differential HONDA CIVIC 2002 7.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 2002, Model line: CIVIC, Model: HONDA CIVIC 2002 7.GPages: 1139, PDF Size: 28.19 MB

Page 464 of 1139

M/T Differential

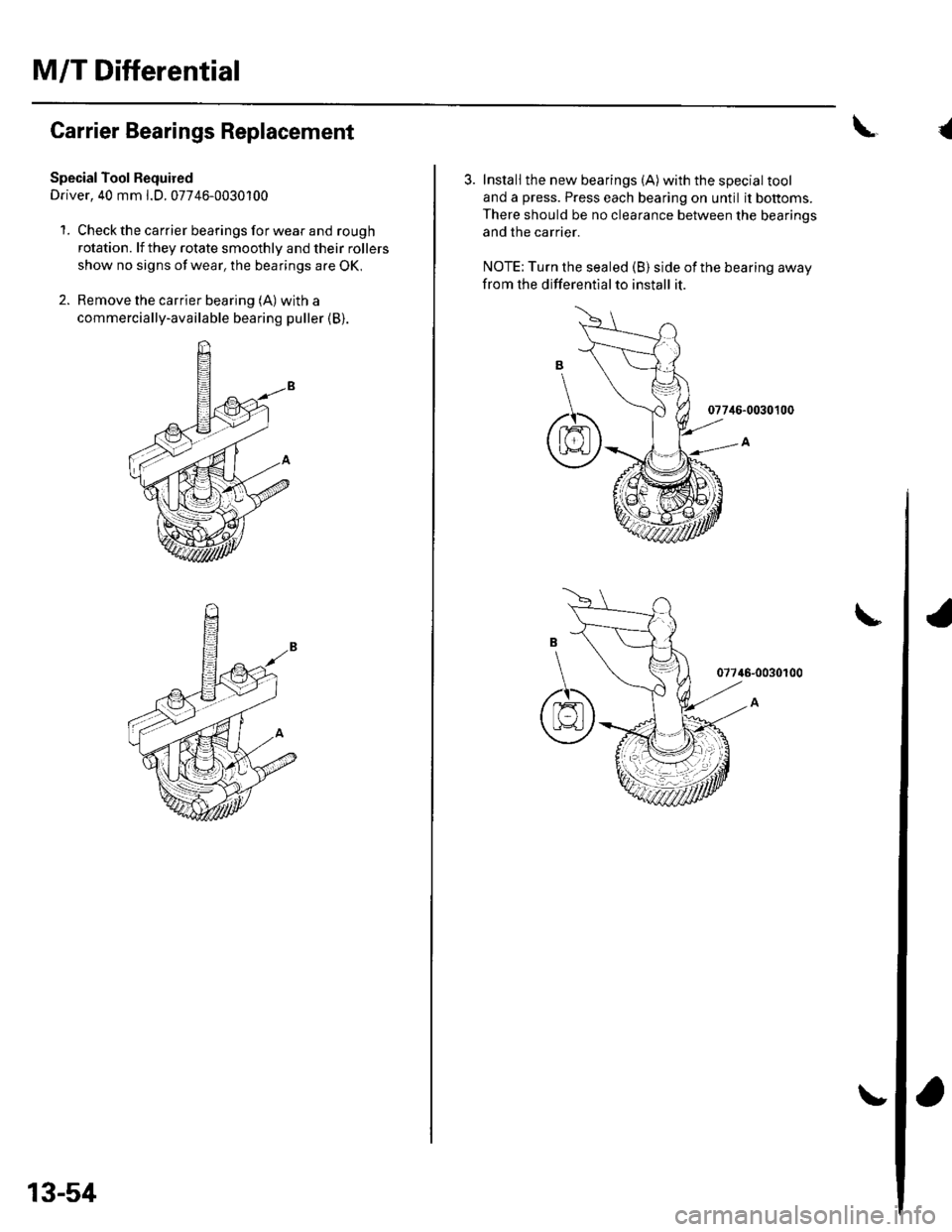

Carrier Bearings Replacement

Special Tool Bequired

Driver, 40 mm l.D. 07746-0030100

1. Check the carrier bearings for wear and rough

rotation. lf they rotate smoothly and their rollers

show no signs of wear, the bearings are OK,

2. Remove the carrier bearing (A) with a

commercially-available bearing puller (B).

13-54

\{

3. Install the new bearings (A)with the special tool

and a press. Press each bearing on until it bottoms.

There should be no clearance between the bearinos

and the carrier.

NOTE: Turn the sealed (B) side of the bearing away

from the differentialto install it.

077i16-0030100

07746-0030100

6

Page 465 of 1139

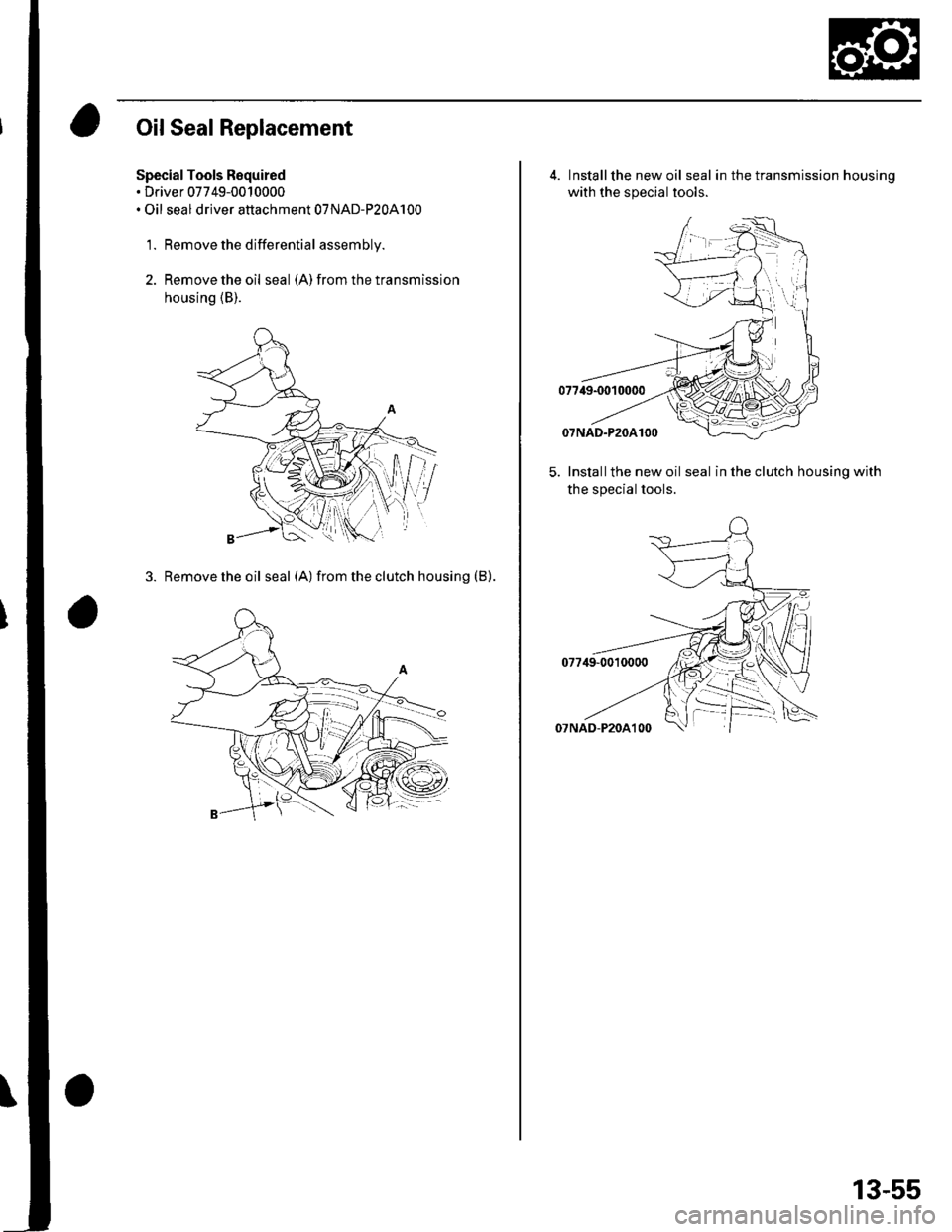

Oil Seal Replacement

Special Tools Required. Driver 07749-0010000. Oil seal driver attachment 07NAD-P20A100

1. Remove the differential assembly.

2. Remove the oil seal (A) from the transmission

housing (B).

3. Removetheoil seal (A) fromtheclutch housing (B).

4. Installthe new oil seal in the transmission housinq

with the special tools.

5. Installthe new oil seal in the clutch housing with

the special tools.

13-55

Page 466 of 1139

M/T Differential

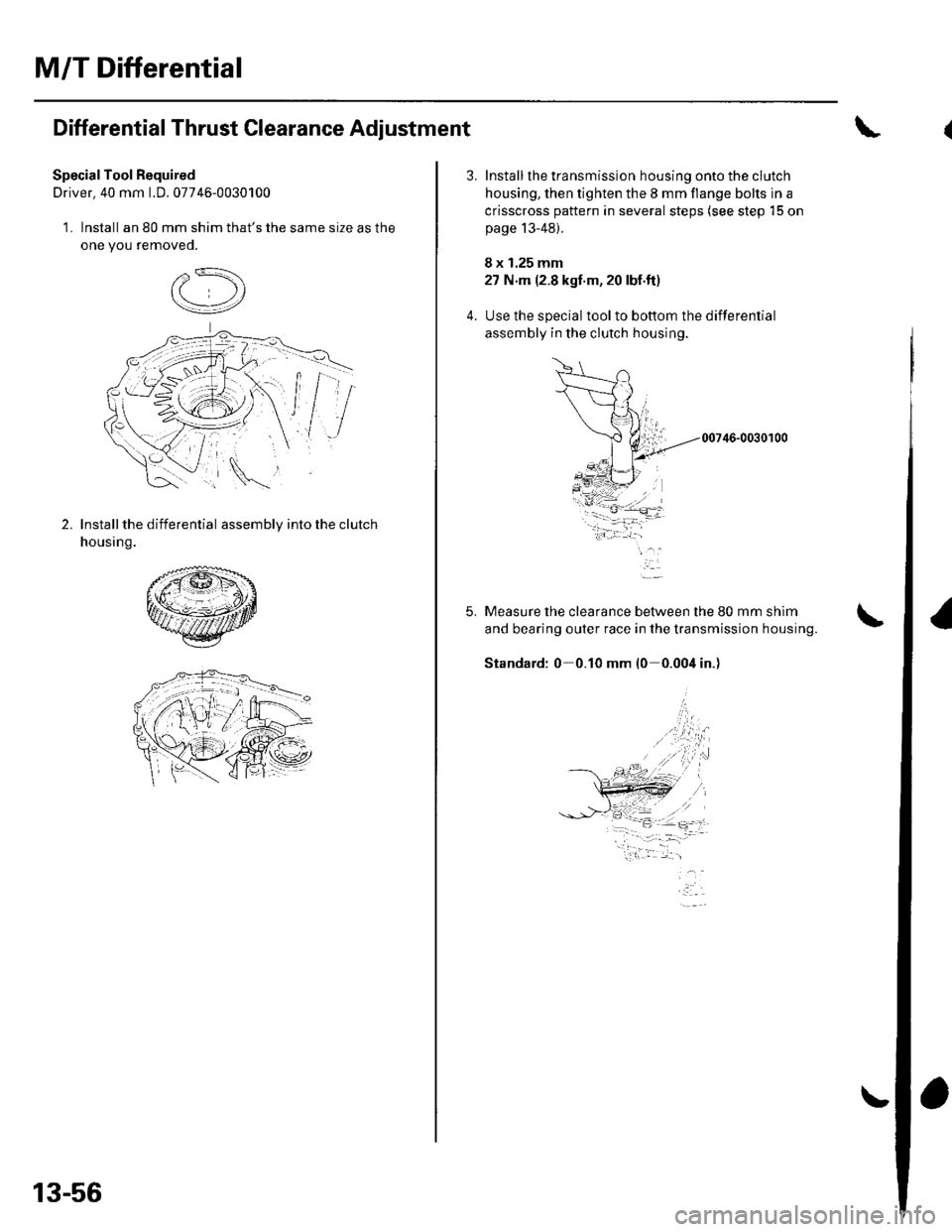

Differential Thrust Clearance Adjustment

SpecialTool Required

Driver. 40 mm LD. 07746-0030100

1. Install an 80 mm shim that's the same size as the

one you removeo.

2.Install the differential assembly into the clutch

housing.

13-56

5.

Install the transmission housing onto the clutch

housing, then tighten the 8 mm flange bolts in a

crisscross pattern in several steps (see step 15 on

page 13-48).

8 x 1.25 mm

27 N m (2.8 kgf'm, 20 lbf.ft)

Use the special toolto bottom the differential

assembly in the clutch housing.

00746-0030100

Measure the clearance between the 80 mm shim

and bearing outer race in the transmission housing.

Standard: 0 0.10 mm l0 0.004 in.)

-i.w.t ..1-- -- :,- -=.

Page 471 of 1139

Driveline/Axle

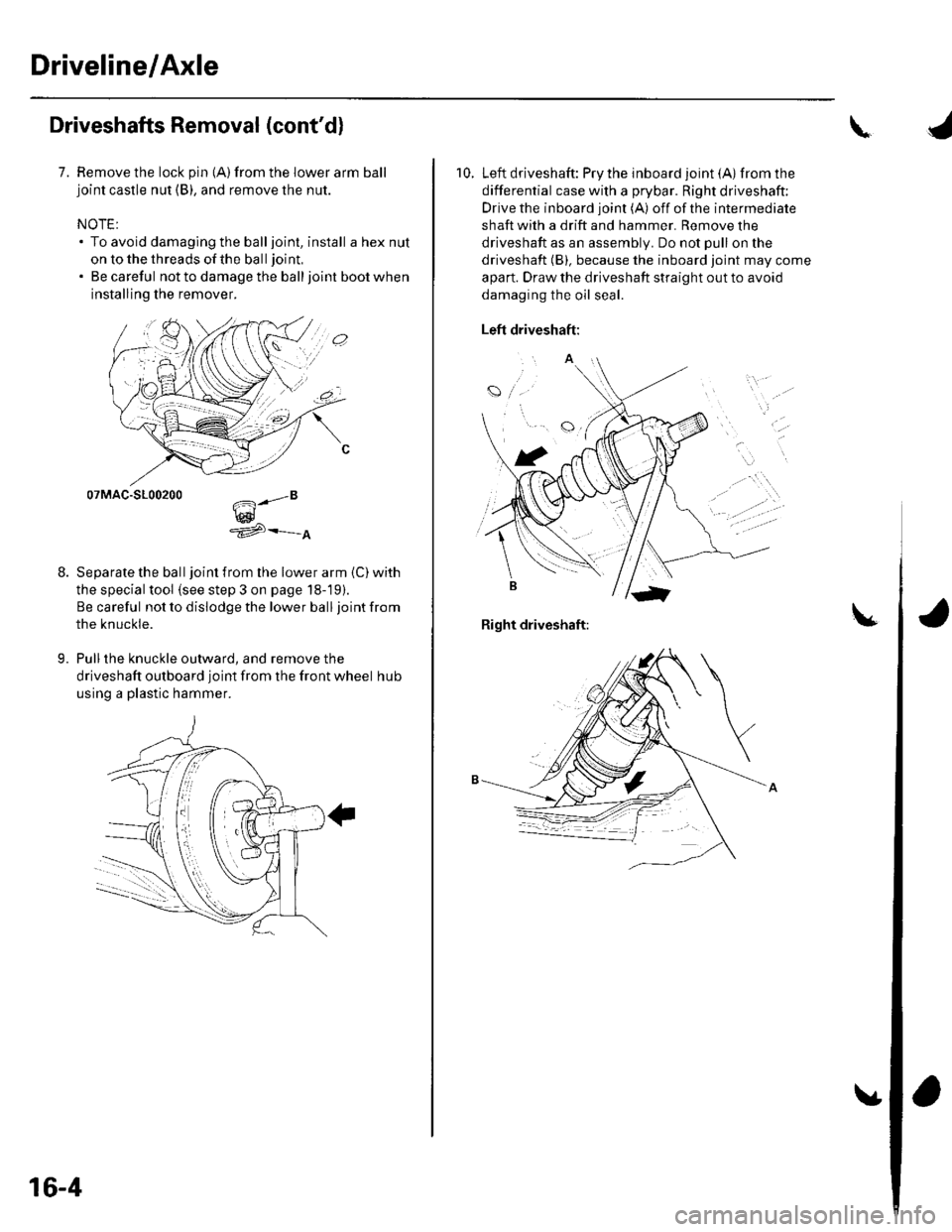

Driveshafts Removal (cont'd)

7. Remove the lock pin {A)from the lower arm balljoint castle nut (B), and remove the nut.

NOTE:. To avoid damaging the balljoint, install a hex nut

on to the threads of the ball joint,

. Be careful not to damage the balljoint boot when

installing the remover.

07MAC-S100200

w^'e

Separate the ball joint from the lower arm (C) with

the special tool (see step 3 on page 18-19).

Be careful not to dislodge the lower ball joint from

the knuckle.

Pull the knuckle outward, and remove the

driveshaft outboard joint from the front wheel hub

using a plastic hammer.

9.

.."8

16-4

\

10. Left driveshaft: Pry the inboard joint (A)from the

differential case with a prybar. Right driveshaft:

Drive the inboard joint (A) off of the intermediate

shaft with a drift and hammer. Remove the

driveshaft as an assembly. Do not pull on the

driveshaft (B), because the inboard joint may come

apart. Draw the driveshaft straight out to avoid

damaging the oil seal.

Left driveshaft:

a

t

Right driveshaft:

Page 485 of 1139

Driveline/Axle

Driveshafts Installation (cont'd)

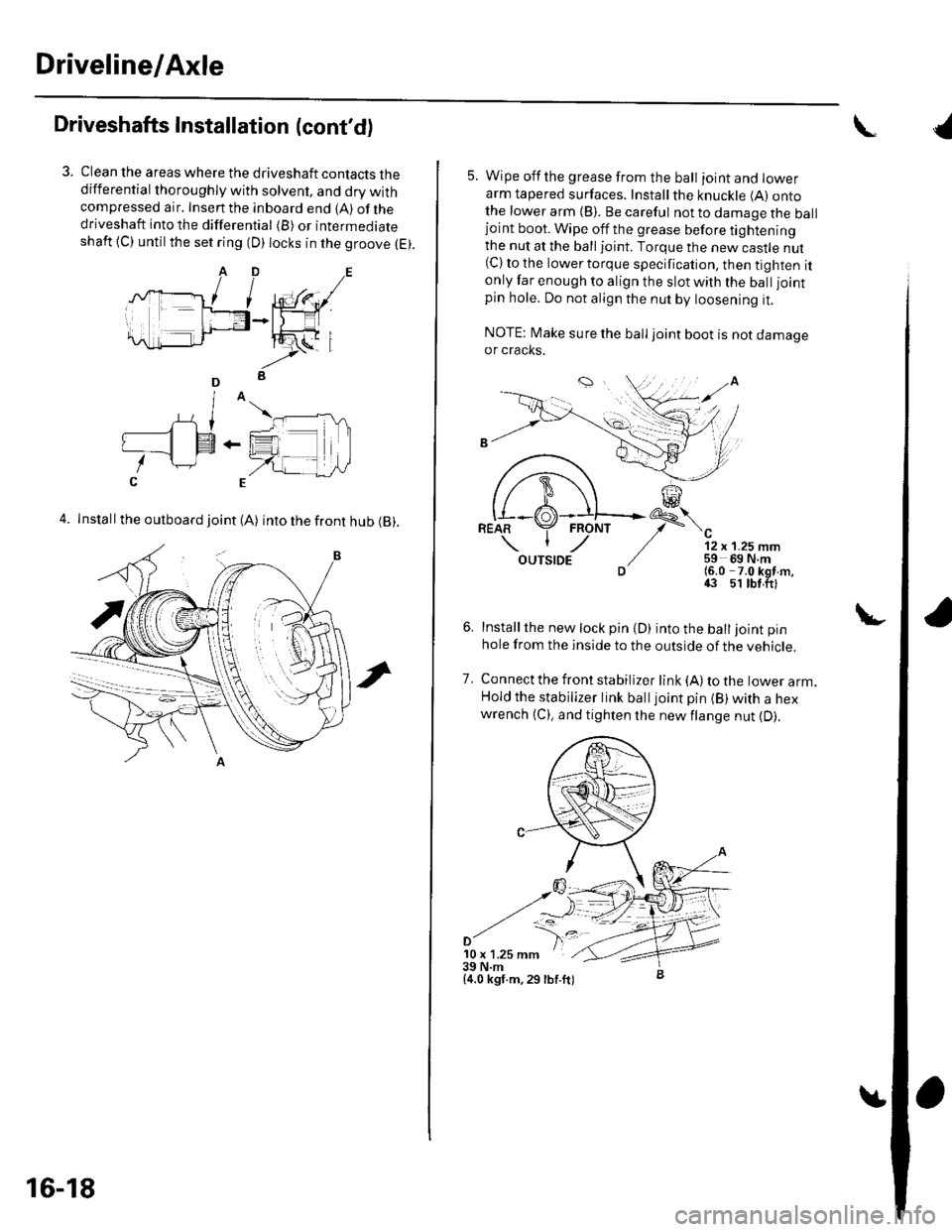

Clean the areas where the driveshaft contacts thedifferential thoroughly with solvent, and dry withcompressed air. Insenthe inboard end {A) ofthedriveshaft into the differential (B) or intermediateshaft {C) until the set ring (D) locks in the groove (E).

4. Install the outboard joint (A) into the front hub (B).

16-18

5. Wipe offthe grease from the ball ioint and lowerarm tapered surfaces. Installthe knuckle (A) ontothe lower arm {B). Be careful not to damage the balljoint boot. Wipe off the grease before tighteningthe nut at the ball joint. Torque the new castle nut(C) to the lower torque specification, then tighten itonly far enough to align the slot with the ball joint

pin hole. Do not align the nut by loosening it.

NOTE: Make sure the ball joint boot is not damageor cracks.

"-'t-

12 x 1.25 mm59 69 N.m(6.0 -7.0 kgf m,43 51 tbt.ftl

Installthe new lock pin {D) into the balljoint pin

hole from the inside to the outside of the vehicle.

Connect the front stabilizer link {A) to the lower arm.Hold the stabilizer link balljoint pin (B) with a hexwrench {C), and tighten the newflange nut {D).

7.

'10 x 1.25 mm39 N.m{4.0 kgf.m,29 lbf.ft)

{

Page 487 of 1139

Driveline/Axle

{Intermediate Shaft Removal

(cont'dl

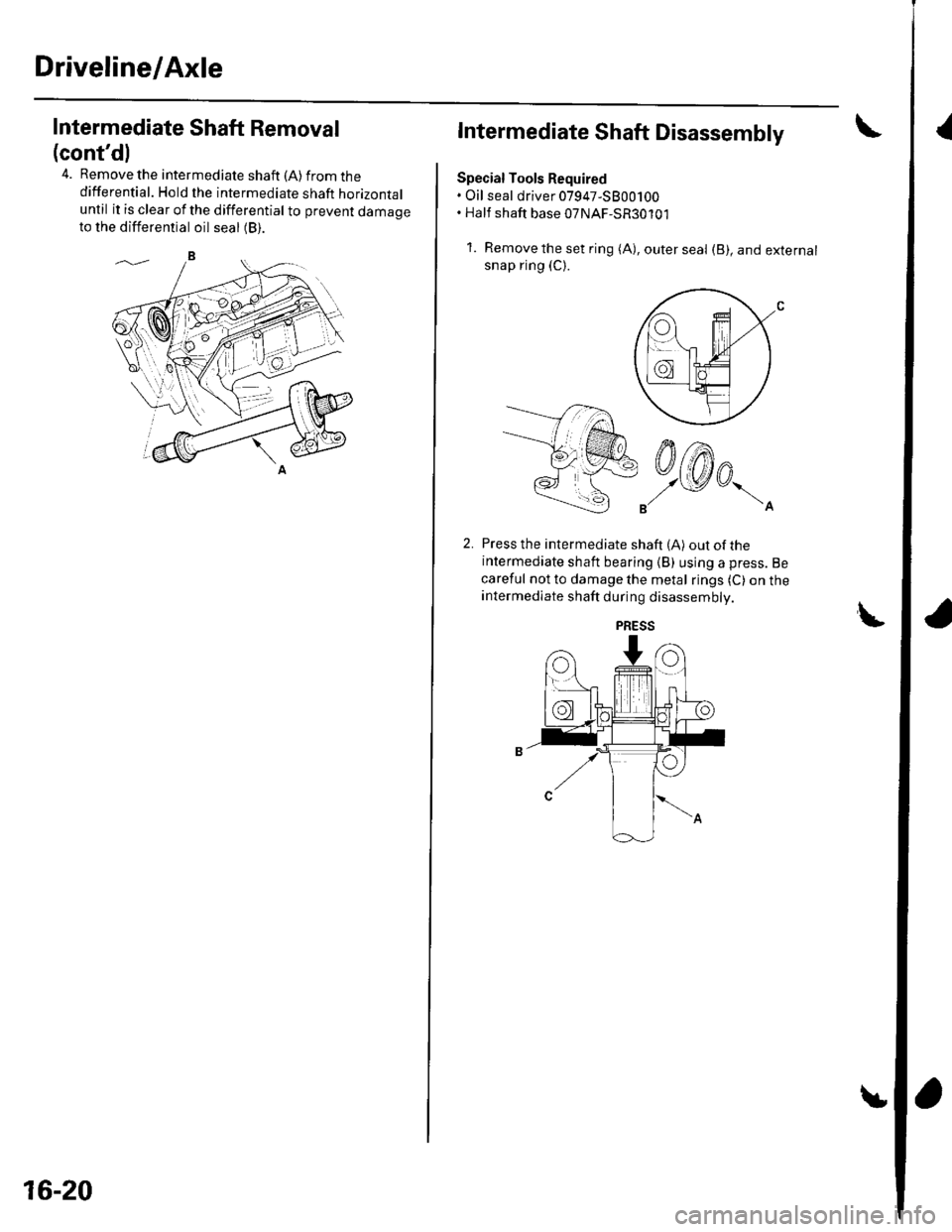

4. Remove the intermediate shaft (A) from thedifferential. Hold the intermediate shaft horizontaluntil it is clear of the differential to prevent damageto the differential oil seal (B).

16-20

Intermediate Shaft Disassembly

Special Tools Required. Oil seal driver 07947-5800100. Half shaft base 07NAF-SR30101

1. Removetheset ring (A), outerseal (B), and externalsnap ring (C).

Press the intermediate shaft (A) out of theintermediate shaft bearing (B) using a press. Be

careful not to damage the metal rings (C) on theintermediate shaft during disassembly.

LPRESS

Page 491 of 1139

Driveline/Axle

Intermediate Shaft Reassembly

(cont'd)

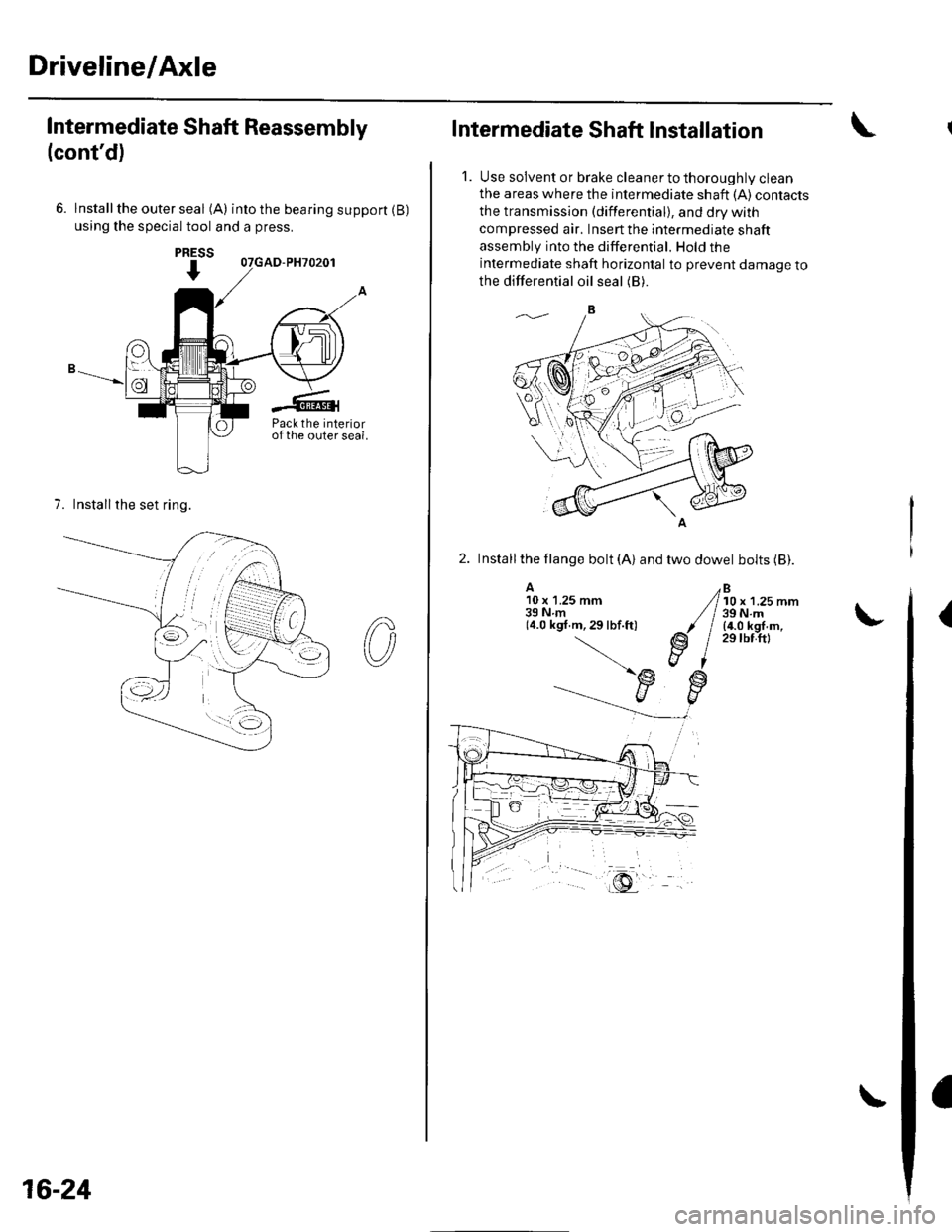

6. lnstallthe outer seal (A) intothebearingsupport(B)

using the special tool and a press.

7. Installthe set ring.

PRESS

I

Pack the interiorofthe outer seal.

16-24

Intermediate Shaft Installation

1. Use solvent or brake cleaner to thoroughly clean

the areas where the intermediate shaft {A) contacts

the transmission (differential), and dry with

compressed air. Insert the intermediate shaft

assembly into the differential. Hold the

intermediate shaft horizontal to prevent damage to

the differential oil seal (B).

2. Installthe llange bolt (A) and two dowel bolts (Bl.

A10 x 1.25 mm39Nm(4.0 kgf.m,29lbf.ft)

Bl0 x 1.25 mm39 N.m(4.0 kgf.m,29 tbf.ftl

(

Page 1134 of 1139

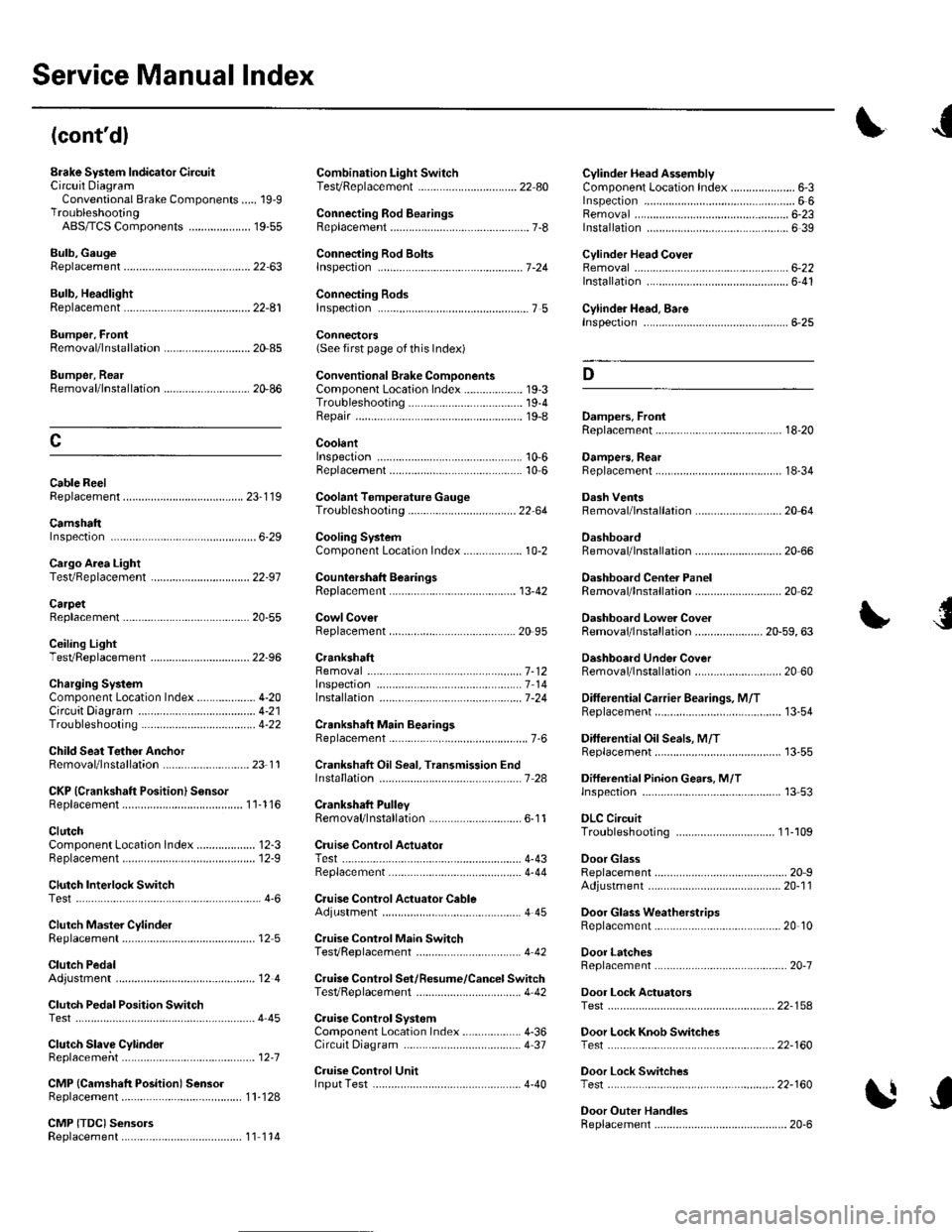

Service Manual Index

(cont'dl

Brake System Indicator CircuitCircuit DiagramConventional Brake Components..... 19-9TroubleshootingABS/TCS Components .... ....... ...... 19-55

Bulb, GeugeRep|acemenl................ .. ............2263

Bulb, HeadlightReplacement ......................................... 22-A1

Bumper, FrontRemoval/1nsra11ation ............................ 20 85

Bumper, RearRemoval/lnstallation... ... . .....20.86

Combination Light SwilchTesVReplacement ..............................22 80

Connecting Rod BearingsRep|acement...................... .......-....7-8

Connecting Rod Boltsf nspection ....................-.-.-.-.................... 7 -24

Connecting RodsInspection ........,,.,.,...,.,.,.,.,,,,.,,,.,.,.,.,.,.,.,.. 7 5

Connectors(See first page of this Index)

Conventional Brake Component3Component Location Index ................... 19'3Troub1eshootin9 ..................................... 19-4

Cylinder Head AssemblyComponent Location Index ..................... 6-3Inspection ................................................. 6 6Removal ..........&�23Insta11alion .............................................. 6 39

Cylinder Head Cover8emova1 ..............-.-................................. 6-22Installation ..............................................6-41

Cylinder Head, BareInspecton..,.....,.

D

c

Cable ReelReplacement....................................... 23-1 19

CamshaftInspection .......................-...-................... 6-29

Cargo Area LightTesVRep1acement ................................ 22-97

CarpetReplacement.....-...-..... ... ......-.20-55

Ceiling Light-estrReplacement ................................ 22.96

Charging SystemComponent Location Index................... 4-20Circuit Diagram ...................................... 4-21

19-8

CoolantInspection .................. ..... .. 106Replacement................. ... . .. 10 6

Coolant Temperature Gat|geTroub1eshootin9................................... 22 64

Cooling SyslemComponent Location Index................... 10-2

Countershaft BearingsReplacement............... ..................... 13-42

Cowl CoverReplacement............... .. ..... ....20-95

CrankshaftRemoval .................................................. 7 -12

Repair ..................

Inspec(on,,,,,........1 14

Dampers. FrontReplacement................ ..................... 18 20

Oampers, RearRep1acement......................................... 18-34

Dash VentsBemoval/lnstallation .-.......................... 20-64

DashboardBemoval/1nsta11ation ............................ 20-66

Oashboard Center PanelRemoval/1nstaf 1ation ............................ 20 62

Dashboard Lower CoverRemoval/lnstallation ...................... 20-59, 63

Dashboard Under CoverRemoval/lnstallation ............................ 20 60

Diff erential Carrier Bearings, M/TRep1acement,,......,...,...,.,.,,,.,.,,,........,.,. 13-54

Ditferential Oil Seals, M/T8ep1acement......................................... 13-55

Differential Pinion Gears, M/TInspection .,....-,.,,,.,..,.-,.,.........,.,.,,, 13 53

OLC CircuitTroubleshooting ................................ 1 1-109

Door GlassRep1acement.,.,,,,,,,,,,,.,,,,,,,,,,.,.,.,.,.,,,,,,.,, 20-9Adjustment. .. .....................20-11

Door Glass WeathelstripsReplacement .............-.. . . . ..........-......20 10

Door LatchesReplacement ..........-.-.............................. 20-7

Door Lock ActuatorsTest ...................................................... 22-154

Door Lock Knob SwitchesTest -......... . . . - . . . . . . . . ......22-160

Door Lock SwitchesTest ........... ............................ ............. 22-160

Door Outer HandlesRep1acemen1 ........................................... 20-6

3

Child Seat Tether AnchorRemoval/lnstaf lat;on .. ........................ 23 11

CKP (Crankshaft Position) SonsorReplacement....................................... 1 1-116

ClutchComponentLocation 1ndex................... 12-3Rep1acemen1........................................... 12-9

Clutch InteYlock SwitchTest.....-........-...-............. ...---.-.......4-6

Clutch Master CylinderReplacement........................................... 12 5

clutch PedalAdjustment ............................................. 12 4

Clutch Pedal Position SwitchTest.,.,,,,,.,,,.,.,,,,,,.,.,,,,,,,,,.,,,,,.. ......445

lnstallation.................. . ..... .....1-24

Crankshalt Main BearingsReplacement........-.-.................................. 7-6

CrankshaftOil Seal,Transmission End1nstanation .............................................. 7 28

Crankshafl PulleyRemoval/lnstallation -..................-.......... 6-1 1

Cruise Control Actuator

Troubleshooting

Clutch Slave CylindorBeplacemeit...

...................... 4-43

.......4-22

Test

12-1

RepIacement........................................... 4-44

Cruise Control Actuator CableAdjustment ............................................. 4 45

Cruise Control Main SwitchTesVRep1acement .................................. 4 42

Cruise Control Set/Resume/Cancel SwitchTesVRep1acement .................................. 4 42

Cruise Control SystomComponent Localion Inde\................... 4-36Circuit Diagram ....-................................. 4 37

Cruise Control UnitInputTest.............................. .. ...4,40CMP {Camshaft Positionl Senso]Replacement....-...-.............................. 1 1-128

CMP (TDC) SensorsReplacement............-.......................... 1 1 1 14

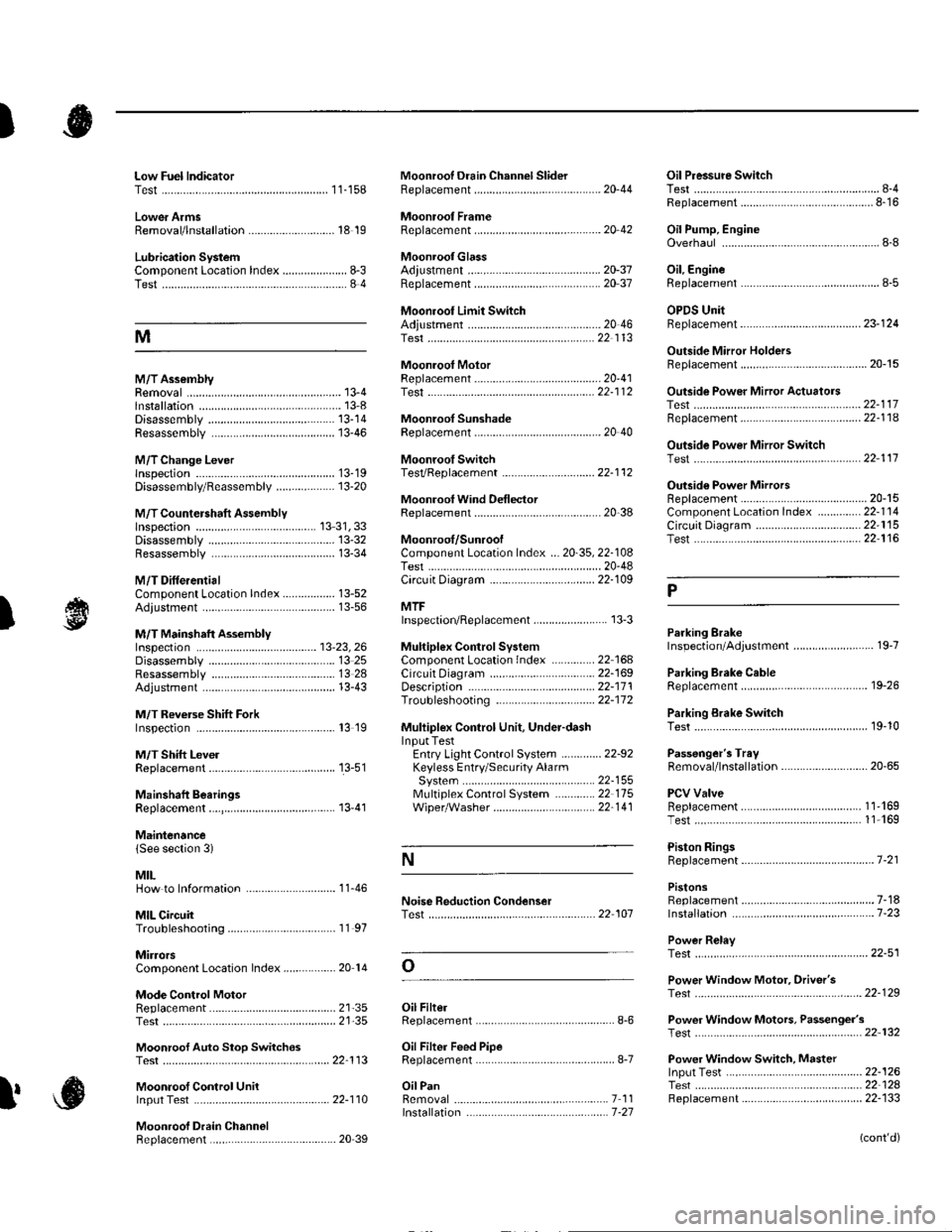

Page 1137 of 1139

)

Low Fuel lndicatorTest.....................11-158Moonroof Drain Channel SliderReplacement......................................... 20'44

Moonroof FrameRep1acement,,,,,,,,,,.,.,.,.,.,.,.,,,,,,............ 20 42

MoonroolGlassAdiustment ........................................... 20-37Rep1acement......................................... 20 37

Moonroot Limit SwitchAdjustment ........................................-.- 20 46Test ...................................................... 22 113

Moonrool MotorReplacement....-.................................... 2D-41

Oil Pressure SwitchTest ................-.-........-................................ 8-4Replacement.........-................................. 8-16

Oil Pump, EngineOverhau1 ................................................... 8-8

Oil, EngineReplacement...-................-.-...................... 8-5

OPDS UnitReplacement....................................... 23- 124

Outside Mirror HoldersBeplacement......................................... 20-15

Outside Power Mirror ActuatorsTest ...................................................... 22-117Bepf acement..-.................................... 22-1 14

Outside Power Mirror SwitchTest ..-................................................... 22-111

Outsid€ Power MirrorsReplacement............................ ... .. . . . 20-15Component Location lndex .............. 22- 114Circuit Diagram .................................. 22-115Test -..................................................... 22-116

Lower ArmsRemoval/1nsta11ation............................ 18 19

Lubrication SystemComponent Location Index..................... 8-3Test............................................................ 8 4

M

M/TAssemblyRemoval.......... 13-4 Test...................... 22-1 12lnstallation............. 13-8

.........21,35

Disassembly ......................................... 13-14Resassembly .. ... ................. 13-46

M/TChange Leverlnspection ............................................. 13-19Disassembly 8eassemb1y ................... 13-20

M/T Countershaft AssemblyInspection ....................................... 13 31, 33Disassemb1y ......................................... 13-32Resassemb|y ........................................ 13-34

M/T DifferentialComponentLocation Index................. 13-52Adiuslment ........................................... 13-56

M/T Maifthaft Assembly1nspection ... ................................... 13-23, 26Disassembly ......................................... 13 25Resassembly ........................................ 13 28Adjustment ........................................... 13-43

M/T Reverse Shift ForkInspection .................... ........................ l3 19

M/T Shift LevelReplacement......................................... 13-51

Mainshaft BearingsReplacement....,.................................... 13 41

MairtenancelSee section 3)

MILHow to Informatron ............................. 1 1.46

MIL CircuitTroubleshooting .......... .- . . . . ......... 11 97

MirrorsComponentLocation Index................. 20'14

Mode Control MotorReplacement

Moonrool SunshadeRep1acement....................... . . ............. 20 40

Moonroof SwitchTesVRep1acement .............................. 22- l 12

Mooniool Wind Def lectorReplacement.......................-................. 20-38

Moonroof/SunroofComponent Location Index ... 20-35, 22-108Test ........................................................ 20-48Cf rcuit Diagram .................................. 22- 109

MTFInspection/Rep1acement. .......... ........... 13-3

Muhiplex Control SystemComponentLocation lndex ..............22 168Circuit Diagram .................................. 22-1690escription ......................................... 22-17 1Troubleshooting ................................ 22-17 2

Muliiplex Control Unit, Under-dashInput TestEntry Light Control Sysiem ............. 22-92Keyless Entry/Security AlarmSystern .-....................................... 22-155MultiplexControl System .............22 115Wiper/Washer................................. 22'1 41

NoiseTest,,Reduction Condenser

Parking ErakeInspection Adjustment ........... .............. 19-7

Parking Brake CableRep1acement......................................... 19-26

Parking Erake Switch

P

l

Test ...................... 19-10

Test............................... . ...........2135

Moonroof Auto Stop SwitchosTest ...................................................... 22'113

Moon.oot Control Unillnput Test ............................................ 22-110

Moonroof Drein ChannelBeplacement ... . ....... ......................... 20 39

Oil Filte]Replacement............................................. 8-6

Oil Filter Feed PipeReplacement............... . ..-,...,.,,,,,,,,8-7

Oil PanRemoval .............,.,,,,,,,,,,,,.,.,,,.........-....... 7 1 1lnstallation .............................................. 7 -27

Passenger's TraVRemoval/lnstallation ............................ 20-65

PCV ValveBeplacement....................................... 1 1'169Test........................................... l1 169

Piston Rings8ep1acement................................-.-...-.- 7-21

PistonsReplacement...................-....................... 7-181nsta|1ation ...................................... ...1-23

Power R€layTest ...............-.-...................................... 22-51

Power Window Motor, Driver'stesl.....,,,, .,.,,,............

Power Window Motors, Passenger's

Power Window Switch, Masterlnput Test ..........-.........-....................... 22-126Tesr ....... . ............................................ 22 124Replacement....................................... 22-133

N

..............22 101

o

l' ,e

(cont'd)