boot HONDA CIVIC 2002 7.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 2002, Model line: CIVIC, Model: HONDA CIVIC 2002 7.GPages: 1139, PDF Size: 28.19 MB

Page 472 of 1139

Driveshafts Disassembly

Special Tools Required. Threaded adaDter.22 x 1.5 mm 07XAC-001010A. Slide hammer, commercially available. Boot band pincers, commercially available

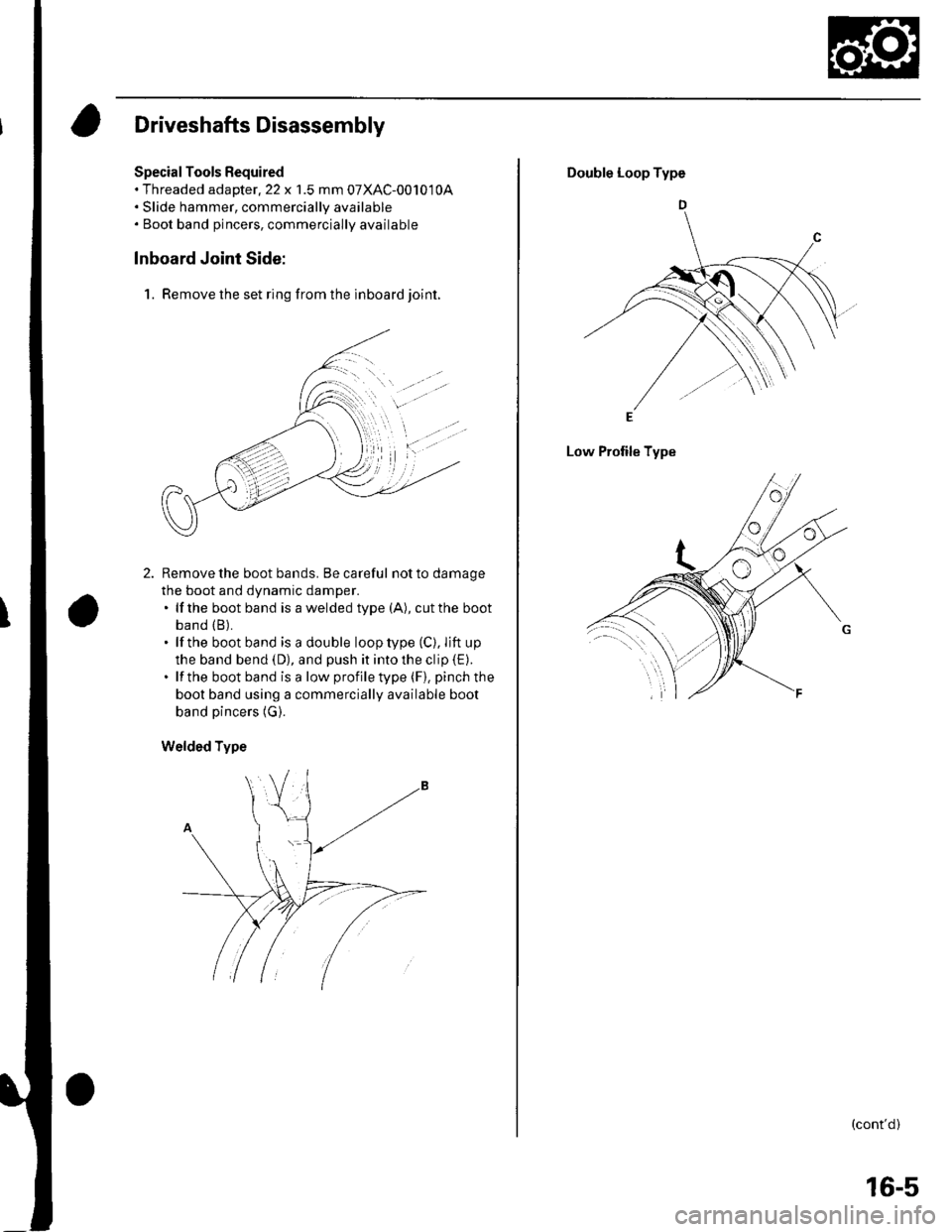

Inboard Joint Side:

1. Remove the set rlng from the inboard joint.

Remove the boot bands. Be careful not to damage

the boot and dynamic damper.. lf the boot band is a welded type (A), cut the boot

band (B).

. lf the boot band is a double loop type (C), lift up

the band bend (D), and push it into the clip (E).

. lf the boot band is a low profile type (F), pinch the

boot band using a commercially available boot

band pincers (G).

Welded Type

Low Profile Type

(cont'd)

16-5

Page 473 of 1139

Driveline/Axle

Driveshafts Disassembly {cont'd)

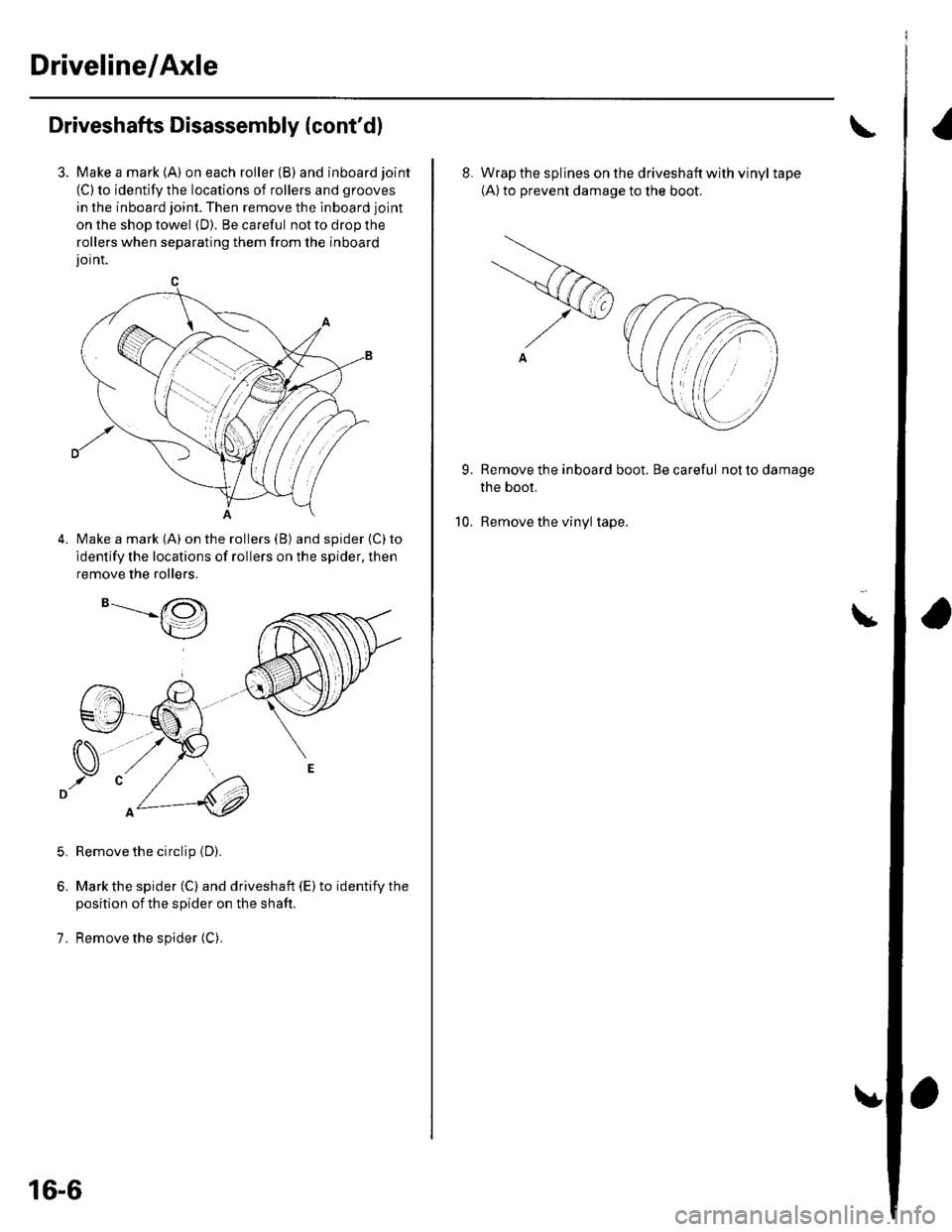

Make a mark (A) on each roller (B) and inboard joint

(C) to identify the locations of rollers and grooves

in the inboard joint. Then remove the lnboard joint

on the shop towel (D). Be careful not to drop the

rollers when separating them from the inboard

Jornt.

N4ake a mark (A) on the rollers (B) and spider (C) to

identify the locations of rollers on the spider, then

remove the rollers.

Remove the circlip {D).

Mark the spider (C) and driveshaft (E) to identify the

position of the spider on the shaft,

Remove the spider (C).

6.

7.

16-6

8. Wrap the splines on the driveshaft with vinyl tape(A) to prevent damage to the boot.

9. Remove the inboard boot. Be careful nottodamaoe

the boot.

10. Remove the vinyl tape.

\

Page 474 of 1139

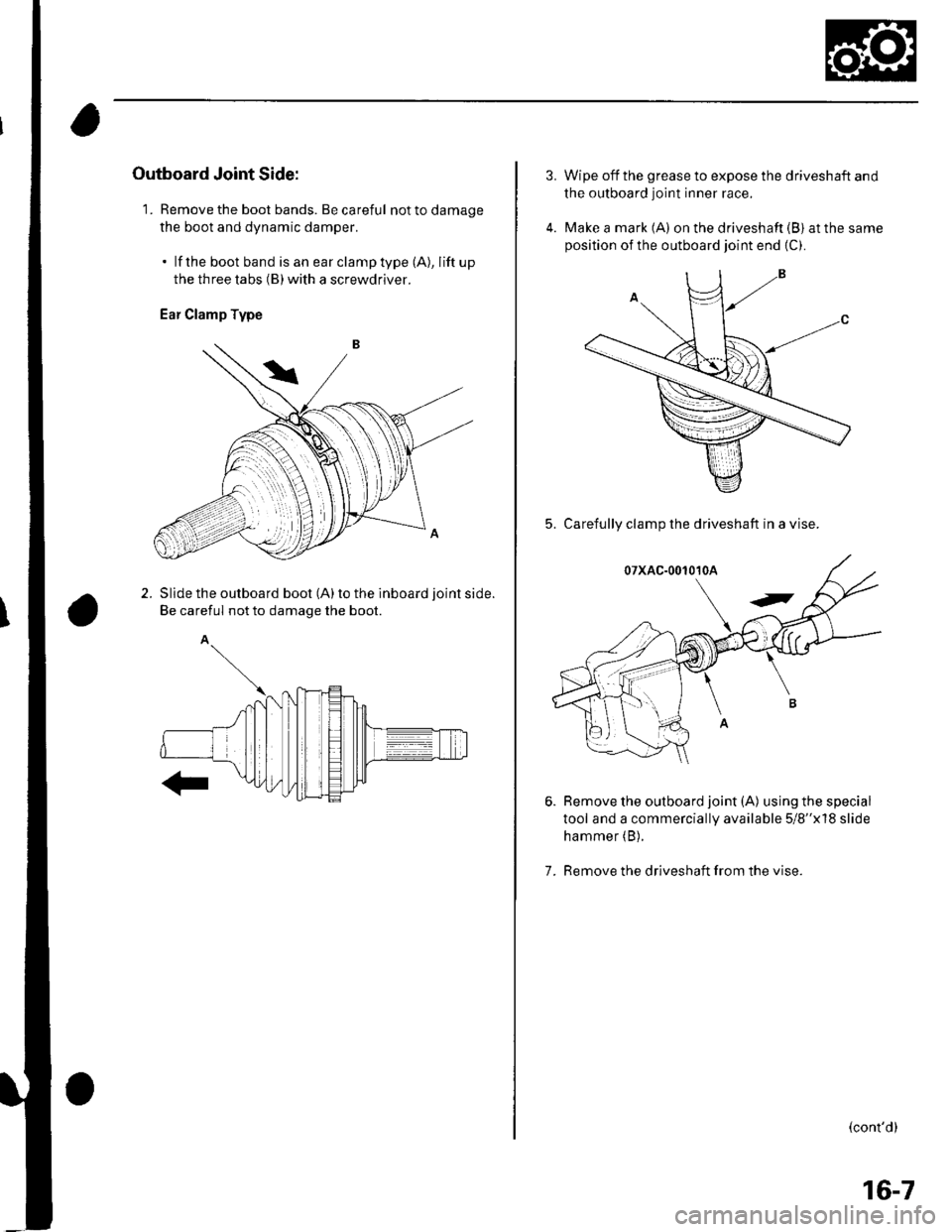

Outboard Joint Side:

1. Remove the boot bands. Be careful nottodamage

the boot and dynamic damper.

. lf the boot band is an earclamptype (A), lift up

the three tabs (B) with a screwdriver.

Ear Clamp Type

Slide the outboard boot (A) to the inboard ioint side.

Be careful not to damaoe the boot.

2.

4.

Wipe off the grease to expose the driveshaft and

the outboard joint inner race.

Make a mark (A) on the driveshaft (B) at the same

position of the outboard joint end {C).

5. Carefullv clamp the driveshaft in a vise.

Remove the outboard joint (A) using the special

tool and a commercially available 5/8"x18 slide

hammer (B).

Remove the driveshaft from the vise.

(cont'd)

7.

16-7

Page 475 of 1139

Driveline/Axle

9.

Driveshafts Disassembly (cont'dl

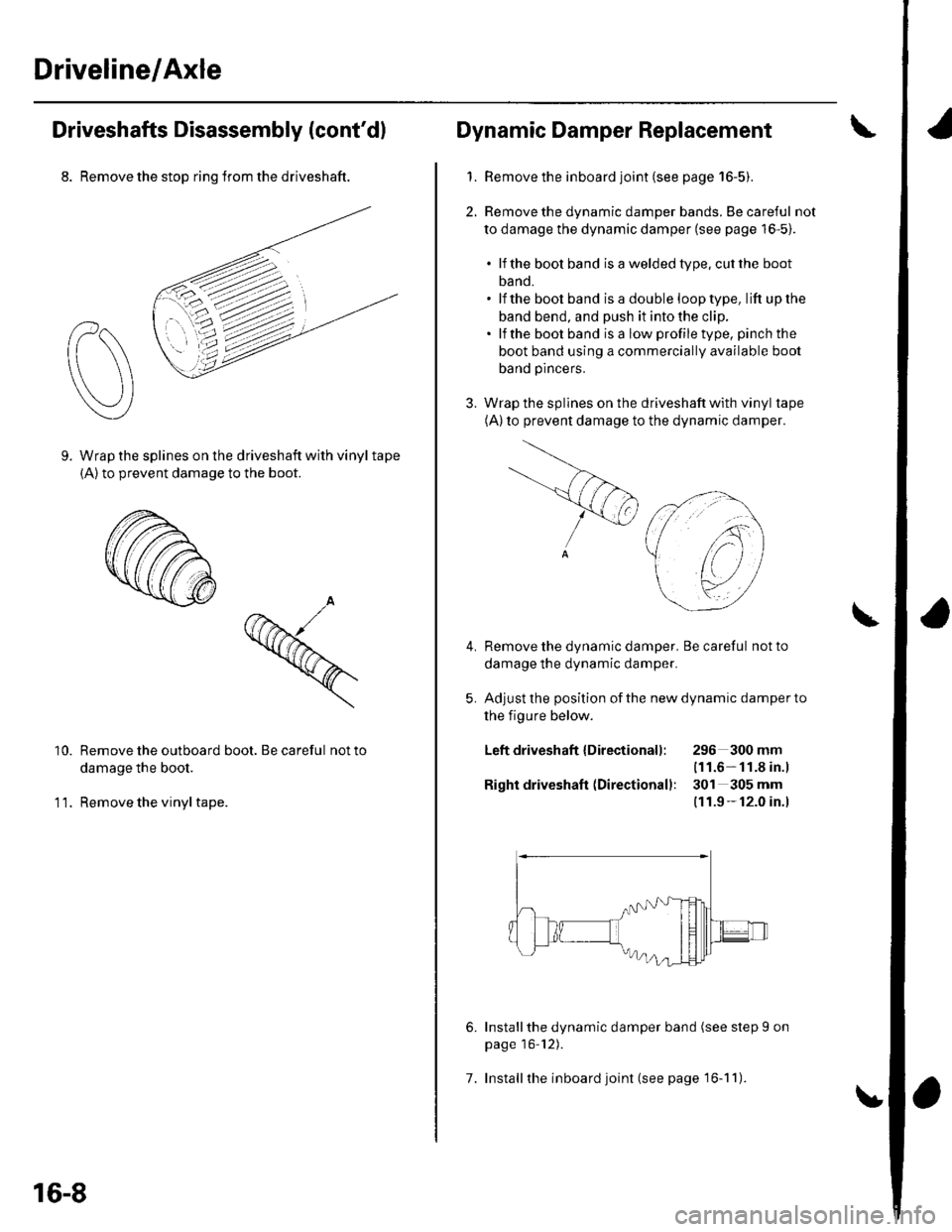

8. Remove the stop ring trom the driveshaft.

Wrap the splines on the driveshaft with vinyl tape(A) to prevent damage to the boot.

Remove the outboard boot. Be careful not to

damage the boot.

Remove the vinyl tape.

10.

11.

16-8

7.

Dynamic Damper Replacement

1. Remove the inboard joint (see page 16-5).

2, Remove the dynamic damper bands. Be careful not

to damage the dynamic damper (see page 16-5).

. lf the bool band isaweldedtype.cutthe boot

band.. lf the boot band isa double looptype, lift upthe

band bend, and push it into the clip.. lfthe boot band is a low profile type, pinch the

boot band using a commercially available boot

band pincers.

3. Wrap the splines on the driveshaft with vinyl tape

(A)to prevent damage to the dynamic damper.

Remove the dynamic damper. Be careful not to

damage the dynamic damper.

Adjust the position of the new dynamic damper to

the figure below.

Left driveshaft {Directionall: 296 300mm(11.6- 11.8 in.)

Right driveshaft (Directionall: 301 305 mm

(11.9 - 12.0 in.l

5.

6.Installthe dynamic damper band (see step I on

page 16'12).

Install the inboard joint (see page 16-1 1).

Page 476 of 1139

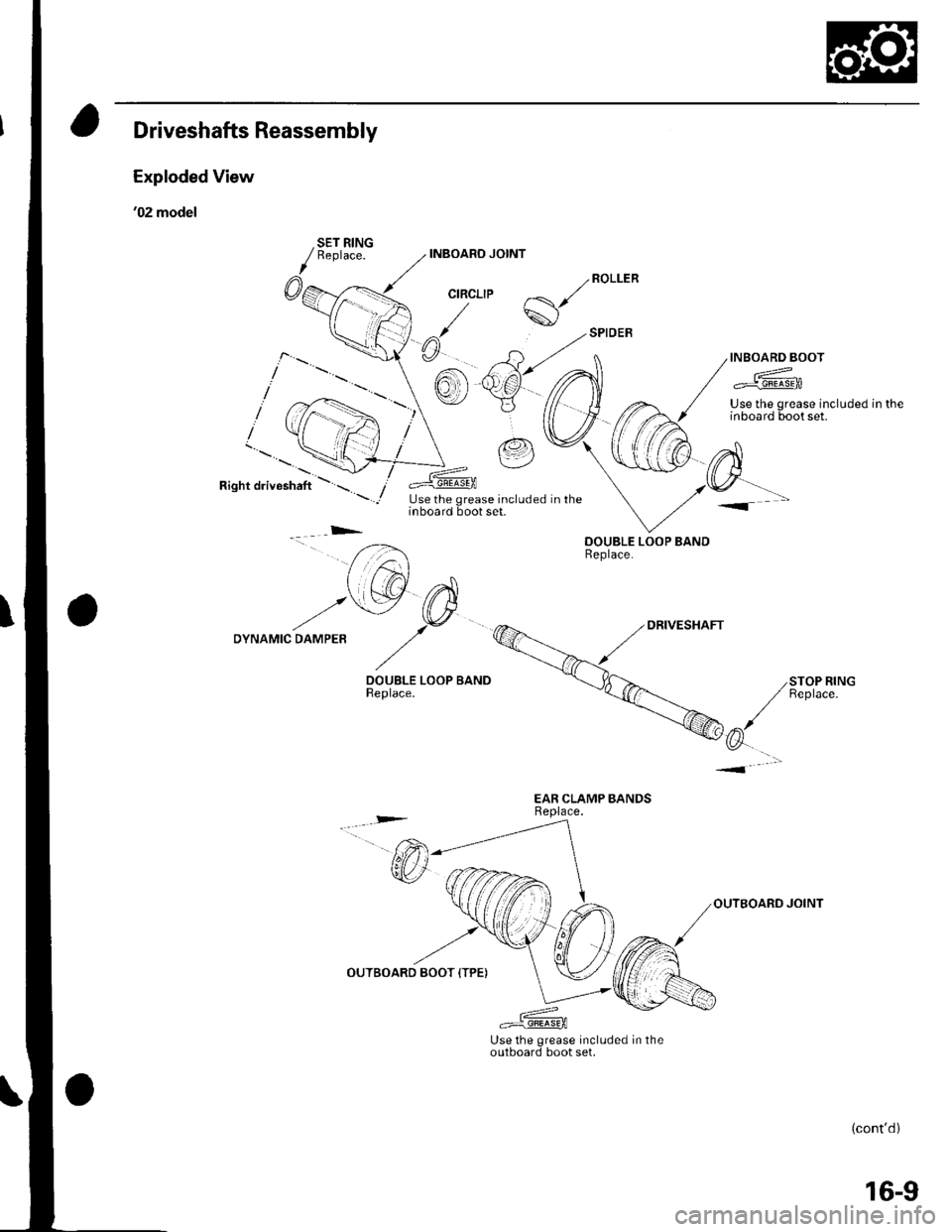

Driveshafts Reassembly

Exploded View

'02 model

/

0e

SET RINGReplace.

6)

YJ

/''"oH?"'

/ #'g!!a$il

/ Use the grease rrI inboard boot set.?-- / Use the grease Included in the// " , inboard boot set.

// /,/7\II t,//> {\

\1lg n

r. .'(9 --.-

- l>-

/'..-:'\/ .-\I .^-.1I | //^\l r\

,\VL/ A

.'' y

DYNAMTC DAMPER ,///DOUBLE LOOP BANDReplace.

EAR CLAMP BANDS

-<

OUTBOARD JOINT

STOP RINGReplace.

(cont'd)

//ROLLER

)

Use the grease included in theinboard boot set.

OOUBLE LOOP BANDReplace.

Use the grease included in theoutboard boot set,

16-9

Page 477 of 1139

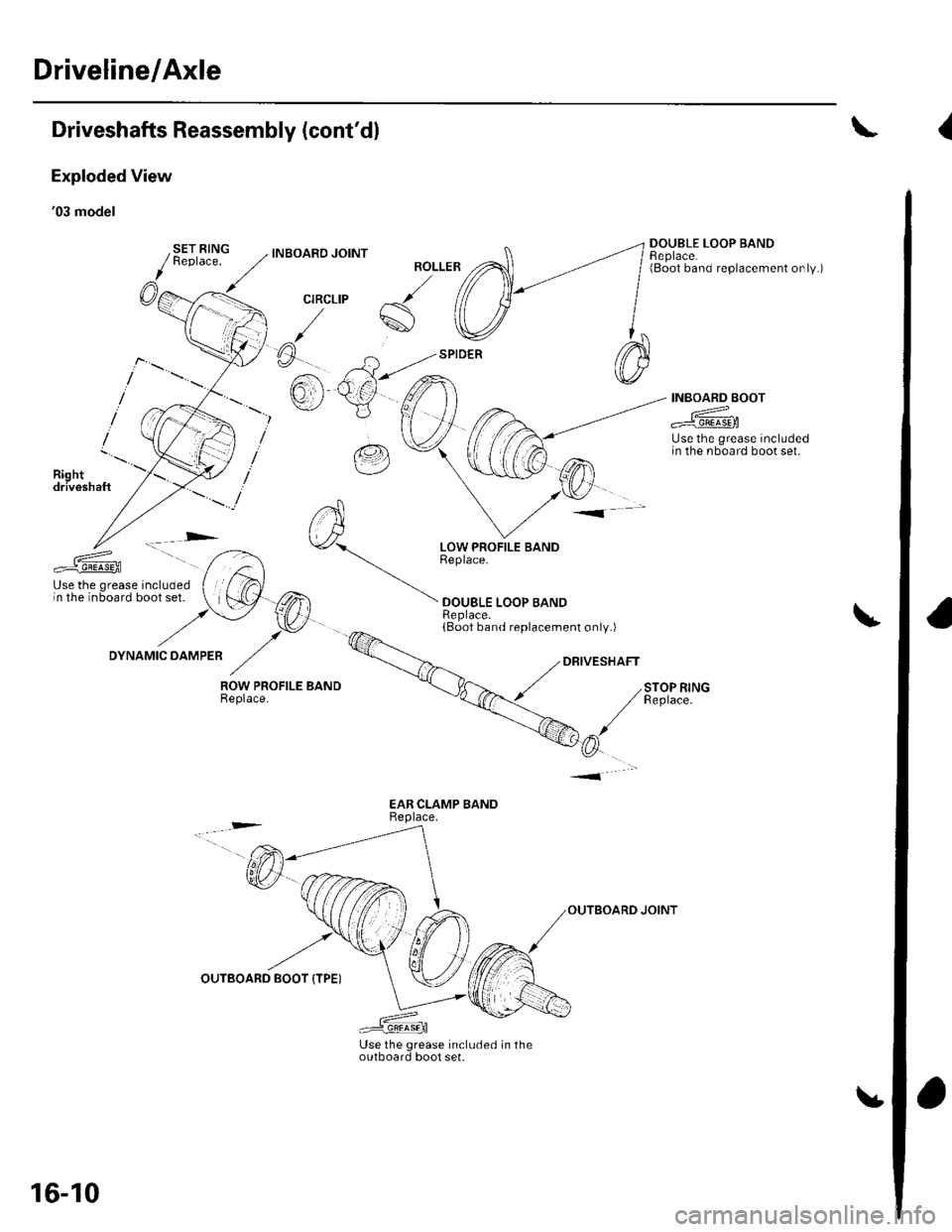

Driveline/Axle

Driveshafts Reassembly (cont'dl

Exploded View

'03 model

INBOARO JOINT

CIRCLIP

E.

@(

ROLLEB

sl

DOUBLE LOOP BANDReplace.(Boot band replacement only.)

Use the grease includedin the nboard boot set.(^Y \\_,/

Use the grease includedin the inboard boot set.

LOW PROFILE BANDBeplace.

DOUBLE LOOP BANDReplace.

DYNAMIC DAMPER

OUTBOARD JOINT

at-OUTBOARD BOOT ITPI

SET RING

/ Replace.,

-"-,,,

>

(Boot band replacement only.)

16-10

Use the grease included in theoutboard boot set.

I

Page 478 of 1139

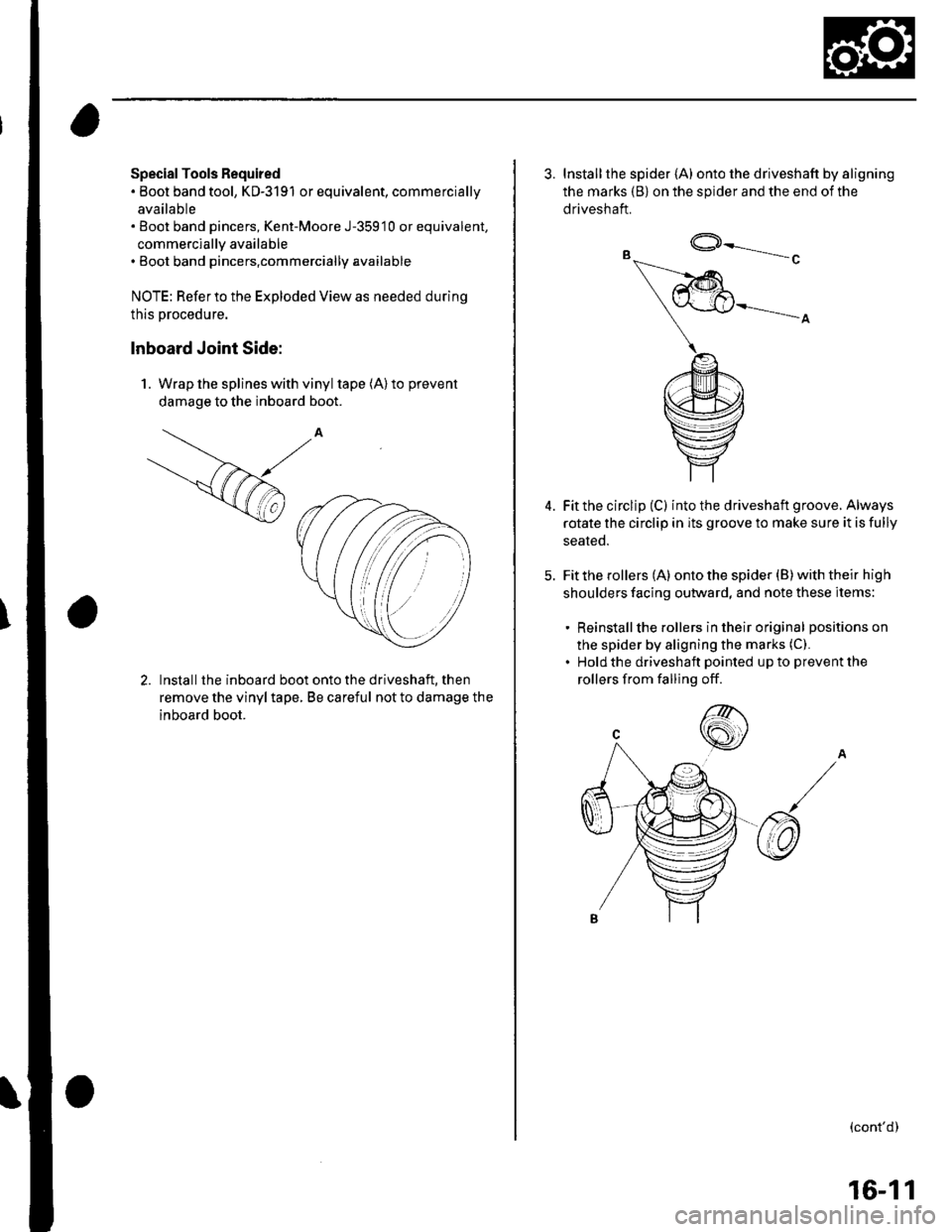

Special Tools Required. Boot band tool, KD-3191 or equivalent, commercially

available. Boot band pincers, Kent-Moore J-359'10 or equivalent,

commerclally available. Boot band pincers,commercially available

NOTE: Refer to the Exploded View as needed during

this procedure.

lnboard Joint Side:

1. Wrap the splines with vinyl tape (A) to prevent

damage to the inboard boot.

Install the inboard boot onto the driveshaft, then

remove the vinyl tape, Be careful not to damage

inboard boot.

Ine

4.

5

3. Installthe spider (A) onto the driveshaft by aligning

the marks (B) on the spider and the end of the

driveshaft.

Fit the circlip (C) into the driveshaft groove. Always

rotate the circlip in its groove to make sure it is fully

seated.

Fit the rollers (A) onto the spider {B) with their high

shoulders facing outward, and note these items:

' Reinstallthe rollers in their original positions on

the spider by aligning the marks (C).

. Hold the driveshaft pointed up to prevent the

rollers from falling off.

(cont'd)

@\

(u

16-11

Page 479 of 1139

Driveline/Axle

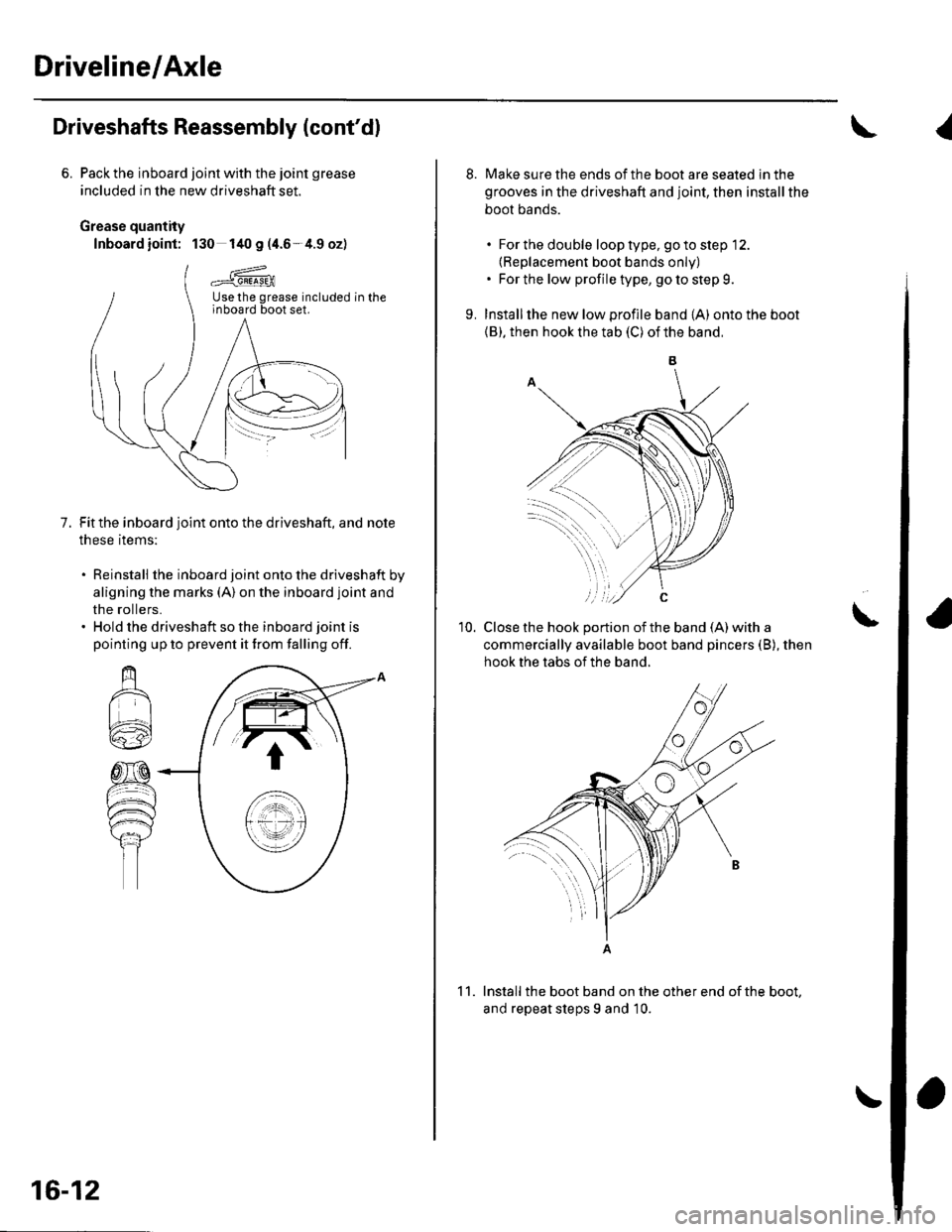

6.

Driveshafts Reassembly (cont'd)

Pack the inboard joint with the joint grease

included in the new driveshaft set.

Grease quantity

Inboard ioint: 130 140 g (4.6-4.9 oz)

Use the grease included in theinboard boot set.

Fit the inboard joint onto the driveshaft, and note

these items:

. Reinstall the inboard joint onto the driveshaft by

aligning the marks (A) on the inboard joint and

the rollers.. Hold the driveshaft so the inboard joint is

pointing up to prevent it trom falling off.

7.

16-12

11.

8.Make sure the ends of the boot are sealed in the

grooves in the driveshaft and joint, then installthe

boot bands.

. For the double loop type, go to step 12.(Replacement boot bands only). For the low profile type, go to step 9.

Installthe new low profile band {A) onto the boot

{B). then hook the tab (C) of the band,

Close the hook portion of the band (A) with a

commercially available boot band pincers (B), then

hook the tabs of the band.

Install the boot band on the other end of the boot,

and reoeat steos 9 and 10.

9.

\10.

I

Page 480 of 1139

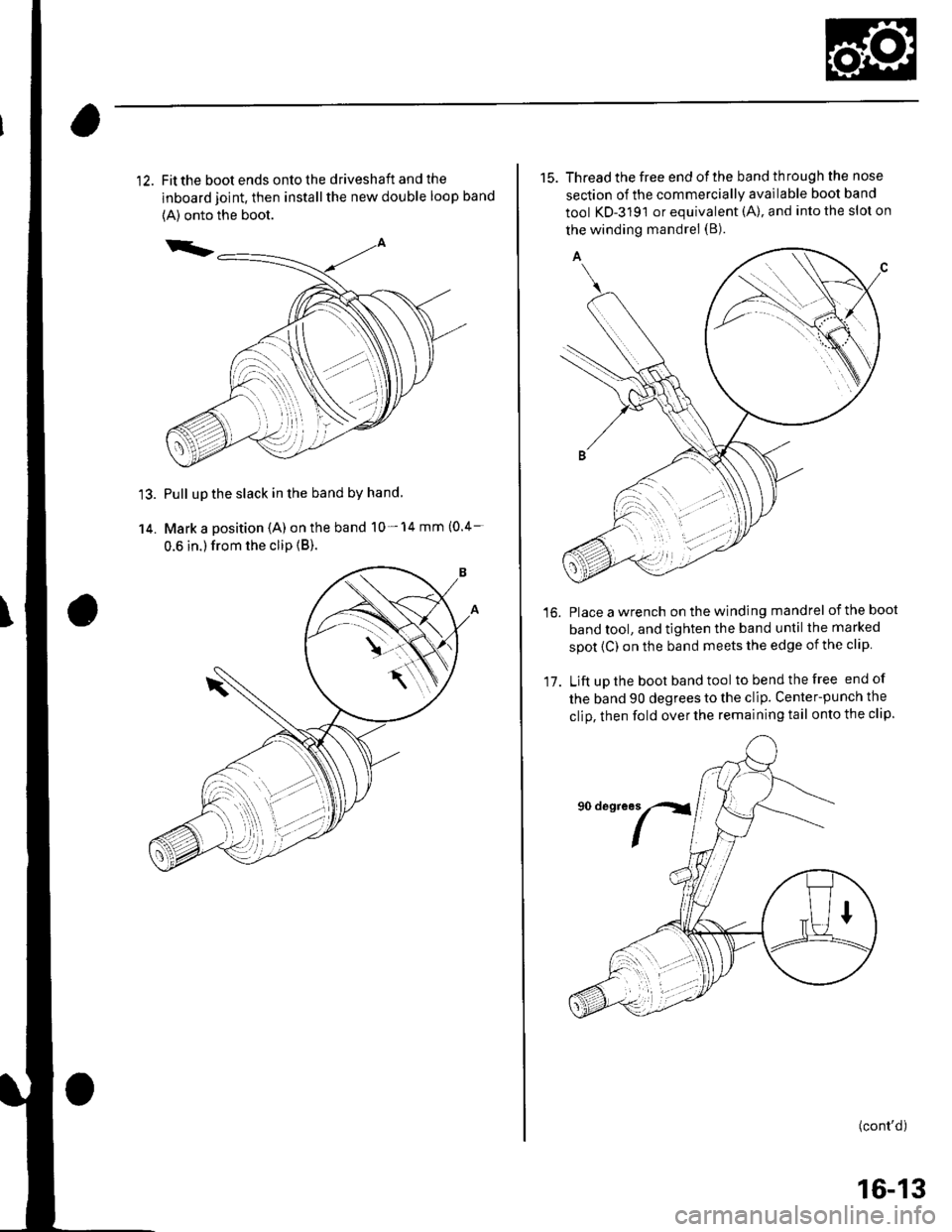

Fit the boot ends onto the driveshaft and the

inboard joint, then install the new double loop band

{A) onto the boot.

Pull up the slack in the band by hand

Mark a position (A) on the band 10- 14 mm (0.4-

0.6 in.) from the clip {B).

15. Thread the free end ofthe band through the nose

section of the commercially available boot band

tool KD-3191 or equivalent (A), and into the slot on

the winding mandrel (B).

Place a wrench on the winding mandrel of the boot

band tool, and tighten the band until the marked

spot (C) on the band meets the edge of the clip

Lift uD the boot band tool tobendthefree end of

the band 90 degrees to the clip. Center-punch the

clio, then fold over the remaining tail onto the clip.

16.

17.

(cont'd)

16-13

Page 481 of 1139

Driveline/Axle

Driveshafts Reassembly (cont'dl

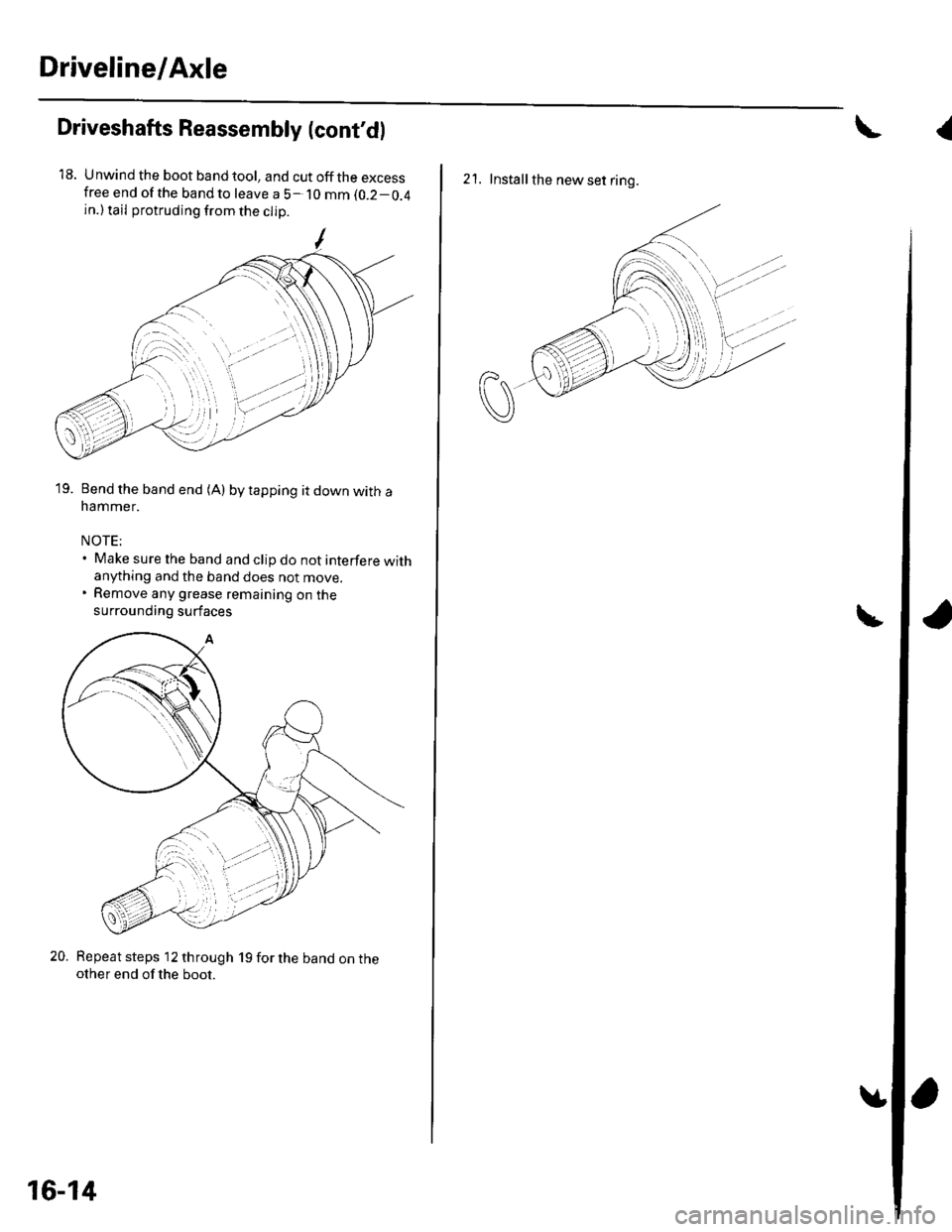

18. Unwind the boot band tool, and cut off the excessfree end of the bandto leave a 5- 10 mm (0.2-0.4

in.) tail protruding from the clip

19. Bend the band end (A) by tapping it down with anammer.

NOTE;. Make sure the band and clip do not interfere withanything and the band does not move.. Remove any grease remaining on the

surrounding surfaces

20. Repeat steps 12 through 19 for the band on theother end of the boot.

16-14

{

2'1. Installthe new set ring.