fuse panel HONDA CIVIC 2002 7.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 2002, Model line: CIVIC, Model: HONDA CIVIC 2002 7.GPages: 1139, PDF Size: 28.19 MB

Page 895 of 1139

Gauges

2.

3.

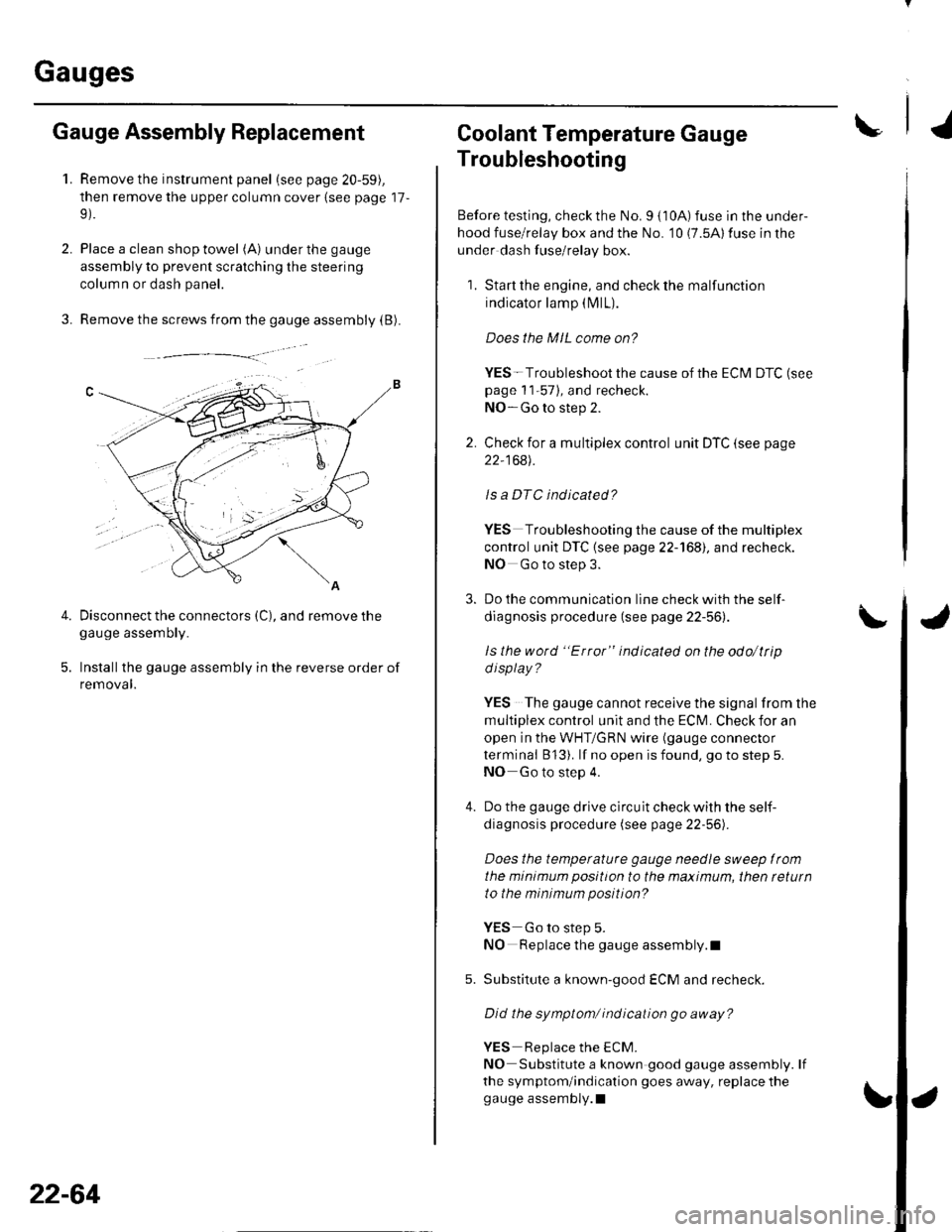

Gauge Assembly Replacement

1.Remove the instrument panel (see page 20-59),

then remove the upper column cover {see page 17-

Place a clean shop towel (A) under the gauge

assembly to prevent scratching the steering

colum n or dash panel.

Remove the screws from the gauge assembly (B).

Disconnect the connectors (C), and remove thegauge assemDry.

Installthe gauge assembly in the reverse order of

removal.

Coolant Temperature Gauge

Troubleshooting

Before testing, check the No. I { 10A) fuse in the under-

hood fuse/relay box and the No. '10 (7.5A) fuse in the

under dash fuse/relay box.

1. Start the engine, and check the malfunction

indicator lamp (MlL).

Does the MIL come on?

YES- Troubleshoot the cause of the ECM DTC (see

page 1 1-57), and recheck.

NO-Go to step 2.

2. Check for a multiplex control unit DTC (see page

22,168).

ls a DTC ind icated?

YES Troubleshooting the cause of the multiplex

control unit DTC {see page 22-168), and recheck.

NO Go to step 3.

3. Do the communication line check with the self-

diagnosis procedure (see page 22-56).

ls the word "Error" indicated on the odo/ttip

d isplay ?

YES The gauge cannot receive the signal from the

multiplex control unit and the ECI\,4. Check for an

open in the WHT/GRN wire (gauge connector

terminal B 13). lf no open is found, go to step 5.

NO Go to step 4.

4. Do the gauge drive circuit check with the self-

diagnosis procedure (see page 22-56).

Does the temperature gauge needle sweep lrom

the minimum position to the maximum, then tetutn

to the minimum position?

YES Go to step 5.

NO Replace the gauge assembly.l

5. Substitute a known-good ECM and recheck.

Did the symptom/ ind ication go away?

YES Replace the ECM.

NO Substitute a known good gauge assembly. lf

the symptom/indication goes away, replace thegauge assembly.l

4.

22-64

Page 935 of 1139

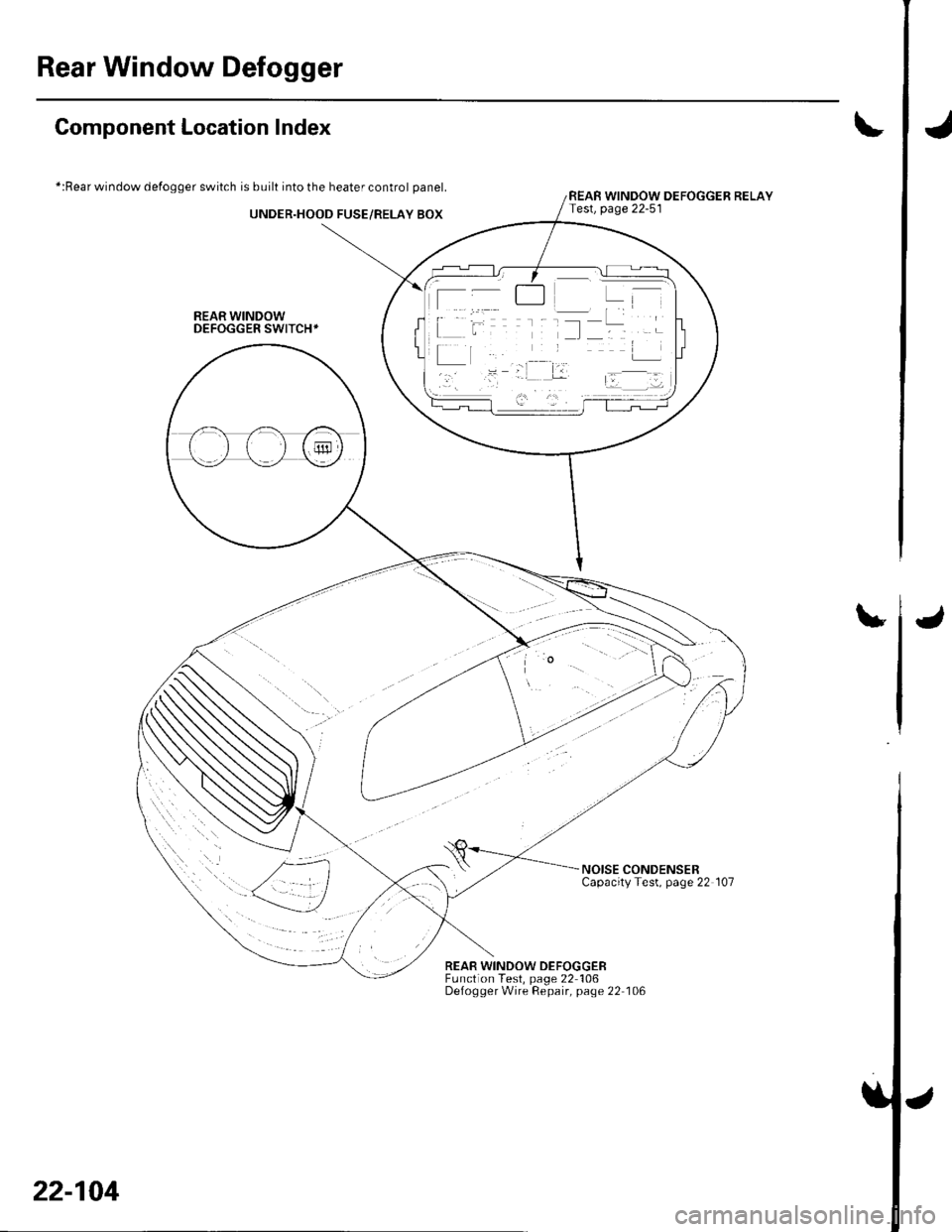

Rear Window Defogger

J

I

Component Location Index

*:Rear window defogger switch is built into the heater control panel.

UNDER.HOOD FUSE/RELAY BOX

REAR WINDOWDEFOGGER SWITCH+

t

REAR WINDOW DEFOGGER RELAYTest, page 22-51

u

NOISE CONDENSERCapacityTest, page 22 107

REAR WINDOW DEFOGGEBFunction Test, page 22 106Defogger Wire Repair, page 22 106

22-104

J

Page 937 of 1139

Rear Window Defogger

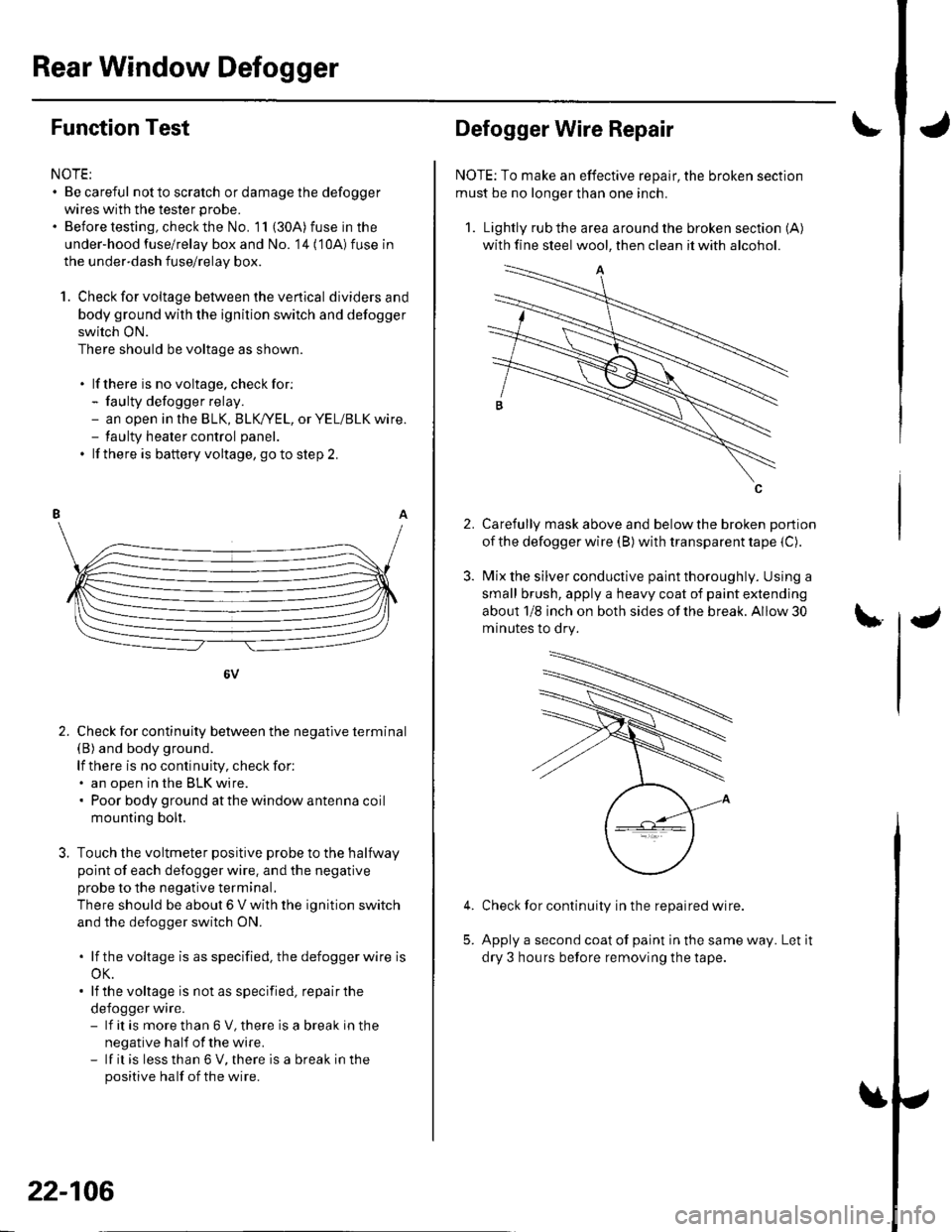

Function Test

NOTE:. Be careful not to scratch or damage the defogger

wires with the tester probe.

. Before testing, check the No. 11 (30A) fuse in the

under-hood fuse/relay box and No. '14 ('10A) fuse in

the under-dash fuse/relay box.

1. Check for voltage between the ve rtica I dividersand

body ground with the ignition switch and defogger

switch ON.

There should be voltage as shown.

. lf there is no voltage. checkfor:- faulty defogger relay.- an open in the BLK, BLK,/YEL, or YEL/BLK wire.- taulty heater control panel.

. lf there is battery voltage, goto step 2.

6V

Check for continuity between the negative terminal(B) and body ground.

lf there is no continuity, check for:. an open in the BLK wire.. Poor body ground at the window antenna coil

mounting bolt.

Touch the voltmeter positive probe to the halfway

point of each defogger wire. and the negative

probe to the negative terminal,

There should be about 6 V with the ignition switch

and the defogger switch ON.

. lf thevoltage is asspecified, the defoggerwlre is

oK.. lf the voltage is not as specified, repair the

defogger wire.- lf it is more than 6 V, there is a break in the

negative half of the wire.- lf it is less than 6 V, there is a break in the

positive half of the wire.

2.

22-106

2.

Defogger Wire Repair

NOTE: To make an effective repair, the broken section

must be no longer than one inch.

1. Lightly rub the area around the broken section (A)

with fine steel wool, then clean it with alcohol.

Carefully mask above and below the broken portion

of the defogger wire (B) with transparent tape {C).

Mix the silver conductive paint thoroughly. Using a

small brush, apply a heavy coat of paint extending

about 1/8 inch on both sides of the break. Allow 30

minutes to dry.

Check for continuity in the repaired wire.

Apply a second coat of paint in the same way. Let it

dry 3 hours before removing the tape.

5.

Page 961 of 1139

Power Windows

1.

2.

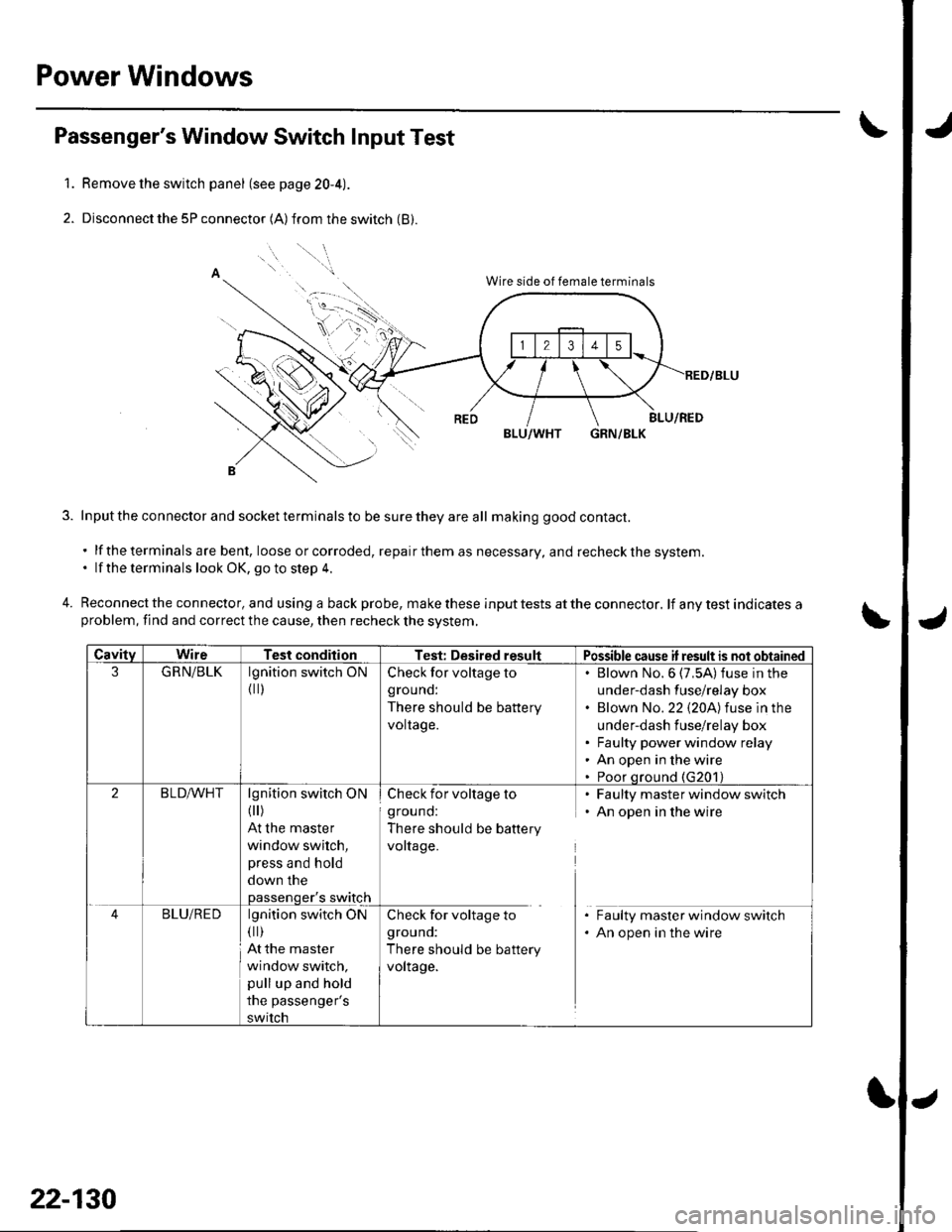

Passenger's Window Switch Input Test

Remove the switch panel (see page 20-4).

Disconnect the 5P connector (A) from the switch (B).

o

'' "'"1.

4.

Wire side of female terminals

BLU/WHTGRN/BLK

Input the connector and socket terminals to be sure they are all making good contact.

. lf theterminals are bent, loose or corroded, repairthem as necessary, and recheckthe system.. lf the terminals look OK, go to step 4.

Reconnect the connector, and using a back probe, make these input tests at the connector. lf any test indicates aproblem, find and correct the cause, then recheck the svstem,

CavitvWireTest conditionTest: Desired resultPossible cause if result is not obtained

3GRN/BLKlgnition switch ON

{ ll)

Check for voltage to

grouno:

There should be battery

voltage.

Blown No.6 (7,5A)fuse in the

under-dash fuse/relay box

Blown No.22 {20A)fuse in the

under-dash fuse/relay box

Faulty power window relay

An open in the wire

Poor qround (G201)

2BLD,A/VHTlgnition switch ON( )

At the master

window switch,

press and hold

down the

passenger's switch

Check for voltage to

ground:

There should be battery

voltage.

Faulty master window switch

An open in the wire

BLU/REDlgnition switch ON(||)

At the master

window switch,

pull up and hold

the passenger's

switch

Check for voltage to

grouno:

There should be battery

voltage.

Faulty master window switch

An open in the wire

22-130

Page 1135 of 1139

)

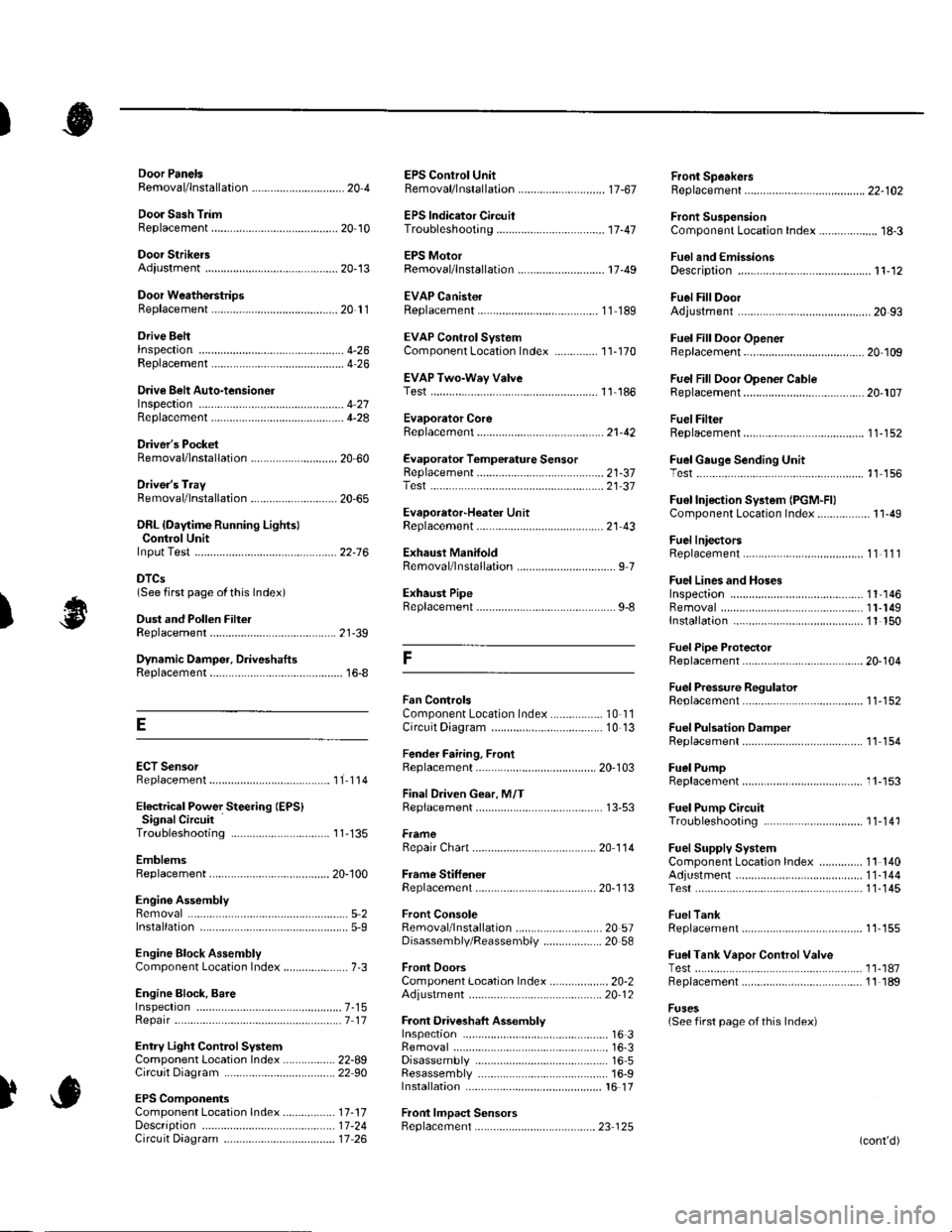

Orive BehInspecaron................ 4-26

Door PanelsRemoval/lnstallation -............................. 20-4

Door Sash TrimRep1acement......................................... 20 10

Door StrikersAdiustment ........................................... 20-13

Door Weatherst psBeplacement...........-............................. 20 1 1

EPS Conirol UnitRemoval/1nsta11ation ..................-......... 17-67

EPS Indicator CircuitTroubleshooting ................................... 17 -47

EPS MotorRemoval/lnstallation .-.......................... 17-49

EVAP CanisterRep1acement......................... ......... 11,189

EVAP Control Syst€mComponentLocation Index ..............'11-170

EVAP Two-Wey ValveTest ..........-.............-............................ 11 186

Evaporetor CoreRep1acement........................ . ... 21-42

Evaporator Tomperature SensorReplacement......................................... 21 -37Test..................................... ..........2137

EvaporrtoFHeater UnitReplacement........................................ 21 43

Exhaust ManifoldRemoval/1nsta11ation ................................ I 7

Exhaust Pipe8ep|acement............................................. 9-8

Front SpeakersRep|acement....................................... 22-102

Front SuspensionComponentLocation Index................... 18-3

Fueland EmissionsDescription ........................................... 11-12

Fuel Fill DoorAdjustment ..........-................................ 20 93

Fuel Fill Door OpenetBeplacement........................ . ............ 20.109

Fuel Fill Door Opener CableReplacement....................................... 20- lO7

Fuel FilterReplacement....................................... 1 1-152

Fuel Gauge Sending UnitTest ......................-.-..........-.................. 11'156

Fuel Injection Syslem (PGM"FIlComponent Location 1ndex................. 11-49

Fuel IniectorsRep1acemen1....................................... 1 1 1 1 l

Fuel Lines and HosesInspection .......................................... 1 1'146Removal ....................... . .. . .... 11-149Insta|1ation .......................................... 1 1 150

FuelPipe ProtectolReplacement....................................... 20-104

Fuel Pressure RegulatotReplacement....................................... 1 1-152

Fuel Pulsation DamperReplacemenl................................... 11 154

Fuel PumpReplacement,,,,,.,.,.,,,.,,,,,,,,,,,,.,.,.,,,..,.. 11-153

Fuel Pump CircuitTroubleshooting -.......-....................... 1 1-141

FuelSupply SystemComponent Location lndex .............. 11 140Adjustment................................... 11-144Test........-...-................. ... ............- 11-145

FuelTankBeplacemenl.............. . ..... .. 11 155

Fuel Tank Vapor ControlValveTest ......................-....... ... . . 11-187Replacement,,.,,...,.,,,.,.,,,,... .. .. 11 189

Fuses{See first page ofthis Index)

)

Rep|acement................. ..................... 4 26

Drive Belt Auto-tensionellnspection ............................................... 4 21Rep1acement.................................... ..4-28

Driver's PocketRemoval/lnstallation -........................... 20-60

Driver's TrayRemoval/lnstallation .........................-.- 20-65

DRL {Daytime Running LightslControl Unitlnput Test .................... ........ . . . ......22-16

DTCs(See first page olthis Index)

Dust and Pollen FillerReplacement......................................... 21-39

Dynamic Damper, DriveshaftsReplacement........................................... 16-8

ECT SensorReplacement.,.,,,.,.,,,,,,,,,,,,,,................ 1 1-1 14

El€ctrical Power Steering IEPS)Signal CircuitTroubleshooting ........ ... .. 11-135

EmblemsReplacement......................-................ 20-100

Engine AssemblyRemova1 .................................................... 5 2Installation ............._.................................. 5-9

Engine Block AssemblyComponent Location Inder ..................... 7.3

Engine Block, BareInspect|onRepair

Fan ControlsComponent Location Index................. 10'l 1Circuit Diagram .. ..... . .. . .................. 10 13

Fender Fairing, FrontReplacement...-................................... 20-103

Final Driven Gear. M/TReplacement.... . . ................................ 13-53

FrameRepair Chan............ ... ....................... 20 11 4

Frame StiffenelReplacement......-................................ 20- J'13

Front ConsoleRemoval/lnstallation ............................ 20 5lDisassembJy/Reassemb|y ................... 20 58

Front DoorsComponent Location Index................... 20-2Adiustment ........................................... 20.12

Front Driveshaft AssemblyInspeclion .................... ... ....16 3Remova1...................-...... ... .....16-3Disassembly ............................... .....165Resassemb|y ................................-......... 16-9Insta11arion ........................ ...... ............ l6 17

Front lmpact SensorsRep1acement............................ ...23 125

................7-15................1 11

)

Entry Light Control SystemComponent Location Index ...............-. 22-89Circuit Dia9ram .................................... 22 90

EPS ComponentsComponent Location 1ndex..........-...... 17-!7Description ........................ ...... ..17-24Circuit Diagram11 26(cont'd)