boot HONDA CIVIC 2002 7.G Owner's Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2002, Model line: CIVIC, Model: HONDA CIVIC 2002 7.GPages: 1139, PDF Size: 28.19 MB

Page 482 of 1139

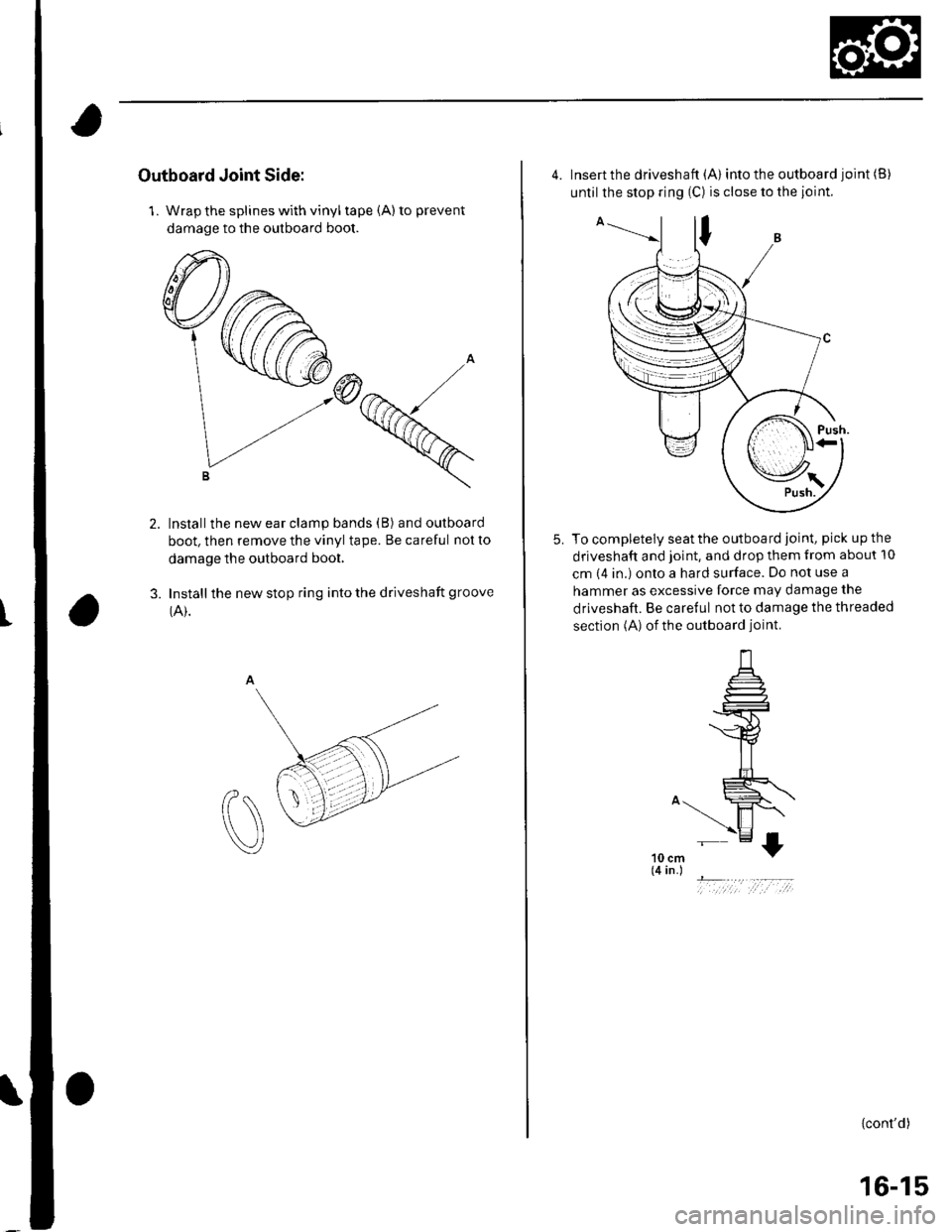

Outboard Joint Side:

1. Wrap the splines with vinyl tape (A) to prevent

damage to the outboard boot.

Installthe new ear clamp bands (B) and outboard

boot, then remove the vinyl tape. Be careful not to

damage the outboard boot.

Install the new stop ring into the driveshaft groove

(A).3.

t

4. Insert the driveshaft (A) into the outboard joint (B)

until the stop ring (C) is close to the joint.

To completely seat the outboard joint, pick up the

driveshaft and joint, and drop them from about 10

cm (4 in.) onto a hard surface. Do not use a

hammer as excessive force may damage the

driveshaft. Be careful not to damage the threaded

section (A) of the outboard joint.

5.

10 cm(4 in.)

- ..,..,1 ;,t ,:-,;

{cont'd)

16-15

Page 483 of 1139

Driveline/Axle

Driveshafts Reassembly (cont'd)

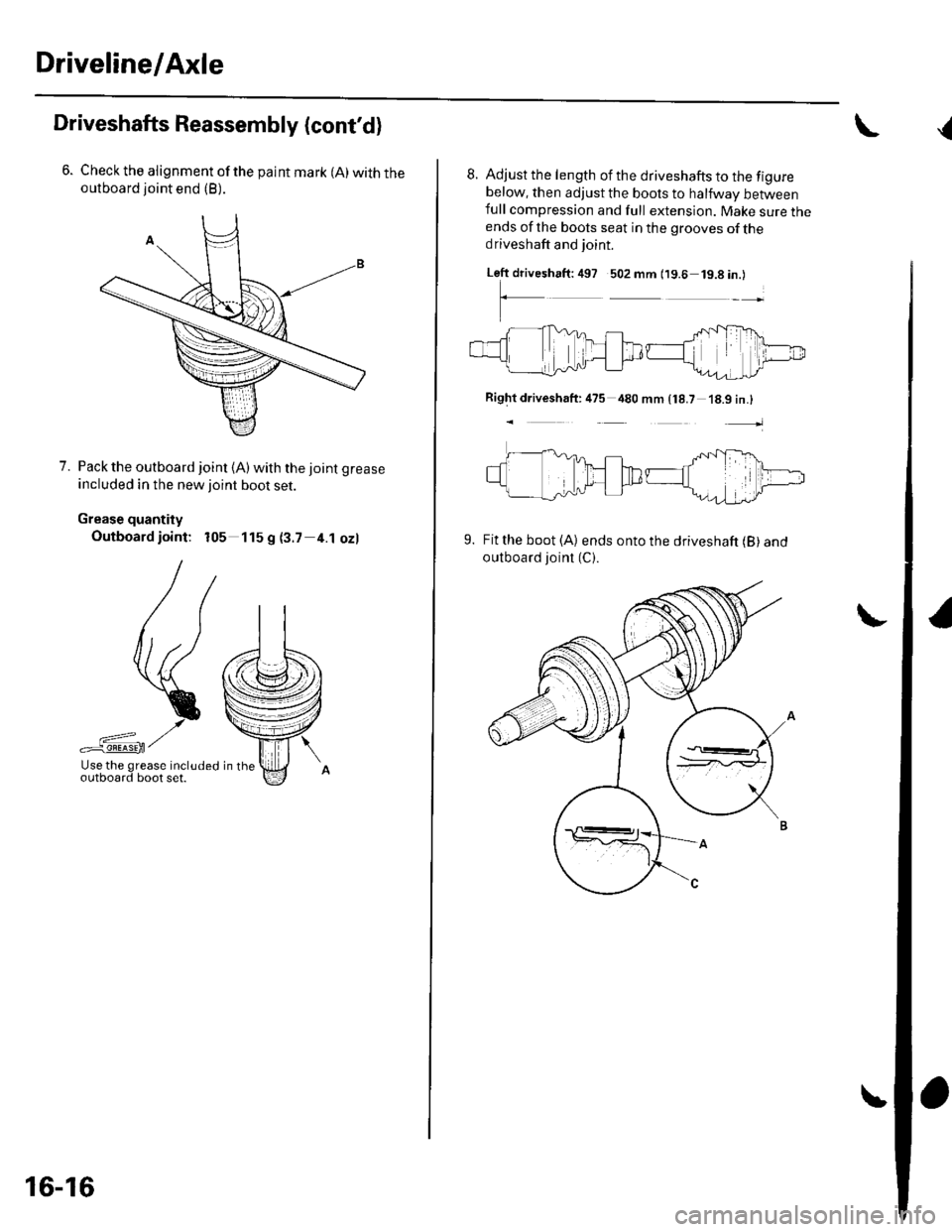

Check the alignment of the paint mark (A) with theoutboard joint end (B).

7. Pack the outboard joint (A)with the joint grease

included in the new ioint boot set.

Grease quantity

Outboard ioint: 105 115 g (3.7 4.1 ozl

/r

llt ,)

\{(

-*>

:;,"0'A?g.fff :l:f '., o "o

16-16

8. Adjust the length of the driveshafts to the figurebelow, then adjust the boots to halfway betweenfull compression and full extension. Make sure theends of the boots seat in the grooves of thedriveshaft and joint.

Left driveshaft:497 502 mm (19.6 19.8in.)

Rightdriveshaft: 475 480 mm {18.7

t

-tTfi'.D.ilTD

18.9 in.l

Fit the boot (A) ends onto the driveshaft (B) andoutboard joinl (C).

9.

{

Page 484 of 1139

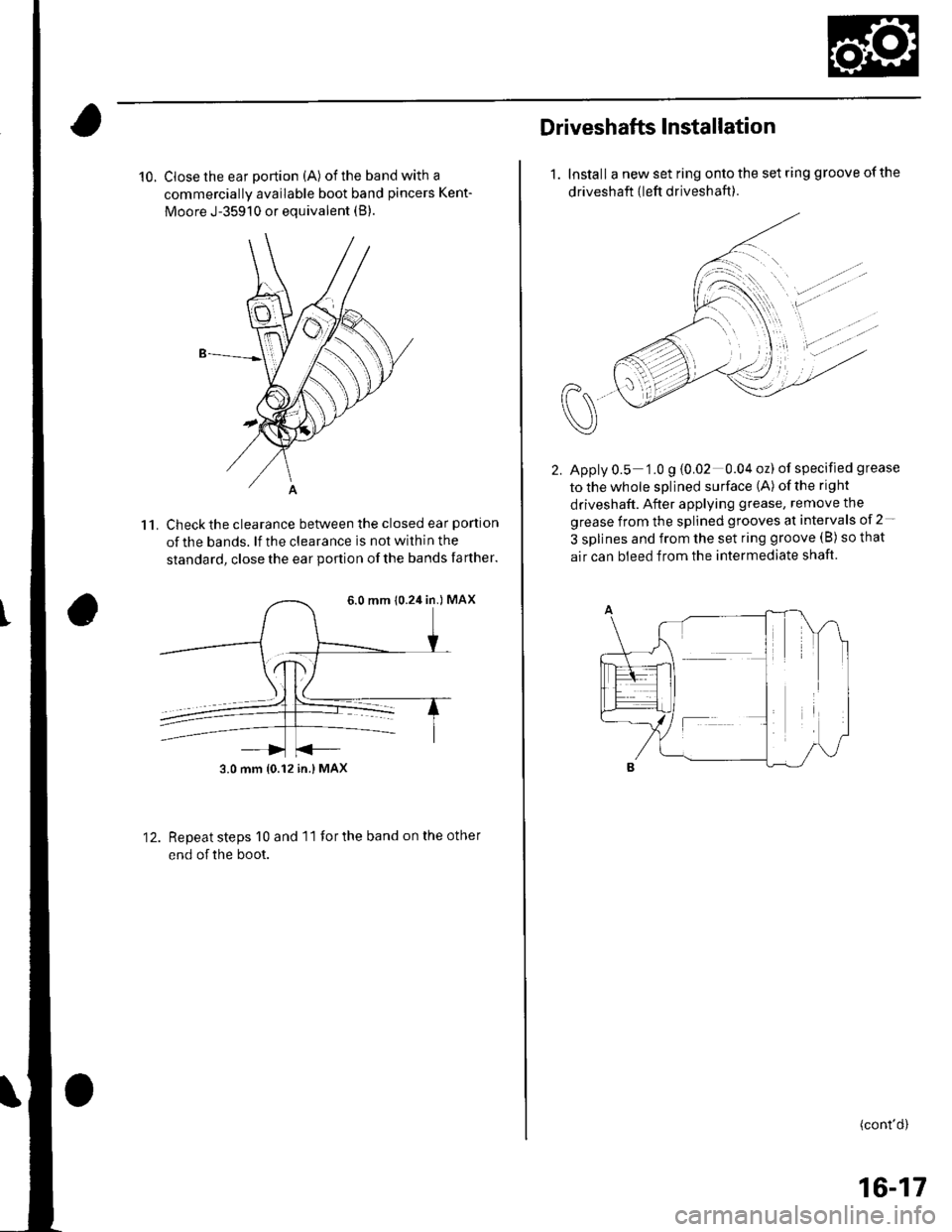

10. Close the ear portion (A) of the band with a

commercially available boot band pincers Kent-

Moore J-35910 or equivalent (B).

Check the clearance between the closed ear portlon

of the bands. lf the clearance is not within the

standard, close the ear podion of the bands farther.

11.

12.Repeat steps 10 and 11 for the band on the other

end of the boot.

6.0 mm 10.24 in.) MAX

3.0 mm {0.12 in.} MAX

Driveshafts Installataon

1. Install a new set ring onto the set ring groove of the

driveshaft {left driveshaft ).

Apply 0.5 1.0 g {0.02 0.04 oz) of specified grease

tothewhole splined surface (A) ofthe right

driveshaft. After applying grease, remove the

grease from the splined grooves at intervals of 2-

3 splines and from the set ring groove (B) so that

air can bleed from the intermediate shaft.

(cont'd)

16-17

Page 485 of 1139

Driveline/Axle

Driveshafts Installation (cont'd)

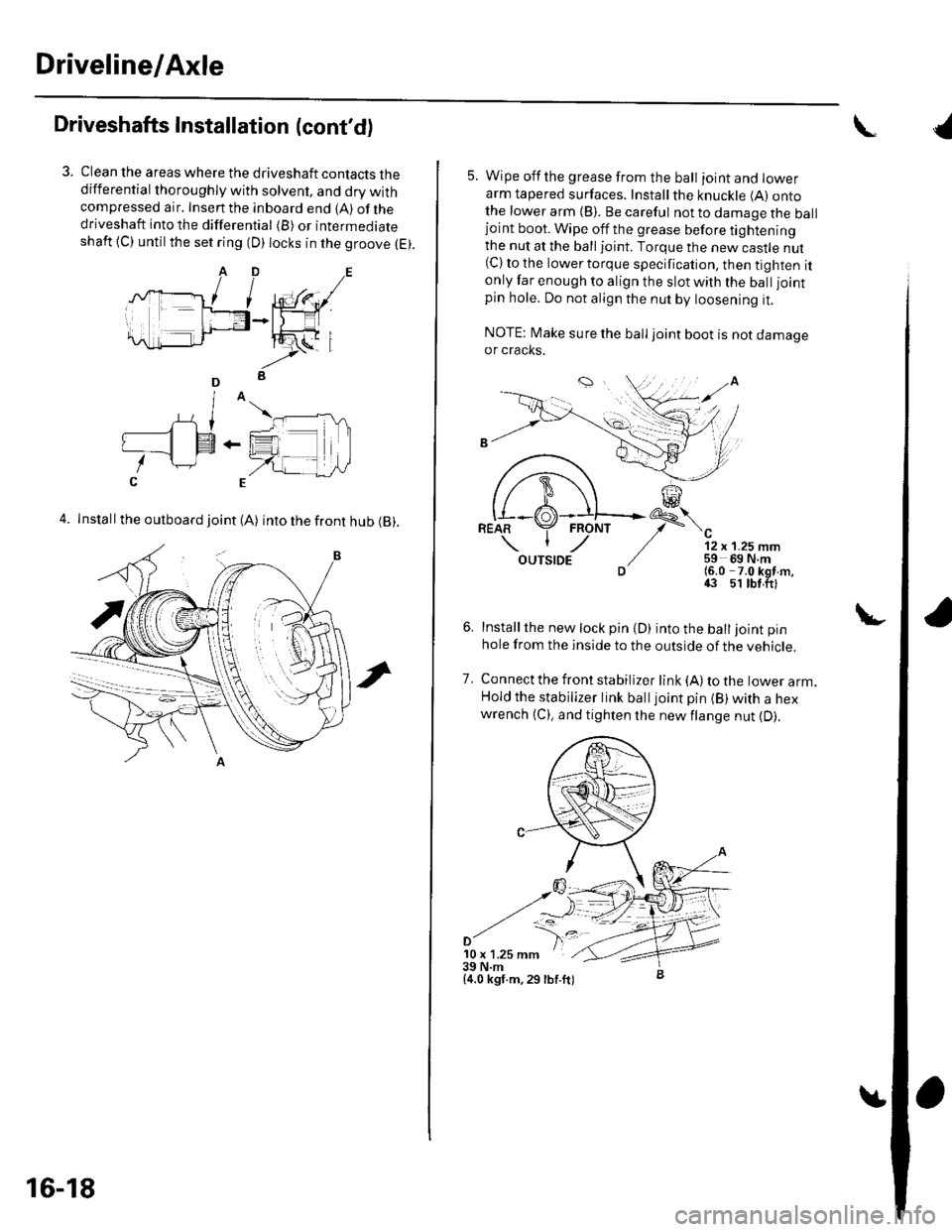

Clean the areas where the driveshaft contacts thedifferential thoroughly with solvent, and dry withcompressed air. Insenthe inboard end {A) ofthedriveshaft into the differential (B) or intermediateshaft {C) until the set ring (D) locks in the groove (E).

4. Install the outboard joint (A) into the front hub (B).

16-18

5. Wipe offthe grease from the ball ioint and lowerarm tapered surfaces. Installthe knuckle (A) ontothe lower arm {B). Be careful not to damage the balljoint boot. Wipe off the grease before tighteningthe nut at the ball joint. Torque the new castle nut(C) to the lower torque specification, then tighten itonly far enough to align the slot with the ball joint

pin hole. Do not align the nut by loosening it.

NOTE: Make sure the ball joint boot is not damageor cracks.

"-'t-

12 x 1.25 mm59 69 N.m(6.0 -7.0 kgf m,43 51 tbt.ftl

Installthe new lock pin {D) into the balljoint pin

hole from the inside to the outside of the vehicle.

Connect the front stabilizer link {A) to the lower arm.Hold the stabilizer link balljoint pin (B) with a hexwrench {C), and tighten the newflange nut {D).

7.

'10 x 1.25 mm39 N.m{4.0 kgf.m,29 lbf.ft)

{

Page 497 of 1139

I

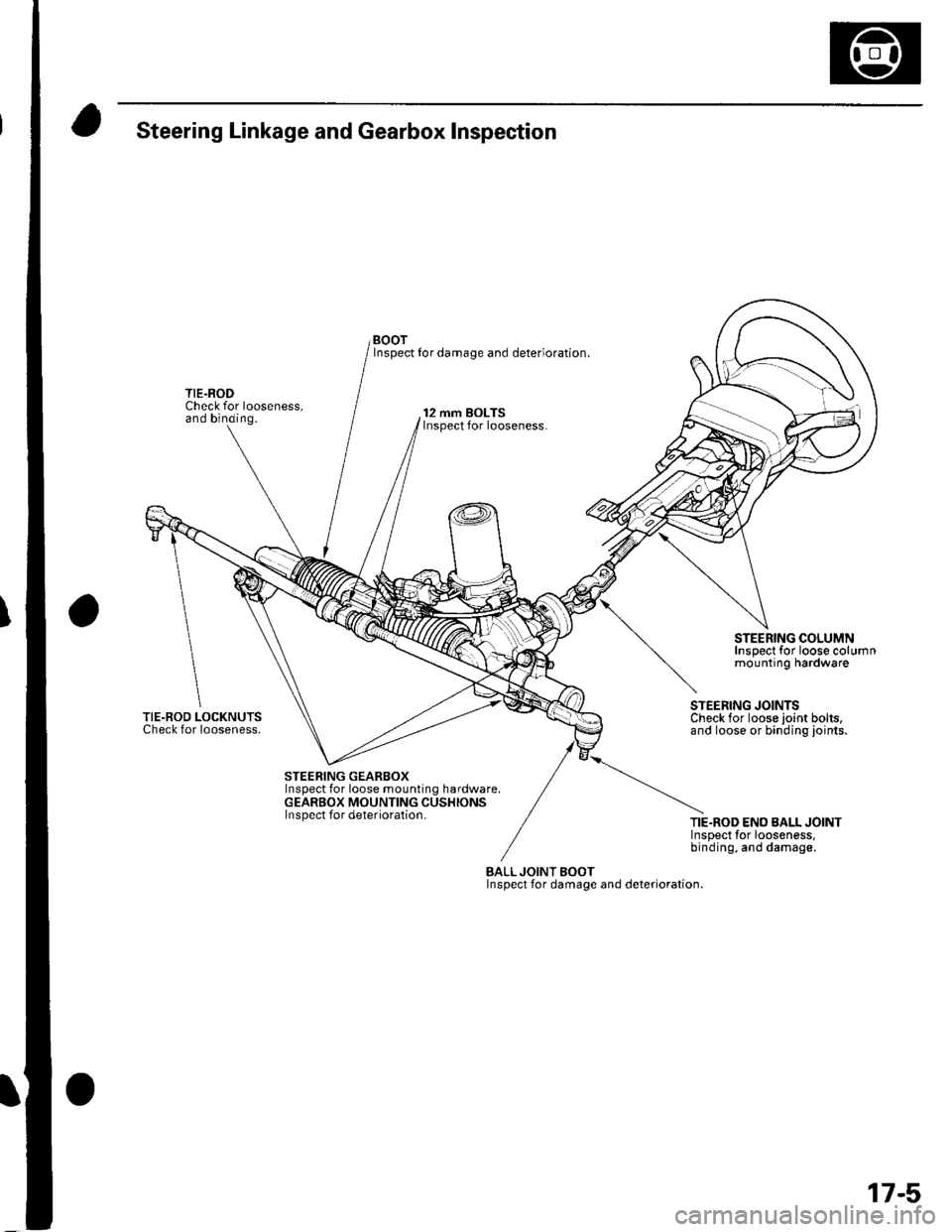

Steering Linkage and Gearbox Inspection

Check for looseness,and binding.

TIE.ROD LOCKNUTSCheck for looseness.

BOOTInspect Ior damage and deterioration.

12 mm BOLTSInspect for looseness.

STEERING COLUMNInspect for loose columnmounting hardware

STEERING GEARBOXInspect for loose mounting hardware.GEARBOX MOUNTING CUSHIONSInspect for deterioration.

STEERING JOINTSCheck for loose ioint bolts,and loose or binding ioints.

TIE.ROD ENO BALL JOINTlnsoect tor looseness,binding, and damage.

BALLJOINT BOOTInspect for damage and deterioration.

17-5

Page 506 of 1139

Electrical Power Steering (EPSI

SpecialTools ............. 17 -16

Component Location Index ......................................... 17-17

General Troubleshooting Information ....................... 17-18

DTC Troubleshooting Index .............. 17-22

Symptom Troubleshooting Index ............................... 17 -23

System Description ................. ........... 17-24

Circuit Diagram ......... 17-26

DTC Troubleshooting ............... .......... 17-28

EPS lndicator Circuit Troubleshooting ....................... 17-47

Motor Removal/lnstallation ............... 17-49

Steering Gearbox Removal ............... 17-51

Steering Gearbox Overhaul ............... 17-55

Steering Gearbox Installation ........... 17-63

EPS Control Unit Remova l/lnsta llation ....................... 17-67

Tie-rod Ball Joint Boot Replacement .......................... 17-67

Page 546 of 1139

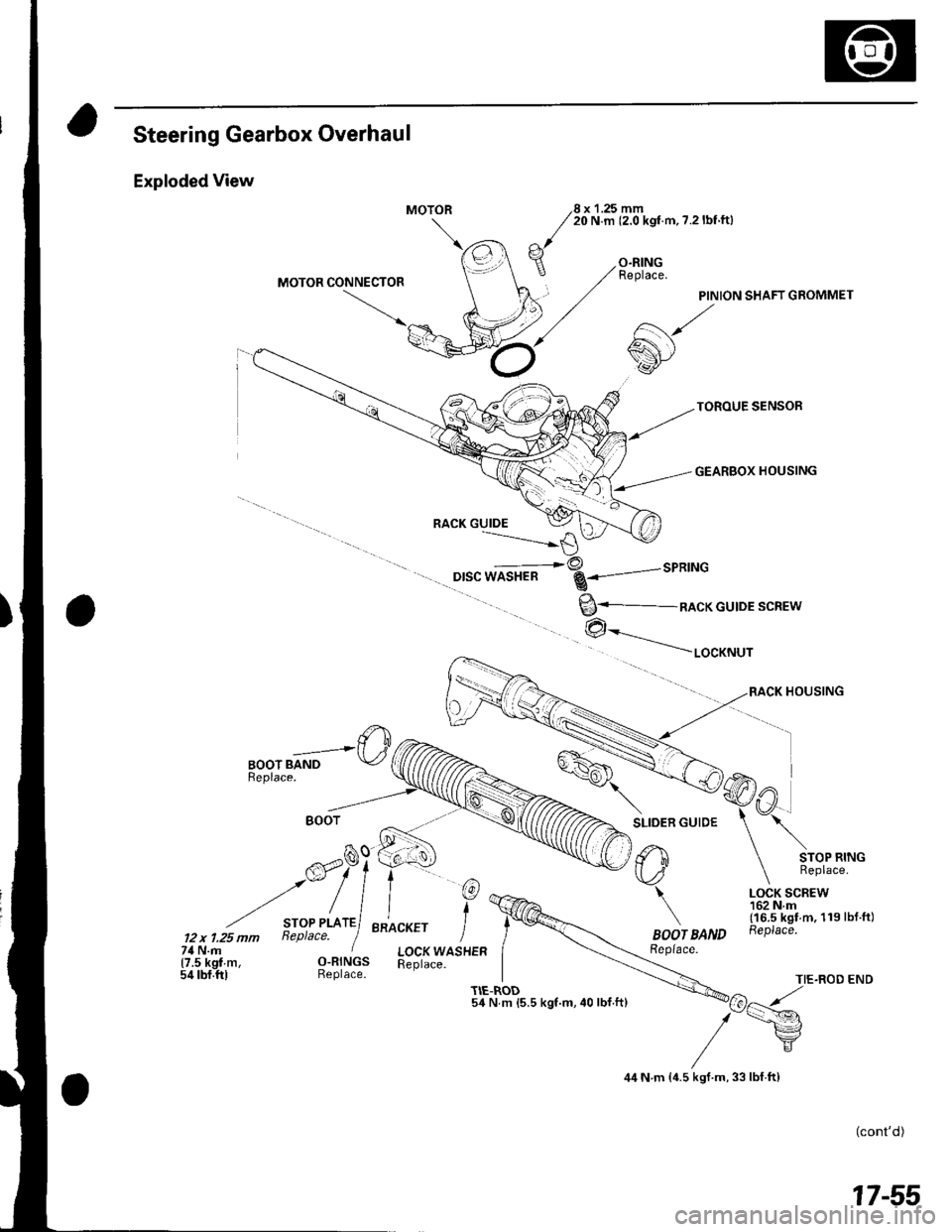

I x '1.25 mm20 N.m (2.0 kgf.m,7.2lbt ftl

O.RINGReplace.

PINION SHAFT GROMMET

-'t ''

v

\>--. i-*\{i#r^i

. s(./t' J

SLTDER GUIDE

-l

\

{^il stot *,tttc

\J" Renrace

LocK scREw '162 N.m lto.s rgf m,119lbf ft)

BOOTBAND Beqtace.

- Replace.

@

II

ASHER

rtE54

TIE.ROD END

CONNECTOR

Steering Gearbox Overhaul

Exploded View

RACK GUIDE

6^:,;�

BOOT BAND '"''/

Beplace.

. -@ -sPRrNG. DISC WASHEB @'---g

L)-RACKGUIDE SCREW

6v---\' \.oc**u.

SRACKET

LOCK WReplace.

-RODN m {5.5 kgf.m,40lbf ft)

kgf.m,

(cont'd)

17-55

33 tbt.ft)44 N m {4.5

Page 548 of 1139

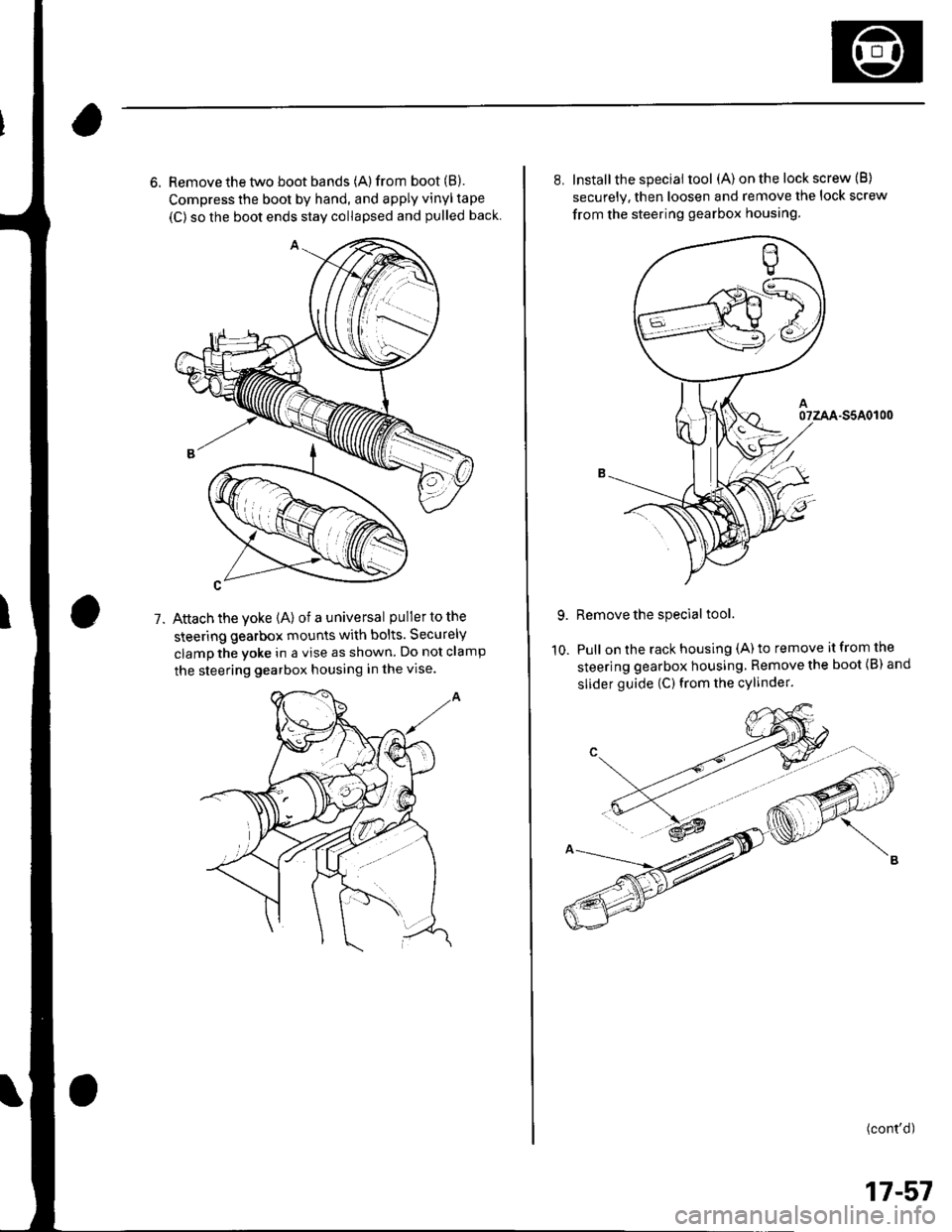

6. Remove the two boot bands (A) from boot (B).

Compress the boot by hand, and apply vinyl tape

(C) so the boot ends stay collapsed and pulled back

Attach the yoke (A) of a universal puller to the

steering gearbox mounts with bolts. Securely

clamp the yoke in a vise as shown. Do not clamp

the steering gearbox housing in the vise.

1.

10.

8. Installthe special tool (A) on the lock screw (B)

securely. then loosen and remove the lock screw

from the steering gearbox housing.

07zAA-S5A0r00

Remove the special tool.

Pull on the rack housing (A) to remove it from the

steering gearbox housing, Remove the boot {B) and

slider guide (C) from the cylinder.

(cont'd)

17-57

Page 550 of 1139

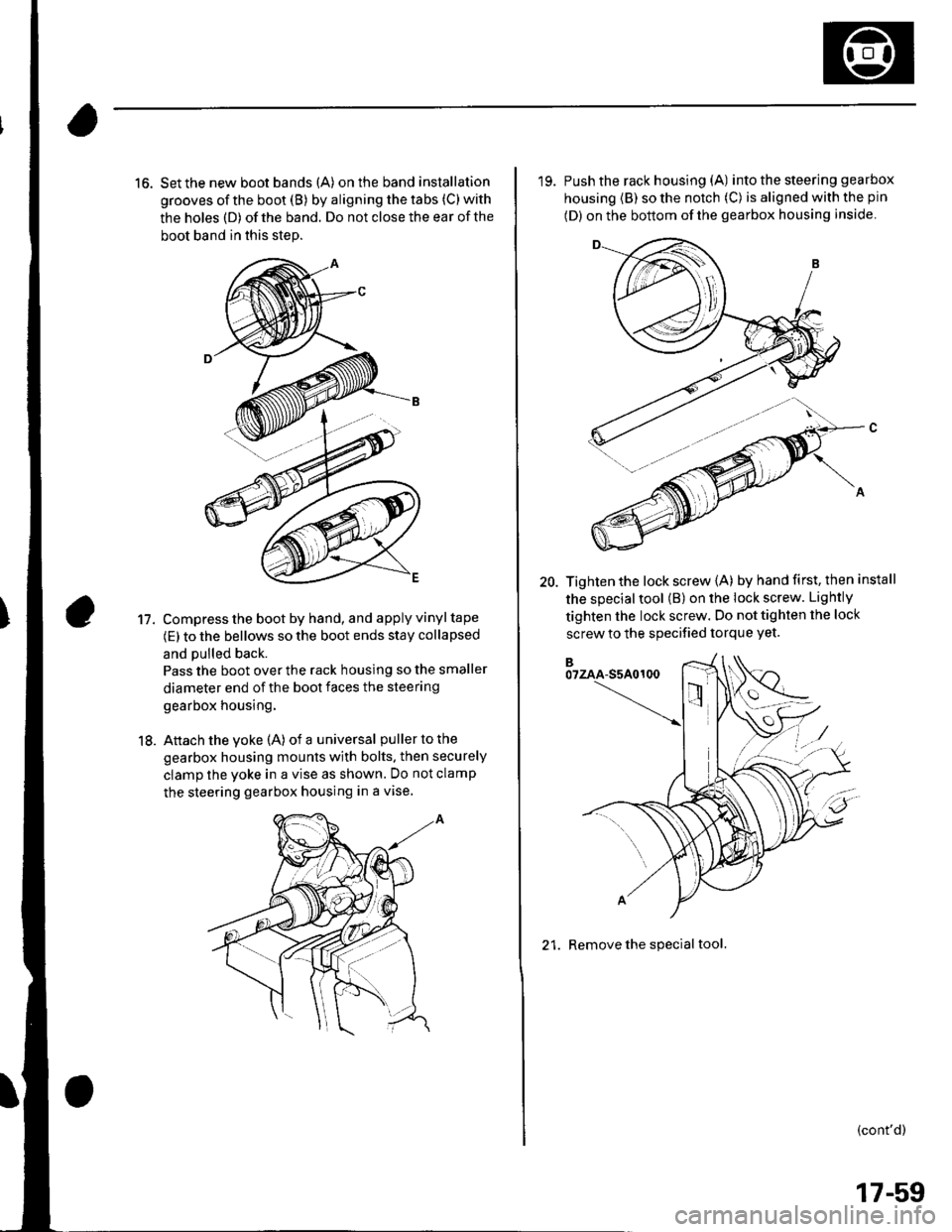

16. Set the new boot bands (A) on the band installation

grooves of the boot (B) by aligning the tabs (C) with

the holes (D) of the band. Do not close the ear of the

boot band in this step.

Compress the boot by hand, and apply vinyl tape

(E) to the bellows so the boot ends stay collapsed

and pulled back.

Pass the boot over the rack housing so the smaller

diameter end of the boot faces the steering

gearbox housing.

Attach the yoke (A) of a universal puller to the

gearbox housing mounts with bolts. then securely

clamp the yoke in a vise as shown. Do not clamp

the steering gearbox housing in a vise.

11.

18.

'19. Push the rack housing (A) into the steering gea rbox

housing (B) so the notch (C) is aligned with the pin

(D) on the bottom of the gearbox housing inside

20. Tighten the lock screw {A) by hand first, then install

the special tool (B) on the lock screw. Lightly

tighten the lock screw. Do not tighten the lock

screw to the specified torque Yet.

21. Remove the special tool.

(cont'd)

17-59

Page 551 of 1139

EPS Components

{Steering Gearbox Overhaul (cont'dl

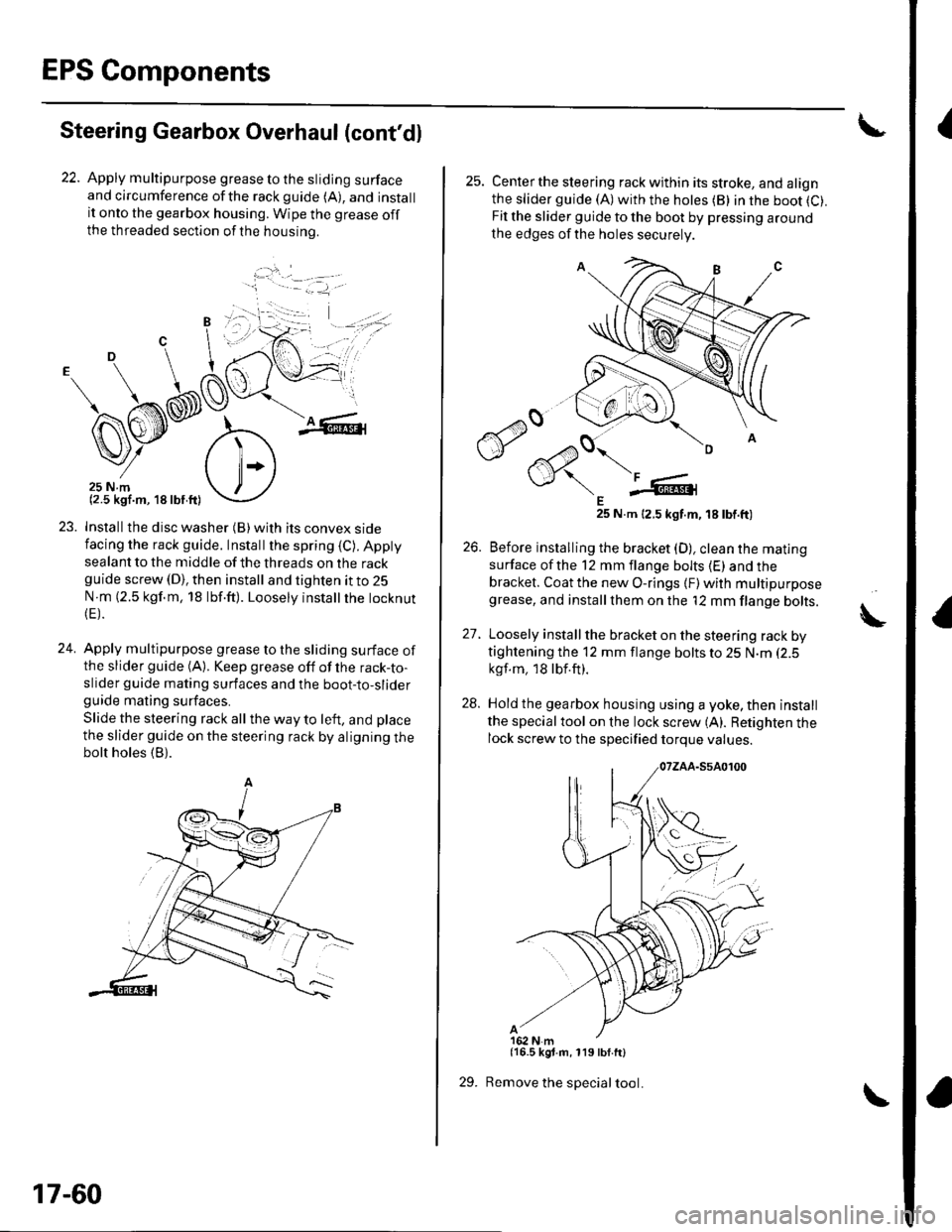

22. Apply multipurpose grease to the sliding surfaceand circumference ofthe rackguide (A), and installit onto the gearbox housing. Wipe the grease offthe threaded section ofthe housrno.

...'.

,. ,l

.j

23. Installthe disc washer (B)with its convex sidefacing the rack guide. Installthe spring (C). Appty

sealant to the middle of the threads on the rackguide screw (D), then install and tighten it to 25

N m (2.5 kgf.m, 18 lbf.ft). Loosely instatlrhe tocknut(E).

24. Apply multipurpose grease to the sliding surface ofthe slider guide (A). Keep grease off of the rack-to-slider guide mating surfaces and the boot-to-sliderguide mating surfaces.

Slide the steering rack all the way to left, and place

the slider guide on the steering rack by aligning thebolt holes (B).

'1 - .- =-1, -

17-60

29.

25. Centerthe steering rack within its stroke, and alignthe slider guide (A)with the hotes (B) in the boot (C).

Fit the slider guide to the boot by pressing around

the edges of the holes securely

E25 N.m 12.5 kgt.m, 18 tbt.ft)

26. Before installing the bracket (D), clean the mating

surface ofthe 12 mm flange bolts (E) and thebracket. Coat the new O-rings {F) with multipurposegrease, and installthem on the '12 mm flange bolts.

27. Loosely install the bracket on the steering rack bytightening the 12 mm flange bolts to 25 N.m (2.5

kgf.m, 18lbf.ft).

28. Hold the gearbox housing using a yoke, then install

the specialtool on the lock screw (A). Retighten thelock screw to the specified torque values.

{16.5 kgt.m, 119 lbf.ft}

Remove the special tool.

A