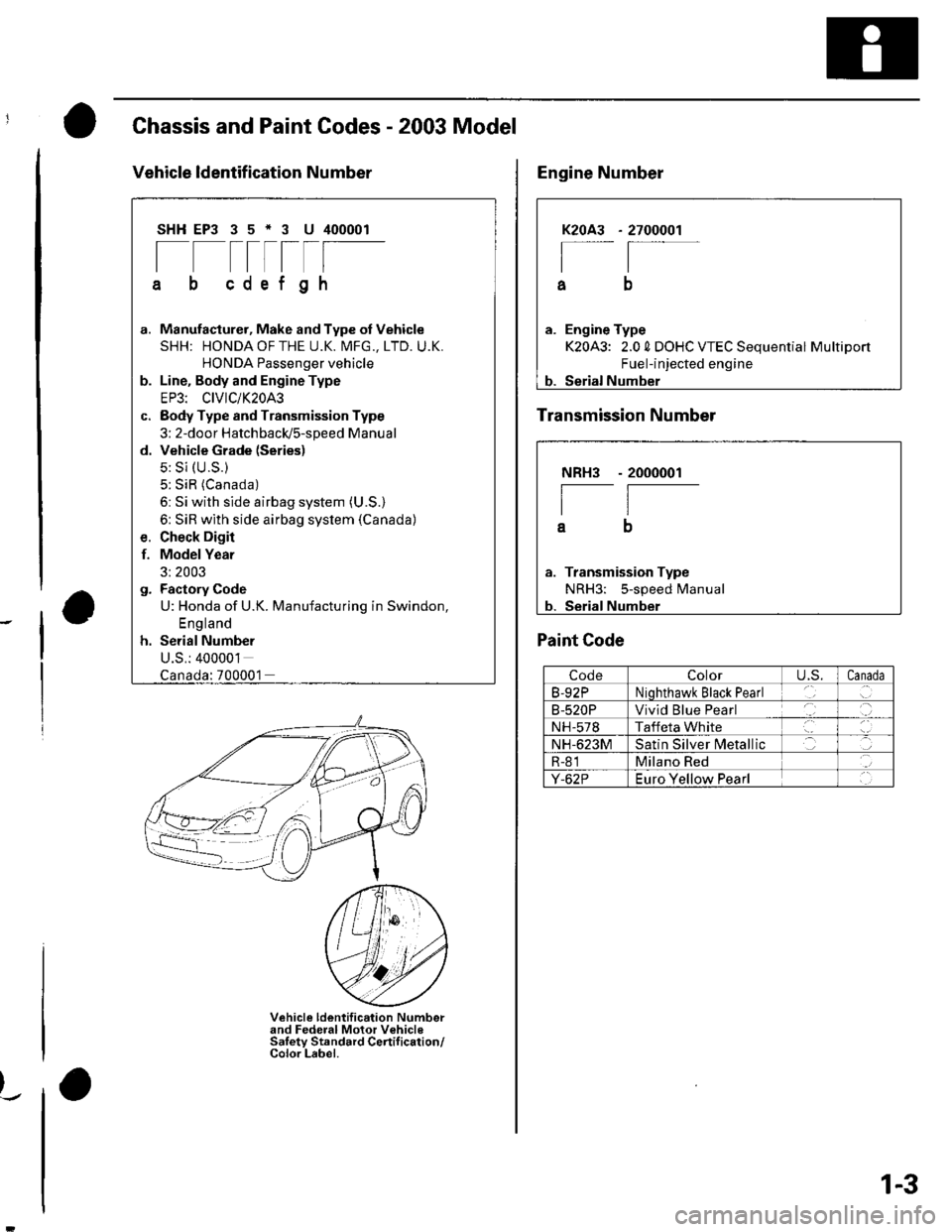

Chassis and Paint Codes - 2003 Model

Vehicle ldentif ication Number

SHHEP3 35*3 U 400001

[--t-rlF

cdef gh

G.

d.

Manufacturer, Make and Type of Vehicle

SHH: HONDAOFTHE U.K. MFG., LTD. U.K.

HONDA Passenger vehicle

Line. Body and Engine Type

EP3: CIVIC/K20A3

Body Type and Transmission Type

3: 2-door HatchbacldS-speed Manual

Vehicle Grade (Series)

5: Si (U.S.)

5: SiR (Canada)

6: Si with side airbag system (U.S.)

6: SiR with side airbag system (Canada)

Check Digir

Model Year

3: 2003

Factory Code

U: Honda of U.K. Manufacturing in Swindon,

England

Serial Number

U.S.: 400001

f.

:700001

Vehicle ldentification Numberand Federal Motor VehicleSaletv Standard Certif ication/Color Label.

)_.

2700001K2OA3

I

a

a. Engine Type

K20A3: 2.0 0 DOHC VTEC Sequential Multiport

Fuel-injected engine

b. Serial Number

Engine Number

Transmission Number

NRH3

I

a

Transmission Type

NRH3: 5-speed Manual

Serial Number

- 2000001

Paint Code

CodeColorU,S.Canada

B-92PNiohthawk Black Pearl

B-520PVivid Blue Pearl

NH-578Taffeta White

NH-623MSatin Silver N4etallic

R-81Milano Red

Y-62PEuro Yellow Pearl

1-3

Page 24 of 1139

cont'

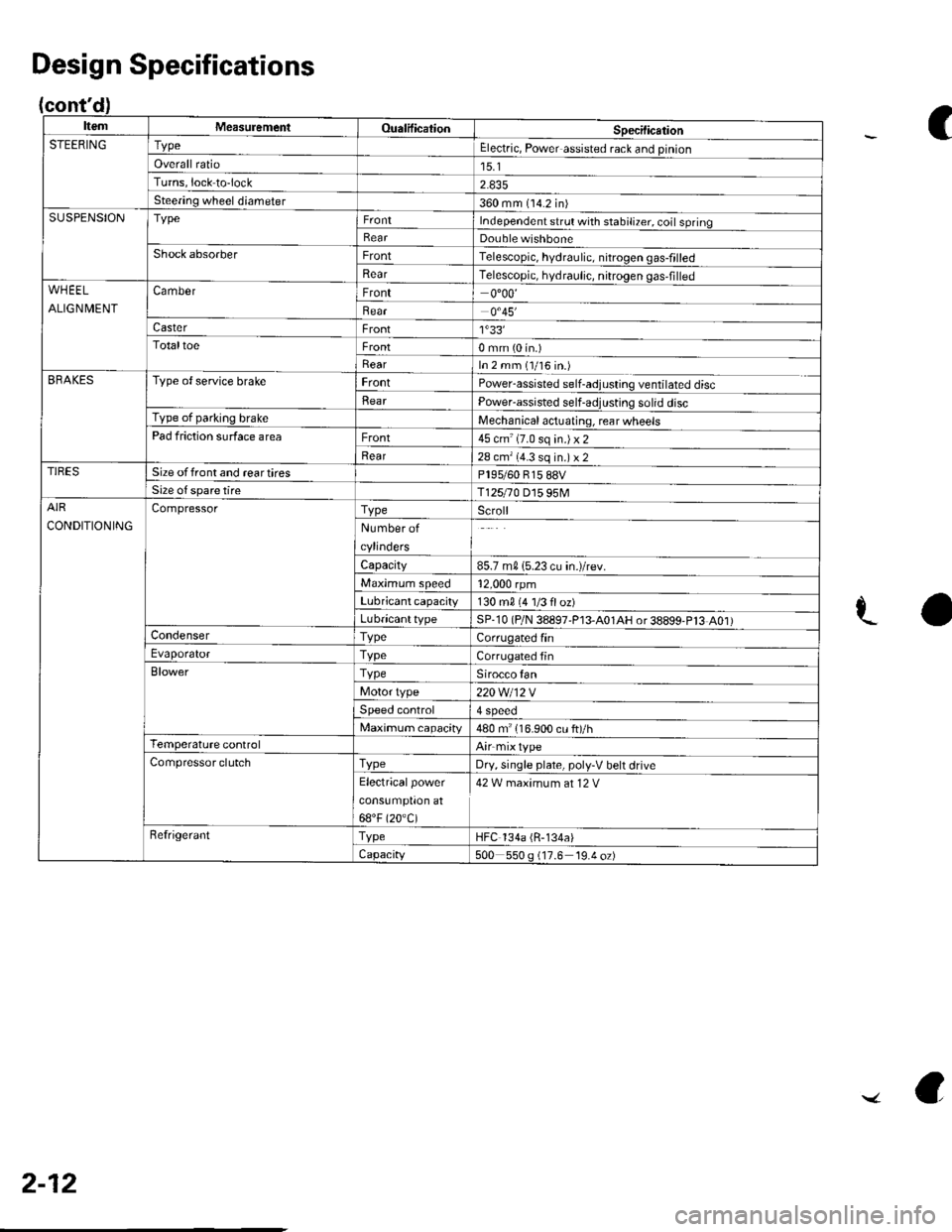

ItemMeasuremeniOualificationSpecilicationSTEERINGTypeElectric, Power assisted rack and pinion

Overall ratio15.1Turns,lock to-lock

Steering wheel diameter360 mm (14.2 in)SUSPENSIONTypeIndependent srrul with stabiliTer. coil springRearDouble wishboneShock absorberFrontTelescopic, hydraulic. nitrogen gas-frlled

RearTelescopic, hydraulic, nitrogen gas,filledWHEEL

ALIGNMENT

CamberFront0"00'

Bear0.45'�

CasterFront1'33'�TotaltoeFront0 mm (0 in.)

RearIn 2 mm (1/16 in.)BRAKESType of service brakeFrontPowerassisted self-adjusling ventilated disc

BearPower-assisted self-adjusting solid discType of parking brakeMechanical actuating, rear wheelsPad friction surface areaFront45 cm'(7.0 sq in.)x2

Rear28 cm'(4.3 sq in.) x 2TIRESSize offront and reartiresPl95/60 815 88VSize o{ spare tireT125r0 D15 95MAIR

CONDITIONING

CompressorTypeScroll

Number of

cylinders

Capacity85.7 m015.23 cu in.)/rev.

Maximum speed12,000 rpm

Lubricant capacity130 m0 {4 1/3 floz)

LubricanttypeSP-10 (P/N 38897'P13-A01AH or38899-P13 A01)CondenserTypeCorrugated finEvaporatorTvpeCorrugated fin

BlowerTypeSirocco fan

Motor type220 Wl12 V

Speed control4 Speeo

Maximum capacity480 m" 116.900 cu ft)/hTemperature controlAirmixtype

Compressor clutchTvpeDry, single plate, poly-V belt drive

Electricalpower

cons!mptron at

68"F (20.C)

42 W maximum at 12 V

RefrigerantTypeHFC 134a (R-134a)

Capacity500 550 g (17.6 19.4 oz)

Design Specifications

C

aL

2-12

../ a

Page 28 of 1139

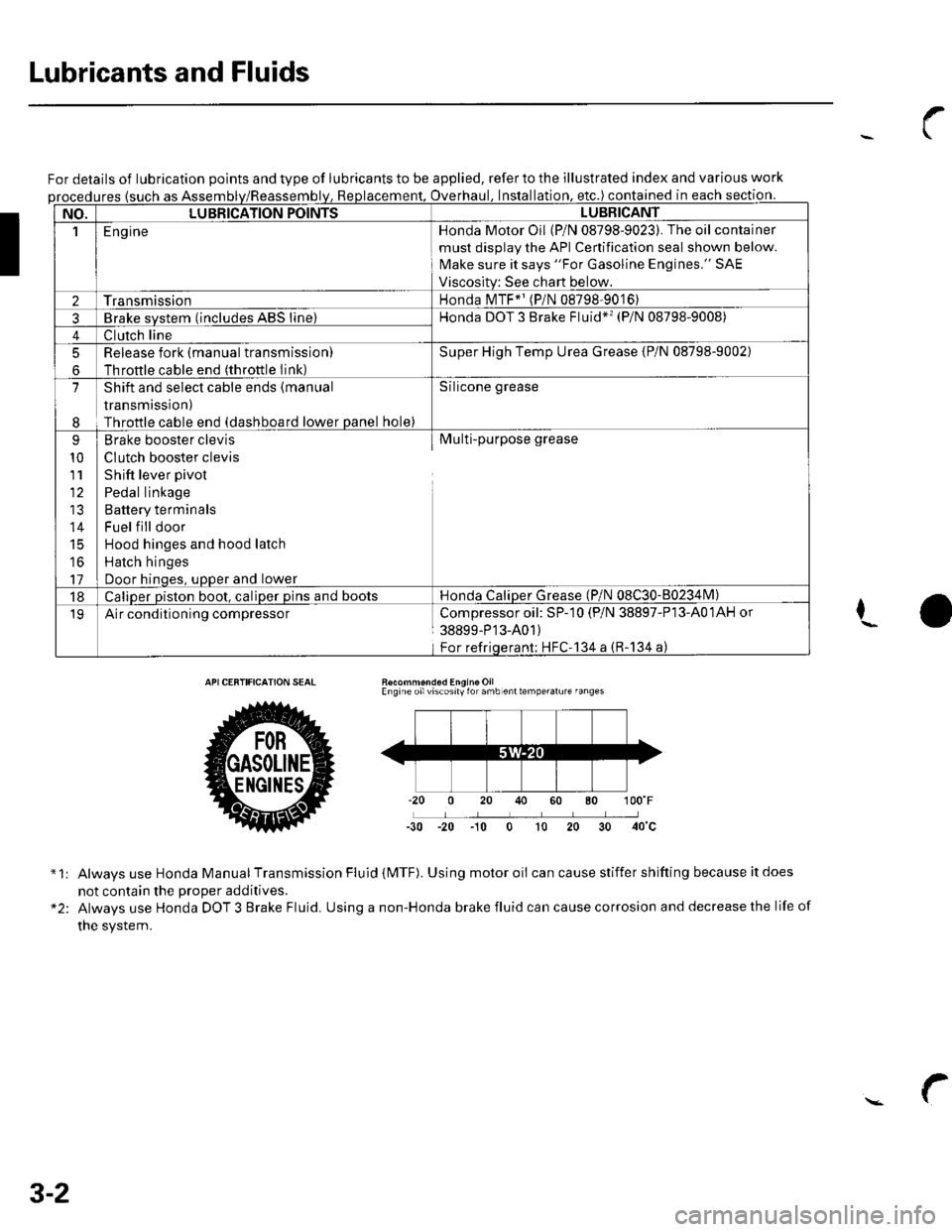

Lubricants and Fluids

For details of lubrication points and type of lubricants to be applied, refer to the illustrated index and various work

ures {such as Assemoverhaul. lnstallation. etc.) contained in each section.

NO.LUBBICATION POINTSLUBBICANT

1E ng ineHonda Motor Oil (P/N 08798-9023). The oil container

must disolav the API Cenification seal shown below.

Make sure it says "For Gasoline Engines." SAE

Viscositv: See chart below.

2TransmissionHonda MTF*' (P/N 08798-9016)

3Brake svstem (includes ABS line)Honda DOT 3 Brake Fluid*'� (P/N 08798-9008)

4Clutch line

5

6

Release fork (manual transmissionl

Throftle cable end (throttle Iink)

Super High Temp Urea Grease {P/N 08798-9002)

7

I

Shift and select cable ends (manual

transmission)

Throttle cable end (dashboard lower panel hole)

Silicone grease

9

10

111'

14

16

17

Brake booster clevis

CIutch booster clevis

Shift lever pivot

Pedal linkage

Battery terminals

Fuel f ill door

Hood hinges and hood latch

Hatch hinges

Door hinoes, uoDer and lower

Multi-purpose grease

18Caliper piston boot, caliper pins and bootsHonda CaliDer Grease (P/N 08C30-80234lvl)

19Air conditioning compressorCompressoroil: SP-10 (P/N 38897-P13-A01AH or

38899-P'13-A01)

For refriqerant; HFC'134 a (R-134 a)

I

Recommond6d Engine OilEngine oilviscosily for amb enttemperalure fanges

-30 -20 -10 0 t0 20

*1:

"2:

Always use Honda Manual Transmission Fluid (MTF). Using motor oii can cause stiffer shifting because it does

not contain the Drooer additives.

Always use Honda DOT 3 Brake Fluid. Using a non-Honda brake fluid can cause corrosion and decrease the life of

the system.

3-2

Page 43 of 1139

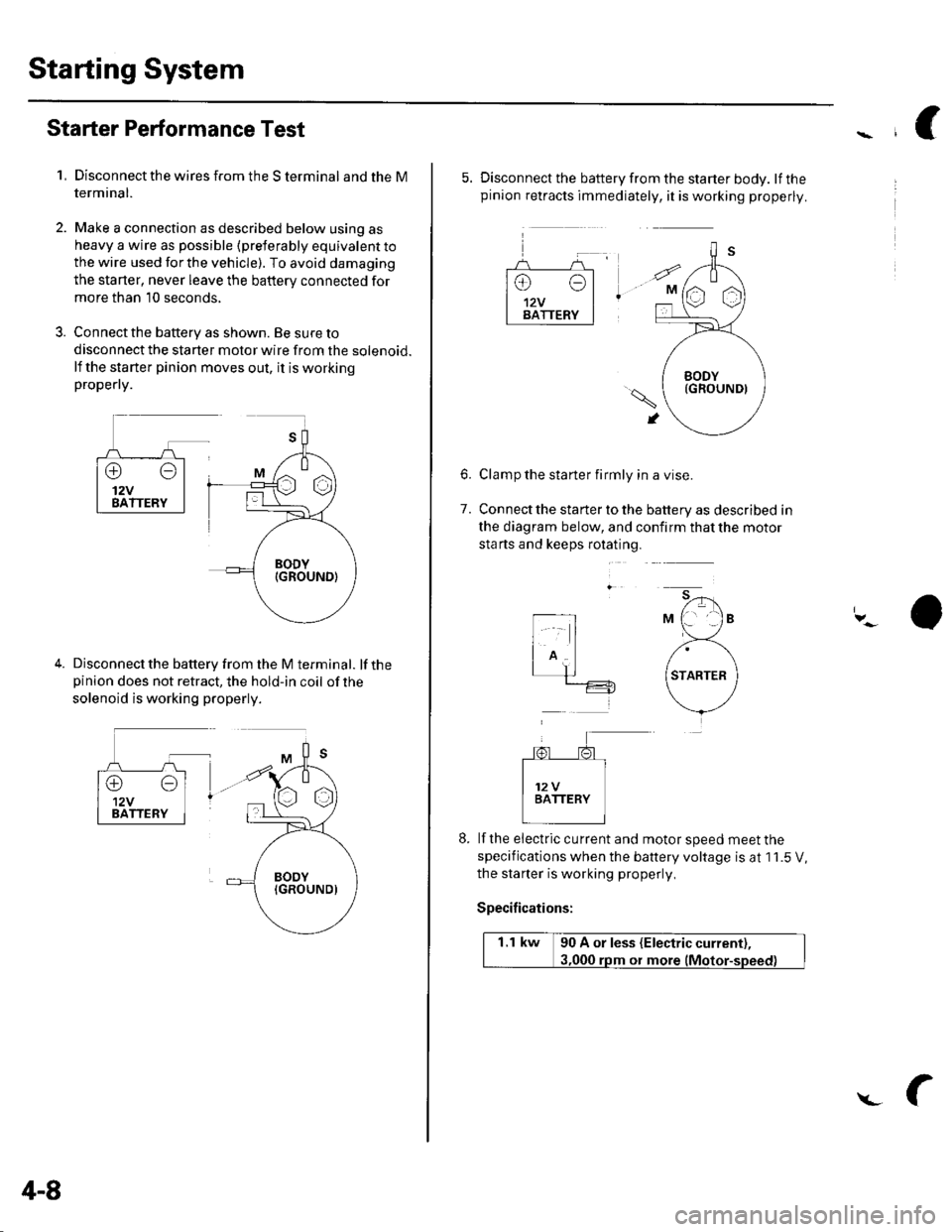

Starting System

Starter Performance Test

1,Disconnect the wires from the S terminal and the M

termrnal.

Make a connection as described below using as

heavy a wire as possible (preterably equivalent to

the wire used for the vehicle). To avoid damaging

the starter, never leave the battery connected for

more than 10 seconds,

Connect the battery as shown. Be sure to

disconnect the starter motor wire from the solenoid.

lf the starter pinion moves out, it is workingpropefly.

Disconnect the battery from the M terminal. lf thepinion does not retract, the hold-in coil of the

solenoid is working properly.

4-8

L

5. Disconnect the battery from the starter body. lfthepinion retracts immediately, it is working properly.

Clamp the starter firmly in a vise.

Connect the starter to the battery as described in

the diagram below, and confirm that the motor

sta rts and keeps rotating.

6.

7.

lf the eiectric cu rrent and motor speed meet the

specifications when the battery voltage is at 1 1.5 V,

the staner is working properly,

Specifications:

1.1 kw 90 A or less (Electric current),

ot more

Page 59 of 1139

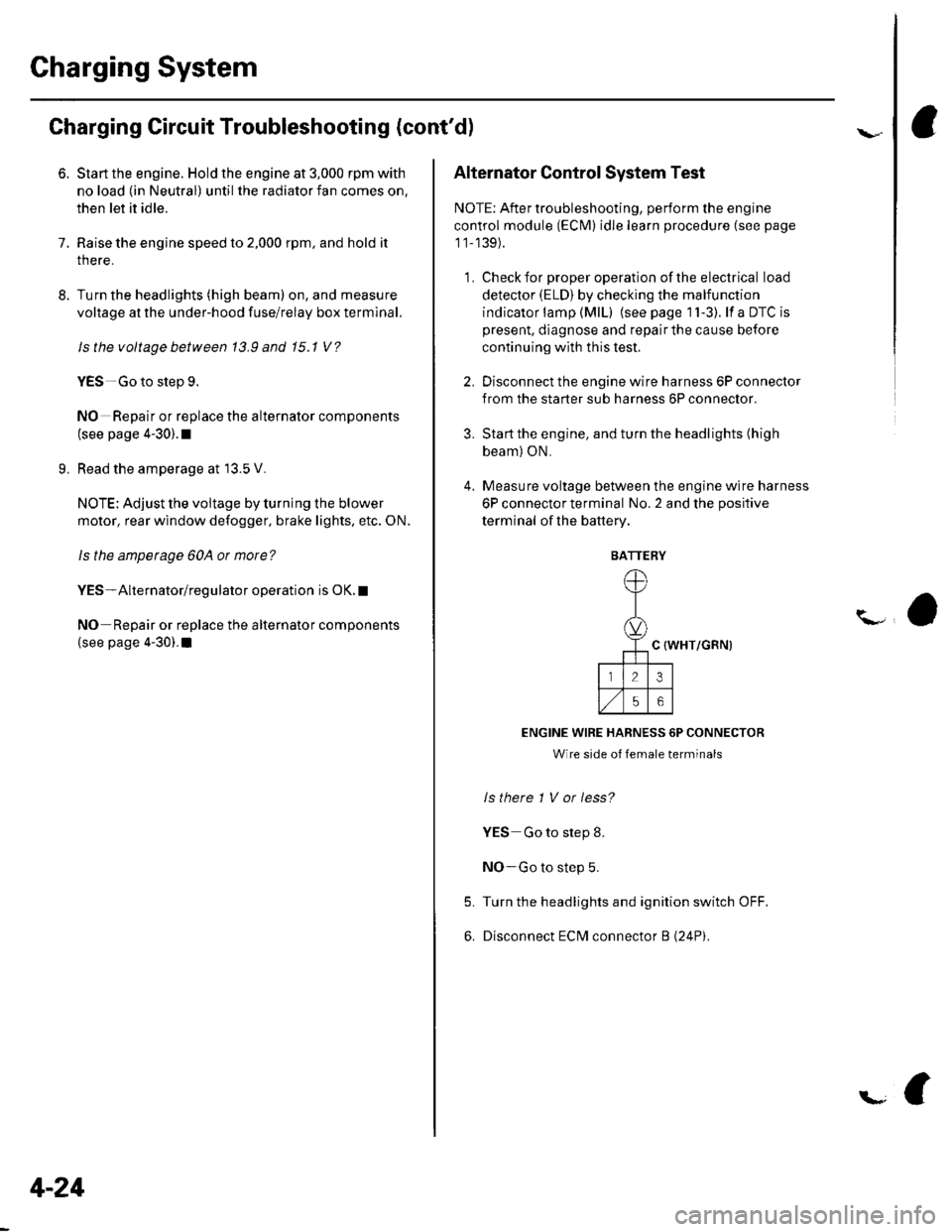

Gharging System

Charging Circuit Troubleshooting (cont'd)

6. Start the engine. Hold the engine at 3,000 rpm with

no load (in Neutral) until the radiator fan comes on,

then let it idle.

7. Raise the engine speed to 2,000 rpm, and hold it

there.

8. Turn the headlights (high beam) on, and measure

voltage at the under-hood fuse/relay box terminal.

ls the voltage between 13.9 and 15.1 v?

YES-Go to step 9.

NO Repair or replace the alternator components

(see page 4-30).1

9. Read the amperage at '13.5 V.

NOTE: Adjust the voltage by turning the blower

motor, rear window defogger, brake lights. etc. ON.

ls the amperage 604 ot morc?

YES-Alternator/regulator operation is OK. I

NO Repair or replace the alternator components(see page 4-30).1

4-24

\,

Alternator Control System Test

NOTE: After troubleshooting, perform the engine

control module (ECM) idle learn procedure (see page

11-139).

1 . Check for proper operation of the electrical load

detector (ELD) by checking the malfunction

indicator lamp (MlL) (see page 1 l-3). lf a DTC is

present, diagnose and repair the cause before

continuing with this test.

2. Disconnect the engine wire harness 6P connector

from the starter sub harness 6P connector.

3. Start the engine, and turn the headlights (high

beam) ON,

4. Measure voltage between the engine wire harness

6P connector terminal No. 2 and the positive

terminal of lhe battery.

C {WHT/GRN)

ENGINE WIRE HARNESS 6P CONNECTOR

Wire side of female terminals

ls there 1 V or less?

YES Go to step 8.

NO-Go to step 5.

Turn the headlights and ignition switch OFF.

Disconnect ECM connector B (24P).

5.

6.

BATTERY

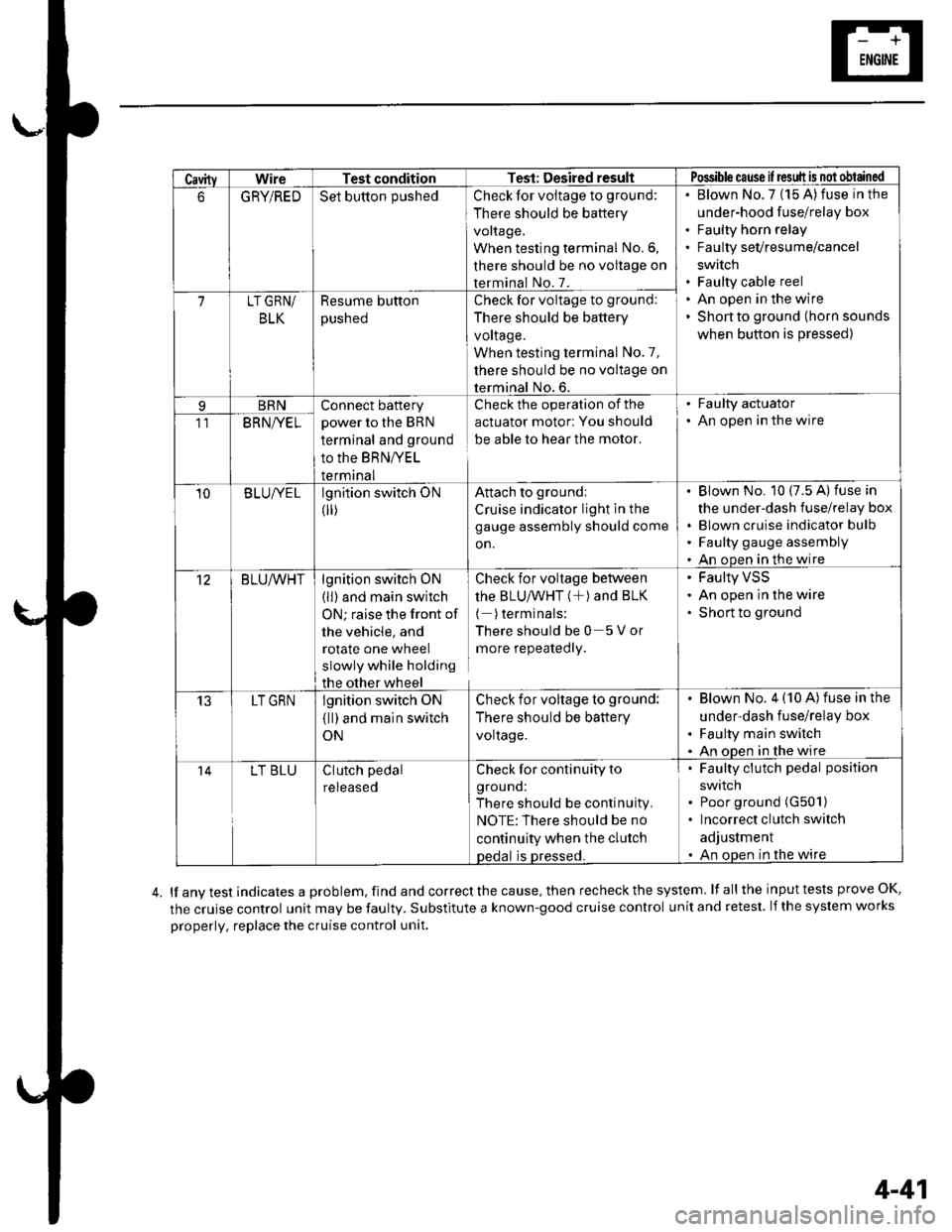

Page 76 of 1139

CavityWireTest conditionTest: Desired resultPossible cause il result is not obtained

6GRYiREDSet button pushedCheck for voltage to ground:

There should be battery

voltage,

When testing terminal No.6,

there should be no voltage on

terminal No. 7.

Blown No.7 (15 A)fuse in the

under-hood fuse/relay box

Faulty horn relay

Faulty sevresume/cancel

swrtch

Faulty cable reel

An open in the wire

Shon to ground (horn sounds

when button is pressed)

7LT GRN/

BLK

Resume button

pusneo

Check for voltage to ground:

There should be battery

voltage.

When testing terminal No.7,

there should be no voltage on

terminal No. 6.

BRNConnect battery

power to the BRN

terminal and ground

to the BRNIVEL

termrnal

Check the operation of the

actuator motor: You should

be able to hear the motor.

. Faulty actuator. An open in the wire11BRNI/EL

10B LUIVE Llgnition switch ON

0r)

Attach to groundi

Cruise indicator light in the

gauge assembly should come

on.

Blown No. 10 (7.5 A) fuse in

the under-dash fuse/relay box

Blown cruise indicator bulfl

Faulty gauge assembly

An open in the wire

12BLU/VVHTlgnition switch ON

(ll) and main switch

ON; raise the front of

the vehicle, and

rotate one wheel

slowly while holding

the other wheel

Check for voltage between

thE BLU/VVHT (+) ANd BLK

( )terminals:

Thereshouldbe0 5Vor

more repeatedly.

Faulty VSS

An open in the wire

Short to ground

13LT GRNlgnition switch oN

{ll) and main switch

ON

Check for voltage to ground:

There should be battery

voltage.

Blown No. 4 (10 A)fuse in the

under-dash fuse/relay box

Faulty main switch

An oDen in the wire

14LT BLUClutch pedal

reteaseo

Check for continuity to

grouno:

There should be continuity.

NOTE:There should be no

continuity when the clutch

oedal is Dressed.

Faulty clutch pedal position

swtlcn

Poor ground (G501)

Incorrect clutch switch

adjustment

An open in the wire

lf any test indicates a problem, find and correct the cause, then recheck the system. lf all the input tests prove OK,

the cruise control unit may be faulty. Substitute a known-good cruise control unit and retest. lf the system works

properly, replace the cruise control unit.

4-41

Page 78 of 1139

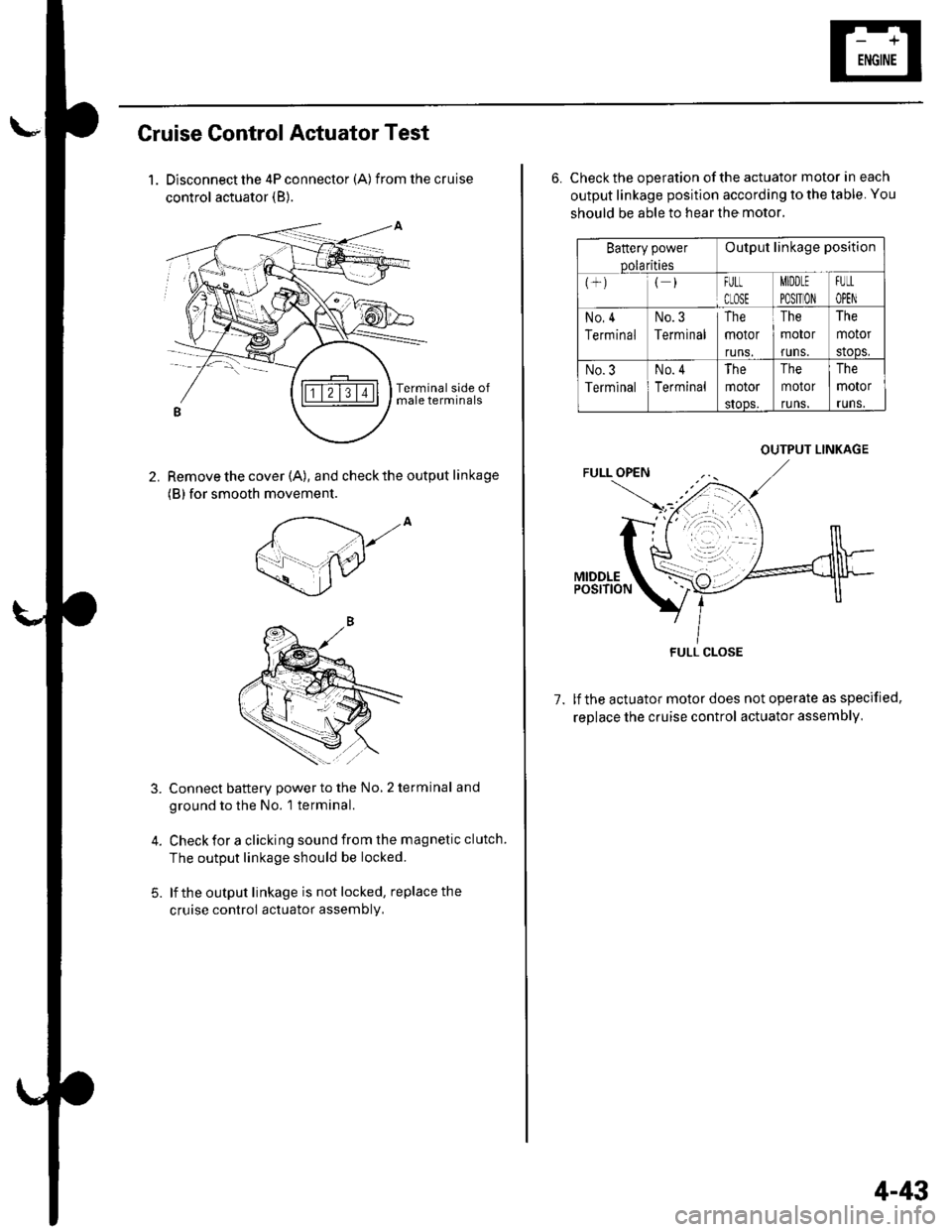

Cruise Control Actuator Test

1. Disconnect the 4P connector (A) from the cruise

control actuator (B).

Remove the cover (A), and check the output linkage

(B) for smooth movement.

2.

,to

5.

Connect battery power to the No, 2 terminal and

ground to the No. 1 terminal.

Check for a clicking sound from the magnetic clutch.

The output linkage should be locked.

lf the output linkage is not locked, replace the

cruise control actuator assembly,

6. Check the operation of the actuator motor in each

output linkage position according to the table. You

should be able to hear the motor.

Battery power

Dolarities

Output linkage position

FULt

CLOSE

MIDDLE

PO$TION

FUtL

OPEN

No,4

Terminal

No.3

Terminal

The

motor

runs.

The

motor

runs.

The

motor

stoDs,

No.3

Terminal

No. 4

Terminal

The

motor

sIoos.

The

motor

runs.

The

motor

runs.

1.lf the actuator motor does not operate as specified,

replace the cruise control actuator assembly,

OUTPUT LINKAGE

FULL CLOSE

4-43

Page 101 of 1139

Cylinder Head

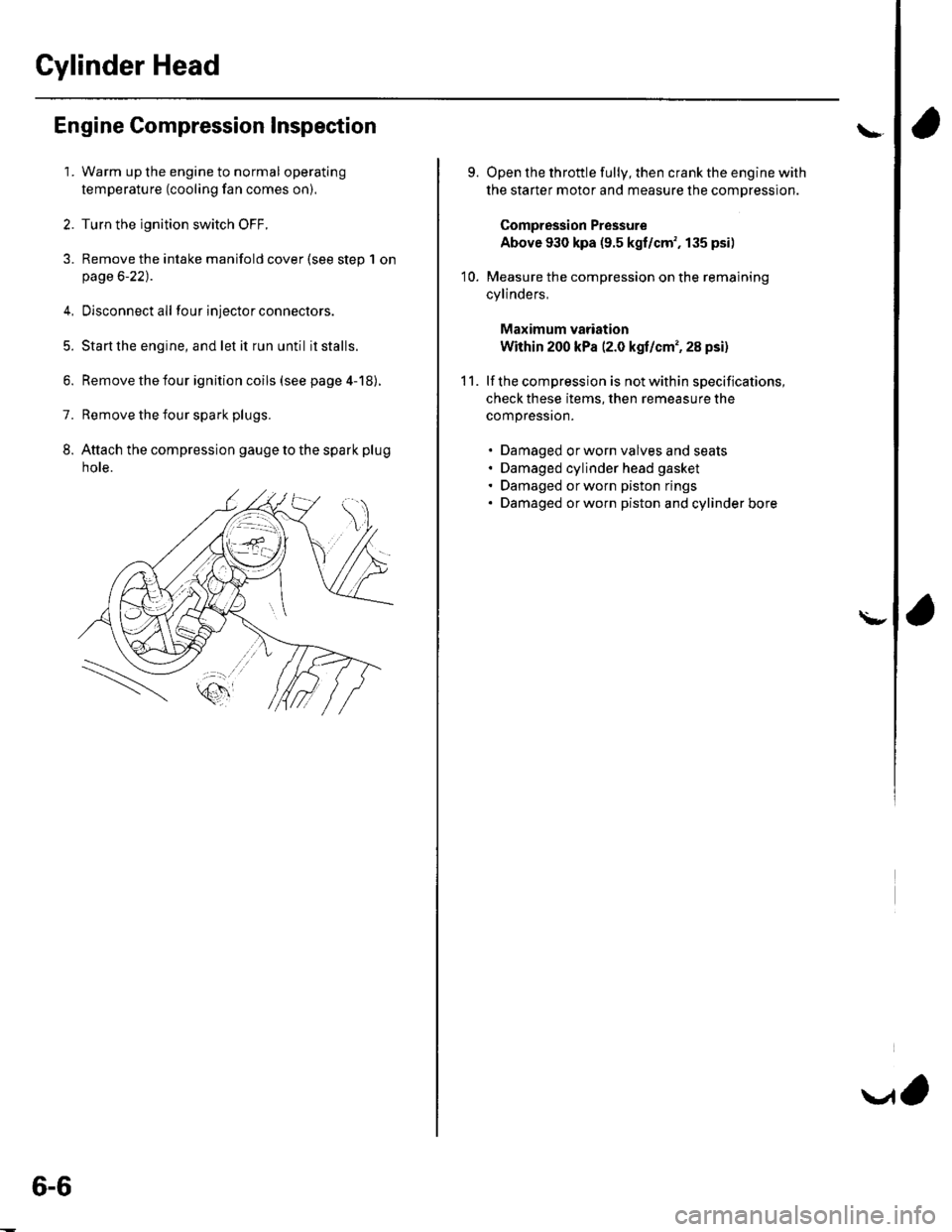

Engine Compression Inspection

1. Warm up the engine to normal operating

temperature (cooling fan comes on).

2. Turn the ignition switch OFF.

3. Remove the intake manifold cover (see step 1 onpage 6-22).

4, Disconnect all four injector connectors.

5. Start the engine, and let it run until it stalls.

6. Remove the iour ignition coils (see page 4-18).

7. Remove the four spark plugs.

8. Attach the compression gauge to the spark plug

note.

6-6

V,

\

9.

10.

Open the throttle fully, then crank the engine with

the starter motor and measure the compression.

Compression Pressure

Above 930 kpa (9.5 kgf/cm', 135 psi)

Measure the compression on the remaining

cylinders,

Maximum vadation

Within 200 kPa (2.0 kgf/cm', 28 psi)

lf the compression is not within specifications,

check these items, then remeasure the

compressron.

. Damaged orworn valves and seats. Damaged cylinder head gasket. Damaged or worn piston rings. Damaged orworn piston and cylinder bore

11.

\-