light HONDA CIVIC 2002 7.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 2002, Model line: CIVIC, Model: HONDA CIVIC 2002 7.GPages: 1139, PDF Size: 28.19 MB

Page 105 of 1139

Gylinder Head

IValve Clearance Adjustment (cont'd)

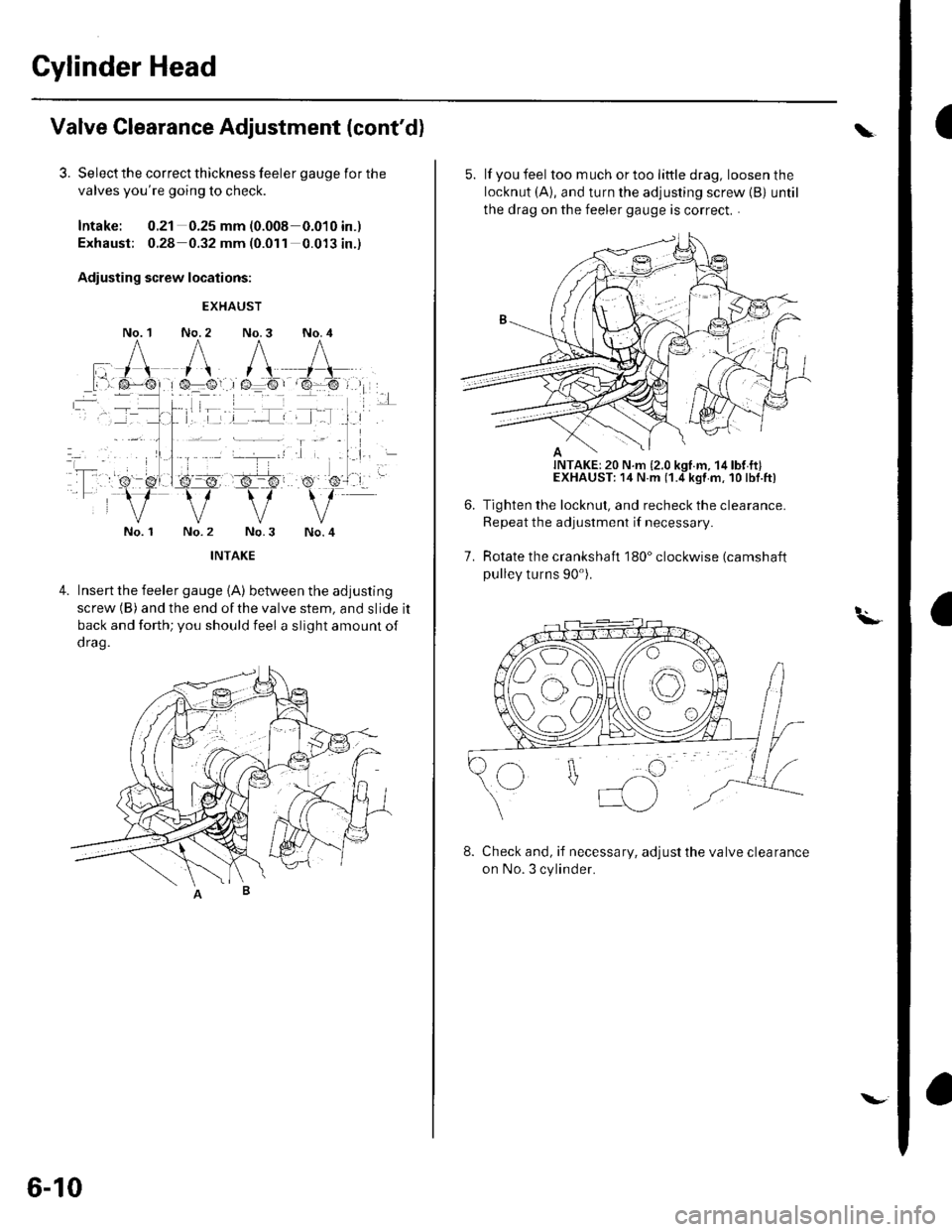

3. Select the correct thickness feeler gauge for the

valves you're going to check.

Intake: 0.21 0.25 mm (0.008-0.010 in.)

Exhaust; 0.28 0.32 mm (0.011 0.013 in.)

Adiusting screw locations:

No. 1

EXHAUST

No. 2 No.3 No. 4

No. 1No.4

4.Insert the feeler gauge {A) between the adjusting

screw (B) and the end ofthe valve stem, and slide it

back and forth; you should feel a slight amount of

d rag.

6-10

\.

5. lf you feel toomuchortoolittledrag, loosenthe

locknut (A), and turn the adjusting screw {B) until

the drag on the feeler gauge is correct. .

Tighten the locknut, and recheck the clearance.

Repeat the adjustment if necessary

Rotate the crankshaft 180" clockwise (camshaft

pulley turns 90').

7.

t.\-

8. Check and, if necessary, adjust the valve clearance

on No. 3 cylinder.

Page 126 of 1139

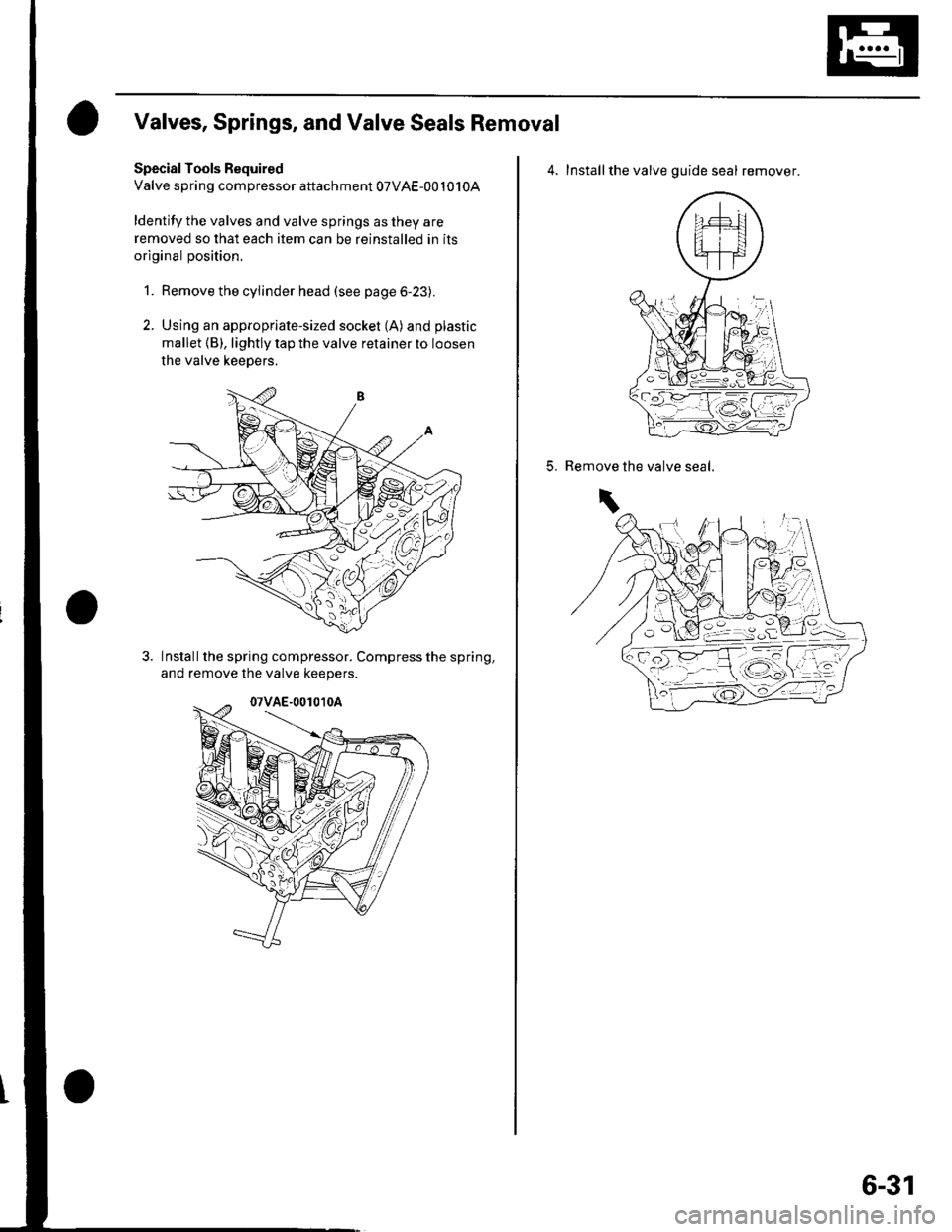

Valves, Springs, and Valve Seals Removal

Special Tools Bequired

Valve spring compressor attachment 07VAE-001010A

ldentify the valves and valve springs as they are

removed so that each item can be reinstalled in its

original position.

1. Remove the cylinder head (see page 6-23).

2. Using an appropriate-sized socket (A) and plastic

mallet {B), lightly tap the valve retainer to loosen

the valve keepers.

Install the spring compressor. Compress the spring,

and remove lhe valve keepers.

4. Installthe valve guide seal remover.

5.the valve seal.Remove

\

6-31

Page 130 of 1139

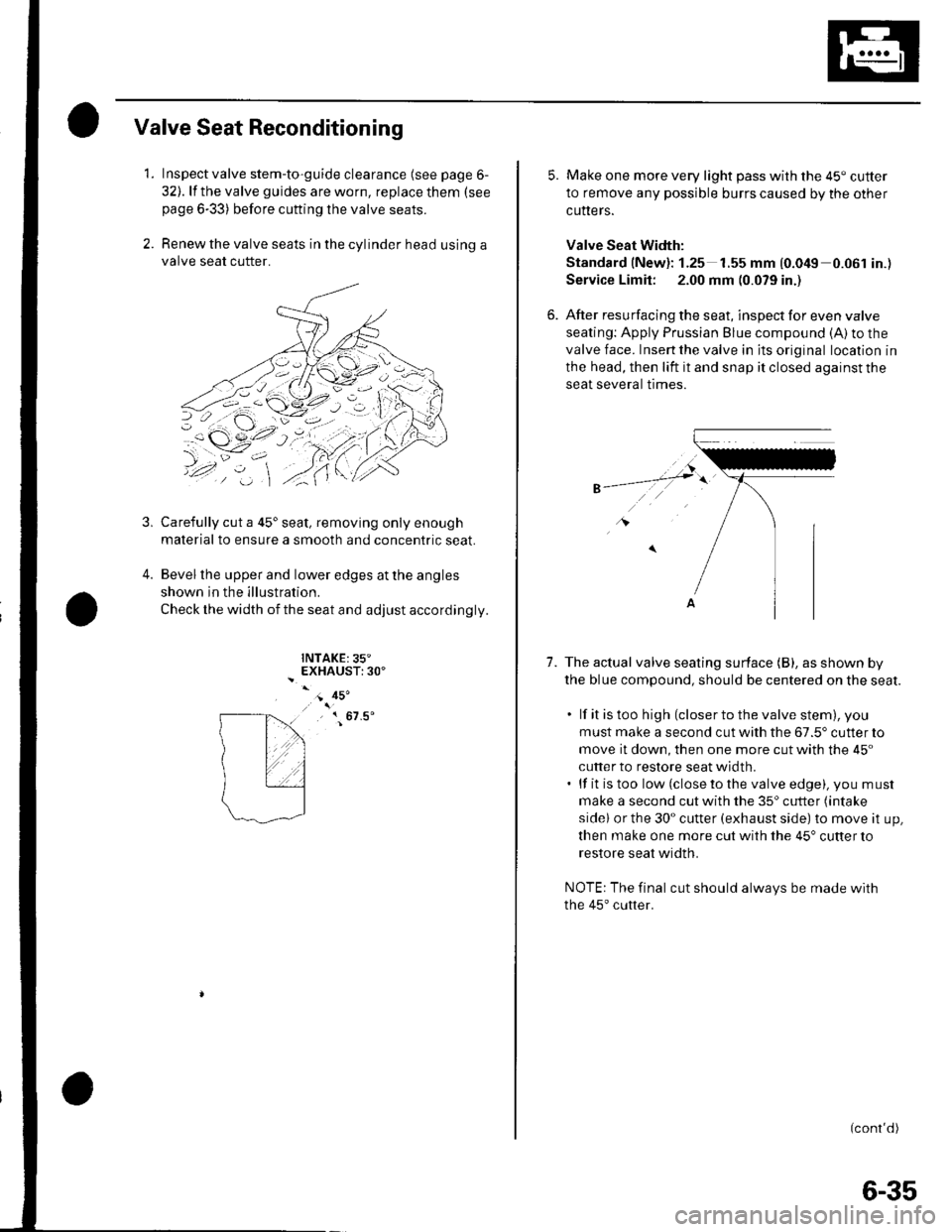

Valve Seat Reconditioning

1. Inspect valve stem-to-guide clearance (see page 6-

32). lf the valve guides are worn, replace them (see

page 6-33) before cutting the valve seats.

2. Renew the valve seats in the cylinder head using a

valve seat cutter.

Carefully cut a 45'seat, removing only enough

material to ensure a smooth and concentric seat.

Bevel the upper and lower edges at the angles

shown in the illustration.

Check the width of the seat and adjust accordingly.

INTAKE:35"EXHAUST:30'

3,

4.

- 45'

, { 67.5'

5. Make one more very light pass with the 45" cutter

to remove any possible burrs caused by the other

cutters.

Valve Seat Width:

Standard (New): 1.25 1.55 mm {0.049 0.061 in.)

Service Limit: 2.00 mm (0.079 in.)

6. After resurfacing the seat, inspect for even valve

seating: Apply Prussian Blue compound (A) to the

valve face. Insert the valve in its original location in

the head, then lift it and snap it closed against the

seat several trmes.

1.The actual valve seating surface (B), as shown by

the blue compound, should be centered on the seat.

. lf it is too high (closer to the valve stem), you

must make a second cut with the 67.5' cutter to

move it down, then one more cut with the 45"

cutter to restore seat width.. lf it is too low (close to the valve edge), you must

make a second cut with the 35'cutter (intake

sidel or the 30" cutter (exhaust side) to move it up,

then make one more cut with the 45" cutter to

restore seat width.

NOTE: The final cut should always be made with

the 45'cutter.

(cont'd)

6-35

Page 132 of 1139

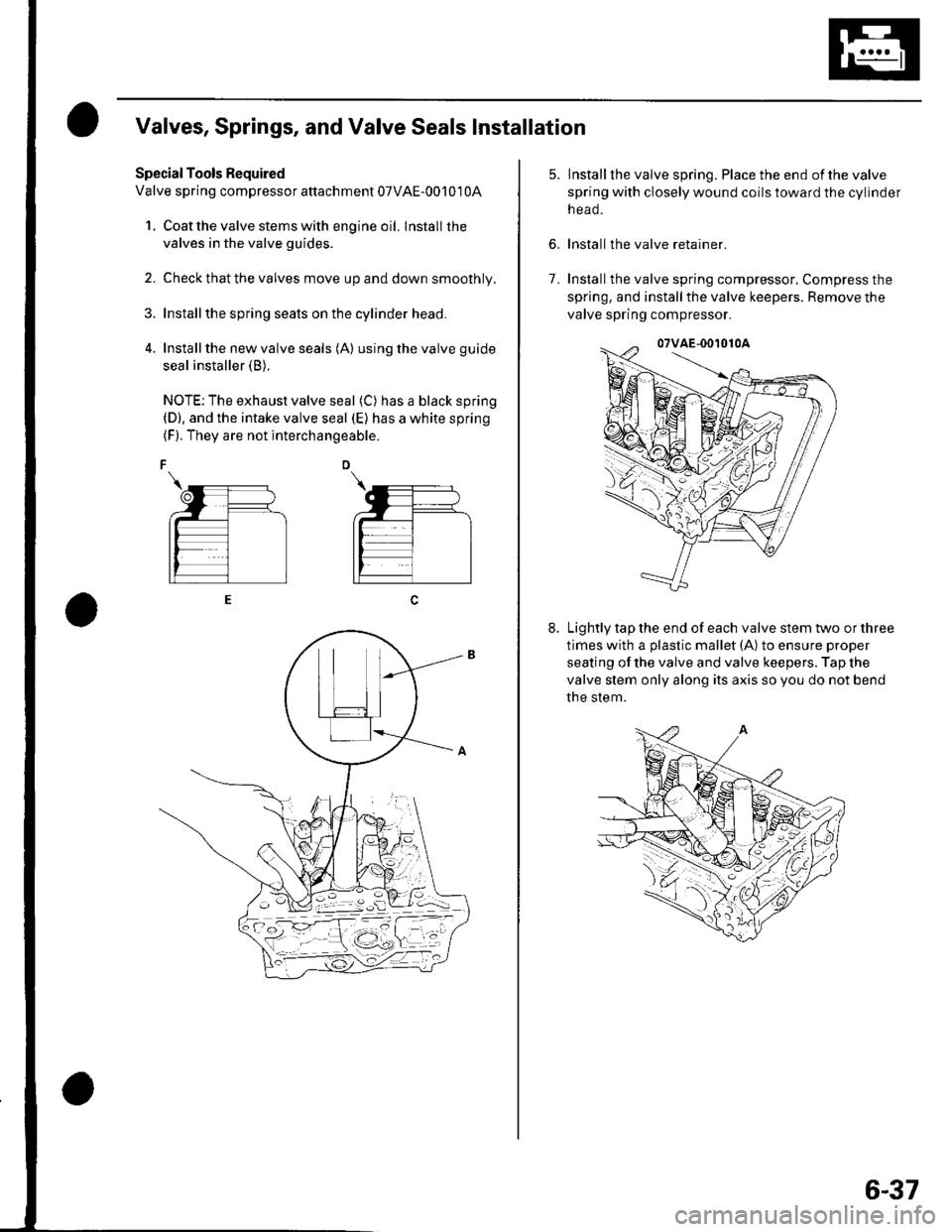

Valves, Springs, and Valve Seals Installation

Special Tools Required

Valve spring compressor attachment 07VAE-00101 0A

1. Coat the valve stems with engine oil. lnstall the

valves in the valve guides.

2. Check that the valves move up and down smoothly.

Installthe spring seats on the cylinder head.

Install the new valve seals (A) using the valve guide

seal installer (B).

NOTE: The exhaust valve seal (C) has a black spring(D), and the intake valve seal (E) has a white spring(F). They are not interchangeable.

6.

lnstallthe valve spring. Place the end ofthe valve

spring with closely wound coils toward the cylinder

n eao.

Install the valve retainer.

Installthe valve spring compressor, Compress the

spring, and install the valve keepers. Remove the

valve spring compressor.

Lightly tap the end of each valve stem two or three

times with a plastic mallet (A) to ensure proper

seating of the valve and valve keepers. Tap the

valve stem only along its axis so you do not bend

the stem.

7.

6-37

Page 137 of 1139

Gylinder Head

Cylinder Head Gover Installation (cont'd)

Set the spark plug seals (A) on the spark plug tubes.

Once the cylinder head cover (B) is on the cylinderhead, slide the cover slightly back and forth to seat

the head cover gasket.

Inspect the cover washers (C). Replace any washer

that is damaged or deteriorated.

6-42

7. Tighten the bolts in two or three steps. In the final

step, tighten all bolts, in sequence, to 9.8 N.m (1.0

kgf.m, 7.2 lbf.ft).

8. Install the dipstick (A) and breather hose iB).

\

\l'

Page 155 of 1139

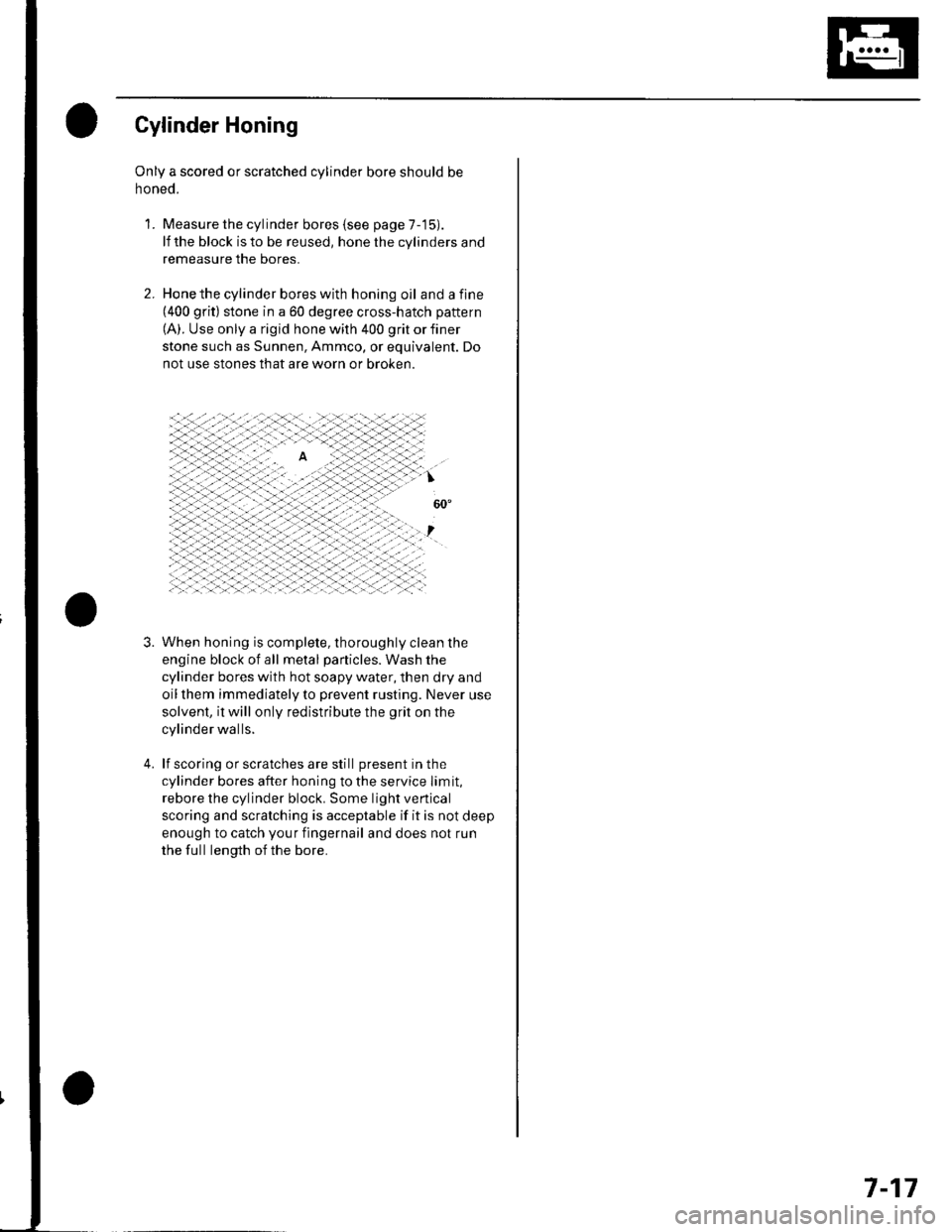

Cylinder Honing

Only a scored or scratched cylinder bore should be

noneo.

Measure the cylinder bores {see page 7-15).

lf the block is to be reused, hone the cylinders and

remeasure the bores.

Hone the cylinder bores with honing oil and a fine(400 grit) stone in a 60 degree cross-hatch pattern

(A). Use only a rigid hone with 400 grit or finer

stone such as Sunnen, Ammco, or equivalent. Do

not use stones that are worn or broken.

When honing is complete, thoroughly clean the

engine block of all metal particles. Wash the

cylinder bores with hot soapy water, then dry and

oil them immediately to prevent rusting. Never use

solvent, it will only redistribute the grit on the

cylinder walls.

lf scoring or scratches are still present in the

cylinder bores after honing to the service limit,

rebore the cylinder block. Some light vertical

scoring and scratching is acceptable if it is not deep

enough to catch your fingernail and does not run

the full length of the bore.

'L

3.

7-17

Page 172 of 1139

Engine Lubrication

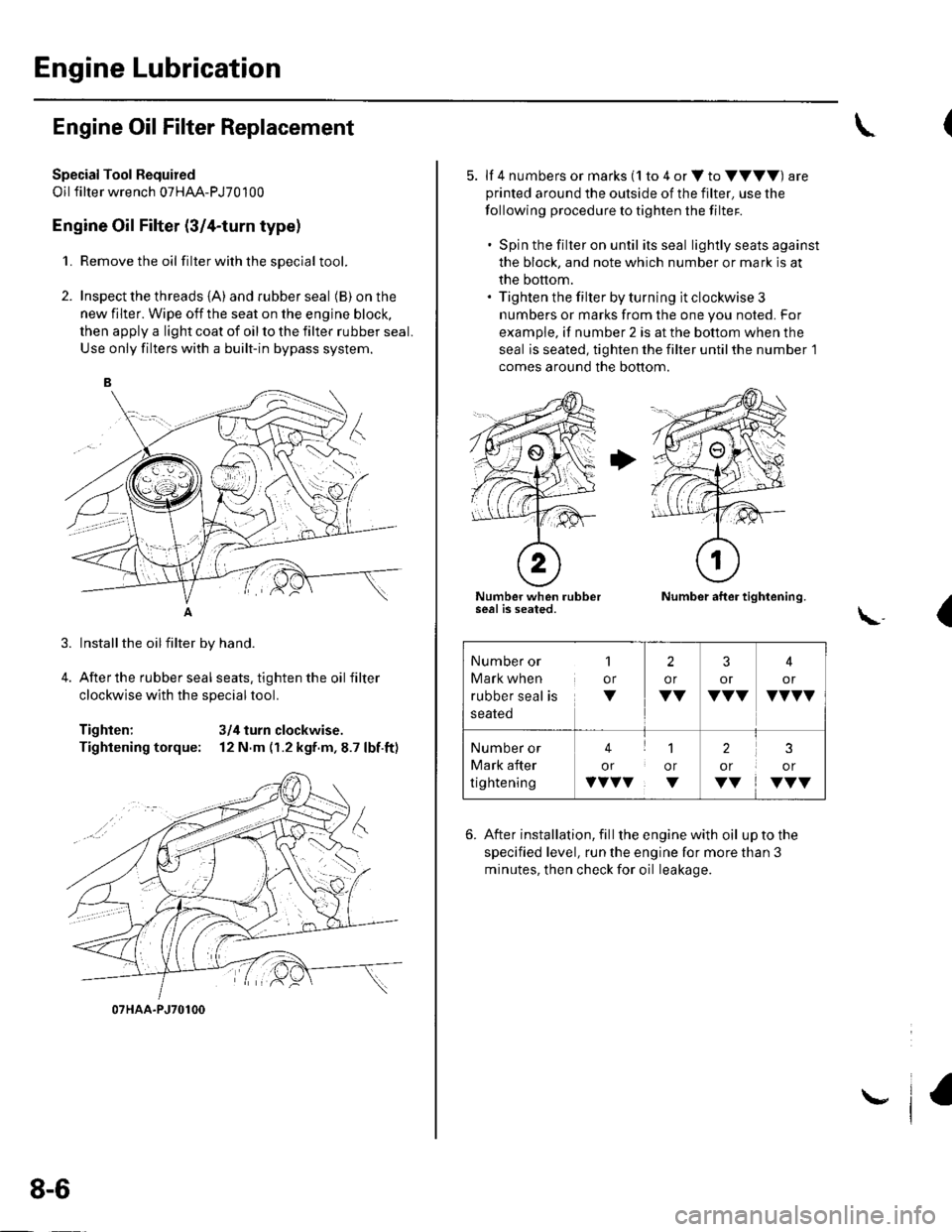

Engine Oil Filter Replacement

Special Tool Fequired

Oil filter wrench 07HAA-PJ70100

Engine Oil Filter (3/4-turn type)

1. Remove the oil filterwiththesDecial tool.

2. Inspect the threads {A) and rubber seal (B) on the

new filter. Wipe off the seat on the engine block,

then apply a light coat of oil to the filter rubber seal.

Use only filters with a built-in bypass system.

Installthe oilfilter by hand.

After the rubber seal seats, tighten the oil filter

clockwise with the special tool.

Tighten: 3/4 turn clockwise.

Tightening torque: 12 N.m (r.2 kgf.m,8.7 lbf.ft)

07HAA-PJ70100

8-6

\,

5. lf 4 numbers or marks (1 to 4 or V to VVVV) are

printed around the outside of the filter, use the

following procedure to tighten the filter.

. Spin the filter on until its seal lightly seats against

the block, and note which number or mark is at

the bottom.. Tighten the filter by turning it clockwise 3

numbers or marks from the one you noted. For

example, if number 2 is at the bottom when the

seal is seated, tighten the filter until the number 1

comes around the bottom.

Number when rubberseal is seated.Number after tightening.

(\..

6. After installation, fill the enginewith oil uptothe

specified level, run the engine for more than 3

minutes, then check for oil leakage.

Number or

Mark when

rubber seal is

1

or

V

2

or

VV

3

or

VVV

4

or

VVVV

Number or

Mark after

tightening

41

or or

vvvv. v

2

or

VV

3

or

VVV

Page 213 of 1139

Fuel and Emissions Systems

General Troubleshooting Information (cont'd)

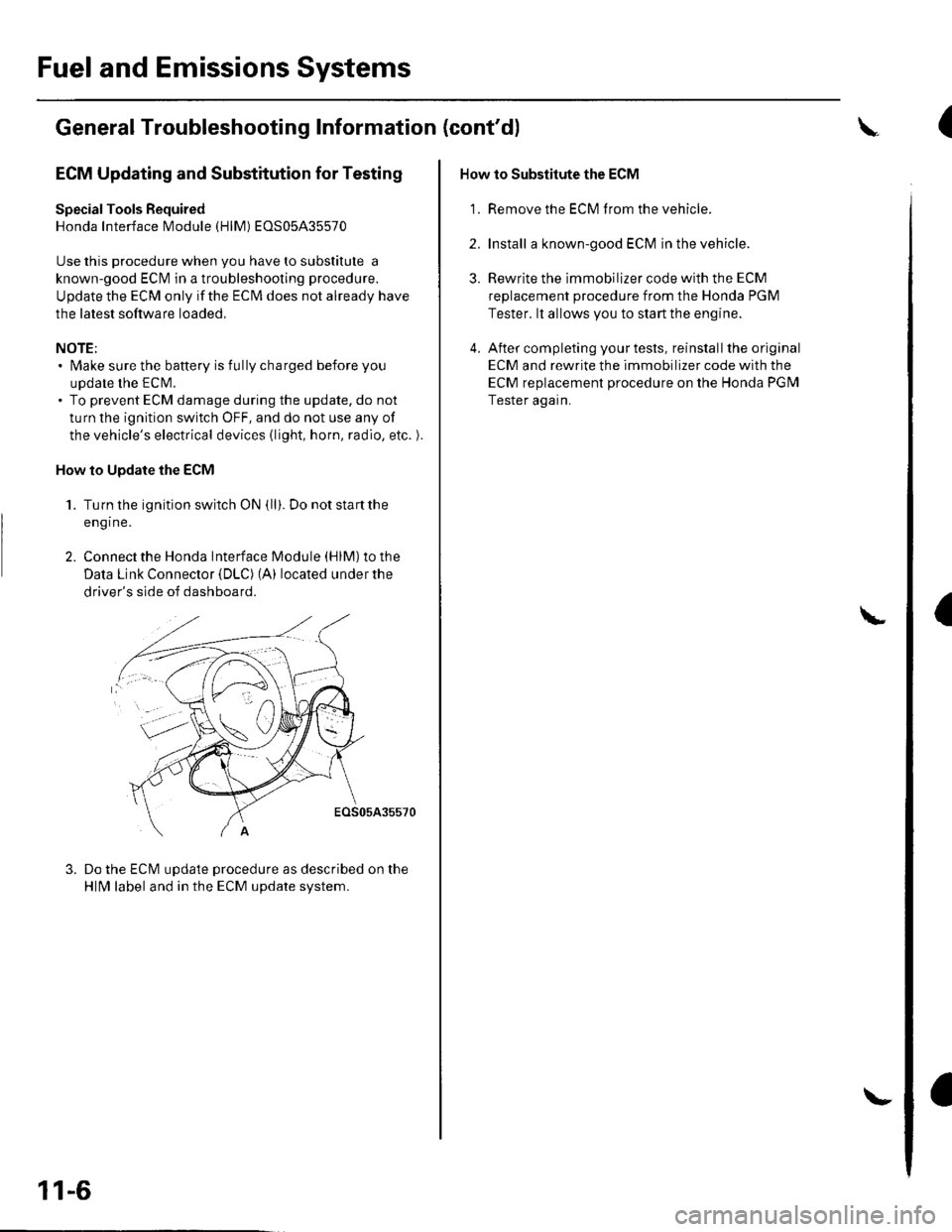

ECM Updating and Substitution for Testing

Special Tools Bequired

Honda Interface Module (HlM) EOS05435570

Use this procedure when you have to substitute a

known-good ECM in a troubleshooting procedure.

U pdate the ECM only if the ECN4 does not already have

the latest software loaded,

NOTE;. lMake sure the battery is fully charged before you

update the ECN4.. To prevent ECM damage during the update, do not

turn the ignition switch OFF, and do not use any of

the vehicle's electrical devices (light, horn, radio, etc. ).

How to Update the ECM

1. Turn the ignition switch ON (ll). Do not startthe

eng Ine.

2. Connect the Honda lnterface Module (HlM) to the

Data Link Connector {DLC) (A) located under the

driver's side of dashboard.

EOS05A35570

Do the ECM update procedure as described on the

HlN4 label and in the ECM update system.

11-6

\-

How to Substitute the ECM

'1. Remove the ECM f rom the vehicle.

2. Install a known-good ECM in the vehicle.

3. Rewrite the immobilizer code with the ECM

replacement procedure from the Honda PGM

Tester. lt allows you to start the engine.

4. After completing your tests, reinstall the original

ECM and rewrite the immobilizer code with the

ECM replacement procedure on the Honda PGM

Tester again.

L

(

I

Page 236 of 1139

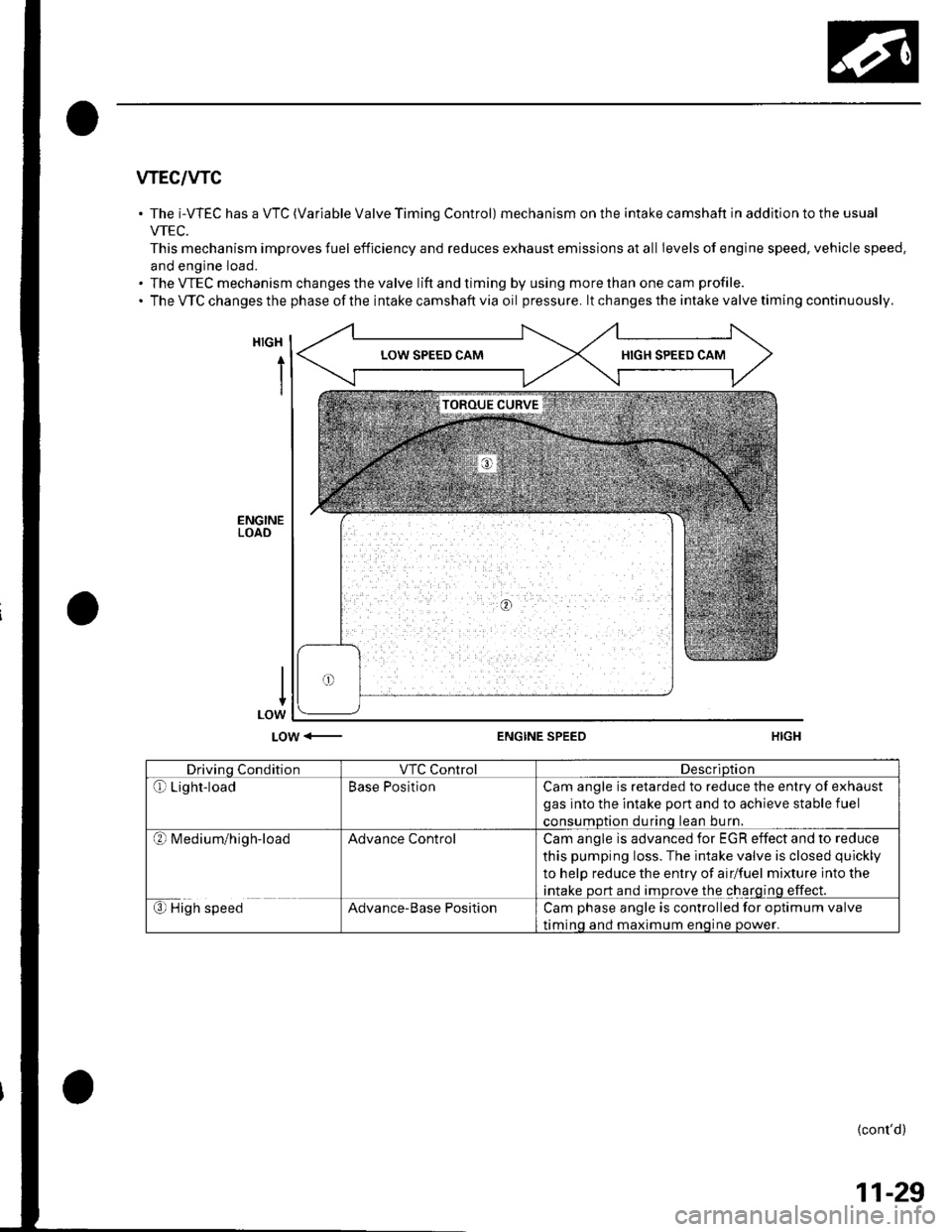

wEc/wc

The i-WEC has a VTC (Variable Valve Timing Control) mechanism on the intake camshaft in addition to the usual

VTEC.

This mechanism improves fuel efficiency and reduces exhaust emissions at all Ievels of engine speed, vehicle speed.

and engine load.

The VTEC mechanism changes the valve lift and timing by using more than one cam profile.

The VTC changes the phase of the intake camshaft via oil pressure. lt changes the intake valve timing continuously.

HIGH

i

LOW <-ENGINE SPEED

Drivino ConditionVTC ControlDescriDtion

Qr Light-loadBase PositionCam angle is retarded to reduce the entry of exhaust

gas into the intake port and to achieve stable fuel

consumDtion durinq lean bu rn.

?l M ed iu m/h ig h-loadAdvance ControlCam angle is advanced for EGR effect and to reduce

this pumping loss. The intake valve is closed quickly

to help reduce the entry of airlfuel mixture into the

intake port and improve the charging effect.

€) High speedAdvance-Base PositionCam phase angle is controlled for optimum valve

timinq and maximum enoine oower.

{cont'd)

11-29

Page 299 of 1139

PGM-FI System

I

a

DTC Troubleshooting (cont'dl

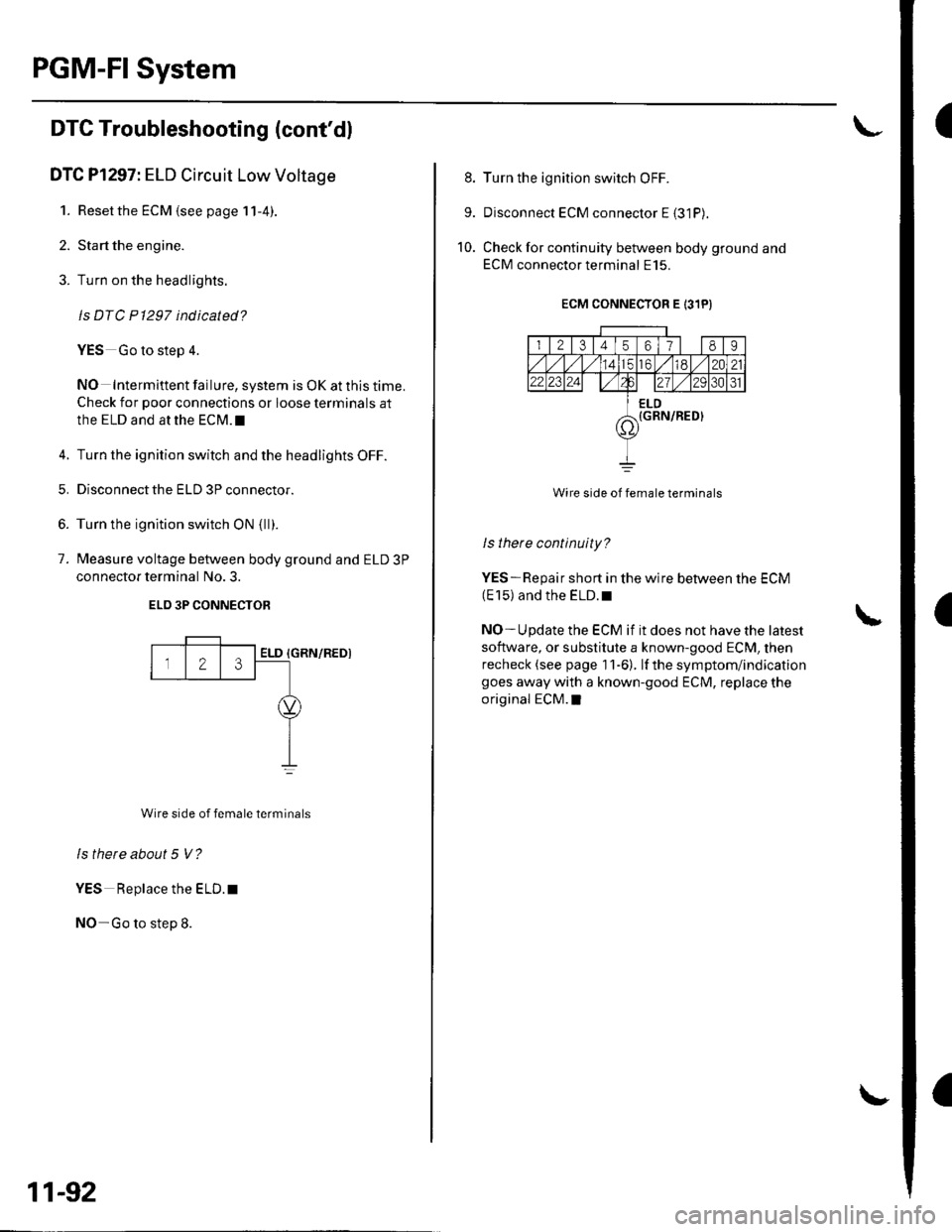

DTC Pl297: ELD Circuit Low Voltage

1. Reset the ECM {see page 11-4).

2. Start the engine.

3. Turn on the headlights.

ls DTC P1297 indicated?

YES Go to step 4.

NO Intermittent failure, system is OK at this time.

Check for poor connections or loose terminals at

the ELD and at the ECM.I

4. Turn the ignition switch and the headlights OFF.

5. Disconnectthe ELD 3P connector.

6. Turn the ignition switch ON {ll).

7. Measure voltage between body ground and ELD 3P

connector terminal No. 3.

ELO 3P CONNECTOB

{GRN/REDI

Wire side of female terminals

ls there about 5 V?

YES Replace the ELD. t

NO-Go to step 8.

Z3ELD

11-92

8. Turn the ignition switch OFF.

9. Disconnect ECM connector E {31P).

10. Check for continuity between body ground and

ECM connector terminal E15.

ECM CONNECTOR E 131PI

I l2l3456178I

totd/ 12021,2 2al2/tA31

ELD(GRN/RED}7\'

Wire side of female terminals

ls there continuity?

YES-Repair short in the wire between the ECM(E 15) and the ELD. r

NO- U pdate the ECM if it does not have the latest

software, or substitute a known-good ECM, then

recheck (see page 1 1-6). lf the symptom/indication

goes away with a known-good ECM, replace the

original ECM.I